94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Mater., 17 September 2021

Sec. Ceramics and Glass

Volume 8 - 2021 | https://doi.org/10.3389/fmats.2021.741560

This article is part of the Research TopicRecent Advances in Low-Positive, Zero, and Negative Thermal Expansion Materials: Fundamentals and ApplicationsView all 5 articles

This review presents the history of materials in the A2M3O12 and related ceramic families, including their unusual thermal expansion and the present understanding of its mechanism, and related factors such as hydroscopicity and the monoclinic to orthorhombic phase transition. Other properties, including thermomechanical, thermal and ionic conduction and optical properties, are presented in terms of current knowledge, challenges and opportunities for applications. One of the largest challenges is the production of monoliths, and various methods for consolidation and sintering are summarized. These ceramics have considerable promise when combined with other materials, and recent advances in such composites are presented. These matters are placed in the context of the potential applications of negative and near-zero thermal expansion ceramics, which still present challenges for future materials researchers.

The A2M3O12 ceramic family,1 in which A stands for a trivalent cation, in the range of cation radii from Al3+ to Dy3+ and M generally stands for W6+ or Mo6+, offers extraordinary flexibility in terms of chemistry, while preserving the same basic crystal structure. Many of the members of this family display negative thermal expansion along one or more lattice vectors, leading to unusual (near-zero, negative or low-positive) values of the coefficient of thermal expansion. The origins of this unusual behavior and its relationship to materials chemistry, structure, and physical properties, is the main topic of this review. More general aspects of negative thermal expansion materials have been addressed thoroughly in our previous review (Romao et al., 2013).

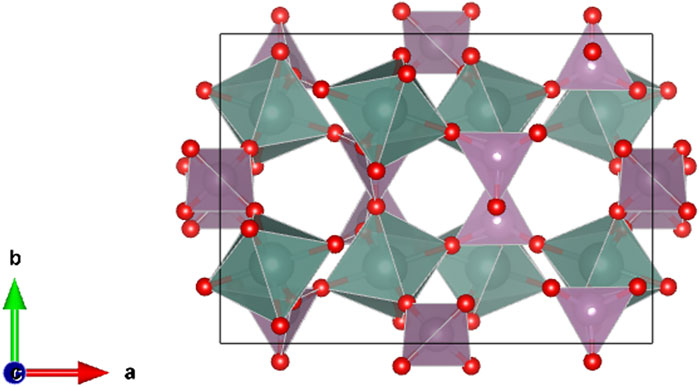

In addition to the vast range of options for A3+ ions, it is also possible to substitute A3+ with a mixture of tetravalent, trivalent and/or divalent cations with concomitant partial substitution of M6+ with pentavalent cations to preserve charge neutrality, while maintaining the same general structure (Figure 1). Therefore, it is possible to categorize materials from such cation replacements into three major sub-families according to the degree of M6+ substitution by pentavalent cations, as ABM3O12, ABM2XO12 and A2MX2O12. These subfamilies are described briefly here, with the main focus of this review on A2M3O12.

FIGURE 1. Sc2W3O12-type orthorhombic structure (Pbcn space group), shown for Y2Mo3O12 at room temperature, oriented along the c-axis direction, indicating void spaces due to vacant dodecahedral, 8-fold sites (which are fully occupied in the garnet structure).

The ABM3O12 sub-family requires A and B as tetravalent and divalent cations, respectively. Their presence in 1:1 atomic ratio does not require substitution of W6+/Mo6+ with pentavalent cations. Since the 2004 report of HfMgW3O12 (Suzuki and Omote, 2004), many other compounds from this sub-family have been reported (Baiz et al., 2008; Marinkovic et al., 2008a; Omote et al., 2011; Song et al., 2013; Zhang et al., 2015; Romao et al., 2015b; Li et al., 2017). Most of these compounds are tungstates or molybdates of Hf4+/Zr4+ and Mg2+. Therefore, these three elements are archetypical for A4+ and B2+ in ABM3O12. The ABM3O12 structure maintains the same framework connectivity of octahedra and tetrahedra through the vertices as in A2M3O12 (see Figure 1 and Section 2 for structure details), although in the orthorhombic Pna21 space group. However, A4+ and B2+ occupy crystallographically unique atomic sites, thereby splitting the single A3+ site in A2M3O12. In some instances, A4+ can be shared by two tetravalent cations Hf4+/Zr4+ (Shen et al., 2018), while in some other materials B2+ can be a mixture of two divalent cations such as Mg2+ and Zn2+ (Li et al., 2018; Madrid et al., 2020; Marinkovic et al., 2021). The special importance of the substitution at B2+ is due to HfMg1-xZnxMo3O12 and ZrMg1-xZnxMo3O12, which have near-zero thermal expansion. Intermediate compounds between A2M3O12 and ABM3O12 such as In0.5(ZrMg)0.75Mo3O12 (Prisco et al., 2016a), In(HfMg)0.5Mo3O12 (Miller et al., 2012b) and Cr(ZrMg)0.5Mo3O12 (Song et al., 2014) also exist.

The ABM2XO12 sub-family requires the A and B cations to be tetravalent and trivalent, respectively. Therefore, 1/3 of W6+ or Mo6+ must be replaced with P5+ or V5+, as in the case of HfScW2PO12 and related materials (Zhang et al., 2015; Cheng et al., 2016; Ge et al., 2016c; Cheng et al., 2017). Even more complex substitution patterns are possible in ABM2XO12 (Liang et al., 2017; Yuan et al., 2020) permitting further adjustments of their physical properties. The structures from this sub-family preserve the same framework connectivity through vertices as in A2M3O12, and also take on the same orthorhombic space group (Pbcn).

The A2MX2O12 sub-family was reported (Piffard et al., 1987) prior to the first report of negative thermal expansion in A2M3O12 (Evans et al., 1997). They presented studies of Zr2SP2O12 and since then it is known that this sub-family shares exactly the same crystal structure and space group as the A2M3O12 family. In the A2MX2O12 family, A is necessarily a tetravalent cation, which offers only limited chemical flexibility since A4+ could be only Hf4+ or Zr4+, with Zr4+ generally reported (Evans et al., 1995; Cetinkol et al., 2009; Cetinkol and Wilkinson, 2009; Shang et al., 2013). To preserve charge neutrality, the compounds from the A2MX2O12 sub-family have 2/3 of the W6+, Mo6+ or S6+ ions replaced by P5+.

Negative and near-zero thermal expansion are common for all these sub-families, and therefore their properties and insights complement studies of the A2M3O12 family.

Although this review centers on properties of materials in the A2M3O12 family, some comments concerning synthesis are pertinent. Most of the materials in the A2M3O12 and related sub-families can be synthesized through the classical solid-state reaction method (Romao et al., 2013). This method is simple, straightforward and avoids sophisticated chemistry, so its use is understandable when the goal is to prepare novel materials and to evaluate their fundamental physical properties. However, due to the inherent drawbacks of the synthesized powders, solid-state reactions are usually not useful to produce powders to form the monolithic bodies required for many applications (see Section 8), even with consolidation and sintering (see Section 6). The inherent drawbacks of the powders prepared by solid-state reaction methods are phase inhomogeneity (i.e., formation of secondary phases), and large and strongly agglomerated particles. These characteristics do not permit the required formation of highly dense solids with fine microstructure. From an industrial viewpoint, this method also is expensive since it uses high temperatures and long processing times.

Therefore, soft-chemistry routes are better to provide nanometric to sub-micronic powders with high specific area and low agglomeration. There are currently significant efforts aimed at the development of protocols capable of providing powders with desired properties, including co-precipitation (Yordanova et al., 2012; Pontón et al., 2017; Pourmortazavi et al., 2017; Marzano et al., 2019), sol-gel methods (Zhang et al., 2008; Ari et al., 2011; Prisco et al., 2013), non-hydrolytic sol-gel methods (Gates et al., 2006; Baiz et al., 2008; Truitt et al., 2015; Young et al., 2016) and hydrothermal routes (Li et al., 2019; Isobe et al., 2020). Low-temperature combustion was also reported for preparation of fine Al0.5Sc1.5W3O12 powders (Dasgupta et al., 2012).

The present review presents the history of studies of materials in the A2M3O12 and related ceramic families, the findings of unusual thermal expansion and the present understanding of the mechanism, and related factors such as hydroscopicity, and the monoclinic to orthorhombic phase transition. Other properties, including thermomechanical, thermal and electric conduction and optical properties, are presented in terms of current knowledge, challenges and opportunities for applications. One of the largest challenges is the production of monoliths, and various methods for consolidation and sintering are summarized. These ceramics have considerable promise when combined with other materials, and recent advances in such composites are presented. All of these matters are placed in the context of the applications of the A2M3O12 and related ceramic families, which still present challenges for future materials researchers.

Before negative thermal expansion (NTE, also known as thermomiotic behavior) and near-zero thermal expansion (NZTE) were discovered in the orthorhombic crystal phases (space group 60: Pbcn, alternatively Pnca) of A2M3O12 and related compounds in the late 1990s (Evans et al., 1997), many of these materials were already known and studied for other purposes.

An 1895 paper (Hitchcock, 1895) on co-precipitation synthesis of several tungstates and molybdates from the A2M3O12 family likely is the first report in the scientific literature of A2M3O12 phases. There is scant other new information until the 1963 report (Borchardt, 1963a) of Y2W3O12 (denoted as Y2O3 × 3WO3 in the paper), synthesized through a solid-state reaction route, which acknowledged that the unit cell, space group and crystal structure of this new compound were not known at the time. The author reported that the X-ray diffraction (XRD) pattern of Y2W3O12 at room temperature was characterized by a few broad and weak diffraction lines, providing the first, although indirect, observation of hygroscopicity in the A2M3O12 family.

Soon after, Borchardt published another study (Borchardt, 1963b) on the rare-earth (Sc to Lu) tungstates in the A2M3O12 family. That report concentrated on optical properties with special interest in their luminescence (see also Section 5.3). Although the crystal structure was not determined, the author preliminarily indicated three different types of X-ray powder diffraction (XRPD) patterns, depending on the size of the rare-earth cations. The author suggested the existence of three structures at room temperature: one for the tungstates in the ranges from La to Dy, another from Ho to Y, and a third for the tungstates of Lu and Sc which are the two smallest rare-earth cations. Interestingly, Borchardt (1963a) discerned that Dy2W3O12, when quenched from a temperature higher than 1273 K, adopts the structure of the tungstates from the Ho-Y group, which led the author to propose that Dy2W3O12 transforms to a Ho2W3O12-type structure above 1273 K. This finding was confirmed in 2016 (Cao et al., 2016).

Shortly after Borchardt’s pioneering research, it was suggested (Nassau et al., 1964) that four different crystal structures exist for the rare-earth tungstates from La to Lu, depending on cation size, and also on temperature. For the first time, the orthorhombic crystal system was ascribed to some of the A2M3O12 tungstates, such as Yb2W3O12 and Sc2W3O12. A year later the same authors published a landmark paper (Nassau et al., 1965) which described synthesis of 66 different tungstates and molybdates from A2M3O12 family, encompassing the phases with rare-earth and non-rare-earth trivalent cations, as well as some solid solutions. The authors distinguished several tungstate crystal structures. The tungstates from La to Dy appeared to be isostructural, adopting the monoclinic space group C2/c with four chemical formulae per unit cell at room temperature. The crystal structure for Eu2W3O12 had been solved a few years prior (Templeton and Zalkin, 1963), showing that W6+ occupied two independent tetrahedra sites, while Eu3+ was coordinated by eight oxygens. Nassau et al. concluded that all tungstates from La to Dy adopted this same structure, with unit cell dimensions decreasing in accord with the lanthanide contraction rule, with the exception of Tb2W3O12. In addition, they recognized explicitly, for the first time, the existence of hydrated phases at room temperature for tungstates and molybdates of heavy rare earths, for Y and Dy to Lu. When heated to 393 K, these materials lost water and converted into orthorhombic phases, as demonstrated by high-temperature X-ray diffraction. In the same report (Nassau et al., 1965), they also correctly proposed the space group of the orthorhombic phases as Pnca. The same authors also suggested that the molybdates from La to Nd and from Sm to Gd crystallized in two different structures, but did not give further details. They also referred to a tetragonal structure adopted, supposedly, by the molybdates with trivalent cations from Pr to Ho, and observed that tungstates and molybdates of non-rare-earth trivalent cations were not hygroscopic.

Soon after those reports, the crystal structure of orthorhombic Sc2W3O12 was reported (Abrahams and Bernstein, 1966). This was a significant step forward and Sc2W3O12 became the archetypal structure, shared by other 23 tungstates and molybdates from the A2M3O12 family, mainly those containing heavy rare-earth and non-rare-earth cations, e.g., Al2W3O12 (Craig and Stephenson, 1968). In contrast with the Eu2W3O12 structure, where the trivalent cations adopt 8-fold coordination, in the Sc2W3O12 structure the trivalent cations adopt octahedral coordination. The Sc2W3O12-type structure also has W6+ in two independent crystallographic positions, and oxygens in six independent crystallographic sites, with four formula units per unit cell.

The division between the two types of structure (Eu2W3O12 and Sc2W3O12) for the series of rare-earth elements from La to Lu obeyed the first Pauling rule (coordination number dictated by radius ratio) quite well (Abrahams and Bernstein, 1966). A cation-to-anion radius ratio >0.732 led to 8-fold cation coordination, while lower ratios favored octahedral (6-fold) coordination. Also, for the first time, it was recognized that octahedra and tetrahedra in the orthorhombic Sc2W3O12-type structure shared mutual vertices (more specifically, each octahedron is connected to six tetrahedra through vertices, while each tetrahedron is connected to four octahedra at the same manner) (Abrahams and Bernstein, 1966), a feature that would be identified, 3 decades later, as the essential structural motif underlying the vibrational mechanism of NTE or NZTE.

In those early days the potential for applications of A2M3O12-type materials was already recognized, in the high intrinsic optical transparency of A2M3O12 phases over a wide wavelength range from 0.35 to 5 μm, including visible and infra-red ranges (Nassau et al., 1965), and the use of Gd2Mo3O12 as a laser host material when doped with Nd (Borchardt and Bierstedt, 1966).

The unit cell parameters of some rare earth molybdates, from Sm to Dy, were reported in 1971 (Brixner et al., 1971). A few years later a milestone paper was published (Sleight and Brixner, 1973), showing that phases with the orthorhombic structure (Sc2W3O12-type) could undergo a displacive phase transformation at lower temperatures to the monoclinic space group P21/a (space group 14). Even more importantly, the authors correlated the temperatures of the phase transformations with the electronegativity of the trivalent cations, showing that higher electronegativity of the trivalent cations results in phase transitions at higher temperatures. Although there are a few exceptions from this electronegativity correlation, such as the case of ScAlMo3O12 (Truitt et al., 2015), the plot constructed by Sleight and Brixner for five different A2M3O12 molybdates has been generally affirmed in many further investigations (Romao et al., 2013) and is still of fundamental importance to understanding the main mechanism controlling this important phase transition in the A2M3O12 family.

A thorough review on rare-earth molybdates was published in 1979 (Brixner et al., 1979). The authors explicitly delineated the phase transition temperatures and structural types for all molybdates from La to Lu, while also showing that the unit cells of molybdates adopting the Pba2 space group (defined as the β’ modification) obey the lanthanide contraction in the range from Pr to Ho. In the same timeframe, the crystal structure for the monoclinic, lower-temperature modification of heavy rare-earth and non-rare-earth tungstates and molybdates was solved for Fe2Mo3O12 (Chen, 1979).

Luminescence studies of Al2W3O12, Sc2W3O12 and Lu2W3O12, undoped and doped with Eu3+ or Cr3+, were published in 1980 but the last two tungstate phases were found to be so hygroscopic that their luminescence was not efficient (Blasse and Ouwerkerk, 1980).

In the late 1980s, Zr2SO4(PO4)2 was synthesized and shown to be isostructural with Sc2W3O12 (Piffard et al., 1987). This report was the first time a phase with two chemically different tetrahedra and with a tetravalent cation in an octahedral position had been identified as having the orthorhombic Sc2W3O12 structure. More recently, similar materials have been denoted as the A2MX2O12 sub-family of A2M3O12 (Madrid et al., 2020). It has been suggested that S6+ and P5+ are randomly distributed over two independent tetrahedral sites at room temperature (Piffard et al., 1987).

In 1995, Evans et al. published the crystal structure of Zr2WO4(PO4)2, another compound isostructural to Zr2SO4(PO4)2 and Sc2W3O12 (Evans et al., 1995). The authors discussed the relationship between this structure and the garnet structure. Although this issue had been previously discussed in Russian literature (Plyasova et al., 1967), Evans et al. importantly pointed out that the Sc2W3O12-type structure can be understand as a deficient garnet structure, with completely vacant 8-coordinated sites (Figure 1). This structural feature allows the Sc2W3O12-type structure to accommodate atomic and molecule species within the empty 8-fold sites, which form continuous channels along the c-crystallographic direction (for the Pbcn space group; for Pcna, the channels are directed along the a-axis). The properties, such as hygroscopicity (Marinkovic et al., 2005) and high ionic conductivity (Imanaka et al., 1998) of some A2M3O12 phases with large channels owing to large A site cations, are likely a direct consequence of the deficient garnet structure. Evans et al. (1995) concluded their paper by anticipating unusual negative thermal expansion in Zr2WO4(PO4)2 and of some other (unspecified) Sc2W3O12-type materials. Surprisingly, 30 years after the original report of the synthesis of Y2W3O12 (Borchardt, 1963a), aside from a brief report in the Russian literature (Balashov et al., 1975), no study on thermal expansion of A2M3O12 family had been reported and the issue remained obscure. The 1995 paper by Evans et al. ended the pre-NTE period and brought new research insights concerning this vast group of ceramics.

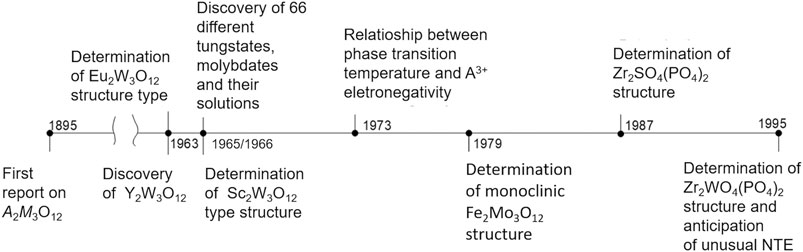

Figure 2 summarizes the timeline of the main discoveries and milestone papers in the pre-NTE period of the A2M3O12 family.

FIGURE 2. Timeline of the main discoveries and milestone papers in the pre-NTE era of the A2M3O12 family of ceramics.

The first report of NTE and NZTE in the A2M3O12 family was in 1997 (Evans et al., 1997): linear coefficients of thermal expansion (CTE) for 21 tungstates and molybdates, mainly measured by dilatometry, although some CTEs were measured by XRPD. Most of the reported tungstates and molybdates were based on Al3+ and Sc3+, partially substituted by different rare-earth or non-rare-earth cations. In addition, a few members of the related A2MX2O12 family (A = Zr4+ or Hf4+; X = P5+; M = W6+ or Mo6+) also were reported. An NTE mechanism for the A2M3O12 family was proposed in the seminal 1997 paper and discussed further from a more general viewpoint in related subsequent publications (Sleight, 1998; Evans et al., 1998a; Evans et al., 1998b; Evans, 1999) and in more detail for Sc2W3O12 (Evans et al., 1998b) and Sc2Mo3O12 (Evans and Mary, 2000).

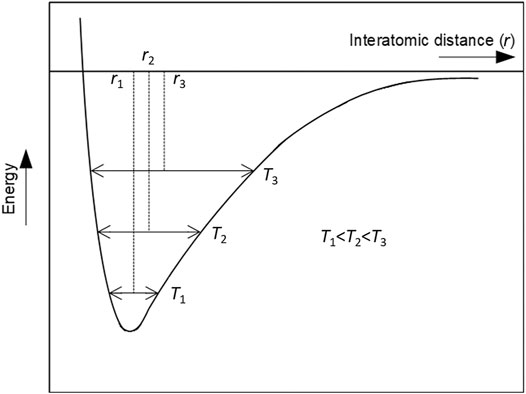

In the late 1990s, the mechanism proposed for NTE and NZTE in the A2M3O12 leaned heavily on understanding of the unusual thermal expansion and phase transitions in a structurally related family, the framework silicates such as quartz and cristobalite (Giddy et al., 1993; Swainson and Dove, 1995; Hammonds et al., 1996). The known mechanism for the framework silicates, where SiO4 tetrahedra share vertices in an open crystal structure, explained the phase transition between high- and low-temperature structures, and also addressed NTE and NZTE observed in β-quartz and β-cristobalite (the high-temperature forms). The mechanism was based on low-energy phonon modes capable of tilting rigid SiO4 units in a correlated manner, causing NTE or NZTE over relatively limited temperature ranges, well above room temperature. In β-quartz and β-cristobalite, this unusual negative contribution to the overall thermal expansion overwhelmed the well-understood positive contribution due to bond-length (Si-O in this case) extension with increased temperature, originating from the inherent asymmetry of the interatomic potential well (Figure 3). There is no doubt that the small thermal dilatation of the strong Si−O bonds, ∼0.02 Å, along a wide temperature range of ∼1273 K (Tucker et al., 2000), together with the framework vertex-shared structure, were the fundamental factors for emergence of the unusual dimensional response to temperature changes in β-quartz and β-cristobalite. In addition, an earlier contribution (Blackman, 1957) concerning softening of low-energy vibrational modes with volume reduction in structures composed from polyhedra with low coordination numbers (i.e., with low-density, open crystal structures) was also indirectly used early on to rationalize the mechanism causing NTE/NZTE in the A2M3O12 family.

FIGURE 3. Schematic representation of an asymmetric interatomic potential well. The positions r1, r2 and r3 show the evolution of mean interatomic distances with increasing temperature, with the mean interatomic distance increasing with increasing temperature as in normal (positive) thermal expansion.

The mechanism causing NTE/NZTE in the A2M3O12 family is now understood as asymmetrical framework librations, caused by low-energy phonons, leading to coupled tilting of quasi-rigid polyhedra. Since the 1966 report (Abrahams and Bernstein, 1966) it is known the materials in the A2M3O12 family have framework structures when orthorhombic (Figure 1) with polyhedra connected through vertices. Therefore, the oxygens, which are shared by two polyhedra (an octahedron and a tetrahedron), are coordinated by only two cations (one A3+ and one M6+). This structural feature permits the vertex-shared oxygens to be capable of vibrating in a transverse manner on heating. When free of interstitial ions/molecules, such a lattice arrangement presents no steric hindrance to the librational movements guided by 2-fold oxygens.

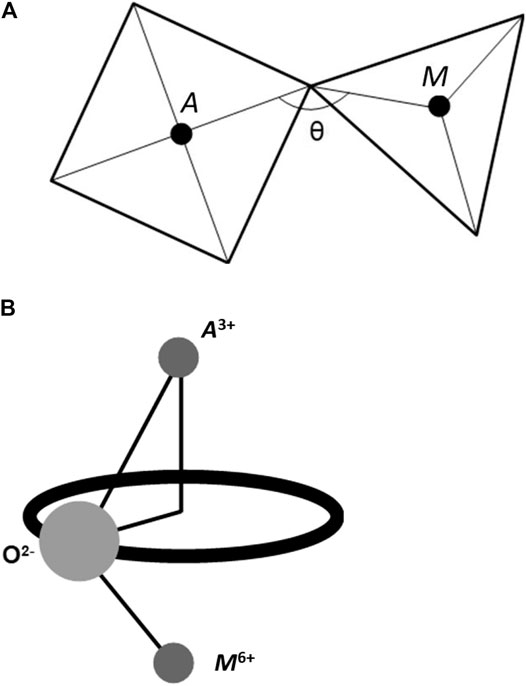

With the local structural motif of A2M3O12 composed from one octahedron and one tetrahedron connected through a vertex, an asymmetric transverse vibration of the 2-fold oxygen is capable of contracting the A−M non-bonding distance and decreasing the A−O−M angle (Figure 4A). The six crystallographically different A−O−M angles in orthorhombic A2M3O12 are never equal to 180°, and their angles, which some decrease with temperature, are between 140° and 175° (Evans et al., 1998b; Evans and Mary, 2000; Marinkovic et al., 2009).

FIGURE 4. (A) Contraction of the A−M non-bonding distance and decrease of the A−O−M angle (θ) in the octahedron-tetrahedron local structural motif in an A2M3O12 structure, arises with increasing temperature due to the asymmetric transverse vibration of the 2-fold oxygen at the shared vertex, and leads to negative thermal expansion. (B) Transverse thermal vibrations of 2-fold oxygens in the A2M3O12 family, describing a torus geometrical figure, causing reduction of the apparent bond distances (A3+−O2- and, especially, M6+−O2-).

The peculiar lattice dynamics in the A2M3O12 family, with the existence of many low-energy vibrational modes, has been demonstrated by several different experiments.

Especially for ceramics and minerals, the constituent additivity model, based on constituent oxides, can accurately predict heat capacities of complex ceramics, such as, for example, sodalite (Qiu and White, 2001). However, the constituent additivity model underestimates the heat capacity at low temperatures for the NTE/NZTE A2M3O12 phases. For example, in HfMgMo3O12 the constituent additivity model does not accurately described the low-temperature experimental heat capacity below 150 K, since its constituent (positive CTE) oxides, HfO2, MgO and MoO3, do not present low-energy vibration modes (Miller et al., 2012a).

Another experimental proof of the contribution of low-energy modes to NTE/NZTE is the finding of negative mode Grüneisen parameters (γn) for low-energy vibration modes (Liang et al., 2008; Torres Dias et al., 2013). The softening of low-energy vibration modes with reduction of volume in keeping with the relationship:

where ωn is the frequency of mode n and V is the volume of the unit cell, contributes to negative thermal expansion in A2M3O12 materials.

The quasi-rigidity of polyhedra in A2M3O12 with changing temperature was first suggested for Sc2W3O12 (Evans et al., 1998b), demonstrating that small distortions of polyhedra occur. The distortions can be evaluated, for example, through temperature evolution of individual ScO6ca. 90° angles, showing, on average, not higher than 0.53° change over a temperature interval of more than several hundred Kelvin. Another study (Marinkovic et al., 2009) showed a mean variation of YO6∼ 90° angles over 723 K as high as 1.23°, corroborating the quasi-rigidity of polyhedra in A2M3O12. The earlier investigation (Evans et al., 1998b) also concluded that the apparent Sc−O and W−O bond lengths decreased with increasing temperature. This feature was later reported for many other A2M3O12 materials (Forster and Sleight, 1999; Marinkovic et al., 2009; Marinkovic et al., 2010) and likely can be understood as an artefact partially caused by the Rietveld analysis of Bragg lines in XRPD of the A2M3O12 structure where the vibrations of 2-fold oxygens are complex and cannot be described by simple thermal spheres or ellipsoids. This apparent bond-length reduction has no physical relationship to true bond lengths, and is not the origin of NTE. It is a consequence of transverse thermal vibrations of 2-fold oxygen ions, which possibly describe a torus (Figure 4B), not an ellipsoid, between the two neighboring cations. This artefact is enhanced due to strong A−O and, especially, W−O/Mo−O bonds with very low individual thermal expansion coefficients (Hazen and Prewitt, 1977). Another factor is that the tetrahedra, such as WO4, are even more rigid than the octahedra (Evans et al., 1998a). This finding has been corroborated by showing that YO6 are intrinsically more distorted than MoO4 (Marinkovic et al., 2009).

The AO6 and MO4 polyhedra are slightly distorted from their ideal shapes and volumes, even at very low temperatures, close to 0 K (Marinkovic et al., 2009), possibly in order to satisfy connectivity of polyhedra in a framework made by vertex sharing (Forster and Sleight, 1999). In addition, it has been suggested that the NTE mechanism in the A2M3O12 structure is intrinsically associated with continuously increasing slight distortions of the quasi-rigid polyhedra with increasing temperature (Forster and Sleight, 1999). This rationalization was proven for octahedra by XRPD (Marinkovic et al., 2009): octahedral distortion, calculated as volume distortion parameter, increased with increasing temperature. This structural feature is a peculiarity of the A2M3O12 structure and is not observed for ZrW2O8, another classic NTE material (Marinkovic et al., 2009). In the next section, it will be shown that larger AO6 octahedra distort more with temperature than smaller octahedra, a feature which intrinsically controls CTE in the A2M3O12 family.

The A2M3O12 crystal framework presents a pseudo two-dimensional structure since b-c layers are connected along the a-crystallographic direction (in the Pbcn space group) by only a few oxygen linkages per unit area, which is distinct from the situation in the other two crystallographic directions. This is reflected in the elastic tensors, which show reduced stiffness along a compared to b and c (Romao et al., 2016); this elastic anisotropy is reduced as the CTE becomes more negative, indicating a correlation between three-dimensional network-like behavior and NTE. Such a crystal framework causes, in general, NTE along the b and c directions, while the a-axis shows positive thermal expansion. However, the overall volume (aV) and average linear CTEs (αℓ =

At this point it should be highlighted that XRPD and dilatometry do not necessary give the same values for CTE for A2M3O12 materials. This situation is distinct from cubic materials, such as AM2O8, and is a result of the anisotropic A2M3O12 structure. The differences in CTEs are attributed to microstructural factors, principally microcracks (Evans et al., 1997), which can grow on sintering due to thermal stresses caused by mismatched CTEs along different crystallographic directions in orthorhombic A2M3O12 (For further discussion, see Section 5.1). On subsequent heating in a dilatometer, sintering tends to close the microstructural flaws. This factor leads to lower dilatomeric CTEs than from XRPD, which additionally can vary from sample to sample due to inhomogeneous microstructures. Therefore, CTEs of A2M3O12 materials are classified as either: 1) intrinsic CTE, originating from intrinsic competition of two crystal lattice factors such as bond-length thermal dilatation and asymmetric librations due to low-energy phonons, as determined by XRPD, or 2) extrinsic CTE determined by dilatometry, which additionally includes microstructural factors.

The existence of an orthorhombic-to-monoclinic phase transition is deleterious to these materials since the monoclinic phase shows normal, high, positive thermal expansion (Gates et al., 2006; Marinkovic et al., 2010), while the orthorhombic phase exhibits NTE or NZTE. In this section the focus is on the mechanism of the phase transition. (The factors controlling the widely ranging transition temperatures within the A2M3O12 family, varying from ∼180 to ∼780 K, are discussed in Section 4.3.) The orthorhombic modifications in A2M3O12 are considered to be the higher-temperature form, capable of transforming to monoclinic at lower temperatures, although in some rare cases this transition appears to be completely absent at ambient pressure (Romao et al., 2013).

The transition from the monoclinic to the orthorhombic form is a displacive, endothermic, low enthalpy change (typically ΔH ∼ 1 kJ mol−1), reversible phase transition (Varga et al., 2007). Thermodynamically, this phase transition is driven by the increase of thermal (vibrational) entropy on transition to the lower-density orthorhombic form. No primary bonds are broken during this phase transition. Thus, from the thermodynamic viewpoint, the monoclinic phase is enthalpically stabilized on cooling. But what is happening from the lattice dynamic and structural viewpoints? The low-energy phonons, responsible for NTE/NZTE in the higher-temperature orthorhombic phase, freeze out on cooling through the transition, due to the formation of secondary van der Waals interactions between 2-fold oxygens from the neighboring polyhedra motifs (Figure 5), therefore frustrating transverse vibrations and increasing the density of the newly formed monoclinic phase. This event leads to an abrupt decrease in volume on transition to the low-temperature phase (Figure 6), loss of most of the symmetry elements of the orthorhombic phase, and consequent reduction of the crystal symmetry to the monoclinic P21/a space group. Without the NTE contribution of lower-energy phonons, the only contribution to thermal expansion is bond-length thermal expansion, resulting in positive thermal expansion (PTE) of the monoclinic form.

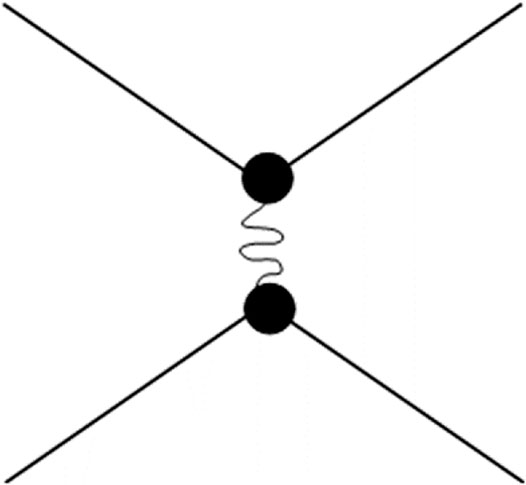

FIGURE 5. The orthorhombic-to-monoclinic phase transition on cooling coincides with formation of secondary van der Waals bonds (as represented here by a spring) between 2-fold oxygens from the neighboring octahedra-tetrahedra motifs. Asymmetric framework librations freeze out at the phase transition to the monoclinic form.

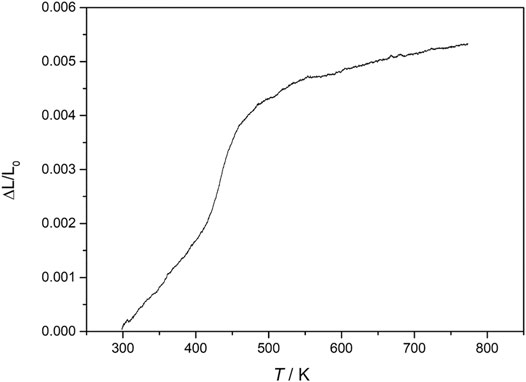

FIGURE 6. Dilatometric heating curve of AlInW3O12 phase, showing change in length (ΔL) relative to the original length (L0) and the monoclinic-to-orthorhombic phase transition at ca. 473 K. The low-temperature monoclinic form has higher density (lower molar volume), and therefore, there is volume expansion on transition to the lower-density (higher molar volume) orthorhombic form (Cerón Cortés et al., 2021).

Most of the studies on A2M3O12 phases and their solid solutions are driven by the vast chemical flexibility of this family while preserving the Sc2W3O12-type structure, and the consequent possibility to change, control and even finely tune the CTE through chemical substitutions, especially of the cations at the crystallographically unique octahedral site (Wu et al., 2006; Wu et al., 2007a; Wu et al., 2007b; Xiao et al., 2008b; Wu et al., 2009a; Miller et al., 2012b; Prisco et al., 2016a; Muller et al., 2019; Machado et al., 2021).

However, are the influences of the cation substitutions to be relegated to empirical approaches, through trial-and-error, or are there rational rules governing their influence on CTE in A2M3O12 materials and related sub-families?

In an early short report, it was shown (Forster et al., 1998) that complete substitution of Sc3+ [r(VI) = 0.745 Å, where r is the ionic radius and “VI” stands for octahedral coordination] by Lu3+ [r(VI) = 0.861 Å] made the value of the linear CTE more negative, changing it from −2.2 × 10–6 K−1 for Sc2W3O12 to −6.8 × 10–6 K−1 for Lu2W3O12. Those authors anticipated that Ho2W3O12 would have the most negative linear CTE among tungstates, since Ho3+ [r(VI) = 0.901 Å] is the largest cation capable of forming the orthorhombic Sc2W3O12-type structure at room temperature. Their prediction concerning the highest negative linear CTE for Ho2W3O12 was experimentally confirmed as −8.25 × 10–6 K−1 (Liu Q. et al., 2015). The same tendency was observed (Sumithra et al., 2005) for a series of tungstates including the trivalent cations of Lu, Yb, Er and Y, where negative linear CTEs increased from Lu2W3O12 to Y2W3O12, following the increase of cationic radius from Lu to Y in the A crystallographic site. The same trend was identified for molybdates, for example in the Yb2-xCrxMo3O12 system where the partial substitution of larger Yb3+ by smaller Cr3+ changed the linear CTE to less negative values, in the compositional range 0 ≤ x ≤ 0.4 (Wu et al., 2009b).

Therefore, early reports directly correlated values of linear CTE with the radius of A3+, i.e., larger cation radius causes more negative linear CTE. This relationship was rationalized in terms of capacity for distortion of AO6, which would increase with increased cationic radius (Forster et al., 1998). In their view, distortions of AO6 would be required to permit asymmetrical framework librations and, therefore, NTE or NZTE. Larger cations form larger polyhedra and favor polyhedral deformability through reduction of oxygen-to-oxygen repulsions, since oxygen-to-oxygen distances are increased inside larger polyhedra.

However, with more information it became evident that the A3+ radius was not the only factor that influences the CTE (Ari et al., 2008; Peng et al., 2008; Yu et al., 2008; Xiao et al., 2008a). It was shown that some phases and solid solutions did not follow the A3+ radius model (Ari et al., 2008): Cr3+ [r(VI) = 0.62 Å] has a smaller radius than Fe3+ [r(VI) = 0.65 Å], but the linear CTE of Cr2Mo3O12 was smaller (0.67 × 10–6 K−1) than for Fe2Mo3O12 (1.72 × 10–6 K−1). The linear CTE of Cr2Mo3O12, almost identical to the value measured by Ari et al., was also reported by other authors (Wu et al., 2009b). Furthermore, some phases within the Al2-xFexMo3O12 solid solution (x = 1 and 1.4) presented linear CTEs higher than for pure Al2Mo3O12 and Fe2Mo3O12 (Ari et al., 2008), a feature which would not be expected based on the A3+ radius model. Similarly, reports for Y2-xNdxW3O12 (Peng et al., 2008), Y2-xSmxW3O12 (Yu et al., 2008) and Sc2-xAlxW3O12 (Liu H. et al., 2021) showed that partial substitution with rare earths with higher ionic radius, such as Nd and Sm for Y and Al for Sc did not cause a continuous change of CTE between the limits of CTEs of the end-member phases; instead the linear CTE seemed to change in a random fashion.

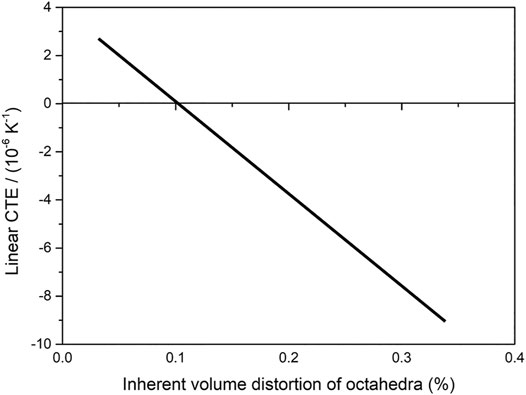

A more general rule has been proposed concerning control of CTE in A2M3O12 and related families (Marinkovic et al., 2009; Marinkovic et al., 2010; Romao et al., 2015b). The principal parameter that correlates with linear CTE is the inherent volume distortion parameter for AO6. The volume distortion parameter of polyhedra was previously reported in the literature as a general quantitative measure of polyhedral deformability (Makovicky and Balic-Zunic, 1998). In the present context, the inherent volume distortion parameter was defined as deformation at the lowest temperature from which diffraction data are available (Marinkovic et al., 2009). The accurate calculation of the inherent volume distortion parameter is based on correctly refined atomic site coordination, obtained via the Rietveld method or from single-crystal diffraction. Increasing inherent volume distortion of AO6 correlates well with decreasing linear CTE (Figure 7), i.e., more distorted octahedra contribute more to the mechanism causing NTE/NZTE (Marinkovic et al., 2009).

FIGURE 7. Schematic representation of the dependence between linear CTE and inherent volume distortion of octahedra. The increase of inherent volume distortion of AO6 corresponds to decrease in linear CTE (styled from data in Marinkovic et al., 2009).

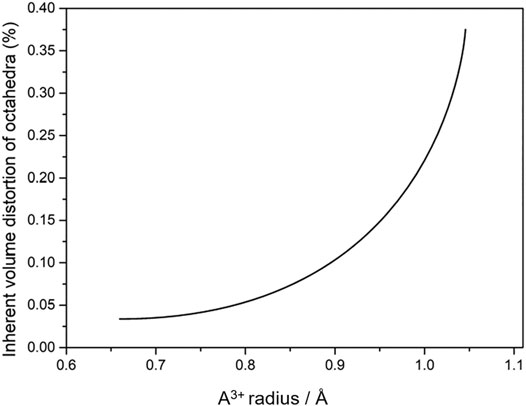

Although inherent volume distortion can be correlated with cation radius, this correlation is non-linear and increases more rapidly for larger cations, as can be seen from Figure 8 (Romao et al., 2015b). Higher octahedral distortion in rare earths with larger radii, such as Er, Y and Ho (and probably of Dy, when stabilized in Sc2W3O12) might be a sign of decreasing stability of the octahedral coordination as the cationic size increases, since rare-earth cations with radii as large or larger than Dy adopt 8-fold coordination. Also, there is another interesting feature of octahedral distortion that makes its correlation with cationic radii more complex. In some cases, such as ZrO6 and MgO6 in ZrMgMo3O12, two octahedra with nearly the same cationic radii present rather different inherent volume distortions (Romao et al., 2015b).

FIGURE 8. Schematic view of the dependence between inherent volume distortion of octahedra and radius of A3+ in the A2M3O12 family (styled from data in Romao et al., 2015b).

In this matter, it is critical to evaluate the temperature evolution of octahedral volume distortion of each type of octahedron with temperature to determine if it is rigid or quasi-rigid. Quasi-rigid polyhedra are fundamental for sustaining the NTE mechanism in the A2M3O12 family as the topology of the Sc2W3O12 structure is too constrained to permit rigid unit modes (Hammonds et al., 1998), and therefore transverse vibrations of the type shown in Figure 4 necessarily distort the coordination polyhedra. For example, volume distortion of YO6 increases linearly with temperature over a temperature span of approximately 1673 K (Forster and Sleight, 1999; Marinkovic et al., 2009) showing that these octahedra are quasi-rigid and contribute to NTE mechanism.

The extent of polyhedral distortion can be rationalized at a more fundamental physical level as a function of A−O bond attractive energies or forces. The attractive energy, Ea, in a predominantly ionic bond, is described as

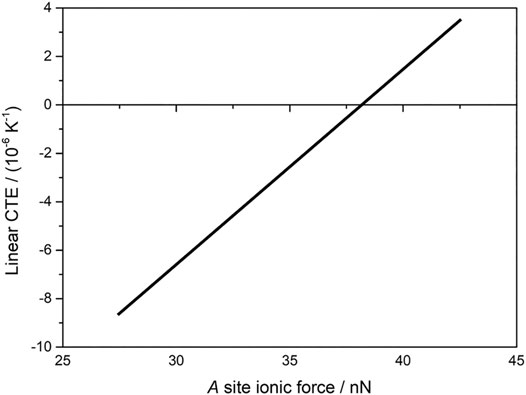

where Z1 is the valence of the cation, Z2 is the valence of the anion, e is the elementary charge, ε0 is electrical permittivity in vacuum and R is the sum of the cation and anion radii (i.e., equilibrium bond length). The attractive ionic force (Fa) is the first derivative of the attractive energy with respect to interionic distance. More rigid polyhedra are those with highly attractive ionic energy (strong force), which hampers bond and angle deformation within the polyhedra as temperature increases, and thus inhibits the NTE mechanism within A2M3O12. Figure 9 shows schematically the relationship between linear CTE and ionic force (given in nN) between A3+ and O2- (Romao et al., 2015b). This view explains why Al2W3O12 and Al2Mo3O12 have the most positive linear CTE since their ionic forces between A3+ and O2- are the highest.

FIGURE 9. Schematic view of the relationship between linear CTE and ionic force between A3+ and O2- in the A2M3O12 family (styled from data in Romao et al., 2015b).

Another interesting feature is that the tetrahedra are less intrinsically distorted than the octahedra in these structures, and their distortion increases with temperature less than for octahedra (Marinkovic et al., 2009). On this basis, the tetrahedral contribution to the NTE mechanism seems to be minor, which can be understood in terms of highly attractive ionic forces between M6+ and O2- which hamper deformation of the tetrahedra. That tetrahedra are more rigid than octahedra in A2M3O12 was also concluded through ab initio lattice dynamics calculations (Rimmer and Dove, 2015). Those authors pointed out that O-Y-O bond angles, and therefore YO6, significantly deform on NTE, while WO4 remain rigid. In addition, Weck et al., studying Zr2WO4(PO4)2 using density functional perturbation theory, showed that ZrO6 octahedra distort significantly, while WO4 and PO4 tetrahedra remain almost ideal (Weck et al., 2018). The authors pointed out that the bond angle variances for ZrO6 were as high as 20.4°, while for WO4 and PO4 they were as low as 0.5° and 0.4°, respectively.

Based on the data currently available in the literature for the A2M3O12 family, the intrinsic linear CTEs vary widely, from −11.6 × 10–6 K−1 for Ho2Mo3O12 from 200 to 700°C (Xiao et al., 2008a) to about 3 × 10–6 K−1 for Al1.4Fe0.6Mo3O12 from 593 to 1023 K (Ari et al., 2008). For a thorough table of linear CTEs for the A2M3O12 family, the reader is directed to another recent review (Liu H. et al., 2021).

Hygroscopic behavior in A2M3O12 materials can lead to material degradation, and can suppress NTE/NZTE. Furthermore, it has been reported that Y2Mo3O12 partially amorphizes in air at temperatures below 403 K due to its hygroscopic behavior (Marinkovic et al., 2005). Hygroscopicity also was confirmed in all other tungstates and molybdates of the heavy rare earths from Lu to Ho (Wu et al., 2007b; Xiao et al., 2008a; Wu et al., 2009b; Wu et al., 2012; Wu et al., 2016). On the other hand, tungstates and molybdates of non-rare-earth A3+ cations, which have smaller cationic radii, are not hygroscopic (Muller et al., 2019). The channels are the key structural feature permitting entrance and accommodation of water molecules in the interior of the open orthorhombic Sc2W3O12-type structure. These empty one-dimensional spaces are aligned along the c-axis directions (Figure 1). Their diameters are controlled by the size of A3+, and therefore smaller cations form narrow channels, which can inhibit uptake of water.

Another possible explanation why tungstates and molybdates of smaller trivalent cations are not hygroscopic has been presented based on a first-principles study (Wu et al., 2016): the chemical interactions between water molecules and the crystal framework in the tungstate and molybdates of smaller A3+ are weaker and lead to lower absorption energies. Therefore, these phases are resistant to humidity. Water molecules likely interact with the framework through hydrogen bonding and it has been proposed that the oxygen atoms from water molecules intact with A3+ or M6+, while hydrogen atoms from water molecules interact with the framework 2-fold oxygens (Wu et al., 2016). These interactions between water molecules and the framework can cause amorphization in molybdates and tungstates (Marinkovic et al., 2005; Yu et al., 2008; Li et al., 2012) or even change the crystal symmetry in some tungstates (Kol’tsova, 2001; Sleight, 2003; Cao et al., 2016; Pontón et al., 2017; Machado et al., 2021). Symmetry lowering by transformation to the monoclinic phase, or the presence of water molecules in channels, will inhibit, or attenuate, the asymmetrical framework librations of the quasi-rigid polyhedra, due to freezing of polyhedra rocking motions or due to steric effects, respectively. A similar feature has been reported for some zeolites, such as ZSM-5 (Marinkovic et al., 2004; Marinkovic et al., 2008b). Although zeolites neither amorphize in the hygroscopic form nor change symmetry, their NTE is inhibited unless totally dehydrated, proving that water molecules, or any other atom/molecule which occupies void spaces in the deficient garnet structure, will inhibit NTE (Marinkovic et al., 2004; Marinkovic et al., 2008b).

It is important to distinguish between hygroscopicity in molybdates and tungstates. Molybdates become amorphous when hygroscopic and lose water at temperatures higher than 403 K (Sumithra and Umarji, 2004; Sumithra and Umarji, 2006). Tungstates, on the other hand, lose water more easily, at temperatures not higher than 373 K and do not necessary become amorphous (Yu et al., 2008; Muller et al., 2019; Machado et al., 2021). It has been proposed that differences in hygroscopicity between tungstates and molybdates are due to lower absorption energies of water molecules into the crystal framework in tungstates (Wu et al., 2016).

There are two main ways to reduce or inhibit hygroscopicity in tungstates and molybdates. One is to partially substitute larger A3+ for smaller cations, such as in the cases of Er2-xFexMo3O12 and Yb2-xGaxW3O12 (Cheng et al., 2007; Machado et al., 2021). Suppression of hygroscopic behavior also has been achieved by coating the hygroscopic A2M3O12 material with a hydrophobic material, such as C3N4 (Liu et al., 2017).

The orthorhombic to monoclinic phase transformation is another property of great importance for practical applications of A2M3O12 materials. It appears, however, that the temperatures of this phase transition vary widely within the A2M3O12 family, for example 785 K for Fe2Mo2O12 and 178 K for Sc2Mo3O12 (Evans and Mary, 2000; Ari et al., 2008). For a thorough table of phase transition temperatures, see another recent review (Liu H. et al., 2021).

Interestingly, the phase transition has not been detected for a few A2M3O12 materials; for example, for Y2Mo3O12 and Y2W3O12 it has not been detected at temperatures as low as 2 and 10 K, respectively (Forster and Sleight, 1999; Marinkovic et al., 2009), suggesting that the monoclinic form is not stable under ambient pressure. Note that at higher pressures and ambient temperature, Y2Mo3O12 transforms to a lower-symmetry structure, likely the monoclinic phase (Torres Dias et al., 2013).

The main question, however, is which feature or features govern the temperature of the orthorhombic-to-monoclinic phase transition. This information could be important to control the transition temperature and especially to suppress the monoclinic phase stability range to below room temperature, allowing broader use of the special CTE properties of the orthorhombic phase. Based on five different molybdates, an electronegativity rule which linearly correlates the electronegativity of the trivalent cations with the temperature of phase transition has been proposed (Sleight and Brixner, 1973). Higher electronegativities of the trivalent cations lead to higher phase transition temperatures.

The physics behind the proposed rule is relatively simple. More electronegative trivalent cations, such as Fe [1.83; electronegativities here on the Allred scale (Allred, 1961)] and Cr (1.66), would diminish the effective oxygen anion charge far from the nominal value of −2, much more than, for example, Y (1.22) or Sc (1.36). Since oxygen anions, with reduced effective valences, would then be able to interact with each other through induced dipole secondary interactions (Figure 5), low-energy phonons would be frozen and the higher-density monoclinic form would be stable up to higher temperatures. It is worth noting that similar oxygen−oxygen interactions are responsible for the existence of molecular oxides, such as OsO4 and RuO4 (Evans et al., 1997; Pley and Wickleder, 2005).

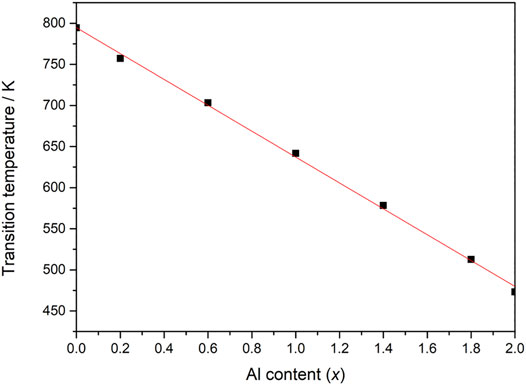

Most of the A2M3O12 materials and their solid solutions, such as Al2-xFexMo3O12, Al2-xCrxMo3O12 and Cr2-xFexMo3O12 (Ari et al., 2008), to mention just a few, closely obey the electronegativity rule (Figure 10). However, there are some exceptions, such as AlScMo3O12 (Truitt et al., 2015) and some materials in the Al2-xInxW3O12 (x = 0.2; 0.4 and 0.7) family (Cerón Cortés et al., 2021). Since Al2Mo3O12 and Sc2Mo3O12 have phase transitions at 473 and 178 K, respectively, it would be expected that the phase transition in AlScMo3O12 might occur at around 340 K, but it does not occur at all, at least not above 100 K (Truitt et al., 2015). It is still not clear why this phase does not follow the electronegativity rule, although it has been suggested that the great difference between cationic radii for Al [r(VI) = 0.54 Å] and Sc [r(VI) = 0.75 Å] might contribute in some manner to this deviation (Truitt et al., 2015).

FIGURE 10. Temperature of monoclinic-to-orthorhombic phase transition in Fe2-xAlxMo3O12 as a function of Al content (x) (styled from data in Ari et al., 2008).

The reports on the existence of the orthorhombic structure of Fe1.5Y0.5Mo3O12 down to 103 K (Li et al., 2011) and AlInW3O12 at room temperature (Mary and Sleight, 1999) are still under debate (Truitt et al., 2015).

Thermoelasticity (i.e., how a material’s elastic properties and stress/strain state change with temperature) is inherently connected to thermal expansion and therefore to NTE and NZTE. A theoretical background is presented here, in order to expose a deeper understanding of this important property, starting with the CTE−elastic connection from Grüneisen’s definition of the thermal expansion for a cubic or isotropic solid as:

where Ce is the volumetric heat capacity at constant strain, K is the bulk modulus, and γ is the Grüneisen parameter (Grüneisen, 1912). (Note that the Grüneisen parameter presented in Equation 1, γn, is for a given vibrational mode n, whereas γ of Equation 3 is for the overall lattice. The connection between the mode Grüneisen parameters γn and the bulk Grüneisen parameter γ is made through the quasiharmonic approximation.) Dimensional analysis reveals that Ceγ has SI units of J m−3 K−1 = Pa K−1, and therefore the numerator of Equation 3 represents a thermal pressure, arising from vibrational anharmonicity, which acts against the bulk modulus to cause thermal expansion. Therefore, in general, stiffer materials will have smaller magnitudes of the thermal expansion coefficient.

The general connection between stiffness and elasticity was investigated early on by Barker, who found that for a broad range of metals, alloys, polymers, and polymer-matrix composites, there is a general relationship between linear thermal expansion, αℓ, and Young’s modulus (Y) at room temperature following Yαℓ2≈ 15 Pa K−2 (Barker, 1963). Within Barker’s sample of conventional materials, those with low CTEs (αℓ < 10–6 K−1) have γ ≈ 1, those with intermediate CTEs (10–6 K−1 < αℓ < 10–5 K−1) have γ ≈ 2, and those with the largest CTEs (αℓ > 10–5 K−1) somewhat surprisingly have the smallest Grüneisen parameters (γ < 1), because they are polymers with many vibrational degrees of freedom that involve stiff C–C bonds (Barker, 1963). Therefore, for conventional materials, differences in thermal expansivity can largely be explained by differences in stiffness rather than differences in vibrational anharmonicity.

Of course, network solids such as amorphous SiO2 and many thermomiotic materials do not follow this simple relationship, but stiffness and the magnitude of NTE can still be expected to be inversely related. A direct reduction of the bulk modulus by entropic elasticity (i.e., an increase in entropy upon compressive strain) has been found in floppy networks, including ScF3 (Tkachenko and Zaliznyak, 2021), indicating an underlying mechanism that reduces the bulk modulus in flexible frameworks. This relationship is not absolute (e.g., α-ZrW2O8 is stiffer than the thermomiotic A2M3O12 oxides and has a more negative CTE (Drymiotis et al., 2004; Varga et al., 2006; Romao et al., 2016; Young et al., 2018)), because the Grüneisen parameters of thermomiotic materials vary considerably, and because of the effects of anisotropy, which require further discussion.

The relationship expressed in Equation 3 applies only to materials with isotropic thermal expansion. In anisotropic materials, there are distinct Grüneisen parameters for each independent element of the CTE tensor, each of which is related to the elastic properties of that axis. In the limit of zero external pressure, directional thermal expansion can be related to directional Grüneisen parameters (γii) and directional Young’s moduli (Yii) through:

by defining the corresponding directional mode Grüneisen parameters of mode n (γii,n) in relation to uniaxial stress (σ) perturbations along direction i (Romao, 2017):

Therefore, the coefficient of thermal expansion in an arbitrary direction is inversely proportional to the elastic stiffness in that direction. The definition of the directional Grüneisen parameters given in Equation 5 is simpler than the form given in Barron and Munn (1967) which is based on uniaxial strain perturbations; the definition given by Equation 5 (Romao, 2017) has the significant advantage that the thermal expansion along each axis is related to a single Grüneisen parameter, allowing identification of the modes which lead to anomalous thermal expansion even in anisotropic materials (Dolabdjian et al., 2018; Romao, 2019). Many thermomiotic materials have flexible structures, i.e., they have a mixture of stiff and compliant directions.

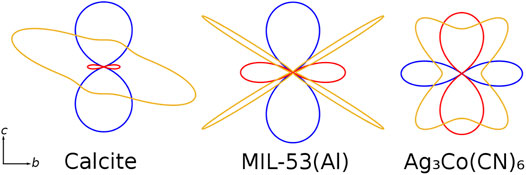

Application of Equation 4 along with the constraints of crystallographic symmetry on the thermal expansion and elastic tensors allows understanding of how anisotropic elasticity and thermal expansion are connected, as maxima and minima in the CTE tensor lie in directions corresponding to stiffness minima, as shown in Figure 11 (Romao, 2017). Maxima in the stiffness tensor lie near minima in the magnitude of the CTE, which necessarily correspond to nodal planes due to the symmetry of the CTE tensor (for orthotropic systems). The relationship between structural flexibility and anisotropic thermal expansion even allows mechanisms of bending to be deduced from structural changes upon heating (Rather and Saha, 2021).

FIGURE 11. Indicatrices of directional thermal expansion (positive: blue; negative: red) and Young’s modulus (orange) for three materials with axial NTE (Rao et al., 1968; Ramachandran and Srinivasan, 1972; Goodwin et al., 2008; Ortiz et al., 2012; Fang et al., 2014b; Nanthamathee et al., 2015). Maxima in stiffness correspond to minima in the magnitude of the CTE, following Equation 4; symmetry constraints on the CTE tensor cause these minima to correspond to nodal planes and a mixture of directional PTE and NTE results. Adapted from Romao (2017).

Other connections between NTE and elasticity exist outside of the Grüneisen theory, including the tendency of thermomiotic materials to undergo pressure-induced softening (Fang et al., 2013a; Fang and Dove, 2013b; Fang et al., 2014b; Hester et al., 2016; Wei et al., 2020). For simple solids, the pressure derivative of the bulk modulus can be expressed as follows:

and therefore modes with negative Grüneisen parameters decrease the pressure derivative of the bulk modulus (Hofmeister, 1991). Pressure-induced softening can be seen to arise from simple models of chains of atoms which exhibit the tension effect (Fang et al., 2014a), suggesting that the softening is a consequence of thermomiotic materials’ tendency to undergo buckling of floppy linkages upon the application of both pressure and temperature. The pressure-induced softening reaches values of up to (∂K/∂p)T = −220 in ScF3 (Wei et al., 2020), much larger in magnitude than the value of (∂K/∂p)T ≈ 4 seen in many conventional materials (Hofmeister, 1991). Thermal expansion is also directly connected to the temperature derivatives of the elastic constants, as these depend on the anharmonicity of the interatomic force constants (Rao, 1974). Changes in the elastic constants with temperature can therefore directly affect the CTE (Karunarathne et al., 2021). Other mechanical properties beyond the elastic regime, such as hardness and even creep, can show pronounced temperature-induced softening in NTE materials (Heinen et al., 2018).

These relationships between thermal expansion and elasticity are therefore required to understand the origins of thermal expansion, and are also important for many potential applications of thermomiotic materials, especially those where NTE is used to compensate for PTE. In such applications, the mechanical interactions between the PTE and NTE components, which reduce the overall thermal strain, lead to thermal stresses in both components (Holzer and Dunand, 1999; Jakubinek et al., 2010; Miller et al., 2010; Zhou et al., 2017). The magnitudes of these thermal stresses, and, in fact, the thermal strains (and therefore the amount of NTE component required to achieve a desired degree of thermal expansion reduction) all depend on the elastic and thermomechanical properties of the components. The thermal stresses are a necessary consequence of the CTE mismatch, and are proportional both to the difference in CTE and to material stiffness (Kreher, 1990).

In a randomly mixed composite material, the interactions between the components can result in different behavior ranging from the rule of mixtures (ROM), where the bulk CTE is an average of the components (White, 2019), and that described by the Turner model, where the bulk CTE is an average of the components weighted by their bulk moduli (Schapery, 1968). These two behaviors refer to two different types of stress distribution in the composite: in the ROM case the stresses are fully isochoric and in the Turner model case the stresses are fully volumetric. Therefore, in the usual intermediate case, the ability of a thermomiotic material to compensate for PTE will depend on its stiffness. This effect is seen experimentally in cases where large amounts of relatively compliant NTE filler are required (Sharma et al., 2012; Shi et al., 2016) and offers an argument in favour of using, for example, non-vibrational thermomiotic materials in composites for applications which only require a relatively narrow temperature range of use (Takenaka and Ichigo, 2014), due to their higher bulk moduli (Nakamura et al., 2009), or other non-conventional thermomiotic materials such as carbon nanotubes (Shirasu et al., 2017). The properties of microstructured (e.g., lamellar) composites do not necessarily fall between the ROM and Turner limits (Lim, 2011), and therefore their design offers another route to control thermal expansion. It has even been demonstrated that the combination of two materials with different CTEs and void space in a structured fashion can generate metamaterials with arbitrary CTEs, although stiffness consequently falls off at the CTE extremes (Sigmund and Torquato, 1997; Wang et al., 2016; Qu et al., 2017). Another possibility is the creation of composite materials whose dimensions and elastic properties are constant over some temperature range (Keuter et al., 2020).

The ability of thermomiotic materials to counteract PTE is also affected by the fact that vibrational NTE is related to proximity to dynamic instability, and therefore pressure-induced phase transitions are common (Occhialini et al., 2018). These phase transitions can cause significant reductions in volume and the magnitude of the CTE, and therefore, in combination with the pressure-induced softening described above, present a significant challenge to the use of materials which exhibit vibrational NTE in composites (Holzer and Dunand, 1999; Zhou et al., 2017), especially those using stiff PTE components. Interestingly, a stiff matrix might be able to stabilize an intermediate state during a pressure-induced phase transition, wherein the filler undergoes constrained collapse and therefore has negative stiffness (Romao and White, 2016). This intermediate state would therefore be unable to effectively counteract PTE, but its negative stiffness could be useful in the design of novel metamaterials (Kochmann and Bertoldi, 2017).

Thermal stress also influences the properties of single-phase materials when they are polycrystalline and anisotropic. This stress arises from CTE mismatch between grains, which can be severe enough to reach GPa levels of stress (Romao et al., 2016), leading to microcracking, decreased material strength and decreased thermal shock resistance (Prisco et al., 2013; Prisco et al., 2019). These issues can be ameliorated by achieving a high degree of consolidation and small crystallite size (see Section 6). The CTE mismatch within polycrystals can cause their bulk CTEs to differ from those of the corresponding powder, not only because of microcracking and microcrack healing effects which are observable in dilatometry (Prisco et al., 2013) but also because elastic anisotropy leads to the CTEs of the stiffer axes having a larger impact on the bulk CTE (Kreher, 1996). This effect can lead to relatively large discrepancies in CTE for materials with volumetric CTEs close to zero (up to several 10–6 K−1 in the A2M3O12 family) (Romao et al., 2016). An extreme example of this phenomenon is found in CaRuO4−y polycrystals, where CTE anisotropy, elastic anisotropy, and the presence of voids combine to increase the bulk NTE nearly sevenfold over that of the corresponding powder (Takenaka et al., 2017; Takezawa et al., 2018).

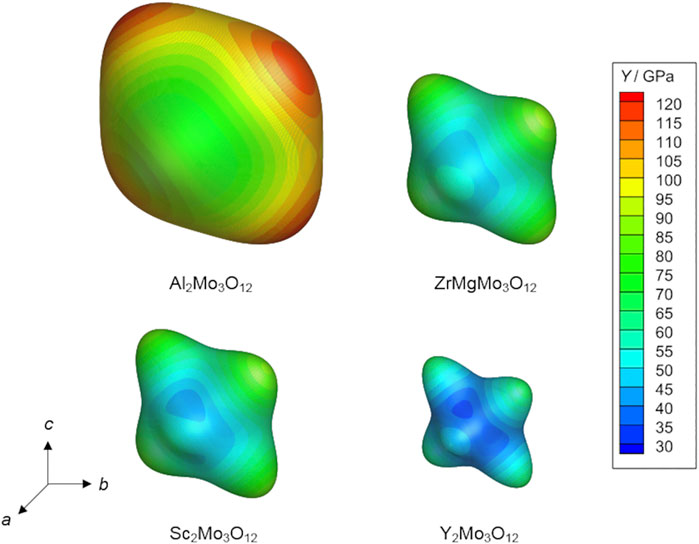

The elastic properties of A2M3O12 materials are known to vary significantly with composition and therefore with their CTEs, with the magnitude of NTE being negatively correlated with stiffness (Varga et al., 2005; Romao et al., 2016). As shown in Figure 12, NTE is also correlated with elastic anisotropy; local stiffness maxima coincide with the [011] and [100] directions (in Pbcn or P21nb settings) (Romao et al., 2016). A2M3O12 materials are also prone to pressure-induced phase transitions and/or amorphization (Secco et al., 2001; Karmakar et al., 2004; Varga et al., 2005), although these instabilities often require pressures on the order of 1 GPa and therefore lie well beyond the expected compressive strengths of these materials. The use of A2M3O12 materials as thermomiotic components in applications therefore depends on finding methods to compensate for their relatively low stiffnesses and the generation of thermal stress due to thermal expansion mismatch. These goals can be accomplished by, for example, the use of compliant matrices and processing techniques which enhance material strength, as described in Section 7.4.

FIGURE 12. Directional Young’s moduli of orthorhombic Al2Mo3O12, ZrMgMo3O12, Sc2Mo3O12, and Y2Mo3O12 (Romao et al., 2014; Romao et al., 2016) in the Pbcn or P21nb setting, shown as contour plots generated using the nanoHUB Anisotropy Calculator – 3D Visualization Toolkit (Zuluaga et al., 2014). Adapted from Romao et al. (2016).

A major aim for NZTE materials is to allow the material to withstand large changes in temperature without fracture. This property can be quantified as the thermal shock resistance coefficient, Rs:

where κ is the thermal conductivity, σ is the material strength and Y is the Young’s modulus (White, 2019), and higher values of Rs indicate greater resilience on thermal shock. Clearly, the closer the absolute value of the CTE is to zero, the greater the thermal shock resistance. However, the thermal conductivity also plays a role, with high values preferable, as they reduce temperature gradients within the material and hence lead to high thermal shock resistance.

The thermal conductivity of an insulating solid can be approximated by the Debye model:

where CV is the heat capacity per unit volume, νs is the mean phonon speed (speed of sound) and λ is the phonon mean free path (White, 2019). High thermal conductivity is favoured by stiff materials (high speed of sound) and high purity (long phonon mean free path).

The flexible structures of the “traditional” AB2O8 NTE materials are associated with low-frequency optic modes which can interfere with the heat-carrying acoustic modes, lowering the phonon mean free path and leading to low thermal conductivity, 0.51 W m−1 K−1 at room temperature for Zr2W2O8 (Kennedy and White, 2005) and 0.64 W m−1 K−1 for HfMo2O8 (Kennedy et al., 2007). Furthermore, both Zr2W2O8 and HfMo2O8 exhibit glass-like thermal conductivity, low and decreasing as the temperature drops. Normally the phonon mean free path has a very strong and opposite dependence on temperature, such as 1 nm at T = 300 K and 104 nm at T = 2 K for a rigid inorganic solid (White, 2019), which leads to a peak in the temperature profile of the thermal conductivity for a typical crystalline solid. For Zr2W2O8 and HfMo2O8 the mean free path is very short and less temperature dependent. The main temperature-dependent factor in the thermal conductivity is the heat capacity which falls as T → 0 K, leading to glass-like thermal conductivity (Kennedy and White, 2005; Kennedy et al., 2007).

In the A2M3O12 and related families, thermal conductivities have been reported for HfMgMo3O12 (Miller et al., 2012a), Y2Mo3O12 (Romao et al., 2014) and Al2W3O12 (Prisco et al., 2016b) and again are low with room-temperature values of 1.04, 0.80 and 0.63 W m−1 K−1, respectively. By comparison, oxides developed specifically to have low thermal conductivities and thus to act as thermal barrier coatings, have higher values of κ at room temperature, ranging from ∼1 to ∼3 W m−1 K−1 (Pan et al., 2012). Furthermore, the thermal conductivity for Y2Mo3O12 drops as the temperature goes down, again due to the short phonon mean free path: ∼1 nm at T = 300 K and ∼30 nm at T = 6 K (Romao et al., 2014). HfMgMo3O12 behaves similarly (Miller et al., 2012a). However, despite the low thermal conductivity, the thermal shock resistance of Al2W3O12 has been shown to be as high as for sapphire (Prisco et al., 2016b), the state-of-the-art material for thermal-shock resistant infrared windows, largely due to the relatively low magnitude of the CTE (even though not as low as some A2M3O12 compounds) and the low Young’s modulus due to the flexible lattice, which both mitigate against the low thermal conductivity.

Typically, ceramics in the A2M3O12 and related families are electrical insulators. A theoretical investigation of Y2Mo3O12 showed an indirect band gap of 3.6 eV at T = 0 K (Romao et al., 2014).

However, high ionic conductivity has been observed in some compounds in this family, including 2.5 × 10–2 Ω−1 m−1 for MgHfW3O12 at 600°C (Omote et al., 2011) and 4.1 × 10–4 Ω−1 m−1 for ZrMgMo3O12 at 520°C (Romao et al., 2015b). The ionic conductivity mechanism is likely due to motion of the Mg2+ ions, which are arranged alternately with the Hf/Zr ions along the (010) direction, as they move with low activation energies of ca. 80 kJ mol−1 through cavities provided by the AO6 and MO4 polyhedra (Omote et al., 2011; Romao et al., 2015b). With the potential for low thermal expansion combined with high electrical conductivity, such materials could have applications in the field of solid electrolytes and electrode materials for batteries (Andersen et al., 2018).

The A2M3O12 and related ceramics exhibit interesting optical properties, stemming both from the intrinsic ceramics, and also via doping. The flexibility of choice of A and M again is an asset. The low magnitude CTE is a special attribute for several optical properties, allowing both dimensional stability with changing temperature and also temperature-independent interatomic distances and correspondingly stable optical properties over a wide temperature range. The ability to prepare some of the structures from the melt is an advantage over ceramics that have competing high-temperature phases.

An important optical property was reported in early studies of A2M3O12 ceramics, namely very high optical transparency, over wavelengths from 350 to 4500 nm, of single crystals pulled from the melt, for Sc2W3O12 and Gd2Mo3O12, with the latter showing close to 100% transparency (Nassau et al., 1965). The low CTE combined with high transparency in the visible-to-infrared range makes these oxides promising for optical applications, including as hosts for rare earth ions due to lack of interference from intrinsic effects. (See also Section 8.)

Another early work (Borchardt, 1963b) on the rare-earth (from Sc to Lu) tungstates in the A2M3O12 family reported optical properties with special interest in their luminescence. While most of the tungstates were white powders, most also exhibited luminescence through a broad band within the white light spectra, peaking between 475 and 500 nm. The luminescence mechanism was attributed to W6+, while in some cases, such as Eu2W3O12 and Tb2W3O12, narrower emissions were found and attributed to rare-earth emission following energy transfer from W6+. For example, in the case of Eu2W3O12 and Tb2W3O12, the W6+ ion acted as sensitizer (Borchardt, 1963b).

Further early luminescence studies were carried out for Al2W3O12, Sc2W3O12 and Lu2W3O12, both undoped and doped with Eu3+ or Cr3+ (Blasse and Ouwerkerk, 1980). The undoped compounds did not luminesce at room temperature, but blue-green emission under UV excitation was observed at lower temperatures, increasing with decrease in temperature to 4 K. Eu3+-doped samples showed a medium-intensity red emission at room temperature, and doping with Cr3+ resulted in a deep red/infrared emission. As noted elsewhere, Sc2W3O12 and Lu2W3O12 are highly hygroscopic, but the Eu3+ emission can be used to quantify the moisture content (Blasse and Ouwerkerk, 1980).

Also in the 1980s, the use of Al2W3O12 as the host for Cr3+ for solid-state high-gain laser applications was shown (Petermann and Mitzscherlich, 1987). Laser action was observed at 800 nm.

In more recent work, HfScW2PO12 has been shown to have intense blue photoluminescence from room temperature to 10 K (Cheng et al., 2017). The authors conclude that this ceramic could have potential applications as a near-UV LED-convertible blue-emitting phosphor for white LEDs. The low magnitude CTE (1.3 × 10–6 K−1) over the temperature range 140–1469 K leads to good thermal stability in the photoluminescence (Cheng et al., 2017), which would be an asset for optical applications. (See also Section 8).

Investigations of ZrxAl2-xMo3-xVxO12 have shown broad band luminescence from 370 to 650 nm, i.e., across almost the entire visible spectrum, becoming most intense at x = 0.5 (Wang et al., 2021). The luminescence was ascribed to the Zr4+ (replacing Al3+) and V5+ (replacing Mo6+) ions, which introduce donor and acceptor levels in the band gap. The structure has four formula units, allowing for multiple distinct pairs of donor (centre of octahedron) and acceptor (centre of tetrahedron) sites, with different donor-acceptor spacings and therefore different fluorescence bands, giving a total luminescence band that covers most of the visible range. For x = 0.5, the monoclinic to orthorhombic transition was at ca. 420 K, and the CTE was 2.53 × 10–6 K−1 over the temperature range 420–773 K. The low CTE and the essentially white luminescence show considerable potential for LEDs and other optoelectronic devices (Wang et al., 2021). See also Section 8.

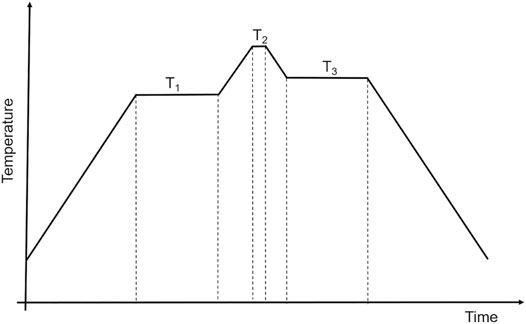

The A2M3O12 and related ceramic families have aroused the interest of researchers mainly due to their chemical flexibility, and the possibility of obtaining negative thermal expansion and near-zero thermal expansion. Consolidation and sintering processes play a critical role in determination of the final properties of monolithic (bulk) ceramic materials. To obtain a ceramic with high thermal shock resistance, for instance, it is necessary to have a high-density microstructure, with mean grain sizes smaller than the critical size for crack formation (Prisco et al., 2016b). Optical transparency also requires ceramics with small grain and pore sizes and low porosity. These features can be only reached through careful consolidation and sintering stages. The current best approaches to consolidation and sintering of A2M3O12 and related ceramic families and current understanding of related properties are reviewed in this section.

In a study from 2012, Al0.5Sc1.5W3O12 powder was synthesized by the low-combustion-temperature method (Dasgupta et al., 2012). The as-prepared powder was suspended in n-butanol to form a slurry with 70 mass% solid in the load, aiming to fabricate slip-cast compacts. To stabilize the slurry, a phosphate ester dispersant was used, and 9 mass% polyethylene glycol (PEG) was added as a binder to enhance the strength of the compacts. To obtain an agglomerate-free powder, the suspension (slurry) was planetary milled for 3 h at 300 rpm using 5 mm diameter stabilized zirconia as the grinding medium. According to the authors, reduction of the powder agglomeration did not significantly influence its specific surface area. However, the milling process allowed the powder to pack more efficiently, which led to green bodies with higher densities. The slurry was cast into plaster molds and, after drying, conventional sintering was carried out in air at 1373 K for 3 h, followed by hot isostatic pressing (HIP) for 2 h at 1373 K and 100 MPa in an 80% Ar/20% O2 atmosphere. The conventionally sintered compacts revealed a density of 97% of the theoretical density (TD), while after HIPing the compacts reached very high bulk density of 99.5% TD, with grain sizes between 2 and 3 µm. The investigators also determined linear CTE from high temperature XRPD (−0.32 × 10–6 K−1 from 303 to 873 K) and by dilatometry measurements (−0.15 × 10–6 K−1 from 298 to 973 K). The difference between the two CTEs, intrinsic and extrinsic, respectively, was attributed to the presence of microcracks (see also Section 3.1). The authors also evaluated infrared optical properties of the bulk ceramic after HIPing, on a 1.03 mm thick disk. The sample showed an in-line transmittance of 64–73% within the 3–5 µm mid-IR wavelength range. The theoretical maximum reflection-limited transmission for the studied phase was about 86–88% near 2500 cm−1 (4.0 μm). The peak transmittance of 73% at 2300 cm−1 (4.3 μm) represents an optical loss of about 14%. This optical loss was attributed to optical scatter at grain boundaries and pores. Therefore, the authors achieved an excellent combination of near-zero CTE and high IR transmittance, two important properties for some high thermal shock resistance applications (Dasgupta et al., 2012).

In another study (Prisco et al., 2013), Al2Mo3O12 powder in its orthorhombic form, stable at T > 473 K, was used to investigate the influence of mean grain size on the linear coefficient of thermal expansion, as evaluated by dilatometry. The grain size investigation was motivated by knowledge that microcrack formation occurs when the grain sizes of ceramic body exceed a certain critical size, giving rise to a discrepancy between the intrinsic and extrinsic CTE. Nanometric and micrometric powders of Al2Mo3O12 were used to produce monolithic ceramics. Both powders were pressed at 1 GPa for 1 min to form green bodies. Sintering was performed at 1063 K over 24 h, and this procedure resulted in cylindrical bulk samples with low densities, 54.8% TD and 82.3% TD for the nanometric and micrometric powder, respectively. The sample prepared from the nanometric powder showed (Prisco et al., 2013) a bulk linear CTE (0.9 × 10–6 K−1 from 473 to 973 K) closer to the intrinsic CTE (2.4 × 10–6 K−1 between 523 K and 973) than for the sample prepared from the micrometric powder (−2.2 × 10–6 K−1 in the range from 473 to 923 K). The two samples presented completely different microstructures. The one from nanometric powders was very porous and had crystals of ca. 100 nm diameter, whereas the one from micrometric powders had crystals larger than 5 µm and presented intergranular and transgranular microcracks. The larger grains exceeded the critical size required to inhibit severe microcracking on cooling of Al2Mo3O12, and resulted in a linear CTE rather different (opposite sign) from the intrinsic one, underlining the importance of microstructure especially in these low CTE materials (Prisco et al., 2013).