- 1Desert Science and Engineering College, InnerMongolia Agricultural University, Hohhot, China

- 2Inner Mongolia Academy of Forestry, Hohhot, China

- 3Inner Mongolia Key Laboratory of Sandy (Desert) Ecological System and Ecological Engineering, Hohhot, China

To explore the sand stabilization effects of the Robinia pseudoacacia sand stabilizer, a series of spraying experiments was conducted using different dry matter dosages (0.5, 1, 2, 3, 4, and 5 g/m2). The sand stabilization effects, mechanical properties, and wind erosion conditions of the stabilizer were measured. The results show the following: 1) after spraying the sand stabilizer, a consolidated layer with a thickness of 1–14 mm is formed on the sand surface. The average compressive strength increased by 206.21% compared to the control group (0 g/m2), and wind erosion was reduced by 35.47%–65.92%. 2) The compressive strength of the consolidation layer positively correlated with the dosage and thickness (the depth or the vertical dimension of the consolidation layer) (p < 0.05) and inversely correlated with wind erosion and total porosity. As the dosage increased, the total porosity decreased, the thickness of the consolidation layer increased, and the compressive strength increased even more, making the material more resistant to wind erosion.

1 Introduction

Land desertification is a global environmental and resource issue, posing a significant threat to human habitat (Bestelmeyer et al., 2015; Meng et al., 2013). In recent years, China has increasingly focused on desertification control. While the technology for combating desertification has rapidly evolved, numerous challenges remain unresolved (Zhong et al., 2018). For instance, there is a lag in technological advancements, and the slow progress in developing new techniques and materials hinders meeting the demands of desertification control and ecological construction. Windbreak and sand fixation are crucial in desertification control and management, mainly involving engineering, chemical, and biological measures. Engineering measures increase the surface roughness by setting up sand barriers (Luo et al., 2023), offering quick but short-lived effects and requiring substantial labor and resources. Biological sand fixation, through vegetation or microbial coverage of exposed sand bodies, stabilizes deeper soil layers but faces significant initial challenges in desertified areas (Zang et al., 2015). Chemical sand fixation creates a consolidation layer on the sand surface using sand stabilizers, fixing the sand and retaining moisture, thus providing a conducive environment for plant growth (Duan, 2013). Its convenience and significant effects (Li and Song, 2002) have made it a recent research focus.

Since the 1960s, Chinese scholars have conducted extensive research on chemical sand fixation. Traditional chemical sand fixatives include water, glass, petroleum-based, and synthetic polymer materials (Gong et al., 2021; Huang et al., 2022; Yuan et al., 2023; Yang et al., 2007a). New types of chemical sand fixatives comprise organic–inorganic composite materials, polyurethane sand fixatives, and bio-based modified chemical sand fixatives (Yang et al., 2007b; Liu et al., 2017; Liu et al., 2018; Ma et al., 2015; Tao et al., 2018; Yang, 2012).

With the extensive use of traditional sand fixatives, their limitations have become increasingly apparent. The wind erosion-resistant shells formed are not durable, and the materials may cause secondary environmental pollution (Liang et al., 2021; Dang et al., 2017; Dong et al., 2008; Yang et al., 2007), limiting vegetation growth and recovery (Pei et al., 2023; Yangliu, 2011; Liu et al., 2016). To address this, scholars have researched plant-based sand stabilizers made from pure natural plant gums. For example, Artemisia gum, a hydrophilic colloid extracted from the seed coat of the perennial semi-shrub Artemisia, binds sand grains under its influence, exhibiting excellent wind erosion resistance and water retention. It promotes the germination of pioneer plants’ seeds, such as Agriophyllum squarrosum and Artemisia (Dang et al., 2017). Flaxseed cake also contains high-viscosity natural seed gum. When extracted with water and sprayed on mobile sand surfaces, it effectively stabilizes the sand. Moreover, this seed gum is a natural, green sand stabilizer, posing no pollution to the environment (Ting et al., 2019; Yan et al., 2021).

Robinia pseudoacacia sand stabilizer is extracted from the seeds of the deciduous tree Robinia pseudoacacia L. belonging to the Fabaceae family. It is a hydrophilic colloidal substance, structurally a polysaccharide compound composed of galactose and mannose residues, characterized by high viscosity and excellent water absorption. As a gelling agent, thickener, water-retainer, adhesive, and coagulant, its unique properties make it suitable for sand fixation applications. Therefore, this study conducted spraying experiments with different concentrations of the Robinia pseudoacacia sand stabilizer. The structure of the sand fixation samples was analyzed by scanning electron microscopy (SEM) to investigate the thickness of the sand surface consolidation layer, compressive strength, and wind erosion resistance, aiming to provide an environmentally friendly new material for sand fixation, thereby offering theoretical support for the development and application of eco-friendly sand stabilizers and new approaches and methods for desertification control.

2 Materials and methods

2.1 Materials

The Robinia pseudoacacia sand stabilizer, derived from Robinia pseudoacacia seeds, is a plant gum, with its primary components being mannose and galactose. It exhibits high viscosity and significant potential for complex modification, making it an excellent thickening and stabilizing agent and a food-grade, safe viscous material. The preparation of the Robinia pseudoacacia sand stabilizer follows the method in Zheng Jianyou’s patent, “A Method for Preparing High-Quality Robinia Pseudoacacia Gum” (Zheng and Guo, 2018).

The dry matter dosage of the Robinia pseudoacacia sand stabilizer was selected as 0.5, 1, 2, 3, 4, and 5 g/m2, with a uniform spraying volume of 3 kg/m2. The control group (0 kg/m2) involved spraying an equal volume of clean water. Each experimental group was repeated three times, and the average of three experimental data sets was calculated. The dosages of 0.5, 1, 2, 3, 4, and 5 g/m2 represent the amount of the Robinia pseudoacacia sand stabilizer powder used per square meter, dissolved in an equal volume of water. For example, for the 0.5 g/m2 dosage, 0.5 g of the Robinia pseudoacacia sand stabilizer is dissolved in 3 kg of water; similarly, for the 1 g/m2 dosage, 1 g is dissolved in 3 kg of water and so on.

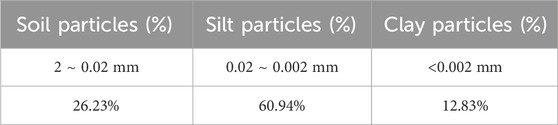

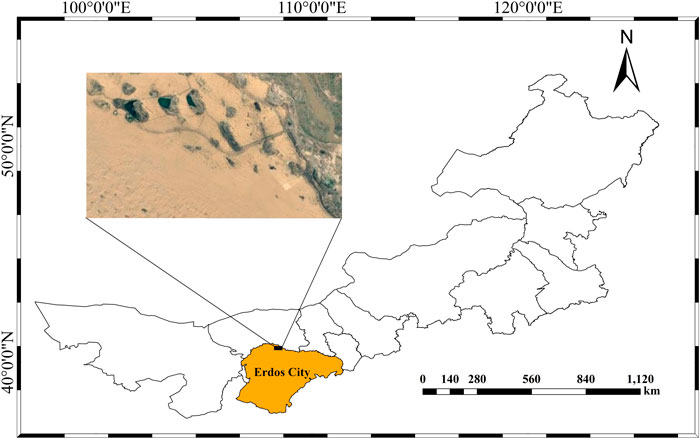

The experimental soil was collected from Dalad Banner, Ordos City, Inner Mongolia, located at the northern edge of the Kubuqi Desert. The soil type is aeolian sandy soil. The surface layer of soil (0–20 cm depth) was excavated, sieved to remove impurities, and air-dried to a constant weight for use. The mechanical composition of the soil was determined by the sieving method, with each soil sample sieved for 5 min. The soil particle size composition is shown in Table 1.

2.2 Methods

2.2.1 Wind erosion test

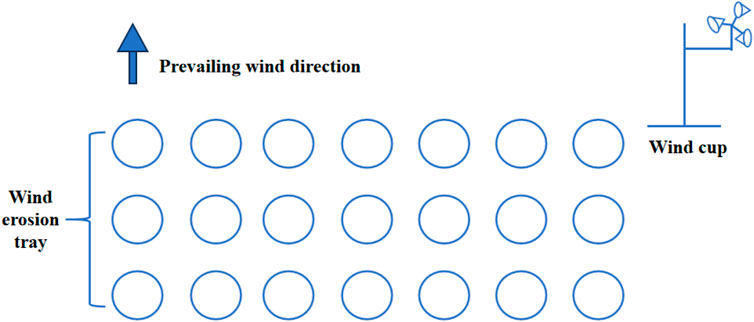

A wind erosion control experiment with the sand stabilizer was conducted at the northern edge of the Kubuqi Desert (Figure 1). The experimental soil was placed in a circular wind erosion tray with a diameter of 36 cm and a depth of 5 cm. The soil surface was leveled to be flush with the tray’s edge (Figure 2). The sand stabilizer was uniformly sprayed onto the soil surface of the wind erosion tray, according to the experimental design dosages. After naturally drying until the moisture content returned to the pre-spray level, the trays were placed in an unobstructed, flat, and hardened open area for the experiment. The experiment was conducted with six different dosages, with an equal volume of clean water sprayed as the control group (0 g/m2). Each treatment was replicated three times. The trays were weighed, and data were recorded. The formula for determining the index is as follows Formula 1:

where Wf is the wind erosion quantity per unit area (kg/m2), W is the total wind erosion quantity over the entire section (kg), and S is the surface area of the soil exposed to wind erosion (cm2).

2.2.2 Physical property test

Compressive strength test of the consolidation layer: The compressive strength was measured using a thrust meter. Dried test soil was packed into a cylindrical PVC pipe-made barrel with a closed bottom, an inner diameter of 11 cm, a wall thickness of 0.5 cm, and a height of 15 cm. The sand stabilizer was sprayed according to the experimental design dosage. After the consolidation layer had fully dried, the compressive strength (KPa) was measured using a thrust meter (SL-100 Tri-range Digital Push–Pull Gauge, converting the sustainable thrust into compressive strength). Each treatment was replicated three times.

Thickness measurement of the consolidation layer: The consolidation layer inside the PVC pipe was removed, and its thickness (mm) was measured using a vernier caliper. Each treatment was replicated three times.

Bulk density, capillary porosity, and total porosity: An equal amount of experimental soil was placed inside a ring knife, and the sand stabilizer was sprayed inside the ring knife. Based on the thickness of the consolidation layer, its dosage was calculated. The data obtained from this ring knife test represented the physical properties of the consolidation layer at that dosage Formulas 2–7.

where F1 is the soil bulk density; F2 is the maximum water-holding capacity/saturation water-holding capacity (%); F3 is the capillary water-holding capacity (%); F4 is the non-capillary porosity (volume %); F5 is the capillary porosity (volume %); F6 is the total porosity (volume %); M1 is the weight of the ring knife (g); M2 is the weight of the ring knife with dry soil (g); M3 is the wet soil mass after 12 h of soaking (g); M4 is the dry soil mass (g); M5 is the wet soil mass after 12 h of soaking, followed by 2 h of drying on dry sand (g); V is the volume of the ring knife (cm³), which is 100 cm³; ρsoil is the soil density; and ρwater is the water density.

SEM of the fixed sand sample: The experimental soil was packed into a cylindrical PVC pipe-made barrel with a closed bottom. The sand stabilizer was sprayed onto the soil surface at a calculated dosage per area, with 0 g/m2 receiving an equal volume of deionized water as the control group. After the formation of the dry consolidation layer, the layer was fully removed and observed under a TM-300 scanning electron microscope for its bonding conditions.

3 Result analysis

3.1 Soil wind erosion inhibition by the sand stabilizer

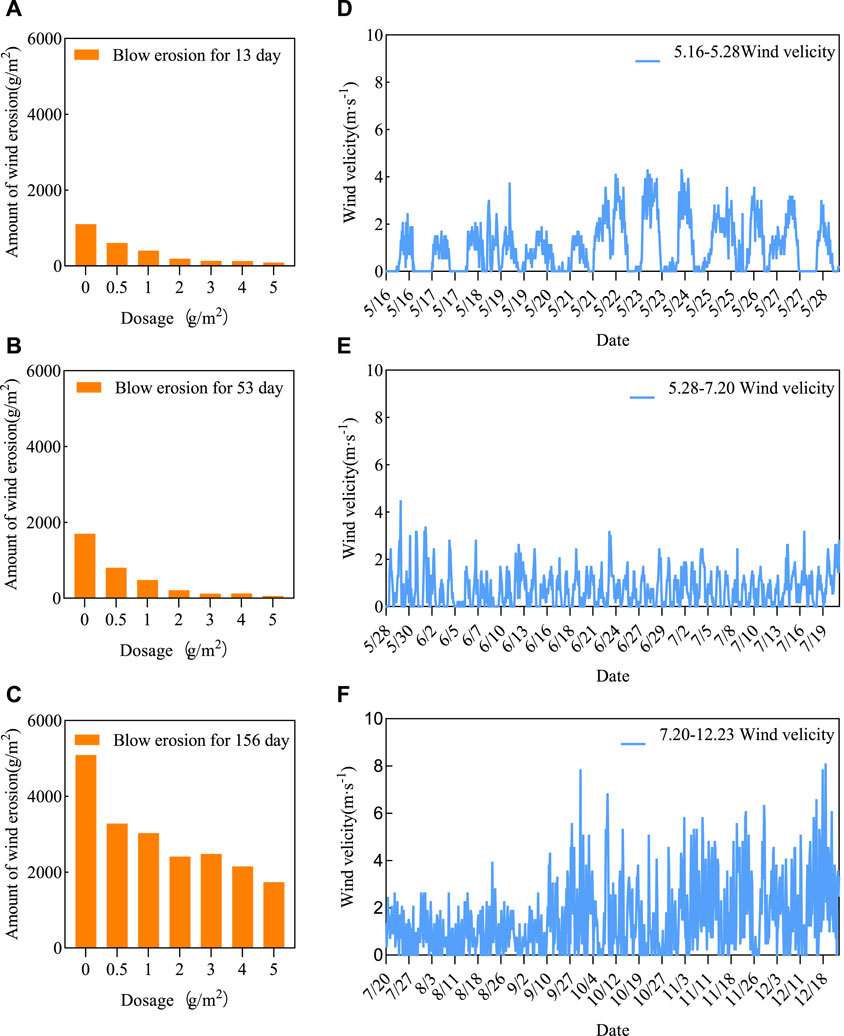

Figure 3 presents the soil wind erosion volumes after spraying the Robinia pseudoacacia sand stabilizer at various dosages. As shown in the figure, the wind erosion volume accumulates with an increase in the number of days of aeolian erosion, and it tends to decrease with increasing dosages of the sand stabilizer. After 13 and 53 days of aeolian erosion, the wind erosion volume in treatments with 0 g/m2 and 0.5 g/m2 showed significant changes, while the changes were minimal or nonexistent in the 1 g/m2 to 5 g/m2 treatments. After 156 days, the average wind erosion volume increased by 739.86% compared to that after 53 days, indicating a substantial increase in wind erosion. After 156 days of aeolian erosion, all treatments showed a significant rise in the wind erosion volume. The untreated control had the most wind erosion over time, while all treated samples had less erosion than the untreated control. After 13 days of aeolian erosion, the wind erosion volumes in the 0.5 g/m2 to 5 g/m2 treatments decreased by 30.31%–91.81%; after 53 days, they decreased by 52.69%–96.65%. After 156 days, the wind erosion volume reduced compared to the control, and with the sand stabilizer dosages increasing from 0.5 g/m2 to 5 g/m2, the erosion volume reduced by 35.47%–65.92%, indicating a gradual increase in wind erosion resistance. It is evident that the application of the Robinia pseudoacacia sand stabilizer progressively enhances wind erosion resistance with increasing dosage. The 1 g/m2 to 5 g/m2 dosages show effective wind erosion resistance in the short term, but in the long term, the effectiveness of the sand stabilizer in resisting wind erosion significantly decreases.

FIGURE 3. Characteristics of soil wind erosion under different sand fixing agents and different dosage treatments. (A): 13 day wind erosion amount, (B): 53 day wind erosion amount, (C): 156 day wind erosion amount, (D): Wind velicity from May 16th to 28th, (E): Wind velicity from May 28th to July 20th, (F): Wind velicity from July 20th to December 23th.

3.2 Scanning electron microscopy of the Robinia pseudoacacia sand stabilizer consolidation layer

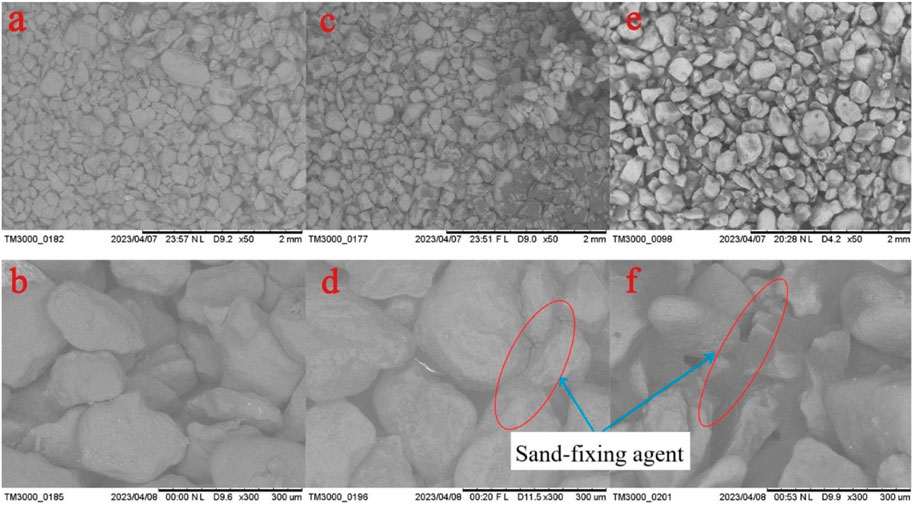

After different dosages of the Robinia pseudoacacia sand stabilizer were sprayed and dried, sand models were analyzed by SEM. Figure 4 shows SEM images at different magnifications for the control group (0 g/m2) and treatment with 3 g/m2 and 5 g/m2 dosages. As indicated in Figures 4D, F (within the red circles), the gaps between sand grains are filled and bonded by the sand stabilizer, with higher-dosage treatments showing more apparent bonding effects. Samples without sand stabilizer treatment contain more gaps between sand grains, resulting in lower wind erosion resistance. In samples treated with the sand stabilizer, sand grains are closely contacted and bonded by the stabilizer, forming a consolidation layer that impedes sand grain movement and effectively inhibits wind erosion.

FIGURE 4. SEM micrographs of the consolidation layer. Note: (A, B) represent 0 g/m2; (C, D) for a concentration of 3 g/m2; and (E, F) for a concentration of 5 g/m2.

3.3 Physical properties of the Robinia pseudoacacia sand stabilizer consolidation layer

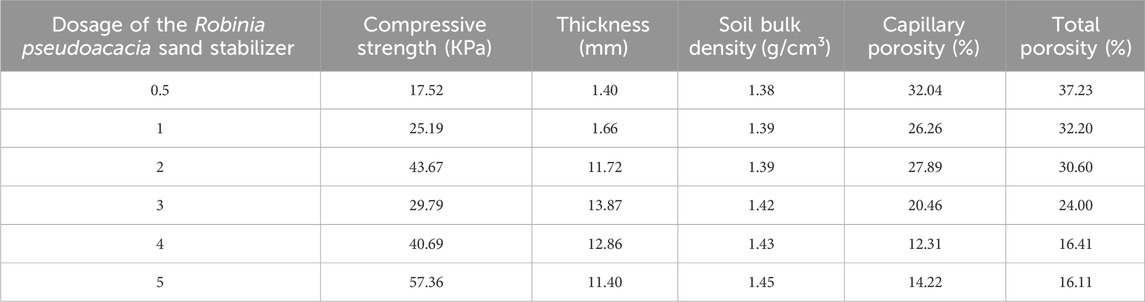

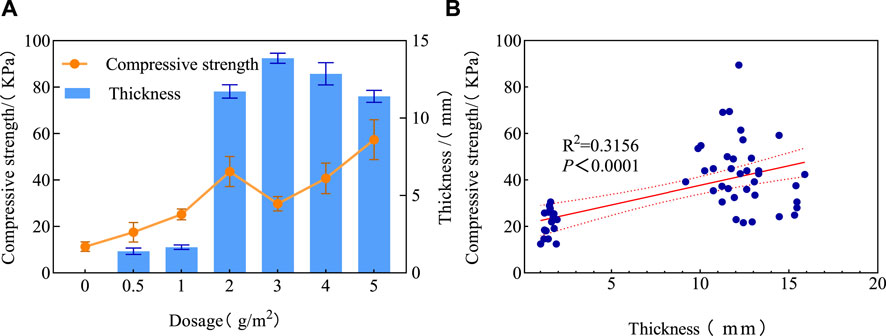

After spraying different dosages of the sand stabilizer on the sand surface, the stabilizer fully bonds with the sand grains upon water evaporation, forming a consolidation layer of a certain thickness. The cohesion and binding forces between sand grains can be indicated by the compressive strength of the consolidation layer. Figure 5A shows that the compressive strength increases as the amount of Robinia pseudoacacia sand stabilizer used increases. The average compressive strength of the layer that forms is 215.41% higher than that of the control group (0 g/m2). In the 0 g/m2 treatment, there was almost no binding force between sand grains, and no consolidation layer was formed, thus making it impossible to measure its thickness. At a dosage of 2 g/m2, a turning point in the consolidation layer thickness is observed, significantly increasing by 606% compared to 1 g/m2, and the compressive strength increased by 73.36%. Correlation analysis indicates a significant positive correlation between the thickness of the consolidation layer and compressive strength (p < 0.0001), with the fitted equation being Y = 1.684 X + 20.86. The physical properties of the consolidation layer under six dosage treatments of the Robinia pseudoacacia sand stabilizer are shown in Table 2. From a general trend analysis, soil bulk density is proportional to dosage, while capillary porosity and total porosity are inversely proportional.

FIGURE 5. Coupling relationship between the thickness and compressive strength of the consolidation layer. (A): The thickness and compressive strength of the consolidation layer, (B): The fitting relationship between the thickness of the consolidation layer and the compressive strength.

Therefore, at a dosage of 2 g/m2, there is a significant increase in the thickness and hardness of the consolidation layer, marking a turning point. Soil bulk density is proportional to the dosage, whereas capillary porosity and total porosity are inversely proportional.

4 Discussion

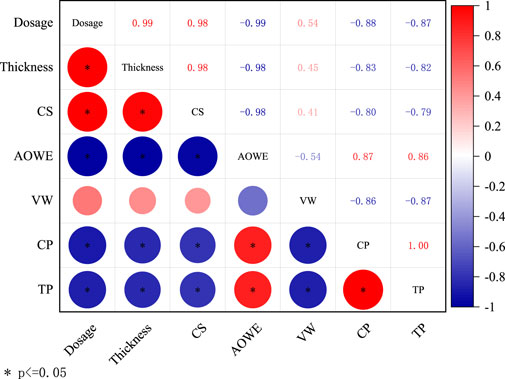

Aeolian activity is the movement of air and solid matter close to the earth’s surface. Such an activity can be mitigated by sand stabilizers that bind loose surface sand grains, which can reduce surface sand lifting and extend the saturated path of sand flow, thus effectively stabilizing moving sand. The effectiveness of a sand stabilizer depends on the strength and hardness of the consolidation layer it forms. The Robinia pseudoacacia sand stabilizer used in this study is a novel plant-based sand fixative. When sprayed onto the sand surface, it forms a consolidation layer on the loose sand grains that can resist wind erosion. The bonded consolidation layer acts as a “sand crust” with a certain shear strength on the surface of the moving sand, isolating the underlying loose sand grains from near-surface wind-blown sand. Compressive strength and thickness are key indicators of the mechanical properties of the consolidation layer (Meng et al., 2013; Liu et al., 2012). Our study finds that with an increase in the amount of sand stabilizer used, the consolidation layer becomes thicker, and the compressive strength increases (Figure 5). This makes the sand surface more resistant to wind erosion. Previous research indicates a direct proportionality between the compressive strength and the concentration of the sand stabilizer. At low concentrations, the stabilizer forms a thin and dispersed consolidation layer with low compressive strength, prone to breakage. At high concentrations, the consolidation layer becomes thick and dense, with high compressive strength, making it less likely to break (Wu et al., 2011). Our results are consistent with those found by Wu Zhiren et al. The study by Dang et al. (2017) concluded that Artemisia gum, infiltrating into soil particles, enhances soil particle cohesion. The greater the concentration of Artemisia gum, the thicker the consolidation layer and the greater the compressive strength. This study aligns with these results, showing a positive correlation between compressive strength and dosage/thickness (p < 0.05) and a negative correlation with wind erosion, capillary porosity, and total porosity (Figure 6). As the dosage increases, both capillary porosity and total porosity decrease, and the thickness of the consolidation layer increases.

FIGURE 6. Correlation between soil physical properties and consolidation layer properties after spraying the Robinia pseudoacacia sand stabilizer. Note: CS, compressive strength; AOWE, amount of wind erosion; VW, volumetric weight; CP, capillary pore; TP, total porosity.

Research indicates that surfaces with consolidation layers demonstrate stronger resistance to wind erosion compared to bare sand surfaces untreated with sand stabilizers. The consolidation layer protects the loose sand surface, isolating the sand grains from the wind-blown sand. Aeolian activities cannot effectively erode the sand surface, and with the increase in the thickness of the consolidation layer, its abrasion resistance is further enhanced, making it more durable. The primary reason is that the sand-laden airflow, while passing over the sand surface, causes sand particles in the wind to collide with the surface sand grains, continuously eroding the consolidation layer. As the thickness of the consolidation layer increases, it requires a longer duration of erosion to lose its protective function against the surface, thereby exhibiting greater durability. The study also found that the consolidation layer formed by low-dose treatments of the Robinia pseudoacacia sand stabilizer is thin and less resistant to wind erosion. Once the consolidation layer is damaged, erosion under the airflow action occurs downward along the layer, leading to the escape of sand and soil particles and the hollowing out beneath the sand surface, resulting in the complete destruction of the surface consolidation layer. The sample then loses its protection and begins to experience intense wind erosion, similar to untreated samples, consistent with previous research findings (Li and Wang, 2017). The consolidation layer not only reduces the sand-lifting capacity of the sand-laden flow but also increases the wind speed required to lift the sand grains, which directly affects the amount of wind erosion (Chen et al., 2006). The same principle of wind erosion resistance applies to materials like Artemisia gum and other gelatinous substances.

5 Conclusion

In evaluating the sand-fixing effectiveness of the Robinia pseudoacacia sand stabilizer, analysis of experimental results on the resistance and mechanical properties of the stabilizer’s consolidation layer leads to the following conclusions:

(1) Spraying the sand stabilizer forms a consolidation layer on the sand surface with a thickness ranging from 1 to 14 mm. The average compressive strength increased by 206.21% compared to the control group (0 g/m2). The compressive strength of the consolidation layer is positively correlated with the dosage and thickness (P < 0.05) and negatively correlated with the wind erosion volume, capillary porosity, and total porosity. As the dosage increases, capillary porosity and total porosity decrease, the thickness of the consolidation layer increases, and the compressive strength further improves, resulting in higher wind erosion resistance.

(2) The effectiveness of the Robinia pseudoacacia sand stabilizer against wind erosion progressively strengthens with increasing dosage. However, its wind erosion resistance diminishes over time; it exhibits good wind erosion resistance in the short term, but this effect significantly decreases over longer periods of aeolian erosion. In practical applications, its durability should be considered.

(3) The Robinia pseudoacacia sand stabilizer shows excellent short-term sand-fixing capability and is environmentally friendly. Due to its unique consolidation properties, it can be applied to sandy farmlands. During spring cultivation and windy seasons, when wind erosion exposes the soil in cultivated lands, making plant survival challenging, the sand stabilizer can be used to prevent wind erosion of seedlings. This provides a new material for wind and sand control in sandy farmlands and offers theoretical and practical references for the development and application of sand stabilizers.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

TR: Writing–original draft, Writing–review and editing. YG: Conceptualization, Methodology, Writing–original draft. LY: Methodology, Supervision, Validation, Writing–review and editing. CZ: Conceptualization, Writing–review and editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This work was supported by the National Key Research and Development Program (2022YFF1303404).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bestelmeyer, B. T., Okin, G. S., Duniway, M. C., Archer, S. R., Sayre, N. F., Williamson, J. C., et al. (2015). Desertification, land use, and the transformation of global drylands. Front. Ecol. Environ. 13 (1), 28–36. doi:10.1890/140162

Chen, Q., Jiang, P., Lei, T. u, Li, R., and Tang, Z. (2006). Wind tunnel ex periment on the impacts of polyacrylamide on w ind erosion of loosen soil materials. Transactions CSAE 22 (10), 7–11.

Dang, X., Chen, H., and Shan, Z. (2017). Preparation and characterization of poly (Acrylic acid)—corn starch blend for use as chemical sand-fixing materials. Mater. Res. Express 4 (7), 075506. doi:10.1088/2053-1591/aa760f

Dong, Z., Wang, L., and Zhao, S. (2008). A potential compound for sand fixation synthesized from the effluent of pulp and paper mills. J. Arid Environ. 72 (7), 1388–1393. doi:10.1016/j.jaridenv.2008.02.008

Duan, L. (2013). Synthesis and research of starch grafted acrylic acid/vinyl acetate sand fixing agent. Beijing: Beijing University of Chemical Technology. (in Chinese with English abstract).

Gong, W., Li, M., and Liu, B. (2021). How the surfactants mixed with emulsion can enhance the sand-fixation ability in the high salt-affected sandy land. Environ. Technol. 42 (16), 2516–2526. doi:10.1080/09593330.2019.1705918

Huang, W., Geng, X., Li, J., Zhou, C., and Liu, Z. (2022). Molecular dynamics study on the adsorption and modification mechanism of polymeric sand-fixing agent. Polymers 14 (16), 3365. doi:10.3390/polym14163365

Li, J., and Song, Z. (2002). Research on lignosulfonates and its graft products as sand stabilisers. For. Prod. Chem. Industry (01), 17–20.

Liang, J., Ning, R., Sun, Z., Liu, X., Sun, W., Zhou, X., et al. (2021). Preparation and characterization of an eco-friendly dust suppression and sand-fixation liquid mulching film. Carbohydr. Polym. 256, 117429. doi:10.1016/j.carbpol.2020.117429

Liu, J., Shi, B., Lu, Y., Jiang, H., Huang, H., Wang, G., et al. (2012). Effectiveness of a new organic polymer sand-fixing agent on sand fixation. Environ. Earth Sci. 65, 589–595. doi:10.1007/s12665-011-1106-9

Liu, J., Zhang, Y., Qin, S., Wei, F., Sun, Y., Wang, Li, et al. (2016). Sand fixation experiment of Artemisia sphaerocephala Krasch. gum with different concentrations. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 32 (5), 149–155. doi:10.11975/j.issn.1002-6819.2016.05.021

Li, Y., and Wang, Z. (2017). Wind tunnel experiment on polypeptide derivatives in controlling wind erosion. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 33 (5), 149–155. doi:10.11975/j.issn.1002-6819.2017.05.022

Liu, J., Feng, Q., Wang, Y., Bai, Y., Wei, J., Song, Z., et al. (2017). The effect of polymer-fiber stabilization on the unconfined compressive strength and shear strength of sand. Adv. Mater. Sci. Eng. 1–9. doi:10.1155/2017/2370763

Liu, J., Chen, Z., Song, Z., Bai, Y., Qian, W., Wei, J., et al. (2018). Tensile behavior of polyurethane organic polymer and polypropylene fiber-reinforced sand. Polymers 10 (5), 499. doi:10.3390/polym10050499

Luo, X., Li, J., Tang, G., Li, Y., Wang, R., Han, Z., et al. (2023). Interference effect of configuration parameters of vertical sand-obstacles on near-surface sand transport. Front. Environ. Sci. 11. doi:10.3389/fenvs.2023.1215890

Ma, G., Feng, E., Ran, F., Dong, Z., and Lei, Z. (2015). Preparation and sand-fixing property of a novel and eco-friendly organic-inorganic composite. Polymer-Plastics Technol. Eng. 54 (7), 703–710. doi:10.1080/03602559.2014.974271

Meng, X., Peng, G., Liu, B., Wang, B., Chen, H., Luo, R., et al. (2013). Synthesis and sand-fixing property of cationic poly (vinyl acetate-butyl acrylate-DMC) copolymer emulsions. J. Macromol. Sci. Part D, Rev. Polymer-Plastics Technol. Eng. 52 (9), 931–939. doi:10.1080/03602559.2013.763374

Pei, X., Liu, B., and Zhang, C. (2023). A bibliometric study on desertification control based on Web of Science and CNKI. Tianjin Agric. Sci. 29 (07), 71–81. doi:10.3969/j.issn.1006-6500.2023.07.013

Tao, L., Yang, X., Lv, Y., Tian, C., Zhang, W., Ren, J., et al. (2018). Characterization and performance study of concave convex rod based polymer sand fixing materials. Silic. Bull. 37 (02), 547–552. doi:10.16552/j.cnki.issn1001-1625.2018.02.028

Ting, Y., Deren, Y., and Na, Q. (2019). Water soluble seed gum sand fixing agent and its application effect. For. Sci. Technol. Commun. (05), 109–111. doi:10.13456/j.cnki.lykt.2018.06.28.0003

Wu, Z., Gao, W., Wu, Z., Iwashita, K., and Yang, C. (2011). Synthesis and characterization of a novel chemical sand-fixing material of hydrophilic polyurethane. J. Soc. Mater. Sci. Jpn. 60 (7), 674–679. doi:10.2472/jsms.60.674

Yan, D., Qu, N., and Xue, B. (2021). Study on the preparation conditions of water-soluble flaxseed gum sand fixing agent. Inn. Mong. For. Sci. Technol. 47 (04), 19–24.

Yangliu, (2011). Development and application of new chemical sand fixation materials. Lanzhou: Lanzhou University.

Yang, M. (2012). Preparation and performance study of cellulose based environmental sand retention agent. Beijing: Beijing University of Chemical Technology.

Yang, J., Wang, F., Fang, L., and Tan, T. (2007a). The effects of aging tests on a novel chemical sand-fixing agent–Polyaspartic acid. Compos. Sci. Technol. 67 (10), 2160–2164. doi:10.1016/j.compscitech.2006.10.02

Yang, J., Wang, F., Fang, L., and Tan, T. (2007b). Synthesis, characterization and application of a novel chemical sand-fixing agent-poly (aspartic acid) and its composites. Environ. Pollut. 149 (1), 125–130. doi:10.1016/j.envpol.2006.12.021

Yuan, J., Pei, Z., Yang, S., Yu, H., Hu, X., Liu, H., et al. (2023). Preparation and characterization of an eco-friendly sand-fixing agent utilizing nanosilica/polymer composites. J. Appl. Polym. Sci. 140 (18), e53804. doi:10.1002/app.53804

Zang, Y. X., Gong, W., Xie, H., Liu, B. L., and Chen, H. L. (2015). Chemical sand stabilization: a review of material, mechanism, and problems. J. Environ. Technol. Rev. 4 (1), 119–132. doi:10.1080/21622515.2015.1105307

Zheng, J., and Guo, D. (2018). A method for preparing high-quality locust bean gum. Fujian: CN108410922A.

Keywords: sand stabilizer, biomaterials, environmental protection, desertification control, wind erosion resistance

Citation: Ren T, Gao Y, Yuan L and Zhao C (2024) Robinia pseudoacacia sand stabilizer: its sand fixation effects and mechanical properties. Front. Environ. Sci. 12:1304830. doi: 10.3389/fenvs.2024.1304830

Received: 30 September 2023; Accepted: 11 January 2024;

Published: 01 February 2024.

Edited by:

Tao Wang, Chinese Academy of Sciences (CAS), ChinaReviewed by:

Chong Jiang, Guangdong Academy of Science (CAS), ChinaGuo Dong Tang, China Institute of Water Resources and Hydropower Research, China

Guang-Lei Gao, Beijing Forestry University, China

Copyright © 2024 Ren, Gao, Yuan and Zhao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yong Gao, MTM5NDg4MTU3MDlAMTYzLmNvbQ==

Tingjie Ren

Tingjie Ren Yong Gao1*

Yong Gao1*