95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater. , 09 December 2020

Sec. Structural Materials

Volume 7 - 2020 | https://doi.org/10.3389/fmats.2020.603938

This article is part of the Research Topic Development and Application of Bituminous Materials for Civil Infrastructures View all 20 articles

Although crumb rubber modified asphalt (CRMA) has a better performance than matrix asphalt (MA) in road engineering, the application bottlenecks of this material lies in its high viscosity, poor workability and bad storage stability. Microwave technology is one of the solutions to the above problems. The objective of this study was to investigate the physical and chemical changes before and after aging of CRMA which was prepared by microwave activated crumb rubber, and the aging mechanism of microwave-activated crumb rubber modified asphalt (MACRMA). Through penetration, softening point, ductility, viscosity and DSR test, the high and low temperature performance and temperature sensitivity of MA, CRMA and MACRMA before and after aging were studied. These tests results revealed that microwave treatment can improve the anti-rutting ability and the anti-aging performance of rubber asphalt. According to gel permeation chromatography (GPC) test, the distribution changes of the internal molecular content of the three asphalts were determined during the aging process. Its test results showed that aging effect accelerated the conversion of small molecules to large molecules in asphalt, and the value of large molecular size (LMS) increases more after long-term aging. The microwave activation made the swelling reaction more intense, thereby delayed the conversion of LMS in the rubber asphalt. In addition, LMS has a high correlation with test indicators. The fourier transform infrared spectroscopy (FTIR) test was used to measure the functional group changes of each asphalt. The FTIR spectra indicated that microwave activation is mainly a process of physical change. The carbonyl and sulfoxide functional group indices of MACRMA were lower than those of MA and CRMA, which also confirmed that MACRMA has a better anti-aging ability.

Currently, the process of global industrialization has become more and more complete, it is exploring towards environmental protection and sustainable development (Jeong et al., 2010; Presti, 2013; Sangiorgi et al., 2017). As a common problem in industrial development, the disposal and reuse of solid organic waste have been puzzling many researchers (Shu and Huang, 2014). Waste tires are one of the main sources of solid organic waste, its massive accumulation and combustion treatment have caused serious resource waste and environmental pollution (Navarro et al., 2005; Moreno et al., 2012). There is an efficient recycling method, which is to prepare waste tires into crumb rubber (CR) modifier and apply it to pavement engineering. European countries and Asian and African countries have used CR modifier as pavement construction materials for many years (George et al., 2012). The performance of asphalt binder prepared with CR modifier can be improved remarkably (Paje and Bueno, 2010). Crumb rubber modified asphalt (CRMA) can improve rut resistance, reduce fatigue cracking and decrease water damage of pavement (Thodesen et al., 2009). Also, anti-aging ability of CRMA is stronger, which is because the crumb rubber increase the thickness of rubber asphalt film, and the crumb rubber contains carbon black and other antioxidant components. Compared with SBS modified asphalt which is more widely used in pavement (Xiang et al., 2015), CRMA has an obvious economic advantage due to its wide sources of raw materials and low processing cost (Karlsson and Isacsson, 2003; Shen et al., 2009; Putman and Amirkhanian, 2010).

However, there are bottlenecks in the application of CRMA: poor workability due to high viscosity, bad storage stability on account of poor compatibility between CR modifier and matrix asphalt (MA) (Elvira, 2013). The most effective solution is to pre-activate CR. Treatment methods of activate CR includes: microwave method, ultrasonic method, active gas method, biological desulfurization method and so on (Nikolskii et al., 2014; Torretta et al., 2015; Kedarisetty et al., 2016). Study found that most of the pre-treatment is not controlled or activation process is complicated (Shatanawi et al., 2009), such as: ultrasonic method will destroy the C-C bond which is a useful chemical bond inside the asphalt during the activation process. Active gas method needs to feed the degraded CR with strong oxidizing gas under high temperature conditions, this process is complicated and expensive, which is not suitable for industrial production. This study use microwave technology to motivate CR.

Many studies revealed that microwave treatment is not only effective, but also easy to control, and is suitable for the application of pavement engineering. Xu found that microwave-activated crumb rubber asphalt (MACRMA) is superior to CRMA in terms of fatigue resistance and aging resistance (Xu et al., 2015). For the physical and chemical changes of CR, Aoudia found that microwave activation can break the C-S and S-S bonds, at the same time maintain the C-C bond (Aoudia et al., 2017). Ming used a microwave oven to irradiate 50 g of CR each time, the activation process lasts for 5 min and the power of the microwave oven is 500 W. He found that microwave has an effect of degradation and de-vulcanization on CR (Liang et al., 2017). When Zhang desulfurized the CR particles, he found that a shorter microwave action time can activate the CR more effectively (Poyraz et al., 2013). Long microwave exposure periods resulted in breaking of chemical bonds, decrease of insoluble phase content and increase the rubber fluidity (Garcia et al., 2015). Furthermore, microwave treatment can change the apparent morphology of the CR, which mainly increases the roughness of CR and sometimes makes CR appear holes (Yin et al., 2013). Although the microwave treatment has higher activation efficiency, the activation mechanism is still unclear.

With regard to the aging research, all asphalt materials will age due to light, oxygen, water, high temperature and other factors, and MACRMA are no exception (Sun and Lu, 2003; Kang et al., 2007). Many studies have been reported about the aging simulation of rubber asphalt materials (Huang et al., 1996; Ghavibazoo and Abdelrahman, 2014). The international tests for short-term aging and long-term aging of asphalt are thin film oven test (TFOT) and pressure aging vessel (PAV) test. Rubber asphalt, due to the complex components, will undergo various polymerization, cracking and oxidation reactions after aging, and one or more reactions will occur simultaneously depending on the degree of aging. The CR will absorb the light components in asphalt and cause swelling. The swelling reaction will occur continuously during aging and lead to the difference of performance after aging (González et al., 2010). But Amir found that the aging of matrix asphalt is not affected by ordinary CR, and the anti-aging ability of CRMA cannot be increased by increasing the amount of CR (Ghavibazoo and Abdelrahman, 2014). He believed that aging made the temperature sensitivity of rubber asphalt worse, and the degree of aging depends on the interaction between crumb rubber and asphalt. Churchill and Mohamed found that with the aging continue, the penetration and ductility decreased, the softening point increased, the saturated and aromatic content in asphalt decreased, and the macromolecular substances such as gums increased (Dhalaan, 1982; Churchill and Amirkhanian, 1995).

As a kind of polymer, the physical and chemical properties of CRMA can be analyzed by many methods. For example, Mohamed used X-ray technology to analyses the changes of chemical substances in aged asphalt (Siddiqui et al., 2002). In this study, the technology of GPC and FTIR were used to test microstructure of asphalt materials. GPC is a simple and fast separation analysis technique developed in the 1960s, this method was used originally to study the molecular distribution characteristics of polymers in asphalt (Lee et al., 2009). Putman found that the asphaltenes which has the most molecular in asphalt have excellent correlation with the large molecular size fraction. At the same time, Doh showed that the content of LMS was correlated with the viscosity and temperature sensitivity of asphalt (Doh et al., 2008). FTIR can describe the changes of asphalt components intuitively, and it has been widely used in the research of asphalt blending mechanism and aging characteristics. Lu used FTIR-ATR to study the aging process of SBS modified asphalt, and he found that the number of hydroxyl in asphalt gradually increased, and pointed out that the addition of antioxidants could inhibit the increase of hydroxyl (Lu, 2010). Liu studied the functional groups of rubber asphalt during the aging process by FTIR, and found that the number of carbonyl group was significantly changed by aging effect (Liu et al., 2017). According to the current research, the explanation of aging mechanism is not uniform, and the influence of microwave activation on CRMA is not clear.

Pre-treating crumb rubber with microwave treatment to prepare MACRMA has already reported in our previous research. Thus, this work aims to further study the change mechanism of the rubber asphalt performance after microwave treatment from the perspective of physical and chemical changes, as well as the effect of aging on MACRMA. Three kinds of asphalt (MA, CRMA, MACRMA) are analyzed by four common tests (penetration, softening point, ductility and viscosity test) and DSR test to study the physical indicators changes. GPC and FTIR techniques were used to quantitatively analyze the molecular composition and functional group changes of asphalt before and after aging. Finally, this work try to explain the mechanism of MACRMA changes by doing a statistical analysis of the correlation between the indicators.

Matrix asphalt of penetration grade 80/100 was used to produce MACRMA, Table 1 shows the basic properties of matrix asphalt.

The 40-mesh (the sieve size is 0.45 mm) CR which was made at room temperature was used in this study. Table 2 shows the basic properties of CR.

In this study, the preparation of MACRMA mainly includes three steps (Li et al., 2019). Figure 1 shows some detailed information of this process.

Step 1: Put the original CR in a constant temperature oven at 60°C for 30 min to dry and then weigh 100 g of dried CR for microwave treatment. The activation process lasts for 90 s and the power of the microwave oven is 800 W. Put treated CR in a desiccator to cool down for 24 h.

Step 2: Weigh 500 g of matrix asphalt binder into a beaker and heat it to a fully flowing state (approximately 135°C). Then put the beaker into a thermostatic magnetic stirrer for heat preservation.

Step 3: Raise the temperature of stirrer rapidly to 190°C and add the treated CR slowly to the matrix asphalt binder, at the same time start stirring. The stirring rate needs to be slowly increased to 1500 r/min. After 60 min of mixing and development, the MACRMA is ready.

In addition, preparation of MACRMA should pay attention to maintaining the reaction temperature of each step. And Figure 2 is SEM images of crumb rubber before and after microwave activation. In the image magnified 500 times, the microwave activation makes the CR fluffy. Many micropores appear on the surface of the CR and the aggregation of micro particles directly increases the specific surface area of CR, which makes the fusion between CR and asphalt more efficient.

FIGURE 2. SEM images of CR before and after microwave activation. (A) CR before microwave activation (B) CR after microwave activation.

The experimental design and test method of this study are shown in Figure 3. Test method of matrix asphalt and CRMA (crumb rubber modified asphalt without microwave activation treatment) is the same as that of MACRMA. There are at least three groups for each test and sample.

This study uses TFOT and PAV test which are international standard test method to simulate the aging phenomenon of bitumen materials. TFOT is used to simulate short-term aging of asphalt during the production, transportation, mixing and construction process under high temperature and oxygen coupling. PAV test is used to simulate long-term aging of asphalt during actual road use.

In addition to the basic physical indicators of asphalt, the viscoelasticity of asphalt was also tested using a DSR. The test temperature of the temperature-sweep tests is 58–82°C, and the change interval is 6°C. The parameters of this test are complex module (G*) and phase angle (δ).

GPC tested is generally used to determine the molecular distribution characteristics of polymers. When the polymer solution flows through the chromatographic column, the larger molecules are excluded from the pores of particles, which can only pass through the interparticle Spaces between particles at a faster rate; while the smaller molecules can enter the holes in the particles at a much slower rate. Previous studies have shown that the content of asphaltene in asphalt has a good correlation with the macromolecules. In this study, the Waters 1,515 gel permeation chromatography produced by Waters Corporation of the United States was used. The mobile phase was tetrahydrofuran (THF), the flow rate was 1.0 ml/min, and the concentration of the sample solution was 1.0 mg/ml. The GPC tests were carried out on asphalt before and after aging to analyze the changes in molecular weight during asphalt aging.

A Thermo Fisher Scientific Nicolet iS10 fourier transform infrared spectrometer matching the ATR accessory was used. Its infrared accessory is made of diamond crystal (refractive index 2.4), and the optical path is single reflection attenuated total reflection. The number of scans during the test is set to 32, the resolution is 4 cm−1, and the wavenumber range is 4,000–650 cm−1. This test method is simple, convenient and fast. Only need to smear or titrate asphalt on the diamond crystal plate to quickly collect its infrared spectrum test spectrum.

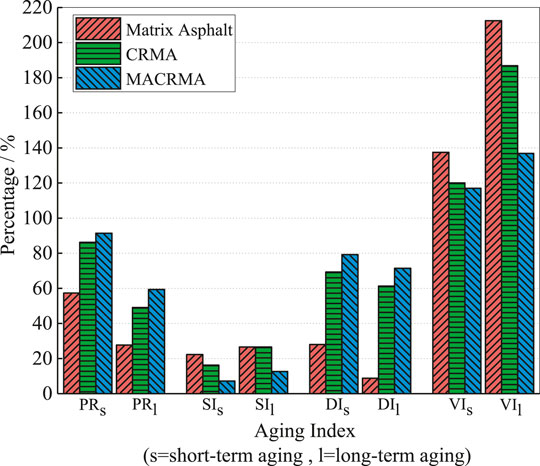

The changes of matrix asphalt, CRMA and MACRMA before and after aging were calculated by using penetration, softening point, ductility and viscosity as evaluation indexes, and used as aging factors to evaluate the aging resistance of rubber asphalt (as shown in Figure 4), so as to explore the effect of microwave activation of crumb rubber on the anti-aging properties of rubber asphalt.

FIGURE 4. The changes of penetration, softening point, ductility and viscosity of three kinds of asphalt during experiment.

The asphalt will become brittle and hard after aging, and the penetration will be reduced to varying degrees. The reduction of penetration can reflect the degree of aging of asphalt. The larger the reduction value, the less likely the asphalt is to age. The value of PR is calculated as follows:

where P0 is the value of penetration before aging, P is the value of penetration after aging.

Table 3 shows the penetration test results of three kinds of asphalt before and after aging. Whether the short-term aging or long-term aging stage, the PR values of matrix asphalt is significantly lower than other two rubber asphalt, which indicates that the aging resistance of matrix asphalt is poor. The PRS and PRL of CRMA were 0.86 and 0.49 respectively. Compared with matrix asphalt, the aging resistance of CRMA is significantly improved. In addition, the PR value of MACRMA is 0.91 in the short-term aging and 0.58 in the long-term aging, indicating that the aging resistance of MACRMA is further improved compared with matrix asphalt and CRMA. There are two main reasons for the improvement of the aging resistance of MACRMA. On the one hand, the specific surface area of activated crumb rubber is larger than that of ordinary crumb rubber, it is easier to contact with asphalt binder. Therefore, there is still a severe swelling reaction in the aging process, which slows down the aging effect of asphalt. On the other hand, the activated crumb rubber contains internal content when it is dissolved into asphalt. Carbon black and other natural anti-aging components can be dissolved in asphalt, so as to better resist the thermal and oxygen aging effect to a certain extent. Therefore, the comprehensive action of the two can improve the anti-aging property of activated rubber asphalt.

Many studies have shown that it is highly reliable to use the softening point rise rate as the index to evaluate the anti-aging property of asphalt. The softening point of asphalt will increase after asphalt aging. By comparing the softening point difference before and after aging, the aging degree of asphalt can be evaluated. The softening point of different bituminous specimens is quite different. The higher the rate of softening point increase, the greater the increase in softening point after aging and the worse aging resistance. The value of SR is calculated as follows:

where SP0 is the value of softening point before aging, SP is the value of softening point after aging.

Table 4 shows the softening point test results of three kinds of asphalt before and after aging. It can be seen from the table that the softening point of matrix asphalt before aging is 47.1°C. And the softening points of CRMA and MACRMA are 62.9 and 68.7°C, which are significantly higher than that of matrix asphalt. In addition, the increase rate of softening point of matrix asphalt is significantly higher than that of other two rubber asphalt, either in the short-term or long-term aging stage, which indicates that the aging resistance of matrix asphalt is the worst. Compared with the increase rate of CRMA and MACRMA after aging, in the short-term aging stage the increase rate of CRMA is 0.16, and that of MACRMA is 0.07; in the long-term aging stage, the increase rate of CRMA is 0.23, and that of MACRMA is 0.13. The increase rate is small, and microwave can significantly improve the aging resistance of rubber asphalt and slow down the attenuation of asphalt performance.

Ductility is a test index to characterize the low-temperature performance of asphalt. The larger the ductility is, the better the low-temperature deformation ability of asphalt is, the stronger the low-temperature crack resistance is, and the less likely the asphalt pavement is to crack. In order to distinguish the low temperature ductility and flexibility between the matrix asphalt and rubber asphalt better, the test temperature of matrix asphalt is 10°C, and the test temperature of rubber asphalt is 5°C. Compared with the ductility value before and after aging, the greater the reduction is, the better the aging resistance of asphalt is. The value of DR is calculated as follows:

where D0 is the value of ductility before aging, D is the value of ductility after aging.

Table 5 shows the ductility test results of three kinds of asphalt in different aging stages. It can be seen from the table that the ductility value of three kinds of asphalt declines to different degrees after aging. The ductility value is related to the distribution of molecular content of asphalt. The more small molecular content is, the softer the asphalt is, and the greater the ductility value is. Aging changes the structure of components in asphalt, some small molecular substances such as aromatics are transformed into macromolecular substances such as asphaltic, which makes asphalt hard. Reduce the ductility. The ductility of matrix asphalt decreased significantly compared with rubber asphalt ductility. DRS and DRL were 0.28 and 0.09, which were lower than CRMA and MACRMA. The DRS and DRL values of MACRMA are 0.79 and 0.71, indicating that they have good aging resistance of short-term aging and long-term aging.

Another important index to evaluate the performance of rubber asphalt is viscosity values. The degree of change of viscosity of rubber asphalt with temperature reflects its temperature sensing performance, and the change of aging rubber asphalt with chemical structure must cause the change of viscosity. The value of VR is calculated as follows:

where V0 is the value of viscosity before aging, V is the value of viscosity after aging.

Table 6 shows the viscosity values of three kinds of asphalt in different aging stages. It can be seen from the table that the viscosity value of both matrix asphalt and rubber asphalt increases significantly after aging, which is due to the increase of macromolecular content in asphalt, the increase of friction resistance between asphalt molecules and the decrease of fluidity. According to the changes of VR value, the aging resistance of three kinds of asphalt is sorted: MACRMA > CRMA > MA, which is basically the same as those of above results.

Due to the chemical properties of asphalt is complexity, the routine physical index test can not characterize the asphalt performance completely. Therefore, this section uses DSR to test the viscoelasticity of asphalt and tries to establish a connection between the test indicators and pavement performance.

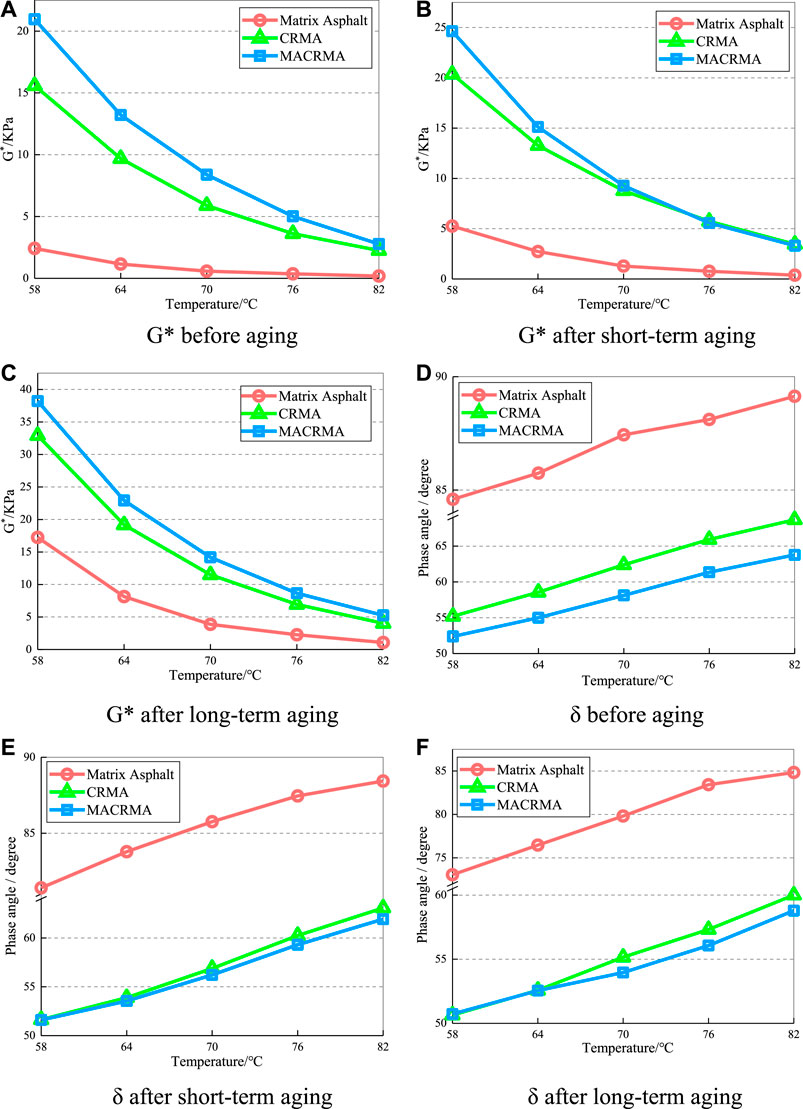

Figure 5 present the temperature scanning curves of G* and δ of three kinds of asphalt. As seen from the data, the value of G* (Figures 5A–C) decreases with the increase of test temperature, while the value of δ (Figures 5D–F) shows the opposite trend, which is proportional to the increase of temperature. The increase of temperature changes the proportion of viscoelasticity of asphalt. The change trend of the temperature scanning curve of CRMA and MACRMA is the same as that of matrix asphalt, but the microwave action makes the height of the curve of G* increase, and the curve from high to low is in order: MACRMA > CRMA > matrix asphalt. At the same time, the microwave action makes the curve height of δ decrease, the height of the curve from high to low is: matrix asphalt > CRMA > MACRMA.

FIGURE 5. The test results of G* and δ. (A) G* before aging, (B) G* after short-term aging, (C) G* after long-term aging, (D) δ before aging, (E) δ after short-term aging (F) δ after long-term aging.

It should be noted that the effect of aging on the same rheological index is different. The gap between G* of three kinds of asphalt is gradually widened as the aging effect deepens. When the test temperature is 58°C, the G* of matrix asphalt before aging is 2.421 KPa, and the G* after short-term aging and long-term aging is 5.262 and 17.246 KPa, with an increase in 117.4 and 612.4% respectively. However, for CEMA and MACRMA, the effect of aging on the growth rate of G* is significantly reduced. After short-term and long-term aging, the growth rates of G* in CRMA are 30.6 and 111.1%, and that in MACRMA are 17.5 and 82.3%. Therefore, the effect of thermal oxygen aging on matrix asphalt is more significant than that of CRMA and MCMA. For MACRMA, compared with long-term aging, the temperature curve of G* after short-term aging has little difference with that before aging, indicating that long-term aging has a greater influence of MACRMA.

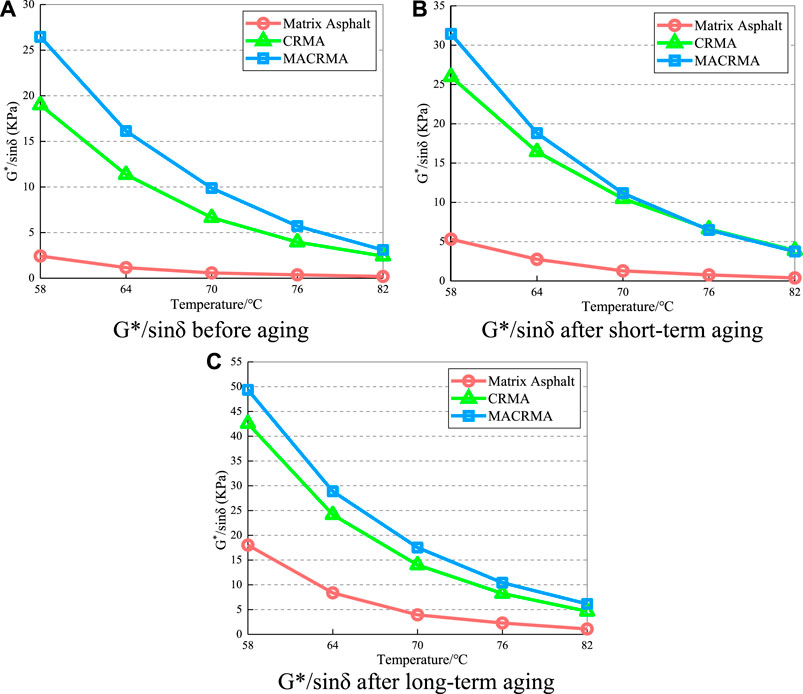

The rutting factor (G*/sinδ) is used to describe the ability of asphalt materials to resist permanent deformation at high temperatures. The larger the G*/sinδ, the better the high temperature stability.

The test results of G*/sinδ was shown in Figure 6. From the data, G*/sinδ of three kinds of asphalt decrease with the increase of scanning temperature, which shows that the viscosity of asphalt increases with the increase of temperature. The height of G*/sinδ always meets the change of MACEMA > CRMA > matrix asphalt. Therefore, microwave activation enhances the high-temperature deformation resistance of rubber asphalt. With the aging process, the gap between G*/sinδ of three kinds of asphalt increases gradually, but the increasing multiple of G*/sinδ decreases gradually. When the test temperature is 58°C, the G*/sinδ of the matrix asphalt before aging is 2.432 KPa, that of CRMA and MACRMA are 18.988 and 26.459 KPa, and the increase times are 6.81 and 9.88. After short-term aging and long-term aging, enhancement range of G*/sinδ of three kinds of asphalt decreased. In short-term aging, that of CRMA and MACRMA were 25.977 and 31.426 KPa, with the increase times of 3.88 and 4.91. In long-term aging, that of CRMA and MACRMA were 42.573 and 49.361 KPa, with the increase times of 1.36 and 1.74. The results shown that aging can improve the high-temperature deformation resistance of rubber asphalt.

FIGURE 6. The results of G*/sinδ. (A) G*/sinδ before aging, (B) G*/sinδ after short-term aging, (C) G*/sinδ after long-term aging.

Three kinds of asphalts were tested by GPC before and after aging, and the LMS value can be calculated from the chromatogram. In the chromatogram, the abscissa is transit time and the ordinate is signal value. The change in the curve area represents the changes in the content of different molecules in the asphalt. The GPC chromatogram can be divided into thirteen equal parts, which are divided into Large Molecular Size (LMS) (one to five equal parts), Medium Molecular Size (MMS) (six to nine equal parts) and Small Molecular Size (SMS) (10–13 equal parts) from left to right. Previous studies have shown that the value of LMS has a good correlation with asphalt properties (Kim and Lee, 2013), so this study only consider the changes of LMS.

The calculation result of LMS value is shown in Figure 7. From the data, the values of LMS of the matrix asphalt among three kinds of asphalts is the lowest, with an average of only 16.07%. Then it is CRMA, with an average of 19.77%, and the highest LMS content is MACRMA, with an average of 20.37%. Compared with the matrix asphalt, crumb rubber is added to the asphalt. After high-speed shearing, the light components inside asphalt enter the rubber network structure, changing the colloidal structure of asphalt, increasing the asphaltene and saturated content, so the value of LMS increases. After microwave treatment, the surface activity of crumb rubber is enhanced, the mutual solubility between crumb rubber and asphalt is more intense, and the conversion of light components into asphaltene becomes easier, so the LMS content of MACRMA is further increased.

Comparing the LMS values under different aging states, it can be found that after short-term aging and long-term aging, the LMS content of the three asphalts shows a significant increase trend. The LMS content of the matrix asphalt increased by 16.7 and 48.5% compared with that before aging, CRMA growth rates were 10.9 and 28.0%, and MACRMA growth rates were 6.6 and 27.3%. Obviously, the conversion rate of LMS content of MACRMA is the lowest. According to our previous research results (Yang, 2017), the specific surface area of the crumb rubber after microwave treatment for 90 s can reach 1.15 times that of untreated. Zhang’s research shows that the crumb rubber surface is rough before aging, there are many angled small holes, after aging crumb rubber surface will become flat and smooth, the number of small holes reduced (Zhang, 2018). It can be reasonably inferred from this that because the microwave action increases the microscopic surface pores of the crumb rubber in advance, so that the crumb rubber can resist a longer aging effect, so the swelling reaction between the microwave activated crumb rubber and matrix asphalt can last longer. In the same aging time, the LMS value of MACRMA only reached a low level. Similarly, for the same LMS value, MACRMA can resist the aging effect for a longer time.

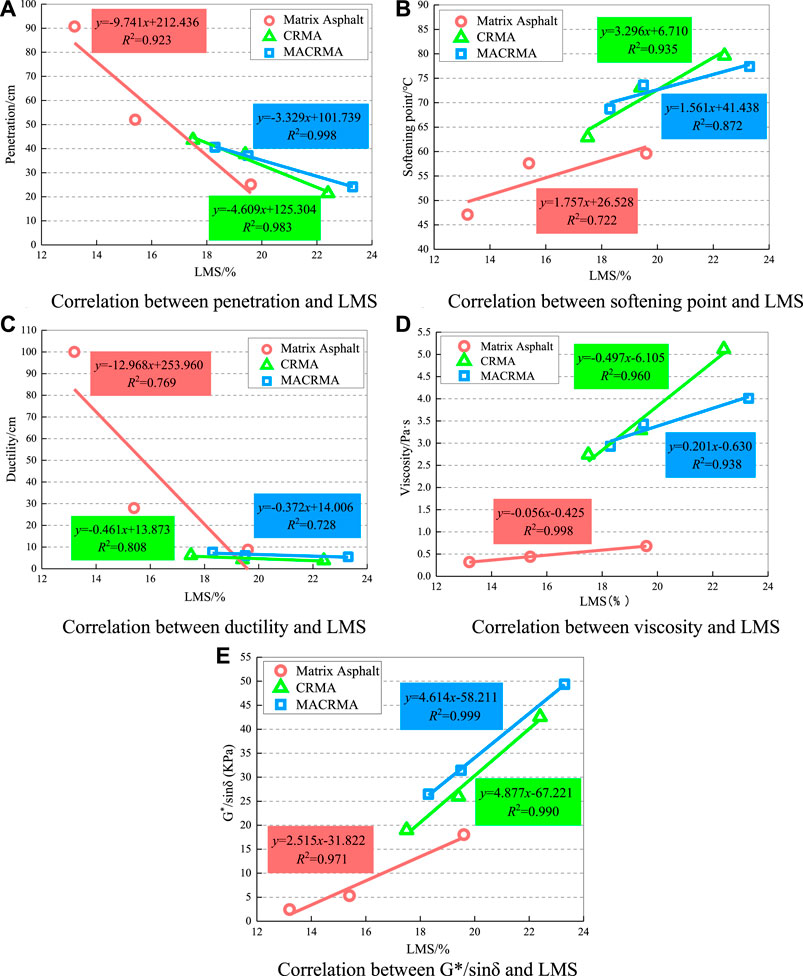

Correlation analyses of LMS content and test indicators can reveal the aging mechanism and explore the relationship between micro mechanism and macro law. The results are shown in Figure 8. The data presents that the correlation coefficients between the LMS content and the various indexes are high. For indicators of penetration, viscosity and rutting factor, their correlation coefficients are all greater than 0.9, especially between LMS and rutting factor, the correlation coefficient is 0.999. This proves that the LMS content has a significant effect on the penetration, viscosity and rutting factor of rubber asphalt. As for the ductility, the correlation is lower with the value of 0.808. The reason may be that, in ductility test, matrix asphalt will have a higher deformation, and the low fluidity caused by the friction between the rubber particles will hinder the deformation of asphalt, then the concentration of stress at the interface between the crumb rubber and the matrix asphalt makes the rubber asphalt fracture irregularly. The gradual increase of LMS value proves that during the aging process, the light components in rubber asphalt are constantly volatilizing and are constantly being converted into asphaltenes. The change of LMS content has a significant impact on the test index. So, the performance change and aging state can be quantitatively characterized by LMS in rubber asphalt.

FIGURE 8. Correlation analyses between test indicators and LMS. (A) Correlation between penetration and LMS, (B) Correlation between softening point and LMS, (C) Correlation between ductility and LMS, (D) Correlation between viscosity and LMS, (E) Correlation between G*/sinδ and LMS.

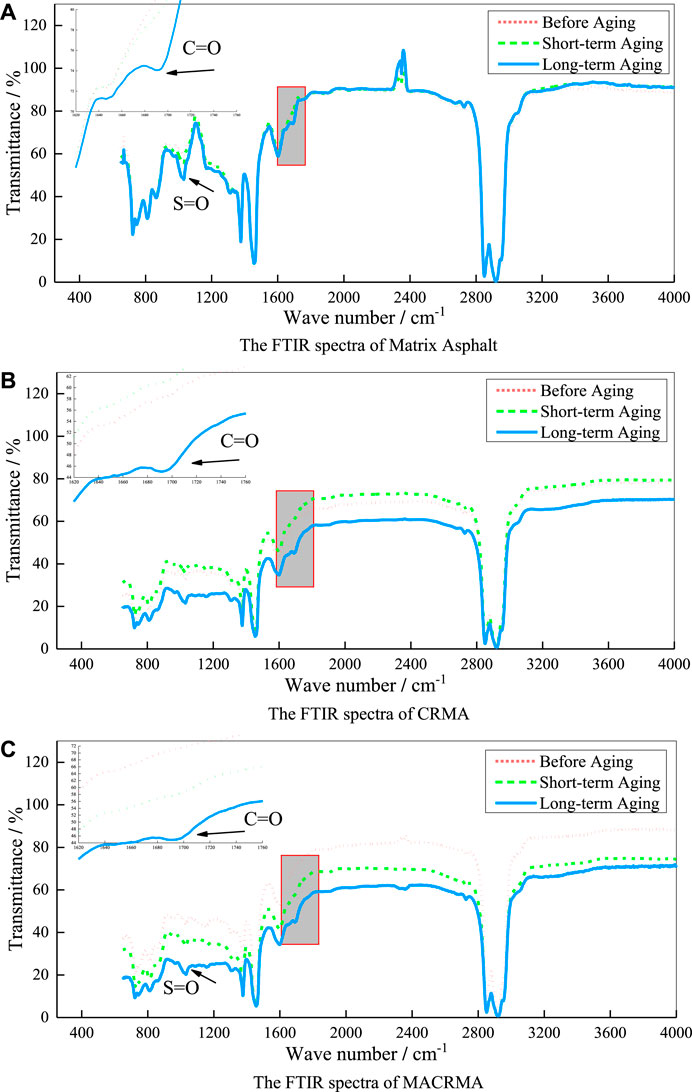

The microstructure changes of three kinds of asphalts before and after aging are quantitatively analyzed by FTIR. The test results are shown in Figure 9.

FIGURE 9. Changes in the FTIR spectra of three kinds of asphalt before and after aging. (A) The FTIR spectra of Matrix Asphalt, (B) The FTIR spectra of CRMA, (C) The FTIR spectra of MACRMA.

Firstly, by comparing different asphalt materials, we found that the functional groups in spectrum are basically the same. There are no new characteristic peaks and functional groups appeared in the MACRMA spectrum, only the peak intensity changed. It shows that the microwave effect is mainly physical, and it can only enhance or weaken certain properties of CRMA.

Then mainly discuss the effect of aging on rubber asphalt. Among the hydroxyl and carboxyl groups of asphalt aging products, only carboxyl groups are related to oxidation. All polymer materials will produce carboxyl groups after aging, so carboxyl groups have the effect of accelerating oxidation (Wang et al., 2015). Observing the spectrum of CRMA and MACRMA, it can be found that the absorption peaks (caused by the C=C skeleton vibration of the conjugated double bond of the benzene ring) of the two rubber asphalts around 1,600 cm−1 are slightly weakened. Compared with the unaged spectrum, the short-term aging of rubber asphalt did not appear new functional groups, and the long-term aging samples showed a weak carbonyl absorption peak near 1,700 cm−1, indicating the formation of carboxylic acid or ketone in the asphalt. The characteristic peak at 3,400 cm−1 is the amines produced after the degradation of the crumb rubber in the asphalt. So, an important conclusion can be drawn from this phenomenon, that is the aging of rubber asphalt materials includes two parts: one is the aging of matrix asphalt, and the other is the aging of crumb rubber.

During the short-term aging process, the characteristic peak of C=C is enhanced. During the long-term aging, the carbonyl and sulfoxide groups increase. This is because the light components in MACRMA react chemically with oxygen in the air to generate new chemical functional groups with macromolecular structures such as aldehydes, ketones, and sulfoxide groups. These functional groups have polarity, which makes the macromolecular substances in MACRMA aggregate with each other, promotes the conversion of light oils to asphaltenes on a microscopic level, increases the consistency of MACRMA on a macroscopic scale, and accelerates the hardening of MACRMA. These conclusions also explain the reason why the LMS value will continue to increase from a chemical point of view.

In long-term aging, the crumb rubber in asphalt will still undergo a strong swelling reaction. However, the swelling reaction of the crumb rubber in long-term aging is basically over, the asphalt materials mainly undergoes oxygen absorption reaction to generate carbonyl and sulfoxide groups. This is also consistent with the phenomenon of LMS content change in the previous section. The aging action causes the oxidation reaction of the functional groups in the rubber asphalt, which increases the interaction between the asphalt molecules, thereby hardening the asphalt and increasing the stiffness. In the range of 2000∼4000 cm−1, the spectrum of MACRMA is basically similar to that of CRMA, indicating that the thermal oxygen reaction process of MACRMA and CRMA is basically the same, the main difference is only the intensity of the characteristic peak.

The greater the content of carbonyl and sulfoxide groups, the more severe the oxidation of asphalt. In order to further research the changes of chemical structure of three kinds of asphalt before and after aging, this work used carbonyl index and sulfoxide index to quantitatively characterize the evolution of functional groups during aging. The calculation methods and results are as follows:

where CI represents the carbonyl index, SI represents the sulfoxide index, AC=O represents the carbonyl absorption peak area, AS=O represents the sulfoxide absorption peak area, AC–H represents the saturated C–H bond absorption peak area.

From the data in Table 7, we can see that the SI of asphalt materials shows an increasing trend with the increase of aging. There is no carbonyl functional group in the short-term aging stage, but only in the long-term aging stage, indicating that the presence or absence of carbonyl and sulfoxide groups in CRMA cannot be used as a sign of rubber asphalt aging, it can only be used to show whether a chemical reaction has occurred. It can be seen from the data that MACRMA does not show carbonyl groups in the short-term aging stage, but appears in the long-term aging, indicating that long-term aging can significantly accelerate the process of asphalt oxidation reaction. In addition, the sulfoxide index of MACRMA increases with the aging which is similar to the change law of CRMA. Comparing the functional group indexes of three kinds of asphalt, it was found that the carbonyl and sulfoxide functional group indexes of MACRMA are lower than those of CRMA and matrix asphalt, indicating that the aging resistance of MACRMA has been significantly improved, which is related to the physical modification of the crumb rubber by microwave treatment. It is also related to the fact that the activated crumb rubber contains many antioxidant components. The combined effect of the two makes MACRMA have a good anti-aging property.

This work used DSR, GPC, FTIR and other test methods to comprehensively study the physical properties and chemical microstructure changes of MACRMA, and make a comparison with CRMA and matrix asphalt. The discussion results obtained from the test are mainly as follows:

Compared with CRMA and matrix asphalt, MACRMA has the least performance degradation after aging. The order of anti-aging ability is as follows: MACRMA > CRMA > MA.

The aging effect reduces the penetration and ductility of rubber asphalt, increases the softening point and viscosity.

The LMS value of rubber asphalt gradually increased with the intensification of aging. The LMS has a high correlation with the test indicators, and the LMS can be used to quantitatively characterize the anti-aging degree of rubber asphalt materials.

Microwave activation is mainly a physical process, it does not cause chemical changes of CR.

The strong anti-aging ability of MACRMA caused by two parts: one is that the CR is physically modified by microwave activation, and the other is CR contains a lot of antioxidants.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

TZ Conceptualization, Methodology. JZ Conceptualization, Writing—Original Draft and Editing, Visualization. QL Investigation. BL Conceptualization, Funding acquisition, Writing—Editing. All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

The research work reported in this paper was supported by the National Natural Science Foundation of China (51668038 and 51868042), Industry Support and Guidance Project by University and College in Gansu Province (2020C-13), the Distinguished Young Scholars Fund of Gansu Province (1606RJDA318).

Authors JZ and BL were employed by the company Gansu Highway and Bridge Construction Group Co., Ltd. Author QL was employed by the company Gansu Hengda Road and Bridge Group Co., Ltd.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The authors gratefully acknowledge many important contributions from the researchers of all reports cited in our paper. The authors thank the reviewers of this paper for their comments and suggestions.

Aoudia, K., Azem, S., Gratton, M., Pettarin, V., and Seghar, S. (2017). Recycling of waste tire rubber: microwave devulcanization and incorporation in a thermoset resin. Waste Manag. 60, 471–481. doi:10.1016/j.wasman.2016.10.051

Churchill, E. V., and Amirkhanian, S. N. (1995). HP-GPC characterization of asphalt aging and selected properties. J. Mater. Civ. Eng. 7 (1), 41–49. doi:10.1061/(ASCE)0899-1561(1995)7:1(41)

Dhalaan, M. A. (1982). Characterization and design of recycled asphalt concrete mixture using indirect tensile test methods. Austin, TX: The University of Texas at Austin

Doh, Y. S., Amirkhanian, S. N., and Kim, K. W. (2008). Analysis of unbalanced binder oxidation level in recycled asphalt mixture using GPC. Construct. Build. Mater. 22 (6), 1253–1260. doi:10.1016/j.conbuildmat.2007.01.02

Elvira, (2013). Micro-analysis of physicochemical interaction between the components of asphalt mixtures with rubber. Ames, IA: Iowa State University

Garcia, P. S., Sousa, F. D. B. D., Lima, J. A. D., and Cruz, S. A. (2015). Devulcanization of ground tire rubber: physical and chemical changes after different microwave exposure times. Express Polym. Lett. 9 (11), 1015–1026. doi:10.3144/expresspolymlett.2015.91

González, V., Martínez-Boza, F.J., Navarro, F.J., Gallegos, C., Pérez-Lepe, A., and Páez, A. (2010). Thermomechanical properties of bitumen modified with crumb tire rubber and polymeric additives. Fuel Process. Technol. 91, 1033–1039. doi:10.1021/ef049699a

George, B., Way, P. E., Kaloush, , and Kamil, E. (2012). Asphalt rubber standard practice guide. Available at: http://www.rubberpavements.org/ARTIC/Guidelines/ARTIC_Guidelines_RPA_A1751.html

Ghavibazoo, A., and Abdelrahman, M. (2014). Effect of crumb rubber modification on short term aging susceptibility of asphalt binder. Int. J. Pavem. Res. Technol. 7 (4), 297–304. doi:10.6135/ijprt.org.tw/2014

Huang, S. C., Tia, M., and Ruth, B. E. (1996). Laboratory aging methods for simulation of field aging of asphalts. J. Mater. Civ. Eng. 8 (3), 147–152. doi:10.1155/2018/3428961

Jeong, K. D., Lee, S. J., and Amirkhanian, S. N. (2010). Interaction effects of crumb rubber modified asphalt binders. Construct. Build. Mater. 24 (5), 824–831. doi:10.1155/2013/415246

JTG E20-2011 (2011). Standard test methods of asphalt and asphalt mixtures for Highway engineering: JTG E20-2011; Ministry of Communications of the People’s Republic of China: Beijing, China,

Kang, A. H., Xiao, P., and Ma, A. Q. (2007). Research on performance of microwave radiation CRM asphalt and its mixture Highway 2, 34. doi:10.3969/j.issn.0451-0712.2007.02.033

Karlsson, R., and Isacsson, U. (2003). Laboratory studies of diffusion in bitumen using markers. J. Mater. Sci. 38 (13), 2835–2844. doi:10.1023/A:1024476217060

Kedarisetty, S., Biligiri, K. P., and Sousa, J. B. (2016). Advanced rheological characterization of Reacted and Activated Rubber (RAR) modified asphalt binders. Construct. Build. Mater. 122 (30), 12–22. doi:10.1016/j.conbuildmat.2016.06.043

Kim, H., and Lee, S. J. (2013). Quantification of oxidative aging of polymer-modified asphalt mixes made with warm mix Technologies. J. Mater. Civ. Eng. 25 (1), 1–8. doi:10.1061/(ASCE)MT.1943-5533.0000479

Lee, S. J., Amirkhanian, S. N., and Kim, K. W. (2009). Laboratory evaluation of the effects of short-term oven aging on asphalt binders in asphalt mixtures using HP-GPC. Construct. Build. Mater. 23 (9), 3087–3093. doi:10.1016/j.conbuildmat.2009.03.012

Li, B., Zhou, J. N., and Zhang, Z. H. (2019). Effect of short-term aging on asphalt modified using microwave activation crumb rubber. Materials 12 (7), 1039. doi:10.3390/ma12071039

Liang, M., Xin, X., and Fan, W. (2017). Thermo-stability and aging performance of modified asphalt with crumb rubber activated by microwave and TOR. Mater. Des. 127, 84–96. doi:10.1016/j.matdes.2017.04.060

Liu, Y. J., Ye, Z. G., and Zhang, Y. Z. (2017). Study on the aging performance of crumb rubber modified asphalt. Construct. Technol. 46 (11), 53–56, 104. doi:10.7672/sgjs2017110053

Lu, J. J. (2010). Performance influence factors and mechanism of rubber asphalt. Xi'an, China: Chang’an University.

Moreno, F., Rubio, M. C., and Martinez-Echevarria, M. J. (2012). The mechanical performance of dry-process crumb rubber modified hot bituminous mixes: the influence of digestion time and crumb rubber percentage. Construct. Build. Mater. 26 (1), 466–474. doi:10.3390/su12198045

Navarro, F. J., Partal, P., and Martinez-Boza, F. (2005). Influence of crumb rubber concentration on the rheological behavior of a crumb rubber modified bitumen. Energy Fuels. 19 (5), 1984–1990. doi:10.1021/ef049699a

Nikolskii, V. G., Dudareva, T. V., and Krasotkina, I. A. (2014). Development and properties of new nanomodifiers for road pavement. Russ. J. Phys. Chem. B., 577–583. doi:10.1134/S1990793114040071

Paje, S. E., and Bueno, M. (2010). Acoustic field evaluation of asphalt mixtures with crumb rubber. Appl. Acoust. 71, 578–582. doi:10.1016/j.apacoust.2009.12

Poyraz, S., Liu, Z., Liu, Y., and Zhang, X. (2013). Devulcanization of scrap ground tire rubber and successive carbon nanotube growth by microwave irradiation. Curr. Org. Chem. 17, 2243–2248. doi:10.2174/13852728113179990049

Presti, D. L. (2013). Recycled tyre rubber modified bitumens for road asphalt mixtures: a literature review. Construct. Build. Mater. 49 (6), 863–881. doi:10.1016/j.conbuildmat.2013.09.007

Putman, B. J., and Amirkhanian, S. N. (2010). Characterization of the interaction effect of crumb rubber modified binders using HP-GPC. J. Mater. Civ. Eng. 22 (2), 153–159. doi:10.1061/%28ASCE%290899-1561%282010%2922%3A2%28153%29

Sangiorgi, C., Eskandarsefat, S., and Tataranni, P. (2017). A complete laboratory assessment of crumb rubber porous asphalt. Construct. Build. Mater. 132 (FEB.1), 500–507. doi:10.1016/j.conbuildmat.2016.12.016

Shatanawi, K., Biro, S., and Thodesen, C. (2009). Effects of water activation of crumb rubber on the properties of crumb rubber-modified binders. Int. J. Pavem. Eng. 10 (4), 289–297. doi:10.1080/10298430802169424

Shen, J., Amirkhanian, S., and Xiao, F. (2009). Surface area of crumb rubber modifier and its influence on high-temperature viscosity of CRM binders. Int. J. Pavem. Eng. 10 (5), 375–381. doi:10.1080/10298430802342757

Shu, X., and Huang, B. (2014). Recycling of waste tire rubber in asphalt and portland cement concrete: an overview. Construct. Build. Mater. 67, 217–224. doi:10.1016/j.conbuildmat.2013.11.027

Siddiqui, M. N., Ali, M. F., and Shirokoff, J. (2002). Use of X-ray diffraction in assessing the aging pattern of asphalt fractions. Fuel 81 (1), 51–58. doi:10.1016/S0016-2361(01)00116-8

Sun, D. Q., and Lu, W. M. (2003). Investigation and improvement of storage stability of SBS modified asphalt. Petrol. Sci. Technol. 21, 901–910. doi:10.1081/LFT-120017456

Thodesen, C., Xiao, F., and Amirkhanian, S. N. (2009). Modeling viscosity behavior of crumb rubber modified binders. Construct. Build. Mater. 23 (9), 3053–3062. doi:10.1016/j.conbuildmat.2009.04.005

Torretta, V., Rada, E. C., and Ragazzi, M. (2015). Treatment and disposal of tyres: two EU approaches. A review. Waste Manag. 45, 152–160. doi:10.1016/j.wasman.2015.04.018

Wang, Q., Yuan, Y., and Ouyang, C. F. (2015). Research on aging of waste rubber modified asphalt. Polym. Bull. 6, 19–28. doi:10.14028/j.cnki.1003-3726.2015.06.003

Xiang, L., Cheng, J., and Kang, S. (2015). Thermal oxidative aging mechanism of crumb rubber/SBS composite modified asphalt. Construct. Build. Mater. 75, 169–175. doi:10.1016/j.conbuildmat.2014.08.035

Xu, M., Liu, J., Li, W., and Duan, W. (2015). Novel method to prepare activated crumb rubber used for synthesis of activated crumb rubber modified asphalt. J. Mater. Civ. Eng. 27, 04014173. doi:10.1061/(ASCE)MT.1943-5533.0001115

Yang, J. Y. (2017). Research on modification mechanism of rubber asphalt prepared by microwave activated powder. Lanzhou, China: Lanzhou Jiaotong University.

Yin, J. M., Wang, S. Y., and Lv, F. R. (2013). Improving the short-term aging resistance of asphalt by addition of crumb rubber radiated by microwave and impregnated in epoxidized soybean oil. Construct. Build. Mater. 49, 712–719. doi:10.1016/j.conbuildmat.2013.08.067

Keywords: rubber asphalt, microwave-activated, aging, physico-chemical properties, gel permeation chromatography, Fourier transform infrared spectroscopy

Citation: Zhou T, Zhou J, Li Q and Li B (2020) Aging Properties and Mechanism of Microwave-Activated Crumb Rubber Modified Asphalt Binder. Front. Mater. 7:603938. doi: 10.3389/fmats.2020.603938

Received: 08 September 2020; Accepted: 16 November 2020;

Published: 09 December 2020.

Edited by:

Zhanping You, Michigan Technological University, United StatesCopyright © 2020 Zhou, Zhou, Li and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bo Li, bGlib0BtYWlsLmx6anR1LmNu

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.