- 1Things2i s.r.l., Parma, Italy

- 2Internet of Things Laboratory, Department of Engineering and Architecture, University of Parma, Parma, Italy

- 3Department of Economics and Management, University of Parma, Parma, Italy

Research advances in the last decades have allowed the introduction of Internet of Things (IoT) concepts in several industrial application scenarios, leading to the so-called Industry 4.0 or Industrial IoT (IIoT). The Industry 4.0 has the ambition to revolutionize industry management and business processes, enhancing the productivity of manufacturing technologies through field data collection and analysis, thus creating real-time digital twins of industrial scenarios. Moreover, it is vital for companies to be as “smart” as possible and to adapt to the varying nature of the digital supply chains. This is possible by leveraging IoT in Industry 4.0 scenarios. In this paper, we describe the renovation process, guided by things2i s.r.l., a cross-disciplinary engineering-economic spin-off company of the University of Parma, which a real manufacturing industry is undergoing over consecutive phases spanning a few years. The first phase concerns the digitalization of the control quality process, specifically related to the company's production lines. The use of paper sheets containing different quality checks has been made smarter through the introduction of a digital, smart, and Web-based application, which is currently supporting operators and quality inspectors working on the supply chain through the use of smart devices. The second phase of the IIoT evolution—currently on-going—concerns both digitalization and optimization of the production planning activity, through an innovative Web-based planning tool. The changes introduced have led to significant advantages and improvement for the manufacturing company, in terms of: (i) impressive cost reduction; (ii) better products quality control; (iii) real-time detection and reaction to supply chain issues; (iv) significant reduction of the time spent in planning activity; and (v) resources employment optimization, thanks to the minimization of unproductive setup times on production lines. These two renovation phases represent a basis for possible future developments, such us the integration of sensor-based data on the operational status of production machines and the currently available warehouse supplies. In conclusion, the Industry 4.0-based on-going digitization process guided by things2i allows to continuously collect heterogeneous Human-to-Things (H2T) data, which can be used to optimize the partner manufacturing company as a whole entity.

1. Introduction

In the last decades, there has been a digital revolution in manufacturing factories, especially related to the adoption of new digital tools for the company and business processes management. Today, we are participating to the ongoing convergence of real and virtual worlds, which can be considered as the main driver of innovation and changes in all sectors of our industrial economy. Moreover, the progressive establishment of Information and Communication Technology (ICT) and the possibility to employ modern technologies to collect continuously growing amount of data, are strongly changing the concept of company. Hence, the first change in the industrial scenarios corresponds to an advanced digitalization process that, in combination with Internet-based and future-oriented technologies (including, as an example, Smart Objects–SOs), leads to the new paradigm of the industrial production denoted as Industry 4.0. This new concept, whose name is also due to the fact that this wave of changes is considered as the fourth industrial revolution in modern history, promotes the vision of a factory as a modular and efficient manufacturing system, in which the products control their own manufacturing process. Industry 4.0 is strongly related to the Industrial IoT (IIoT) paradigm, which is still in an explorative stage. At this time, there seems to be no clear solutions, generally employed in manufacturing industries, that can bridge the gap between IoT and legacy systems. Nevertheless, there are many uses cases and IoT deployments offering a rapid return and enabling manufacturers to realize digital transformations from several perspectives: efficiency, automation, customer-centricity, competitive benefits, together with the advantages offered by using data across the manufacturing value chain, thus turning into new revenue sources; this undoubtedly represents a key aspect of digital transformation in manufacturing, as highlighted by Ustundag and Cevikcan (2018). In industries there are many opportunities to leverage IoT in connecting physical and digital worlds, collecting data from various assets such as machines, production assets, and various additional objects not strictly related to the production process, generating a vast information network as described by Borangiu et al. (2019) and Civerchia et al. (2017). As highlighted before, even in this case this innovation process is an important element, since in manufacturing-oriented companies, we typically tend to think about physical goods and products, while bigger opportunities for manufacturers come and lie in Cyber-physical Systems (CPS), looking to new service economy models and information opportunities.

In this work, we present the description of the innovation and digitalization process, following the Industry 4.0 paradigm, implemented in a partner company in order to improve its “performance” in the overall departments, through the introduction of modern technologies in the business processes in both control quality and production planning tasks. The process has been completely guided by things2i, a cross-disciplinary engineering-economic spin-off of the University of Parma and, in particular, involves two applications: the first one, denoted as SmartFactory, has been developed to improve the production monitoring and the control quality activities. The second application, denoted as SmartPlanner, is a Web-based tool aiming at supporting the production planning staff in the complex activity of scheduling the manufacturing orders on the production lines proper of the partner company. Finally, we will discuss about IoT-based evaluation of the developed systems.

The rest of this paper is organized as follows. In section 2, an overview of related works on Enterprise Resource Planning (ERP) and digitalization adoption is provided. In section 3, a description of the partner company and of its internal business organization is given. In section 4, a detailed overview of the innovations adopted in order to improve the performance of the control quality department is presented. A detailed description of the second phase of the digitalization process actuated in the target company is detailed in section 5, while in section 6 an overview of future developments is presented. Finally, conclusions are drawn in section 7.

2. State of the Art

Among the different technologies characterizing the evolution process of a company, the ERP adoption is one of the most important, due to the significant effects that it could have on the entire production process. Several studies highlight that companies, depending on their size, approach ERP implementations in different ways, and have to face heterogeneous issues. At the same time, it has been also demonstrated that benefits coming from the ERP adoption differ on the basis of the company size itself: Mabert et al. (2001) argue that, in general, smaller companies benefit of better performance in manufacturing and logistics, while larger companies show improvements and benefits in financial fields. Regardless of the company size, understanding, and optimizing business processes represents a success factor in fast-changing environments, like the one proper of previously highlighted scenarios. Mabert et al. (2003) improved the definition of ERP, highlighting that it allows to better manage resources, integrate processes, and enforce data integrity, while it has to include integrated modules for accounting, finance, sales and distribution, human resources, materials management and other business functions based on a common architecture that links the enterprise to both customers and suppliers. Moreover, ERPs allow a seamless integration of processes across functional areas with improved workflow, standardization of various business practices, improved order management, accurate accounting of inventory, and better supply chain management. Hence, as highlighted by Raymond (1990), the adoption of an ERP has different effects on the company's lifecycle, thus involving interventions in different aspects and layers of the business, ranging from higher layers (e.g., e-business) to lower layers (e.g., in-factory supply chain management). Davenport (1998) analyzes the effects of the introduction of ERPs on the operative side, highlighting that companies of different sizes tend to follow a different behavior in their implementations. In particular, there are differences between large and small enterprises over a range of issues, including: (i) the motivation that leads to the adoption of an ERP system in the factory; (ii) the kind of adopted system; (iii) the implementation strategies effectively adopted; and (iv) the customization and re-engineering's degree of the system operating with the ERP. Moreover, Ein-Dor and Segev (1978) and Yap (1990) highlight that there exist several differences even in the outcomes attained to an ERP adoption, in particular regarding the relationship between structural variables proper of a company (e.g., industry type, size, and organizational structure) and their impact on various operations, having that the organizational size is the most frequently examined issues associated with innovation, R&D expenditures, and market power. Thus, Swanson (1994) suggests that small companies tend to lag behind large factories in implementing new technologies, also employing different practices, whereas larger manufacturers are more likely to be early adopters of information technology innovations, being also more suited to have an internal IT office handling all the networking operations.

Other aspects that have to be kept in mind in choosing an ERP system are: (i) the software installation complexity—this, however, normally represents just a part of the process, due to the fact that a successful ERP implementation involves more than having sophisticated software and advanced computing technologies; (ii) the motivation guiding a company to implement an ERP; (iii) the type of ERP that is to be implemented and the resulting system configuration; (iv) the implementation strategies adopted by the manufacturing company; (v) the degree of customization required to the ERP developers; and (vi) the implementation cost required by the ERP adoption, with the consequent investment revenues and returns. Based on these additional aspects (Gremillion, 1984; Harris and Katz, 1991) state that smaller companies are more likely to change their processes to fit the system, while larger companies are more likely to customize the system. This leads to the fact that any change to the system can have major implications. Generally, modifications lead to higher costs, longer implementation times and more complicated implementations.

Another key point, which raised attention in the last decade and is characterizing the evolution process of a company, relates to the digitalization—or digital transformation process—which has been identified as one of the major trends changing society and business, since digitalization causes changes for companies due to the adoption of digital technologies in the operation environment or in the organization. Parviainen et al. (2017) and Zimmermann et al. (2016) highlight that the changes introduced by the digitalization can cover different factory levels, such as (i) the process level (streamlining processes by reducing manual steps and adopting new digital tools), (ii) the organization level (offering new services and existing services in new ways, and discarding obsolete practices), (iii) the business domain level (changing value chains and roles inside ecosystems), and (iv) the society level (e.g., changing type of work). Huberty (2015) and Quinton and Simkin (2016) motivate the fact that replacing paper and manual processes with software-based solutions allows to automatically and quickly collect data that can be mined to better understand the rick causes and the process performance. Finally, Iivari et al. (2016) and Wank et al. (2016) highlight the importance of the user interfaces which a digitalization process has to be equipped with, where real-time reports and dashboards on digital-process performance allow managers to address problems before they become critical.

3. A Real Manufacturing Factory: Before the Evolution

The factory target of the activities described in this paper has been founded at the end of 1970's and represents an important independent thermoplastic hose manufacturer for medium, high, and very high pressures. The company Head Quarter (HQ) and the production factory are located in Italy, where thermoplastic hoses are produced and assembled. Through a network of relevant distributors, the produced hoses are then distributed in 65 different countries around the worlds. The annual company workload can be assessed in more than 13 millions meters (42 millions feet) of hoses, made for different industrial employments, such as: hydraulic systems for forklifts, aerial platforms, cranes, mobile devices, rescue tooling, high pressure sewer jetting, gas and water supply, paint spray markets, and air conditioning and refrigeration. Niche markets are also covered with, as an example, hoses for air breathable management systems and applications where high temperatures or aggressive fluids resistance are required.

More in detail, as of today, the company activity focuses on four major segments:

• HYDRAULIC, with thermoplastic hoses for hydraulic applications;

• INDUSTRIAL, with thermoplastic hoses for industrial applications;

• Multi-spiral Ultra High Pressure (UHP), with hoses for very high pressures (up to 4,000 bar/58,000 psi);

• GOMAX, corresponding to a product line composed of thermoplastic hoses and fittings for air conditioning and refrigeration.

The high quality standards followed by the company for its products and services have made its success at the international level and have driven its constant attention to technological innovation and modern research, in order to continuously improve each stage in production and organization activities.

The production activity of the company is divided into 7 departments, where a single production phase is performed. Each thermoplastic article is thus produced across a few consecutive departments which are shared, with different configurations, among the production processes of several articles. Moreover, each department has one or more lines that can work simultaneously.

The main actors operating in the company and being involved in the activities related to this work are mainly the following three.

• Production Scheduling Managers (PSMs): they are in charge of controlling and organizing the production schedule of all lines available in the factory, taking into account (i) the desired stock policy and (ii) the commissions and orders placed from customers.

• Quality Inspectors (QIs): they are responsible to perform continuous checks on products and semi-finished products directly on the lines in the factory. Each QI is assigned to a set of lines, and each item produced in the company has a predefined set of checks that should be performed to guarantee conformity to quality standards. For this reason, during the manufacturing activity, the QIs, conforming to the diary schedule defined by PSMs, move between lines, in order to inspect the production process.

• Line Operators (LOs): they are responsible for preparing and activating the production machines on the production lines, conforming to the diary schedule. Some production lines require a dedicated LO to work, while, in other cases, a single LO can simultaneously manage few lines. When machines on lines are active, LOs have to take measurement to monitor the production, and also perform “self” quality checks on the hoses, which are then validated by QIs.

The aspects of the manufacturing process that are of interest for the digitalization process described in this paper are mainly two, namely: the manufacturing process monitoring and the production planning management. In the following, the management of these two aspects in the target company, before the digitalization introduction are described in detail.

3.1. Manufacturing Process Monitoring

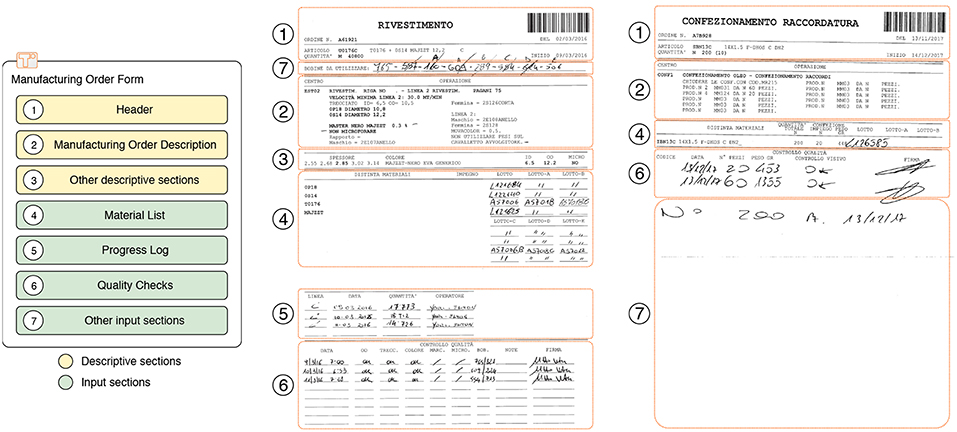

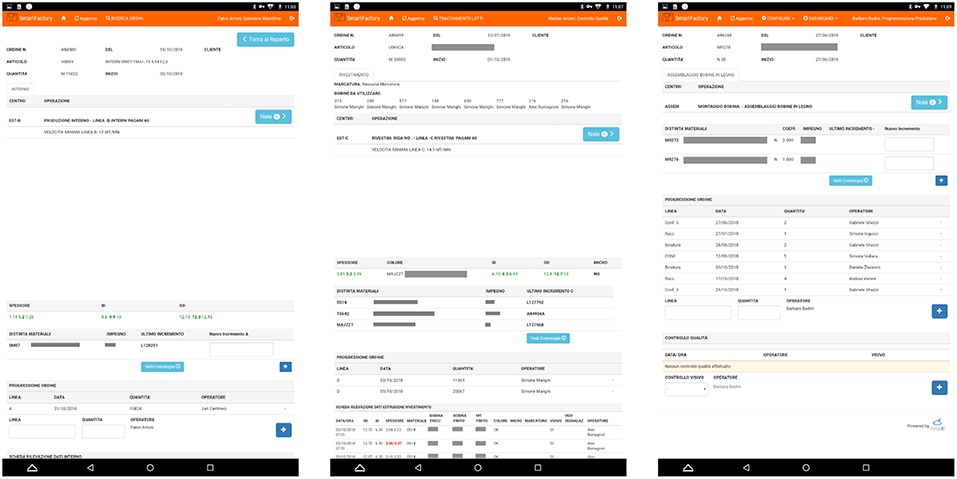

In order to maintain and guarantee to customers an always growing quality level of produced items, the company has defined a precise protocol to be followed during the manufacturing process. More in detail, after the definition of the schedule for each line, performed by PSMs, each article to be produced is separated into a set of N Manufacturing Orders (MO), one per department involved in the productive process. Each MO is then assigned to a specific line in the factory. In this way, a LO working on a production line is granted to have a daily activity (namely a list of MOs) to perform on the line which he/she is responsible for. The protocol of manufacturing monitoring defined by the company and set up during the years of its activity was initially performed through the use of MO Forms (MOFs) printed on paper sheets. Even though each department in the company has a specific layout for the MOF, in terms of input information types and number of sections, one can find a common set of sections. Some of the sections are descriptive, aiming at showing some important information for the manufacturing process (i.e., configurations, measures, customizations); some other are instead input sections and require that someone (among LOs, QIs, or PSMs) inserts some data or measurements. The possible section types identified during the preliminary analysis activity are described in the following and depicted in Figure 1.

The Header section does not require any input, and simply identifies the MOF type, among the overall available, through the title together with a start date and an order alphanumeric code. The Manufacturing Order Description section is another part of the documents which does not require any input from LOs, hence is containing a list of textual information describing the steps needed for the order completion and the machine configuration. The Material List section contains the names and quantity of the raw materials that should be used by LOs during the manufacturing process: depending on the kind of MO, this section may differ in some aspects such as, for example, in the structure of the list and the shown details. Nevertheless, the overall material lists require that the LO working on the line hand-writes in the form the codes of the material lots employed during the production, in order to trace the use of materials. The Progress Log section is filled out by LOs in order to write the quantity of hose products made during their shift. This is motivated by the fact that the completion of a MO could require multiple work shifts and, in some cases, some days; with this section, the LOs can check and trace the development status of an order, and inform LOs starting their work in the following shift. The Quality Checks section contains the results of data surveys performed during the production process, in order to verify that the products comply with the required standards. This section has a different layout depending on the MOF type, as different production articles require specific quality checks. Moreover, this section is periodically filled out by both LOs and QIs. Finally, the Other Input section in Figure 1 is used to indicate other and more specific document parts, which are present only in some kinds of MOFs and are used to include additional quality checks, additional descriptive sections, or additional inputs required by the specific production task. In general, these parts correspond to extra paper sheets printed and directly provided to the operators. In Figure 1, some examples of filled out MOFs are shown.

Due to their internal structure, most MOF layouts can be printed in a single paper sheet, while, in other cases, a single MOF, requiring more data, should be printed in more pages, up to a maximum of 4 pages. The protocol adopted by the company in order to monitor the productive process considers the following daily steps.

1. Each morning, the PSM staff prints the MOFs corresponding to the MOs planned for the current work day.

2. The printed MOFs are distributed and delivered to the supervisors of all factory departments. Then, the supervisor subdivides the MOFs on each department's production line.

3. Each LO starts his/her work and, during the shift, fills out all MOFs received by the supervisor.

4. Each QI starts his/her work and, moving among the lines, he/she periodically completes the quality section of the MOFs.

5. In the evening, each department supervisor collects the MOFs, corresponding to the completed MOs, and delivers them to the PSM staff.

6. Finally, the PSM staff manually scans all paper sheets and stores the obtained digital image, where inputs are only hand written.

3.2. Production Planning Management

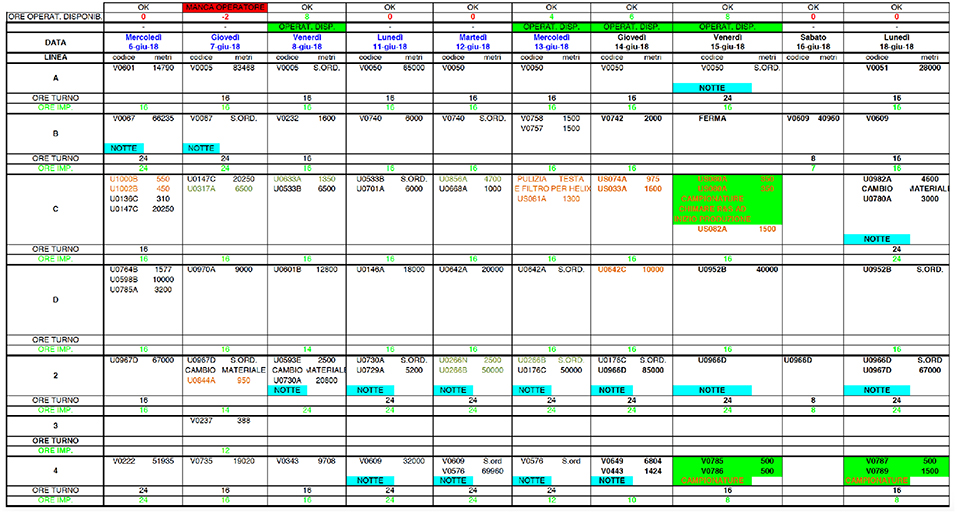

The work related to the production planning is an extremely important and time-consuming task for the partner company, as it strongly affects both results and performance of the subsequent activities. The planning, on one side, should fulfill the customer requirements and, on the other side, should try to use efficiently both machines and human resources on the lines. This activity is performed by the PSM staff with a sliding time window of about 2 months. At the beginning of the analysis described in this paper, the production planning was managed through the use of Excel-based spreadsheets, with different layouts and protocols depending on the specific department. An example of this kind of spreadsheet is shown in Figure 2, in which each row represents a production line in the department, while each column represents a working day. The thermoplastic hose items to be produced, with their required quantity (measured in meters), are placed inside the Excel cells (whose intersection identifies the evasion of an order on a specific working day and on a specific production line). In order to improve the productivity per line, each single production line is able to produce more than one article per day.

As can be easily understood, this manual process is extremely complicated and time-consuming for the PSMs, because it requires to take into account several factors, such as those explained in the following sections, and is not exempt from possible errors during data insertion.

3.2.1. Items to Be Produced

The first aspect that has to be considered in activity planning is related to the items (namely, the articles) that have to be produced. Handling this task requires to take into account several factors, such as: (i) the number of orders requested by the customers; (ii) the minimum stock quantity of goods that the company desires to maintain; and (iii) the workload of the lines, as it is desirable to schedule the activities without any production interruption and guarantying continuity.

3.2.2. Machine Characteristics and Configurations

The company, during the years of its activity, has incrementally acquired different machines with heterogeneous characteristics, in terms of efficiency and work velocity. Because of this, the same article may require a different production time depending on its specific production line and the corresponding machines: the newer ones can work faster, while the older ones may require more time. Moreover, each article has a suitable (optimal) production speed. Considering this element, the PSMs have to often perform a research in the historical data, to find the last production line and speed at which the specific article has been produced.

3.2.3. Workers Availability

Since the production lines are always managed by a LO, the planning activity must take into account the availability of the workers during each working day. The information related to the holidays, permissions, diseases and absences of the workers are stored in an external software that must be checked during the planning process, each time the planning process task has to be executed. More in detail, PSMs should know the total number of available hours, for each working day and factory department. In this way, person hours can be allocated on production lines during activity planning.

3.2.4. Configurations and Setup Delays

As stated before, the company can rely on several machines, distributed in various departments, with different performance. In order to start the production, each machine has to be configured and loaded with a specific amount of raw material required by the production schedule. This activity, here denoted as start delay, can require from 0 to 150 min, and must be repeated each time a restart of the machines on the line is needed. Other aspects to deal with are the setup delays, comprising all the delays introduced when raw materials should be substituted with other ones. As an example, since the company analyzed here can produce hoses of different colors, if the production planning switches from an article with color colorA to an article with color colorB, the LO on the line has to perform the following actions: (i) empty the machine from thermoplastic residues of color colorA; (ii) clean the machine to remove traces of colorA; (iii) load the machine with the new thermoplastic material with colorB; and (iv) setup the machine to start the production. This kind of operations can require up to 4 h, which represents a detrimental (in terms of wasted time) eventuality, corresponding to 50% of a regular work shift. If the PSMs ignore start and setup delays in the planning activity, the production rate can significantly degrade. Therefore, it is extremely important to minimize these setup times, maintaining, whenever possible, a production continuity of articles characterized by similar characteristics (such as colors and materials).

At the end of the planning process, the PSMs have filled an Excel file for a pre-defined time slot (generally, 1 month). In order to share the planning with the production departments, the PSMs have to manually insert the planned orders, one by one, into the company's ERP system. Moreover, a copy of the week planning is printed on paper sheets for the supervisors of each production department. The same behavior happens when the production planning should be modified because of delays and/or urgent requests coming from the customers.

3.3. Toward Industry 4.0: What to Change

Even if activities in the partner company are well organized and coordinated, the production management operated through paper sheets introduces several delays and does not scale, considering the gradually growing workload for the production. Also the planning phase has become extremely time-consuming, from a management point of view, as it requires to take into account a large number of details, and a deep knowledge of the production departments characteristics. Due to these reasons, the HQ management has decided to start a digitalization process with the aim of gradually removing inefficiencies and simplify processes. The company is already equipped with an ERP system that needs to be extended and integrated in order to manage also the aspects still involving the use of paper. In the following, the main identified issues and requirements are thus summarized.

Considering the manufacturing process monitoring activity, the company has highlighted several issues, among which the difficulty in managing updates in the production program is the most important one. In fact, if an order requires a modification, the steps to be followed to perform this change are the following: (i) the order is updated in the company ERP by the PSM and a new MOF version is generated; (ii) the new copy of the POF is printed; and (iii) the paper sheet is given to the LO on the line in the involved department. This operation can take even an hour or more, if the involved production order has already started. Another important weakness identified is that data related to production checks and monitoring are hand-written and stored as images, so that it is impossible to exploit them in post production analysis or, more simply, there is no way to perform searches and analyses in documents with automated tools. Moreover, data hand-writing is easily prone to errors, alterations, and checks are extremely difficult (as an example, if a LO or a QI make an error in writing a lot code number or a thickness measurement). Finally, the time required for the POFs management in the whole company is very long, considering all the steps, namely print, distribution, form filling, and data collection and scanning. In fact, in the partner company there is a specific employee who is exclusively dedicated to this activity. For this reason, the company was interested in starting a digitalization process with the aim of replacing paper sheets with a cross-platform and smart application, to be used by all the actors involved in the production monitoring task, through the use of mobile devices—in particular, tablets—which represent a viable and efficient solution where the use of PCs is not possible (e.g., next to factory lines).

Instead, considering the production planning activity, one of the main issues highlighted by the company is the impossibility to calculate, in a realistic way, the time required for the production of an article on a specific line. This is due to the fact that the production time can be calculated only considering all the aspects already highlighted in section 3.2: this requires the PSMs to retrieve all needed data asking information from different data sources and software (including, for example: the company ERP for stock levels; the external software to determine available LOs; the historical machine data on lines to define the correct production velocity to use; and so on). This approach is not scalable, as it makes PSMs waste a lot of time and requires a deep knowledge of the production processes. Moreover, also in this case there is a clear difficult in efficiently coping with production request updates, since each modification in the production planning (e.g., the deferment of an order from a day to the next one) can strongly affect the timing, on the same line, of adjacent orders, because new start or setup delays may be generated. For this reason, the company was looking for a new tool able to manage all these heterogeneous data sources, thus automatically performing the calculations needed to define orders duration and to notify the PSMs of possible delays. The Industry 4.0 tool developed by things2i hides the complexity of planning to the PSMs, making this task easily manageable also to employees who do not know in detail all the details associated with the production processes and machines.

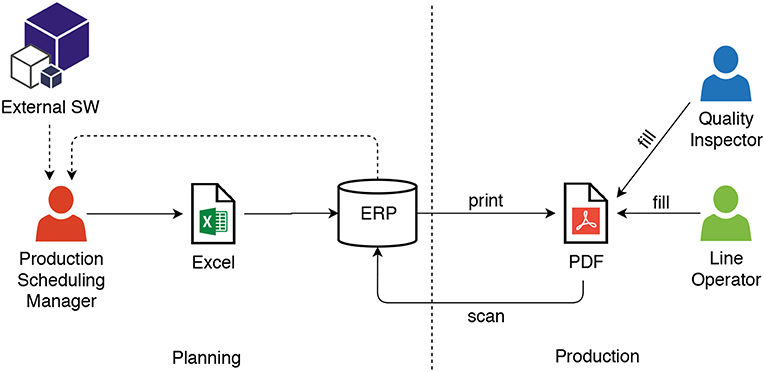

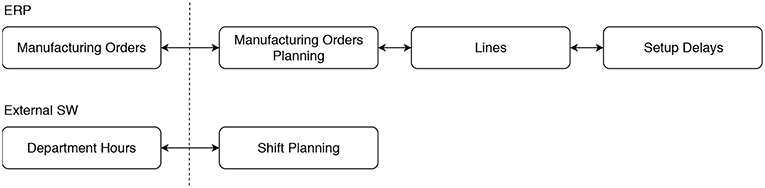

In Figure 3, the data flow going from the planning phase to the effective production, before the digitalization process, is summarized.

4. Production Monitoring Innovation

The main goal of the innovation process described in this section, adopted in the production monitoring, is to replace the use of MOFs, made by paper sheets, with a smart and digital application, thus allowing to:

• Collect data, related to the production, in a fast and easy way;

• Get rid of costs related to the print-scanning process;

• Facilitate the work of QIs and LOs in the different departments, through the adoption of mobile devices (e.g., tablets);

• Efficiently manage updates and changes in the production process, as well as face off with rising workload.

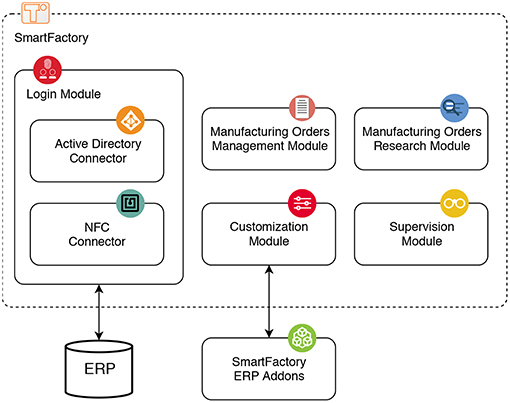

In order to abide by these requirements, a smart Web-based application, denoted as SmartFactory, has been designed and developed. The SmartFactory application is cross-platform, as it is used over different platforms (namely, PCs and mobile tablets), and is designed to be integrated with the company IT and ERP systems.

4.1. Digitalization of Data

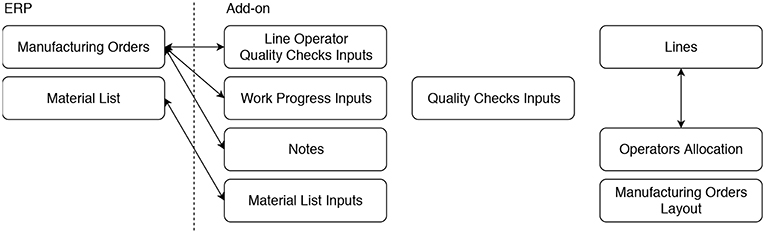

The first phase of the process has been devoted to a deep analysis of the MOFs layout employed in the different departments of the company, in order to characterize both nature and structure of the data to be collected, and to design a coherent database infrastructure able to efficiently store this kind of data. The company already relies on an ERP system, in which the orders to be produced are saved: on the basis of these, MOFs are generated and printed on paper sheets. The new SmartFactory application has been designed to interact with a renovated database structure, in order to store new data collected by users. More in detail, the new entities involved in the data digitalization process, shown in Figure 4, can be described as follows.

• Lines: the manufacturing lines active in the factory have been described in the ERP, in order to define their digital equivalent representation.

• Operators Allocation: even if the list of LOs is already existing in the company's ERP system, the SmartFactory application needs to know the authorization information related to which departments can be accessed by each LO.

• Manufacturing Orders Layout: each MO belongs to a specific department and is assigned to a specific line. This uniquely identifies the structure of the POF and, because of this, the possible sections composing POFs have been outlined in the ERP in order to allow the SmartFactory application to work.

• Quality Checks Inputs: the structure of the data inserted by QIs during their quality checks.

• Material List Inputs: contain a set of information inserted by LOs, in order to trace the usage of (raw) materials during the production.

• Work Progress Inputs: data submitted by LOs and concerning the work progression of each production order.

• LO Quality Checks Inputs: set of information related to LOs annotations, which in turn perform quality checks themselves during the production progress.

• LOs Specific Inputs: reflect the information that LOs are required to insert into the MOFs, such as the state of the order progression, as well as other information more specific for the specific order.

• Notes: additional annotations that can be added to the order by the authorized factory users (LOs, QIs, and PSMs).

4.2. SmartFactory Application

The SmartFactory application has been designed following the requirements of the partner company, targeting the use of Android platforms and smart devices with a limited screen size (in particular, tablets).

The first encountered problem, during both analysis of the requirements and deployment, is the log-in process, required to authenticate and authorize users on the access to the application and on their different internal functions. In fact, the SmartFactory application has been provided with two different log-in ways.

The first log-in mode is reserved to the PSMs, who access to the application from their office PCs and desire to access to the SmartFactory application through the same credentials they already use to access the company's network resources. The Authentication, Authorization, and Accounting (AAA) policies are already managed, in the company, through the use of the Windows Active Directory (AD) paradigm. Owing to this approach, the SmartFactory's log-in module has to interact with the company's AD, sending the submitted user credentials to the AD module, in order to check if the joining user is authorized or not to access to the company's resources.

The second log-in mode is specifically designed for LOs, who do not have centralized credentials in the company's AD and, accessing to SmartFactory in mobility through the use of tablets, can be authorized only using their personal Near Field Communication (NFC) badges, which are already employed in the company to access to the buildings. Due to this constraint, the log-in module of SmartFactory needs to include an NFC-based service, enabled only for mobile devices. By relying on the list of enabled NFC badges, in an AS400-based company's ERP, when a LO starts the SmartFactory application and puts his/her NFC badge near the tablet, SmartFactory retrieves the LO's User ID (UID) encoded into the NFC card, forwards it to a Web Service (WS) that, in turn, verifies if the UID is present in the ERP and, eventually, authorizes the user to log in the SmartFactory application.

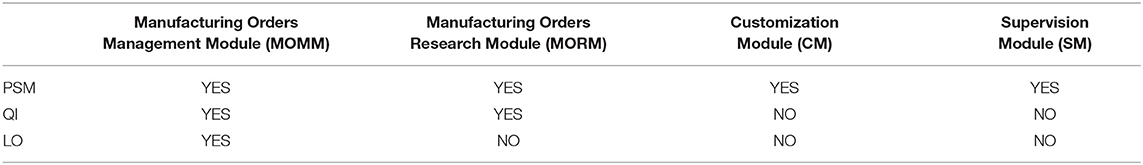

After the log-in phase, SmartFactory redirects the user to a separate home page, customized depending on his/her role. More in detail, the application is structured in different modules and each role defines the associated data visibility to the users; then, inside each specific module, each user is allowed to perform different operations (namely, Read-Only - RO, and Read-Write - RW). In the following, each module of the SmartFactory application is detailed. Table 1 summarizes the modules activated for each role.

The Manufacturing Orders Management Module (MOMM) allows users to view and manage data related to MOs and, in detail, represents the digital translation of paper-based MOFs. After the data retrieval on the order from the pre-existent ERP, MOMM builds the complete form view joining all sections needed for the orders of the current department. Unlike forms printed on paper, in the SmartFactory application the view of a single manufacturing order is personalized for the current user, enabling the interaction only on sections of his/her strict competence. In fact, LOs are allowed to view, as editable, only (i) the Material List section, (ii) the Progress Log section, and (iii) a customized Quality Check section. Moreover, in the application, LOs view only the active orders in the departments where they are enabled to work. Once completed, MOs become hidden to LOs on the lines. Instead, QIs are allowed to view, as editable, only the Quality Check sections, which can vary depending on the department. Finally, being PSMs views considered like supervisor views, they can interact with all sections of the MOFs in a RW way, for both active and completed orders. It is important to underline that sections which are not editable for some of the available roles are not hidden, but are shown in RO mode. In this way, all actors related to the production are always informed about the inserted inputs. In Figure 5, we show an example of a MOF in the SmartFactory application and how the MOMM changes the visualization for each of the three different user roles.

Figure 5. Detail page of an order for different roles, respectively (A) LOs view, (B) QIs view and, (C) PSMs view.

The view appearance has been designed, in collaboration with the partner company, in order to highlight problems and reduce errors. In fact, if the values inserted by LOs or QIs are not compliant with the article standards (i.e., the thickness of the hose is smaller or larger than the required one) the data are highlighted in red, in order to alert the user.

An essential feature, required in the digitalization process started by companies, is the possibility to find data of interest in a simple way. For this reason, SmartFactory includes a Manufacturing Orders Research Module (MORM), useful for both QIs and PSMs to find, in real time, data related to orders in production and, at the same time, to perform searches on historical data. More in detail, this module provides, to the users, a set of input parameters useful to filter orders and view inputs submitted during the production. Another functionality allows to find all MOs in which a raw material lot has been employed.

Another important aspect to take into account during the design of ERP-connected applications is to guarantee an acceptable degree of customization to the users. For this reason, the Customization Module (CM) has been included in SmartFactory, in order to allow the users, in particular the PSMs, to customize some aspects of the orders view. As an example, PSMs require to customize the colors of some portions of text in the MOF Description defined in section 3.1, in order to highlight some important production steps. As the color rules can be changed frequently, PSMs can manage them autonomously through the CM in the SmartFactory interface.

Finally, the Supervision Module (SM) allows the PSMs to verify the presence of problems related to the production orders. This module manages a specific page in SmartFactory, where the orders requiring a supervision from the PSMs are shown. The data to be checked, in order to identify this kind of problems, has been defined in conjunction with the partner company.

The overall architecture of the SmartFactory application, with reference to the modules and their interactions previously presented, is shown in Figure 6.

4.3. Technologies and Implementation

The SmartFactory application is a Single Tenant Web application written in PHP, HTML5, and JavaScript languages. The structure of the source code is organized in order to follow the Model-View-Controller (MVC) pattern, a software development approach aiming at separating the application logic from visual presentation and data interaction. More in detail, the main entities composing the SmartFactory tool are the following.

• Models: used to represent data structures and interact with the databases. They typically contain several methods needed to retrieve, insert, and update data inside the database tables.

• Views: used to present contents to the application user. They typically contain different Web-oriented fragments code (in particular, exploiting HTML, JavaScript, and CSS languages) that combine to compose the complete User Interface (UI) of the application.

• Controllers: used to implement the logic of the application. They act as intermediary entities between the Models, the Views, and any other resource needed to process the HTTP request and generate a Web page.

In order to guarantee a certain degree of interoperability, the new database has been included in the partner company's AS400 installation, and accessed through PHP-based Open DataBase Connectivity (ODBC) drivers.

4.4. Main Advantages

The SmartFactory application has been developed and gradually introduced in the partner company after a first phase of test and setup. After a first period of utilization, lasted a year, a report of gained benefits, advantages, and possible enhancements can be drawn. A first and more tangible effect is related to time saving, due to the fact that forms are no longer printed on paper sheets and nor manually scanned. Even the way to insert data from different actors has been simplified, since SmartFactory allows a simultaneous access to MOFs, allowing QIs, LOs, and PSMs to input and view data on the same production order without interfering with each other (while before the digitalization process, the MOFs paper sheet had to be shared, and PSMs cannot view the inserted data without going directly to the production lines, or having to wait the order completion). Another important aspect to be considered is the quantity of structured data gained with the adopted digitalization revolution, that are continuously collected and can be employed to real-time monitor the status of the production, but also constitute a basis for further analysis and statistics. We also asked the partner company to identify and quantify the positive aspects related to the introduction of SmartFactory. The results of these interviews can be detailed as follows:

• Visible data in the SmartFactory application are always up-to-date;

• Reduced paper consumption: avoiding printing 50,000 pages per year and scanning 50,000 filled pages, saving about 220 working hours per year and a non-negligible amount of storing errors;

• Digital logs of the processing activities;

• Digital traceability of the production history;

• Errors and non-conformity reduction, quantified in a saving range between €10,000 and €20,000 per year;

• Improvement of the know-how of the company related to digitalization aspects.

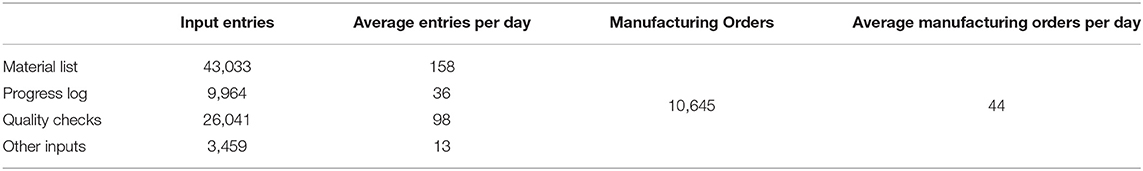

From a design point of view, the modular architecture characterizing SmartFactory makes the application itself easily extensible. In fact, new features can be integrated into the existent modules and new modules can be integrated ex-novo, in the case new roles or users appear in the manufacturing process. In Table 2, the quantity of inputs collected through the SmartFactory application during a one year period (namely, from November 1, 2017 to October 31, 2018) are summarized.

Table 2. Summary of the digitalized entries collected during the first year after the SmartFactory application introduction.

5. Production Planning Innovation

5.1. A Web-Based Production Planning Tool

After the conclusion of the first phase concerning the digitalization of the production monitoring activity, the innovation process has continued to analyze and include the production planning department of the partner company. The main goal of this second phase of the digitalization work is the replacement of the spreadsheet-based method, introducing a new planning tool, specifically designed for the company characteristics, and thus allowing to:

• Merge and display, in the same window, all the information needed to the PSMs for their planning activity;

• Speed up the production planning process;

• Hide the complexity behind the intersections among all the documents that have to be filled, the planning allocation calculations, and to reduce the effort required to the PSMs during their daily activity;

• Enable the integration with the subsequent modules of the company's ERP system (namely, the production and the SmartFactory application).

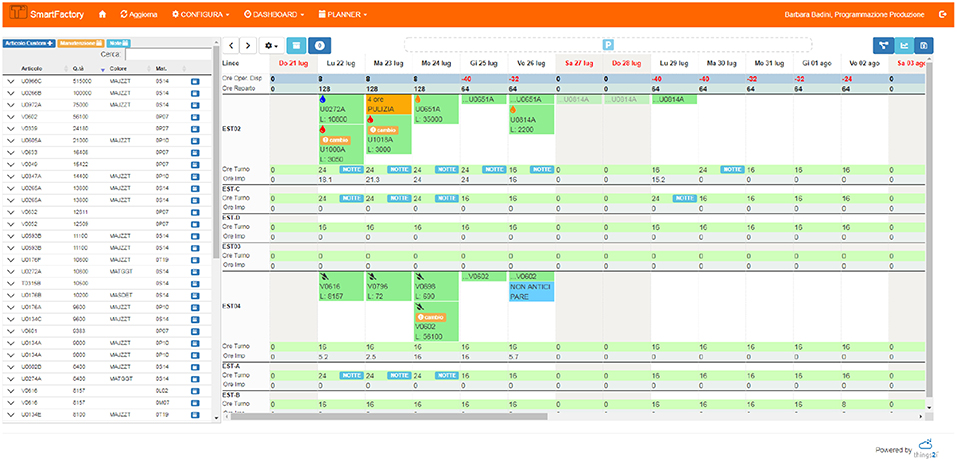

To fit these requirements, a smart and Web-based planning tool, denoted as SmartPlanner, has been designed and developed. The SmartPlanner application is intended to be used only by PSMs through a PC, and should be integrated with the company IT and ERP systems.

5.2. Data Digitalization

The planning activity is currently assigned to highly qualified staff, with a deep knowledge of all mechanisms regulating the whole workflow in the company, from provision office to sales department. Because of this, a first step toward a complete analysis of the planning procedures followed by PSMs has been an unavoidable requirement. This work has been aimed at gaining a comprehensive point of view concerning the PSMs way of thinking and their priorities, thus highlighting the differences between the different departments in the companies, and the variables that PSMs desire to maximize. After that, another ERP extension has been designed, in order to store all data related to the planning activity, which are not already registered in the company's ERP system. More in detail, the new entities involved are the following.

• Setup Delays: the description of possible delays that should be considered during the planning activity.

• Lines: the description of available production lines (corresponding to production machineries) and their associated delays.

• Planned MOs: the events list representing a planned order, namely the production of a specific quantity of an item assigned to a production line in a specific working day.

• Shift Planning: the number of hours allocated, for each working day, on each production line. In fact, PSMs define how long the production shifts have to be: generally, each shift can assume a value among 8, 16, or 24 h.

In Figure 7, the digitalized entities for the SmartPlanner application are summarized.

5.3. The SmartPlanner Application

The development of the SmartPlanner application is currently in progress, in order to reach all the features required by the partner company. As already stated, the application is targeted only for PSMs; thus, for the log-in phase, it has been reused the Microsoft AD connector proper of the SmartFactory's log-in module. Moreover, users PSMs access the application through their PCs, so that a single-page Web application paradigm has been followed. Moreover, the design phase has highlighted as indispensable the module described in the following.

The Scheduling Suggestions Module (SSM) is responsible for accessing the ERP system, in order to retrieve and show, to the PSMs, a list of articles to be produced. This list, updated by the company ERP system every night, is not complete, as it does not take into account the PSMs priorities; nevertheless, it represents a starting point onto which work. This module also provides the user the possibility to plan (in production) an item not already present in the suggestions list and also to plan special events, such as expected/unexpected production stops (i.e., for machine maintenance or faults).

The Shifts Manager Module (SMM) aims at managing all information related to LOs shifts. SMM contains two main components: (i) the People Connector, which retrieves the hours available in the department of interest, in a specific range of days, requesting data to an external WS adopted by the partner company to manage all employee presences; and (ii) the Shift Customizer, which allows PSMs to modify the amount of hours available in the department. This is needed as PSMs may decide to move LOs from a department to another one, to deal with high workload or unexpected events not yet saved in the People Connector component.

The Planning Events Module (PEM) is the core module of the SmartPlanner application, being responsible to manage the Graphical User Interface (GUI), made as a weekly-organized calendar, and the interactions with PSMs. As shown in Figure 8, the GUI allows PSMs to drag-and-drop manufacturing orders on the calendar-based view in which, in a representation similar to that of a spreadsheet structure, columns show the working days, while rows represent the production lines in the department subject to the planning activity. Thus, MOs are here considered as events on a calendar which contains also other types of information, such as shifts, employed hours, maintenance events and so on. The PEM is also responsible for calculating the effective duration of a MO event once it is placed on a specific cell (corresponding to the intersection of a specific working day and a specific production line). This calculation is performed considering: (i) the requested length of the hose; (ii) the production line's velocity, retrieved analyzing historical data from the ERP; (iii) the shift duration planned for the specific day; and (iv) configurations and setup delays.

Finally, the Production Manager Module (PMM) is responsible to store data inserted by PSMs and managing the interaction with the company ERP system, in order to move planned events to the production system, making digital MOs visible also in the SmartFactory application.

In Figure 8, the described modules and their interactions are shown. We remark that the adopted the same technologies are the same of those described in section 4.3 for the development of the SmartPlanner application.

5.4. Expected Advantages

As already stated, the SmartPlanner application is currently under development, and the following advantages are expected after its introduction. One of the most important advantage is the saved time, concerning different aspects: the first relates to the reduction of the number of hours directly spent by PSMs for the MOs scheduling activity, but it is important to consider also the reduction of time needed to train a new person dedicated to activity planning. In fact, the SmartPlanner application, hiding all aspects related to MOs' duration calculations and providing the user all required information in single view, strongly simplifies the work of PSMs, making possible for the company to assign this activity also to other people, with a minimized learning phase. Finally, the complete digitalization and automation of the planning process has allowed to make the complete company plan available to all interested users.

As an additional point of discussion and evaluation, we asked the partner company to identify and quantify their current costs related to the planning activity (in term of time spent for this activity, involving all the different tasks that the planning office has to perform daily), and the consequent benefits expected after the complete integration of the SmartPlanner tool. The benefits highlighted by these interviews are the following.

• Currently, the “hand-made” planning activity requires about 10 h per day. Owing to the introduction of the SmartPlanner tool, the partner company estimates a reduction on the order of 20% of the hours employed in the planning activity (about 500 h per year). This reduction is mainly due to the fact that the SmartPlanner tool can automatically send MOs from the planner directly to the production department. Thus, PMs will no longer be required to manually add MOs to the ERP system, thus leading to an error reduction in the data entry activity. Moreover, the partner company expects to employ the saved time in different activities with an higher value (e.g., improving the customer care support through a more timely assistance in case of errors and doubts).

• Finally, the partner company expects a certain improvement in the in-house know-how related to digitalization aspects.

6. Next Steps: Introducing IoT

The research efforts, in the last years, focusing on IoT have recently allowed the introduction of these technologies and paradigms also in several industrial application scenarios, leading to the concept of Industrial IoT (IIoT), which is strongly affecting both industry management and business processes. The digitalization and innovation process started by the partner company and described in the previous sections, constitutes a strong basis for new innovations, such as the introduction of IoT technologies, in order to reach a finer production monitoring, thus enhancing both productivity and quality of manufacturing technologies, and the introduction of distributed ledger-based technologies in order to provide a scalable traceability of activities and products. The work of Alaba et al. (2017) presents the development of IoT in industries, providing the current IoT key enabling technologies, research trends and challenges. The first fundamental technology identified for IIoT is the RFID technology, which allows microchips to transmit the identification information to a reader through wireless communication. RFID readers and tags are thus largely employed in the manufacturing to identify, track, and monitor any objects. Another important technology is the wireless sensor networks (WSNs), which mainly use interconnected intelligent sensors to sense and monitoring in the industrial environment. Moreover, many other heterogeneous technologies and devices have been included, spanning from barcodes and smartphones, till social networks, and Cloud Computing, as introduced by Belli et al. (2015, 2016). Instead, Shrouf et al. (2014) focus their work on the sustainability perspective, proposing an approach for energy management in smart factories based on IoT technologies, following different steps.

With regards to the application of distributed ledger-oriented technologies in industrial scenarios, it can be interesting to analyze the use of the blockchain concept since, as introduced by Miller (2018), it allows to store and share relevant data, captured from several IoT-oriented industrial machinery, on a decentralized and distributed ledger, which the business network's actors can access to. In IIoT, the blockchain can be useful for both the companies and their customers. In the case of companies, each component of a final product can be traced from its purchase to the inclusion in the final product itself, thus providing a complete traceability, and allowing a more easier warehouse inventory. In the case of customers, the blockchain allows them to know the status of purchased goods and, in case of problems, it is easier to alert the company of possible lots of failed pieces. Another benefit brought by the introduction of a blockchain-oriented approach is the prevention and prediction of failures for manufacturing plant equipment, leading to the predictive maintenance concept. More in detail, as highlighted in the work of Teslya and Ryabchikov (2017), sensors would detect conditions which might lead to operator injury or failures; then, the application of threshold-based decisions would be used to detect trends and facilitate proactive maintenance, acting before the failure occurs (being able to create a Digital Twin emulating the real production lines' operations). The application of Business Intelligence (BI)-oriented analytics would increase reliability, optimize maintenance, and allow operational personnel to gain more accurate insights into asset performance. Hence, these events can be recorded inside the blocks of the chain and ease rapid and precise inspections and certifications by external regulatory entities, having that these storage operations have to be tamper-proof, thus not requiring real-time execution constraints (as known, interactions with the blockchain require time to be confirmed (either in permissioned or permissionless blockchains).

7. Conclusions

The proposed work describes the process of renovation followed by a real manufacturing company and guided by the University of Parma's spin-off things2i s.r.l. This process, started two years ago and currently on-going, has focused on two main aspects of the company management. The first phase of the work is related to the digitalization and renovation of the monitoring process proper of production lines, through the introduction of SmartFactory, a smart Web-based application, which is now deployed in the company and accessed by different roles related to production, namely LOs, QIs, and PSMs. SmartFactory overcomes the use of paper sheets, initially used in the company to perform the same activity. The second phase of the process, which is currently ongoing, is targeted only to PSMs in the company, and is related to the production lines scheduling. The result of this work, denoted as SmartPlanner, is a Web-based tool which help to organize the production, hiding complex calculations needed to estimate the duration of production orders. The changes introduced in the partner company have led to significant advantages and improvements, in terms of: (i) significant reduction of cost, considering the amount of time and used materials saved; (ii) better and finer quality control of the products; (iii) possibility of real-time detection and reaction to supply chain issues and production errors; (iv) significant reduction of time spent in planning activity; and (v) optimized resources employment, thanks to the minimization of unproductive setup times of production lines.

The advantages brought by SmartFactory and SmartPlanner justify both efforts and investments made by the partner company, allowing a very fast return of investments. The provided real application shows how the transition from a usual business process management concept to the upcoming Industry 4.0 is feasible, following consecutive and incremental steps.

Author Contributions

LB, LD, and GF have made substantial contributions to the following: drafting the article and revising it critically, and final approval of the version to be submitted. AM and PM revise and approve the final version of the manuscript to be submitted. Each of the authors has read and concurs with the content in the manuscript. The manuscript and the material within have not been and will not be submitted for publication elsewhere.

Funding

The work of LD was also partially funded by the University of Parma, under Iniziative di Sostegno alla Ricerca di Ateneo program, Multi-interface IoT systems for Multi-layer Information Processing (MIoTYMIP) project.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

All the staff of things2i s.r.l. would like to thank Transfer Oil S.p.A., and in particular Massimo Conti, Moris Bandini, Barbara Badini, Marco Palermo, Luca Gambardella, Marco Brunelli, Corrado Chezzi, and Fabio Rametta, for their support in the definition and development of the Industry 4.0 approach explained in this work.

References

Alaba, F. A., Othman, M., Hashem, I. A. T., and Alotaibi, F. (2017). Internet of things security: a survey. J. Netw. Comput. Appl. 88, 10–28. doi: 10.1016/j.jnca.2017.04.002

Belli, L., Cirani, S., Davoli, L., Ferrari, G., Melegari, L., Montón, M., et al. (2015). A scalable big stream cloud architecture for the internet of things. Int. J. Syst. Ser. Orient. Eng. 5, 26–53. doi: 10.4018/IJSSOE.2015100102

Belli, L., Cirani, S., Davoli, L., Ferrari, G., Melegari, L., and Picone, M. (2016). Applying security to a big stream cloud architecture for the internet of things. Int. J. Distribut. Syst. Techn. 7, 37–58. doi: 10.4018/IJDST.2016010103

Borangiu, T., Trentesaux, D., Thomas, A., Leitão, P., and Barata, J. (2019). Digital transformation of manufacturing through cloud services and resource virtualization. Comput. Indust. 108, 150–162. doi: 10.1016/j.compind.2019.01.006

Civerchia, F., Bocchino, S., Salvadori, C., Rossi, E., Maggiani, L., and Petracca, M. (2017). Industrial internet of things monitoring solution for advanced predictive maintenance applications. J. Indust. Inform. Integrat. 7, 4–12. doi: 10.1016/j.jii.2017.02.003

Davenport, T. H. (1998). Putting the enterprise into the enterprise system. Harvard Bus. Rev. 76, 121–131.

Ein-Dor, P., and Segev, E. (1978). Organizational context and the success of management information systems. Manage. Sci. 24, 1064–1077.

Gremillion, L. L. (1984). Organization size and information system use: an empirical study. J. Manage. Inform. Syst. 1, 4–17.

Harris, S. E., and Katz, J. L. (1991). Firm size and the information technology investment intensity of life insurers. MIS Quart. 15, 333–352.

Huberty, M. (2015). Awaiting the second big data revolution: from digital noise to value creation. J. Indust. Compet. Trade 15, 35–47. doi: 10.1007/s10842-014-0190-4

Iivari, M., Ahokangas, P., Komi, M., Tihinen, M., and Valtanen, K. (2016). Toward ecosystemic business models in the context of industrial internet. J. Busin. Models 4, 42–59. doi: 10.5278/ojs.jbm.v4i2.1624

Mabert, V. A., Soni, A., and Venkataramanan, M. (2001). Enterprise resource planning: common myths versus evolving reality. Busin. Horiz. 44, 69–76. doi: 10.1016/S0007-6813(01)80037-9

Mabert, V. A., Soni, A., and Venkataramanan, M. (2003). The impact of organization size on enterprise resource planning (ERP) implementations in the US manufacturing sector. Omega 31, 235–246. doi: 10.1016/S0305-0483(03)00022-7

Miller, D. (2018). Blockchain and the internet of things in the industrial sector. IT Profess. 20, 15–18. doi: 10.1109/MITP.2018.032501742

Parviainen, P., Tihinen, M., Kääriäinen, J., and Teppola, S. (2017). Tackling the digitalisation challenge: how to benefit from digitalisation in practice. Int. J. Inform. Syst. Project Manage. 5, 63–77. doi: 10.12821/ijispm050104

Quinton, S., and Simkin, L. (2016). The digital journey: reflected learnings and emerging challenges. Int. J. Manage. Rev. 19, 455–472. doi: 10.1111/ijmr.12104

Raymond, L. (1990). Organizational context and information systems success: a contingency approach. J. Manage. Inform. Syst. 6, 5–20.

Shrouf, F., Ordieres, J., and Miragliotta, G. (2014). “Smart factories in Industry 4.0: a review of the concept and of energy management approached in production based on the Internet of Things paradigm,” in 2014 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM) (Bandar Sunway: IEEE), 697–701.

Swanson, E. B. (1994). Information systems innovation among organizations. Manage. Sci. 40, 1069–1092.

Teslya, N., and Ryabchikov, I. (2017). “Blockchain-based platform architecture for industrial IoT,” in 2017 21st Conference of Open Innovations Association (FRUCT) (Helsinki), 321–329.

Ustundag, A., and Cevikcan, E. (2018). Industry 4.0: Managing The Digital Transformation. Cham: Springer.

Wank, A., Adolph, S., Anokhin, O., Arndt, A., Anderl, R., and Metternich, J. (2016). Using a learning factory approach to transfer industrie 4.0 approaches to small- and medium-sized enterprises. Procedia CIRP 54, 89–94. doi: 10.1016/j.procir.2016.05.068

Yap, C. S. (1990). Distinguishing characteristics of organizations using computers. Inform. Manage. 18, 97–107.

Keywords: Internet of Things, Industry 4.0, business process, SmartFactory, SmartPlanner, digitalization

Citation: Belli L, Davoli L, Medioli A, Marchini PL and Ferrari G (2019) Toward Industry 4.0 With IoT: Optimizing Business Processes in an Evolving Manufacturing Factory. Front. ICT 6:17. doi: 10.3389/fict.2019.00017

Received: 01 February 2019; Accepted: 13 August 2019;

Published: 28 August 2019.

Edited by:

Francesca Odone, University of Genoa, ItalyReviewed by:

Thinagaran Perumal, Putra Malaysia University, MalaysiaGiorgio Delzanno, University of Genoa, Italy

Copyright © 2019 Belli, Davoli, Medioli, Marchini and Ferrari. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luca Davoli, bHVjYS5kYXZvbGlAdW5pcHIuaXQ=; bHVjYS5kYXZvbGlAdGhpbmdzMmkuY29t

Laura Belli

Laura Belli Luca Davoli

Luca Davoli Alice Medioli

Alice Medioli Pier Luigi Marchini1,3

Pier Luigi Marchini1,3 Gianluigi Ferrari

Gianluigi Ferrari