- 1School of Civil Engineering, Changsha University of Science and Technology, Changsha, China

- 2School of Civil Engineering, Southeast University, Nanjing, China

- 3Department of Physics, Umm Al-Qura University, Mecca, Saudi Arabia

- 4Structural Engineering and Construction Management Department, Future University in Egypt, New Cairo, Egypt

- 5Department of Civil Engineering, The Higher Institute of Engineering, El Shrouk, Cairo, Egypt

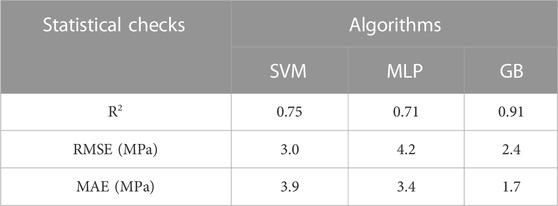

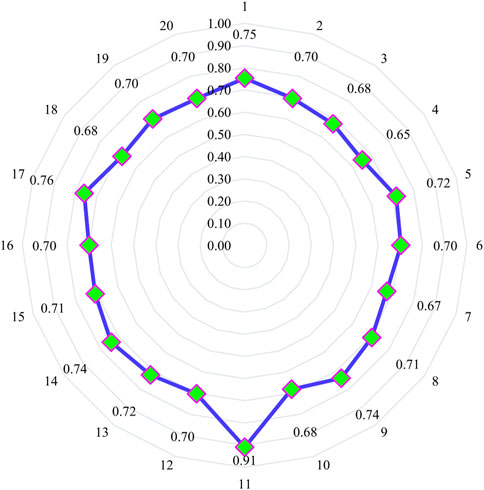

The effect of various parameters on the flexural strength (FS) of ultra-high-performance concrete (UHPC) is an intricate mechanism due to the involvement of several inter-dependent raw ingredients. In this digital era, novel artificial intelligence (AI) approaches, especially machine learning (ML) techniques, are gaining popularity for predicting the properties of concrete composites due to their better precision than typical regression models. In addition, the developed ML models in the literature for FS of UHPC are minimal, with limited input parameters. Hence, this research aims to predict the FS of UHPC considering extensive input parameters (21) and evaluate each their effect on its strength by applying advanced ML approaches. Consequently, this paper involves the application of ML approaches, i.e., Support Vector Machine (SVM), Multi-Layer Perceptron (MLP), and Gradient Boosting (GB), to predict the FS of UHPC. The GB approach is more effective in predicting the FS of UHPC precisely than the SVM and MLP algorithms, as evident from the outcomes of the current study. The ensembled GB model determination coefficient (R2) is 0.91, higher than individual SVM with 0.75 and individual MLP with 0.71. Moreover, the precision of applied models is validated by employing the k-fold cross-validation technique. The validity of algorithms is ensured by statistical means, i.e., mean absolute error and root mean square errors. The exploration of input parameters (raw materials) impact on FS of UHPC is also made with the help of SHAP analysis. It is revealed from the SHAP analysis that the steel fiber content feature has the highest influence on the FS of UHPC.

Introduction

The development of a new generation of concrete named ultra-high-performance concrete (UHPC) is based on four principles that include 1. Microstructure improvement; ii. Reduction in porosity; iii. Enhancement in toughness; and iv. Increase in homogeneity (Shi et al., 2015; Wu et al., 2016). The significantly higher strength (i.e., more than 150 MPa) of UHPC, superior durability, and toughness are well known (Habel et al., 2006; Park et al., 2012). Hence, UHPC is potentially applicable as a precast structural component in bridges and various industrial products to have lightweight, durable, flexible, and aesthetic structures (Schmidt and Fehling, 2005; Wang et al., 2015). For achieving these superior properties of UHPC, low water-to-cement ratio, higher cement content, fine powders (silica fume, quartz, etc.), high-range water-reducing admixtures, and well-graded aggregates are deployed to get minimum lowest porosity with good consolidation and flow, and more particle packing density (Zhang and Ali, 2021; Ali et al., 2022b). Various studies have been conducted in the recent past to determine UHPC mechanical properties having different mix designs and ingredients (Yu et al., 2014; Yoo and Banthia, 2016; Zhou et al., 2018). Precisely, the incorporation of eco-friendly supplementary cementitious materials (SCMs), like; ground granulated blast slag furnaces (GGBFS), fly ash (FA) etc., has gained the attention of researchers (Chen et al., 2018; Khan et al., 2018; Khan and Ali, 2019; Zhang et al., 2019; Jiang et al., 2020a; Arshad et al., 2020; Jiang et al., 2020b; Jiang et al., 2022a; Jiang et al., 2022b; Tariq et al., 2022). Plain UHPC has brittle nature that may restrict its applications (Wang et al., 2015; Le Hoang and Fehling, 2017; Jiang et al., 2020b; Larsen and Thorstensen, 2020; Raza et al., 2022b). Hence different fibers, including artificial and steel fibers, have been commonly incorporated to enhance composites’ impact resistance and ductility (Zhang and Huang, 2022). Multiple researchers have explored the addition of steel/synthetic/natural fibers to concrete as reinforcement for improving characteristics like fatigue resistance, toughness, ductility, and resist propagation of cracks in concrete (Cao et al., 2018; Ali et al., 2021; Li et al., 2021b; Cao and Khan, 2021; Deifalla et al., 2021; Khan et al., 2021; Xie et al., 2021; Ali et al., 2022a; Khan et al., 2022a; Li et al., 2022b; Ali et al., 2022c; Ali et al., 2022d; Farooqi and Ali, 2022; Hu et al., 2022; Meng et al., 2022; Zhang N et al., 2022). Steel fibers are incorporated into concrete to enhance its post-cracking phenomenon and toughness (Deifalla, 2020; Li et al., 2021a; Li et al., 2022a; Raza et al., 2022a; Khan et al., 2022b; Khan et al., 2022c; Khan et al., 2022d). However, researchers have also reported that fibers do not help improve the UHPC compressive strength, whereas the matrix particle packing density and cement hydration degree have a more significant role in the development of UHPC strength (Liang et al., 2018; Arora et al., 2019; Larsen and Thorstensen, 2020; Baili et al., 2022; El Ouni et al., 2022; Zheng et al., 2022). Such research findings highlight the information lacking to predict the UHPC behavior having different mixture ingredients. So, there is a need of modelling for developing a relationship among input parameters and the outcomes (Huang et al., 2022).

Recently, due to the recent advancements in Artificial Intelligence (AI), Machine Learning (ML) techniques have come out as an interesting tool for modelling that is suitable for a wide-ranging variety of scientific domains such as materials engineering (Worden and Manson, 2007; Cao and Li, 2018; Cui et al., 2018; Musumeci et al., 2018; Ebid and Deifalla, 2021; Andalib et al., 2022; Nawaz et al., 2022; Pandey et al., 2022). Keeping this in mind, an inclination has recently been made towards employing ML approaches for concrete strength prediction (Aiyer et al., 2014; Asteris et al., 2016; Sonebi et al., 2016; Dutta et al., 2017; Bayrami, 2022; Sarkhani Benemaran et al., 2022; Shah et al., 2022; Wang et al., 2022; Wang and Wu, 2022). These approaches may be used for numerous applications such as classification, regression, clustering, and correlation (Nehdi et al., 2001; Nguyen et al., 2020; Asri et al., 2022; De-Prado-Gil et al., 2022; Kumar and Kumar, 2022). Due to the development in ML techniques, it is thus easier to determine the concrete strength (Balf et al., 2021; Kovačević et al., 2021; Zhang Z et al., 2022). Mahjoubi et al. (2022a) performed an auto-tune learning framework for UHPC prediction and considered different multiple-function models (Mahjoubi et al., 2021; Mahjoubi et al., 2022b). Marani et al. (2020) employed the Gradient Boosting (GB) ML approach for the compressive strength prediction of UHPC. The research was conducted on 28 days of concrete strength prediction in significantly less time. The study concluded with the highly precise prediction of UHPC compressive strength, having an R2 of 0.96. Lu et al. (2019) have applied the Support Vector Machine (SVM) modelling approach to determine the lithium-slag effect on the properties of cementitious mortar and resulted in an 11% enhanced and improved prediction performance of SVM with respect to other ML models. Similarly, Solhmirzaei et al. (2020) also reported the effective prediction of SVM modelling in the case of shear capacity for UHPC beams. Abellán-García (2020) employed the four-layer Multi-Layer Perceptron (MLP) for predicting the UHPC compressive strength and resulted in the satisfactory capability of MLP for strength prediction. A similar type of finding was also found in the literature for MLP modelling prediction (Abellán-García et al., 2020; Fan et al., 2021; Abellán-García and García-Castaño, 2022). Although, the application of these algorithms for UHPC compressive strength is reported several times in the literature; however, the employment of these models for predicting the flexural strength of UHPC has limited. Further, the available studies have considered a limited number of variables for prediction modelling. Moreover, applying a post hoc model-agnostic technique called SHapley Additive exPlanations (SHAP) provides insight into ML algorithms (Lundberg and Lee, 2017; Lauritsen et al., 2020; Johnsen et al., 2021). The interpretation of correlation among characteristics and a structure in different domains like; material science (Lauritsen et al., 2020; Johnsen et al., 2021), nanophotonic structures behavior (Yeung et al., 2020), low-alloy steel corrosion rate (Yan et al., 2020), inorganic materials synthesis (Tang et al., 2020), finances (Mokhtari et al., 2019), text classification (Zhao et al., 2020), and biomedical engineering (Lundberg et al., 2018), may be achieved effectively by the application of SHAP. But the employment of ML with SHAP for the flexural properties of UHPC is not common enough yet.

Importance of current study

For evaluating the superior properties of UHPC, the laboratory procedures for its manufacturing and testing, such as specimen casting, curing, and testing, are a major concern in terms of high cost and time consumption. Modern methods of ML are now gaining attention to predict the UHPC mechanical behavior to avoid the issues mentioned above. The current study focuses on the FS prediction of UHPC considering extensive input parameters (21) by employing ML techniques which are still limited in the literature. The importance of this study is the prediction of UHPC FS by using both ensemble ML techniques (i.e., Gradient Boosting) and individual ML techniques (i.e., SVM and MLP) along with the exploration of raw ingredients effect and interaction by applying SHAP analysis. A total of 21 input factors, i.e., the content and type of cement, its compressive strength and strength class, the content of fine and coarse aggregates, the content of fly ash, slag, silica fume, limestone powder, nano silica, quartz powder and super-plasticizer, the maximum size of aggregates, water content, content, length and diameter of polystyrene and steel fiber, and time of curing, are considered for FS as an output parameter. The anaconda navigator software is used with Python programming to execute the required prediction models. The data training of twenty boosting sub-models is done for ensembled ML models to achieve maximum precision. Moreover, the test data is confirmed by employing k-Fold cross-validation in combination with MAE, R2, and RMSE. Further, the performance of statistical checks is used to compare individual and ensemble models. At last, the SHAP analysis is also included to analyze the contribution level for every input factor toward the FS of UHPC. This is aimed at ensuring the accuracy of this study. The effective, efficient and economical design for durable structures can be achieved by precisely predicting concrete properties, which would ultimately reduce the time consumption in selecting adequate materials. Also, the application of SHAP analysis is significant for illustrating raw ingredients’ impact on the FS of UHPC. The employed prediction approaches enable researchers to devise novel materials smartly."

Dataset description

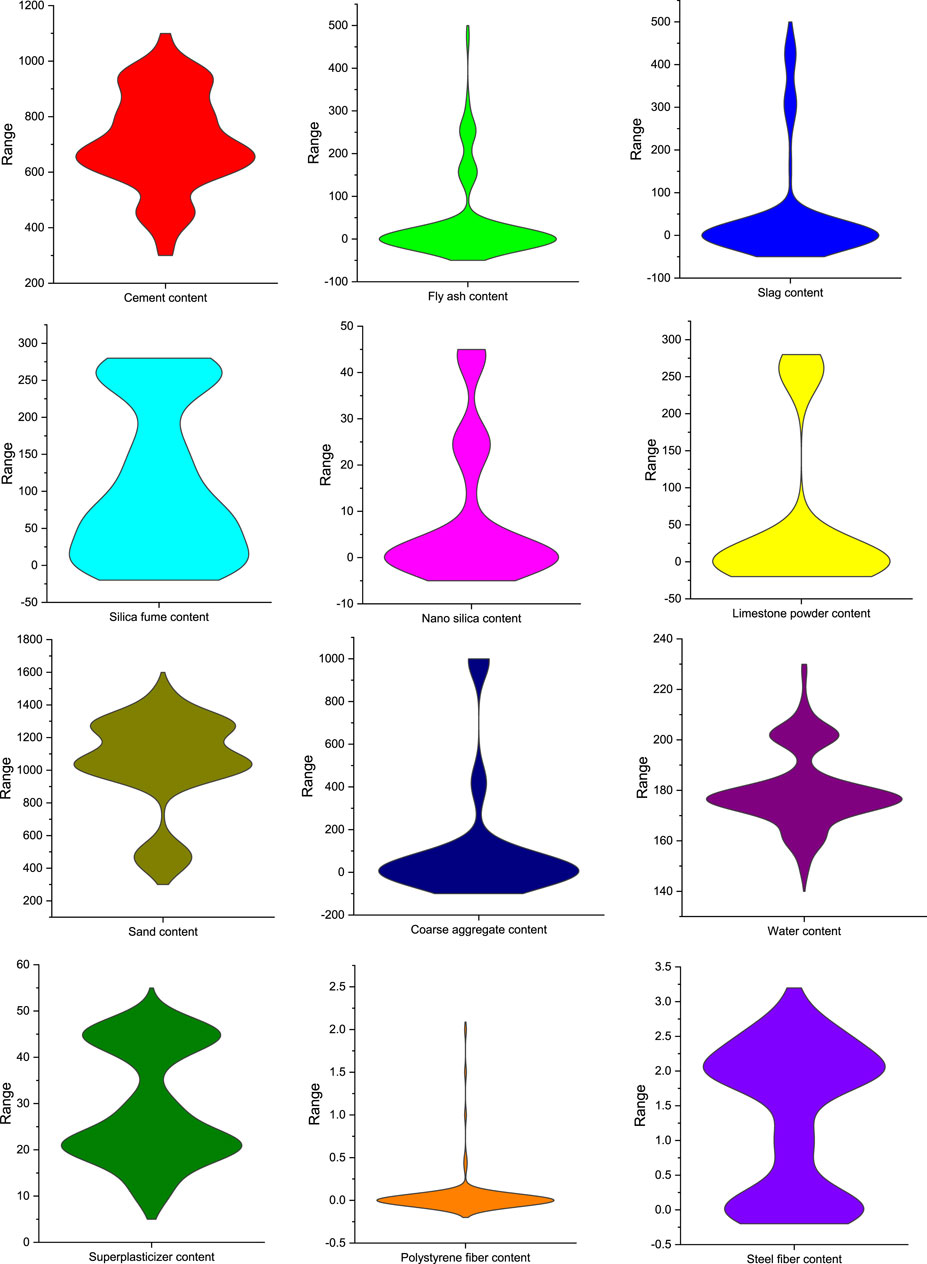

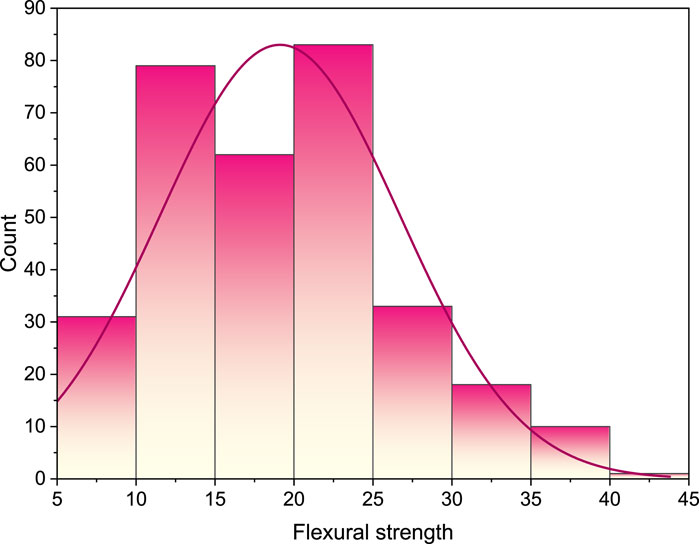

A total of 317 data points are used for running the employed algorithms. The UHPC database used to run the algorithms for predicting its FS is extracted from the available literature (Soroush and Bao, 2021). A total of 21 input factors, i.e., (i) the cement content (kg/m3), (ii) cement type and strength class, (iii) cement compressive strength (MPa), (iv) fine aggregates content (kg/m3), (v) coarse aggregates content (kg/m3), (vi) fly ash content (kg/m3), (vii) slag content (kg/m3), (viii) silica fume content (kg/m3), (ix) limestone powder content (kg/m3), (x) nano silica content (kg/m3), (xi) quartz powder content (kg/m3), (xii) super-plasticizer content (kg/m3), (xiii) the maximum size of aggregates (mm), (xiv) water content (kg/m3), (xv) polystyrene fiber content (%), (xvi) steel fiber content (%), (xvii) polystyrene fiber length (mm), (xviii) steel fiber length (mm), (xix) polystyrene fiber diameter (mm), (xx) steel fiber diameter (mm), and (xxi) time of curing (days), are considered for flexural strength as an output parameter. Figure 1 illustrates the violin plot distribution against considered input parameters. Furthermore, the graphs provide the output parameter’s relative frequency dispersion, as presented in Figure 2. Relative frequency distributions are essential in recognizing a database’s typical value. In regression analysis, the VIF, i.e., Variance Inflation Factor, is the multicollinearity severity. In current data, the correlation was weak (i.e., less than 0.5) for most of the input parameters; therefore, in this situation, there would be no multicollinearity issues as the result of microscopic differences. In the case of stronger correlation (i.e., near to 1), the multicollinearity issues would be higher, and the input variables would have a significantly higher impact that ultimately would influence the outcomes and may offer less precise findings (Amin et al., 2022; Pan et al., 2022).

Brief methodology and employed machine learning algorithms

Anaconda navigator software python coding plays a significant role in running all the applied algorithms. The data was split into two parts, i.e., 70% as training data and 30% as model testing data. The k-fold cross-validation technique is adopted for the validation of the required algorithm. For the reduction in data complexity, the data pre-processing approach is adopted. The pre-processing of data for data mining resolves a critical issue from the renowned knowledge discovery out of data procedure. Data preparation involves data reduction techniques for decreasing the complexity of data by identifying and eliminating noisy and inappropriate data items. The analysis model is made with the help of error distribution and regression methods. In addition, the SHAP analysis was also performed because the considered input factors have a significant effect on output. Consequently, the impact of all the input factors is evaluated to estimate the FS of UHPC via SHAP analysis. Statistical checks have also been applied to assess the level of accuracy of employed algorithms. The implementation processes for the employed algorithms are presented below.

Support vector machine

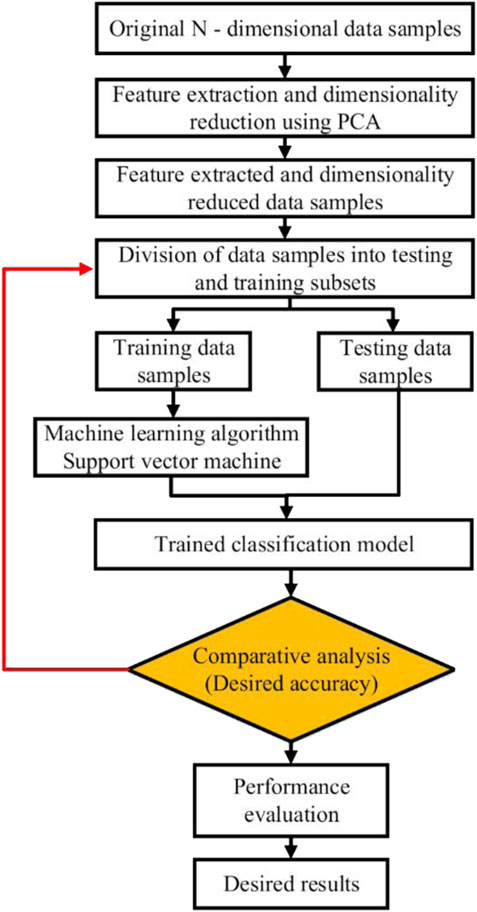

Support Vector Machine (SVM) is an algorithm used to connect learning models employed for data evaluation in the case of both classification and regression. An SVM approach describes the samples as space points drawn so that a distinct vector bifurcates the different classification patterns with the highest possible gap. Figure 3 shows the execution technique for the SVM model. This algorithm is utilized to evaluate the strength of the material, considering the impact of various parameters. The optimization technique is adopted to determine the SVM model’s parameters.

FIGURE 3. SVM model implementation process (Muzzammel and Raza, 2020).

Multi-layer perceptron

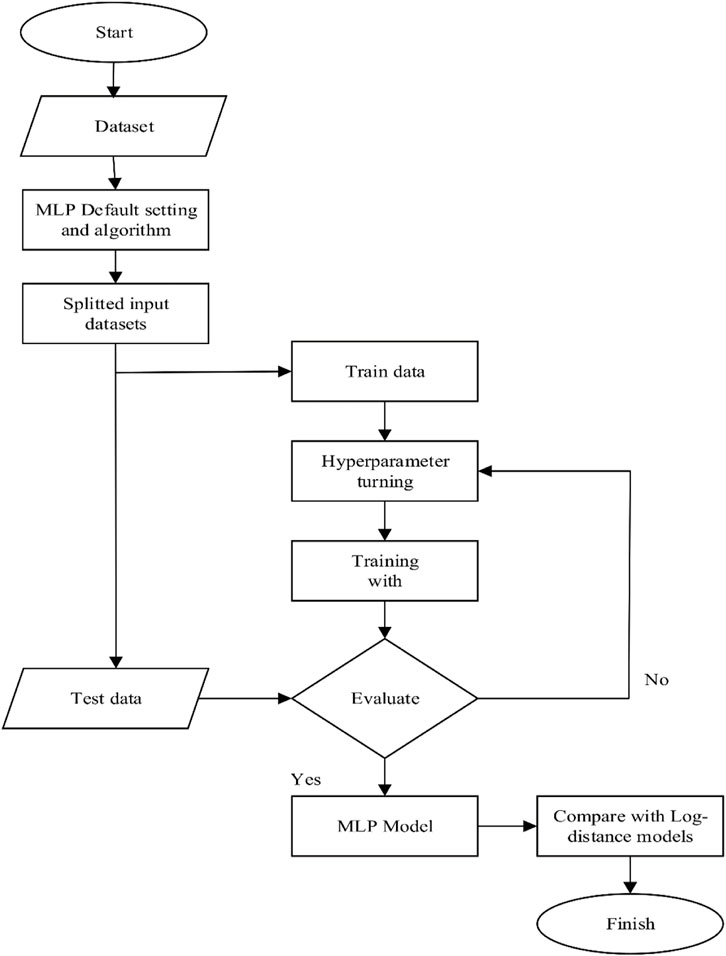

A Multi-Layer Perceptron (MLP) is an ANN type which converts a set of input parameters into an output. A targeted graph connects many input-node layers among input and output layers (Umeonyiagu and Nwobi-Okoye, 2015a; Umeonyiagu and Nwobi-Okoye, 2015b; Abubakar and Tabra, 2020). Backpropagation is used in MLP to train the network (Boukhatem et al., 2012). It may also use for connecting several loops in a targeted graph, with unidirectional moving signals across the nodes. Each entity (except input nodes) owns its distinct non-linear activation function (Abellán-García, 2020). MLPs use backpropagation during learning methods (Boukhatem et al., 2012). MLP is usually regarded as an AI technique due to using several neuron layers (Bikku, 2020). MLP is generally utilized in studies of imputation, supervised learning, pure science, and parallel distributed processing. Image recognition, machine translation, and speech recognition are their applications. To start with, the selection of predictors is made by the algorithm utilized during the whole phase of regression for locating the Variance Inflation Factor (VIF). VIF then identifies the change in the predicted regression coefficient due to collinearity (Lin et al., 2011; Kroll and Song, 2013). The MLP model procedural flowchart is shown in Figure 4.

FIGURE 4. MLP model implementation process (Isabona et al., 2022).

Gradient boosting

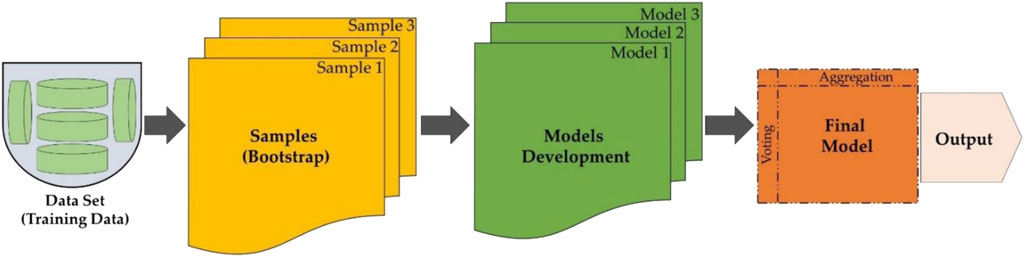

Friedman (2001) recommended this ensemble technique, i.e., gradient boosting (GB), for regression and classification. The GB approach is similar to other boosting approaches, but the regression is limited. In this approach, the random selection for each iteration of the training set is made, and its validation by the base model is done, as shown in Figure 5. In the case of GB, the precision level of execution and speed may be improved by sub-sampling of the training set randomly, which aids in avoiding overfitting. A more regression speed for fitting more minor model data on every iteration can be achieved by having a smaller fraction of training data. GB regression requires n-trees and shrinkage rate tuning factors, where n-trees express the grown trees’ quantity. It may be noted here that the value of n trees must not be minimal, and the learning rate, i.e., shrinkage factor, is applicable in the case of every expansion tree.

K-fold cross-validation outcomes and statistical metrics

The application of k-fold and statistical checks is also made for validating ML models in use (Figure 6). Conventionally, the k-fold cross-validation method is employed to evaluate the practicability of an approach by randomly dividing and distributing the related data into ten sub-groups. Nine groups are utilized for training ML models, whereas one is used for their validation. The ML method is highly precise when there are fewer errors, i.e., MAPE, RMSE, and MAE, and higher R2 value. Furthermore, this method must be repeated ten times to attain the desired result. This bulk quantity work is a major reason behind the highly precise model. In addition, Nazar et al. (2022) derived the below-mentioned equations, i.e., Eq. 1 and Eq. 2, to evaluate the performance of prediction approaches statistically. These equations are also applied in the current study.

Where;

FIGURE 6. K-fold cross-validation approach (Zou et al., 2022).

Results and discussion

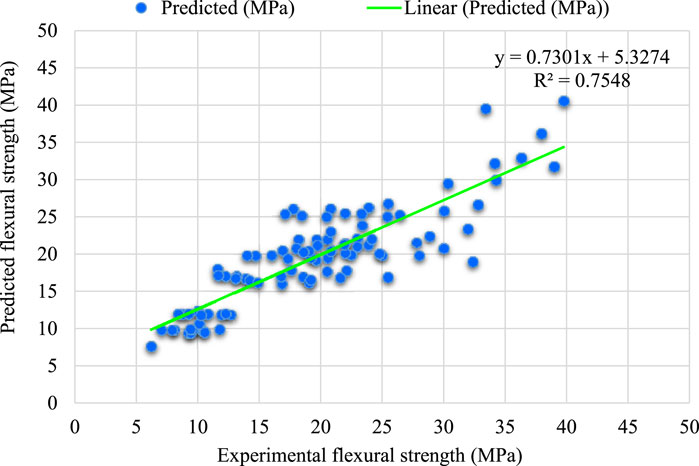

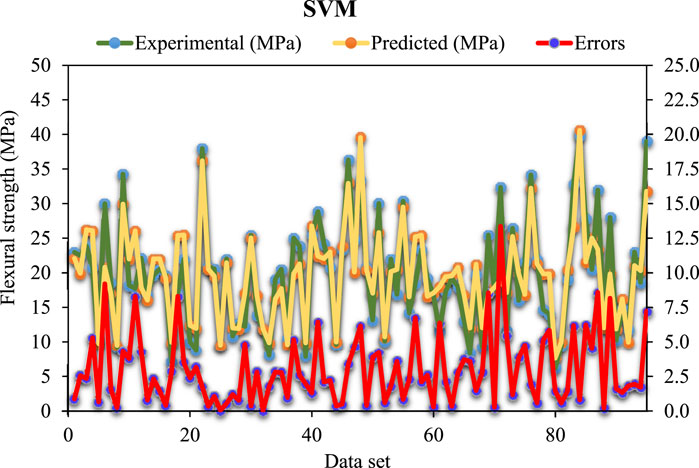

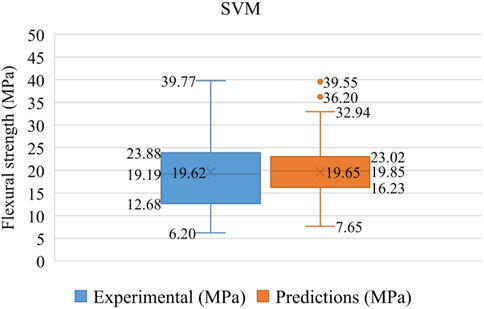

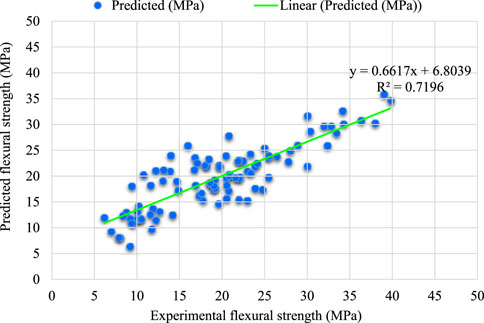

Support vector machine model output

Figure 7 depicts that the SVM model offers a more precise relationship between the experimental and predicted UHPC FS results upon comparison with the MLP algorithm, which results in a 0.75 R2 value. It may be noted here that the vertical and horizontal axes depict the predicted and experimental values, respectively, in the case of FS. Figure 8 illustrates data distribution, representing the difference between the actual and predicted outcomes. Here, the horizontal axis depicts the dataset for testing or training the models, whereas the predicted FS values are shown on the vertical axis. Based on this distribution, the highest, lowest, and average values are 13.3, 2.99, and 0.02 MPa, respectively. Moreover, 63.16% of values are found from 0.02 to 3 MPa, 22.11% of values are found from 3 MPa to 6 MPa, and the remaining 14.74% of values are more than 6 MPa. Furthermore, in Figure 9, the additional statistics like the lowest, mean, highest, median, first, and third quartile values for predicted and experimental outcomes from the test data set are shown. It is evident from the graph data that a difference is there between the actual and predicted results. Jueyendah et al. (2021) also reported similar findings for SVM with a higher correlation coefficient and lesser errors in the FS prediction of cementitious mortar.

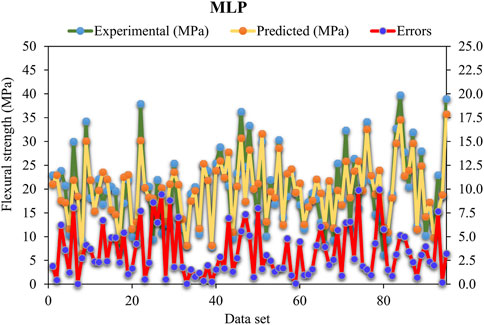

Multi-layer perceptron model outcome

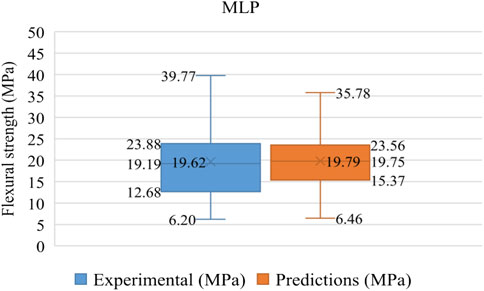

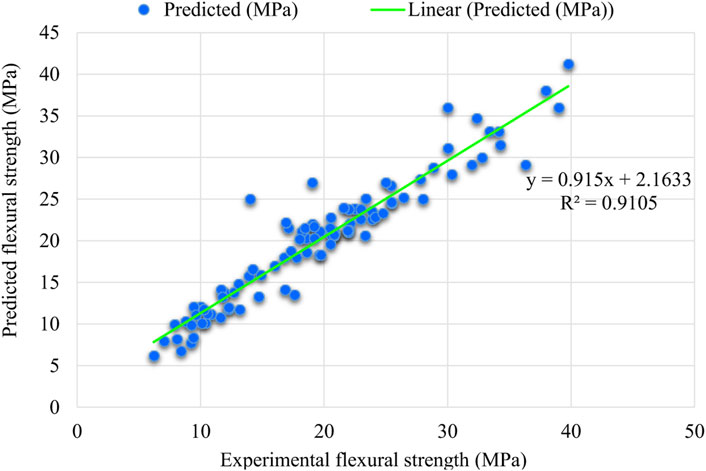

Figure 10 depicts the relationships between the actual and predicted UHPC FS values. This relationship provides 0.71 as the determination coefficient (R2) value. It may be noted here that the vertical and horizontal axes depict the predicted and experimental values, respectively, in the case of FS. Figure 11 shows the difference between the actual and predicted outcomes. Here, the horizontal axis depicts the dataset for testing or training the models, whereas the predicted FS values are shown on the vertical axis. The difference shows the higher values, i.e., 9.96 MPa, and lower values, i.e., 0.04 MPa. Furthermore, it is found that the 57.89% difference in data lies from 0.04 to 3 MPa, and 22.11% of data lies from 3 to 6 MPa. Where only 20% of data is found which is more 6 MPa. In Figure 12, the box plot depicts the statistical information like the maximum, mean, minimum, first and third quartile and median values for the experimental and estimated results from the test dataset. The difference between actual and predicted outcomes can be seen from the values on the graph. Abellán-García (2020) performed MLP analysis demonstrating an acceptable precision for the compressive strength of UHPC.

Gradient boosting model outcome

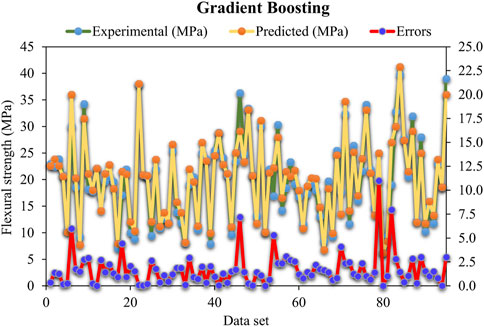

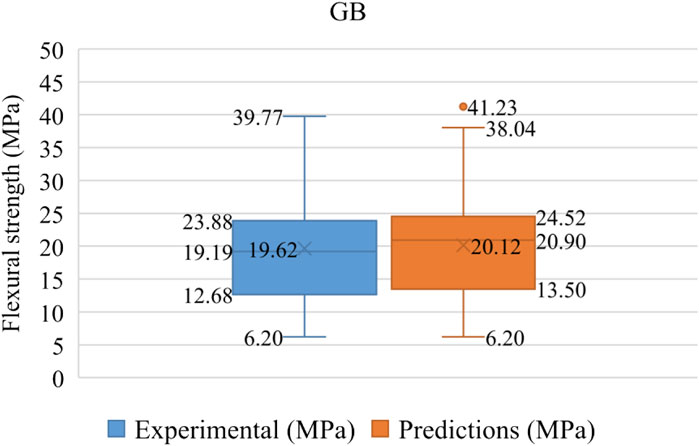

Figure 13 shows the outcome of the GB model depicting a strengthened and improved relation with experimental results in the case of UHPC FS as compared to SVM and MLP prediction models. It may be noted here that the vertical and horizontal axes depict the predicted and experimental values, respectively, in the case of FS. Also, it comes out with a 0.97 R2 value, which contrasts with SVM and MLP predictions. The visuals for error distribution are presented in Figure 14, an additional point of interest. Here, the horizontal axis depicts the dataset for testing or training the models, whereas the predicted FS values are shown on the vertical axis. The variation gives data with a minimum of 0 MPa, an average of 1.71 MPa, and a maximum of 11 MPa. Furthermore, it is observed that 91.58% of data lies from 0 to 3 MPa, 5.26% of data lies from 3 to 6 MPa, and the remaining 3.16% of data is found to be more than 6 MPa. Additionally, more statistical information is illustrated in the Box Plot shown in Figure 15, showing the lowest, mean, highest, median, first, and third quartile values for predicted and experimental test set outcomes. The difference between the expected and actual results is represented graphically. Marani and Nehdi (2020) also employed the GB algorithm for predicting the compressive strength of cementitious composites integrated with phase change materials. It was concluded that the GB model shows the maximum precision among all the considered algorithms. In the current study, the output precision from the GB algorithm is higher for flexural strength, contrary to both SVM and MLP algorithms.

K-statistical checks and k-fold analysis

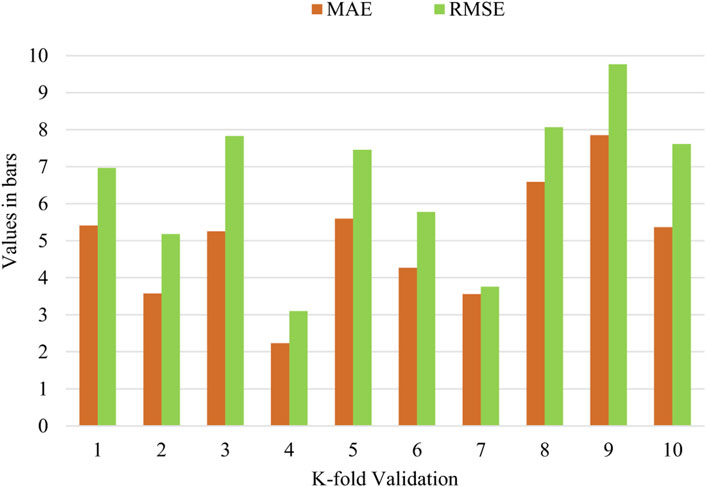

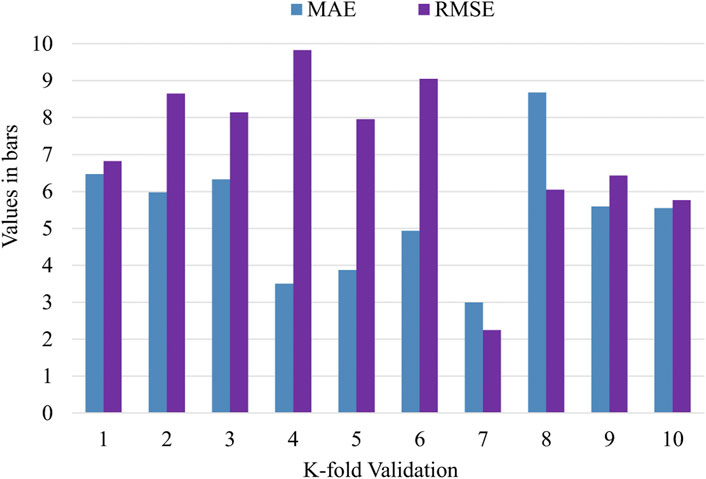

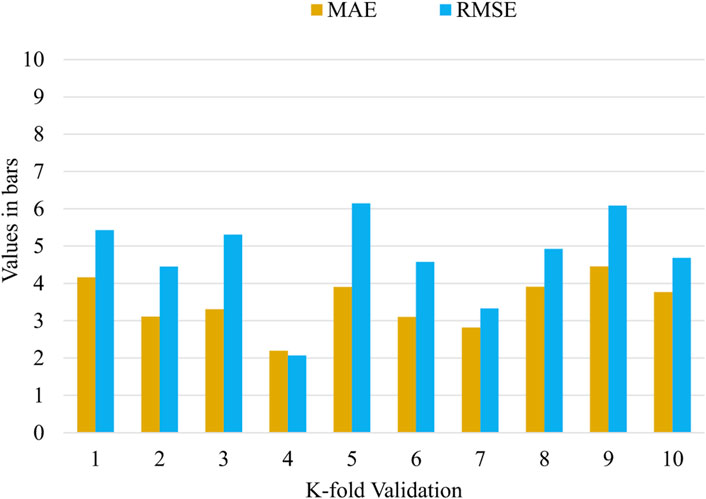

The statistics extracted from the algorithms are provided in Table 1. A check named the k-fold cross-validation test is applied as a standard for determining of model’s legitimacy. For the investigation of outcomes, the statistical checks, i.e., R2, RMSE, and MAE, are considered. Likewise, the highest RMSE and MAE in SVM models come out as 9.76 and 7.85 MPa, as presented in Figure 16. As per this check, the RMSE and MAE values in the case of MLP models are higher, i.e., 9.82 and 8.68 MPa, respectively, as shown in Figure 17. But, in the case of boosting, the higher RMSE and MAE values come out as 6.14 MPa and 4.45 MPa, respectively, as illustrated in Figure 18.

Discussion

The current work explains the flexural strength performance in prediction for 3 ML models. The support vector machine (SVM), multi-layer perceptron (MLP), and gradient boosting (GB) are employed for the analysis. Although SVM and MLP come under the umbrella of individual machine learning approaches, the accuracy of their prediction outcomes is observed to be in an acceptable range. The GB comes under the umbrella of ensemble machine learning techniques, which usually undergo the splitting process of the model into twenty sub-models to optimize the accurate result. Figure 19 shows the boosting sub-model outcome. It is observed that the input factors and data points numbers have a considerable effect on desired results. Accordingly, the input data’s relative frequency distribution and descriptive statistics to determine their impact on the outcome are incorporated into the study. A satisfactory correlation is observed between experimental and predicted results for UHPC FS from all the models employed. The k-fold cross-validation method assesses the legitimacy of models.

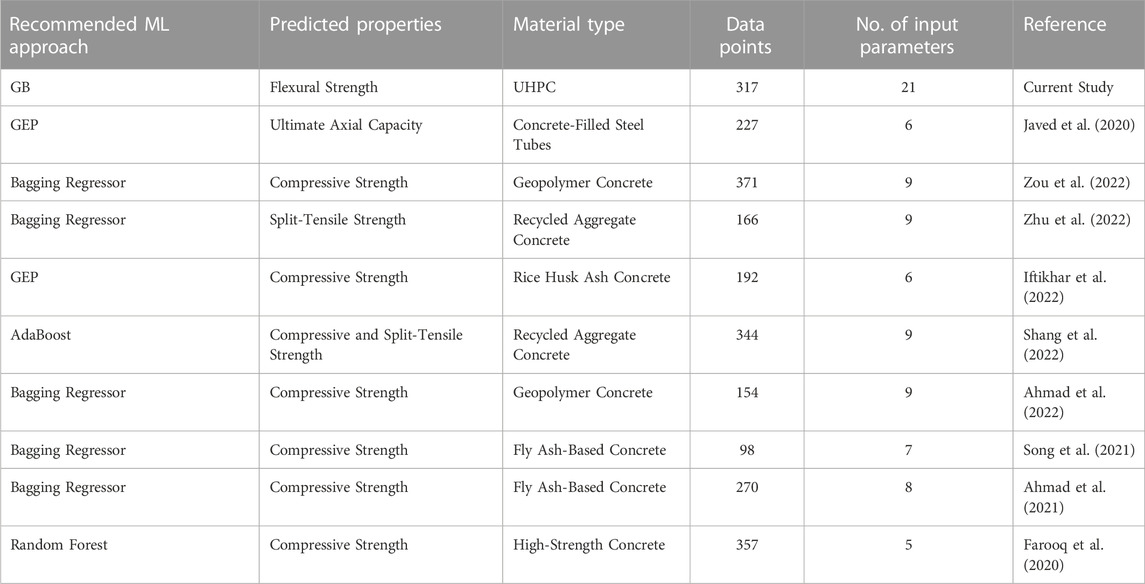

The application of advanced machine learning techniques is gaining attention nowadays in various engineering fields (Chen et al., 2022). In the recent past, several studies have been conducted by employing different algorithms to predict various properties of other cementitious materials such as Recycled Aggregate Concrete, Geopolymer Concrete, Rice Husk Ash Concrete, and Fly Ash-Based Concrete etc. The number of considered input parameters was from 5 to 9, and the minimum number of considered dataset points was 98. It may be noted from Table 2 that the dataset points range from 98 to 357 in numbers. The details from the different studies regarding the employment of ML algorithms (GEP, Bagging Regressor, AdaBoost, Random Forest) for predicting various properties of different cementitious composites (compressive, splitting-tensile and shear strengths) are summarized in the literature and are presented in Table 2. The maximum data points and the number of input parameters extracted from this literature-based summary in Table 2 are 357 and 9, respectively. However, in the current study, as also demonstrated in the first row of Table 2 in comparison with other reported studies, a total of 317 data points are considered, and 21 input parameters are taken for the flexural strength prediction of UHPC which is in the acceptable range of prediction.

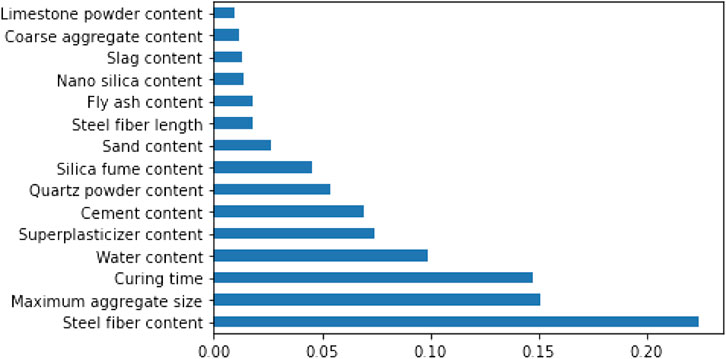

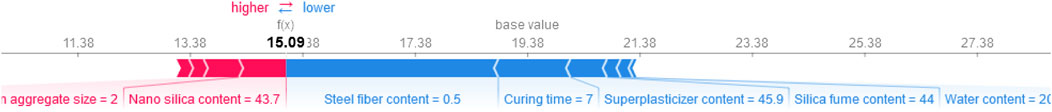

SHAP analysis

The current research provides an in-depth explanation of the ML algorithm and interactions and dependencies for every feature. The application of the SHAP tree explainer on the entire dataset and an enhanced illustration of influences of global features by merging SHAP local explanations are also provided. The tree-like SHAP prediction technique, named TreeExplainer, is applied (Lundberg et al., 2019). In this method, the interior structure of tree-based models is explored, which is summing up of a calculations set linked with the tree model leaf node, leading to low-order complexity (Lundberg et al., 2019). The model interpretation is made for UHPC FS by applying SHAP. The relationship of different features with UHPC FS is depicted by the SHAP values, as presented in Figure 20. It is observed that the highest SHAP value is for steel fiber content for UHPC FS prediction. It is renowned that the bridging mechanism is achieved by incorporating steel fibers, ultimately enhancing the strength factors (Deifalla et al., 2021). Consequently, enhancing steel fiber content would produce a higher FS of UHPC. In the second place, the maximum aggregate size has the highest SHAP value, which is more or less the same as curing time, which is in third place in terms of more SHAP value, as shown in Figure 20. In cementitious concrete composites, more curing time would come up with improved bonds and strengths of the matrix, thus contributing to its better mechanical characteristics. It may be due to the more binders in UHPC, i.e., fly ash, silica fume, slag etc., due to which more curing time is required by the process of hydration, which would ultimately result in improved FS. Subsequently, the water and super-plasticizer contents have the fourth and fifth highest SHAP values, respectively. The strength of UHPC mainly depends on the theory of particle packing density; hence there is a requirement to have limited water content, and the super-plasticizer plays the main role in the development of strength. Meanwhile, the quarts and silica fume also influence UHPC FS. Other features like limestone powder content, coarse aggregate content, contents of slag, nano-silica, sand and fly-ash fine/coarse aggregates, and steel fibers length influence the UHPC FS slightly. All the mentioned features have a specific impact on UHPC FS.

Similarly, Figure 21 illustrates the correlation for the importance of features UHPC FS. It can be noted that the enhancing steel fiber content is increasing the UHPC FS and vice versa. As far as the water content is concerned, it is influencing negatively, as it can be seen from Figure 21 that the increasing water content results in the reduction of UHPC FS. However, in the case of cement content, it shows a positive influence which means the more the content of cement is, the higher will be the FS of UHPC. Similarly, enhancing silica fume content results in more FS of UHPC. The dataset employed in this study is the basis for the conducted prediction, and highly accurate outcomes may be achieved by having more data points.

Conclusion

To assess the improved properties of UHPC, the laboratory procedures for its manufacturing and testing, such as specimen casting, curing, and testing, are a major concern point in terms of excessive cost and time consumption. Modern AI methods especially machine learning (ML) are now gaining attention to predict the mechanical behavior of UHPC. In this study, flexural strength (FS) estimation of UHPC is done by applying both ensemble techniques (i.e., gradient boosting) and individual techniques (i.e., SVM and MLP) along with the exploration of raw ingredients effect and interaction by applying SHAP analysis. A total of 21 input parameters are considered, i.e., the cement content (kg/m3), cement type and strength class, cement compressive strength (MPa), fine aggregates content (kg/m3), coarse aggregates content (kg/m3), fly ash content (kg/m3), slag content (kg/m3), silica fume content (kg/m3), limestone powder content (kg/m3), nano silica content (kg/m3), quartz powder content (kg/m3), super-plasticizer content (kg/m3), the maximum size of aggregates (mm), water content (kg/m3), polystyrene fiber content (%), steel fiber content (%), polystyrene fiber length (mm), steel fiber length (mm), polystyrene fiber diameter (mm), steel fiber diameter (mm), and time of curing (days). The following conclusions are drawn based on the study findings:

• The employed ensemble machine learning algorithm (Gradient boosting) successfully predicted FS of UHPC using python coding with higher accuracy of R2 value than that of individual algorithms (SVM and MLP). Twenty sub models with 10–200 predictors are used to optimize the FS prediction of UHPC.

• The gradient boosting (GB) algorithm is superior in precision with a low error rate (MAE = 1.7) as to that of SVM (MAE = 3.9) and MLP (MAE = 3.4) algorithms.

• The higher R2 of 0.91 is attained through a relationship of experimental and predicted values in the GB algorithm, which depicts its higher precision for FS of UHPC than that of SVM (R2 = 0.75) and MLP (R2 = 0.71) algorithms.

• The validity of the applied algorithms is also ensured with the help of RMSE and k-fold cross-validation. It is found that RMSE for the GB algorithm is 2.4, which is lower than that of the SVM (RMSE = 3.0) and MLP (RMSE = 4.2) algorithms

• The influence of all the considered input factors on the FS of UHPC is determined by SHAP analysis, which reveals that the steel fiber content feature has the highest impact on UHPC FS. This is due to the bridging effect of steel fibers that ultimately results in improved FS.

• In general, employing ensembled machine learning approaches provides a cost-effective and better way to analyze the characteristics of complex materials like ultra-high-performance concrete. The current research would give academics in civil engineering in-depth insight into adopting adequate ML models to predict the strength properties of any concrete type. Further, this work explains the importance of input parameters for the targeted outcome using ML approaches.

UHPC is a modern cementitious composite with enhanced mechanical properties compared to conventional concrete. The research interest towards the exploration of UHPC is gaining popularity day by day. However, based on this study’s outcomes, the following future recommendations are proposed:

• The nature of the correlation between the raw components of UHPC mix design and its characteristics is a major parameter influencing the model selection. This non-linear relation requires the application of ML algorithms. But optimizing applied algorithms through metaheuristic models is an effective way to attain more accurate results and enhanced processes.

• Although a suitable dataset is being considered in this research; however, a further extended dataset should be taken to improve the effectiveness of applied algorithms.

• Furthermore, increasing the dataset quantity through experimental evaluations can enhance the performance of ML algorithms for highly accurate prediction.

• Moreover, increasing the type of input parameters, like the chemical formation of raw components and the climatic impacts (i.e., humidity and temperature), can result in more precision of ML models. Additionally, this study aimed to predict UHPC flexural strength, so its other parameters would also be taken in ML prediction.

• The application of hybrid ANN and SVM models can also be explored for predicting UHPC characteristics regarding the process and precision. Although it will improve the computation time, applying these models on an expanded database with appropriate feature selection will provide highly accurate results.

• The detailed exploration of UHPC load–slip modelling in terms of steel fibers impacts regarding the age of the matrix and strength needs to be explored.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

YQ: Conceptualization, methodology, investigation, validation, writing-original draft, supervision, writing—reviewing and editing. MS: Methodology, formal analysis, validation, visualization, writing—reviewing and editing. AH: Funding acquisition, data curation, writing—reviewing and editing. AF: Funding acquisition, resources, software, visualization, writing—reviewing and editing. AE: Formal analysis, resources, software, writing—review and editing, validation.

Acknowledgments

The authors would like to thank the Deanship of Scientific Research at Umm Al-Qura University for supporting this work by Grant Code: (22UQU4250045DSR23).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

AI, Artificial Intelligence; ANN, Artificial Neural Network; FA, Fly Ash; FS, Flexural Strength; GB, Gradient Boosting; GEP, Gene Expression Programming; GGBFS, Ground Granulated Blast Slag Furnace; MAE, Mean Absolute Error; ML, Machine Learning; MLP, Multi-Layer Perceptron; R2, Determination Coefficient; RMSE, Root Mean Square Error; SCM, Supplementary Cementitious Material; SHAP, SHapley Additive exPlanations; SVM, Support Vector Machine; UHPC, Ultra-High-Performance Concrete.

References

Abellán-García, J., and García-Castaño, E. (2022). Development and research on ultra-high-performance concrete dosages in Colombia: A review. ACI Mater. J. 119, 209–221. doi:10.14359/51734617

Abellán-García, J., Fernández-Gómez, J. A., Torres-Castellanos, N., and Núñez-López, A. M. (2020). “Machine learning prediction of flexural behavior of UHPFRC,” in RILEM-Fib international symposium on fibre reinforced concrete (Germany: Springer), 570–583.

Abellán-García, J. (2020). Four-layer perceptron approach for strength prediction of UHPC. Constr. Build. Mater. 256, 119465. doi:10.1016/j.conbuildmat.2020.119465

Abubakar, A., and Tabra, M. (2020). Predictive capabilities of Multilayer Perceptron (MLP) in WEKA algorithm for high strength concrete with steel fiber addition. Cem. Based Compos 2, 13–18. doi:10.36937/cebacom.2020.002.003

Ahmad, A., Farooq, F., Niewiadomski, P., Ostrowski, K., Akbar, A., Aslam, F., et al. (2021). Prediction of compressive strength of fly ash based concrete using individual and ensemble algorithm. Materials 14, 794. doi:10.3390/ma14040794

Ahmad, A., Ahmad, W., Aslam, F., and Joyklad, P. (2022). Compressive strength prediction of fly ash-based geopolymer concrete via advanced machine learning techniques. Case Stud. Constr. Mater. 16, e00840. doi:10.1016/j.cscm.2021.e00840

Aiyer, B. G., Kim, D., Karingattikkal, N., Samui, P., and Rao, P. R. (2014). Prediction of compressive strength of self-compacting concrete using least square support vector machine and relevance vector machine. KSCE J. Civ. Eng. 18, 1753–1758. doi:10.1007/s12205-014-0524-0

Ali, A. H., Mohamed, H. M., Chalioris, C. E., and Deifalla, A. (2021). Evaluating the shear design equations of FRP-reinforced concrete beams without shear reinforcement. Eng. Struct. 235, 112017. doi:10.1016/j.engstruct.2021.112017

Ali, B., Azab, M., Ahmed, H., Kurda, R., El Ouni, M. H., and Elhag, A. B. (2022a). Investigation of physical, strength, and ductility characteristics of concrete reinforced with banana (Musaceae) stem fiber. J. Build. Eng. 61, 105024. doi:10.1016/j.jobe.2022.105024

Ali, B., Farooq, M. A., El Ouni, M. H., Azab, M., and Elhag, A. B. (2022b). The combined effect of coir and superplasticizer on the fresh, mechanical, and long-term durability properties of recycled aggregate concrete. J. Build. Eng. 59, 105009. doi:10.1016/j.jobe.2022.105009

Ali, B., Farooq, M. A., Kurda, R., Alyousef, R., Noman, M., and Alabduljabbar, H. (2022c). Effect of type and volume fraction of recycled-tire steel fiber on durability and mechanical properties of concrete. Eur. J. Environ. Civ. Eng., 1–22. doi:10.1080/19648189.2022.2103590

Ali, B., Hawreen, A., Kahla, N. B., Amir, M. T., Azab, M., and Raza, A. (2022d). A critical review on the utilization of coir (coconut fiber) in cementitious materials. Constr. Build. Mater. 351, 128957. doi:10.1016/j.conbuildmat.2022.128957

Amin, M. N., Ahmad, W., Khan, K., Ahmad, A., Nazar, S., and Alabdullah, A. A. (2022). Use of artificial intelligence for predicting parameters of sustainable concrete and raw ingredient effects and interactions. Materials 15, 5207. doi:10.3390/ma15155207

Andalib, A., Aminnejad, B., and Lork, A. (2022). Grey wolf optimizer-based ANNs to predict the compressive strength of self-compacting concrete. Appl. Comput. Intell. Soft Comput. 2022, 1–17. doi:10.1155/2022/9887803

Arora, A., Yao, Y., Mobasher, B., and Neithalath, N. (2019). Fundamental insights into the compressive and flexural response of binder-and aggregate-optimized ultra-high performance concrete (UHPC). Cem. Concr. Compos. 98, 1–13. doi:10.1016/j.cemconcomp.2019.01.015

Arshad, S., Sharif, M. B., Irfan-Ul-Hassan, M., Khan, M., and Zhang, J.-L. (2020). Efficiency of supplementary cementitious materials and natural fiber on mechanical performance of concrete. Arabian J. Sci. Eng. 45, 8577–8589. doi:10.1007/s13369-020-04769-z

Asri, Y. E., Aicha, M. B., Zaher, M., and Alaoui, A. H. (2022). Prediction of compressive strength of self-compacting concrete using four machine learning technics. Mater. Today Proc. 57, 859–866. doi:10.1016/j.matpr.2022.02.487

Asteris, P., Kolovos, K., Douvika, M., and Roinos, K. (2016). Prediction of self-compacting concrete strength using artificial neural networks. Eur. J. Environ. Civ. Eng. 20, s102–s122. doi:10.1080/19648189.2016.1246693

Baili, J., Raza, A., Azab, M., Ali, K., El Ouni, M. H., Haider, H., et al. (2022). Experiments and predictive modeling of optimized fiber-reinforced concrete columns having FRP rebars and hoops. Mech. Adv. Mater. Struct., 1–20. doi:10.1080/15376494.2022.2108527

Balf, F. R., Kordkheili, H. M., and Kordkheili, A. M. (2021). A New method for predicting the ingredients of self-compacting concrete (SCC) including fly ash (FA) using data envelopment analysis (DEA). Arabian J. Sci. Eng. 46, 4439–4460. doi:10.1007/s13369-020-04927-3

Bayrami, B. (2022). Estimation of splitting tensile strength of modified recycled aggregate concrete using hybrid algorithms. Available at SSRN 3992623 44, 375–392.

Bikku, T. (2020). Multi-layered deep learning perceptron approach for health risk prediction. J. Big Data 7, 50–14. doi:10.1186/s40537-020-00316-7

Boukhatem, B., Kenai, S., Hamou, A., Ziou, D., and Ghrici, M. (2012). Predicting concrete properties using neural networks(NN) with principal component analysis(PCA) technique. Comput. Concr. 10, 557–573. doi:10.12989/cac.2012.10.6.557

Cao, M., and Khan, M. (2021). Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 22, 535–549. doi:10.1002/suco.201900228

Cao, M., and Li, L. (2018). New models for predicting workability and toughness of hybrid fiber reinforced cement-based composites. Constr. Build. Mater. 176, 618–628. doi:10.1016/j.conbuildmat.2018.05.075

Cao, M., Mao, Y., Khan, M., Si, W., and Shen, S. (2018). Different testing methods for assessing the synthetic fiber distribution in cement-based composites. Constr. Build. Mater. 184, 128–142. doi:10.1016/j.conbuildmat.2018.06.207

Chen, T., Gao, X., and Ren, M. (2018). Effects of autoclave curing and fly ash on mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 158, 864–872. doi:10.1016/j.conbuildmat.2017.10.074

Chen, J., Tong, H., Yuan, J., Fang, Y., and Gu, R. (2022). Permeability prediction model modified on kozeny-carman for building foundation of clay soil. Buildings 12, 1798. doi:10.3390/buildings12111798

Cui, L., Yang, S., Chen, F., Ming, Z., Lu, N., and Qin, J. (2018). A survey on application of machine learning for Internet of Things. Int. J. Mach. Learn. Cybern. 9, 1399–1417. doi:10.1007/s13042-018-0834-5

Deifalla, A. F., Zapris, A. G., and Chalioris, C. E. (2021). Multivariable regression strength model for steel fiber-reinforced concrete beams under torsion. Materials 14, 3889. doi:10.3390/ma14143889

Deifalla, A. (2020). “Torsion design of lightweight concrete beams without or with fibers: A comparative study and a refined cracking torque formula,” in Structures (Netherland: Elsevier), 786–802.

De-Prado-Gil, J., Palencia, C., Silva-Monteiro, N., and Martínez-García, R. (2022). To predict the compressive strength of self compacting concrete with recycled aggregates utilizing ensemble machine learning models. Case Stud. Constr. Mater. 16, e01046. doi:10.1016/j.cscm.2022.e01046

Dutta, S., Murthy, A. R., Kim, D., and Samui, P. (2017). Prediction of compressive strength of self-compacting concrete using intelligent computational modeling. Comput. Mater. Contin. 53, 167–185. doi:10.3970/cmc.2017.053.167

Ebid, A. M., and Deifalla, A. (2021). Prediction of shear strength of FRP reinforced beams with and without stirrups using (GP) technique. Ain Shams Eng. J. 12, 2493–2510. doi:10.1016/j.asej.2021.02.006

El Ouni, M. H., Raza, A., Elhadi, K. M., Azab, M., and Arshad, M. (2022). “Parametric investigation of GFRP-RCC jute fibre-reinforced recycled aggregate concrete elements,” in Structures (Netherland: Elsevier), 1043–1061.

Fan, D., Yu, R., Fu, S., Yue, L., Wu, C., Shui, Z., et al. (2021). Precise design and characteristics prediction of Ultra-High Performance Concrete (UHPC) based on artificial intelligence techniques. Cem. Concr. Compos. 122, 104171. doi:10.1016/j.cemconcomp.2021.104171

Farooq, F., Nasir Amin, M., Khan, K., Rehan Sadiq, M., Faisal Javed, M., Aslam, F., et al. (2020). A comparative study of random forest and genetic engineering programming for the prediction of compressive strength of high strength concrete (HSC). Appl. Sci. 10, 7330. doi:10.3390/app10207330

Farooqi, M. U., and Ali, M. (2022). A study on natural fibre reinforced concrete from materials to structural applications. Arabian J. Sci. Eng., 1–21. doi:10.1007/s13369-022-06977-1

Friedman, J. H. (2001). Greedy function approximation: A gradient boosting machine. Ann. statistics, 1189–1232. doi:10.1214/aos/1013203451

Habel, K., Viviani, M., Denarié, E., and Brühwiler, E. (2006). Development of the mechanical properties of an ultra-high performance fiber reinforced concrete (UHPFRC). Cem. Concr. Res. 36, 1362–1370. doi:10.1016/j.cemconres.2006.03.009

Hu, C.-F., Li, L., and Li, Z. (2022). Effect of fiber factor on the workability and mechanical properties of polyethylene fiber-reinforced high toughness geopolymers. Ceram. Int. 48, 10458–10471. doi:10.1016/j.ceramint.2021.12.254

Huang, Y., Zhang, W., and Liu, X. (2022). Assessment of diagonal macrocrack-induced debonding mechanisms in FRP-strengthened RC beams. J. Compos. Constr. 26, 04022056. doi:10.1061/(asce)cc.1943-5614.0001255

Iftikhar, B., Alih, S. C., Vafaei, M., Elkotb, M. A., Shutaywi, M., Javed, M. F., et al. (2022). Predictive modeling of compressive strength of sustainable rice husk ash concrete: Ensemble learner optimization and comparison. J. Clean. Prod. 348, 131285. doi:10.1016/j.jclepro.2022.131285

Isabona, J., Imoize, A. L., Ojo, S., Karunwi, O., Kim, Y., Lee, C.-C., et al. (2022). Development of a multilayer perceptron neural network for optimal predictive modeling in urban microcellular radio environments. Appl. Sci. 12, 5713. doi:10.3390/app12115713

Javed, M. F., Farooq, F., Memon, S. A., Akbar, A., Khan, M. A., Aslam, F., et al. (2020). New prediction model for the ultimate axial capacity of concrete-filled steel tubes: An evolutionary approach. Crystals 10, 741. doi:10.3390/cryst10090741

Jiang, X., Xiao, R., Zhang, M., Hu, W., Bai, Y., and Huang, B. (2020a). A laboratory investigation of steel to fly ash-based geopolymer paste bonding behavior after exposure to elevated temperatures. Constr. Build. Mater. 254, 119267. doi:10.1016/j.conbuildmat.2020.119267

Jiang, X., Zhang, Y., Xiao, R., Polaczyk, P., Zhang, M., Hu, W., et al. (2020b). A comparative study on geopolymers synthesized by different classes of fly ash after exposure to elevated temperatures. J. Clean. Prod. 270, 122500. doi:10.1016/j.jclepro.2020.122500

Jiang, X., Xiao, R., Bai, Y., Huang, B., and Ma, Y. (2022a). Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 340, 130778. doi:10.1016/j.jclepro.2022.130778

Jiang, X., Zhang, Y., Zhang, Y., Ma, J., Xiao, R., Guo, F., et al. (2022b). Influence of size effect on the properties of slag and waste glass-based geopolymer paste. J. Clean. Prod. 383, 135428. doi:10.1016/j.jclepro.2022.135428

Johnsen, P. V., Riemer-Sørensen, S., Dewan, A. T., Cahill, M. E., and Langaas, M. (2021). A new method for exploring gene–gene and gene–environment interactions in GWAS with tree ensemble methods and SHAP values. BMC Bioinforma. 22, 230–329. doi:10.1186/s12859-021-04041-7

Jueyendah, S., Lezgy-Nazargah, M., Eskandari-Naddaf, H., and Emamian, S. A. (2021). Predicting the mechanical properties of cement mortar using the support vector machine approach. Constr. Build. Mater. 291, 123396. doi:10.1016/j.conbuildmat.2021.123396

Khan, M., and Ali, M. (2019). Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mater. 203, 174–187. doi:10.1016/j.conbuildmat.2019.01.103

Khan, U. A., Jahanzaib, H. M., Khan, M., and Ali, M. (2018). “Improving the tensile energy absorption of high strength natural fiber reinforced concrete with fly-ash for bridge girders,” in Key engineering materials (Switzerland: Trans Tech Publ), 335–342.

Khan, M., Cao, M., Hussain, A., and Chu, S. (2021). Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 300, 124046. doi:10.1016/j.conbuildmat.2021.124046

Khan, M., Cao, M., Ai, H., and Hussain, A. (2022a). Basalt fibers in modified whisker reinforced cementitious composites. Period. Polytech. Civ. Eng. 66, 344–354. doi:10.3311/ppci.18965

Khan, M., Cao, M., Chu, S., and Ali, M. (2022b). Properties of hybrid steel-basalt fiber reinforced concrete exposed to different surrounding conditions. Constr. Build. Mater. 322, 126340. doi:10.1016/j.conbuildmat.2022.126340

Khan, M., Cao, M., Xie, C., and Ali, M. (2022c). Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 16, e00941. doi:10.1016/j.cscm.2022.e00941

Khan, M., Cao, M., Xie, C., and Ali, M. (2022d). Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 23, 346–364. doi:10.1002/suco.202000472

Kovačević, M., Lozančić, S., Nyarko, E. K., and Hadzima-Nyarko, M. (2021). Modeling of compressive strength of self-compacting rubberized concrete using machine learning. Materials 14, 4346. doi:10.3390/ma14154346

Kroll, C. N., and Song, P. (2013). Impact of multicollinearity on small sample hydrologic regression models. Water Resour. Res. 49, 3756–3769. doi:10.1002/wrcr.20315

Kumar, B. N., and Kumar, P. P. (2022). Prediction on flexural strength of high strength hybrid fiber self compacting concrete by using artificial intelligence. J. Artif. Intell. 4, 1–16. doi:10.36548/jaicn.2022.1.001

Larsen, I. L., and Thorstensen, R. T. (2020). The influence of steel fibres on compressive and tensile strength of ultra high performance concrete: A review. Constr. Build. Mater. 256, 119459. doi:10.1016/j.conbuildmat.2020.119459

Lauritsen, S. M., Kristensen, M., Olsen, M. V., Larsen, M. S., Lauritsen, K. M., Jørgensen, M. J., et al. (2020). Explainable artificial intelligence model to predict acute critical illness from electronic health records. Nat. Commun. 11, 3852–3911. doi:10.1038/s41467-020-17431-x

Le Hoang, A., and Fehling, E. (2017). Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra high performance concrete. Constr. Build. Mater. 153, 790–806. doi:10.1016/j.conbuildmat.2017.07.130

Li, L., Khan, M., Bai, C., and Shi, K. (2021a). Uniaxial tensile behavior, flexural properties, empirical calculation and microstructure of multi-scale fiber reinforced cement-based material at elevated temperature. Materials 14, 1827. doi:10.3390/ma14081827

Li, L., Sun, H.-X., Zhang, Y., and Yu, B. (2021b). Surface cracking and fractal characteristics of bending fractured polypropylene fiber-reinforced geopolymer mortar. Fractal Fract. 5, 142. doi:10.3390/fractalfract5040142

Li, L., Cao, M., Li, Z., Zhang, W., Shi, D., and Shi, K. (2022a). Uniaxial tensile behavior and mechanism characterization of multi-scale fiber-reinforced cementitious materials. Mater. Construcción 72, e271. doi:10.3989/mc.2022.05521

Li, L., Tao, J.-C., Zhang, Y., Sun, H.-X., Yuen, K.-V., and You, P.-B. (2022b). Crack fractal analysis of fractured polyethylene fiber reinforced alkali activated mortar under flexural load. Constr. Build. Mater. 345, 128428. doi:10.1016/j.conbuildmat.2022.128428

Liang, X., Wu, C., Su, Y., Chen, Z., and Li, Z. (2018). Development of ultra-high performance concrete with high fire resistance. Constr. Build. Mater. 179, 400–412. doi:10.1016/j.conbuildmat.2018.05.241

Lin, D., Foster, D. P., and Ungar, L. H. (2011). VIF regression: A fast regression algorithm for large data. J. Am. Stat. Assoc. 106, 232–247. doi:10.1198/jasa.2011.tm10113

Lu, J., Yu, Z., Zhu, Y., Huang, S., Luo, Q., and Zhang, S. (2019). Effect of lithium-slag in the performance of slag cement mortar based on least-squares support vector machine prediction. Materials 12, 1652. doi:10.3390/ma12101652

Lundberg, S. M., and Lee, S.-I. (2017). A unified approach to interpreting model predictions. Adv. neural Inf. Process. Syst. 30.

Lundberg, S. M., Nair, B., Vavilala, M. S., Horibe, M., Eisses, M. J., Adams, T., et al. (2018). Explainable machine-learning predictions for the prevention of hypoxaemia during surgery. Nat. Biomed. Eng. 2, 749–760. doi:10.1038/s41551-018-0304-0

Lundberg, S. M., Erion, G., Chen, H., Degrave, A., Prutkin, J. M., Nair, B., et al. (2019). Explainable AI for trees: From local explanations to global understanding. arXiv preprint arXiv:1905.04610.

Mahjoubi, S., Barhemat, R., Guo, P., Meng, W., and Bao, Y. (2021). Prediction and multi-objective optimization of mechanical, economical, and environmental properties for strain-hardening cementitious composites (SHCC) based on automated machine learning and metaheuristic algorithms. J. Clean. Prod. 329, 129665. doi:10.1016/j.jclepro.2021.129665

Mahjoubi, S., Meng, W., and Bao, Y. (2022a). Auto-tune learning framework for prediction of flowability, mechanical properties, and porosity of ultra-high-performance concrete (UHPC). Appl. Soft Comput. 115, 108182. doi:10.1016/j.asoc.2021.108182

Mahjoubi, S., Meng, W., and Bao, Y. (2022b). Logic-guided neural network for predicting steel-concrete interfacial behaviors. Expert Syst. Appl. 198, 116820. doi:10.1016/j.eswa.2022.116820

Marani, A., and Nehdi, M. L. (2020). Machine learning prediction of compressive strength for phase change materials integrated cementitious composites. Constr. Build. Mater. 265, 120286. doi:10.1016/j.conbuildmat.2020.120286

Marani, A., Jamali, A., and Nehdi, M. L. (2020). Predicting ultra-high-performance concrete compressive strength using tabular generative adversarial networks. Materials 13, 4757. doi:10.3390/ma13214757

Meng, Z., Li, L., Farooqi, M. U., Feng, L., and Wang, L. (2022). Fiber factor for fresh and hardened properties of polyethylene fiber-reinforced geopolymer mortar. J. Build. Eng. 53, 104556. doi:10.1016/j.jobe.2022.104556

Mokhtari, K. E., Higdon, B. P., and Başar, A. (2019). “"Interpreting financial time series with SHAP values,” in Proceedings of the 29th Annual International Conference on Computer Science and Software Engineering, 166–172.

Musumeci, F., Rottondi, C., Nag, A., Macaluso, I., Zibar, D., Ruffini, M., et al. (2018). An overview on application of machine learning techniques in optical networks. IEEE Commun. Surv. Tutorials 21, 1383–1408. doi:10.1109/comst.2018.2880039

Muzzammel, R., and Raza, A. (2020). A support vector machine learning-based protection technique for MT-HVDC systems. Energies 13, 6668. doi:10.3390/en13246668

Nawaz, M. N., Qamar, S. U., Alshameri, B., Karam, S., Çodur, M. K., Nawaz, M. M., et al. (2022). Study using machine learning approach for novel prediction model of liquid limit. Buildings 12, 1551. doi:10.3390/buildings12101551

Nazar, S., Yang, J., Ahmad, A., and Shah, S. F. A. (2022). Comparative study of evolutionary artificial intelligence approaches to predict the rheological properties of fresh concrete. Mater. Today Commun. 32, 103964. doi:10.1016/j.mtcomm.2022.103964

Nehdi, M., El Chabib, H., and El Naggar, M. H. (2001). Predicting performance of self-compacting concrete mixtures using artificial neural networks. Mater. J. 98, 394–401.

Nguyen, T. T., Pham Duy, H., Pham Thanh, T., and Vu, H. H. (2020). Compressive strength evaluation of fiber-reinforced high-strength self-compacting concrete with artificial intelligence. Adv. Civ. Eng. 2020, 1–12. doi:10.1155/2020/3012139

Pan, X., Xiao, Y., Suhail, S. A., Ahmad, W., Murali, G., Salmi, A., et al. (2022). Use of artificial intelligence methods for predicting the strength of recycled aggregate concrete and the influence of raw ingredients. Materials 15, 4194. doi:10.3390/ma15124194

Pandey, P. K., Aggarwal, P., Aggarwal, Y., and Aggarwal, S. (2022). “Prediction of compressive strength of self-compacting concrete containing silica's using soft computing techniques,” in Applications of computational intelligence in concrete technology (Florida: CRC Press), 163–181.

Park, S. H., Kim, D. J., Ryu, G. S., and Koh, K. T. (2012). Tensile behavior of ultra high performance hybrid fiber reinforced concrete. Cem. Concr. Compos. 34, 172–184. doi:10.1016/j.cemconcomp.2011.09.009

Raza, S. S., Ali, B., Noman, M., Fahad, M., and Elhadi, K. M. (2022a). Mechanical properties, flexural behavior, and chloride permeability of high-performance steel fiber-reinforced concrete (SFRC) modified with rice husk ash and micro-silica. Constr. Build. Mater. 359, 129520. doi:10.1016/j.conbuildmat.2022.129520

Raza, S. S., Amir, M. T., Azab, M., Ali, B., Abdallah, M., El Ouni, M. H., et al. (2022b). Effect of micro-silica on the physical, tensile, and load-deflection characteristics of micro fiber-reinforced high-performance concrete (HPC). Case Stud. Constr. Mater. 17, e01380. doi:10.1016/j.cscm.2022.e01380

Sarkhani Benemaran, R., Esmaeili-Falak, M., and Javadi, A. (2022). Predicting resilient modulus of flexible pavement foundation using extreme gradient boosting based optimised models. Int. J. Pavement Eng., 1–20. doi:10.1080/10298436.2022.2095385

Schmidt, M., and Fehling, E. (2005). Ultra-high-performance concrete: Research, development and application in europe. ACI Spec. Publ. 228, 51–78.

Shah, S. a. R., Azab, M., Seif Eldin, H. M., Barakat, O., Anwar, M. K., and Bashir, Y. (2022). Predicting compressive strength of blast furnace slag and fly ash based sustainable concrete using machine learning techniques: An application of advanced decision-making approaches. Buildings 12, 914. doi:10.3390/buildings12070914

Shang, M., Li, H., Ahmad, A., Ahmad, W., Ostrowski, K. A., Aslam, F., et al. (2022). Predicting the mechanical properties of RCA-based concrete using supervised machine learning algorithms. Materials 15, 647. doi:10.3390/ma15020647

Shi, C., Wu, Z., Xiao, J., Wang, D., Huang, Z., and Fang, Z. (2015). A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 101, 741–751. doi:10.1016/j.conbuildmat.2015.10.088

Solhmirzaei, R., Salehi, H., Kodur, V., and Naser, M. (2020). Machine learning framework for predicting failure mode and shear capacity of ultra high performance concrete beams. Eng. Struct. 224, 111221. doi:10.1016/j.engstruct.2020.111221

Sonebi, M., Cevik, A., Grünewald, S., and Walraven, J. (2016). Modelling the fresh properties of self-compacting concrete using support vector machine approach. Constr. Build. Mater. 106, 55–64. doi:10.1016/j.conbuildmat.2015.12.035

Song, H., Ahmad, A., Farooq, F., Ostrowski, K. A., Maślak, M., Czarnecki, S., et al. (2021). Predicting the compressive strength of concrete with fly ash admixture using machine learning algorithms. Constr. Build. Mater. 308, 125021. doi:10.1016/j.conbuildmat.2021.125021

Soroush, M., and Bao, Y. (2021). The key material properties of ultra-high-performance concrete (UHPC). Mendeley Data V1. doi:10.17632/dd62d5hyzr.11

Tang, B., Lu, Y., Zhou, J., Chouhan, T., Wang, H., Golani, P., et al. (2020). Machine learning-guided synthesis of advanced inorganic materials. Mater. Today 41, 72–80. doi:10.1016/j.mattod.2020.06.010

Tariq, H., Siddique, R. M. A., Shah, S. a. R., Azab, M., Qadeer, R., Ullah, M. K., et al. (2022). Mechanical performance of polymeric ARGF-based fly ash-concrete composites: A study for eco-friendly circular economy application. Polymers 14, 1774. doi:10.3390/polym14091774

Umeonyiagu, I., and Nwobi-Okoye, C. (2015a). Predicting flexural strength of concretes incorporating river gravel using multi-layer perceptron networks: A case study of eastern Nigeria. Niger. J. Technol. 34, 12–20. doi:10.4314/njt.v34i1.2

Umeonyiagu, I. E., and Nwobi-Okoye, C. C. (2015b). Modelling compressive strength of concretes incorporating termite mound soil using multi-layer perceptron networks: A case study of eastern Nigeria. Int. J. Res. Rev. Appl. Sci. 24, 19.

Wang, J., and Wu, F. (2022). New hybrid support vector regression methods for predicting fresh and hardened properties of self-compacting concrete. J. Intelligent Fuzzy Syst., 1–15. doi:10.3233/jifs-220744

Wang, D., Shi, C., Wu, Z., Xiao, J., Huang, Z., and Fang, Z. (2015). A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 96, 368–377. doi:10.1016/j.conbuildmat.2015.08.095

Wang, Q., Hussain, A., Farooqi, M. U., and Deifalla, A. F. (2022). Artificial intelligence-based estimation of ultra-high-strength concrete's flexural property. Case Stud. Constr. Mater. 17, e01243. doi:10.1016/j.cscm.2022.e01243

Worden, K., and Manson, G. (2007). The application of machine learning to structural health monitoring. Philosophical Trans. R. Soc. A Math. Phys. Eng. Sci. 365, 515–537. doi:10.1098/rsta.2006.1938

Wu, Z., Shi, C., He, W., and Wang, D. (2016). Uniaxial compression behavior of ultra-high performance concrete with hybrid steel fiber. J. Mater. Civ. Eng. 28, 06016017. doi:10.1061/(asce)mt.1943-5533.0001684

Xie, C., Cao, M., Guan, J., Liu, Z., and Khan, M. (2021). Improvement of boundary effect model in multi-scale hybrid fibers reinforced cementitious composite and prediction of its structural failure behavior. Compos. Part B Eng. 224, 109219. doi:10.1016/j.compositesb.2021.109219

Yan, L., Diao, Y., Lang, Z., and Gao, K. (2020). Corrosion rate prediction and influencing factors evaluation of low-alloy steels in marine atmosphere using machine learning approach. Sci. Technol. Adv. Mater. 21, 359–370. doi:10.1080/14686996.2020.1746196

Yeung, C., Tsai, J.-M., King, B., Kawagoe, Y., Ho, D., Knight, M. W., et al. (2020). Elucidating the behavior of nanophotonic structures through explainable machine learning algorithms. ACS Photonics 7, 2309–2318. doi:10.1021/acsphotonics.0c01067

Yoo, D.-Y., and Banthia, N. (2016). Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 73, 267–280. doi:10.1016/j.cemconcomp.2016.08.001

Yu, R., Spiesz, P., and Brouwers, H. (2014). Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 56, 29–39. doi:10.1016/j.cemconres.2013.11.002

Zhang, C., and Ali, A. (2021). The advancement of seismic isolation and energy dissipation mechanisms based on friction. Soil Dyn. Earthq. Eng. 146, 106746. doi:10.1016/j.soildyn.2021.106746

Zhang, W., and Huang, Y. (2022). Three-dimensional numerical investigation of mixed-mode debonding of FRP-concrete interface using a cohesive zone model. Constr. Build. Mater. 350, 128818. doi:10.1016/j.conbuildmat.2022.128818

Zhang, X., Zhao, S., Liu, Z., and Wang, F. (2019). Utilization of steel slag in ultra-high performance concrete with enhanced eco-friendliness. Constr. Build. Mater. 214, 28–36. doi:10.1016/j.conbuildmat.2019.04.106

ZhangN, ., Yan, C., Li, L., and Khan, M. (2022). Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 319, 126130. doi:10.1016/j.conbuildmat.2021.126130

ZhangZ, ., Liang, G., Niu, Q., Wang, F., Chen, J., Zhao, B., et al. (2022). A Wiener degradation process with drift-based approach of determining target reliability index of concrete structures. Qual. Reliab. Eng. Int. 38, 3710–3725. doi:10.1002/qre.3168

Zhao, W., Joshi, T., Nair, V. N., and Sudjianto, A. (2020). Shap values for explaining cnn-based text classification models. arXiv preprint arXiv:2008.11825.

Zheng, D., Wu, R., Sufian, M., Kahla, N. B., Atig, M., Deifalla, A. F., et al. (2022). Flexural strength prediction of steel fiber-reinforced concrete using artificial intelligence. Materials 15, 5194. doi:10.3390/ma15155194

Zhou, M., Lu, W., Song, J., and Lee, G. C. (2018). Application of ultra-high performance concrete in bridge engineering. Constr. Build. Mater. 186, 1256–1267. doi:10.1016/j.conbuildmat.2018.08.036

Zhu, Y., Ahmad, A., Ahmad, W., Vatin, N. I., Mohamed, A. M., and Fathi, D. (2022). Predicting the splitting tensile strength of recycled aggregate concrete using individual and ensemble machine learning approaches. Crystals 12, 569. doi:10.3390/cryst12050569

Keywords: concrete, UHPC, flexural strength, prediction models, steel fibers, SHAP analysis

Citation: Qian Y, Sufian M, Hakamy A, Farouk Deifalla A and El-said A (2023) Application of machine learning algorithms to evaluate the influence of various parameters on the flexural strength of ultra-high-performance concrete. Front. Mater. 9:1114510. doi: 10.3389/fmats.2022.1114510

Received: 02 December 2022; Accepted: 22 December 2022;

Published: 06 January 2023.

Edited by:

Li Li, Northwest A&F University, ChinaReviewed by:

Muhammad Arslan Ahmad, Shenzhen University, ChinaMuhammad Noman, International Islamic University, Islamabad, Pakistan

Copyright © 2023 Qian, Sufian, Hakamy, Farouk Deifalla and El-said. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Muhammad Sufian, ZHJzdWZpYW4uc2V1QGdtYWlsLmNvbQ==

Yunfeng Qian

Yunfeng Qian Muhammad Sufian

Muhammad Sufian Ahmad Hakamy3

Ahmad Hakamy3 Ahmed Farouk Deifalla

Ahmed Farouk Deifalla Amr El-said

Amr El-said