95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Mater. , 19 December 2022

Sec. Structural Materials

Volume 9 - 2022 | https://doi.org/10.3389/fmats.2022.1100276

This article is part of the Research Topic Sustainable Fiber Reinforced Cementitious Composites for Construction and Building Materials View all 14 articles

Abdulrhman Mohamad Moasas1

Abdulrhman Mohamad Moasas1 Muhammad Nasir Amin1*

Muhammad Nasir Amin1* Waqas Ahmad2

Waqas Ahmad2 Kaffayatullah Khan1

Kaffayatullah Khan1 Mohammed Najeeb Al-Hashem1

Mohammed Najeeb Al-Hashem1 Hisham Jahangir Qureshi1

Hisham Jahangir Qureshi1 Abdullah Mohamed3

Abdullah Mohamed3In the construction industry, pursuing sustainable development by using sustainable materials necessitates using renewable resources. Among different renewable materials, mineral-derived natural fibers are relatively cheaper and abundantly available in various countries. This study summarizes the research advancements on concrete reinforced with mineral-derived natural fibers. This review on the incorporation of mineral fibers in concrete evaluates, identifies, and synthesizes research outcomes for creating a summary of current evidence which can contribute to evidence-based practice. Mapping knowledge, c/o-occurrence, and co-citation are hard gears for innovative research. Accordingly, the present study is aimed at exploring the literature on key features of mineral fiber-reinforced concrete by performing a scientometric analysis. The current study implemented an advanced approach for mining, processing, and analyzing data, interpretation, and presentation of available bibliographic data on mineral fibers in concrete. Furthermore, the discussion on the applications and limitations of using mineral fiber-reinforced concrete in the construction industry is also made. The current research may aid academics in exchanging new ideas and techniques and developing collective efforts.

Establishing novel/alternative construction materials focuses on enhanced properties (i.e., physical/mechanical) and the performance of concrete and relative structures. Generally, concrete is weaker under flexural loading than under compressive loading. To cater to this issue, the concept of short, discrete fibers as dispersed reinforcement is introduced, enhancing the mechanical properties of concrete and improving the resistance against deformation and cracks, ultimately contributing to the durability of concrete (Pukharenko, 2012; de Azevedo et al., 2021a; de Azevedo et al., 2021b; Azevedo et al., 2022; Ali et al., 2022c; Meng et al., 2022). During the past three decades, the emerging concern toward environmental problems arising from conventional concrete manufacturing has gained the attention of researchers in civil engineering to pursue alternative approaches for discovering environment-friendly construction materials (Cabeza et al., 2010; Väntsi and Kärki, 2014; de Azevedo et al., 2017; de Azevedo et al., 2018; Ahmed et al., 2021; Arooj and Ali, 2021; de Azevedo et al., 2021b; de Azevedo et al., 2022a; de Azevedo et al., 2022b; Raza et al., 2022). In 2019, the WGBC reported techniques/standards to design environment-friendly structures to reduce 40% of carbon footprints by 2030 and eliminate CO2 emissions by 2050 (Alhawat et al., 2022). Utilization of substitute fuels, engrossing CO2, enhancing energy efficiency within the boiler, and replacing ordinary Portland cement with waste/supplementary materials such as silica fume, sugarcane bagasse ash, plastic waste fibers, recycled tires, etc., to produce green/environment-friendly cementitious concrete are the advised measures (Kaïkea et al., 2014; Pogorelov and Semenyak, 2016; Li and Cao, 2018; Ali et al., 2021; Nafees et al., 2021; Thomas et al., 2021; Ali, 2022; Ali et al., 2022e; Li et al., 2022; Nafees et al., 2022).

The fibers are usually classified as metallic, organic, and mineral (Ali et al., 2022d). The selection of these fibers is made based on distinct dominant properties. The literature reported that the concrete strength could be improved by enhancing the modular ratio, aspect ratio, degree of alignment, and content of fiber (Aydın, 2013; Farooqi and Ali, 2019; Ali et al., 2022a; Azevedo et al., 2022). The specific fiber property is only emphasized at the molecular level (Ali et al., 2022b; Farooqi and Ali, 2022). Figure 1 reveals that the incorporation of mineral fibers in concrete will help in terms of both the economy and environment, as these fibers are naturally available and would result in reduced amounts of conventional materials such as cement and aggregates, for conventional cementitious concrete, ultimately conserving natural resources and reducing CO2 emissions (Khan et al.; Mechtcherine et al., 2016; Khan et al., 2018; Cao et al., 2019b; Li et al., 2019a). Mineral fibers such as basalt fiber are categorized as raw materials that meet the technical requirements and environmental aspects (Khan et al., 2018; Khan et al., 2021b; John and Dharmar, 2021). These fibers have the following excellent properties: 1) effective mechanical properties; 2) substantial bond behavior among epoxies, glues, and metals; and 3) extra-ordinary electrical, thermal, and acoustic properties (Khan et al., 2021a; Khan and Cao, 2021). These mineral basalt/wool/CaCO3 whisker fibers are famous for their energy-absorption capability and binding ability (Jerman and Černý, 2012; Luo et al., 2014; Xin et al., 2015; Stonys et al., 2016; Khan et al., 2018; Yliniemi et al., 2018; Cao et al., 2019a; Li et al., 2019b; Cao et al., 2019c; Li L. et al., 2020; Khan et al., 2022; Khan et al., 2022f). After replacement with natural/mineral fibers, conventional fibers reduce the damage to different industry zones and social aspects (Farooqi and Ali, 2018a; Farooqi and Ali, 2018b; Farooqi and Ali, 2018c; Li et al., 2019c; Li et al., 2021; Khan et al., 2022a; Khan et al., 2022e).

As the mineral fiber-reinforced concrete research is enhanced due to rising concerns against environmental issues resulting from conventional cementitious concrete, researchers are facing restrictions in terms of information available, which may limit the innovation in academic and research collaborations. Therefore, it is critical to establish and execute a process that aids academicians in obtaining necessary information from the most authentic sources. Employing a software tool, a scientometric approach can aid in overcoming the said lacking factors (Figure 2). Accordingly, the current study is focused on performing a scientometric analysis on published bibliographic data in the mineral fiber-reinforced concrete research area up to December 2022. A scientometric evaluation may conduct a quantitative investigation of a bulk volume of the bibliographic database by applying a suitable software tool. Typical review-based research studies show a deficiency in its capability to comprehensively and precisely connect different literature aspects. Scientific visualization, co-occurrence, and co-citations are the main complex features of modern research (Udomsap and Hallinger, 2020; Yang et al., 2022). It is from the scientometric analysis that revealed sources and authors with maximum publications, keyword co-occurrences, actively contributing countries, and publications with maximum citations in mineral fiber-reinforced concrete research. The Scopus search engine is made for attaining abstracts, keywords, bibliographies, citations, funding, and other relevant data from 912 related articles. VOSviewer tool is applied to process these data afterward. The statistical and graphical mappings of countries and scientists/researchers in this work would help research scholars exchange novel ideas and approaches and establish collaborative research-based activities. As the scientometric analysis demonstrates subject-relevant keywords and the most appropriate literature review, the current research discussed and emphasized the latest applications of mineral fiber-reinforced concrete, the limitations related to the application and production of mineral fiber-reinforced concrete and possible solutions. This research will help engineering field academicians who belong to different areas/regions/locations establish joint ventures, exchange innovative and novel techniques/ideas, and develop research collaborations resulting from the statistical and graphical depictions of authors and countries.

FIGURE 2. Scientometric review process (Zheng et al., 2021a).

In the current research, scientometric analysis is performed on bibliographic data (Xu et al., 2018; Darko et al., 2019; Xiao et al., 2019) to quantify several properties of said bibliographic data. Scientific mapping is utilized in the scientometric study, an approach developed by academics to analyze bibliometric data (Markoulli et al., 2017; Amin et al., 2022). Abundant publications have been found on the subject; therefore, it is vital to employ a reliable search engine. Scopus and Web of Science are two highly accurate databases perfectly suitable for said objective (Afgan and Bing, 2021; Huang S. et al., 2022). The highly recommended database, i.e., Scopus, is employed to gather information regarding the bibliography for current research on mineral fiber-reinforced concrete. As of today, a search of mineral fibers in concrete on Scopus yielded 912 results. Several filters are employed to scrutinize needless papers. A comprehensive procedural flowchart showing the steps such as retrieval of data, analysis, and different filters used while performing the study are shown in Figure 3.

Moreover, other researchers have also reported on the same technique (Oraee et al., 2017; Jin et al., 2018; Park and Nagy, 2018). Applying the said filters on the Scopus database, 912 results remained. These records are stored in a Comma Separated Values (CSV) format for evaluation by a relevant tool. VOSviewer (version 1.6.18) is employed to develop the attained material’s quantitative assessment and scientific visualization. VOSviewer is an open-source and freely accessible mapping tool usually used in discrete research areas (Zuo and Zhao, 2014; Darko et al., 2017; Ahmad et al., 2021). The subsequent CSV file is uploaded on VOSviewer for additional assessment while keeping the data consistent and reliable. In the scientometric analysis, the most widely used keywords, the publishing sources, the contribution of different states, and the publications having the highest citations are evaluated. The aspects, co-occurrences, and interrelationships are demonstrated with the help of maps. Furthermore, the respective quantitative data are provided in tables. Colors are assigned to the clusters for the identification of a particular item on the map. In addition, different color schemes, such as plasma, viridis, and rainbow, are used for density visualization, and the rainbow option is used in the current work for density mapping.

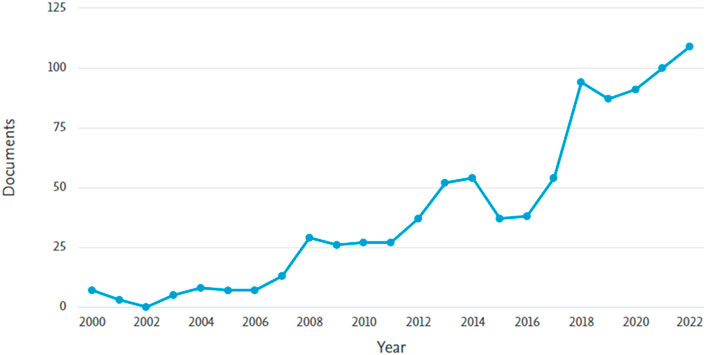

A Scopus analyzer is utilized to perform this assessment to identify the most relevant research areas. Figure 4 shows that Engineering, Materials Science, and Environmental Science are the three leading disciplines in the generation of documents, having almost 41%, 27%, and 6% of documents, respectively. As a whole, these three disciplines contribute 74% of papers. Moreover, the analysis on the Scopus database is also made to assess the publication types having subject research area documents (Figure 5). This assessment revealed that there are almost 56% of journal papers, around 29% of conference articles, 8% of conference reviews, and nearly 4% of journal reviews. The annual trend of published articles in the considered research area from 2011 to December 2022 is illustrated in Figure 6. Until 2014, a slight rise was observed in mineral fiber-reinforced concrete research publications. Following that, the publication trend was reduced to less than 40 articles in a year for two years, i.e., 2015 and 2016. The number of publications was enhanced considerably from 2016 to 2018. Again, from 2019–2020, the publications were slightly comprised, followed by a significant increase afterward. In the current year, the number of articles on the considered study field is more than 100 so far (as of December 2022). It is interesting to note that the attention of researchers is focused on using mineral fibers in concrete to have sustainable construction materials.

FIGURE 6. Annual publication trend of published articles on mineral fiber-reinforced concrete research till December 2022.

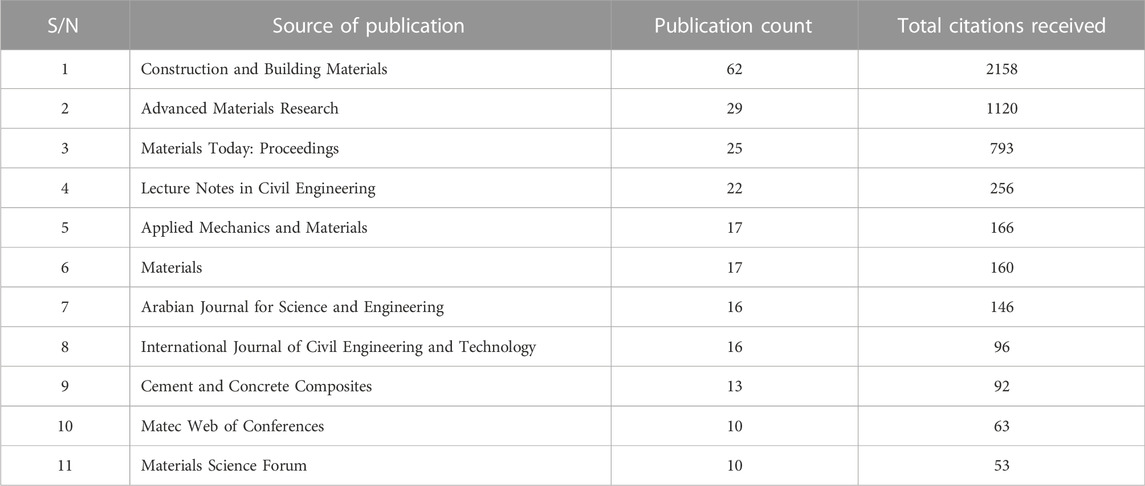

The sources of the publication are assessed by employing the VOSviewer on the bibliographic data. A minimum of ten papers from one source is specified, and 11 out of the 912 sources met the requirement. The publication sources have at least ten publications on mineral fibers in concrete research up to December 2022, and the received number of citations is enlisted in Table 1. The top three publication sources are “Construction and building materials”, “Advanced materials research”, and “Materials today: proceedings”, having 62, 29, and 25 papers, respectively, and 2,158, 1,120, and 793 citations up to December 2022, respectively. Exceptionally, via this assessment, a foundation is attained for upcoming scientometric analysis on mineral fibers in concrete research. Furthermore, the recent typical review-based research was incapable of providing systematic graphs. The visualization of publication sources having a minimum of ten articles is depicted in Figure 7. The frame size in Figure 7A shows the influence of the source on the current study research field as per document count, which means that the bigger the frame size, the more significant the impact. For example, the frame size for “Construction and building materials” is more than the others, depicting the significance of this journal in the considered research area. The formation of five groups is made, and a unique color represents each one on the map (red, yellow, green, purple, and blue). Group development is done based on publication source-extent or the co-citation frequency with comparable publications (Wuni et al., 2019). VOSviewer establishes the groups as per the co-citation tendencies in research publications. Seven journals in the red cluster are frequently co-cited in the same research. Furthermore, the link among closely placed publication sources in a particular group is more when compared to widely spread frames, for example, “Cement and concrete composites” majorly correlates with “Journal of cleaner production” than with “Procedia engineering” or “Construction and building materials”. As evident from Figure 7B, several tints correspond to different journal-density concentrations. Red color has the highest concentration. Blue, green, and yellow colors are afterward. “Construction and building materials” depict a red shade indicating its higher involvement in the mineral fiber-reinforced concrete research.

TABLE 1. Publication sources having a minimum of 10 publications on mineral fiber-reinforced concrete research.

FIGURE 7. Mapping of sources having at least 10 publications. (A) Network visualization; (B) density.

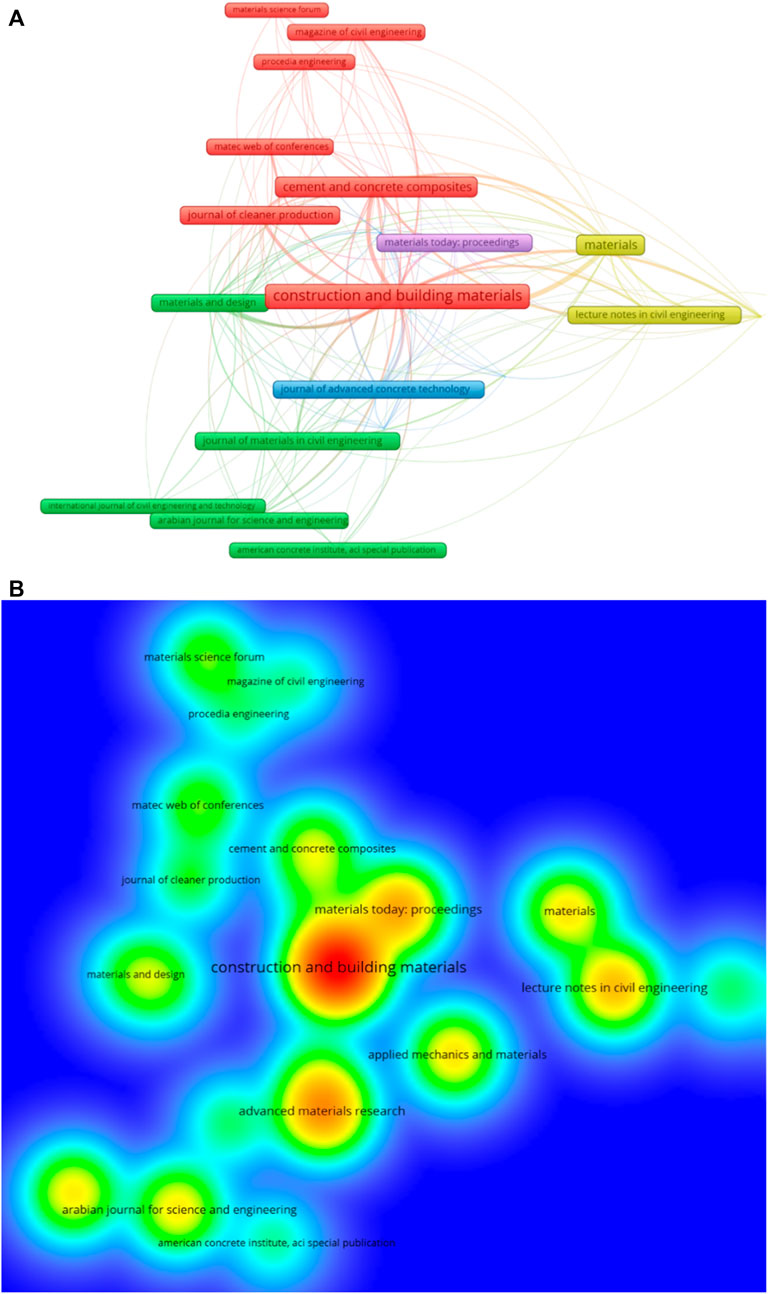

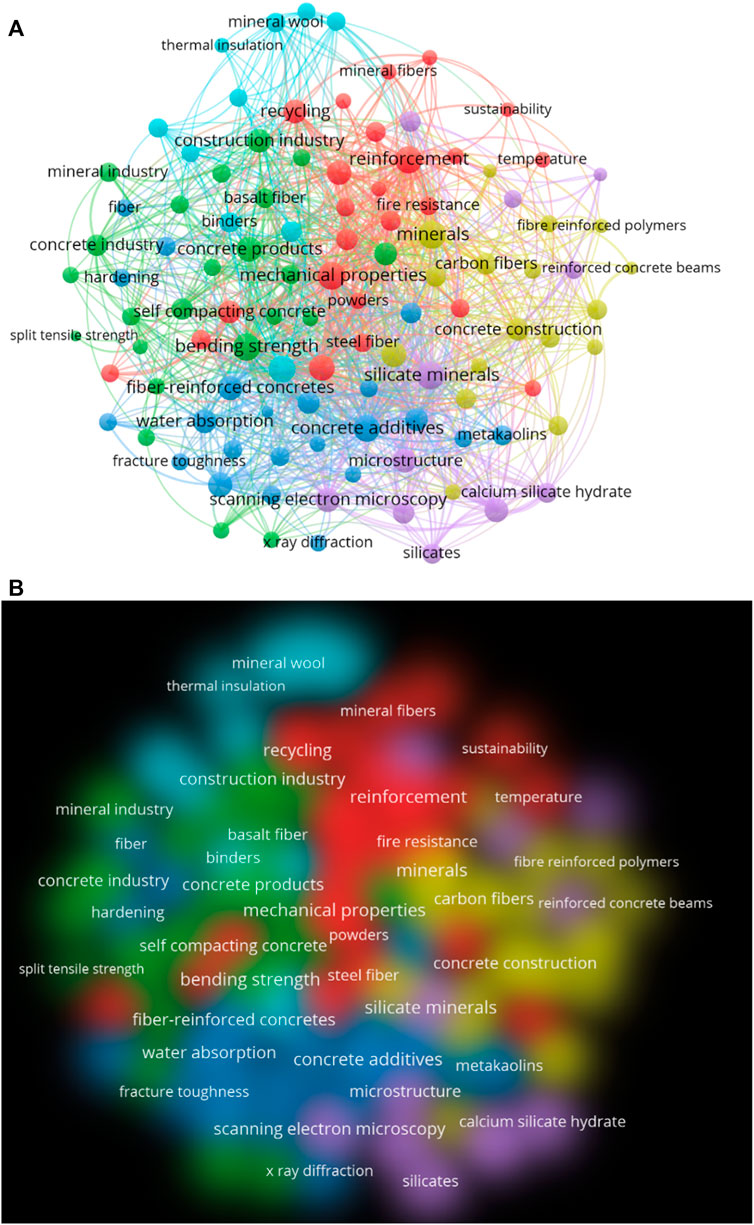

In research, keywords are important as the main subject of the research study domain is emphasized and distinguished by them (Song et al., 2021). The keyword recurrence requirement is set to at least 15. In this way, 20 keywords are preserved, as enlisted in Table 2. Mechanical properties, fiber-reinforced concrete, natural fibers, minerals, and basalt fiber are the five most widely occurring keywords in the considered research field. The keyword analysis revealed that mineral fibers in concrete have mainly been explored to have an alternative sustainable construction material. Depending upon the co-occurrences, density, and connections related to their frequency of occurrence, a graph is presented in Figure 8. The frame size of a keyword in Figure 8A indicates its frequency, where the position of the frame represents the co-occurrence. Moreover, the top keywords show larger frames than the rest, indicating that these are important keywords to investigate the reinforced concrete research of the mineral fibers. The clustering is also done to represent the co-occurrences of keywords in various published articles, as seen from the graph. Different colors are assigned to each group to represent keyword recurrences. In Figure 8A, the diverse shades of the five clusters are shown. The density concentrations for different keywords are also represented by unique colors, as shown in Figure 8B. The shades yellow, red, blue, and green show their densities. Mechanical properties, mineral fibers, sustainability, concrete construction, and other significant keywords show red or yellow tints representing more occurrences of density. This outcome would assist determined scientists in selecting keywords, reducing the effort to discover published articles on a definite topic.

TABLE 2. List of the top twenty most-used keywords in the research of mineral fiber-reinforced concrete.

FIGURE 8. Mapping of keywords having at least 15 publications. (A) Network visualization; (B) density.

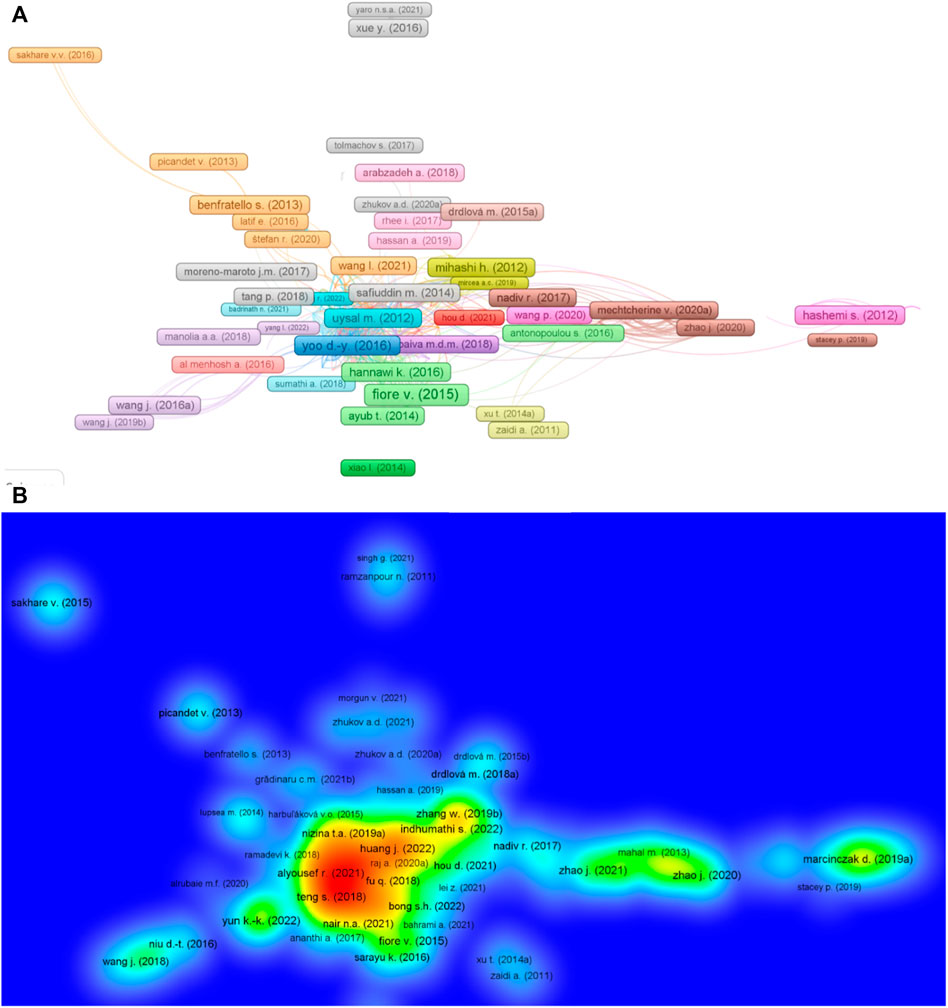

The impact of a certain paper in a specific research area is depicted by its citations. Articles with higher citations pioneer in a particular research area. The scientific visualization of citations based on inter-connected publications and concentration of published papers in considered research areas, i.e., mineral fibers in concrete, is presented in Figure 9. Figure 9A represents the interlinked publications via citations, evaluated using VOSviewer analysis. The size of the frame for a particular document is directly proportional to the impact of that specific article in the considered research domain, i.e., mineral fibers in concrete. Moreover, in Figure 9B, the density mapping reveals the enhanced density concentration of the leading articles as per citations.

FIGURE 9. Systematic map of articles; (A) citation, base-linked articles; (B) density of connected articles.

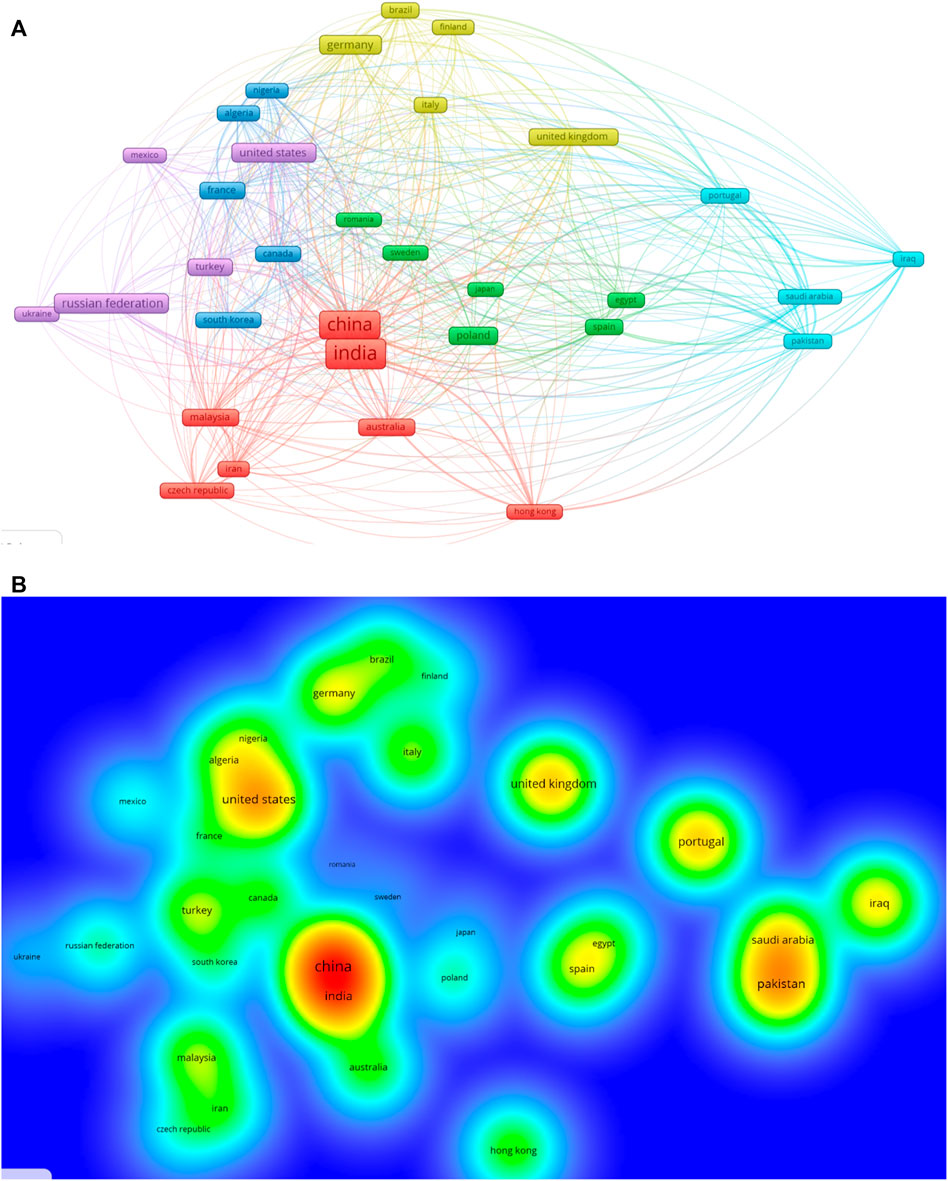

Several countries have produced articles in the considered domain, and these countries aim to keep contributing. A systematic plot is developed for bibliophiles to assess the countries enthusiastic about researching mineral fibers in concrete to predict their properties. For this analysis, the criteria of minimum articles per nation are set as 10, and 21 countries have met this requirement, as listed in Table 3. Among all the countries, India, China, and the Russian Federation have contributed the maximum articles having 166, 138, and 48 articles, respectively. Moreover, China received 1,754 citations, followed by Italy and the United States with 1,031 and 834 citations, respectively. The systemic map and density concentrations for citation-based linked countries are presented in Figure 10. The impact of a specific country in terms of article quantity on the subject-research domain is depicted from the frame size of that particular country (Figure 10A). As shown in Figure 10B, the countries with the most publications have more density. The quantitative output and graphical representation of the contributing countries would help young researchers establish scientific associations, initiate joint ventures, and exchange inventive approaches and ideas. Researchers from countries concerned with establishing research on mineral fibers in concrete may work with experts in this domain to yield aid from their expertise.

FIGURE 10. Systematic mapping of countries having at least 10 publications. (A) network map; (B) density.

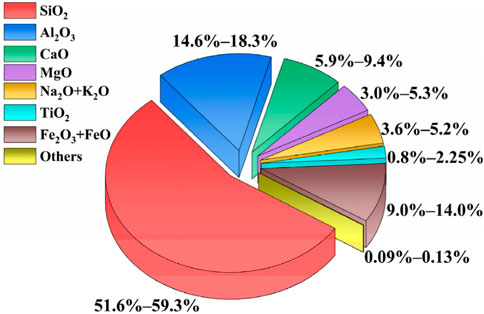

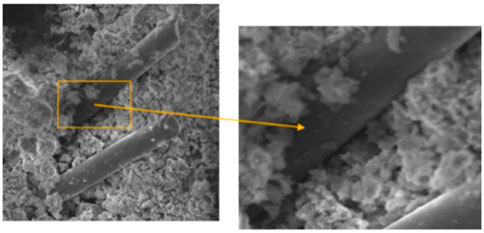

The remarkable enhancement in concrete’s mechanical properties due to the incorporation of mineral fibers is mainly due to its capability of forming an even spatial net structure in concrete, improvement in internal stress redistribution and mode of damage, enhancement in concrete’s internal mechanical stability, and improvement in the microstructure (Gao et al., 2021). Hence, it is vital to develop linkages to damages at the macroscopic level by the fiber distribution response properties and pore structure to demonstrate its mechanical performance. Accordingly, a generalized summary regarding mineral fiber-reinforced microstructure is also discussed in this study. The incorporation of mineral fibers in manufacturing dispersed fiber-reinforced cementitious concrete is promising for multiple reasons. Basalt roving and thin-staple fiber are examples of mineral fibers, primarily formed by using the centrifugal-spinneret technique and categorized by even characteristics, diameter uniformity, and lesser waste content. The mineral fibers are attained using an electro-thermal process to melt raw materials (Buyantuev et al., 2012). The chemical resemblance of mineral fibers enables their interaction with Portland cement. The typical chemical composition and physical appearance of basalt fibers are shown in Figure 11 and Figure 12, respectively, as reported by Liu H. et al. (2022). But, this feature might badly affect the mineral fibers and decrease the reinforcing effect. Saraikina et al. (2012) reported various methods for resolving this issue and summarized the primary ways for the protection of mineral fibers from the alkaline-medium effects of cement: 1) utilization of cement-less binders in concrete having fibers; 2) alteration in the surfaces of mineral fibers; 3) modification in the structure of mineral fibers; and 4) the incorporation of admixtures that decrease the alkalinity of fiber-reinforced concrete medium. Globally, the popularity of mineral fiber-reinforced concrete is gaining popularity in the research field with a possibility of coming out as one of the most sustainable construction materials. As incorporating mineral fibers in concrete is a comparatively new approach, it lacks in guidelines for design than typical concrete; therefore, more experimental studies are important to fill the research gaps in this field (Khan et al., 2022d; Kirthika and Singh, 2018; Yang et al., 2019; Gebremariam et al., 2021; Khan et al., 2018).

FIGURE 11. Basalt fiber’s typical chemical composition (Liu H. et al., 2022).

FIGURE 12. Basalt fiber’s physical appearance, (A) sheet, (B) short fibers, and (C) SEM image of basalt fiber (Liu H. et al., 2022).

In case of mineral fiber-reinforced concrete, the durability is considered in the form of impermeability, wear resistance, freeze–thaw resistance, and chloride-corrosion resistance (Zheng et al., 2021b). It has been observed that concrete has considerable susceptibility toward plastic cracking during the processes of setting and hardening (Huang Y. et al., 2022), that would adversely impact the respective project’s long-term durability due to cement species, additives, water–cement ratio, aggregate grading, and the construction environment (Xiaomei et al., 2019). Khan et al., 2018 evaluated the durability of mineral-based basalt fiber-reinforced concrete after its exposure to different accelerated environmental conditions. The weight loss, water absorption, and compressive strength of basalt fiber-reinforced concrete were determined experimentally after undergoing ageing conditions, i.e., immersion in sulphate and acidic solutions, for 90 days after 28 days of curing. The incorporation of basalt fibers resulted in improved concrete properties, i.e., water absorption and compressive strength, even after exposure to sulfate and acidic attacks. Zhang Z. et al. (2021) reported that the addition of CeO2 may also resist crack formation. Furthermore, the utilization of curing with moisture retaining (i.e., (e.g., steam curing or film curing) (Wei and Pengcheng, 2020), expansion agents like additives (Guoxin et al., 2018), or the incorporation of an adequate content of fibers may effectively reduce or may even resist the early plastic cracks-occurrence in concrete (Shi et al., 2022). There would be as lesser chances for occurrence of plastic-cracking in concrete as earlier as the conservation of moisture starts (Li et al., 2004). In case of more aspect ratio of fiber, the volume fraction would be higher and, subsequently, the adhesion strength at the fiber–matrix interface would be more (Sheng et al., 2021), which would enhance the repressive strength to resist plastic-cracking in concrete and ultimately improve the durability performance of the respective concrete (Jia et al., 2021). In case of durability of conventional concrete, steel fiber-reinforced concrete, and polymer fiber-reinforced concrete, the research has already been the subject of multiple reports (Zhang P. et al., 2021); however, in case of durability of mineral fiber-reinforced concrete, the research is still relatively small.

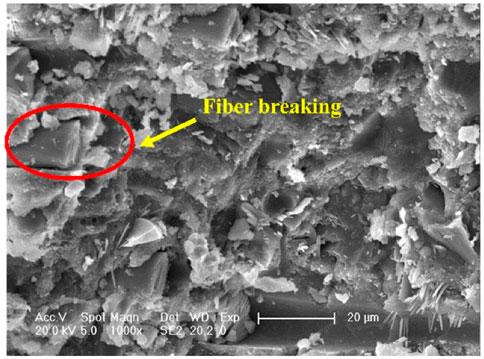

The SEM analysis is very important to explore the microstructure of concrete having mineral fibers. Li Y. et al. (2020) examined the mineral-derived basalt fiber-reinforced concrete by using SEM (Figure 13). Instead of fiber slippage, a cement paste coating was observed on the fiber surface, depicting an effective bonding among the mineral fiber and cement slurry (Figure 13). The cementitious material stuck on the fibers indicates its proper bonding, ultimately resulting in fiber fracture, as shown in Figure 14. It may be noted that crack propagation/expansion is limited due to proper bridging and bonding of embedded mineral-derived basalt fiber in the cementitious matrix. So, it can be said, based on the findings mentioned previously, that mineral fibers have considerably enhanced the concrete mechanical properties and thus, it can offer a stable structure in terms of load-bearing in concrete and resist the initiation and propagation of micro-cracks. Furthermore, adding mineral fibers in concrete can increase the pore and capillary contents, improve pore connectivity, and prevent the deterioration of the concrete-pore structure.

FIGURE 13. SEM image of mineral-derived basalt fiber-reinforced concrete (Li Y. et al., 2020).

FIGURE 14. SEM image of mineral-derived basalt fiber fracture in concrete (Liu M. et al., 2022).

Nowadays, sustainable development is in demand. Global warming resulting from swift ozone layer depletion due to bad environmental impacts is a severe problem. Ecological disintegration is due to the extreme consumption of fossil fuels and natural resources. So, leading toward sustainable development, the contributing factors toward ozone layer depletion must be eliminated as per the sustainable development goals. Waste mineral fibers are one of the major contributors. Furthermore, the increasing demand for fossil fuel and natural resources to meet the construction industries’ requirement has also accumulated toward ecological degradation. Therefore, incorporating such mineral fibers in concrete can significantly play its role in achieving UNDP’s sustainable development goals (Figure 15). This incorporation would not only contribute toward a reduction in the overall cost of the respective concrete, but it would also decline the conventional material consumption, ultimately leading to a reduction of natural resource consumption. In addition, the environmental pollution caused by CO2 emissions from these waste fibers (such as mineral fibers) may also be decreased significantly. Hence, green, sustainable, and economic development can be achieved by utilizing mineral fibers as reinforcement in cementitious concrete.

Research on cementitious concrete reinforced with mineral-derived natural fibers is evolving due to enhancing demand for the utilization of sustainable materials, as well as the strength, low density, low cost, and abundant local availability of these fibers. In recent years, the abundantly produced scientific information, in addition to new communication channels, encouraged the research community to suggest the metric which provided the basis for the novel bibliometrics field. It employs statistical and mathematical analytic approaches to attain reliable quality gauges. Hence, there is a feasibility to evaluate the number of published documents by a nation, institution, individual, or research group having the highest scientific outcome. Bibliometric research is a suitable technique to identify the literature growth trend and volume, focusing on mineral fiber-reinforced concrete-related examinations that will benefit young scholars. The main aim of the current study is to perform a scientometric analysis of the literature available on mineral fiber-reinforced concrete to assess multiple aspects. The obtained conclusions are as follows:

• Mineral fibers are categorized as natural materials and are one such material that meets the technical requirements and environmental needs. These fibers have excellent properties such as 1) effective mechanical properties; 2) substantial bond behavior; and 3) extra-ordinary reinforcing, thermal, and acoustic properties. Mineral fibers considerably enhance the concrete mechanical properties and thus, offer a stable structure in terms of load-bearing in concrete and resist the initiation and propagation of micro-cracks.

• It is revealed from the assessment of publication sources of a search on mineral fibers in concrete that “Construction and building materials,” “Advanced materials research,” and “Materials today: proceedings” are the leading three sources, with 62, 29, and 25 publications, respectively. As far as total citations are concerned, here again, the top three sources are “Construction and building materials” with 2,158 citations, “Advanced materials research” with 1,120 citations, and “Materials today: proceedings” with 793 citations.

• Keywords assessment in the mineral fiber-reinforced concrete research domain reveals that mechanical properties, fiber-reinforced concrete, natural fibers, minerals, and basalt fibers are the most frequently occurring five terms. This analysis also reveals that mineral fibers in concrete have mainly been explored to have sustainable construction materials.

• The leading countries are determined by the contribution of mineral fiber-reinforced concrete research, and it is summarized that 32 countries have published at least five articles. Among all the nations, India, China, and the Russian Federation have contributed the maximum number of articles having 166, 138, and 48 articles, respectively. Moreover, China received 1,754 citations, followed by Italy and the United States with 1,031 and 834 citations, respectively.

• The incorporation of mineral fibers in cementitious concrete decreases their brittleness and significantly improves their properties, including toughness, energy-absorption capacity, and tensile strength. Mineral fibers endorse the reinforcing effect via adhesion bonding among cementitious matrix and mineral fibers. The bonding mechanism is based on the respective concrete manufacturing method and content, orientation, dimension, and distribution of mineral fibers.

• The appropriate proportion of mineral fibers may significantly improve the impermeability, resistance against sulfate and chloride erosion, resistance against the freeze–thaw cycle, and high-temperature durability of mineral fiber-reinforced concrete. Furthermore, adding mineral fibers to concrete can increase the pore and capillary contents, improve pore connectivity, and prevent the deterioration of the concrete’s pore structure. However, it is important to explore the in-depth durability of concrete having mineral fibers and to develop specific test procedures for this purpose.

• It is evident from the reported SEM analysis that the string bonding among mineral fibers and the surrounding cementitious matrix offers an effective bridging mechanism that shows its ability to reduce stress concentrations and eliminates the probable internal degradation, ultimately leading to an improved mechanical performance of mineral fiber-reinforced concrete.

• This incorporation of mineral fibers in concrete would not only contribute toward a reduction in the overall cost, but it would also decline the consumption of conventional materials, ultimately leading toward sustainable development by reducing the adverse environmental impacts.

• The large-scale production and corresponding applications of mineral fiber-reinforced concrete are limited due to lacking information on various aspects such as long-term durability, Life Cycle Cost Analysis (LCCA), and Life Cycle Assessment (LCA) for mineral fiber-reinforced concrete. Therefore, mineral fiber-reinforced concrete needs to be further investigated in depth in terms of the aspects mentioned previously before its large-scale production and applicability.

The bibliographic mapping and statistical analysis of research data on mineral fiber-reinforced concrete fields are conducted in this systematic review. The already available conventional, i.e., manual, review-based research studies are insufficient to comprehensively and accurately relate different literature aspects. The most widely-adopted keywords, publications (journals), and sources having the most published articles, the most contributing countries in the form of publications and the authors having maximum citations in the mineral fiber-reinforced concrete research field are identified in the current research. As per the keyword’s evaluation, mechanical properties have been widely used to develop sustainable construction materials. Moreover, the literature and citation-based linkages are used to recognize the most participating and highly committed countries depending on the number of publications. The quantitative analysis and graphical representation of contributing countries and researchers would aid young researchers in establishing scientific collaborations, sharing progressive concepts and techniques, and developing joint ventures. Researchers from countries contributing to escalating the research on mineral fiber-reinforced concrete applications may collaborate with experts of the same discipline to benefit from their expertise. After evaluating the keywords in the considered research area with the help of scientometric analysis and reviewing the closely related literature, the current research emphasized the future perspectives of mineral fiber-reinforced concrete. Usually, research on mineral fiber wastes is not as deep as on other waste materials. For more efficiency and commercial feasibility in reusing after repurposing and recycling waste minerals, the following perspectives are proposed for the future:

• Before developing an appropriate technique to cater for the waste, a transparent classification of mineral-waste fibers from multiple sources is to be done. The said classification should mainly cover the mineral fiber type, prior usage, source, contaminant types, chemical composition, and physical conditions.

• The currently employed comminution method does not cost much and is energy-effective for treating waste–rock–mineral–wool fibers. This method seems to be a critical parameter in reducing the overall cost and developing more attention toward research development (Yap et al., 2021).

• The incorporation of additional admixtures such as; air-entraining agents, superplasticizers, and pozzolanic materials such as fly ash and silica fume also need to be explored to improve the mechanical properties and flow of concrete.

• Further enhancement in mineral fiber-reinforced cementitious concrete demands thorough research to assess the durability of concrete having mineral fibers (Awoyera et al., 2022).

• In the future, the aim of research should be toward optimizing and altering building materials, including simplified environmental analysis at a minimum level, as the ecological effect mitigation signifies a significant challenge to the current society. The efficiency of the existing building in terms of eco-friendly links less-energy requirement maintenance and embodied energy (Fořt et al., 2021; Zhang et al., 2022).

• Moreover, manual mixing for concrete preparation is hectic in the case of fiber-incorporation, resulting in a non-homogeneous mix. Therefore, the specific chemical addition may also be explored to replace manual and machine mixing.

• Further research is also suggested for the large-scale production of mineral fiber-reinforced concrete and the construction of a relevant structure to ensure the actual capability of mineral fibers in concrete and to portray the application of this sustainable material in the construction industry.

• The structural applications, such as pavements, bridge girders, etc., of mineral fiber-reinforced concrete should also be explored in detail if its long-term durability evaluation provides satisfactory outcomes.

• Furthermore, nowadays, researchers are giving significant attention to the 3D-printing technique to determine the performance of structures made by different types of cementitious concrete for optimizing their materials to get improved mechanical properties by conserving natural resources. Hence, the exploration of mineral fibers for 3D-printing concrete would be an exciting horizon to explore.

• Moreover, the exploration of concrete incorporating different fiber (i.e., mineral and synthetic) combinations, i.e., hybrid fiber-reinforced cementitious concrete, should also be made in parallel with the employment of novel techniques for producing said concrete.

• Although the incorporation of waste mineral fibers in concrete tends to decrease the overall cost of material, as reported in the literature, Life Cycle Cost Analysis (LCCA) should also be performed before its application in real-life structures.

• The reported reduced CO2 emissions in the case of mineral fiber-reinforced concrete should also be validated by conducting Life Cycle Assessment (LCA), from the cradle to the grave, for mineral fiber-reinforced concrete when intended to be used in bulk quantities.

AM: visualization, funding acquisition, writing, reviewing, and editing. MA: conceptualization, validation, investigation, project administration, funding acquisition, writing, reviewing, and editing. WA: conceptualization, data acquisition, methodology, validation, software, supervision, writing–original draft, reviewing, and editing. KK: conceptualization, methodology, resources, supervision, software, validation, investigation, writing original draft, reviewing, and editing. MA-H: data curation, methodology, visualization, writing, reviewing, and editing. HQ: investigation, formal analysis, writing, reviewing, and editing. AM: resources, validation, investigation, writing, reviewing, and editing.

This work was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (Project No. GRANT1997), through its KFU Research Summer Initiative.

The authors acknowledge the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (Project No. GRANT1997), through its KFU Research Summer Initiative. They extend their appreciation for the financial support that made this study possible.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Afgan, S., and Bing, C. (2021). Scientometric review of international research trends on thermal energy storage cement based composites via integration of phase change materials from 1993 to 2020. Constr. Build. Mater. 278, 122344. doi:10.1016/j.conbuildmat.2021.122344

Ahmad, W., Khan, M., and Smarzewski, P. (2021). Effect of short fiber reinforcements on fracture performance of cement-based materials: A systematic review approach. Materials 14 (7), 1745. doi:10.3390/ma14071745

Ahmed, T., Farooqi, M., and Ali, M. (2020). “Compressive behavior of rice straw-reinforced concrete for rigid pavements,” in Proceeding of the IOP conference series: Materials science and engineering (IOP Publishing), 012004.

Alhawat, M., Ashour, A., Yildirim, G., Aldemir, A., and Sahmaran, M. (2022). Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 50, 104104. doi:10.1016/j.jobe.2022.104104

Ali, B., Azab, M., Ahmed, H., Kurda, R., El Ouni, M. H., and Elhag, A. B. (2022a). Investigation of physical, strength, and ductility characteristics of concrete reinforced with banana (Musaceae) stem fiber. J. Build. Eng. 61, 105024. doi:10.1016/j.jobe.2022.105024

Ali, B. (2022). Development of environment-friendly and ductile recycled aggregate concrete through synergetic use of hybrid fibers. Environ. Sci. Pollut. Res. 29 (23), 34452–34463. doi:10.1007/s11356-022-18627-y

Ali, B., Farooq, M. A., El Ouni, M. H., Azab, M., and Elhag, A. B. (2022b). The combined effect of coir and superplasticizer on the fresh, mechanical, and long-term durability properties of recycled aggregate concrete. J. Build. Eng. 59, 105009. doi:10.1016/j.jobe.2022.105009

Ali, B., Farooq, M. A., Kurda, R., Alyousef, R., Noman, M., and Alabduljabbar, H. (2022c). Effect of type and volume fraction of recycled-tire steel fiber on durability and mechanical properties of concrete. Eur. J. Environ. Civ. Eng., 1–22. doi:10.1080/19648189.2022.2103590

Ali, B., Hawreen, A., Ben Kahla, N., Talha Amir, M., Azab, M., and Raza, A. (2022d). A critical review on the utilization of coir (coconut fiber) in cementitious materials. Constr. Build. Mater. 351, 128957. doi:10.1016/j.conbuildmat.2022.128957

Ali, B., Kurda, R., Ahmed, H., and Alyousef, R. (2022e). Effect of recycled tyre steel fiber on flexural toughness, residual strength, and chloride permeability of high-performance concrete (HPC). J. Sustain. Cement-Based Mater., 1–17. doi:10.1080/21650373.2021.2025165

Ali, B., Raza, S. S., Hussain, I., and Iqbal, M. (2021). Influence of different fibers on mechanical and durability performance of concrete with silica fume. Struct. Concr. 22 (1), 318–333. doi:10.1002/suco.201900422

Amin, M. N., Ahmad, W., Khan, K., and Sayed, M. M. (2022). Mapping research knowledge on rice husk ash application in concrete: A scientometric review. Materials 15 (10), 3431. doi:10.3390/ma15103431

Arooj, K., and Ali, M. (2021). Mechanical, dynamic and absorption properties of hybrid fiber reinforced concrete for rigid pavements application. Masters Civ. Eng. Capital University of Science & technology.

Awoyera, P. O., Odutuga, O. L., Effiong, J. U., De Jesus Silvera Sarmiento, A., Mortazavi, S. J., and Hu, J. W. (2022). Development of fibre-reinforced cementitious mortar with mineral wool and coconut fibre. Materials 15 (13), 4520. doi:10.3390/ma15134520

Aydın, S. (2013). Effects of fiber strength on fracture characteristics of normal and high strength concrete. Per. Pol. Civ. Eng. 57 (2), 191–200. doi:10.3311/ppci.7174

Azevedo, A. R., Lima, T. E., Reis, R. H., Oliveira, M. S., Candido, V. S., and Monteiro, S. N. (2022). Guaruman fiber: A promising reinforcement for cement-based mortars. Case Stud. Constr. Mater. 16, e01029. doi:10.1016/j.cscm.2022.e01029

Buyantuev, S., Mognonov, D., and Badmayev, B. (2012). The mini plant producing thermal insulation materials from basalt on the basis of electromagnetic melting units with low energy consumption. Bull. East Sib. State Univ. Technol. Manag. 1 (36), 16–20.

Cabeza, L. F., Castell, A., Medrano, M., Martorell, I., Pérez, G., and Fernández, I. (2010). Experimental study on the performance of insulation materials in Mediterranean construction. Energy Build. 42 (5), 630–636. doi:10.1016/j.enbuild.2009.10.033

Cao, M., Li, L., Yin, H., and Ming, X. (2019a). Microstructure and strength of calcium carbonate (CaCO3) whisker reinforced cement paste after exposed to high temperatures. Fire Technol. 55 (6), 1983–2003. doi:10.1007/s10694-019-00839-3

Cao, M., Ming, X., Yin, H., and Li, L. (2019b). Influence of high temperature on strength, ultrasonic velocity and mass loss of calcium carbonate whisker reinforced cement paste. Compos. Part B Eng. 163, 438–446. doi:10.1016/j.compositesb.2019.01.030

Cao, M., Xie, C., Li, L., and Khan, M. (2019c). Effect of different PVA and steel fiber length and content on mechanical properties of CaCO<sub>3</sub> whisker reinforced cementitious composites. Mat. construcc. 69 (336), e200. doi:10.3989/mc.2019.12918

Darko, A., Chan, A. P., Huo, X., and Owusu-Manu, D.-G. (2019). A scientometric analysis and visualization of global green building research. Build. Environ. 149, 501–511. doi:10.1016/j.buildenv.2018.12.059

Darko, A., Zhang, C., and Chan, A. P. (2017). Drivers for green building: A review of empirical studies. Habitat Int. 60, 34–49. doi:10.1016/j.habitatint.2016.12.007

de Azevedo, A. R., Alexandre, J., Xavier, G. d. C., and Pedroti, L. G. (2018). Recycling paper industry effluent sludge for use in mortars: A sustainability perspective. J. Clean. Prod. 192, 335–346. doi:10.1016/j.jclepro.2018.05.011

de Azevedo, A. R., Costa, A. M., Cecchin, D., Pereira, C. R., Marvila, M. T., and Adesina, A. (2022a). Economic potential comparative of reusing different industrial solid wastes in cementitious composites: A case study in Brazil. Environ. Dev. Sustain. 24 (4), 5938–5961. doi:10.1007/s10668-021-01630-7

de Azevedo, A. R. G., Alexandre, J., Zanelato, E. B., and Marvila, M. T. (2017). Influence of incorporation of glass waste on the rheological properties of adhesive mortar. Constr. Build. Mater. 148, 359–368. doi:10.1016/j.conbuildmat.2017.04.208

de Azevedo, A. R., Marvila, M. T., Antunes, M. L. P., Rangel, E. C., and Fediuk, R. (2021a). Technological perspective for use the natural pineapple fiber in mortar to repair structures. Waste Biomass Valorization 12 (9), 5131–5145. doi:10.1007/s12649-021-01374-5

de Azevedo, A. R., Marvila, M. T., Tayeh, B. A., Cecchin, D., Pereira, A. C., and Monteiro, S. N. (2021b). Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 33, 101675. doi:10.1016/j.jobe.2020.101675

de Azevedo, A. R., Nascimento, M., do Carmo, D., Marvila, M. T., Xavier, G. d. C., and Monteiro, S. N. (2022b). Environmental and durability perspective of the use of curaua fiber treated in mortars.

Farooqi, M. U., and Ali, M. (2022). A study on natural fibre reinforced concrete from materials to structural applications. Arab. J. Sci. Eng. doi:10.1007/s13369-022-06977-1

Farooqi, M. U., and Ali, M. (2018a). Contribution of plant fibers in improving the behavior and capacity of reinforced concrete for structural applications. Constr. Build. Mater. 182, 94–107. doi:10.1016/j.conbuildmat.2018.06.041

Farooqi, M. U., and Ali, M. (2018b). “Effect of fibre content on compressive strength of wheat straw reinforced concrete for pavement applications,” in Proceeding of the IOP Conference Series: Materials Science and Engineering (United Kingdom: IOP Publishing), 012014.

Farooqi, M. U., and Ali, M. (2018c). “Effect of fibre content on splitting-tensile strength of wheat straw reinforced concrete for pavement applications,” in Key engineering materials (Switzerland: Trans Tech Publ), 349–354.

Farooqi, M. U., and Ali, M. (2019). Effect of pre-treatment and content of wheat straw on energy absorption capability of concrete. Constr. Build. Mater. 224, 572–583. doi:10.1016/j.conbuildmat.2019.07.086

Fořt, J., Kočí, J., and Černý, R. (2021). Environmental efficiency aspects of basalt fibers reinforcement in concrete mixtures. Energies 14 (22), 7736. doi:10.3390/en14227736

Gao, L., Adesina, A., and Das, S. (2021). Properties of eco-friendly basalt fibre reinforced concrete designed by Taguchi method. Constr. Build. Mater. 302, 124161. doi:10.1016/j.conbuildmat.2021.124161

Gebremariam, A. T., Vahidi, A., Di Maio, F., Moreno-Juez, J., Vegas-Ramiro, I., Łagosz, A., et al. (2021). Comprehensive study on the most sustainable concrete design made of recycled concrete, glass and mineral wool from C&D wastes. Constr. Build. Mater. 273, 121697. doi:10.1016/j.conbuildmat.2020.121697

Guoxin, Z., Yi, L., Youzhi, L., Songhui, L., and Lei, Z. (2018). Reviews on temperature control and crack prevention of high concrete dam. J. Hydraulic Eng. 49 (09), 1068–1078.

Huang, S., Wang, H., Ahmad, W., Ahmad, A., Ivanovich Vatin, N., Mohamed, A. M., et al. (2022a). Plastic waste management strategies and their environmental aspects: A scientometric analysis and comprehensive review. Int. J. Environ. Res. Public Health 19 (8), 4556. doi:10.3390/ijerph19084556

Huang, Y., Zhang, W., and Liu, X. (2022b). Assessment of diagonal macrocrack-induced debonding mechanisms in FRP-strengthened RC beams. J. Compos. Constr. 26 (5), 04022056. doi:10.1061/(asce)cc.1943-5614.0001255

Jerman, M., and Černý, R. (2012). Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 53, 39–46. doi:10.1016/j.enbuild.2012.07.002

Jia, F., Yao, Y., and Wang, J. (2021). Influence and mechanism research of hydration heat inhibitor on low-heat portland cement. Front. Mat. 8. doi:10.3389/fmats.2021.697380

Jin, R., Gao, S., Cheshmehzangi, A., and Aboagye-Nimo, E. (2018). A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 202, 1202–1219. doi:10.1016/j.jclepro.2018.08.195

John, V. J., and Dharmar, B. (2021). Influence of basalt fibers on the mechanical behavior of concrete—a review. Struct. Concr. 22 (1), 491–502. doi:10.1002/suco.201900086

Kaïkea, A., Achoura, D., Duplan, F., and Rizzuti, L. (2014). Effect of mineral admixtures and steel fiber volume contents on the behavior of high performance fiber reinforced concrete. Mater. Des. 63, 493–499. doi:10.1016/j.matdes.2014.06.066

Khan M, M., Cao, M., Chaopeng, X., and Ali, M. (2022). Experimental and analytical study of hybrid fiber reinforced concrete prepared with basalt fiber under high temperature. Fire Mater. 46 (1), 205–226. doi:10.1002/fam.2968

Khan, M., Cao, M., Ai, H., and Hussain, A. (2022a). Basalt fibers in modified whisker reinforced cementitious composites. Period. Polytech. Civ. Eng. 66 (2), 344–354. doi:10.3311/ppci.18965

Khan, M., Cao, M., and Ali, M. (2018). Effect of basalt fibers on mechanical properties of calcium carbonate whisker-steel fiber reinforced concrete. Constr. Build. Mater. 192, 742–753. doi:10.1016/j.conbuildmat.2018.10.159

Khan, M., Cao, M., and Ali, M. (2018). Experimental and empirical study of basalt fibber reinforced concrete. Building Tomorrow's Society. Paper ID–MA39_0610035833.

Khan, M., Cao, M., and Ali, M. (2022b). “Influence of CaCO3 whiskers, steel fibers and basalt fibers hybridization on flexural toughness of concrete,” in Proceeding of the Fifth International Conference on Sustainable Construction Materials and Technologies, London.

Khan, M., Cao, M., Chu, S., and Ali, M. (2022d). Properties of hybrid steel-basalt fiber reinforced concrete exposed to different surrounding conditions. Constr. Build. Mater. 322, 126340. doi:10.1016/j.conbuildmat.2022.126340

Khan, M., and Cao, M. (2021). Effect of hybrid basalt fibre length and content on properties of cementitious composites. Mag. Concr. Res. 73 (10), 487–498. doi:10.1680/jmacr.19.00226

Khan, M., Cao, M., Hussain, A., and Chu, S. (2021a). Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 300, 124046. doi:10.1016/j.conbuildmat.2021.124046

Khan, M., Cao, M., Xie, C., and Ali, M. (2022e). Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 16, e00941. doi:10.1016/j.cscm.2022.e00941

Khan, M., Cao, M., Xie, C., and Ali, M. (2021b). Efficiency of basalt fiber length and content on mechanical and microstructural properties of hybrid fiber concrete. Fatigue Fract. Eng. Mat. Struct. 44 (8), 2135–2152. doi:10.1111/ffe.13483

Khan, M., Cao, M., Xie, C., and Ali, M. (2022f). Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 23 (1), 346–364. doi:10.1002/suco.202000472

Kirthika, S., and Singh, S. (2018). Experimental investigations on basalt fibre-reinforced concrete. J. Inst. Eng. India. Ser. A 99 (4), 661–670. doi:10.1007/s40030-018-0325-4

Li, J., Peng, X., Cao, J., Chen, G., Tian, J., Wang, X., et al. (2004). Research of high belite cement dam concrete with low-heat and high carack resistance. JOURNAL-CHINESE Ceram. Soc. 32 (3), 364–371.

Li, L., and Cao, M. (2018). Influence of calcium carbonate whisker and polyvinyl alcohol-steel hybrid fiber on ultrasonic velocity and resonant frequency of cementitious composites. Constr. Build. Mater. 188, 737–746. doi:10.1016/j.conbuildmat.2018.08.154

Li, L., Cao, M., Ming, X., Yin, H., and Sun, Y.-n. (2019a). Microstructure of calcium carbonate whisker reinforced cement paste after elevated temperature exposure. Constr. Build. Mater. 227, 116609. doi:10.1016/j.conbuildmat.2019.07.335

Li, L., Cao, M., Xie, C., and Yin, H. (2019b). Effects of CaCO3 whisker, hybrid fiber content and size on uniaxial compressive behavior of cementitious composites. Struct. Concr. 20 (1), 506–518. doi:10.1002/suco.201800185

Li, L., Cao, M., and Yin, H. (2019c). Comparative roles between aragonite and calcite calcium carbonate whiskers in the hydration and strength of cement paste. Cem. Concr. Compos. 104, 103350. doi:10.1016/j.cemconcomp.2019.103350

Li, L., Gao, D., Li, Z., Cao, M., Gao, J., and Zhang, Z. (2020a). Effect of high temperature on morphologies of fibers and mechanical properties of multi-scale fiber reinforced cement-based composites. Constr. Build. Mater. 261, 120487. doi:10.1016/j.conbuildmat.2020.120487

Li, L., Li, Z., Cao, M., Tang, Y., and Zhang, Z. (2021). Nanoindentation and porosity fractal dimension of calcium carbonate whisker reinforced cement paste after elevated temperatures (up to 900∘ C). Fractals 29 (02), 2140001. doi:10.1142/s0218348x21400016

Li, L., Xie, C., Cao, M., Zhou, X., and Li, Z. (2022). Synergistic effect between CaCO 3 whisker and steel-PVA fiber cocktail in cement-based material at elevated temperature. J. Mat. Civ. Eng. 34 (2), 04021415. doi:10.1061/(asce)mt.1943-5533.0004103

Li, Y., Shen, A., and Wu, H. (2020b). Fractal dimension of basalt fiber reinforced concrete (BFRC) and its correlations to pore structure, strength and shrinkage. Materials 13 (14), 3238. doi:10.3390/ma13143238

Liu, H., Yu, Y., Liu, Y., Zhang, M., Li, L., Ma, L., et al. (2022a). A review on basalt fiber composites and their applications in clean energy sector and power grids. Polymers 14 (12), 2376. doi:10.3390/polym14122376

Liu, M., Dai, W., Zhong, C., and Yang, X. (2022b). Study on mechanical properties and microstructure of basalt fiber reactive powder concrete. Buildings 12 (10), 1734. doi:10.3390/buildings12101734

Luo, X., Xu, J.-y., Bai, E.-l., and Li, W. (2014). Study on the effect of basalt fiber on the energy absorption characteristics of porous material. Constr. Build. Mater. 68, 384–390. doi:10.1016/j.conbuildmat.2014.06.072

Markoulli, M. P., Lee, C. I., Byington, E., and Felps, W. A. (2017). Mapping human resource management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 27 (3), 367–396. doi:10.1016/j.hrmr.2016.10.001

Mechtcherine, V., Schneider, K., and Brameshuber, W. (2016). “Mineral-based matrices for textile-reinforced concrete,” in Textile fibre composites in civil engineering (Elsevier), 25–43.

Meng, Z., Li, L., Farooqi, M. U., Feng, L., and Wang, L. (2022). Fiber factor for fresh and hardened properties of polyethylene fiber-reinforced geopolymer mortar. J. Build. Eng. 53, 104556. doi:10.1016/j.jobe.2022.104556

Nafees, A., Amin, M. N., Khan, K., Nazir, K., Ali, M., Javed, M. F., et al. (2021). Modeling of mechanical properties of silica fume-based green concrete using machine learning techniques. Polymers 14 (1), 30. doi:10.3390/polym14010030

Nafees, A., Khan, S., Javed, M. F., Alrowais, R., Mohamed, A. M., Mohamed, A., et al. (2022). Forecasting the mechanical properties of plastic concrete employing experimental data using machine learning algorithms: DT, MLPNN, SVM, and RF. Polymers 14 (8), 1583. doi:10.3390/polym14081583

Oraee, M., Hosseini, M. R., Papadonikolaki, E., Palliyaguru, R., and Arashpour, M. (2017). Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 35 (7), 1288–1301. doi:10.1016/j.ijproman.2017.07.001

Park, J. Y., and Nagy, Z. (2018). Comprehensive analysis of the relationship between thermal comfort and building control research-A data-driven literature review. Renew. Sustain. Energy Rev. 82, 2664–2679. doi:10.1016/j.rser.2017.09.102

Pogorelov, S., and Semenyak, G. (2016). Frost resistance of the steel fiber reinforced concrete containing active mineral additives. Procedia Eng. 150, 1491–1495. doi:10.1016/j.proeng.2016.07.088

Pukharenko, Y. (2012). Restoration and construction: The potential of fiber reinforced materials and products. Mod. problems Sci. Educ. 4, 1–7.

Raza, S. S., Amir, M. T., Azab, M., Ali, B., Abdallah, M., El Ouni, M. H., et al. (2022). Effect of micro-silica on the physical, tensile, and load-deflection characteristics of micro fiber-reinforced high-performance concrete (HPC). Case Stud. Constr. Mater. 17, e01380. doi:10.1016/j.cscm.2022.e01380

Saraikina, K., Golubev, V., and Semkova, E. (2012). Alkali resistance of basalt fiber and methods of its improvement. Constr. Archit. 1, 185–192. Bulletin of Perm National Research Polytechnic University.

Sheng, C., He, G., Hu, Z., Chou, C., Shi, J., Li, J., et al. (2021). Yarn on yarn abrasion failure mechanism of ultrahigh molecular weight polyethylene fiber. J. Eng. Fibers Fabr. 16, 155892502110527. doi:10.1177/15589250211052766

Shi, T., Liu, Y., Zhao, X., Wang, J., Zhao, Z., Corr, D. J., et al. (2022). Study on mechanical properties of the interfacial transition zone in carbon nanofiber-reinforced cement mortar based on the PeakForce tapping mode of atomic force microscope. J. Build. Eng. 61, 105248. doi:10.1016/j.jobe.2022.105248

Song, H., Liu, J., He, K., and Ahmad, W. (2021). A comprehensive overview of jute fiber reinforced cementitious composites. Case Stud. Constr. Mater. 15, e00724. doi:10.1016/j.cscm.2021.e00724

Stonys, R., Kuznetsov, D., Krasnikovs, A., Škamat, J., Baltakys, K., Antonovič, V., et al. (2016). Reuse of ultrafine mineral wool production waste in the manufacture of refractory concrete. J. Environ. Manag. 176, 149–156. doi:10.1016/j.jenvman.2016.03.045

Thomas, B. S., Yang, J., Bahurudeen, A., Abdalla, J. A., Hawileh, R., Hamada, H. M., et al. (2021). Sugarcane bagasse ash as supplementary cementitious material in concrete–A review. Mater. Today Sustain. 15, 100086. doi:10.1016/j.mtsust.2021.100086

Udomsap, A. D., and Hallinger, P. (2020). A bibliometric review of research on sustainable construction, 1994–2018. J. Clean. Prod. 254, 120073. doi:10.1016/j.jclepro.2020.120073

Väntsi, O., and Kärki, T. (2014). Mineral wool waste in europe: A review of mineral wool waste quantity, quality, and current recycling methods. J. Mat. Cycles Waste Manag. 16 (1), 62–72. doi:10.1007/s10163-013-0170-5

Wei, H., and Pengcheng, W. (2020). Key methods for non-cover-weight consolidation grouting of super high dam foundations. J. Tsinghua Univ. Sci. Technol. 60 (7), 582–588.

Wuni, I. Y., Shen, G. Q., and Osei-Kyei, R. (2019). Scientometric review of global research trends on green buildings in construction journals from 1992 to 2018. Energy Build. 190, 69–85. doi:10.1016/j.enbuild.2019.02.010

Xiao, X., Skitmore, M., Li, H., and Xia, B. (2019). Mapping knowledge in the economic areas of green building using scientometric analysis. Energies 12 (15), 3011. doi:10.3390/en12153011

Xiaomei, W., Qiang, G., Hao, D., and Yueming, F. (2019). Flexural fatigue performance of concrete prepared with low-heat portland cement. J. Southwest Jiaot. Univ. 54 (2).

Xin, L., Jin-Yu, X., Weimin, L., and Zhi-Kun, W. (2015). Comparative study of the effect of basalt fiber on dynamic damage characteristics of ceramics cement–based porous material. J. Mat. Civ. Eng. 27 (8), 04014224. doi:10.1061/(asce)mt.1943-5533.0001178

Xu, Y., Zeng, J., Chen, W., Jin, R., Li, B., and Pan, Z. (2018). A holistic review of cement composites reinforced with graphene oxide. Constr. Build. Mater. 171, 291–302. doi:10.1016/j.conbuildmat.2018.03.147

Yang, H., Liu, L., Yang, W., Liu, H., Ahmad, W., Ahmad, A., et al. (2022). A comprehensive overview of geopolymer composites: A bibliometric analysis and literature review. Case Stud. Constr. Mater. 16, e00830. doi:10.1016/j.cscm.2021.e00830

Yang, Y., Zhou, Q., Li, X., Lum, G. C., and Deng, Y. (2019). Uniaxial compression mechanical property and fracture behavior of hybrid inorganic short mineral fibers reinforced cement-based material. Cem. Concr. Compos. 104, 103338. doi:10.1016/j.cemconcomp.2019.103338

Yap, Z. S., Khalid, N. H. A., Haron, Z., Mohamed, A., Tahir, M. M., Hasyim, S., et al. (2021). Waste mineral wool and its opportunities—a review. Materials 14 (19), 5777. doi:10.3390/ma14195777

Yliniemi, J., Laitinen, O., Kinnunen, P., and Illikainen, M. (2018). Pulverization of fibrous mineral wool waste. J. Mat. Cycles Waste Manag. 20 (2), 1248–1256. doi:10.1007/s10163-017-0692-3

Zhang, P., Wang, J., Li, Q., Wan, J., and Ling, Y. (2021a). Mechanical and fracture properties of steel fiber-reinforced geopolymer concrete. Sci. Eng. Compos. Mater. 28(1), 299–313. doi:10.1515/secm-2021-0030

Zhang, Z., Liang, G., Niu, Q., Wang, F., Chen, J., Zhao, B., et al. (2022). A Wiener degradation process with drift-based approach of determining target reliability index of concrete structures. Qual. Reliab. Eng. Int. 38 (7), 3710–3725. doi:10.1002/qre.3168

Zhang, Z., Yang, F., Zhang, H., Zhang, T., Wang, H., Xu, Y., et al. (2021b). Influence of CeO2 addition on forming quality and microstructure of TiC -reinforced CrTi4-based laser cladding composite coating. Mater. Charact. 171, 110732. doi:10.1016/j.matchar.2020.110732

Zheng, Y., Zhang, W., Baca Lopez, D. M., and Ahmad, R. (2021a). Scientometric analysis and systematic review of multi-material additive manufacturing of polymers. Polymers 13 (12), 1957. doi:10.3390/polym13121957

Zheng, Y., Zhang, Y., and Zhang, P. (2021b). Methods for improving the durability of recycled aggregate concrete: A review. J. Mater. Res. Technol. 15, 6367–6386. doi:10.1016/j.jmrt.2021.11.085

Zheng, Y., Zhuo, J., Zhang, Y., and Zhang, P. (2022). Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete. Nanotechnol. Rev. 11 (1), 2169–2189. doi:10.1515/ntrev-2022-0134

Keywords: concrete, mineral fiber, construction material, natural fiber, scientometric analysis

Citation: Mohamad Moasas A, Amin MN, Ahmad W, Khan K, Al-Hashem MN, Qureshi HJ and Mohamed A (2022) Bibliographic trends in mineral fiber-reinforced concrete: A scientometric analysis. Front. Mater. 9:1100276. doi: 10.3389/fmats.2022.1100276

Received: 16 November 2022; Accepted: 02 December 2022;

Published: 19 December 2022.

Edited by:

Pshtiwan Shakor, Institute of Construction Materials, AustraliaReviewed by:

Junfeng Guan, North China University of Water Conservancy and Electric Power, ChinaCopyright © 2022 Mohamad Moasas, Amin, Ahmad, Khan, Al-Hashem, Qureshi and Mohamed. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Muhammad Nasir Amin, bWdhZGlyQGtmdS5lZHUuc2E=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.