95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater. , 18 January 2021

Sec. Structural Materials

Volume 7 - 2020 | https://doi.org/10.3389/fmats.2020.611409

This article is part of the Research Topic Development and Application of Bituminous Materials for Civil Infrastructures View all 20 articles

The graded mineral aggregate composed of coarse aggregate, fine aggregate, and mineral powder is the main component of hot asphalt mixture (HMA), and it occupies a mass ratio of more than 95% in HMA. The gradation variability of mineral aggregate is frequently an unavoidable problem in the construction of asphalt pavement engineering. In order to investigate the effect of gradation variability on the volume parameters and key performances of HMA, the asphalt concrete with a nominal maximum particle size of 20 mm (AC20) was selected as the research carrier. Firstly, a benchmark mineral aggregate gradation (BMAG) was designed based on the theory of dense skeleton gradation presented in the paper. Secondly, six types of HMA (that is, AC20) with variable gradations were also determined and all the specimens were prepared by rotary compaction process with the same optimum asphalt content (gradation varies but asphalt content remains the same), and finally based on asphalt pavement analyzer, the performances of all the specimens of each gradation were tested. The results show that, compared with the BMAG-HMA, the volume parameters such as air voids, voids in mineral aggregate, and voids filled with asphalt of the variable-graded HMA change in different directions, but the water stability and high-temperature performance both degrade greatly. The experimental results also show the feasibility and effectiveness of the dense skeleton gradation design theory adopted in this study.

Hot mix asphalt mixture (HMA) has become the main material of flexible pavement because of its good performance. However, due to the aggregate particles with different sizes and the inevitable variability of aggregate sources in actual engineering, HMA often has a certain degree of gradation variability in the construction process. Gradation variability can take many forms. For example, compared with the design gradation at the beginning, the overall gradation curve deviates upward causing the mixture to become finer or deviates downward causing the mixture to become coarser, or coarse aggregate and fine aggregate separate producing segregation and so on. The varying of mineral aggregate gradation must have some influence on the volume parameter and performance of HMA. Cominsky et al. (1994) have shown that the air voids (AV) and voids in mineral aggregate (VMA) are the two most important volume parameters of HMA. Therefore, people often use AV and VMA as the volume parameter for evaluation in research on HMA. By the rank-sum test method, Tan et al. (2012), Xu (2007) analyzed the law between the AV and the trend of the gradation curve through the study of 11 gradation curves, and the results show that the change of fine aggregate has the greatest influence on the AV under the condition that the content of asphalt and the amount of mineral powder remain unchanged. Liu et al. (2005) studied the influence of gradation curve on AV based on the principle of gray correlation analysis and believed that the greater the correlation between the gradation curve and the theoretical maximum density line, the smaller the AV. Wang et al. (2002) found a good correlation between VMA and the pass rate of 2.36 mm sieve size through statistical analysis for 150 groups of HMA. Lin (2005) studied the influence of gradation change on VMA and gave an equation to estimate its value. Praticò and Vaiana (2013) also showed that gradation is the internal factor that affects the VMA of HMA. By Bailey method Vavrik et al. (2002a), Vavrik et al. (2002b) indirectly showed the effect of gradation changes on the volume parameters, and gradation variability also affects the high-temperature performance, water stability, low-temperature performance, and fatigue performance of HMA. Yan (2007) showed that the effect of gradation on HMA accounts for 60–70%. Li (2016) conducted rutting tests on six gradations at 60°C under the condition of the optimum asphalt content and concluded that the dynamic stability is larger when the percentage passing the sieve of 2.36, 4.75, and 9.5 mm approaches the median gradation. Vavrik et al. (2004) analyzed the influence of the coarse aggregate ratio above the 4.75 mm sieve size on the high-temperature performance of the stone matrix asphalt (SMA), and the results show that the increase of larger particle size in the coarse aggregate can improve the high-temperature performance to a certain extent. Chen (2003) showed that increasing the amount of aggregate of 4.75–9.5 mm is conducive to improving high-temperature performance. Golalipour et al. (2012) divided the gradation range into upper, middle, and lower regions, analyzed the effects of gradation changes on rutting through Marshall Tests and dynamic creep tests, and found that the permanent deformation decreases when the gradation curve is close to the upper limit of the gradation. Matthews and Monismith (1992) studied, respectively, the effects of four kinds of temperature, two kinds of gradation and two kinds of asphalt on rutting, and found that when the gradation curve is close to the median gradation, the high-temperature performance is better than that of the coarse gradation. Using asphalt pavement analyzer (APA) as a test method, Kim et al. (2009) studied the high-temperature performance of four gradations, located, respectively, in the upper areas and lower areas beyond the control zone and the control zone. And the results show that the coarser gradation is more likely to produce ruts and the factor that affects the gradation performance is the degree of roughness and fineness of the gradation rather than the restricted area. Cheng et al. (2006) carried out the immersion Marshall test and freeze-thaw splitting test on four graded HMA with their respective optimal asphalt content (OAC), and the results show that the closer the gradation curve is to the theoretical maximum density line, the better the water stability is. Peng et al. (2013) selected five different gradations for the immersion Marshall test and found that the water stability of HMA near the middle gradation is the best and the water stability of HMA with fine gradation is better than that of the coarse gradation. Xie (2011) showed that the best water stability of rubber HMA belongs to gap gradation. Huang et al. (2011) studied the effect of gradation on the water stability of AC13 (asphalt concrete with a nominal maximum diameter of 13 mm) using fractal theory and found that, in order to meet the freeze-thaw splitting strength ratio (>75%) of HMA, the fractal dimension value should not be <2.432.

Zheng et al. (2012) showed that low-temperature damage is closely related to the gradation of HMA. Zhang et al. (2016) selected five kinds of rubber HMA for low-temperature bending test through the comprehensive parameters of bending strength, failure strain, and bending stiffness modulus, and the results show that the intermediate gradation has the best low-temperature performance. Ma et al. (2017) showed that increasing the fine aggregate content of HMA will reduce the resistance to low-temperature cracking. Garcia-Gil et al. (2019) discussed the effect of gradation of HMA overlay on the crack resistance at low temperature and concluded that the smaller the content of fine aggregate is, the smaller the nominal maximum particle size is and the stronger the crack resistance tends to be and concluded that the influence of fine aggregate content on the ductility of the mixture is greater than that of the nominal maximum particle size.

Kasu et al. (2019) evaluated the impact of nominal maximum particle size on the fatigue performance of the mixture at three stress levels and three loading frequencies, and the results show that a smaller nominal maximum particle size is beneficial to the fatigue performance. Valdes-Vidal et al. (2019) showed that fine aggregates could affect the energy dissipating in the process of HMA fatigue damage. Lv et al. (2020) showed that open-graded HMA has a better fatigue life than dense-graded HMA. Liu et al. (2019) used a uniaxial penetration test to study the fatigue performance of five kinds of HMA, and the results show that the fatigue performance of HMA with more fine aggregates and less coarse aggregates is better.

In summary, the above researches show that the aggregate gradation is directly related to the volume parameter, high-temperature performance, water stability, low-temperature performance, and fatigue performance of HMA, or it can be inferred that the change in gradation will bring changes to the volume parameters and performance parameters of HMA. However, firstly, these studies often focus on the direct comparison of HMA with different gradation, rather than specifically designing an aggregate gradation as the benchmark mineral aggregate gradation (BMAG) for comparison; therefore, in the strict sense, they are not studies on the influence of gradation variability on the performance of HMA. Secondly, these studies about the HMA were carried out with OAC of each aggregate gradation. However, in practical engineering, when the gradation variability occurs, the OAC designed for BMAG is often unchanged. Third, some of the conclusions of the above studies, such as the high-temperature performance, are inconsistent with each other. Therefore, it is still worth studying how the aggregate gradation variability quantitatively affects the volume parameters and performance parameters of HMA.

Taking into consideration the fact that the OAC in practical engineering is always strictly controlled and will not change, the gradation inevitably changes due to the instability of the particle composition of aggregates. Hence, the objective of this paper is to study the change of volume parameters, water stability, and high-temperature performance of HMA (the other performances are not discussed in the limited space) when the OAC of BMAG remains unchanged and the gradation of aggregate varies and to provide an important reference for controlling construction quality of asphalt pavement. It should be pointed out that the BMAG, which is used to compare the gradation variability, is designed by using the optimal design theory of mineral aggregate gradation established by the first author.

The HMA used in the study was determined as AC20, and the maximum size of aggregate was selected accordingly. Limestone aggregate with the size of 0∼5, 5–10, and 10–20 mm was used, and the filler was limestone powder.

The specific gravity and water absorption of the aggregate and mineral powder were tested in accordance with the Chinese test method, and the test results were shown in Table 1.

TABLE 1. Specific gravity and water absorption test results of aggregates with different particle sizes and mineral powder.

The results of the sieving tests for aggregates of various particle sizes were shown in Table 2.

SBS-modified asphalt was used. The penetration (25°C, 100 g, 5 s) is 58 (0.1 mm), the ductility at 15°C is greater than 100 cm, and the softening point is 74.5°C, which were all measured according to the stand test method (JTG E20-2011, 2011).

To study the gradation variability problem, there needs a BMAG as the basis for judging the gradation variability. According to the optimal design theory of mineral aggregate gradation (Liu et al., 2015), the research intends to design a dense skeleton gradation (it should be pointed out that the skeleton density gradation here has a relative meaning and is different from SMA) as the basic gradation.

The design idea of the dense skeleton gradation of the literature is three steps (Zhang et al., 2016): firstly, a gradation curve (gradation no. 1) is drawn within the gradation range given in the specification, as shown in Figure 1. Secondly, according to the proportion of the determined mineral aggregate, the bulk specific gravity of composite coarse aggregate and apparent specific gravity of composite fine material (which is made up of fine aggregate and mineral powder) are calculated, and the voids of coarse aggregate as well as fine aggregates (4.75 mm is used as the boundary sieve size of coarse and fine aggregate in the research for AC20; that is, aggregate with particle size greater than 4.75 mm is called coarse aggregate) are measured, respectively. Then, according to Eq. (1), the pass rate of 4.75 mm sieve size of the skeleton density gradation can be calculated.

where

Substituting the above four parameters into Eq. (1), the pass rate of 4.75 mm sieve size can be calculated as 29.5%, and further calculation can give the dense skeleton gradation (gradation no. 2), as shown in Figure 1.

Note that gradation 2 has broken the lower limit of the gradation range. At the same time, it should be pointed out that Eq. (1) is established for graded mineral aggregate without asphalt and based on certain assumptions (such as ignoring the interference of fine aggregates on the arrangement of coarse aggregates). Therefore, the calculated gradation 2 is theoretically a dense skeleton gradation without any asphalt and formed by the vibration test (because the void of coarse aggregate is obtained by the vibration test). Actually, when the coarse aggregates and fine materials are mixed and gradually become dense under a certain compaction process, the fine aggregates inevitably have a certain interference effect on the coarse aggregate arrangement. Therefore, VCA in the actual dense skeleton gradation will certainly be larger than that of the simple coarse aggregate vibration test. The practical dense skeleton gradation curve is necessarily located above the gradation curve 2, and its specific location could be obtained tentatively based on gradation 2.

Assume that the interference of fine aggregate increases the void of coarse aggregate in dense skeleton gradation to

The rotary compactor was employed to make the specimens of HMA; and the bulk specific gravities of the specimens were measured and VMA were calculated, as shown in Figure 3.

It can be seen from Figure 3 that the VMA curve presents an asymmetric concave curve shape and gets the valley value when

There are many possible situations of gradation variability. As an experimental study, this research designs the following three types of gradation variability based on BMAG: 1) Keep the shape of the gradation curve of the coarse aggregate section of the BMAG unchanged and change the gradation curve of the fine material section, and two variable gradations BMAG-F1 and BMAG-F2 are obtained (the two variability gradation curves are both above the BMAG curve. Because of the gradation characteristics of fine material employed in the research, it was not possible to design a variable gradation below the BMAG curve). 2) Keep the shape of the gradation curve of the fine material section of the BMAG unchanged and change the gradation curve of the coarse aggregate section, and two variable gradations BMAG-C1 and BMAG-C2 are obtained. 3) By deviating the whole gradation curve from the BMAG, two variability gradation curves BMAG-U and BMAG-D located, respectively, above and below the BMAG curve are obtained. The above six variability gradation curves are shown in Figures 4–6, respectively.

The asphalt-aggregate ratio (Pa) for the BMAG should be designed firstly. In order to reduce the test workload and improve the efficiency of the study, Pa was estimated according to Eq. (2) and then verified by tests.

where Pa is the asphalt-aggregate ratio, %; AV and VMA are the air voids and voids in mineral aggregate of compacted HMA specimens, respectively, %;

According to Eq. (2), the estimated asphalt-aggregate ratio is 4.3%, and the OAC is 4.1%.

Two specimens were prepared for each gradation through the rotary compaction process, and the bulk specific gravities of specimens were measured according to the test procedures. The AV, VMA, and VFA (void filled with asphalt) were further calculated, which were shown in Table 4.

Since this paper studies the situation of gradation variability and the OAC remains unchanged, therefore, the asphalt content used in each variability gradation is still 4.1%.

By transforming Eq. (2), Eq. (3) is obtained.

It can be seen from Eq. (3) that when the asphalt-aggregate ratio remains unchanged, if the VMA changes due to the gradation variability, the AV will change in the same direction.

AV, VMA, and VFA were selected as the assessment indicators. The volume parameter results of each HMA can be seen in Table 4.

According to Table 4, compared with the volume parameters of BMAG-HMA, the AV and VMA of the BMAG-F1 and BMAG-F2 mixtures became smaller. This is because the composition and dosage of the coarse aggregate remain unchanged, the VCA remains unchanged. When the amount of fine material increases, the extent to which the fine material fills the gap between the coarse aggregate particles increases, so the VMA decreases. Moreover, the variability of density parameter of mineral aggregate gradation is very small and can be ignored; therefore, according to Eq. (3), when the asphalt-aggregate ratio is constant, the decrease in VMA will inevitably lead to a decrease in AV. Compared with BMAG-F1, BMAG-F2 has finer materials, so its ability to fill the gaps of coarse aggregate is stronger, and AV and VMA of it are both smaller. The VFA values of the BMAG-F1 and BMAG-F2 mixtures are larger than those of BMAG. It can be inferred that when the fine material becomes finer than BMAG, the general rule is that the AV and VMA of HMA decrease and VFA increases.

As can be seen from Table 4, compared with the BMAG, AV and VMA of BMAG-C1 and BMAG-C2 mixtures are increased. When analyzing the reasons for the increase of AV and VMA, it should be noted that BMAG mixture is a dense skeleton gradation and its VMA and AV are smaller. With the variability of coarse aggregate, its VCA must change greatly or little. Because the amount of fine material is not changed, the HMA with variable gradation becomes a skeleton void structure or suspension dense structure. According to the law of asymmetric concave shape change of the VMA revealed in the literature (Zhang et al., 2016), it can be inferred that the VMA with variable gradation will inevitably increase. As mentioned above, the density parameters of mineral aggregate gradation after variability can be considered to be approximately constant, so according to Eq. (3), when the asphalt-aggregate ratio is constant, the increase of VMA will lead to AV increasing. As for VFA, the values of BMAG-C1 and BMAG-C2 mixtures are smaller than that of BMAG. It can be speculated that, compared to BMAG gradation, after variability of coarse aggregate, the general rule is that both VMA and AV of the HMA increase, while VFA decreases.

It can be seen from Table 4 that when coarse and fine aggregates have simultaneously variabilities, the VMA and AV of the two gradations of BMAG-D and BMAG-U compacted HMA both increase. The reason is the same as the situation that fine material gradation is basically unchanged but the coarse aggregate is changed visibly.

APA was employed to test the water stability and high-temperature performance of HMA. Because of the modified asphalt, the Hamburger wheel tracking test (HWTT) was conducted with cylindrical specimens under the condition of 60°C water in a bath (Izzo, 1999; Li et al., 2011; Zhang et al. 2018).

Wheel load times and rutting depth are the basic test data of HWTT, regarding the processing of experimental data, the traditional method provided by AASHT0T324 is curve fitting based on data. Then, the postcompaction stage, creep stage, and spalling stage were artificially distinguished to obtain spalling inflection point (SIP) and creep slope, which were used as the evaluation methodology of water stability and high-temperature performance, respectively. Obviously, the traditional method has many subjective factors and lacks a mathematical basis. In order to avoid this defect, Tsai and Harvey (2003) put forward the three-stage Weibull approach to fit rut curve. Based on this, Yin et al. (2014) proposed a new method to evaluate the performance of water stability and high-temperature performance by fitting the whole rutting process and proved the reliability of evaluation parameters. In this paper, the Yin fitting method is used to analyze the test results. The basic steps of the analysis are as follows:

(1) The function of Eq. (4) is used for curve fitting.

where

The fitting curve includes two parts of negative curvature and positive curvature, and the connection point between the two parts is defined as the critical point.

(1) Calculate the load cycle times xSN corresponding to the critical point.

Take the second derivative of both sides of Eq. (4) with respect to x and set the derivative equal to zero to obtain xSN, as shown in Eq. (5). The water stability of HMA is evaluated by xSN, and the larger xSN indicates that the water stability of HMA is better.

(1) Obtain the viscoplastic strain function before the critical point and taking the derivative.

Rutting before the critical point is mainly the viscoplastic deformation of the HMA specimen under load, and Eq. (6) can be used to fit the viscoplastic strain of the deformation stage.

where

Take the derivative of both sides of Eq. (6) with respect to

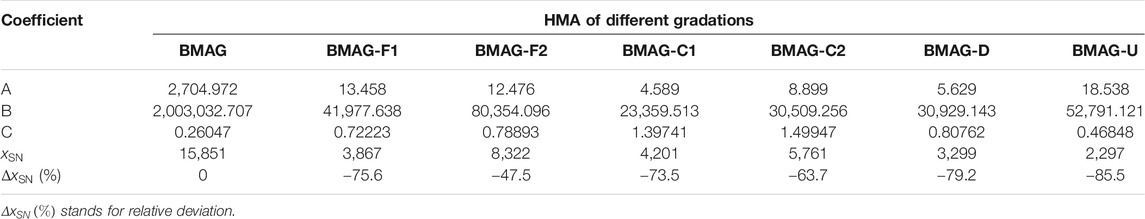

The load cycle times of each gradated HMA and the corresponding rut depth data were fitted with curves as shown in Eq. (4). To save space, for example, only the fitting curves of BMAG, BMAG-F1, BMAG-C1, and BMAG-D are given, as shown in Figure 7. The fitting parameters of all graded HMA are shown in Table 5;

FIGURE 7. Relationship between rut depth and load cycle times of HMA of different gradation: (A) BMAG, (B) BMAG-F1, (C) BMAG-C1, and (D) BMAG-D.

TABLE 5. Coefficient values of regression equations for load cycle times and rut depth of BMAG and variability gradation HMA.

The parameters that affect water stability include the AV, VFA, and asphalt film thickness of HMA. It can be seen from Table 5 that, compared with the HMA of BMAG, the load cycle times of all variable-graded HMA decrease greatly, indicating that the water stabilities all decrease significantly, but the degree of decrease is quite different. As can be seen from Table 4, AVs of HMA of BMAG-F1and BMAG-F2 are both smaller, but BMAG-F1 has more fine materials and smaller asphalt film thickness, so the reduction of xSN of its HMA is larger. The asphalt film thicknesses of BMAG-C1 and BMAG-C2 HMA are close to each other, but it can be seen from Table 4 that AV of the former is larger, so the water stability of the HMA decreases more. The volume parameters of BMAG-U and BMAG-D HMA, such as AV, differ little, but the former's asphalt film thickness is small, so the decrease of water stability is more obvious.

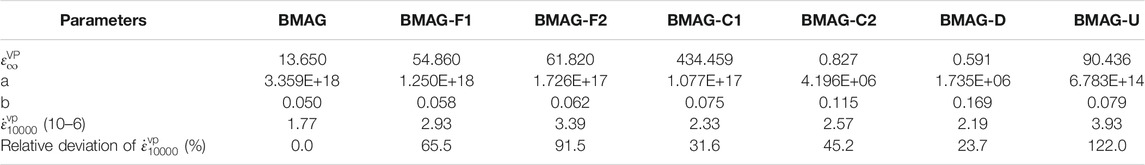

The rutting before the critical point is mainly the viscoplastic deformation of HMA under load, and Eq. (6) can be used to fit the viscoplastic strain of the deformation stage. For water damage of HMA, the strain before the critical point is fitted by the Tseng-Lytton model (6). After obtaining the model parameters, the viscoplastic strain rate

TABLE 6. Viscoplastic strain parameters and high-temperature performance parameters of each gradated HMA.

It has been pointed out earlier that a smaller

Compared with bmag-f1, the fine material of bmag-f2 is finer, resulting in a more obvious viscoplastic strain rate and indicating that even though the HMA is a dense skeleton gradation, its high-temperature performance is very sensitive to the change of fine material. In comparison, the high-temperature performance of BMAG-C1 and BMAG-C2 mixture decreases relatively little, indicating that the high-temperature performance of HMA is less sensitive to the change of coarse aggregate. Compared with BMAG-C2, the high-temperature performance of BMAG-C1 mixture is slightly higher, which should be caused by more stone-stone contact points of the aggregates. Compared with BMAG-U, the overall BMAG-D gradation curve deviates a little bit from BMAG, while the former deviates farther from BMAG. The HMA of BMAG-U is a typical suspended dense structure, being with coarse aggregate particles far away from each other and no stone-stone contact, so its high-temperature performance degradation is more serious.

In practical asphalt pavement engineering, it is inevitable that the gradation of HMA varies (Zhang et al. 2020). From the perspective of qualitative analysis, it is easy to infer that the gradation variability (asphalt content remains unchanged) will inevitably bring about changing of volume parameters and performances of HMA, but the changing direction and influence degree caused by the change may be known only through quantitative research. Based on the design of reasonable BMAG, this paper made an in-depth study on the change of HMA parameters caused by gradation variability and obtained the following main conclusions:

(1) Once the skeleton density gradation designed according to the method in this paper changes, whether the gradation becomes coarser or finer, AV, VMA, and VFA of the compacted HMAs will change in different degrees. Compared with the HMA of BMAG, AV and VMA of the HMA decrease and VFA increases when the fine material becomes finer. AV and VMA of HMA increase while the VFA decreases after the coarse aggregate becomes coarser or finer.

(2) Compared with the HMA of BMAG, the water stability of the designed variable gradation HMAs decreases by more than 50% on the whole. The thickness of asphalt film decreases significantly when the amount of fine material increases, and the more the fine material is, the more the water stability decreases. After the variability of coarse aggregate, the change of asphalt film thickness is relatively small, but the change of AV is large, resulting in a decrease in water stability.

(3) Compared with the HMA of BMAG, the high-temperature performances of all the HMAs of variable gradations decrease significantly. The more the fine material is, the lower the high-temperature performance gets. The higher the degree of suspension is, the greater the degradation of high-temperature performance will be.

(4) The performance degradation of the variable gradation HMA shows that the performance of HMA of BMAG determined by the design theory for dense skeleton gradation is optimal, which indirectly reflects that the design theory for dense skeleton gradation adopted in this study is feasible and effective.

(5) It is very important to determine the BMAG when studying the character change of HMA brought by gradation variation. If the unreasonable gradation is used as the BMAG, the properties of HMA may change in a good direction after gradation variation, so the problems caused by gradation variation cannot be found. As a theoretical basis for the study of gradation variation, the design theory for dense skeleton gradation established by the first author is a key technology, which has its originality and own characteristic.

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding authors.

LS was responsible for the analysis of experimental data and the writing of the manuscript. ZL was mainly responsible for organizing test operation and data proofreading. ZH (the first corresponding author) was primarily responsible for the determination of the overall study program. LT assisted in the conduct of trials and the recording of trial data. JP was responsible for the preparation of test materials. And CW (the second corresponding author) proofread the test plan and supervised the test progress and plan execution.

Authors ZH, LT, JP were employed by Shandong Hi-Speed Technology Development Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

This research was supported by the open fund from the Shandong provincial key laboratory of highway technology and safety assessment, China, and the authors would like to acknowledge the financial support.

Chen, X. Q. (2003). Effect of gradation type on performance of asphalt mixture. Nanjing: Southeast University.

Cheng, Y., He, X., and Dong, D. (2006). Effect of grading on water stability of AC-13C bituminous Mixture. J. Wuhan Univ. Technol. (Transp. Sci. Eng.). 30 (3), 477–480. doi:10.4028/www.scientific.net/amm.178-181.1171

Cominsky, R., Leahy, R. B., and Harrigan, E. T. (1994). Level one mix design: materials selection, compaction, and conditioning. 408.No. SHRP-A-1994.

Garcia-Gil, L., Miró, R., and Félix, E. (2019). Evaluating the role of aggregate gradation on cracking performance of asphalt concrete for thin overlays. Appl. Sci. 9 (4), 628. doi:10.3390/app9040628

Golalipour, A., Jamshidi, E., Niazi, Y., Afsharikia, Z., and Khadem, M. (2012). Effect of aggregate gradation on rutting of asphalt pavements. Proc. Soc. Behav. Sci. 53, 440–449. doi:10.1016/j.sbspro.2012.09.895

Huang, W., Tao, L., and Yang, D. (2011). “Research of grading's influence on asphalt mixture's water stability,” in IEEE international conference on automation and logistics (ICAL), 456–460.

Izzo, R. P. (1999). Evaluation of the use of the hamburg wheel-tracking device for moisture susceptibility of hot mix asphalt. Transp. Res. Rec. 1681 (1), 1999–2085.

JTG E20-2011 (2011). Highway engineering asphalt and asphalt mixture test procedures. Beijing: China Communications Publishing.

Kasu, S. R., Deb, S., Mitra, N., Muppireddy, A. R., and Reddy, K. S. (2019). Influence of aggregate size on flexural fatigue response of concrete. Construct. Build. Mater. 229, 116922. doi:10.1016/j.conbuildmat.2019.116922

Kim, Y. R., Park, H. M., and Lutif, J. E. S. (2009). Effects of aggregate structure on hot-mix asphalt rutting performance in low traffic volume local pavements, Construct. Build. Mater. 23 (6) 2177–2182. doi:10.1016/j.conbuildmat.2008.12.007

Li, E. B. (2016). Effect of gradation variation on high temperature performance of asphalt mixture. Arch. Eng. Technol. Des. 2016 (9), 121–139. doi:10.1109/cecnet.2011.5769181

Li, P., Zhang, Z., Li, H., and Wang, B. (2011). Research on cnditions of Hamburg Wheel Tracking tst and ealuating idicator for aphalt mxture. J. Wuhan Univ. Technol. Transp. Sci. Eng. 35 (1), 113–117. doi:10.3141/2446-10

Lin, X. X. (2005). Revisiting HMA's voids in mineral aggregate VMA. Shang. Highw. 4, 4–9. doi:10.31274/rtd-180813-13953

Liu, G., Zhong chuan, M. A. O., Guo, Ze., and Peng, Yong. (2019). Experimental study on aggregate gradation influence on the performance-related properties of structural-layer asphalt mixtures. Highway. 5, 49. doi:10.31274/rtd-180813-13953

Liu, S., Cao, W., Li, Y., Xue, Z., Zhang, H., and Guan, Y. (2015). Building and application research of physical model of VMA of mineral aggregate without adding asphalt. China J. Highw. Transp. 2, 8–13. doi:10.3403/00131804u

Liu, S. T., Mao, H. L., and Yao, Z. Y. (2005). Research on relationships between volume of air voids and gradation curve of mineral aggregate. J. Shandong Univ. (Eng. Sci.). 14, 98–101. doi:10.31274/rtd-180813-13953

Lv, S., Peng, X., Liu, C., Ge, D., Tang, M., and Zheng, J. (2020). Laboratory investigation of fatigue parameters characteristics of aging asphalt mixtures: a dissipated energy approach. Construct. Build. Mater. 230, 116972. doi:10.1201/9781315281896-72

Ma, H., Zhou, C., Feng, D., and Sun, L. (2017). Influence of fine aggregate content on low-temperature cracking of asphalt pavements. J. Test. Eval. 45 (3), 835–842. doi:10.1520/jte20150240

Matthews, J. M., and Monismith, C. L. (1992). The effect of aggregate gradation on the creep response of asphalt mixtures and pavement rutting estimates. London: ASTM STP.

Peng, H., Wang, F., Yang, T., and Ai, C. (2013). Experimental analysis on effect of aggregate gradation on pavement performance of asphalt mixture. Highw. Eng. 38 (2), 36–39.

Praticò, F. G., and Vaiana, R. (2013). A study on volumetric versus surface properties of wearing courses. Construct. Build. Mater. 38, 766–775. doi:10.1520/stp24226s

Tan, Y. Q., Li, Y., Rui, Z., Ji, L., and Xu, H. N. (2012). Effect of gradation on volume parameter of dense graded asphalt mixture. J. China Foreign Highw. 32 (1), 213–217. doi:10.12652/ksce.2015.35.6.1367

Tsai, B. W., and Harvey, J. (2003). Application of Weibull theory in prediction of asphalt concrete fatigue performance. Transp. Res. Rec. 1832 (1), 121–130. doi:10.3141/1832-15

Valdes-Vidal, G., Calabi-Floody, A., Sanchez-Alonso, E., and Mirób, R. (2019). Effect of aggregate type on the fatigue durability of asphalt mixtures. Construct. Build. Mater. 224, 124–131. doi:10.1520/d8237-18

Vavrik, W., Pine, W., and Carpenter, S. (2002b). Aggregate blending for asphalt mix design: bailey method. Transport. Res. Rec. 1789 (1), 146–153. doi:10.3141/1789-16

Vavrik, W., Pine, W., and Carpenter, S. (2004). The factors that affect SMA mixture resulted from gradation of coarse aggregate. J. Heilongjiang Inst. Technol. 18 (3), 8–10. doi:10.4028/www.scientific.net/amr.700.179

Vavrik, W. R., Huber, G., Pine, W. J., Carpenter, S. H., and Bailey, R. (2002a). Bailey method for gradation selection in HMA mixture design. Transp. Res. Rec. 14, 63–87. doi:10.1063/5.0000102

Wang, D. Y., Zhang, X. N., and Wang, S. H. (2002). Influence of aggregate gradation on volumetric properties of asphalt mixture. J. S. China Univ. Technol. 3, 53–56. doi:10.1063/5.0000102

Xie, S. B. (2011). Application of waste rubber powder modified asphalt in Jiujing expressway pavement project. Journal of Guizhou University of Finance and Economics 12, 47–51. doi:10.22215/etd/1994-09818

Xu, H. N. (2007). The influnce of volume parameter on asphalt mixture′s pavement performance. Harbin: Harbin Institute of Technology.

Yan, Y. Z. (2007). Research on the influence of temperature on the high temperature stability of asphalt mixtures. J. Guizhou Univ. Fin. Econ. 7, 33–47. doi:10.4028/www.scientific.net/amm.405-408.1871

Yin, F., Arambula, E., Lytton, R., Martin, A. E., and Cucalon, L. G. (2014). Novel method for moisture susceptibility and rutting evaluation using Hamburg wheel tracking test. Transport. Res. Rec. 2446 (1), 1–7. doi:10.3390/ma13153269

Zhang, H., Mao, X., Li, W., and Gou, J. (2016). “Effect of gradation and fineness on performance of rubber asphalt mixture at low temperature,” in 6th International conference on machinery, materials, environment, biotechnology and computer. Paris: Atlantis Press.

Zhang, H., Yu, T., and Huang, Y. (2020). Comparative analysis of HMA aggregate variability based on impacting and gyratory compaction. Construct. Build. Mater. 242, 118055–118066. doi:10.1016/j.conbuildmat.2020.118055

Zhang, Z., Luo, Y., and Zhang, K. (2018). Review on Hamburg Wheel-track device evaluation of asphalt mixture. Mater. Rev. 31 (3), 96–105. doi:10.1016/j.conbuildmat.2016.03.171

Keywords: water stability, high-temperature performance, volume parameter, gradation variability, hot mix asphalt mixture

Citation: Liu S, Zhu L, Zhang H, Liu T, Ji P and Cao W (2021) Effect of Gradation Variability on Volume Parameter and Key Performances of HMA. Front. Mater. 7:611409. doi: 10.3389/fmats.2020.611409

Received: 29 September 2020; Accepted: 24 November 2020;

Published: 18 January 2021.

Edited by:

Hui Yao, Beijing University of Technology, ChinaCopyright © 2021 Liu, Zhu, Zhang, Liu, Ji and Cao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Huiqin Zhang, NDc4NjQwNjE5QHFxLmNvbQ==; Weidong Cao, Y3dkMjAwMUBzZHUuZWR1LmNu

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.