- 1State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha, China

- 2State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China

- 3Department of Materials Science and Engineering, The University of Tennessee, Knoxville, TN, United States

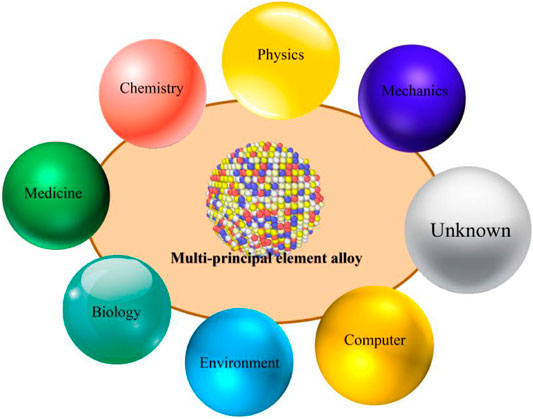

Compared with traditional alloys with one principal component up to 40–90%, multi-principal element alloys (MPEAs) were born in the complicated intermingling of traditional and non-traditional physical metallurgy, and brings us a great amount of excellent performances. Here, we would briefly summarize the potential applications in some key areas, which is helpful for latecomers to quickly and comprehensively understand this new alloy system. Especially, the applications of MPEAs in aerospace, industrial equipment, national defense, energy, navigation and so on are discussed roughly. Subsequently, several emerging areas have also been compared. Finally, some suggestions are given for the future development trend.

Introduction

Metallic materials play an irreplaceable role in the development of industrial civilization, from Bronze Age (about 3000 BC) to intelligent age (since the 21st century). Conventional alloys, such as copper-based alloys, aluminium-based alloys, magnesium-based alloys, and iron-based stainless steel are usually composed of one or two major elements, introducing other metallic/non-metallic elements with appropriate ratios into them to obtain desired performance (Esmaily et al., 2017; Lee et al., 2018; Li et al., 2018; Sun B. et al., 2021). Obviously, this traditional alloy design concept has not satisfied the growth demand about special function materials in modern industrial civilization due to huge limitation on the composition space.

In the past two decades, multi-principal element alloys (MPEAs) or high entropy alloys (HEAs, consisting of five or more elements) with equal or near-equal mole ratio have attracted widespread attention from related researchers because of their excellent properties in mechanics, chemistry and biology (Yeh et al., 2004; Zhang et al., 2014; Li et al., 2016; Yao et al., 2018; Xie et al., 2019). This trend can be attributed to their unique four core effects, i.e., high-entropy effect, sluggish diffusion, cocktail effect, and lattice-distortion effect. High configuration entropy can effectively prevent the formation of harmful intermetallic compounds like some brittle phases because it significantly reduces the Gibbs free energy of a system, thus promoting the formation of single-phase solid solutions, such as face-centered-cubic (FCC) structure, body-centered-cubic (BCC) structure, and hexagonal-close-packed (HCP) structure in MPEAs (Miracle and Senkov, 2017). A sluggish diffusion effect contributes to hinder grain growth, boost the nucleation of nanoprecipitation, and increase the recrystallization temperature, which is conducive to further tuning microstructures of MPEAs, thus enhancing the comprehensive properties (Tsai et al., 2013). Severe lattice distortion induced by different atom sizes can improve the lattice-fraction stress and become a strong impediment to the dislocation movement, resulting in significant solution strengthening in MPEAs (Tsai et al., 2013). The complexity and variety of MPEAs might be attributed to the cocktail effects. The addition of a lightweight alloying element reduces the density of MPEAs, and furthermore, the introduction of refractory alloying elements significantly improves the melting points of MPEAs. Moreover, the complex interactions between each alloying element further impact the performance of MPEAs (Ranganathan, 2003). For instance, the effect of the Al element in AlxCoCrCuFeNi MPEAs is investigated (He et al., 2014). The results suggest that increasing the Al element can enhance the strength whereas decreasing the ductility. This is because that the addition of the Al element promotes the formation of the BCC phase, which acts as a hardening phase.

Up to now, MPEAs as advanced engineering materials have been widely investigated in various fields. For example, four-point-bending high-cycle fatigue and fatigue-crack-growth behaviors of MPEAs are summarized, indicating that before the crack occurs, the plastic deformation behavior is dominated by the nanotwinning (Chen et al., 2018). The effects of composition, crystal structure, valence electron concentration, mixing entropy on the superconducting transition temperatures are reviewed, suggesting that MPEAs can be regarded as a promising superconducting material (Sun and Cava, 2019). In addition, the corrosion-resistant performance of MPEAs and their coatings in various kinds of aqueous solution are discussed in detail. Meanwhile, the influence of composition and processing method on the corrosion resistance are summarized. The results show that element homogenization can significantly improve the corrosion resistance of MPEAs (Shi et al., 2017). However, there is still a lack of a systematic review about engineering/industrial applications of MPEAs. In this review, we will collect and sort out the potential applications in related fields, to navigate the reasonable research direction in the future.

Classification of Engineering Application

To clearly describe the potential applications of MPEAs, the following aspects are divided based on their performances, as shown in Figure 1. For example, the required characteristics of automotive engine materials are high strength for resistance to the combustion pressure, good ductility for preparation of complex engine structures, and light for low carbon energy saving. Here, “7 + X” application areas are discussed in the following section.

Mechanics

The characteristics of engineering materials under various forms of loads are called mechanical properties. Metal materials must reach certain mechanical properties to meet the engineering needs.

Strength and Toughness

Metal materials will deform and even cause damage under the action of an external force. The strength of materials refers to the ability of metal materials that resists plastic deformation and fracture under the action of force. Machine parts often bear impact loads during service process. At this time, toughness is used to measure the performance of materials. Toughness refers to the deformation energy absorbed by metal materials before fracture. The FCC MPEA has good plasticity (Gludovatz et al., 2014), which is a good matrix material. The BCC MPEA has high strength and low toughness, compared with the FCC MPEA (Zou et al., 2014; Senkov and Semiatin, 2015; Gao et al., 2016; Li et al., 2020c; Feng et al., 2020; Peng et al., 2021). Different from the microstructures of traditional alloys, it induces special deformation mechanisms and leads to excellent strength and toughness.

The equiatomic FeCoCrNiMn MPEA with an FCC single solid-solution phase prepared by a rolling-recrystallization process has excellent damage tolerance at low temperatures (Gludovatz et al., 2014), owing to the multiple deforming machine to improve toughness. At the initial stage of deformation, the significant lattice friction of the MPEA makes it difficult for dislocations to move and increases the strength. In the later stage of deformation, due to the low stacking fault energy of FeCoCrNiMn, deformation twins are generated at the crack tip to prevent crack propagation. This toughness level can be compared with several of the best low-temperature steels, such as some austenitic stainless steels and high nickel steels.

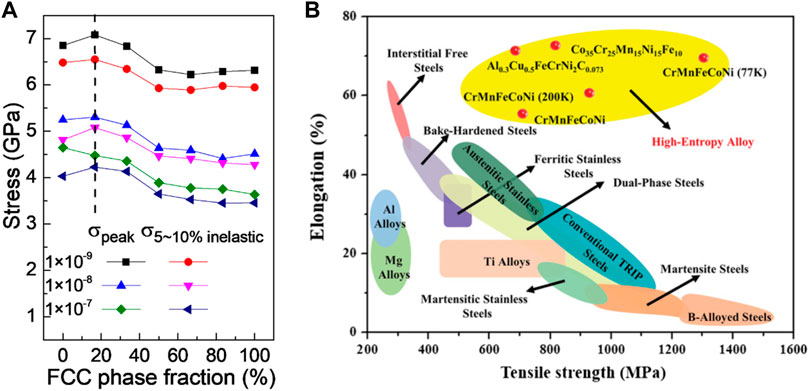

By adjusting the alloy composition, such as reducing the content of Co and Ni and Mn, to reduce the room temperature and low-temperature stability of the FCC phase, the deformation-induced transformation-strengthening can occurs in the MPEA, resulting in very considerable strengthening and plasticizing effect (Bae et al., 2018; Fang et al., 2019; Li et al., 2016; Ren et al., 2021) (Figure 2A). Transformation induced plasticity (TRIP) includes FCC→HCP and FCC→BCC. The deformation induced FCC→HCP transformation process of the Cr20Mn6Fe34Co34Ni6 MPEA leads that its room-temperature tensile strength reaches 1 GPa and tensile plasticity approaches 60% (Fang et al., 2019; Chen et al., 2020). Through the deformation induced FCC→BCC transformation strengthening mechanism, the tensile strength of the V10Cr10Co30Fe50 dual phase MPEA at 77 K increases to 2 GPa (Kim et al., 2019).

FIGURE 2. (A) Yielding stress vs. FCC phase fraction at different strain rates (Fang et al., 2019). (B) The strength and toughness between MPEAs and other conventional alloys (Liu et al., 2021).

A variety of principal components of MPEA leads to a strong atomic-radius mismatch and modulus mismatch between different elements to provide a good solid-solution-strengthening effect, which has a typical application in the room-temperature and high-temperature strengthening of the refractory high entropy alloy (RHEA) of the BCC phase (Senkov et al., 2011a; Senkov et al., 2011b). NbMoTaWV with high strength and low toughness and HfNbTaTiZr with high toughness and low strength are two classical BCC RHEA systems. Thus, the addition of W and Mo elements with high melting points into HfNbTaTiZr causes additional solid solution strengthening to improve room temperature strength, and maintains toughness (yield strength reaches 700 MPa, and fracture strain approaches 35% at 1,200°C) (Wang M. et al., 2019). The oxygen-containing ordered oxygen complexes (OOCs) formed in HfNbTiZr by doping O atoms (Lei et al., 2018). The pinning effect of OOCs on dislocations is stronger than that of interstitial atoms to promote dislocation cross slip, which leads to a large number of dislocation proliferation and induces high strength and toughness (Lei et al., 2018). On the whole, MPEAs have excellent strength and toughness compared with other conventional alloys (Figure 2B).

Wear Resistance

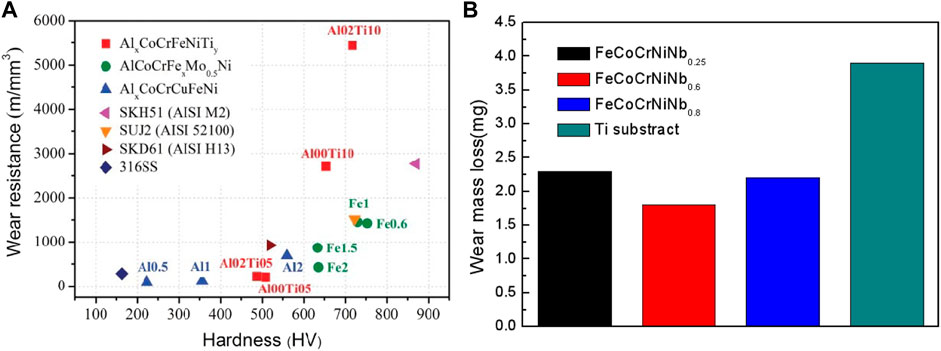

With the rapid development of aerospace, marine and automotive industries, the friction and wear of power systems and moving parts are more serious. Harsh working conditions put forward higher requirements for the wear resistance of friction pair materials. The wear failure of materials has become a technical bottleneck restricting the rapid development of this field. However, the use of existing conventional materials has reached their limit. MPEAs have excellent wear resistance due to the special effects different from traditional alloys, such as lattice distortion and high entropy effect (Yeh et al., 2004). Many MPEAs have better wear resistance than conventional wear-resistant alloys including SKD61 steel and SUJ2 steel (Figure 3A). MPEA wear-resistant materials mainly include MPEA bulks and MPEA coatings.

FIGURE 3. (A) The hardness vs. wear resistances of various HEAs and other conventional alloys (Wu et al., 2006; Hsu et al., 2010; Chuang et al., 2011; Tsai and Yeh, 2014). (B) Wear resistance of FeCoCrNiNbx MPEA coatings (Fang et al., 2018).

The near-infinite compositional space and solid-solution structures of MPEAs provide a huge configuration space for designing new wear-resistance materials (Ding et al., 2019). Many studies have shown that phase structure improves the wear resistance. By arc-melting and casting, the body-centered-cubic (BCC) matrix and L21 phase make the Al0.25Ti0.75CoCrFeNi MPEA the promising candidate for mechanical wear-resistant applications (Gwalani et al., 2018). In MPEAs, the appearance of sigma-phase precipitation in some annealing process hinders the dislocation movement, improving the hardness and leading to excellent wear resistance. By sliding wear at intermediate temperatures (600–800°C), sigma-phase precipitation occurs in the recrystallized wear subsurface of CoCrFeMnNi MPEA, which causes the excellent wear resistance (Joseph et al., 2020). By the annealing process, the sigma phase precipitates occur in the AlCoCrFeNiTi0.5 MPEA, causing the better wear resistance of AlCoCrFeNiTi0.5 MPEA than the conventional alloys of 1Cr18Ni9Ti stainless steel, SiC ceramic preserves, and ZrO2 ceramic (Yu et al., 2014).

In fact, the proportion and type of composition elements determine the solid-solution structure related wear resistance. The additions of Al, V, and Ti elements in MPEAs induce the formation of a strong BCC phase in the matrix, increasing the hardness to improve the wear resistance of MPEAs (Tong et al., 2005; Chen et al., 2006; Löbel et al., 2018). In AlxCoCrCuFeNi MPEAs, the AlCoCrCuFeNi MPEA has better wear resistance, which is mainly attributed to the increased strong bcc phase caused by Al element (Tong et al., 2005). The TiZrHfNb RHEA is prepared by arc melting, based on refractory elements (Ti, Zr, Hf, and Nb), which exhibits the improved wear resistance in comparison with the traditional superalloy of the pure Nb, C103 (Nb-5.4Hf-2Ti), and a commercial superalloy (Inconel 718), resulting from a higher hardness/strength induced by a strong BCC solid solution (Poulia et al., 2016; Ye et al., 2018). The Pb and B elements combine with other elements in MPEAs to produce precipitation, which hinders the movement of dislocations, increasing hardness to improve wear resistance (Liu et al., 2016; Yadav et al., 2018). With the addition of boron in the Al0.5CoCrCuFeNiBx MPEA, boron element forms borides instead of entering the crystal structure to significantly improve wear-resistance, owing to the combination of the large hard borides and ductile and tough FCC matrix (Liu et al., 2016).

The application range of MPEA bulk materials is limited due to the preparation process, materials and preparation cost. When MPEAs are used as coating materials, their flexible preparation process, controllable preparation cost, and excellent performance are suitable for extreme environments in the modern industry. A laser cladding (LC) technology is a process of melting and rapid solidification of metal powder by high-energy laser beam, which is widely used to prepare MPEA coatings. Therefore, the compositions of MPEAs has a great influence on the wear resistance. The Al and Ti elements can promote the formation of a strong BCC phase to improve wear resistance (Cui et al., 2020; Jin G. et al., 2018; Liu et al., 2020; Qiu et al., 2014). For the FeCoCrNiMnAlx MPEA coatings, weight loss of the FeCoCrNiMnAl0.75 cladding layer is approximately 58 and 17% of those of the base metal, respectively (Cui et al., 2020). In the Al2CrFeNiCoCuTix MPEA coatings, the wear resistance of Al2CrFeNiCoCuTi0.5 MPEA coating is better due to the coexistence of BCC and FCC phases (Qiu et al., 2014). The addition of the Nb element changes the phase structure of the coating, which affects the wear resistance of the coating, as shown in Figure 3B (Fang et al., 2018; Liang et al., 2019). The microhardness of AlCrFeNi2W0.2Nbx coatings increases with the increasing Nb content, and the wear resistance of Nb1.5 is excellent (Liang et al., 2019). Boronizing and nitriding are a thermochemical surface-hardening process that improves the surface mechanical performances by the formation of borides and nitrides generated in the diffusion of B and N atoms into the surface of metals/alloys at high temperatures (Wang et al., 2018; Hou et al., 2019). The wear quality with unboronized condition is 12 times of that in the boronized Al0.25CoCrFeNi MPEAs (Hou et al., 2019). The hardness of the nitrided AlCoCrFeNi MPEA increases from HV 522 HV of the as-cast AlCoCrFeNi MPEA to 720 HV of the nitrided MPEA (Wang et al., 2018).

Creep Resistance

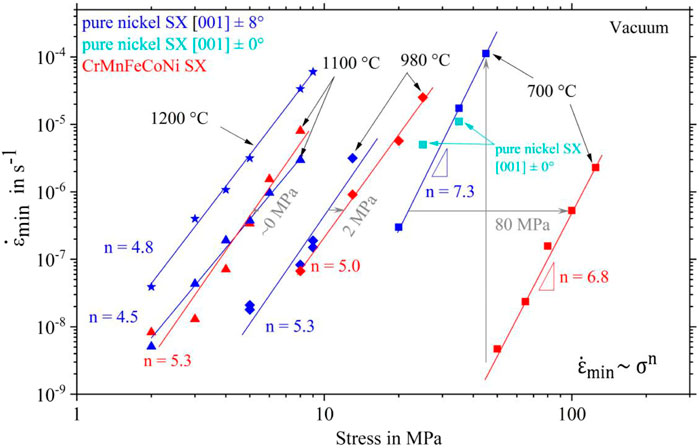

The phenomenon of slow inelastic deformation of metal materials under certain temperature and stress is called creep. Because different forms of fracture failure can occur in metal materials during creep, it is of great significance to study the creep behavior. The MPEA has extraordinary mechanical properties, including the excellent creep resistance, which plays an important role in engineering application at room temperature and low stress, owing to strong diffusion resistance caused by the lattice distortion arising from the difference in atomic sizes (Kang et al., 2018; Tsai et al., 2018; Zhang M. et al., 2021). The CrMnFeCoNi MPEA exhibits excellent creep resistance compared to nickel base alloys as shown in Figure 4 (Gadelmeier et al., 2020). The high creep resistance of CoCrFeMnNi at intermediate temperatures (0.2–0.6 Tm where Tm is the melting temperature) is attributed to the solution strengthening from the large atomic-size misfit of Cr (Kang et al., 2018). The nanosized oxides formed in the MPEA matrix via selective laser melting and mechanical alloying suppress the dislocation movement, which invokes a threshold to improve the high-temperature creep resistance of MPEA (Hadraba et al., 2017; Dobeš et al., 2018). It suggests a way for improving the high-temperature creep resistance of MPEAs using in-situ-formed oxide via high oxygen content in pre-alloy powders.

FIGURE 4. The log-log of minimum creep rate vs. stress of the CrMnFeCoNi MPEA compared with pure nickel at different temperature (Gadelmeier et al., 2020).

The compositions of MPEAs can be tuned to obtain the desired microstructure, including the phase structure, which is also one of the key microstructures affecting the creep properties of MPEAs (Choudhuri et al., 2015; Ma et al., 2016; Kral et al., 2020). Al is added to CoCrFeNiCu MPEA with an FCC structure to prepare a BCC-structured CoCrFeNiCuAl2.5 MPEA with a stronger creep resistance via the magnetron sputtering technique (Ma et al., 2016). During creep of the AlTiVNbZr0.25 MPEA at 1,073 K and a stress of 100–560 MPa, the formation of Nb2Al-type sigma-phase precipitates at the Zr5Al3/B2 interface hindering the dislocation movement to enhance creep resistance (Kral et al., 2020). The addition of Al not only changes the phase structure, but also improves the dislocation activation volume of MPEA. Compared with traditional alloy, such as Mg alloys, Al alloys, and Ti alloys, Ti30Al25Zr25Nb20 MPEA possesses a low creep-strain-rate-sensitive index caused by a high dislocation activation volume, indicating excellent creep properties (Wang D. et al., 2021).

Fatigue Resistance

When subjected to alternating load, many metal materials show the ability to absorb a large amount of accumulated strains before the final failure (Suresh, 1998). The accumulation of fatigue damage leads to crack and final failure, which is a common problem in material applications. For the engineering application of the MPEAs, fatigue fracture is an unavoidable problem (Huang et al., 2007; Miracle and Senkov, 2017). Fatigue-resistant materials of MPEA mainly include MPEA bulks and MPEA films. The single-phase CrMnFeCoNi MPEA has been widely studied, followed by Al-containing CoCrFeNi MPEA and Cu-containing FeMnCoCrSi MPEA.

The microstructure of the material determines the fatigue resistance of the alloy. Due to the ultrafine-grained microstructure delays crack initiation whereas the localized transformation within the crack plastic zone delayed crack propagation, the ultrafine-grained microstructure combined with the transformation-induced plasticity is an effective way to design the next generation of fatigue-resistant alloys (Liu et al., 2018, 2019b; Tian et al., 2019; Picak et al., 2021). The grain-refined Fe42Mn28Cr15Co10Si5 MPEA prepared by friction stir processing exhibits significantly high fatigue strength, as compared with phase transformation induced plasticity steels (Liu et al., 2018). The ultrafine-grained CoCrFeMnNi MPEA prepared by equal channel angular pressing demonstrates a superior fatigue life at relatively low strain amplitude (Picak et al., 2021). The small twin spacing and high twin density would exhibit a remarkable fatigue resistance because of the energy dissipation resulting from detwinning during fatigue loading (Chen et al., 2010; Liu et al., 2014; Hou et al., 2019; Wang et al., 2020). Using radio frequency magnetron sputtering, the CoCrFeMnNi MPEA films with twin spacing spanning across 2 nm show excellent fatigue resistance (Wang et al., 2020). Nanotwinned nanocrystalline CoCrFeNi MPEA film prepared by magnetron sputtering shows the high stability of twin boundaries during cyclic tests because the extremely-stable correlated necklace dislocations moved back and forth along the twin boundaries (Huo et al., 2019).

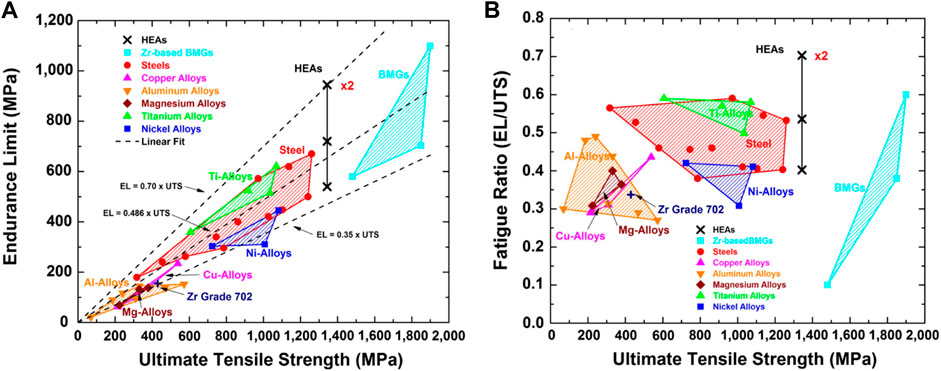

Compared with other conventional alloys, MPEAs show strong application potentials about great fatigue resistance, due to the abundant compositional space available for MPEAs. Figure 5 compares fatigue limit and fatigue ratio in a set of structural materials (Abareshi and Emadoddin, 2011; Fredj et al., 2004; Haidemenopoulos et al., 2013; Hemphill et al., 2012; Islam et al., 2007; Koyama et al., 2017; Ly and Findley, 2016; Sugimouto et al., 1997). The fatigue ratio is defined as the ratio of the fatigue-endurance limit to the ultimate tensile strength (UTS), to further compare the fatigue properties between MPEAs and other alloys (Tang et al., 2015). The DP-5Si HEA has a high fatigue strength than all TRIP steels (Liu et al., 2018), thereby indicating its strong engineering application in cyclic loading. This result is attributed to that both the fatigue limit and UTS can be simultaneously improved by the TRIP effect caused by a metastable γ phase and ultrafine-grained microstructure with the addition of Si. The relationship between the fatigue ratio and UTS shows that Al0.5CoCrCuFeNi MPEAs have relatively high-endurance limits attributed to a two-phase structure with the addition of the Al element (Tang et al., 2015). The lower points of the fatigue ratios of the MPEAs are at the same level, compared with those of steels, Ti alloys, Ni alloys, and Mg-alloys, However, the upper bound is greatly higher than other alloys in the figure (Tang et al., 2015). Overall, Figure 5 suggests that MPEAs have great fatigue strengths for engineering applications (Hemphill et al., 2012).

FIGURE 5. (A) the endurance limit and (B) fatigue ratio vs. UTS for Al0.5CoCrCuFeNi MPEA and other structural materials (Hemphill et al., 2012).

Suggested Future Investigation

In summary, the type and content of the constituent elements of MPEA, the phase structure, the preparation process and the grain size play a key role in the mechanical properties (including strength, wear resistance, creep and fatigue), and have been extensively studied. In addition, there are some new research directions to improve their mechanical properties, such as eutectic structure and gradient structure (Jin X. et al., 2018; Chen et al., 2019; Feng et al., 2021; Joseph et al., 2018).

Physics

In addition to excellent mechanical properties, MPEAs also have attractive physical properties, such as magnetism, resistance, superconductivity and so on (Ye et al., 2016).

Magnetic Behavior

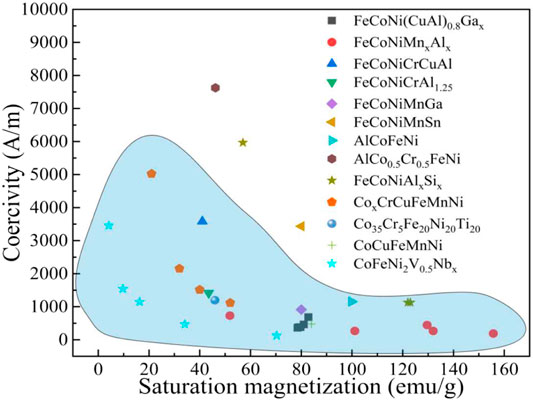

The magnetic properties of alloys are sensitive for component. For MPEAs containing multiple principal element, the addition of more ferromagnetic elements makes it easier to have excellent magnetic properties. There are many studies on the magnetic properties of MPEAs obtained by adding two elements with an equal molar ratio to the FeCoNi matrix, including FeCoNi(A1Si)x (Zhang et al., 2013), FeCoNi(MnSi)x (Li et al., 2019), FeCoNi(NiAl)x (Zhang X. K. et al., 2021), FeCoNi(CuAl)x (Zhang Q. et al., 2017), and FeCoNi (MnAl)x (Li et al., 2017a). The FeCoNi(A1Si)x MPEA with x = 2 presents typical soft magnetic characteristics, which has the characteristics of high saturation magnetization (Ms) and low coercivity (Hc) (Zhang et al., 2013). Here, Ms is the maximum magnetization that can be excited in the external magnetic field; Hc is a physical quantity reflecting the difficulty of the ferromagnet in the excitation and demagnetization stages. Higher Ms/Hc shows better soft magnetic property. The CoFeMn1.2NiGa0.8 exhibits better soft magnetic properties than most reported MPEAs (Sun X. et al., 2021), indicating the addition of Ga can improve the magnetic properties.

The phase constitutions changed by alloying or phase transformation play an important role on the magnetic properties of MPEAs (Marshal et al., 2019; Zhao C. et al., 2021). With the addition of Al in the FeMnCoCr MPEA, the formation of the BCC structure shows a ferromagnetic behavior (Marshal et al., 2019). In the AlCoCrFeNi MPEA, the BCC phase plays a major role to provide a high Ms, but the FCC phase has no effect on magnetic properties (Zhao D. Q. et al., 2021). The effect of the processing technology on the magnetic properties can not be ignored. The annealed FeCoNiMn0.25Al0.25 MPEA exhibits the high Ms and low Hc (Li et al., 2017b), and shows better soft magnetic properties than most other commercialized soft magnets. Therefore, MPEAs have great development potential in the fields of the large power grid equipment, and high-frequency magnetic communication due to excellent magnetic properties (Figure 6).

FIGURE 6. Saturation magnetization vs. coercivity for different MPEA (Li et al., 2021a).

Electrical Property

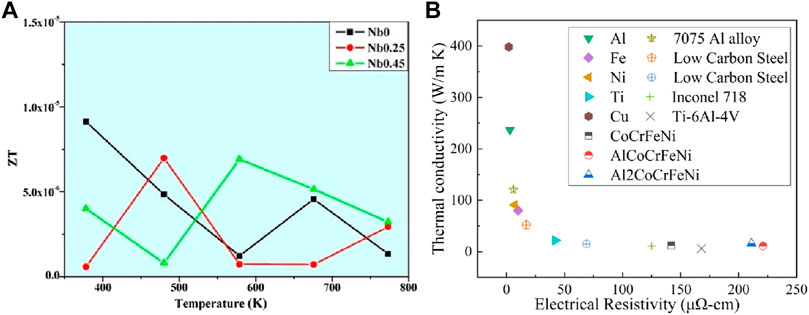

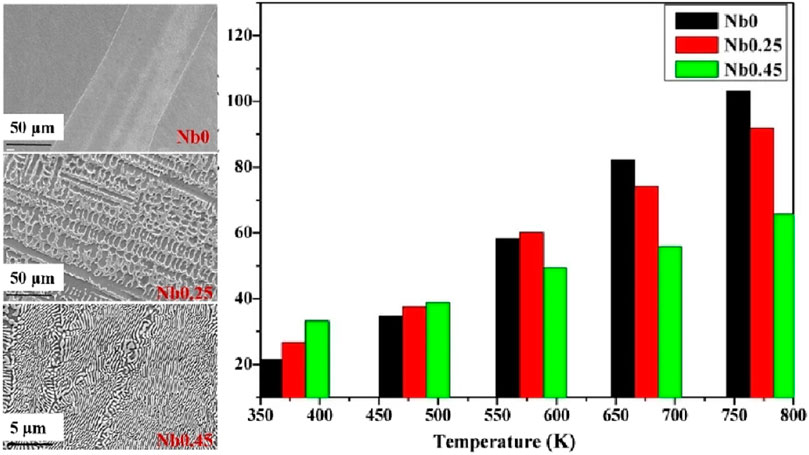

At present, MPEAs have potential applications in the thermoelectric (TE), conductive, and resistive materials due to their good electrical properties. In the global energy shortage environment, the TE generator with efficient waste heat recovery will be an important means to supplement energy in the future. Compared with the traditional TE materials suitable for the low-temperature region, MPEAs are a potential high-temperature TE material (Fan et al., 2017; Han et al., 2020; Shafeie et al., 2015), due to their rich elemental compositions. The La addition improves the Seebeck coefficient and conductivity of the PbSnTeSe MPEA at high temperatures (Fan et al., 2017). As shown in Figure 7A, an appropriate amount of Nb was added to CoCrFeNi to obtain a bulk CoCrFeNiNb0.45 eutectic high-entropy alloy (EHEA) with excellent thermal stability. CoCrFeNiNb0.45 EHEA has a higher thermoelectric figure of merit (ZT) at high temperatures (T > 573 K), showing a great prospect of thermoelectric applications at elevated temperatures (Han et al., 2020). The reduction of the lattice thermal conductivity is one of the most effective ways to improve the properties of thermoelectric materials. In the Sn0.25Pb0.25Mn0.25Ge0.25Te MPEA with excellent thermoelectric properties, the configurational entropy increases to enhance the phonon scattering because various elements exist at the cationic (Sn2+) site, leading to a reduced lattice thermal conductivity (Wang X. et al., 2021). Thus, the high entropy alloying is an effective strategy to reduce the lattice thermal conductivity for improving the thermoelectric property.

FIGURE 7. (A) Thermoelectric figure of merit vs. temperature for CoCrFeNiNbx MPEA (Han et al., 2020). (B) The relationship between electrical resistivity and thermal conductivity for MPEAs and conventional alloys (Chou et al., 2009; Kao et al., 2011).

For achieving higher integration and reliability, the rapid technological progress of nanoscale manufacturing equipment requires the development of advanced resistance films. Lattice distortion can greatly increase the resistivity of the material. The nanotwinned nanocrystalline CoCrFeNi MPEA film prepared by magnetron sputtering has a resistivity as high as 135.1 μΩ cm. The high resistivity is attributed to the strong blocking effect caused by lattice distortion (Huo et al., 2018). The NbMoTaW MPEA films have a strong size-independent electrical resistance (∼170 μΩ cm) (Feng et al., 2018). Hence, lattice distortion plays a major role in resistance. In some industrial applications, the electrical conductivity of the film is also very important. For example, the protective film of the electrical contact plug should have a low resistivity. The Cu addition improves the conductivity of HEAs (Huang K. et al., 2021). The increase of the Cu content changes the electronic structure of the AlCuxNiTiZr0.75 MPEA film, causing the resistivity to drop sharply to 66 μΩ cm at x = 1.4 (Huang K. et al., 2021). The electrical resistivity of MPEAs (from 100 to 220 μω·cm) is 1-2 orders of magnitude than that of many conventional metals, and is similar to that of some bulk metallic glasses (BMGs) (Figure 7B).

Thermal Property

According to the formula K(T) = α(T) × S(T) × ρ(T), thermal conductivity K(T) is generally obtained by measuring the thermal-diffusion coefficient, α(T), specific heat, S(T), and density, ρ(T), of the material at a temperature T, which is an indicator used to measure the thermal-conductivity capacity of materials. The effect of the Al addition on the thermal conductivity is studied in FeCoCrNiNbx, AlxCoCrFeNi and AlxCrFe1.5MnNi0.5Moy alloys (Chou et al., 2009; Lu et al., 2013). Thermal conductivity of AlxCoCrFeNi alloys is from 10 to 27 W/m∙K, and lower compared to that of most pure metals. It is equal to that of heavily-alloyed metals, such as the high-alloy steel and Ni-based alloy (Chou et al., 2009; Shackelford and Alexander, 2000). As shown in Figure 8, the low thermal-conductivity of CoCrFeNiNb0.45 MPEA is attributed to the full eutectic microstructure (Han et al., 2020). The low thermal conductivity of MPEAs is credited to lattice distortion, which causes the serious scattering of phonon. Under medium temperature conditions (from 27°C to 300°C), the thermal conductivity of Al added MPEAs raises with the addition of temperature (Chou et al., 2009; Lu et al., 2013) attributed to the addition of mean-free path of phonon, and the lattice thermal expansion caused by high temperature (Lu et al., 2013). The stainless steel and Inconel alloy have the same trend as Al added MPEAs, but most pure alloys are opposite (Shackelford and Alexander, 2000; Chou et al., 2009). For the AlxCoCrFeNi MPEA, the thermal conductivity in a duplex single-phase region is lower than that in the single phase region, owing to the additional scattering from FCC/BCC phase boundaries (Chou et al., 2009). In the AlxCoCrFeNi MPEA, the electrical conductivity reduces with the increase of temperature. The electrical conductivity shows an opposite trend compared to the thermal conductivity with the increase of temperature. Thus, the Wiedemann-Franz law does not apply for the AlxCoCrFeNi MPEA (Chou et al., 2009). The relationship between thermal expansion coefficients (TEC) and Al content has been studied in the AlxCoCrFeNi alloys (Chou et al., 2009). The TEC of the AlxCoCrFeNi MPEA reduces with the addition of Al content, owing to the formation of the BCC phase. Thus, the BCC phase structure has the effect of reducing TEC in MPEAs.

FIGURE 8. The microstructure and thermal-conductivity of FeCoCrNiNbx MPEA (Han et al., 2020).

Optical Property

With the rapid development of society, energy problems have become increasingly acute. The use of solar energy to obtain thermal energy is an energy harvesting technology that effectively utilizes renewable energy, which can effectively alleviate the increasing energy contradiction (Selvakumar and Barshilia, 2012). Solar selective absorbing coatings (SSACs) are the key components of the concentrating solar power (CSP) systems, among which the spectral selectivity and thermal stability of SSACs are the most important indicators (Wang X. et al., 2017). In order to improve the efficiency of the light-to-heat conversion, SSAC should have high solar absorptance (α) and low thermal emittance (ε) (Gao et al., 2017). Transition metal nitrides have excellent electrical and optical properties (Wu et al., 2015). The high-entropy alloy nitrides (HEANs) synthesized with refractory elements have become an ideal material for manufacturing SSAC, due to their excellent high-temperature resistance and optical properties. The optical properties of NbMoTaWN, MoNbHfZrTiN, and MoTaTiCrN HEANs are investigated, showing the exceptional spectral selectivity (α/ε = 0.944/0.12, 0.934/0.09, and 0.923/0.065 for NbMoTaWN, MoNbHfZrTiN, and MoTaTiCrN) (Guo et al., 2020; He et al., 2020; Yu D. M. et al., 2021; Yu D.-M. et al., 2021; He et al., 2021). These HEANs show excellent thermal stability and corrosion resistance. After annealing at 600°C for 100 h, NbMoTaWN still maintains good optical properties (α/ε = 0.902/0.106) (Yu D.-M. et al., 2021). For MoNbHfZrTiN, the solar absorptance and thermal emittance are only slightly raised and lowered, respectively, (α/ε ranges from 0.935/0.09 to 0.912/0.11) in a 3.5% NaCl solution for 24 h at room temperature (He et al., 2020). The Al, Si, and Cr elements added in MPEA combine with oxygen to produce an oxide film on the surface at high temperature, which gives a barrier for the prevention of further oxidation to improve oxidation resistance. Therefore, MPEAs containing Al, Si and Cr have excellent high temperature thermal stability. AlCrTaTiZrN MPEA has excellent spectral selectivity (α/ε = 0.928/0.051), high temperature thermal stability (little change in the spectral selectivity after annealing at 800°C for 2 h), and long-time thermal stability (little change in the spectral selectivity after annealing at 650°C for 300 h) (He et al., 2021). In addition, AlCrTaTiZrN MPEA achieves the optimal photothermal conversion efficiency at high sunlight exposure (He et al., 2021). Thus, MPEAs with excellent optical and thermal stability properties have the great application potential for the solar-thermal technology.

Challenge and Prospect

In short, the magnetic and optical properties of MPEAs are sensitive for element composition and phase structure. The configuration entropy and lattice distortion are the key factors to control the thermal and electrical conduction of MPEA. Furthermore, there are some challenging topics that need to be studied in depth, including the effects of magnetic moments (Tsai, 2013), spin (Niu et al., 2015), hall coefficient (Kao et al., 2011), and lattice vibration (Körmann et al., 2017) on physical properties.

Chemistry

Corrosion Resistance

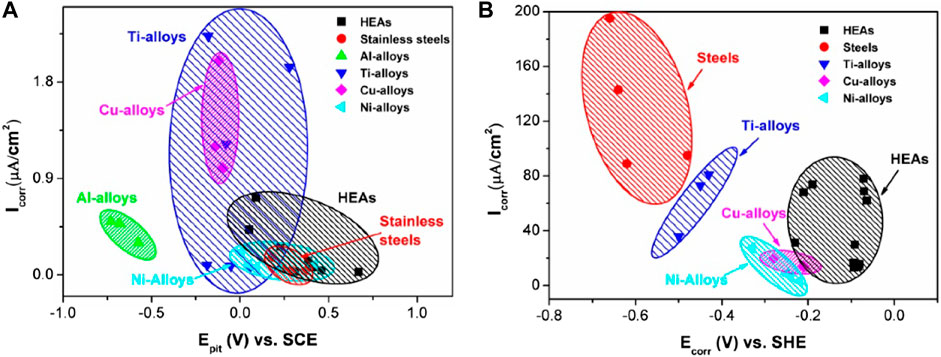

Corrosion is a chemical/electrochemical reaction process between materials and ambient media, such as water, air, acid, and alkali, which greatly affects the service performance and even causes the failure (Hansson, 2011). From a thermodynamic point of view, most of metals, except for some noble metals like Au, Ag, and Pt, are in an unstable state, and tend to oxidize with the ambient medium to form metal oxides. Hence, metal corrosion occurs (Song and Atrens, 2003). In past decades, the corrosion resistance is usually achieved by introducing alloying elements (Cr, Ni, and Mo) into Ni-based alloys, stainless steels, or Ti-based alloys to form a protective passive film on the metal surface (Gupta and Birbilis, 2015). However, the existence of precipitates during the metallurgical process and poor-high temperature stability significantly worsen their corrosion-resistance and mechanical properties, hence limiting their large-scale application in engineering (Nilsson and Wilson, 1993; Cvijović and Radenković, 2006). Recently, MPEAs have been widely reported because of their outstanding corrosion resistance. The corrosion-resistant property of material is usually dominated by the average corrosion rate which can be written as follow:

where icorr refers to the corrosion-current density,

FIGURE 9. The relationship between the corrosion-current density and pitting/corrosion potentials of MPEAs and conventional alloys, respectively, in a salt solution (A) and acid solution (B) (Shi et al., 2017).

In fact, same as the conventional alloys, the resistance of MPEAs to corrosion can be attributed to the formation of passive films on the surfaces. The difference is that the passivation elements in MPEAs are easier to distribute uniformly, contributing to the formation of the denser oxide film and effectively reducing the hallow formation (Zhang S. et al., 2016; Xiang et al., 2016). Recently, three Co-Cr-Ni-Al-Ti system MPEAs are prepared by vacuum arc melting to investigate the effect of the passivation elements like Co, Cr, and/or Ni on the corrosion-resistant performance (Huang L. et al., 2021). The results indicate that the increment of the Cr element can promote the formation of a passive film Cr2O3 in both salt and acid solutions, which plays a significant role in enhancing the corrosion-resistant ability. Meanwhile, the addition of the Co element is helpful for the stability of the passive film, and decreases the hydrolysis of Cr3+. Furthermore, MPEAs containing a Ti element are also widely studied because the presence of a positive electrode potential in the Ti element contributes to form a dense self-healing oxide passivation film. Meanwhile, TiO and TiO2 passive films not only have great resistance to the acid solution, but also improve their high-temperature oxidation resistance (Liu et al., 2019). Based on this trend, the corrosion resistance of the AlCoCrFeNiTi0.5 MPEA is studied in a H2O2 solution. The result shows that the corrosion rate is extremely slow compared to the AlCoCrFeNiCu MPEA (Yu et al., 2015).

On the other hand, the corrosion-resistant performance of MPEA is significantly influenced by different metallurgical processes. Using a laser-cladding-preparation method, the effect of the laser-scanning speed on the corrosion resistance of an AlCrFeCuCo MPEA is investigated (Qiu et al., 2013). The experimental results suggest that the increment of the laser-scanning speed leads to the resistance of the alloy, which firstly becomes better and then worse. The reason for this trend is that lower scanning speed promotes the cooling rate to make a denser surface, whereas a higher scanning speed leads to a rough surface. Moreover, the corrosion resistance of AlCrFeCuCo in a salt solution is better than that in an acid solution. In addition, MPEA coatings with millimetre-scale thicknesses are prepared by electro-spark deposition. Using electro-spark deposition on an AISI 1045 steel, the AlCoCrFeNi MPEA coating has been successfully synthesized, which has a superior corrosion resistance than that of the alloy prepared by casting (Zhang C. et al., 2016). The excellent property stems come from the uniform composition and microstructure as well as the high enough Cr and Al oxide concentrations on the surface. In general, MPEAs have been a promising corrosion-resistant material, which can be suitable for various extreme service environments.

Catalysis

Catalyst not only significantly reduces the energy consumption of reactions, but also effectively improves the reaction speed, and even changes the basic reaction. Therefore, catalyst materials play an irreplaceable role in engineering applications (Guo et al., 2019). Transition metal elements, such as Fe, Cu, Au, Ag, etc. and their alloys are the most widely used catalyst due to their outstanding hydrogenation and dehydrogenation characteristics as well as excellent oxidation and catalytic reforming performance (Tan, 2014). Taking the oxidation of industrial ammonia as an example, PtPdRh-based materials are still the widely employed catalysts. However, the large-scale applications in engineering have been greatly limited by expensive price, high activation-energy-degradation rate, and poor universality (Bagot et al., 2014).

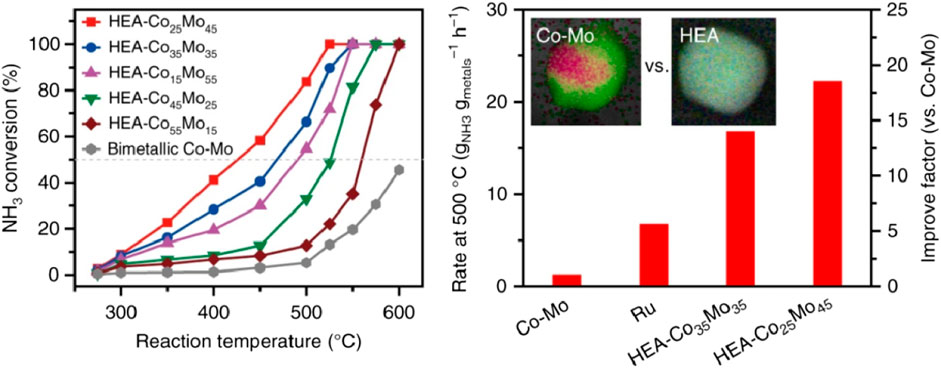

Over the past few decades, the emergency of MPEA has provided an infinity possibility for broadening catalytic materials due to their huge composition space and outstanding catalytic performance. Recently, the equimolar CePdPtRhRu MPEA nanoparticles (NPs) synthesized by the carbothermal shock method have been successfully used in the oxidation of ammonia (Yao et al., 2018). The conversion efficiency of NH3 using NPs can be up to 100%, and meanwhile, the selectivity to NOx can reach 99% under a lower temperature. Furthermore, the CePdPtRhRu multimetallic nanoparticles (MMNPs) are made as a comparison by the wet impregnation method. The selectivity to NOx using MMNPs just approach about 18.7% at the same temperature. The significant improvement of catalyst performance is attributed to the solid-solution phase of NPs rather than phase-separated catalytic materials. Moreover, the increment of the Ru and Ce concentrations not only significantly enhances the catalytic performance, but also reduces the consumption of the precious Pt element. In addition, some researchers are also committed to reducing the content of noble metals like Pt and Ru in catalytic MPEAs. The FeNiCuCoMo MPEA NPs (Figure 10) can enhance the decomposition performance of ammonia with an improvement factor of over 20, which exceeds the Ru catalyst and some conventional Co-Mo catalyst (Xie et al., 2019). More interestingly, the catalytic performance can be controlled by tuning the ratio of Co/Mo, thus providing a feasible avenue to maximize the reaction activity at various conditions. More importantly, MPEAs can be used not only for thermal catalysis mentioned above, but also for the methanol oxidation or hydrogen evolution reaction (HER). The NiCoCuFePd MPEA nanotube arrays (NTAs) synthesized by the electrodeposition method show the superior catalyst performance and more stable for the methanol oxidation than conventional Pd NTAs because of their larger surface area and higher mass activity (Wang et al., 2014). It has been reported that the Ni20Fe20Mo10Co35Cr15 MPEA exhibits the better HER electrocatalyst performance than that of some precious metallic catalyst, whose overpotential is just 107 mV in the acid solution (Zhang G. et al., 2018). Overall speaking, MPEAs can be the promising next generation catalytic materials.

FIGURE 10. The conversion and rate (T = 500°C) of NH3 with different Co/Mo ratio (Xie et al., 2019).

Suggested Future Direction

MPEAs have been the promising corrosion-resistant and catalytic materials. For further understanding their corrosion and catalytic behavior to design the novel MPEAs with superior performance, some recommended future work is presented below: 1) understand the fundamental reason of corrosion resistance of MPEAs from atomic scale; 2) realize the collaborative design of corrosion resistance and mechanical properties of MPEAs; 3) it is significant to extend the types of supporting substance for improving the catalytic performance of MPEAs; 4) The gaps between theory and experiments in catalytic application of MPEAs should be filled.

Computer

Multiscale Simulations

Based on experiments, simulations effectively improve the basic understanding of the relationship between deformation and performance, and improve performance by optimizing material compositions and structures (Demetriou et al., 2011; Wu et al., 2014; Li et al., 2018). According to the density functional theory (DFT), molecular dynamics (MD) simulations, phase-field method (PFM), and finite element method (FEM), the necessary underlying material parameter, dislocation behaviour, lattice distortion, and phase transformation are investigated in detail (Zhang H. et al., 2018; Rahul et al., 2018; Wang D. et al., 2019; Fang et al., 2019; Yin and Curtin, 2019; Li et al., 2020a; Li J. L. et al., 2020; Sagar et al., 2021), to obtain a deep understanding of microstructure evolution on the mechanical properties of MPEAs.

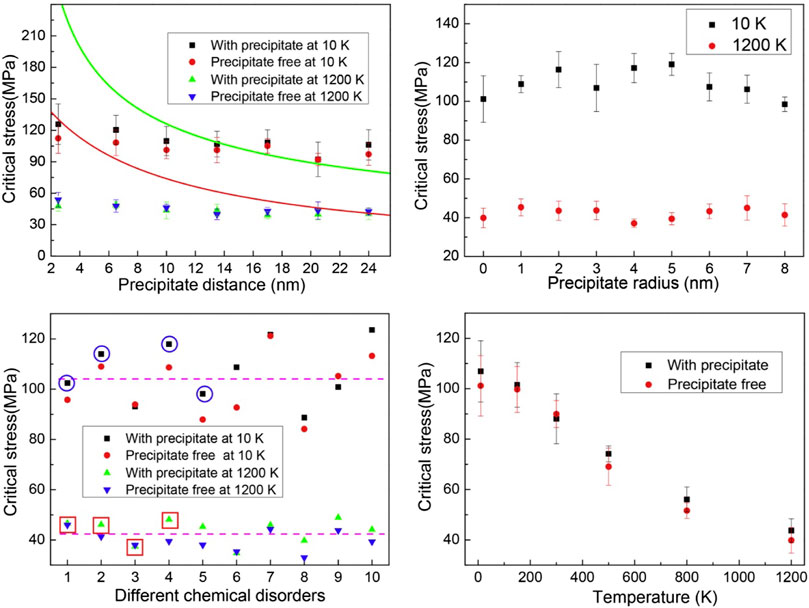

The elemental mismatch volume, lattice/elastic constant, and stable-stacking-fault energy of RhIrPdPtNiCu are calculated by DFT, which are applied in the yield model (Yin and Curtin, 2019). Through MD simulations, the synergistic strengthening of the precipitation and lattice distortion in MPEAs in a wide temperature range is investigated, explaining the effects of temperature, element order, precipitate spacing/size, and dislocation-cut number on precipitates strengthening (Li et al., 2020a) (Figure 11). The coherent BCC/B2 microstructure in BCC AlNiCoFeCr MPEA is studied by PFM to reveal the evolution of the microstructure, which is revealed to assist in the design of new MPEAs (Li J. L. et al., 2020). Using FEM, the strain distribution and material flow of the AlCoCrFeNi2.1 MPEA give a channel to predict the actual material flow during forging (Rahul et al., 2018). The unique characteristics of MPEAs lead to multi-scale microstructures (atomic-scale lattice distortion, nano-scale short-range order, and micro-scale phase transitions) (Song et al., 2017; Chang et al., 2020; Seol et al., 2020), however, simulations for traditional alloy are no longer suitable for studying the deformation and strengthening mechanism of MPEAs. Therefore, in order to accelerate the alloy design to further develop new MPEAs for a wide range of industrial applications, it is necessary to use multi-scale simulations to link the microstructure characteristics of MPEAs with their mechanical behaviors.

FIGURE 11. The precipitate spacing, precipitate size, element disorder, and temperature dependence of the critical stress (Li et al., 2020a).

Machine Learning

The rapid development of the information technology strongly pushes forward the arrival of the “big data” era, when the data acquisition, storage and extraction become easier. The artificial intelligence (AI) driven by mass data has played an irreplaceable role in the modern society. As the powerful tool in AI, machine learning has been widely used in many fields, such as cancer detection, speech recognition and intelligent controls (Zhang et al., 2008; Rupp et al., 2012; Schmidhuber, 2015), because it can look for the best surrogate model to accurately describe the relationship between the data examples without depending on rules-based programming. At present, machine learning has been successfully used in materials science. The combination of a genetic algorithm and artificial neural network is proposed to construct an accurate “composition-heat treatment conditions-mechanical properties” surrogate model of a low alloy steel (Reddy et al., 2015). The high strength and electrical conductivity copper alloys have been successfully designed by the property-oriented machine learning design strategy (Wang C. et al., 2019; Li L. et al., 2021).

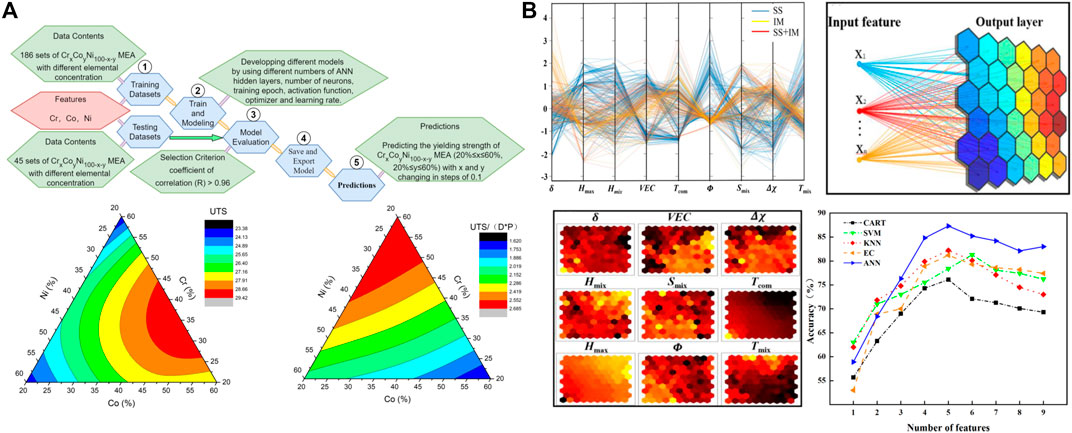

The successful application of machine learning on traditional alloy design has prompted to gradually solve MPEA designs. Recent studies have shown that machine learning methods can further improve the mechanical, physical and chemical properties of MPEAs. For example, the feasible material design method integrating machine learning and experiments (Wen et al., 2019) is proposed to look for the MPEAs with higher hardness in the Al-Co-Cr-Cu-Fe-Ni system. Several alloys with superior hardness than the optimum value in the training dataset have been synthesized via seven experiments. Recently, a method combining high-throughput MD simulations and machine learning is proposed to search for the high strength, low cost and density CoxCryNi(100-x-y) MPEAs (Li et al., 2021b). It has been demonstrated that this method can accurately establish the relationship between composition and ultimate tension strength. The optimum CoCrNi MPEA can be obtained (Figure 12A). More interestingly, some researchers tried to construct an artificial neural networks-like structure to describe the relationship between “composition-heat treatments-microstructures-properties”, for revealing their potential physics mechanism (Steingrimsson et al., 2021). Another important application is to identity and/or optimize the microstructure of MPEAs. The optimal grain size of heterogeneous-grained CrCoFeNi MPEA has been determined by integrating active learning strategy, a physical model and atomic simulation (Li L. et al., 2021). The surrogate model between elemental characteristics and long-term ordering structure in MPEAs is constructed by ANN, whose prediction accuracy can be up to 87% (Zhao C. et al., 2021) (Figure 12B). Furthermore, the deep learning-based optimization, generation, and explanation algorithm (Lee et al., 2021) is proposed to further improve the accuracy and look for the key parameters for phase predictions. The prediction accuracy can be up to 93.1%, which far exceeds results from previous literature. In addition, the mixing entropy and mixing enthalpy are accurately identified.

FIGURE 12. (A) The flowchart of CoCrNi MPEA design strategy by machine learning and high-throughput MD simulations (Li et al., 2021b). (B) An artificial neural networks model describing the relationship between elemental characteristics and long-term ordering structure (Zhao D. Q. et al., 2021).

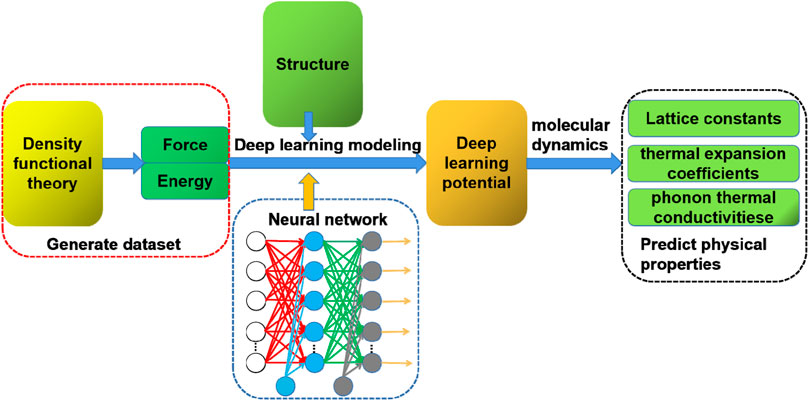

In physics, machine learning is widely used to develop many-body alloy interatomic potentials for MPEAs, such as Gaussian approximation potential (Bartók et al., 2010) and spectral neighbor analysis potential (Chen et al., 2017), whose accuracy can be comparable with that from first principle calculation yet with higher efficiency. Meanwhile, the combination of machine learning potential and MD simulation has been successfully used to predict the physical properties (Dai et al., 2020), such as lattice constant, TEC, and phonon thermal conductivity in (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C MPEA (Figure 13). Furthermore, a combinatorial computational method is proposed to develop the new magnetic MPEAs. High-throughput method is utilized to screen out promising magnetic MPEAs, and then machine learning, additive manufacturing and CALPHAD methods are used to further predict the magnetic property (Chaudhary et al., 2021). Using DFT calculation and machine learning, *OH and *O adsorption energies on the surface of IrPdPtRhRu MPEA can be accurately predicted, which provids a useful strategy to discover the new MPEAs with outstanding catalytic activity (Batchelor et al., 2019). Moreover, this strategy is also used to predict the CO and hydrogen adsorption energies on the surface of CoCuGaNiZn and AgAuCuPdPt MPEAs, which can effectively optimize the MPEA compositions to prevent the formation of molecular hydrogen and accelerate the reduction of CO (Pedersen et al., 2020).

FIGURE 13. The flowchart of the combinatorial approach for predicting the physical properties of (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C MPEA.

Future Research

The combination of machine learning and multi-scale models can quickly and accurately develop high-performance MPEAs to shorten the research-development cycle, and reduces resource costs, as well as broaden the applications of MPEA in mechanics, physics and chemistry. However, the existing multi-scale simulation methods in MPEA have not yet covered the meso-scale microstructures, such as short-range order, dislocation cell and dislocation wall, which is an important challenge in the future. Machine learning could be a feasible method to solve this problem.

Medicine

Biomedical metal materials are adopted to diagnose, replace, and/or repair the damaged cells, tissues, and organs by directly contacting or interacting with the human body. These kinds of special function metal materials have been widely used as medical apparatus and instruments and biological implants, such as the scalpel and artificial bone (Laing et al., 1967; Liu et al., 2004). Over the past few decades, the most widely used metal materials in medical applications are Co-based alloys, titanium alloys, stainless steel, shape-memory alloys (SMAs), and some noble metals (Vidal and Muñoz, 2009; Bertrand et al., 2010). However, many problems have arisen since these conventional biomedical alloys were used in clinical treatments, such as unsatisfactory mechanical properties or corrosion-resistant performance. For example, β-Ti alloys as the most widely employed bio-metallic materials possess lower elastic modulus than other alloys, but they exhibit lower yielding strength (Niinomi et al., 2002). Therefore, these problems extremely limit their large-scale applications in medical engineering.

Human Implants

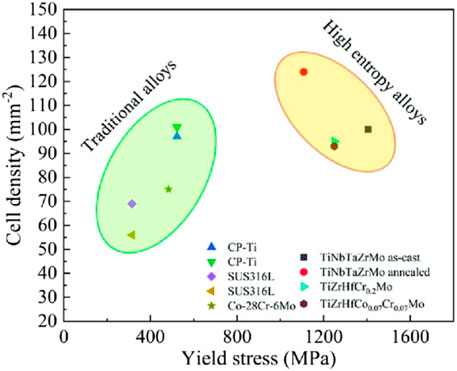

An important application for metallic biomaterials is used as human implants, which requires the materials to have low elastic moduli. The newly developed MPEAs (González-Masís et al., 2021) possess high yielding strength/hardness and corrosion resistance as well as good blood compatibility, compared with conventional alloys. By introducing specific alloying elements, the problem about corrosion resistance and biocompatibility can be easily tackled. The most difficulty is how to effectively achieve the collaborative design between the elastic modulus and yielding strength/hardness to obtain excellent comprehensive mechanical properties. Recently, a novel TiAlFeCoNi MPEA prepared by high-pressure torsion shows an equivalent elastic modulus 170–580% higher hardness and better cellular metabolic activity 260–1,020% compared to Ti-based biomaterials (Edalati et al., 2020). Furthermore, the TiNbTaZr-based MPEAs have also been widely investigated, whose possesses superior yielding strength and better cell density compared with traditional alloys (Figure 14). The equal-atomic TiZrNbTaMo MPEA has compressive yield strength 1,390 MPa, plastic strain 6%, and elastic modulus 153 GPa (Wang and Xu, 2017). Moreover, the proposed TiZrHfCr0.2Mo and TiZrHfCo0.07Cr0.07Mo show better biocompatibility than that of pure Ti and its alloys (Nagase et al., 2020). These excellent properties are generally due to four core effects of MPEAs, the high mixing entropy, severe lattice distortion, sluggish diffusion effect and cocktail effect. For instance, severe lattice distortion not only enhances the lattice-friction stress, but also improves biocompatibility in bio-MPEAs. The cocktail effect enables the advantages of each alloy element to be brought into a full play, which allows special performance requirements to be met. Furthermore, the bio-corrosion behavior and biocompatibility of TiZrHfNbTa MPEA are investigated (Yang et al., 2020). The bio-corrosion performance can be comparable of that of Ti6Al4V alloy under biological fluids attributed to the formation of the oxide passive films on the TiZrHfNbTa surface. Meanwhile, TiZrHfNbTa MPEA provides a suitable environment for the proliferation of MC3T3-E1 pre-osteoblasts, indicating the excellent biocompatibility.

FIGURE 14. Yield strength vs. biocompatibility in MPEAs and traditional alloys (Li et al., 2021a).

Medical Coating

Up to now, NiTi-based SMAs have been the most popular metallic materials in medical applications, such as the metal prosthesis and vascular stent. However, the release of Ni ions with significant cytotoxicity and carcinogenicity from NiTi-based SMAs during applications remains a problem to be tackled (Shabalovskaya et al., 2008; Wang et al., 2011). Conventional surface-treatment processes like physical vapor deposition or oxygen ion implantation are adopted to form a TiO2 passive layer on the surface to prevent the Ni ion release and improve corrosion resistance. Nevertheless, a brittle TiO2 coating is easy to form cracks under complex loads, resulting in the release of Ni ions from the broken points (Aun et al., 2016).

Recently, MPEAs have attracted a widespread attention from medicine and the related area due to their excellent mechanical properties and biocompatibility. The equimolar TiTaNbZrHf MPEA is first proposed as a medical-coating material used in NiTi-based SMAs (Motallebzadeh et al., 2018; Aksoy et al., 2019). Compared with the bare NiTi-based SMAs, the MPEA-coated NiTi-based SMAs keep the release amount of Ni ions below the safe value of 9 ppm in both the artificial saliva and gastric fluid after the 28 days static immersion. Moreover, the equimolar TiTaNbZrHf MPEA is used in the biomedical Ti6Al4V alloy as a coating material (Tüten et al., 2019). The Ti6Al4V alloy is the most commonly-used biomaterials as human implants. However, a high wear rate and the release of the cytotoxic Al and V ions limit its large-scale employment. The MPEA passive films possess a uniform surface morphology and fine-grained amorphous structure, thus improving the comprehensive mechanical properties. In addition, the enhancement of hardness induced by the MPEA passive film can significantly improve the fraction coefficient and wear resistance, thus preventing fatigue, crack, and even failure. Meanwhile, the release of Al and V ions is effectively reduced. Though the equimolar TiTaNbZrHf MPEA performs well as medical coating materials, relevant research is still in its infancy. Therefore, further exploration for other MPEA system like lightweight MPEA is needed for obtaining better performance.

Outstanding Issue

In summary, extraordinary mechanical properties are the fundamental reasons why MPEAs become widely used medical material. Moreover, future investigations are presented as follows. For example, elemental homogenization has been demonstrated to effectively improve MPEAs related biomedical properties. Therefore, how to optimize processing methods to prevent elemental segregation is crucial. In addition, existing coating approaches need to be further improved to adapt the vast composition space of MPEAs.

Biology

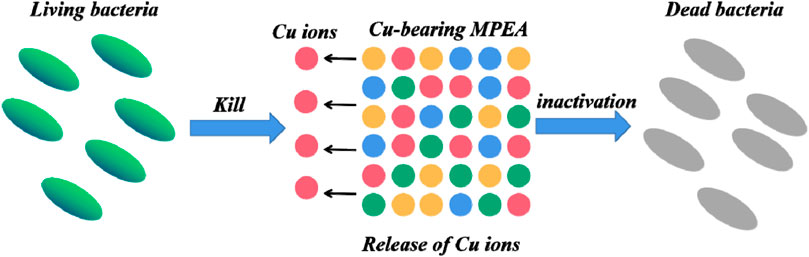

Antibiosis

From ancient times to the present, pathogenic-bacteria/mould-induced diseases, such as influenza, dysentery, and cholera, greatly influences the human health. Therefore, many researchers are committed into developing novel materials with high antibacterial performance. The precipitation of Cu ions in alloys can effectively destroy the protein structure in the bacteria, thus inhibiting the replication of the bacterial DNA and the synthesis of related proteins/enzymes. The release of Ag ions is easy to bind with S atoms in protein, thus effectively destroying bacterial protein structures (Chernousova and Epple, 2013; Lou et al., 2016; Yang et al., 2016). At present, a series of antibacterial stainless steels like ferritic, martensitic as well as austenitic antibacterial stainless steels are developed by introducing an appropriate amount of the Cu element because the Ag element is expensive and difficult to smelt. However, their large scale applications are limited by the insufficient broad-spectrum antibacterial and antibacterial persistence as well as the strict restrictions on the content of the Cu element for maintaining good mechanical properties and corrosion resistance (Nan et al., 2008; Ren et al., 2011).

The MPEAs can contain a high content of the Cu element, which significantly enhances the antibacterial properties of the alloy, while keeping outstanding comprehensive mechanical properties. Meanwhile, due to the huge composition space, using the cocktail effect, MPEAs can be used in various complex service conditions by introducing different elements, which greatly broadens the application range of antibacterial materials and its development prospects. Recently, a novel Al0.4CoCrCuFeNi antibacterial high entropy alloy (AHEA) prepared by arc-melting is proposed, whose mechanical properties and antibacterial performance thoroughly defeat conventional Cu-bearing stainless steels (Zhou et al., 2020). The results show that the antibacterial rate against common marine Gram negative Pseudomonas aeruginosa and Gram positive Bifidobacterium Vietnam can be up to 99%, attributed to a high content of the Cu element induced the release of high concentration of Cu ions from the AHEA, as shown in Figure 15. Meanwhile, the AHEA also possesses superior yielding strengths and corrosion resistance than traditional Cu-bearing stainless steels. Because of the abuse of antibiotics over the whole world, some bacteria exhibit high multi-drug-resistance (MDR). Lately, another CoCrCuFeNi AHEA has been successfully synthesized based on the research on the Al0.4CoCrCuFeNi AHEA (Gao et al., 2022). The experimental results suggest that the bacteria resistance against the Gram-negative Acinetobacter baumannii and Gram-positive methicillin-resistant Staphylococcus aureus of the new CoCrCuFeNi AHEA can approach ∼99%, far exceeding the conventional Cu-bearing stainless steel. Further research shows that the AHEA not only effectively removes the planktonic bacteria, but also prevents the formation of the biofilm. Moreover, compared with the as-cast CoCrCuFeNi AHEA mentioned above, the AHEA prepared using the selective laser melting and in-situ alloying method significantly improves the release of Cu ions, and meanwhile, possesses good mechanical properties. More importantly, the combination of the AHEA and selective laser melting method provides a feasible avenue for fabricating some medical equipment with complex shape or structures and high antibacterial performance.

Antivirus

Different from bacteria, the virus can only survive by replicating themselves in a living body. The virus usually consists of the essential genetic material (RNA or DNA) and a protein shell that wraps and protects genetic material. Since the ancient times, the existence of the virus has been always a great threat for human health due to their various spreading ways like air, surface contact and water, as well as high variability (Alhamlan et al., 2017). Although antiviral drugs can destroy the virus structure and prevent its replication, the spreading of the virus due to the direct contact on the living body cannot be effectively blocked. Therefore, the development of high performance antivirus material is extremely important and necessary.

The MPEAs containing the copper element have attracted widespread attention as the high performance antibacterial materials. In addition, Cu-bearing MPEAs have also been reported as antivirus materials. The inactivation rate against the influenza virus H1N1 and enterovirus 71 of the CuFeCoCrNi MPEA can be over 99% in the surface (Li Z. et al., 2021). It can be attributed to that aqueous corrosion induced the release of copper ions (Cu+ or Cu2+), which can form chelate by destroying the nucleic acids and the proteins of the virus, thus leading to the inactivation of the virus. Besides, the formation of a solid metallic oxide like CuO on the surface of the Cu-bearing MPEA can also result in the denaturation of virus. Based on the design concept of MPEAs, the researchers further prepared the Al0.4CuFeCoCrNi MPEA by the addition of the Al element (Li Z. et al., 2021). The results show that the MPEA not only keeps the same antivirus performance as CuFeCoCrNi MPEA, but also possesses superior corrosion resistance and mechanical properties.

Suggested Future Work

In conclusion, because of excellent antibacterial/antivirus performance, the Cu/Ag-bearing MPEAs can be promising antibacterial/antivirus materials. Nevertheless, current related research activities are still insufficient. The optimization of the design concept and process routes for developing novel bio-MPEAs remains a great challenge to be tackled.

Environment

Hydrogen Storage

The CO2 emission induced by the use of fossil fuels is mainly responsible for global greenhouse effect, which has greatly led to the global climate change. As a feasible clean energy to replace traditional fossil fuels, hydrogen has attracted widespread attention from the related fields. However, hydrogen storage remains a huge obstacle for engineering applications due to the flammability of hydrogen. The common hydrogen-storage technologies include liquefied hydrogen storage, metal-hydride hydrogen storage, and high-pressure hydrogen storage (Durbin and Malardier-Jugroot, 2013; Züttel, 2003, 2004). Among them, metallic hydride is regarded as the outstanding hydrogen-storage material because of its low cost, high volume storage density, and excellent absorption/desorption ability (Sakintuna et al., 2007). Recently, MPEAs have been widely reported as the hydrogen-storage material.

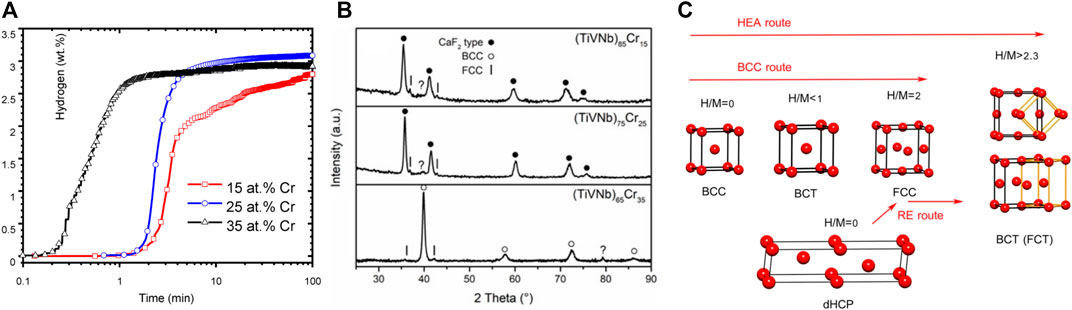

The first proposed MPEAs for hydrogen absorption/desorption are the Co-Fe-Mn-Ti-V-Zr system (Kao et al., 2010). The CoFeMnTixVZr, CoFeMnTiVyZr, and CoFeMnTiVZrz MPEAs have been demonstrated to be capable of hydrogen absorption/desorption when keeping 0.5 ≤ x ≤ 2.5, 0.4 ≤ y ≤ 3.0, 0.4 ≤ z ≤ 3.0, respectively, via the pressure-composition isotherms (PCIs) tests and kinetic tests under an initial pressure of 9.58 atm. The hydrogen-storage performance of the alloys can be optimized by controlling elemental segregation, formation enthalpy of metal hydride, and lattice constant. In addition, high entropy effect induced the formation of single C14 Laves phase in these alloys can further improve hydrogen-storage performance. Recently, the hydrogen-storage performance of three MPEAs synthesized by arc-melting, including (TiVNb)85Cr15, (TiVNb)75Cr25 and (TiVNb)65Cr35, has been studied (Strozi et al., 2021). The three MPEAs are composed of BCC structure, and especially, they can absorb hydrogen without any activation treatment under room temperature, which can be up to H/M ∼2 (Figures 16A,B). Furthermore, the CrFeNiTiVZr MPEA prepared by laser engineered net shaping (LENS) has also been investigated (Kunce et al., 2013). The MPEA consists of the C14 Laves phase and a little α-Ti solid-solution phase. The C14 Laves phase dominates the hydrogen storage, and the hydrogen-storage capacity of the MPEAs can be up to 1.8 wt% of H2. The microstructure evolution in MPEAs during the hydrogen storage is also important for further improving the hydrogen-storage performance. In the recent researches, the hydrogen absorption performance of TiVZrNbHf MPEA is investigated (Sahlberg et al., 2016). The experimental results show that the novel TiVZrNbHf MPEA exhibits maximum H/M ratio of 2.5, whose capability can be comparable to that of rare-earth elements. The excellent hydrogen-storage performance of this MPEA results from the strain in the distorted FCC or BCT structure in metallic hydride, and promotes the occupation of hydrogen on tetrahedral and octahedral sites (Figure 16C). Furthermore, the in situ SR-XRD result shows that the phase transition from BCC phase to FCC dihydride phase occurs during the hydrogen-absorption process in the TiZrNbHfTa MPEA (Zlotea et al., 2019).

FIGURE 16. Kinetic curves of Ti-V-Nb-Cr MPEA system under room temperature. (A) XRD patterns of Ti-V-Nb-Cr MPEA system after hydrogen absorption (B) (Strozi et al., 2021). The evolution of microstructure in TiVZrNbHf MPEA during the hydrogen-storage (C) (Sahlberg et al., 2016).

Decolorization

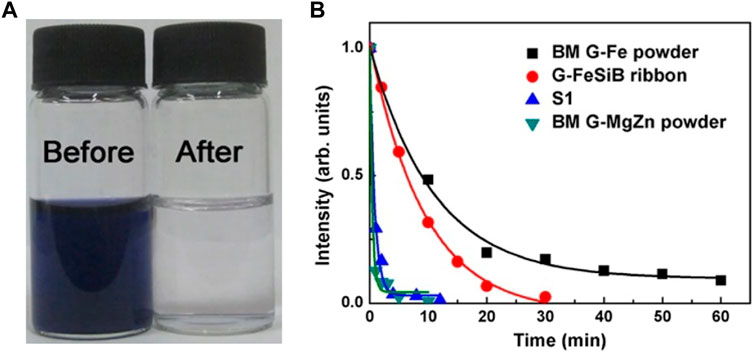

The discharge of industrial wastewater containing azo dyes is a great threat to the environment and human health (Ramirez et al., 2007; Sarlar et al., 2020). However, the degradation of azo dyes remains a huge obstacle due to the existence of a stable azo bond (-N=N-) (Tang and An, 1995). Decolorization of wastewater is an effective way to degrade azo dyes. Recently, metallic materials, such as Fe, Mg, Al, and Zn pure elements and their alloys, have been widely used to achieve the degradation of industrial wastewater due to low cost, high efficiency, and easy preparation compared with other traditional technologies (Wang P. et al., 2017; Zhang C. et al., 2017). Nevertheless, their larger scale applications are greatly limited because of poor corrosion resistance and mechanical properties. Therefore, it is urgent to develop novel alloy systems for the degradation of azo dyes.

Over the few years, due to the excellent decolorizing performance to azo dyes and outstanding mechanical properties, MPEAs have attracted widespread attention. A newly-developed AlCoCrTiZn MPEA prepared by mechanical alloying is studied (Lv et al., 2016). The results show that the novel MPEA possesses a high degradation performance to the Direct Blue 6 (a kind of azo dye), which can be comparable to the results observed in the best amorphous alloy reported to this day. The prominent performance of the MPEA to the decolorization of azo dyes can be attributed to their unique atomic structure compared with traditional alloys, consisting of higher specific surface area, unique chemical composition effects, and severer lattice distortion. These characteristics significantly reduce the activation-energy barrier (∼30 kJ/mol), leading to reaction easier to occur compared to the Fe-based metallic glass (Figure 17). Furthermore, the AlFeMnTiM (M = Cr, Co, and Ni) MPEAs have been successfully synthesized via mechanical alloying, which have high efficiency to the decolorizing of azo dye Direct Blue 6 (Wu et al., 2019). Especially, AlFeMnTiCr shows the best decolorizing efficiency and superior catalytic performance, whose degradation performance towards azo dye far exceeds that of common commercial Fe-Si-B amorphous alloy ribbons, even 100 times better than that of industrial zero-valent iron powders. The outstanding decolorizing efficiency mainly owns to the unique atomic structure and the galvanic-cell effect. In general, MPEAs have proved to be valuable and promising decolorizing material for the degradation of the industrial wastewater.

FIGURE 17. (A) The decolorizing performance to azo dyes DB6, (B) the comparison of decolorizing performance with other alloys (Lv et al., 2016).

Future Direction

In short, the outstanding hydrogen storage capacity and decolorizing performance can be attributed to the unique atomic structure, phase stability, severe lattice distortion and four core effects of MPEAs. Nevertheless, there are still some problems that limit the large-scale commercial application of MPEAs. For example, a high mass element like Hf/Zr could decrease the hydrogen-storage performance. Therefore, the lightweight elements could be introduced in the MPEAs in the future to achieve the higher hydrogen-storage ability. In addition, because of rapid reaction between azo dyes and powder MPEAs, how to effectively control the reaction rate is crucial for reducing the consumption of MPEAs and improving their recyclability.

X Applications

In addition to these disciplines, the dynamic-development trend of MPEAs is bound to affect the following disciplines: 1) Geoscience. The exploitation and utilization of nonmetallic/metallic mines for MEAs affect geology, geomorphology, hydrogeology, mineralogy, petrology, and limnology; 2) Anthropology. The transfer of large-scale mines drives the population movement across regions and countries; 3) Economics. The rare-earth metal and noble metal used in MPEAs would undoubtedly affect the price fluctuation of the products from their compositions; 4) Psychology. The emergency of MPEAs has broken the thinking set in the traditional metallurgy strategy, which is an important breakthrough in the cognitive psychology for natural science; 5) Art. The excellent mechanical properties and unique chemical properties of MPEAs greatly broaden the selection of materials for the artwork, which could be more suitable for artists’ ideas and creation; 6) Linguistics. The infinite combination space of MPEAs requires the corresponding new vocabulary to describe. The different permutations and combinations of its words gave birth to new words and promoted the development of phonology; 7) Cognitive science. The new concept and new composition system of MPEAs have expanded human beings’ new understanding.

Of course, this is an important reflection from the big scientific field, to discuss the impact of the development of MPEAs on the progress of society in a wide range.

Concluding Remarks

This review describes the applications of MPEAs on engineering, including mechanics, physics, chemistry, medical science, biology, environment, computer as well as unknown areas. Based on the performance oriented material research and development mode, this approach make it easier to grasp potential application areas. Several outstanding features are summarized, which include the extreme temperature performance, irradiation performance, catalytic performance, and so on. In the future, some potential development points are also considered. This paper puts more emphasis on the application development, to promote scientific progress and technological change in multi-principal element materials.

Author Contributions

JL, QF, and PL conceived the original ideas and supervised this study. YC and BX wrote original draft. BL and YC carried out the revision of this paper.

Funding

The authors would like to deeply appreciate the National Natural Science Foundation of China (51871092, 12072109, and 12172123), and Natural Science Foundation of Hunan Province (2021JJ40032). PL very much appreciates the supports from the National Science Foundation (DMR-1611180 and 1809640).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abareshi, M., and Emadoddin, E. (2011). Effect of Retained Austenite Characteristics on Fatigue Behavior and Tensile Properties of Transformation Induced Plasticity Steel. Mater. Des. 32, 5099–5105. doi:10.1016/j.matdes.2011.06.018

Aksoy, C. B., Canadinc, D., and Yagci, M. B. (2019). Assessment of Ni Ion Release from TiTaHfNbZr High Entropy alloy Coated NiTi Shape Memory Substrates in Artificial Saliva and Gastric Fluid. Mater. Chem. Phys. 236, 121802. doi:10.1016/j.matchemphys.2019.121802

Alhamlan, F. S., Majumder, M. S., Brownstein, J. S., Hawkins, J., Al-Abdely, H. M., Alzahrani, A., et al. (2017). Case Characteristics Among Middle East Respiratory Syndrome Coronavirus Outbreak and Non-outbreak Cases in Saudi Arabia from 2012 to 2015. BMJ open 7, e011865. doi:10.1136/bmjopen-2016-011865

Aun, D. P., Houmard, M., Mermoux, M., Latu-Romain, L., Joud, J.-C., Berthomé, G., et al. (2016). Development of a Flexible Nanocomposite TiO2 Film as a Protective Coating for Bioapplications of Superelastic NiTi Alloys. Appl. Surf. Sci. 375, 42–49. doi:10.1016/j.apsusc.2016.03.064

Bae, J. W., Seol, J. B., Moon, J., Sohn, S. S., Jang, M. J., Um, H. Y., et al. (2018). Exceptional Phase-Transformation Strengthening of Ferrous Medium-Entropy Alloys at Cryogenic Temperatures. Acta Materialia 161, 388–399. doi:10.1016/j.actamat.2018.09.057

Bagot, P. A. J., Kruska, K., Haley, D., Carrier, X., Marceau, E., Moody, M. P., et al. (2014). Oxidation and Surface Segregation Behavior of a Pt-Pd-Rh Alloy Catalyst. J. Phys. Chem. C 118, 26130–26138. doi:10.1021/jp508144z

Bartók, A. P., Payne, M. C., Kondor, R., and Csányi, G. (2010). Gaussian Approximation Potentials: The Accuracy of Quantum Mechanics, without the Electrons. Phys. Rev. Lett. 104, 136403. doi:10.1103/physrevlett.104.136403

Batchelor, T. A. A., Pedersen, J. K., Winther, S. H., Castelli, I. E., Jacobsen, K. W., and Rossmeisl, J. (2019). High-entropy Alloys as a Discovery Platform for Electrocatalysis. Joule 3, 834–845. doi:10.1016/j.joule.2018.12.015

Bertrand, E., Gloriant, T., Gordin, D. M., Vasilescu, E., Drob, P., Vasilescu, C., et al. (2010). Synthesis and Characterisation of a New Superelastic Ti-25Ta-25Nb Biomedical alloy. J. Mech. Behav. Biomed. Mater. 3, 559–564. doi:10.1016/j.jmbbm.2010.06.007

Chang, X., Zeng, M., Liu, K., and Fu, L. (2020). Phase Engineering of High-Entropy Alloys. Adv. Mater. 32, 1907226. doi:10.1002/adma.201907226

Chaudhary, V., Chaudhary, R., Banerjee, R., and Ramanujan, R. V. (2021). Accelerated and Conventional Development of Magnetic High Entropy Alloys. Mater. Today 49, 231–252. doi:10.1016/j.mattod.2021.03.018

Chen, C., Deng, Z., Tran, R., Tang, H., Chu, I. H., and Ong, S. P. (2017). Accurate Force Field for Molybdenum by Machine Learning Large Materials Data. Phys. Rev. Mater. 1, 043603. doi:10.1103/physrevmaterials.1.043603

Chen, G., Qiao, J. W., Jiao, Z. M., Zhao, D., Zhang, T. W., Ma, S. G., et al. (2019). Strength-ductility Synergy of Al0.1CoCrFeNi High-Entropy Alloys with Gradient Hierarchical Structures. Scripta Materialia 167, 95–100. doi:10.1016/j.scriptamat.2019.04.002

Chen, M.-R., Lin, S.-J., Yeh, J.-W., Chuang, M.-H., Chen, S.-K., and Huang, Y.-S. (2006). Effect of Vanadium Addition on the Microstructure, Hardness, and Wear Resistance of Al0.5CoCrCuFeNi High-Entropy alloy. Metall. Mat Trans. A. 37, 1363–1369. doi:10.1007/s11661-006-0081-3

Chen, P., Lee, C., Wang, S.-Y., Seifi, M., Lewandowski, J. J., Dahmen, K. A., et al. (2018). Fatigue Behavior of High-Entropy Alloys: A Review. Sci. China Technol. Sci. 61, 168–178. doi:10.1007/s11431-017-9137-4

Chen, S., Oh, H. S., Gludovatz, B., Kim, S. J., Park, E. S., Zhang, Z., et al. (2020). Real-time Observations of TRIP-Induced Ultrahigh Strain Hardening in a Dual-phase CrMnFeCoNi High-Entropy alloy. Nat. Commun. 11, 826–828. doi:10.1038/s41467-020-14641-1

Chen, S.-T., Tang, W.-Y., Kuo, Y.-F., Chen, S.-Y., Tsau, C.-H., Shun, T.-T., et al. (2010). Microstructure and Properties of Age-Hardenable AlxCrFe1.5MnNi0.5 Alloys. Mater. Sci. Eng. A 527, 5818–5825. doi:10.1016/j.msea.2010.05.052

Chernousova, S., and Epple, M. (2013). Silver as Antibacterial Agent: Ion, Nanoparticle, and Metal. Angew. Chem. Int. Ed. 52, 1636–1653. doi:10.1002/anie.201205923

Chou, H.-P., Chang, Y.-S., Chen, S.-K., and Yeh, J.-W. (2009). Microstructure, Thermophysical and Electrical Properties in AlxCoCrFeNi (0≤x≤2) High-Entropy Alloys. Mater. Sci. Eng. B 163, 184–189. doi:10.1016/j.mseb.2009.05.024

Choudhuri, D., Alam, T., Borkar, T., Gwalani, B., Mantri, A. S., Srinivasan, S. G., et al. (2015). Formation of a Huesler-like L21 Phase in a CoCrCuFeNiAlTi High-Entropy alloy. Scripta Materialia 100, 36–39. doi:10.1016/j.scriptamat.2014.12.006

Chuang, M.-H., Tsai, M.-H., Wang, W.-R., Lin, S.-J., and Yeh, J.-W. (2011). Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys. Acta Materialia 59, 6308–6317. doi:10.1016/j.actamat.2011.06.041

Cui, Y., Shen, J., Manladan, S. M., Geng, K., and Hu, S. (2020). Wear Resistance of FeCoCrNiMnAlx High-Entropy alloy Coatings at High Temperature. Appl. Surf. Sci. 512, 145736. doi:10.1016/j.apsusc.2020.145736

Cvijović, Z., and Radenković, G. (2006). Microstructure and Pitting Corrosion Resistance of Annealed Duplex Stainless Steel. Corros Sci. 48, 3887–3906. doi:10.1016/j.corsci.2006.04.003

Dai, F.-Z., Wen, B., Sun, Y., Xiang, H., and Zhou, Y. (2020). Theoretical Prediction on thermal and Mechanical Properties of High Entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C by Deep Learning Potential. J. Mater. Sci. Tech. 43, 168–174. doi:10.1016/j.jmst.2020.01.005

Demetriou, M. D., Launey, M. E., Garrett, G., Schramm, J. P., Hofmann, D. C., Johnson, W. L., et al. (2011). A Damage-Tolerant Glass. Nat. Mater 10, 123–128. doi:10.1038/nmat2930

Ding, Q., Zhang, Y., Chen, X., Fu, X., Chen, D., Chen, S., et al. (2019). Tuning Element Distribution, Structure and Properties by Composition in High-Entropy Alloys. Nature 574, 223–227. doi:10.1038/s41586-019-1617-1

Dobeš, F., Hadraba, H., Chlup, Z., Dlouhý, A., Vilémová, M., and Matějíček, J. (2018). Compressive Creep Behavior of an Oxide-Dispersion-Strengthened CoCrFeMnNi High-Entropy alloy. Mater. Sci. Eng. A. 732, 99–104. doi:10.1016/j.msea.2018.06.108

Durbin, D. J., and Malardier-Jugroot, C. (2013). Review of Hydrogen Storage Techniques for on Board Vehicle Applications. Int. J. Hydrogen Energ. 38, 14595–14617. doi:10.1016/j.ijhydene.2013.07.058