94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Ecol. Evol., 28 October 2022

Sec. Environmental Informatics and Remote Sensing

Volume 10 - 2022 | https://doi.org/10.3389/fevo.2022.1033935

This article is part of the Research TopicAdvancement in Quantitative Risk Analysis of Geological Disaster in Reservoir AreasView all 8 articles

The deterioration of rock mass under dynamic mechanical state is difficult to determine, especially when evolution trends of micro-fractures are considered. Taking the limestone from Wuxia section of the Three Gorges Reservoir area as studying case, cross-scale tests and theoretical analysis were adopted to study the influence of dry-wet cycles on rock deterioration. The weakly acidic condition (pH = 6) and the dry environment at 105°C were together constituted the two extreme mechanical states of the dry-wet cycles. Meanwhile, the number of dry-wet cycles and soaking time were used as the main variables to analyze the deterioration trend. After introducing the damage mechanics, the quantitative relationship between the mechanical parameters and changing mechanical states was obtained. Combined with the microstructure obtained by scanning electron microscope (SEM), it can be found that with the increase of dry-wet cycles and soaking time, the morphology of mineral particles changed, the number of secondary pores gradually increased, the surface structure became looser, and the microcracks gradually increased, causing the decrease of macro strength. The related method proposed in this paper could provide significant references to determine the mechanical parameters of rocky reservoir bank.

The development of rock mechanics and engineering involves transportation engineering, geological engineering, civil engineering, hydropower engineering and other professional fields of economic construction (Feng et al., 2019; He et al., 2021; Lawal and Kwon, 2021; Wu et al., 2021; Wang et al., 2022; Zhuang et al., 2022). As a material with heterogeneous, discontinuous and anisotropic, the rock mass’s deformation characteristics can be reflected by the constitutive model. Dougill et al. (1976) firstly proposed the problem of damage mechanics for rock material, and Dragon and Mróz (1979) established a continuum damage mechanics model that can reflect strain softening. Then, the related theory was applied to different aspects, and the damage mechanism was established to study the brittle damage problem based on the structural characteristics of rock mass (Krajcinovic and Fonseka, 1981; Krajcinovic and Silva, 1982). By introducing the damage models, the evolution process of rock can be further quantified. Based on the continuum damage mechanics, Li et al. (2015) proposed a statistical damage constitutive model under the complex stress state, which can reasonably predict the stress-strain relationship of soft rock, especially the strain softening behavior. Based on the constitutive model related to the Weibull distribution and unified strength theory, Shen et al. (2019) developed damage mechanics by considering the statistical damage, strain softening and damage weakening of rocks in the deformation process.

The physical and mechanical properties of rock mass are different, caused by the complexity and variability of the geological environment (Parise et al., 2015; Rehman et al., 2021). There are a large number of landslides and dangerous rock masses in the Three Gorges Reservoir area, posing a severe threat to the property and life of the surrounding people (Yin et al., 2015, 2017; Zhou et al., 2022a). Since the Three Gorges Reservoir stored water in 2008, a hydro-fluctuation belt with a length of more than 150 km is dominated by carbonate rocks (Yin et al., 2016).

Due to the periodic fluctuation of water levels (Wang et al., 2021a,b; Zhou et al., 2022b), the carbonate rocks on the reservoir banks deteriorated under the water-rock action, and their integrity and strength gradually decreased (Zhang et al., 2022). In order to analyze the deterioration trend of rock mass, the dry-wet cycle tests are often used to simulate the complex dynamic mechanical environment (Wang et al., 2020b,c). This indoor test method can mimic the deterioration progress of the actual condition in a relatively short time. After obtaining the test data, the relationship between macro strength and micro damage can be investigated through the damage constitutive model to finish the cross-scale analysis. However, the existing research still has a significant gap with the reservoir banks regarding dynamic mechanical states. In this case, taking the limestone in the Wuxia section in the Three Gorges Reservoir area as the research object, the macro and micro tests were used to study the deterioration of rock samples under water-rock action. Based on the test results, the constitutive models of rock mass were obtained to quantify the deterioration trend. It can provide significant references for the stability evaluation of rocky banks under changing mechanical states.

The Jianchuandong dangerous rock mass is located in the left bank of the Wuxia section of Yangtze River (Figure 1), with an average height of 114 m, a width of 15∼50 m, and a volume of about 35.75 × 104 m3. The landform of the study area was in the shape of a “V” with deep cut and eroded. The overall gradient of the medium-steep slope was 40∼50°. The relatively developed fissures in the lower part had accelerated the water-rock interaction, and the strength of the base rock mass gradually decreased (Wang et al., 2020a,b,c). If this type of rocky reservoir banks collapse, it would directly threat the shipping vessels and cause a surge hazard (Yin et al., 2022). Since this specific carbonate rocks are widely distributed in high-steep canyon areas, it is significant to study their deterioration characteristics.

The compact limestones in the study area were collected, and the mineral contents were tested by the polarized light microscope. The mineral compositions of the rock samples were mainly calcite, with a small amount of bioclastic, clay minerals, chlorite and quartz (Figure 2). Calcite was in the shape of xenomorphic granular, generally less than 0.03 mm in particle size, with micrite structure, prominent amphibious protrusions, and high-grade white interference color. Clay minerals were distributed in irregular stripes with small amounts of chlorite and quartz. Trilobites were fiberglass structures interspersed with a few late-stage calcite veins.

The test method of dry-wet cycles was the basis for studying the rock damage under water-rock action. The differences in drying, saturation and soaking time will directly influence the mechanical states of rock. Scholars have conducted in-depth research on dry-wet cycles with different rocks in recent years. However, previous studies were mainly concentrated on rock samples with high water absorption, the compact rocks were rarely involved. The cylinder rock samples with diameters of 50 mm and heights of 100 mm were used to calibrate the method of dry-wet cycles (Liu et al., 2018; Wang et al., 2020b). Specifically, the vacuum saturation method was used to achieve the saturation process, and the drying process was carried out in an oven at 105°C. These test results provided essential data for subsequent experiments on different water-rock interactions.

It can be found from Figure 3 that after the constant drying environment in the oven, the moisture contents of samples decreased after 48 h and were basically in a stable state, and the moisture contents at this time were about 8%. Under the vacuum-saturated conditions, the sample’s moisture contents reached about 93% in the first 48 h, then gradually increased to 98%. Therefore, based on the preliminary experiments, the drying and saturation time in the subsequent study was 48 h.

According to the related references (Liu et al., 2018; Wang et al., 2020a), the number of dry-wet cycle tests are designed involving 1, 3, 6, 10, 15, and 30 cycles. The prepared limestone samples were placed vertically in a vacuum chamber, and the pump air was used to make the vacuum chamber reach a negative atmospheric pressure, and the pressure was kept for 6 h. Then the valve was turned off and the solution with pH = 6 was added until the samples were completely submerged. After 2 days, the limestone samples were taken out; this state was set as saturated. The samples were moved to an oven and the temperature was set to 105°C, and the samples were taken out after 2 days; this state was set as dry. Under this condition, the soaking time of each cycle was 2 days, and it took about 130 days to complete 30 dry-wet cycles. The specific experimental design for water-rock interactions is shown in Figure 4.

The southwest region used to be one of China’s earliest areas polluted by acid rain (Zhang and McSaveney, 2018). The mineral components in rock will be dissolved under acidic solution, leading to the variation of strength parameters and microstructures. In this case, the solution with pH = 6 prepared with HNO3 was used in the test. Due to the continuous reaction between rock samples and solution during the test, the pH value of solution will change dynamically. Therefore, we periodically kept calibrating the pH of the solution to ensure the pH was at a constant value.

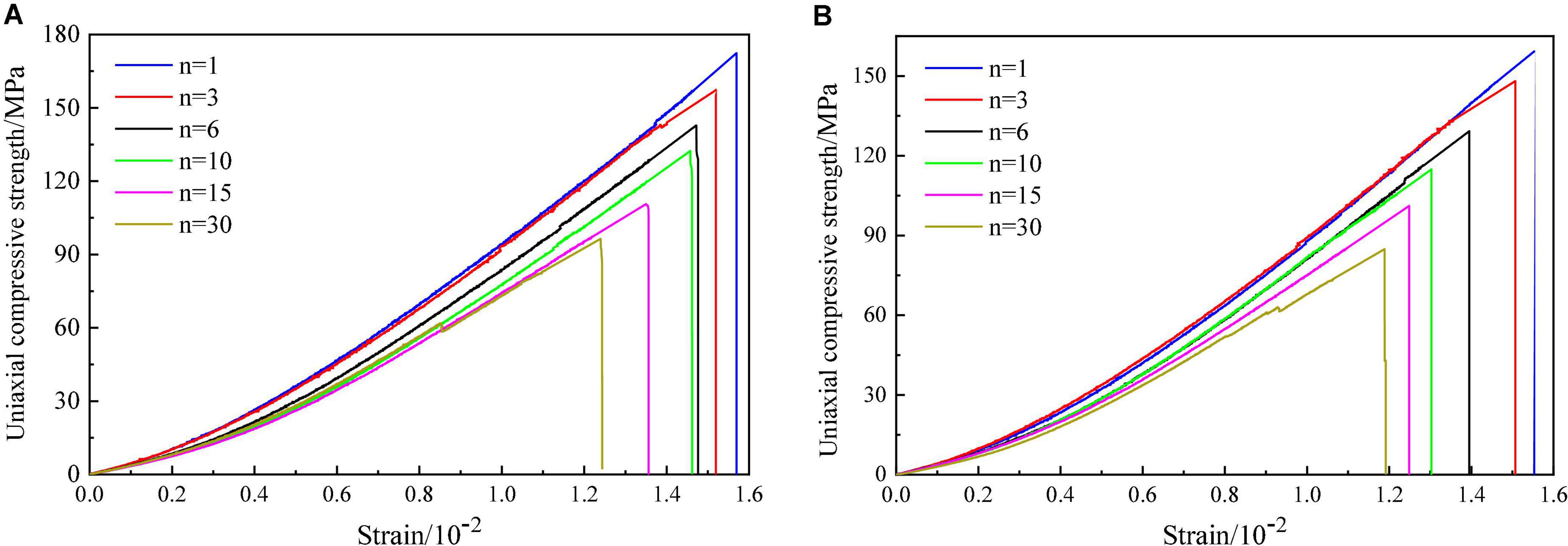

The failure process and the corresponding stress-strain curves under dry-wet cycles were obtained (Figure 5). It can be found that with the increase in the number of dry-wet cycles, the plastic strains of samples decreased obviously. When the strain reached the peak points, the stress dropped instantly, and the samples were instantly destroyed without residual deformation.

Figure 5. Stress-strain curves of the limestone during dry-wet cycles (n represents the number of dry-wet cycles). (A) The dry state of rock samples; (B) the saturation state of rock samples.

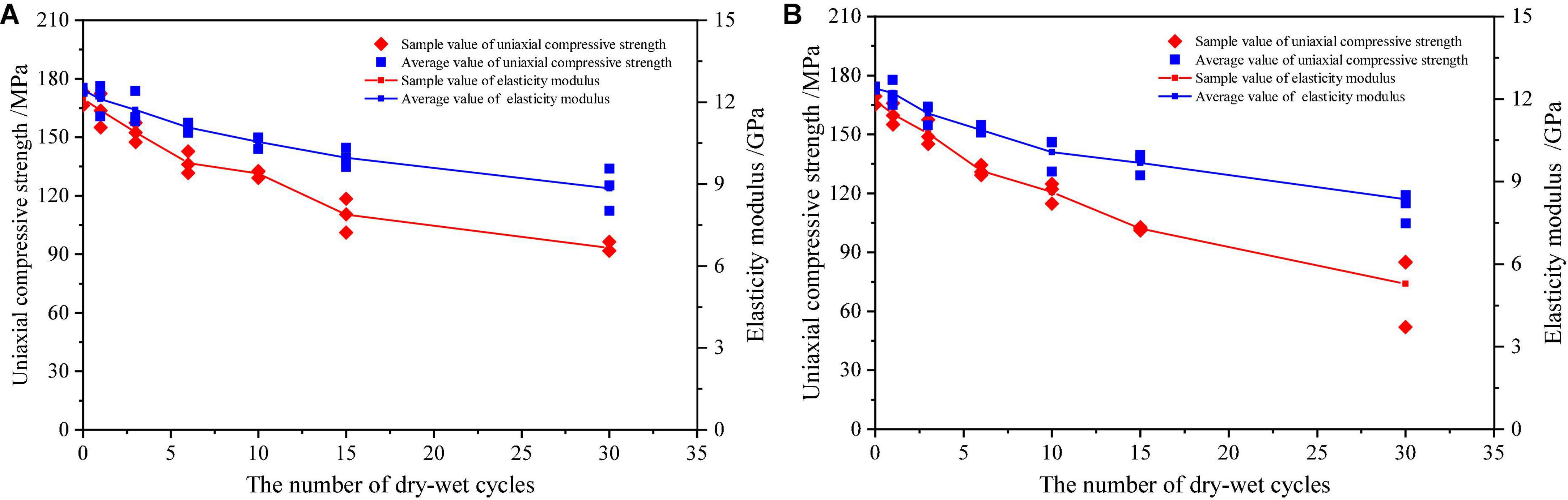

The uniaxial compressive strength (σc) and elastic modulus (E) of the rock samples decreased obviously after dry-wet cycles (Figure 6). Specifically, after 30 dry-wet cycles, the σc and E of samples in the saturation state dropped by 49.20 and 32.53%, respectively. Meanwhile, after 30 dry-wet cycles, the σc and E of samples in the dry state dropped by 45.03 and 29.00%, respectively.

Figure 6. Parameters of the limestones during dry-wet cycles. (A) The dry state of rock samples; (B) the saturation state of rock samples.

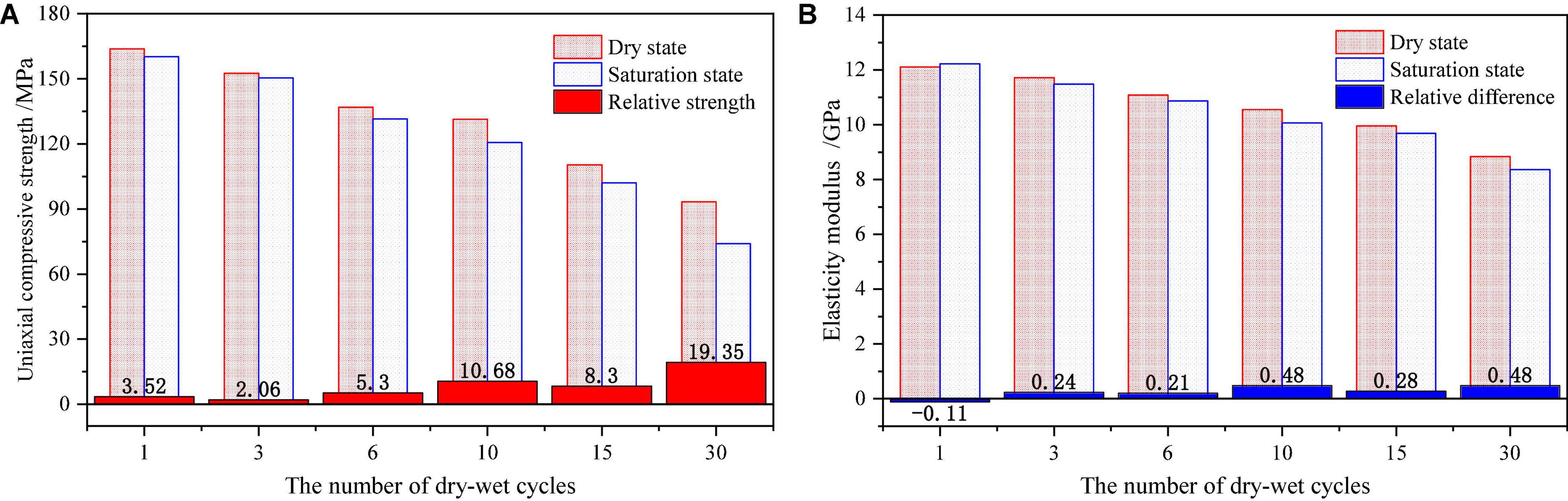

Most researchers studied the strength of the rock in dry state after dry-wet cycles (Liu et al., 2018; Li et al., 2021). However, the influences of dry-wet cycles under different states may be different (Figure 7). The results showed that the mechanical parameters of saturated limestone under the same number of dry-wet cycles (n) are basically smaller than those in the dry state. With the increase in dry-wet cycles, the difference values of σc and E between the saturation and dry state presented increasing trends. After 30 dry-wet cycles, the difference of σc increased from 3.52 to 19.35 MPa, and the difference of E increased from –0.11 to 0.48 GPa. Notably, based on the actual test data, it can be found that there are some conflicts with the overall trend due to the discreteness of the rock sample. However, the error of single data does not affect the status of elasticity modulus. As for the compact limestone used in this paper, due to the low water content, the difference in mechanical parameters between the saturated and dry state at low cycle times was small. With the increase of dry-wet cycles, the influence of moisture content on the strength will be greater.

Figure 7. Relationship between dry-wet cycles and mechanical parameters under different states. (A) The trend of uniaxial compressive strength; (B) the trend of elasticity modulus.

There are tiny fissures on the surface or inside of rock (generally referring to voids or cracks less than 1 mm), and the existence and expansion of fissures are the main reasons for the decline of the strength. When mechanical environments are changed, defects are continuously generated, causing the deterioration of rock or structure. This process is defined as damage (Zhao et al., 2017). As described above, it can be found that under the action of dry-wet cycles, the mechanical strength parameters of rock will gradually decrease, indicating that the internal micro-defects in rock are intensified due to the continuous erosion of the solution.

According to the strain equivalence theory proposed by Lemaitre et al. (1992), the effect of damage on the rock can be expressed in terms of equivalent stress. During the dry-wet cycles, the internal structure of limestone will change, leading to a change in the macro-mechanical strength of limestone. The degree of deterioration D can be used to quantitatively analyze the effect of the dry-wet cycle on the strength of limestone; thus, the total deterioration can be defined as:

The average degree of deterioration within a stage is:

Where σ0 is the initial mechanical parameter of limestone before water-rock interaction (i.e., dry-wet cycle and long-term soaking); σj is the mechanical parameters of limestone after n dry-wet cycles or t days soaking; Nj is the specific number of dry-wet cycles or the soaking day.

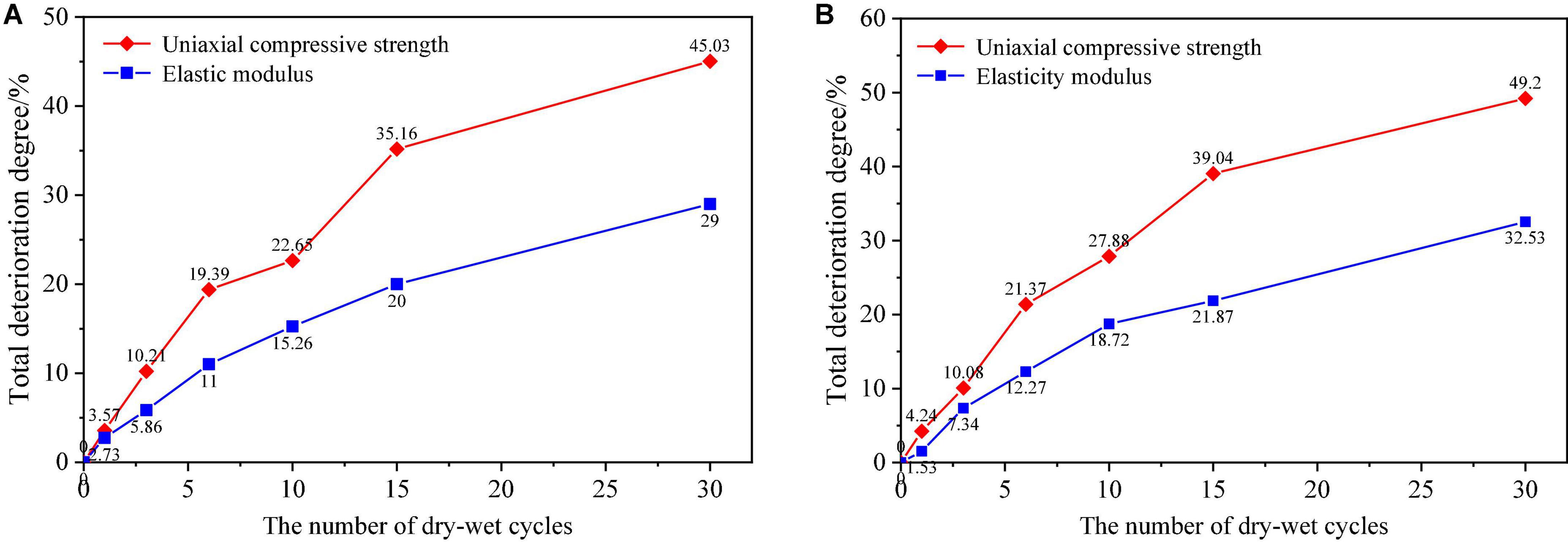

It can be seen from Figure 8 that with the increase of dry-wet cycles, the deterioration degree of σc and E gradually increased, while the deterioration degree of the saturated state was slightly larger than that of the dry state at the same number of cycles. The results indicated that the damage caused by dry-wet cycles is a progressive process. The speed of damage accumulation is fast in the early stage, and gradually tends to be gentle latterly. Moreover, the deterioration degree of the σc was greater than that of E.

Figure 8. The total deterioration under dry-wet cycles. (A) The dry state of rock samples; (B) the saturation state of rock samples.

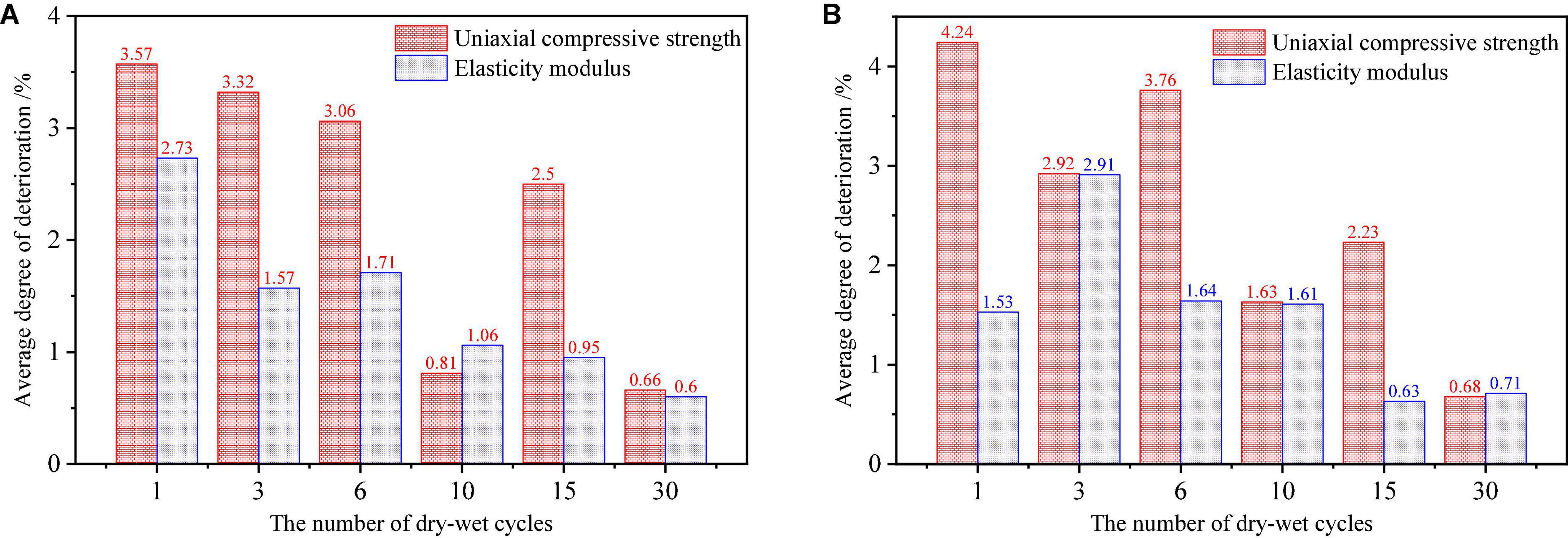

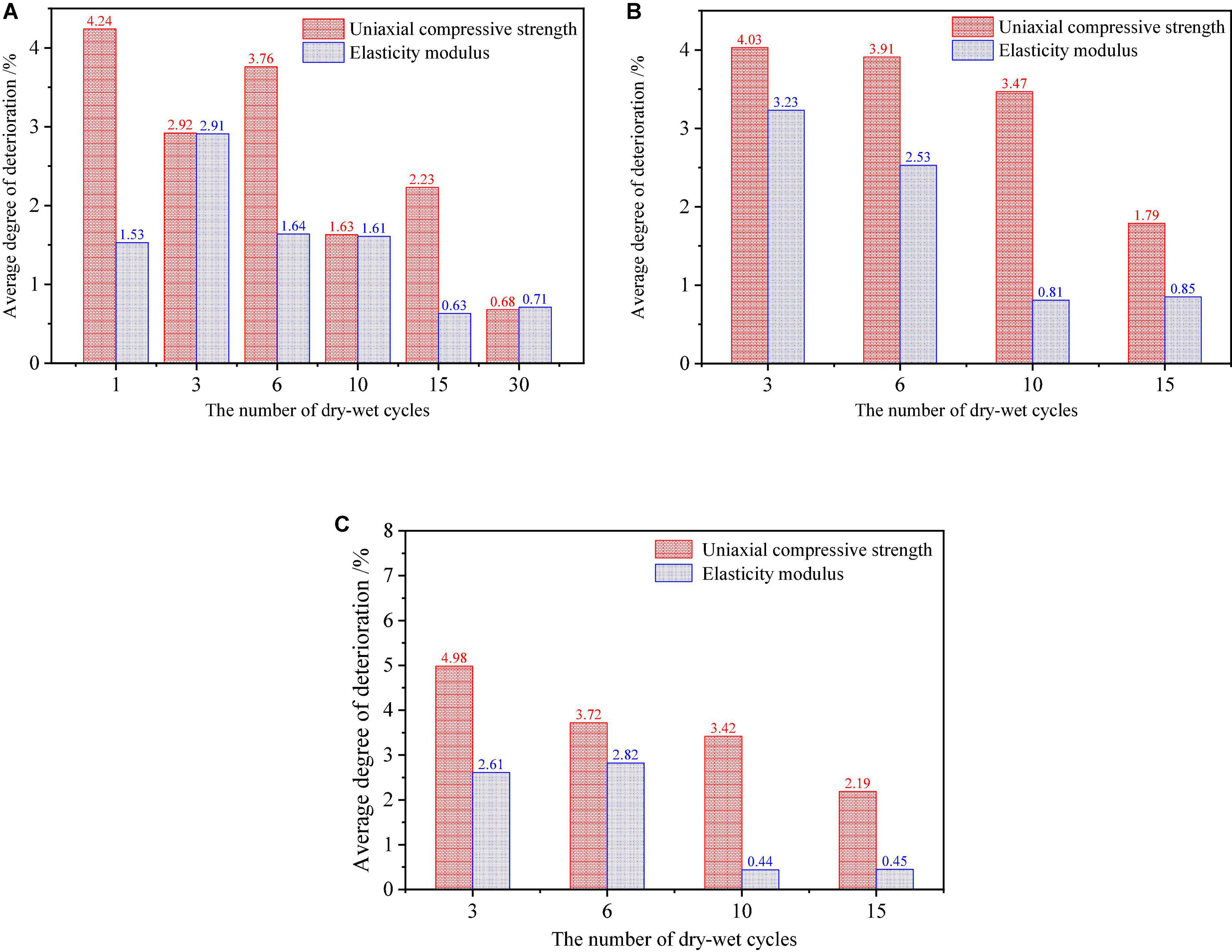

Figure 9 shows the average degree of deterioration under dry-wet cycles. With the increase of dry-wet cycles, the average degree of deterioration of σc basically maintained a gradually decreasing trend. The average degree of deterioration of E exhibited a decreasing trend as a whole. After 10 dry-wet cycles, the degree of deterioration showed a significant decrease. The changing trends of σc and E showed that the damage degree of saturated samples was larger in the early stage and gradually decreased in the later stage.

Figure 9. The average degree of deterioration under dry-wet cycles. (A) The dry state of rock samples. (B) The saturation state of rock samples.

Assuming that σc and E of samples vary continuously with the increase of the number of dry-wet cycles, the experimental data results can be fitted as followings:

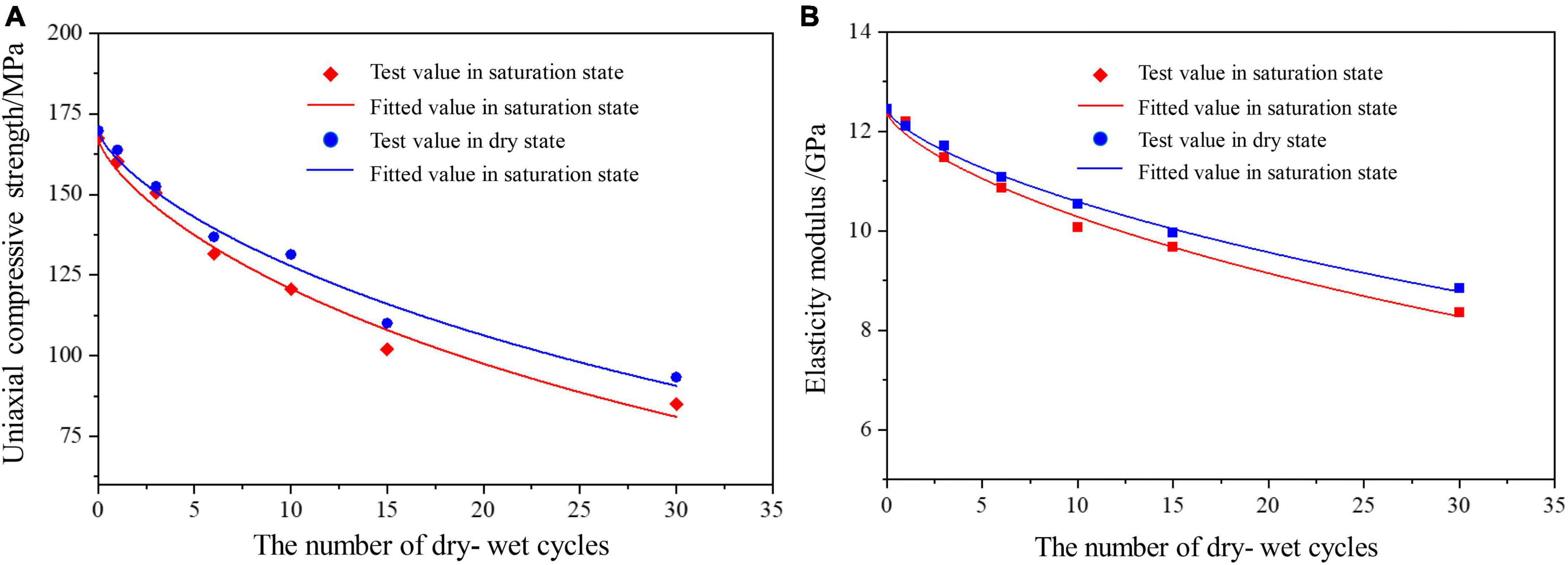

Where and are the uniaxial compressive strength in the initial saturated and dry states; and are the elastic modulus in the initial saturated and dry states. According to the above fitting function formulas, the curves of uniaxial compressive strength and elastic modulus with the number of dry-wet cycles can be obtained (Figure 10).

Figure 10. The changing trends of the uniaxial compressive strength and elastic modulus under dry-wet cycles. (A) The trend of uniaxial compressive strength; (B) the trend of elasticity modulus.

The strength of rock is a random variable affected by various factors. Since these different factors are independent of each other and have specific statistical laws, the strength can be described by the statistical distribution. Assuming that the strength of rock follows the Weibull distribution, its probability density function is:

Where ε is the strain of rock; m and F are the Weibull distribution parameters.

The damage to rock is caused by the destruction of micro-elements inside the rock. Herein, the ratio of the number of damaged micro-elements Nε to the total number of micro-elements N is defined as the rock statistical damage variable D, which is:

According to the theory of continuum damage mechanics, the following constitutive relation can be obtained:

Where E and ε are the elastic modulus and strain of non-destructive rock, respectively. After substituting Equation (6) into Equation (7), the stress-strain relationship can be obtained as:

The parameters m and F in Equation 8 can be determined from the peak point of the stress-strain curve c(εc,σc), and the slope at the peak point is 0, so there are:

Where εc is the peak strain. The peak intensity value c(εc,σc) satisfies the Equation:

According to Equations (9, 10), we can get:

Substituting Equation (12) into Equation (6), the statistical damage evolution Equation can be obtained as:

Therefore, the constitutive relation of rock damage statistics can be established:

According to damage mechanics and statistical evolution Equations, the damage evolution models of limestone under dry-wet cycles can be established. The relative errors between laboratory test values and estimated values were basically less than 10%, and most errors were less than 5%, indicating the validity of the damage constitutive models (Figure 11).

To study the effect of soaking time on the mechanical parameters, two test conditions were performed: the soaking time of 5 and 10 days. On this basis, uniaxial compression tests were carried out after 3, 6, 10, and 15 dry-wet cycles.

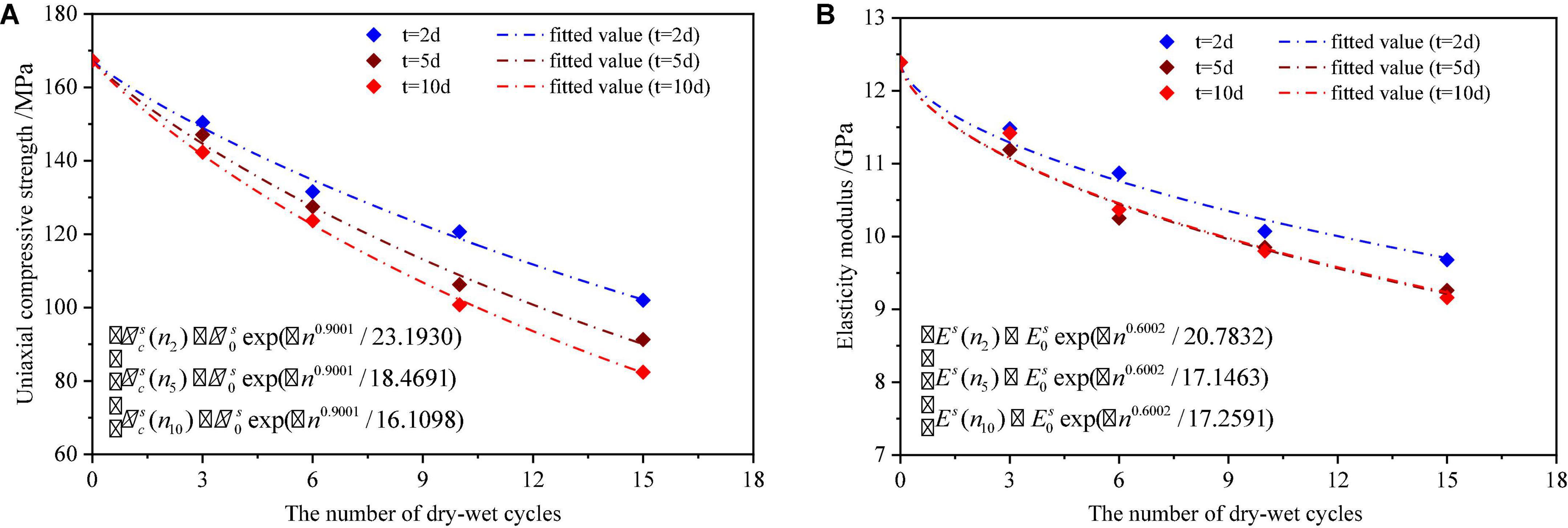

According to the calibration of the previous test, the soaking time during a complete dry-wet cycle test was 2 days. The water-saturated state was taken as an example, and the variation rules of σc and E under different soaking times can be obtained (Figure 12).

Figure 12. Parameters of the limestone after dry-wet cycles under different soaking times. (A) The trend of uniaxial compressive strength; (B) the trend of elasticity modulus.

With the increase in dry-wet cycles, the uniaxial compressive strength, elastic modulus and tensile strength of limestone showed downward trends. When the soaking time was 5 days, the mechanical parameters after dry-wet cycles were obviously lower than those under conventional dry-wet cycles, especially when the water-saturated time was 10 days. During the saturation process, the acid ions in the aqueous solution reacted with the minerals in limestone, resulting in a decrease in mechanical strength. The longer the soaking time in the cycle period, the higher the degree of reaction, leading to the lower the mechanical parameters.

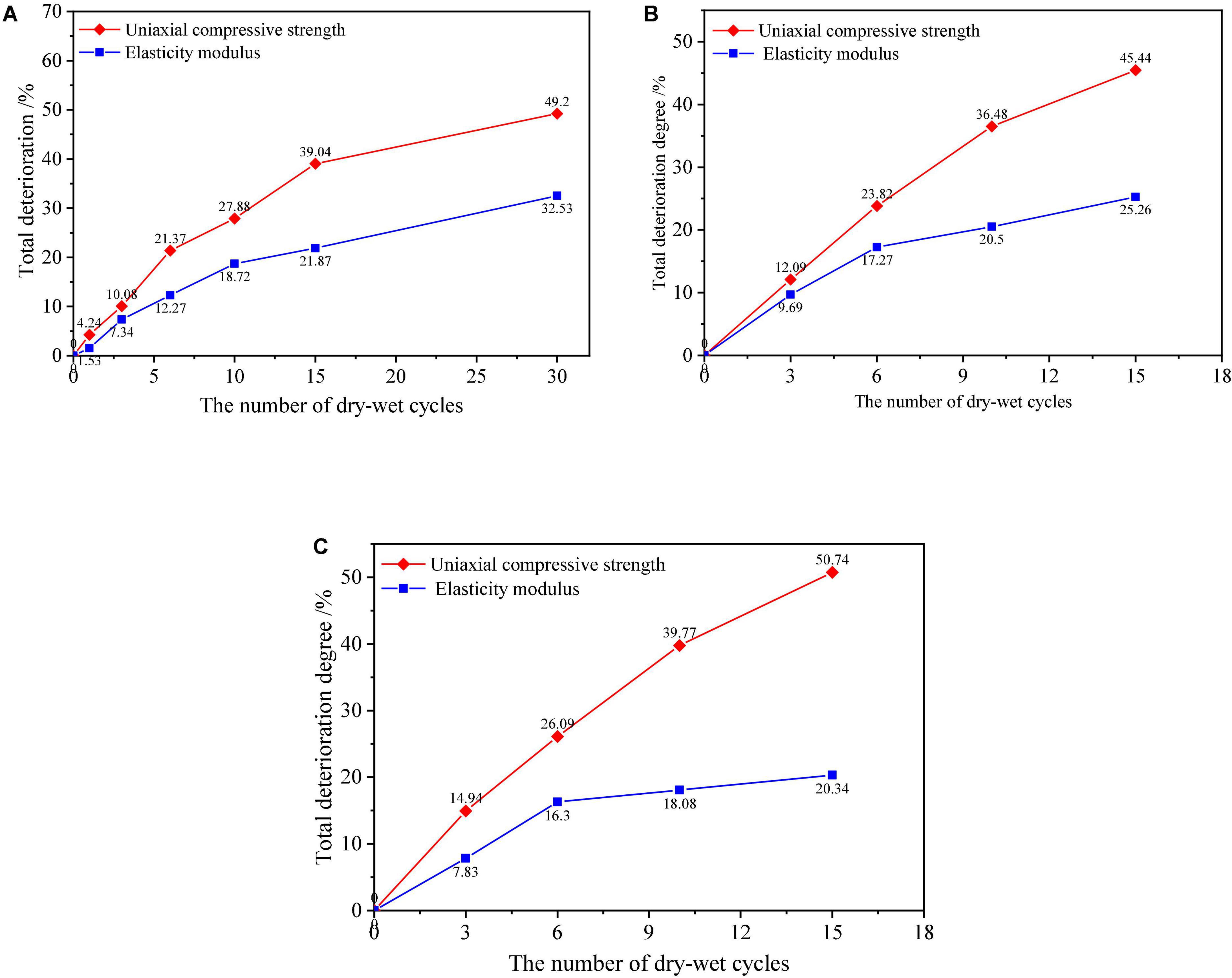

The total deterioration degree increased with the increase of dry-wet cycles (Figure 13), indicating that under the combination of cycling and soaking, the limestone also exhibited continuous deterioration. When the soaking time was 5 days, the uniaxial compressive strength and elastic modulus decreased by 12.09 and 9.69% after three dry-wet cycles, and decreased by 45.44 and 25.26% after 15 cycles. When the soaking time was 10 days, the uniaxial compressive strength and elastic modulus of limestone decreased by 14.94 and 7.83% after three dry-wet cycles, and the decrease rates after 15 cycles reached 50.74 and 20.34 %. Moreover, as for the average degree of deterioration (Figure 14), the uniaxial compressive strength and elastic modulus similarly decreased with dry-wet cycles.

Figure 13. Degradation rules of σc and E under different immersion time. (A) The saturated state after dry-wet cycles (t = 2 day); (B) the saturated state after dry-wet cycles (t = 5 day); (C) the saturated state after dry-wet cycles (t = 10 day).

Figure 14. Average deterioration degree in σc and E under different immersion time. (A) The saturated state after dry-wet cycles (t = 2 day); (B) the saturated state after dry-wet cycles (t = 5 day); (C) the saturated state after dry-wet cycles (t = 10 day).

In-depth studying the microstructural characteristics of samples is beneficial to analyze the influence of dry-wet cycles on mechanical strength. Under the influence of polar molecular charge, thermodynamics and kinetics of the aqueous solution, the ions in the mineral crystal lattice are transferred into the aqueous solution. The crystal lattice damage caused by this process is known as the chemical dissolution of mineral crystals. It is controlled by various factors such as the properties of rock, seepage conditions and its occurrence environment (Su and Zhou, 2020).

The limestone used in this paper was formed by the rapidly accumulate of microcrystals. The grains were small and the internal cleavage was not developed. Therefore, the dissolution process was mainly dominated by the seepage dissolution along the grain edge. In the process of water absorption, it was difficult for the aqueous solution to react with limestone, while the existence of microcracks provided a channel for migration. When the aqueous solution entered these microcracks, chemical reactions occurred. This reaction reduced the bond and friction strength of the structural surface, and the mechanical strength of the rock. To study the influence of the dry-wet cycle on the microscopic morphology of limestone, we carried out the scanning electron microscope (SEM) tests for the samples.

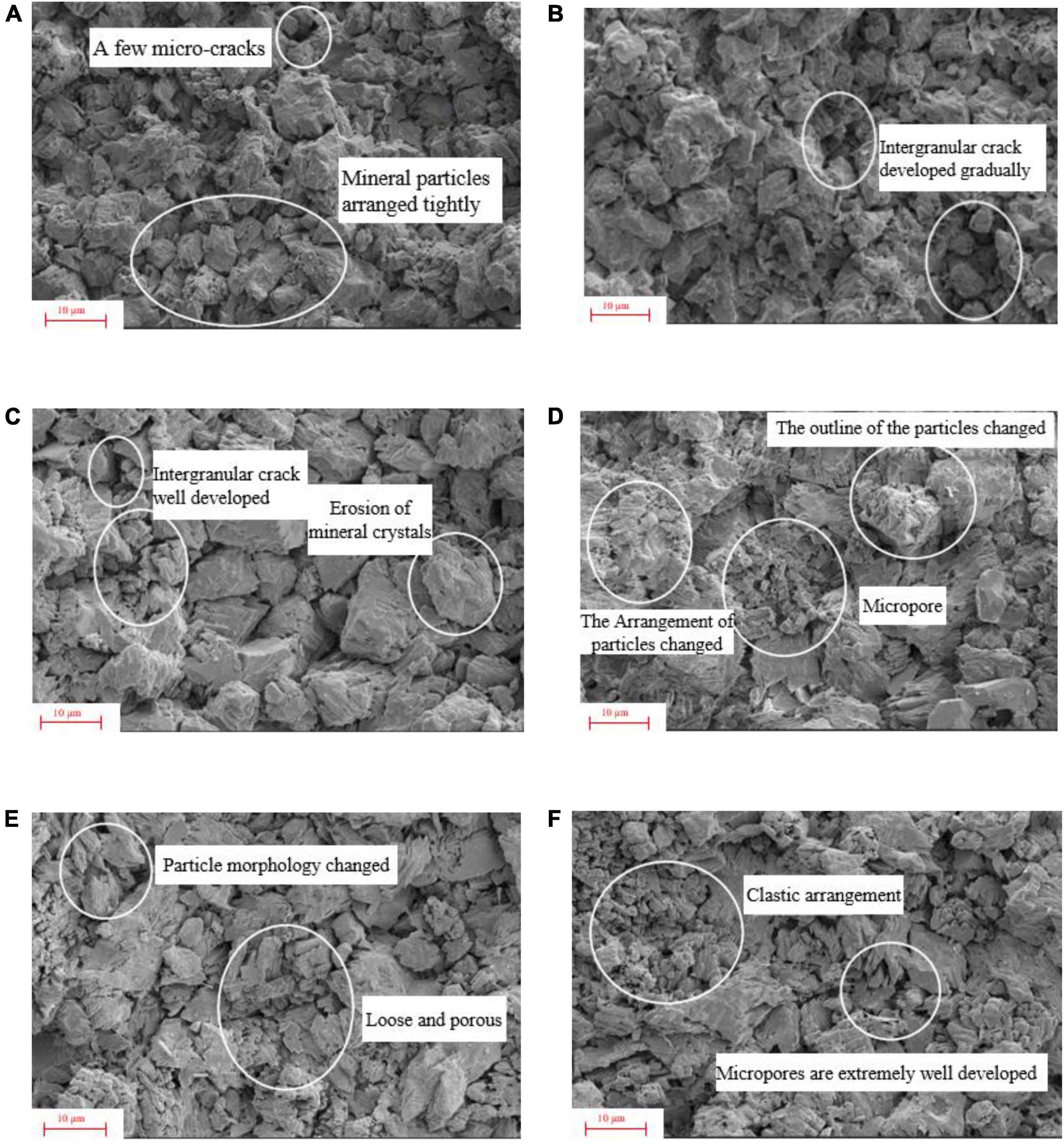

With the increase in dry-wet cycles, the particle size, microstructure characteristics and mineral composition changed obviously (Figure 15). Specifically, the structure of limestone shown in Figure 15A was relatively dense. The development of micro-cracks was not obvious, and the outline of the particles was clear. The arrangement was tight and the size was relatively uniform. The particle size was about 0.03 mm, with compactness and homogeneity. According to the morphological characteristics of pores, the porosity was low and the connectivity was poor. Therefore, the macroscopic strength of the samples was high. As the number of cycles increased, as shown in Figures 15B,C, the microstructure and particle morphology of limestone changed. The surface undulation increased, the different sizes of pores were developed, and the arrangement characteristics of minerals were changed. Some particles were stacked together to generate the bigger particles due to the erosion of the acidic solution. After 10 dry-wet cycles, the morphological characteristics of limestone changed more significantly (Figure 15D). The surface of the particles changed from the initial neatly packed shape to the flocculent shape. After 15 and 30 dry-wet cycles, it can be found from Figures 15E,F that the arrangement of particles gradually transformed into a state of clastic, with a loose and porous microstructure. These changes in the surface microstructure and particle morphology were manifested as a decrease in mechanical parameters on a macroscopic scale.

Figure 15. SEM images of microstructure under different dry-wet cycles (5000 times magnification). (A) 1 dry-wet cycle; (B) 3 dry-wet cycles; (C) 6 dry-wet cycles; (D) 10 dry-wet cycles; (E) 15 dry-wet cycles; and (F) 30 dry-wet cycles.

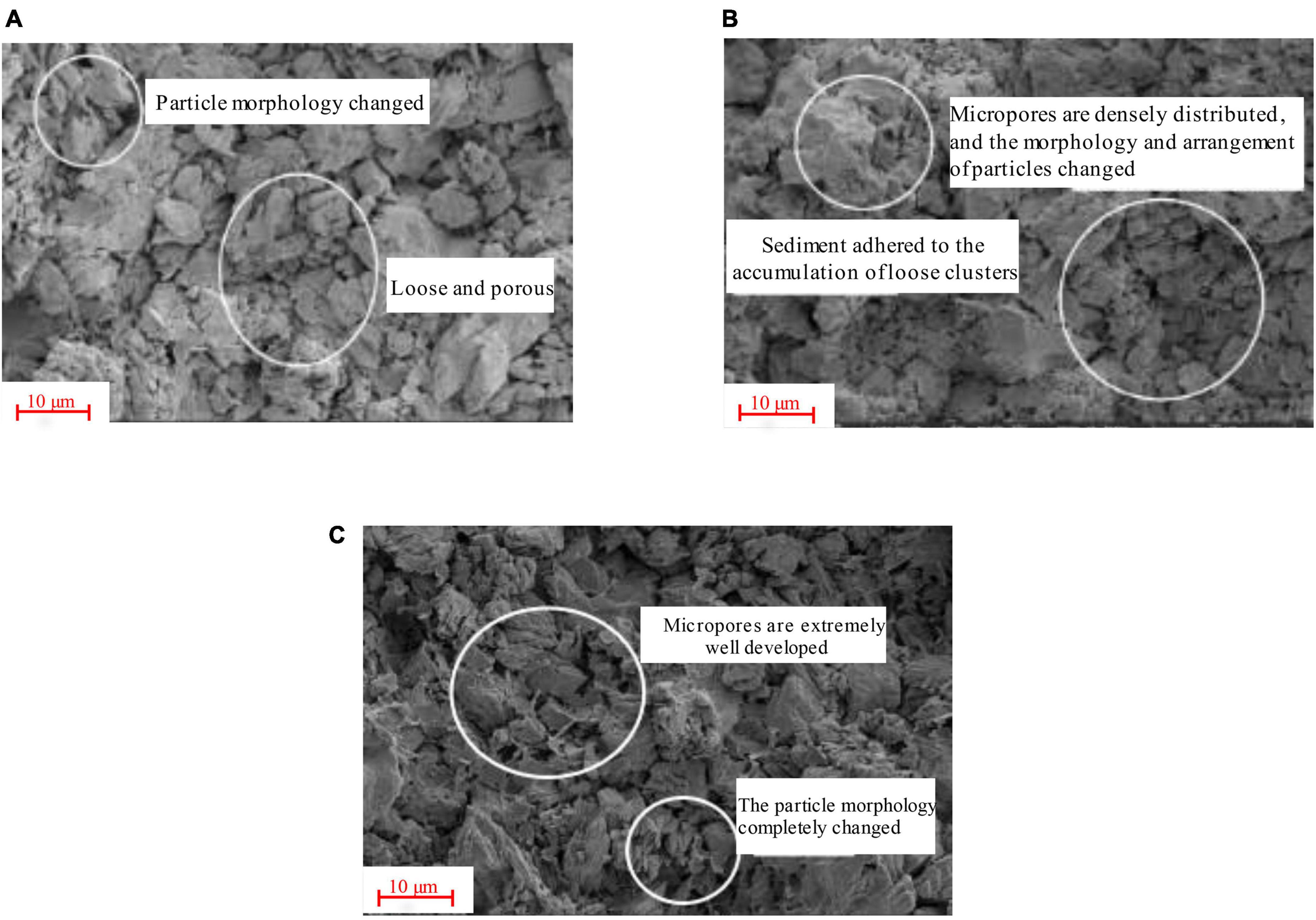

Taking the 10 dry-wet cycles as an example (Figure 16), when the soaking time was 5 days, the particles appeared with an irregular shape, and some of the particles stacked together to form particle clusters due to the erosion of acidic solution. When the soaking time was 10 days, with the increase in dry-wet cycles, there were more obvious dissolution pores and crevices on the surface. The dissolution reaction not only occurred in the cleavage crevices of mineral crystals, but also in mineral crystals, making the microstructure looser. The component of limestone mainly is CaCO3. Under the action of acid condition, the CaCO3 will be decomposed as free Ca2+, which is manifested by the corrosion of crystal structure and the deepening and widening of pores.

Figure 16. The SEM images of microstructure under different soaking time (5000 times magnification). (A) Soaking time of 2 days; (B) soaking time of 5 days; and (C) soaking time of 10 days.

In this paper, the cross-scale tests and theoretical analysis were carried out considering different dry-wet cycles and soaking times. As a result, the deterioration trend of the rock mass on the reservoir banks can be concluded as follows:

The strength parameters of micrite limestone were weakened obviously by dry-wet cycles, and the mechanical parameters of saturated limestone were lower than that of dry state under the same dry-wet cycles. By introducing the damage mechanics and statistical theory, the deterioration models were established. The deterioration degree of compressive strength was obviously greater than that of elastic modulus, indicating that the compressive strength was more sensitive to the effects of dry-wet cycles. It can be found from the trend of fitted curves that the decline was the largest in the initial stage. With the increase in dry-wet cycles, the declining speed of mechanical parameters gradually became slower, while the overall decline process was continuous.

The acidic environment provided a sufficient condition for the reduction of mechanical parameters for carbonate rocks, and continuous immersion was a necessary condition for further reduction. The uniaxial compressive strength and elastic modulus of micrite limestone exhibited a decreasing trend with the increase of soaking time. The microscopic characteristics of limestone were homogeneous and compact originally. With the increase in dry-wet cycles and soaking times, the morphology of mineral particles changed, the number of secondary pores gradually increased, the surface structure became looser, and the microcracks gradually increased, causing the decrease of mechanical parameters on the macro scale.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

XG: methodology. LW: validation. YX and XJ: experiments. BR and YY: writing. All authors have read and agreed to the published version of the manuscript.

This study was supported by the Postdoctoral Innovative Talents Support Program, Chongqing (CQBX2021020), the Natural Science Foundation of China (52178313), and the China Postdoctoral Science Foundation-funded project (2021M700608).

Author YX was employed by Chong Qing Urban Investment Infrastructure Construction Corporation.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Dougill, J., Lau, J., and Burt, N. (1976). “Towards a Theoretical Model for Progressive Failure and Softening in Rock, Concrete and Similar Materials,” in Proceedings of the ASCE-EMD Specialty Conference on Mechanics in Engineering, Waterloo, ON.

Dragon, A., and Mróz, Z. (1979). A continuum model for plastic-brittle behaviour of rock and concrete. Int J. Eng. Sci. 17, 121–137. doi: 10.1016/0020-7225(79)90058-2

Feng, X. T., Zhou, Y. Y., and Jiang, Q. (2019). Rock mechanics contributions to recent hydroelectric developments in China. J. Rock Mech. Geotech. 11, 511–526. doi: 10.1016/j.jrmge.2018.09.006

He, M., Wang, Q., and Wu, Q. (2021). Innovation and future of mining rock mechanics. J. Rock Mech. Geotech. 13, 1–21. doi: 10.1016/j.jrmge.2020.11.005

Krajcinovic, D., and Fonseka, G. U. (1981). The continuous damage theory of brittle materials. Part 1: General Theory. J. Appl. Mech. 48, 809–815. doi: 10.1115/1.3157739

Krajcinovic, D., and Silva, M. A. G. (1982). Statistical aspects of the continuous damage theory. Int J Solids Struct 18, 551–562. doi: 10.1016/0020-7683(82)90039-7

Lawal, A. I., and Kwon, S. (2021). Application of artificial intelligence to rock mechanics: an overview. J. Rock Mech. Geotech. 13, 248–266. doi: 10.1016/j.jrmge.2020.05.010

Lemaitre, J., Chaboche, J. L., and Maji, A. K. (1992). Mechanics of solid materials. J. Eng. Mech. 119, 642–643. doi: 10.1061/(ASCE)0733-9399(1993)119:3(642.2)

Li, H. Z., Liao, H. J., Xiong, G. D., Han, B., and Zhao, G. P. (2015). A three-dimensional statistical damage constitutive model for geomaterials. J. Mech. Sci. Technol. 29, 71–77. doi: 10.1007/s12206-014-1211-2

Li, X. S., Peng, K., Peng, J., and Hou, D. (2021). Experimental investigation of cyclic wetting-drying effect on mechanical behavior of a medium-grained sandstone. Eng. Geol. 293:106335. doi: 10.1016/j.enggeo.2021.106335

Liu, X. R., Jin, M. H., Li, D. L., and Zhang, L. (2018). Strength deterioration of a Shaly sandstone under dry-wet cycles: a case study from the Three Gorges Reservoir in China. B Eng. Geol. Environ. 77, 1607–1621. doi: 10.1007/s10064-017-1107-3

Parise, M., Closson, D., Gutiérrez, F., and Stevanović, Z. (2015). Anticipating and managing engineering problems in the complex karst environment. Environ. Earth Sci. 74, 7823–7835. doi: 10.1007/s12665-015-4647-5

Rehman, H., Naji, A. M., Nam, K., Ahmad, S., Muhammad, K., and Yoo, H.-K. (2021). Impact of construction method and ground composition on headrace tunnel stability in the neelum–jhelum hydroelectric project: a case study review from Pakistan. Appl. Sci. 11:1655. doi: 10.3390/app11041655

Shen, P. W., Tang, H. M., Ning, Y. B., and Xia, D. (2019). A damage mechanics based on the constitutive model for strain-softening rocks. Eng. Fract. Mech. 216:106521. doi: 10.3390/ma15144903

Su, H., and Zhou, W. (2020). Mechanism of accelerated dissolution of mineral crystals by cavitation erosion. Acta Geochim. 39, 11–42. doi: 10.1007/s11631-019-00383-5

Wang, L. Q., Yin, Y. P., Huang, B. L., and Dai, Z. W. (2020b). Damage evolution and stability analysis of the jianchuandong dangerous rock mass in the three gorges reservoir area. Eng. Geol. 265:105439. doi: 10.1016/j.enggeo.2019.105439

Wang, L. Q., Yin, Y. P., Huang, B. L., Zhang, Z. H., Zhao, P., and Wei, Y. (2020c). A study of the treatment of a dangerous thick submerged rock mass in the three gorges reservoir area. B Eng. Geol. Environ. 79, 2579–2590. doi: 10.1007/s10064-020-01724-y

Wang, L. Q., Yin, Y. P., Zhou, C. Y., Huang, B. L., and Wang, W. P. (2020a). Damage evolution of hydraulically coupled Jianchuandong dangerous rock mass. Landslides 17, 1083–1090. doi: 10.1007/s10346-020-01350-5

Wang, L. Q., Zhang, Z. H., Huang, B. L., Hu, M. J., and Zhang, C. Y. (2021a). Triggering mechanism and possible evolution process of the ancient Qingshi landslide in the Three Gorges Reservoir. Geomat. Nat. Haz. Risk 12, 3160–3174. doi: 10.1080/19475705.2021.1998230

Wang, L. Q., Wu, J. H., Zhang, W. G., Wang, L., and Cui, W. (2021b). Efficient seismic stability analysis of embankment slopes subjected to water level changes using gradient boosting algorithms. Front. Earth Sci. 9:807317. doi: 10.3389/feart.2021.807317

Wang, X. B., Wang, L. Q., Zhang, W. G., Zhang, C. S., Tan, C. X., Yan, P., et al. (2022) Ground fissure susceptibility mapping based on factor optimization and support vector machines. Bull. Eng. Geol. Environ. 81:341. doi: 10.1007/s10064-022-02843-4

Wu, F., Wu, J., Bao, H., Li, B., Shan, Z., and Kong, D. (2021). Advances in statistical mechanics of rock masses and its engineering applications. J. Rock Mech. Geotech. 13, 22–45. doi: 10.1016/j.jrmge.2020.11.003

Yin, Y., Huang, B., Liu, G., and Wang, S. (2015). Potential risk analysis on a jianchuandong dangerous rockmass-generated impulse wave in the Three Gorges Reservoir, China. Environ. Earth Sci. 74, 2595–2607. doi: 10.1007/s12665-015-4278-x

Yin, Y., Huang, B., Wang, W., Wei, Y., Ma, X., Ma, F., et al. (2016). Reservoir-induced landslides and risk control in Three Gorges Project on Yangtze River, China. J. Rock Mech. Geotech. 8, 577–595. doi: 10.1016/j.jrmge.2016.08.001

Yin, Y., Xing, A., Wang, G., Feng, Z., Li, B., and Jiang, Y. (2017). Experimental and numerical investigations of a catastrophic long-runout landslide in Zhenxiong, Yunnan, southwestern China. Landslides 14, 649–659. doi: 10.1007/s10346-016-0729-z

Yin, Y. P., Wang, L. Q., Zhang, W. G., and Dai, Z. W. (2022). Research on the collapse process of a thick-layer dangerous rock on the reservoir bank. B Eng. Geol. Environ. 81:109. doi: 10.1007/s10064-022-02618-x

Zhang, K. Q., Wang, L. Q., Dai, Z. W., Huang, B. L., and Zhang, Z. H. (2022) Evolution trend of the Huangyanwo rock mass under the action of reservoir water fluctuation. Nat. Hazards 113, 1583–1600. doi: 10.1007/s11069-022-05359-y

Zhang, M., and McSaveney, M. (2018). Is air pollution causing landslides in China? Earth Planet Sci. Lett. 481, 284–289. doi: 10.1023/b:emas.0000003576.36834.c9

Zhou, C., Cao, Y., Hu, X., Yin, K., Wang, Y., and Catani, F. (2022a). Enhanced dynamic landslide hazard mapping using MT-InSAR method in the three gorges reservoir area. Landslides 19, 1585–1597. doi: 10.1007/s10346-021-01796-1

Zhou, C., Cao, Y., Yin, K., Intrieri, E., Catani, F., and Wu, L. (2022b). Characteristic comparison of seepage-driven and buoyancy-driven landslides in three gorges reservoir area, china. Eng. Geol. 301:106590. doi: 10.1016/j.enggeo.2022.106590

Zhao, Y., Yang, T., Zhang, P., Zhou, J., Yu, Q., and Deng, W. (2017). The analysis of rock damage process based on the microseismic monitoring and numerical simulations. Tunn. Undergr. Spec. Tech. 69, 1–17. doi: 10.1016/j.tust.2017.06.002

Keywords: reservoir banks, dry-wet cycles, deterioration trend, damage evolution, soaking time

Citation: Gao X, Wang L, Xiang Y, Jiang X, Yang Y and Ran B (2022) Study on the deterioration trend of the rock mass on the reservoir banks under dry-wet cycles. Front. Ecol. Evol. 10:1033935. doi: 10.3389/fevo.2022.1033935

Received: 01 September 2022; Accepted: 12 October 2022;

Published: 28 October 2022.

Edited by:

Chao Zhou, China University of Geosciences Wuhan, ChinaReviewed by:

Fei Guo, China Three Gorges University, ChinaCopyright © 2022 Gao, Wang, Xiang, Jiang, Yang and Ran. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luqi Wang, d2xxOTNAY3F1LmVkdS5jbg==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.