94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Environ. Sci., 03 October 2023

Sec. Toxicology, Pollution and the Environment

Volume 11 - 2023 | https://doi.org/10.3389/fenvs.2023.1253108

This article is part of the Research TopicHazardous Contaminants Associated with Plastics: Occurrence and Environmental EffectsView all 7 articles

With the rapid development of China’s express delivery services, environmental concerns have increased owing to the use of plastic packaging bags (PPBs) which have a heavy metal (HM) content due to the incorporation of scrap plastics in the production process. We sourced a variety of PPBs from different express delivery parcels, identified the materials in the samples using Fourier-transform infrared spectrometry, and conducted HM analysis using inductively coupled plasma mass spectrometry. The results demonstrated that the main material type in the PPBs was polyethylene. The results showed that the potential health concerns were posed by the four HMs (nickel [Ni], copper [Cu], zinc [Zn], and arsenic [As]) presented in the PPB samples. The mean concentrations of HMs in the PPBs were ranked as follows (presented in unit mg kg−1): Zn (120.42 ± 85.15)> Cu (45.21 ± 56.55) > lead [Pb] (6.43 ± 6.57) > Cr (6.03 ± 6.82) > Ni (2.13 ± 2.14) > As (0.19 ± 0.15) > mercury [Hg] (0.17 ± 0.71) > cadmium [Cd] (0.14 ± 0.20). HM content varied according to sample type, with a ranking order of Rm > Pm > Bm, corresponding to the degree of environmental and health risk. For Rm samples, high levels of low-toxicity HMs, such as Zn and Cu were detected, with respective maximum values of 365.9 and 184.2 mg kg−1; furthermore, the levels of high-toxicity HMs (i.e., Cd and Hg) exceeded the standard values set by the express delivery sector (0.5 mg kg−1). Thus, more attention should be paid to the effective management of PPBs for polyethylene-based Rm types, such as the limitation of Zn, Cu, Cd, and Hg. This study provides baseline data regarding HM-incorporating PPBs for stakeholders and is expected to support the formulation of relevant products for use in greener packaging policy and, thus, contributes to the re-assessment of China’s “plastic ban” policy.

With the widespread use of plastic materials (PMs), there has been an extensive global focus on the impact of plastics on the environment and human health (Alam et al., 2018a; Ahmed et al., 2020; Xu et al., 2020). Particularly, the incorporation of various additives in PMs to enhance the physical and chemical properties of plastic products has become a serious concern (Turner A., 2016; Ahmed et al., 2020). Generally, PMs are manufactured using different types of polymers to optimize their properties and reduce costs; these enhancements include additives, such as organometallic compounds, which are encapsulated within a polymer matrix (Turner A., 2016; Eriksen et al., 2018; Hahladakis et al., 2018). Such additives are added as catalysts, pigments, or plastic stabilizers, which may contain a variety of heavy metals (HMs), such as lead (Pb), chromium (Cr), cadmium (Cd), mercury (Hg), nickel (Ni), copper (Cu), and zinc (Zn) (Turner A., 2016; Eriksen et al., 2018). However, several HMs are toxic to plants, animals, and microorganisms and have come into particular focus for human health (Alam et al., 2018a; Xu et al., 2020).

Approximately 80% of disposable plastic packaging bags (PPBs) eventually end up in the ocean, and by 2050, a continuation of this trend will result in more plastic than fish in the ocean (Xinhua News, 2018a). Combinations of plastic/additives (e.g., HMs) may be ingested by marine organisms (including humans) and incorporated into the food chain (Conti et al., 2021). There is a danger that beach sand will become polluted with Pb as plastic litter containing a high Pb content (313 ± 247 g) potentially paves a “pathway” of toxic metal accumulation over time, with Pb leaching of 0.6 ± 0.6 g/year (Nakashima et al., 2012). In addition, a recent study reported four types of HMs in the blood samples of plastic industry workers, and their relative potential cancer concern was verified (Ahmed et al., 2020). Previous studies on the characteristics of HMs in PMs have focused mainly on plastic toys and marine plastic litter (Ahmed et al., 2012; Nakashima et al., 2012; Alam et al., 2018a), whereas studies on plastic bags (PBs), especially PPBs used in the express delivery sector, are still insufficient.

In recent decades, with the rapid growth of e-commerce and online shopping in China, Chinese express delivery volumes have markedly increased from 110 million pieces in 2010 to over 108 billion pieces in 2021 (SPBC, 2021). With the explosive growth in delivery volumes, express packing materials are in high demand. One report revealed that approximately 22.3 million pieces of packaging material were used in China in 2016 at the national level, and express delivery PPBs accounted for nearly one-third of the total packaging materials used (SPBC, 2017). The majority of waste PPBs have been mixed into municipal solid waste (MSW) for co-disposal via landfill and incineration. Only 3% of PPBs are recycled (Su et al., 2020), which results in the loss of waste resources and potential environmental damage or pollution (Liu and Yao, 2017). In China, various materials usually used in express delivery PPBs are prepared from recycled plastic in workshops, which are mixtures of various polymers produced by different manufacturers and often contain contaminants, such as metals, poorly soluble elastomers, paper fiber labels, flame retardants, printing inks, pigments, surfactants, residues of binders, and other contact media (fats and oils) (Eriksen et al., 2018; Hahladakis et al., 2018). Owing to the complexity of the raw materials and the uncertainty of the recycling process, it is necessary to analyze the characteristics of the types of PMs and the incorporated HMs to gain a complete understanding of the environmental impacts of PPBs used in express delivery.

Several types of waste PMs of different colors are widely used as PPBs in the express delivery sector, including polyethylene (PE), high-density polyethylene (HDPE), polypropylene (PP), and polystyrene (PS) (Zhou et al., 2014; Alam et al., 2018a). In general, the toxic metal content in these types of polymers is low when derived from raw material; for example, the Pb content in PE-based PBs produced from raw materials was <5 mg kg-1, while the Cd or Cr content was ≤2 mg kg-1 or even below the limit of detection (Mei et al., 2011; Zhou et al., 2014). However, most PBs are not formed using raw materials, and the HM content is generally high and varied according to usage. For example, Pb and Cr detected in garbage plastic bags (GPBs) of different colors were found to be very high (4,779 & 1,138 mg kg-1), even exceeding the recommended standard, while the corresponding values in white plastic carrier bags (PCBs) from supermarkets were considerably low (1.5 and 34 mg kg-1, respectively) (Huerta-Pujol et al., 2010). Owing to their lower toxicity and minor public health concerns, the impacts of other types of HMs, such as Cu, Zn, Ni, and As, have remained under-explored. However, a recent study showed that the Cu and Zn content in HDPE blue GPBs was as high as 429 and 130 mg kg-1, respectively (Alam et al., 2018a).

The Chinese government has recommended/stipulated standard values for several HMs (e.g., Pb, Cr, Cd, and Hg) in PPBs (GB/T 16606.3-2018) (SAC, 2018), while other toxic metals (e.g., As) have been omitted. China’s national standard, as applied for the standardization of HM content in express delivery PPBs (GB/T 16606.3-2018), provides a threshold value, in which the total amount of four toxic HMs (c (Pb) + c (Cr) + c (Cd) + c (Hg) ≤100 mg kg-1) is considered. To effectively manage PPBs in China, it is necessary to quantify the characteristics of various types of HMs in express delivery PPBs and further understand their environmental and health concerns. Previous studies on HMs in PMs have focused primarily on plastic toys and marine plastic litter (Ahmad et al., 2012; Nakashima et al., 2012; Turner A., 2016; Igweze et al., 2020), whereas the relative studies on PBs remain insufficient. Limited studies focused on HMs in PBs have mainly been conducted from the perspective of PCBs from supermarkets and GPBs (Huerta-Pujol et al., 2010; Alam et al., 2018a). Therefore, we aimed to determine the incorporation of HMs in express delivery PPBs.

In the field survey, in early 2019, we collected PPBs for express parcels (3,600 pieces) from different sources in Shenzhen City, including PPBs for various uses, such as inner packaging, external packaging, and filling materials from different express companies. The types and mass of materials were determined. Among the 3,600 surveyed samples, we found three types of express delivery PPBs of different colors: white, green-yellow, and grey-black, with proportions of approximately 5%, 15%, and 80%, respectively. White plastic and pearly-luster bags belong to the “white-collar class” in express packaging materials as they are produced completely from raw materials (Bm type) and are provided by the upstream petrochemical plastic plant. Plastic airbags, which are another type of white plastic packaging material, are used as a protective filling packaging material (Fm). The green-yellow packaging belongs to the “blue-collar class” and is also referred to as miscellaneous plastic materials (Pm). This packaging is prepared by mixing recycled materials (recycled plastics and scrap-leftover from industrial processes) with other raw materials in various proportions. The grey-black package refers to the “grey-collar class” termed recycled plastic materials (Rm), which is made entirely from a variety of recycled PMs. Notably, the white, blue, and grey-collar classes represent the three income levels of Chinese workers: high, middle, and low income, respectively. This indicates that the respective shares of raw materials derived from the three types of express delivery PPBs were at high, middle, and low levels.

In consideration of representativeness and cost/time, four groups were derived from a total of 18 express delivery PPBs, as shown in Table 1: the Rm group (grey-collar class, 11 samples), the Pm group (blue-collar class, 2 samples), and the FM and BM groups (white-collar class, respective 2 samples each). Table 1 shows (a) the samples represented the major types of plastic packaging materials used for express parcels, including the various types of plastic bags described above; (b) random sampling of each plastic type from various sources taking into account variables/factors such as quantity, cities, source/generator; and (c) “Cost”. The available budget guided the sample analysis. The mass of the individual PPB samples was approximately 3-25 g. Detailed information on the samples tested in this study is provided in Table 1.

Fourier transform infrared spectroscopy (FTIR) is often used to reveal the internal structures of plastic samples and provide compelling evidence for plastic identification (Turner A., 2016). FTIR was used to identify the component polymers of PPBs. The specific process was conducted according to the four procedures in Figure 1.

To avoid background particle interference derived from impurities and dust, three pre-processing procedures were conducted by our research team. The first step was the removal of impurities (e.g., plastic tape and expressway bills). The second step involved cleaning the surface with ethanol. In the third step, the samples were cut into small pieces (generally 2 × 2 cm) with scissors to obtain a homogenous size.

After pre-processing, the samples were scanned using the reflective scanning device of the FTIR (Nicolet-6700) with a range of 400–4,000 cm−1 in the mid-infrared (MIR) region. The FTIR parameters included a sample scanning time of 32 s, resolution power of 4 cm−1, sampling gain of 1.0, dynamic mirror speed of 0.6329, and a diaphragm of 100. A DTGS-KBr detector with a KBr beam splitter was used.

Infrared spectrum data were automatically processed using the Nicolet-6700 device in three processing steps. The first step, mainly for the convenience of further comparison and analysis among different samples, involved normalization of the data by mapping the infrared spectrum data in the range of 0–1. The latter two steps were used to extract the characteristic peaks and smooth them to eliminate noise.

A correlation algorithm was used to compare the characteristic peaks in the infrared spectra of unknown plastics with the standard spectra stored in a spectrum database. The unknown plastics were further identified using the correlation coefficient of parameters such as absorbance (Weng and Xu, 2017). After processing the data, the Nicolet-6700 device provided a visual spectrum that included the absorption strength of the absorption peaks.

Inductively coupled plasma-mass spectrometry (ICP-MS) is an effective method for detecting trace amounts of toxic elements (Nardi et al., 2009; Ahmad et al., 2012) and has been used to analyze the concentration of eight types of HMs, namely, lead (Pb), chromium (Cr), cadmium (Cd), mercury (Hg), nickel (Ni), copper (Cu), zinc (Zn), and arsenic (As). Figure 2; Supplementary Figure S1 document the HMs determination procedure for the sampled PPBs. To eliminate the interference from ambient organic matter, a pre-processing procedure was performed. First, 0.2 g of the pretreated sample was placed in a polytetrafluoroethylene micro-digestion tank, to which HNO3 (8.0 mL) and H2O2 (2.0 mL) were added. Finally, samples were digested using a microwave digestion instrument (CEM Xpress, United States) via a three-step procedure. Microwave digestion-A, a recently developed method for sample pretreatment, involves the use of high-pressure digestion and microwave heating, providing the advantages of a rapid digestion rate, complete sample digestion, and high recovery (Bakircioglu et al., 2011; Millour et al., 2011). After digestion, the sample was cooled, and the digested solution was transferred to a 25.0-mL volumetric flask and labeled with 3% nitric acid (guaranteed reagent; GR) to test the constant volume. Before the ICP-MS procedure, blank and standard/control samples were prepared using the sample digestion method. Blank samples were collected and treated using the same procedures as the real samples. Blank corrections were performed by deducting the blank value of each metal from its real sample concentration. Standard/control samples were prepared for the standard content curves of HMs.

Standard HM solutions (National Institute of Metrology, China) at concentrations of 0.00, 0.10, 0.25, 0.50, 1.00, and 2.00 mg/L were prepared in 3% nitric acid to create the calibration curves for each of the tested elements. The digested constant volume solution was quantitatively analyzed using ICP-MS (PerkinElmer NexION 350, United States) in triplicate, and the Pb, Cr, Cd, Hg, Ni, Cu, and Zn in the sampled PPBs (Table 1) were calculated.

Descriptive statistics (mean, standard deviation) and a one-way analysis (ANOVA) were performed using SPSS statistics software (IBM, V26.0). In order to verify whether means obtained for HMs contaminants from different types of samples, including Bm, Rm, Pm, and Fm samples were statistically different at p < 0.05, a multiple comparison test (F test) based on LSD statistical analysis was conducted.

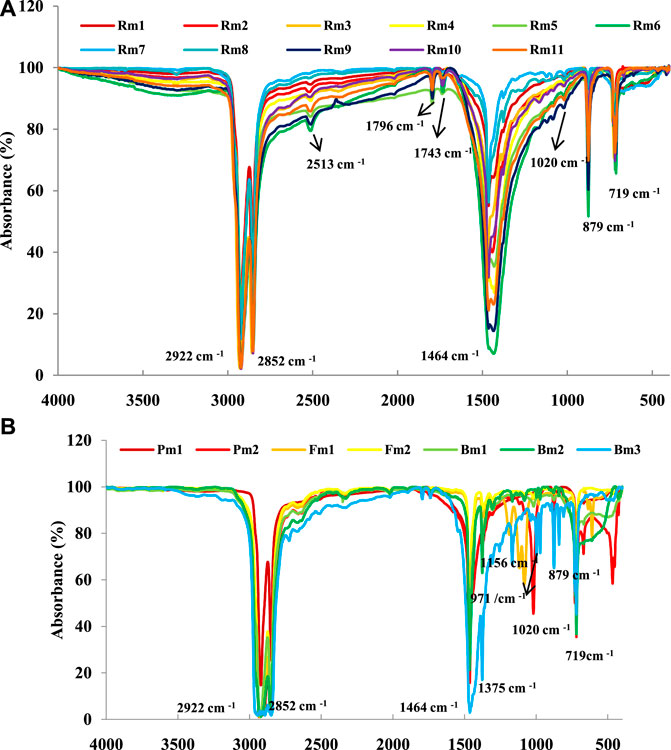

The elemental composition of PBs influences the release of pollutants and their energy recovery efficiency (Alam et al., 2018a). To identify the PPBs samples, detailed information on the internal structure of the samples was examined using FTIR in the present study, and the main components of the PPBs were detected using mid-infrared data, displayed as graphical peaks in the range of 200–4000 cm−1 (2.5–50 um). The specific infrared analysis data are shown in Figure 3; Table 2 (in the range of 700–3,000 cm−1). The test infrared data were compared with the PE-labeled spectra, where the Rm1–11 samples showed absorption peaks at 2,922, 2,852, 1,464, and 719 cm−1, which were among the front peaks corresponding to the antisymmetric stretching vibration, symmetric stretching vibration, and complete vibration of methylene (

FIGURE 3. FTIR-ATR spectra of express plastic bags (wavelength, cm−1). Note: (A) Rm samples (specific data see Supplementary Figure S2) and (B) Pm, Fm, and Bm samples (for the other specific information, see Supplementary Figures S3–S5). Owing to the similarity of plastic materials in each bag sample (including polyethylene or a mixture of PE/PP), the reference spectra for different PPBs appear uniform (with curves of various colors almost overlapping).

Overall, the experimental infrared data were compared with the standard spectra of polyethylene (PE) and polypropylene (PP), which are non-degradable materials, suggesting high environmental and health concerns posed by PPBs. FTIR confirmed that the PPB samples were PE materials based on the comparison, except for sample Bm3, which contained a mixture of PE and PP.

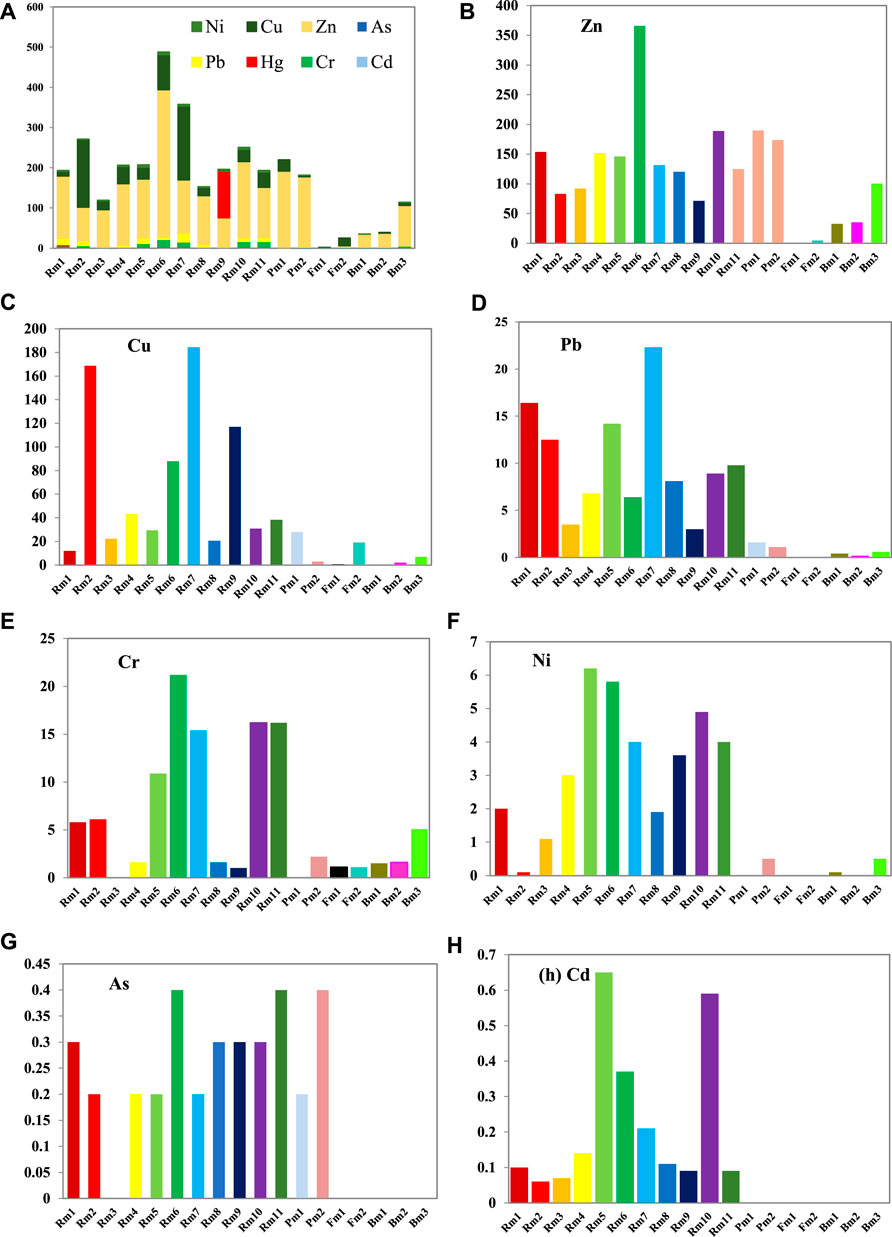

As shown in Figure 3, the mean concentrations of HMs in PPBs are ranked as follows: Zn > Cu > Pb > Cr > Ni > As > Hg > Cd. HM values for the eight types of HMs examined are presented in Figures 4B–H, with the mean values of 120.42 ± 85.15, 45.21 ± 56.55, 6.43 ± 6.57, 6.03 ± 6.82, 2.13 ± 2.14, 0.19 ± 0.15, 0.17 ± 0.71, and 0.14 ± 0.20 mg kg-1, respectively. High levels of Zn, Cu, Pb, and Cr are added in express delivery PPBs, which is in line with some studies related to PCBs sourced from supermarkets (Alam, et al., 2018a). However, the Pb and Cr contents did not exceed the Chinese national standard for the express delivery of PPBs (GB/T 16606.3-2018, 50 mg kg-1 for each) (SAC, 2018). Although the standard (GB/T 16606.3-2018) does not specify restriction values for Ni, Cu, Zn, and As (SAC, 2018), the potential environmental and health concerns related to the four types of HMs should not be overlooked.

FIGURE 4. Heavy metals content (mg kg–1) in express delivery plastic bags: (A) refers to the contents of eight types of HMs for various samples, while (B–H) stand for the contents of Pb, Cr Cd, Ni, Cu, Zn, and As, respectively.

For the four HMs (Pb, Cr, Cd, and Hg) in the PBB samples, both the mean concentration of the individual HMs and their aggregated content meet the standard (restriction) values for PPBs in the express delivery section (GB/T 16606.3-2018) (SAC, 2018; Qi et al., 2019), with individual and aggregated content restriction values of 50, 50, 0.5, 0.5, and 100 mg kg-1, respectively (Qi et al., 2019). The restricted values of the aggregated concentration of the four metals were also in line with the corresponding values in the European Union (EU) in 1996 (94/62/EC, Packaging and Packaging Waste Act). The four types of HMs blended in PB reached a toxic and excess level, which potentially contributed to environmental and public health concerns. However, there is no recommended standard for the addition of Ni, Cu, Zn, or As to PBBs.

The concentration of HMs varied according to the sample type, a significantly higher amount of HMs was observed in the Rm samples than in the other types of PPB samples (Supplementary Table S1). As shown in Figure 4A, the Rm samples presented the highest concentration among the four types of HM samples analyzed, followed by Pm samples (Figures 4B–H). The HM values were low in both Fm and Bm samples.

The physical characteristics of the sampled PPBs, such as roughness, smell, and color, possibly corresponded to the HM content distribution. For example, Rm samples were characterized by a strong smell, rough surface, and black or dark-gray color (Table 1), which was primarily attributed to the pigment and printing ink in the plastic materials containing high levels of HMs (Alam et al., 2018a; b; Huerta-Pujol et al., 2010; Turner A., 2018). In contrast, no smell or smooth surface was observed in the Fm and Bm samples (except a faint smell in Pm2). This finding is in line with other studies; virgin plastic generally contains lower metal concentrations than reprocessed plastic and un-processed plastic waste (Eriksen et al., 2018; Wen et al., 2021).

Among the four low-toxicity HMs, namely, Zn, Cu, Pb, and Cr, the highest level was Zn samples (Figures 4A, B). The Zn detected in all Rm (148.17 ± 80.00 mg kg-1) and Pm (181.90 ± 11.17 mg kg-1) was significantly higher than in other the types of samples, i.e., Fm and Bm (p < 0.05, Supplementary Table S1), especially the Bm samples. Zn values in Rm and Pm samples were significantly higher than in PE-based PCBs from supermarkets (20–112 mg kg-1) (Huerta-Pujol et al., 2010) and higher than in blue HDPE GPBs (130 mg kg-1) (Alam et al., 2018b). The maximum Zn value (365.9 mg kg-1) detected in sample Rm6 was over 20 times that detected in PE-based compostable GPBs (16 mg kg-1) with high biodegradability (denoted as biodegradable GPBs henceforth) (Huerta-Pujol et al., 2010). In compassion, while the Zn detected in Fm and Bm samples was low, the mean values (56.23 ± 38.53 mg kg-1) were still over three times those of the biodegradable PPBs (Huerta-Pujol et al., 2010). Four types of express delivery PBBs examined indicated that environmental and human health concerns from Zn were present. Similarly, the highest Cu levels were detected in Rm samples, and Cu levels were especially high compared to in Bm samples (p < 0.05) (Supplementary Table S1). The Cu content (68.53 ± 61.87 mg kg-1, Figure 4C) in our study was lower than that in the PE-based PCBs from supermarkets (87 ± 42 mg kg-1 mg kg-1), even considerably lower than in the blue HDPE used for garbage collection (429 mg kg-1) (Huerta-Pujol et al., 2010; Alam, et al., 2018b), but was over three times that in the biodegradable PE PBs (20 mg kg-1) (Huerta-Pujol et al., 2010). In the compassion, the Cu values detected in Fm samples and Bm samples (15.50 ± 17.17 mg kg-1 and 3.00 ± 3.61 mg kg-1) were significantly lower (Figure 4C), with respective mean values lower than those in biodegradable PE-based PBs (Huerta-Pujol et al., 2010). Our results indicated environmental and human health concerns related to Cu in Rm express delivery PBBs. The contents of Zn and Cu in the examined samples showed potential correlations, especially in Rm plastics. Given these results, we speculate that some metal-coated plastics were mixed with Rm plastics. Metal-coated plastic refers to the application of coating materials containing metal on the surface of plastic substrates through electroplating, spraying, or hot-pressing processes. Most coated metals include Al, Zn, and Cu elements. Polyolefins containing metal coatings are mainly packaging made of LDPE films, aluminum foils, and vacuum-sprayed PP and PE films. Polyolefin film plastics containing metal coatings are mainly used to fabricate packaging films for high-grade products. Plastic films sprayed with metal layers are usually removed by stripping, scraping, and other logistical methods. Waste plastics with a complicated metal recovery process during cleaning will be mixed and granulated and used as raw materials for low-grade products, which may be sources of recycled materials for express packaging. Due to the potential environmental hazards associated with the use of metal-coated plastic recycling, the Chinese government issued two standards: GB 16487.12-2017 (national) and SN/T 1791.1-2018 (SPC & MEPC, 2017) (industrial association), for classifying metal-coated plastic and related products as generally controlled prohibited imports, with the metal content in coated plastic not exceeding 5% (Cox, 1988). However, due to inadequate supervision, some disqualified plastics are smuggled into mainland China. It is anticipated that the strict enforcement of China’s foreign waste ban policy implemented in 2020, will gradually alleviate this problem.

Pb and Cr presented a similar trend in sample types (Figures 4D, E), with high levels observed in Rm and Pm samples-especially in Rm samples, with mean values of 10.17 ± 5.79 mg kg-1 and 8.73 ± 7.55 mg kg-1, respectively. Furthermore, the Pb value in Rm samples was significantly higher than in the other three types of samples (p < 0.05, Supplementary Table S1); the high concentration of Pb in Rm samples could be explained by the use of lead chromate (PbCrO4) pigment in recycling PMs processing steps, used in impregnation and dyeing (Sakai, et al., 2009). However, Pb and Cr values in Rm samples were significantly lower than those in PE-based disposable PBs (458–4,779 mg kg-1) and marine plastic litter (87 mg kg-1) (Huerta-Pujol et al., 2010; Turner A., 2016), while they were slightly higher when compared to PE-based biodegradable PPBs (Huerta-Pujol et al., 2010), suggesting a low environmental and human health concern regarding Pb and Cr in the Rm PPBs. Correspondingly, the Pb and Cr values in Pm samples (with mean values of 1.35 mg kg-1 and 1.10 mg kg-1, respectively) were slightly above the food standard for fruit and vegetable products (1 mg kg-1, GB 2762-2017) (SHFPC & SFDA, 2017) but lower than the corresponding values in degradable PBs (8 and 2 mg kg-1) with high biodegradability (also called degradable PBs) (Huerta-Pujol et al., 2010). The level was also significantly lower than that indicated for plastic toys in China (4–10 and 2–7 mg kg-1) (Igweze et al., 2020). The Pb values in Fm samples were below the limit of detection (<0.1 mg kg-1), while those in Bm samples, with a mean value of 0.4 mg kg-1, were significantly below the food standard for fruit and vegetable products (1 mg kg-1, GB 2762-2017) (SHFPC & SFDA, 2017).

Figures 4A, F–H present the low-level HMs (Ni, As, Hg, and Cd) observed in the present study. Ni and As were detected in all Rm and Pm samples and were significantly higher than in their respective Fm and Bm samples (p < 0.01, Supplementary Table S1), indicating the wide use/presence of Ni and As in Rm and Fm types of express delivery PBBs. This indicative evidence should not be ignored. The mean value of Ni detected in Rm samples was 3.36 ± 1.86 mg kg-1 (the maximum value of 6.2 mg kg-1 was observed in Rm5), which was considerably lower than that in PE-based marine plastic litter (29 mg kg-1) and PE-based supermarket PCBs with different colors (8.3 ± 2.4 mg kg-1) (Huerta-Pujol et al., 2010), and comparable to the value in PE-based white GPBs (3.7 ± 1.2 mg kg-1). The Ni content in the other types of samples was lower than the detection limit (for four samples) or below 0.5 mg kg-1 (for three samples). Similarly, low As levels were found in Rm and Pm samples, while the As content in Fm and Bm samples was below the detection limit. The individual As level detected in Rm and Pm samples was <0.5 mg kg-1, significantly lower than that in children’s toys with plastic elements (1.5-6.3 mg kg-1), which have been considered of low health concern to Children (Igweze et al., 2020), as well as lower than that acceptable in grain and sugar, according to the National Safety Standard for Pollutants in Food (GB 2762-2017) (SPC & MEPC, 2017). The findings related to Ni and As in the present study suggest low environmental and health concern; however, these two types of metals remain a health concern due to frequent exposure in daily life, as they are widely present in express delivery PBBs. As an example, a relevant health concern is that Ni ions can penetrate the skin through pores and sebaceous glands, causing skin allergies and inflammation (Lidén and Johnsson, 2001; Ahmad et al., 2012).

Although the Cd and Hg values were considerably lower than those of the other six types of HMs, the individual Cd and Hg levels in some Pm samples exceed the respective standard content for express delivery PPBs (GB/T 16606.3-2018) (SAC, 2018; Qi et al., 2019). The content of both Cd and Hg should not exceed 0.5 mg kg-1, according to the standards, while the individual Cd and Hg in some Rm samples, namely, Rm5 and Rm10 for Cd and Rm1 for Hg, amounted to 0.65, 0.59, and 3 mg kg-1, respectively. Our findings suggest that Pm PPBs still pose high environmental and human concerns with respect to their Cd and Hg. However, the Cd content in Pm, Bm, and Fm PPBs was lower than the detection limit (0.05 mg kg-1). The Hg content of 18 samples tested was below the detection limit (<0.1 mg kg-1), indicating that Hg is relatively easy to control. Moreover, Hg is not an essential element in additives related to plastic production and processing, and only a minute amount of Hg is inherent in packaging materials (Mei et al., 2011).

Currently, the vast majority of express delivery PPBs are mixed with domestic waste for co-disposal, eventually entering incineration systems or landfills (Su et al., 2020), where the PPBs gradually release or leach out toxic materials such as HMs (Alam et al., 2018a; Alam et al., 2018b; Xu et al., 2020). Some studies have demonstrated the widespread use of hazardous metals in plastics, which can be released into the environment or absorbed by humans through the food chain (Lin et al., 2023; Peng et al., 2023). HMs do not bind to polymer molecules that originate from additives or contaminants attached to the surface of PPBs (Muthu and Li, 2013); thus, the primary environmental and health concern regarding PPBs is the release of HMs. The leaching behavior of HMs depends on the HM content and type. A considerable amount of leachable HMs has been found in different PE polymers (Alam et al., 2018a; Alam et al., 2018b; Xu et al., 2020). For example, the amount of leaching of Pb, Cd, and Cr from PE-based PBs ranging from 0.70 to 3.58 mg/kg with different temperatures (cooking, sunlight, and heating) (Alam et al., 2018b), markedly exceeded Chinese national drinking water standards (Supplementary Table S2). In particular, Pb is completely desorbed and released into the simulated digestive systems within 10 h (Lin et al., 2023).

Although consumers have minimal daily contact with express bags, a special group comprising express delivery practitioners working with plastic materials should not be overlooked, especially as the sector has shown an upward growth trend. With the advancement of technology, the sorting of express delivery parcels in large regional centers has been professionalized. However, for certain grassroots sites and express delivery processes, contact between express delivery personnel and plastic express bags is inevitable. Furthermore, perspiration by workers may enhance the precipitation of HMs from recycled PBs, which is of great concern in the present study.

The presence of HM-containing PPBs represents a potential source of localized contamination within the ecological environment. The Rm and Pm samples examined in the present study indicated high concentrations of the eight types of HMs discussed in Section 3.1, as well as in most express delivery PPBs from recycling materials (Rm, 80%) or the mixture of original material and recycling materials (Pm, 15%), as indicated in Section 2.1. Hence, these two types of PPBs, especially Rm PPBs, are of particular concern for both the environment and human health. We recommend effective and timely measures to reduce or avoid potential environmental pollution and the toxic effects of PPBs (especially Rm PPBs) on organisms (including humans).

First, it is crucial to address the issue of standards/legislation on additives such as HMs in express delivery PBBs focused on the sources. We urge the Chinese government to announce relative standards/legislations to restrict the content of HMs in Rm and Pm PPBs, particularly with respect to Rm PPBs. Some HM elements, such as Ni, Cu, Zn, and As, should also be restricted, as has been provided for the other four types of HMs in PBBs considered in this study (GB/T 16606.3-2018).

Second, the government and enterprises should take action toward reducing the quantity of manufacture and consumption of Rm PPBs with high HM values; for example, by promoting the use of environmentally friendly PBs, such as biodegradable PPBs. Some studies have verified that biodegradable bags contain low quantities of HMs compared with other disposal PBs (Huerta-Pujol et al., 2010). However, it is difficult to market environmentally friendly PBs to replace recycled PPBs in a short time because of their relatively high cost compared to recycled PPBs (see Supplementary Figure S6). We conducted a comparison analysis of garbage bag prices listed on the Chinese Tmll platform, assessing recycled PBs and various types of degradable PBs (Supplementary Figure S6), which showed that the price of degradable PBs was considerably higher than that of recycled PBs (approximately 2–7 times higher than recycled PBs). Rm plastic materials (recycled PMs) for various purposes (not just express packaging) have a much lower cost than the environmentally friendly express packaging bags in China. Our previous investigation confirmed that e-commerce companies tend to buy inexpensive recycled PBs (Duan et al., 2019). However, the Chinese government has been gradually introducing more rigid and enforceable policies to address and influence this situation through the use of incentive measures (e.g., a subsidy for eco-friendly plastic material producers) (Varma et al., 2016; Song et al., 2018). A good starting point for the effective management of PPBs is China’s ban on the use of disposable non-degradable plastic products in some major cities from the beginning of 2021 (Xinhua News, 2021).

Finally, effective management of PPBs at the end-of-life stage is recommended; for example, the implementation of separate collection and disposal aimed at Pm waste with high HM concentrations. Currently, most PPBs are mixed into MSW channels and disposed of in landfills or incinerated, as mentioned above. Another effective measure is to improve the reuse and recycling rates of PPBs, which has proven to be an effective option for reducing plastic pollution (Gómez and Escobar, 2021; Sakthipriya N., 2021). These PPB materials are usually fossil-based, and reuse and recycling tend to present greater environmental benefits than landfilling or incineration, regardless of energy recovery (Gómez and Escobar, 2021; Sakthipriya N., 2021). This could help reduce the consumption of Rm and Pm PPBs and support the UN General Assembly’s 2018 global campaign against plastic pollution (Liu and Yao, 2017). Considering the low HM concentrations in both the Fm and Bm samples and the high recycling value of the PE type in this study, the reuse and recycling of the two types of express delivery PBBs should be prioritized. Given environmental and health concerns, the content of HMs derived from the additives for the reuse and recycling of these recommended samples should be restricted to meet the standards and legislation during their manufacture.

Reducing the use of disposable PBs and improving the reuse and recycling rate of express delivery PBBs will help curb the “white pollution” and conserve resources. Notably, the Chinese government implemented certain policies, and by 1 June 2008, all Chinese retailers were required to no longer provide free plastic shopping bags, and ultra-thin PBs (those thinner than 0.025 mm) were banned. Between 2008 and 2016, a nationwide campaign reduced the number of PBs consumed in China’s large stores and supermarkets by two-thirds, equivalent to a decrease in PB consumption of 1.4 million tonnes and carbon dioxide emissions of 30 million tonnes (Xinhua News, 2018b). However, this accounts for only 10% of the total amount of PBs. Moreover, this policy has not been strictly implemented in farmers’ markets and grocery stores in China (Xanthos and Walker, 2017). Additionally, the economic cost of recycling disposable PPBs is extremely high. Express delivery companies, e-commerce, and scavengers typically do not intend to recycle express delivery bags without government subsidies. Thus, there is still a long way to go for the effective management of express delivery PPBs.

The present study has some limitations (including some uncertainties and errors).

First, because of cost and time, small sample sizes of PPB samples in Pm and Fm were quantified for the study, and the material type selected primarily focused on PE-based PPBs, which possibly led to some uncertainties or errors regarding the HM content. For a systematic and in-depth understanding of the characteristics of HMs in PPBs, future studies should increase the sample size and material types applied to PPBs, such as PS, HDPE, PP, and PS (Zhou et al., 2014; Alam et al., 2018a).

Second, the environmental and health concerns of PPB samples were analyzed primarily based on HM content, especially for PE-based Rm samples. However, the observed leaching behaviors were widely presented for the types of PBs at their life-end stages, irrespective of the test conditions (Alam et al., 2018a). In particular, considering the presence of contact between express delivery personnel and plastic express bags, to explore the potential threat to health concerns for express delivery practitioners, further studies should be conducted on the leaching behavior of HMs, especially targeting PE-based Rm PPBs, as well as the leaching quantity of HMs.

In this study, the component polymers of express delivery PPBs and their toxic element (HMs) contents were identified using FTIR and ICP-MS, respectively. The main conclusions can be summarized as follows:

1) The findings showed that the PPB samples were PE-based PBs, except for sample Bm3, which contained a mixture of PE and PP materials, suggesting the potential environmental and health concerns of the samples derived from the non-degradability of the materials; thus, the use of biodegradable PPBs should be promoted.

2) The HM content varied by sample type; eight types of HMs were widely present and were found to be higher in the Rm and Pm samples than in the other types of samples. For example, the highest levels of Zn and Cu were detected in the Rm and Pm samples, especially in the Rm samples, and their Cd and Hg concentrations exceeded the standard values, highlighting the high environmental and human concerns regarding recycled PE-based Rm PPBs.

3) Sound management should be conducted to reduce the potential environmental and health concerns posed by HMs, for example, at the material manufacturing stage, to issue the relative standard/legislation restriction for additives in express delivery PBBs aimed at Ni, Cu, Zn, and As; at the materials consumption stage, to reduce the usage of recycled PE-based PPBs; and at the end-of-life stage of PPB waste, separate collection and disposal of recycled PE-based PPB waste should be developed, along with the reuse and recycling of other types of PPBs.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

YJ was involved in investigation, conceptualization, methodology, and writing–original partial draft preparation. GS was involved in supervision, methodology, and writing the original manuscript. HZ was involved in partial formal analysis and methodology, editing the original manuscript, partial formal analysis and data curation, and funding acquisition. All authors contributed to the article and approved the submitted version.

This work was supported by Scientific Research Projects of the Education Department of Hubei Province, P.R. China (Grant No. B2020053).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenvs.2023.1253108/full#supplementary-material

Ahmad, N., Nasibullah, M., Hassan, F., Singh, A. K., Patel, D. K., Khan, A. R., et al. (2012). Heavy metal assessment of leachates of some plastic toys purchased from different districts of UP. Int. Res. J. Environ. Sci. 1, 32–36. doi:10.5897/AJB10.480

Ahmed, M. S., Yesmin, M., Jeba, F., Hoque, M. S., Jamee, A. R., and Salam, A. (2020). Risk assessment and evaluation of heavy metals concentrations in blood samples of plastic industry workers in Dhaka, Bangladesh. Toxicol. Rep. 7, 1373–1380. doi:10.1016/j.toxrep.2020.10.003

Alam, O., Billah, M., and Yajie, D. (2018a). Characteristics of plastic bags and their potential environmental hazards. Resour. Conserv. Recy. 132, 121–129. doi:10.1016/j.resconrec.2018.01.037

Alam, O., Wang, S., and Lu, W. (2018b). Heavy metals dispersion during thermal treatment of plastic bags and its recovery. J. Environ. Manage. 212, 367–374. doi:10.1016/j.jenvman.2018.02.034

Bakircioglu, D., Kurtulus, Y. B., and Ucar, G. (2011). Determination of some traces metal levels in cheese samples packaged in plastic and tin containers by ICP-OES after dry, wet and microwave digestion. Food Chem. Toxicol. 49, 202–207. doi:10.1016/j.fct.2010.10.017

Borkenhagen, J. F., Connor, E. L., and Stafstrom, C. E. (2013). Neonatal hypocalcemic seizures due to excessive maternal calcium ingestion. Pediatr. Neurol. 48, 469–471. doi:10.1016/j.pediatrneurol.2013.02.010

Conti, I., Simioni, C., Varano, G., Brenna, C., Costanzi, E., and Neri, L. M. (2021). Legislation to limit the environmental plastic and microplastic pollution and their influence on human exposure. Environ. Pollut. 288 (80), 117708. doi:10.1016/j.envpol.2021.117708

Cox, J. W. (1988). Industrial applications for substrates of metallized film. J. Plast. Film. Sheet. 4, 43–49. doi:10.1177/875608798800400106

Das, P., and Tiwari, P. (2018). Valorization of packaging plastic waste by slow pyrolysis. Resour. Conserv. Recy. 128, 69–77. doi:10.1016/j.resconrec.2017.09.025

Duan, H. B., Song, G. H., Qu, S., Dong, X., and Xu, M. (2019). Post-consumer packaging waste from express delivery in China. Resour. Conserv. Recy. 144, 137–143. doi:10.1016/j.resconrec.2019.01.037

Eriksen, M. K., Pivnenko, K., Olsson, M. E., and Astrup, T. F. (2018). Contamination in plastic recycling: Influence of metals on the quality of reprocessed plastic. Waste. Manage. 79, 595–606. doi:10.1016/j.wasman.2018.08.007

Gómez, I. D. L., and Escobar, A. S. (2021). The dilemma of plastic bags and their substitutes: A review on lca studies. Sustain. Prod. Consump. 30, 107–116. doi:10.1016/j.spc.2021.11.021

Hahladakis, J. N., Velis, C. A., Weber, R., Iacovidou, E., and Purnell, P. (2018). An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 344, 179–199. doi:10.1016/j.jhazmat.2017.10.014

Heydariaraghi, M., Ghorbanian, S., Hallajisani, A., and Salehpour, A. (2016). Fuel properties of the oils produced from the pyrolysis of commonly-used polymers: Effect of fractionating column. J. Anal. Appl. Pyrol. 121, 307–317. doi:10.1016/j.jaap.2016.08.010

Huerta-Pujol, O., Soliva, M., Giró, F., and López, M. (2010). Heavy metal content in rubbish bags used for separate collection of biowaste. Waste. Manage. 30, 1450–1456. doi:10.1016/j.wasman.2010.03.023

Igweze, Z. N., Ekhator, O. C., and Orisakwe, O. E. (2020). A pediatric health risk assessment of children's toys imported from China into Nigeria. Heliyon 6 (4), 03732. doi:10.1016/j.heliyon.2020.e03732

Lidén, C., and Johnsson, S. (2001). Nickel on the Swedish market before the nickel directive. Contact Dermat. 44 (1), 7–12. doi:10.1034/j.1600-0536.2001.440102.x

Lin, W. H., Wang, H. Y., Kuo, J., and Lo, S. L. (2023). Adsorption and desorption characteristics of heavy metals onto conventional and biodegradable plastics. Chemosphere 333, 138920. doi:10.1016/j.chemosphere.2023.138920

Liu, J. Q., and Liu, Y. (2017). Research on construction of express packaging waste recycling industry in China and its impacts on environment. J. Environ. Sci. Manage. 42 (5), 18–21. https://en.cnki.com.cn/Article_en/CJFDTotal-BFHJ201705004.htm

Mei, N. S., Han, X. S., and Liu, H. (2011). The principle and recommendation of environmental protection assessment for plastic packaging materials. China Packag. 31, 54–58. https://kns.cnki.net/kcms2/article/abstract?v=3uoqIhG8C44YLTlOAiTRKgchrJ08w1e7tvjWANqNvp9NMsnXnm2QBeYOiUv4n-_Ifp2ji0d-3-v9rGSk6UTmnd4pFk8o6P6r&uniplatform=NZKPT

Millour, S., Nol, L., Kadar, A., Chekri, R., Guérin, T., and Guérin, T. (2011). Simultaneous analysis of 21 elements in foodstuffs by ICP-MS after closed-vessel microwave digestion: Method validation. J. Food. Compos. Anal. 24, 111–120. doi:10.1016/j.jfca.2010.04.002

Muthu, S. S., and Li, Y. (2013). “Life cyc1e assessment of grocery shopping bags,” in Assessment of environmental impact by grocery shopping bags, eco. Production (Singapore: Springer).

Nakashima, E., Isobe, A., Kako, S. I., Itai, T., and Takahashi, S. (2012). Quantification of toxic metals derived from macroplastic litter on ookushi beach, Japan. Environ. Sci. Technol. 46 (18), 10099–10105. doi:10.1021/es301362g

Nardi, E. P., Evangelista, F. S., Tormen, L., Saint′Pierre, T. D., Curtius, A. J., Souza, S. S. D., et al. (2009). The use of inductively coupled plasma mass spectrometry (ICP-MS) for the determination of toxic and essential elements in different types of food samples. Elsevier Ltd, Amsterdam, Netherlands.

Nistor, M. T., and Vasile, C. (2013). TG/FTIR/MS study on the influence of nanoparticles content upon the thermal decomposition of starch/poly (vinyl alcohol) montmorillonite nanocomposites. Iran. Polym. J. 22, 519–536. doi:10.1007/s13726-013-0152-4

Peng, G. G., Pu, Z. S. J., Chen, F. Y., Xu, H., Cao, X., Chen, C. C., et al. (2023). Metal leaching from plastics in the marine environment: An ignored role of biofilm. Environ. Int. 177, 107988. doi:10.1016/j.envint.2023.107988

Qi, Y., Zhang, B., Chen, N., and Qing, G. X. (2019). Introduction and detection analysis method of heavy metal elements in express packaging materials. Green Packag. 1400, 43–47. (in Chinese). doi:10.19362/j.cnki.cn10-1400/tb.2019.11.001

SAC (2018). Packings for express service-part 3: Packing bag (GB/T16606.3-2018). Standardization Administration of China SAC. Beijing, China.

Sakai, S. I., Asari, M., Sato, N., and Miyajima, A. (2009). Lead contained in plastic shopping bags and its substance flow. J. Environ. Chem. 19 (4), 497–507. doi:10.5985/jec.19.497

Sakthipriya, N. (2021). Plastic waste management: A road map to achieve circular economy and recent innovations in pyrolysis. Sci. Total Environ. 809 (25), 151160. doi:10.1016/j.scitotenv.2021.151160

SHFPCSFDA (2017). National food safety standards related to limits of contaminants in food (GB 2762-2017), state health and family planning commission and state food and drug administration. SHFPC and SFDA. Ar Riyad, Saudi Arabia.

Song, G. H., Zhang, H., Duan, H. B., and Xu, M. (2018). Packaging waste from food delivery in China's mega cities. Resour. Conserv. Recy. 130, 226–227. doi:10.1016/j.resconrec.2017.12.007

SPBC (2021). China express delivery development index report in 2020. state post bureau of china (spbc) https://www.spb.gov.cn/gjyzj/c100278/202205/4f2917df7dfc4ba28c31949456eb390e.shtml.

SPBC (2017). Development trend and trend report of green packaging in China's express delivery area. https://www.sohu.com/a/190314686_465331.

Spc and Mepc, (2017). Environment protection control standard for imported solid wastes as raw materials-Waste and scrap of plastics (GB 16487.12-2017). Standards Press of China. Beijing, China, (SPC) and Ministry of environmental protection of China (MEPC) (in Chinese).

Su, Y. H., Duan, H. B., Wang, Z. N., Song, G. H., Kang, P., and Chen, D. J. (2020). Characterizing the environmental impact of packaging materials for express delivery via life cycle assessment. J. Clean. Prod. 274 (20), 122961. doi:10.1016/j.jclepro.2020.122961

Turner, A. (2018). Black plastics: Linear and circular economies, hazardous additives and marine pollution. Environ. Int. 117, 308–318. doi:10.1016/j.envint.2018.04.036

Turner, A. (2016). Heavy metals, metalloids and other hazardous elements in marine plastic litter. Mar. Pollu. Bull. 111, 136–142. doi:10.1016/j.marpolbul.2016.07.020

Verma, R., Vinoda, K. S., Papireddy, M., and Gowda, A. (2016). Toxic pollutants from plastic waste- A review. Procedia. Environ. Sci. 35, 701–708. doi:10.1016/j.proenv.2016.07.069

Wen, S. Q., Sun, K., and Lu, C. Q. (2021). Determination of the contents of five heavy metal elements in express packages by ICP-oes. Chin. J. Anal. Chem. 11, 1–3. (in Chinese). doi:10.3969/j.issn.2095-1035.2021.02.0

Weng, S. F., and Xu, Y. Z. (2017). Fourier transform infrared spectroscopy analysis. 3rd edition. Beijing, China: Chemical Industry Press.

Xanthos, D., and Walker, T. R. (2017). International policies to reduce plastic marine pollution from single-use plastics (plastic bags and microbeads): A review. Mar. Pollut. Bull. 118 (1), 17–26. doi:10.1016/j.marpolbul.2017.02.048

Xinhua News (2021). Globa link: china cuts white pollution via plastic ban. http://www.xinhuanet.com/english/2021-01/30/c_139709296.htm.

Xinhua News (2018a). UN general assembly president launches global campaign against plastic pollution. http://www.china.org.cn/world/Off_the_Wire/2018-12/05/content_74240359.htm.

Xinhua News (2018b). Xinhua headlines: China battles plastic pollution. http://www.ecns.cn/m/news/society/2018-06-06/detail-ifyuyvzv3223972.shtml.

Xu, Q., Xiang, J., and Ko, J. H. (2020). Municipal plastic recycling at two areas in China and heavy metal leachability of plastic in municipal solid waste. Environ. Pollu. 260, 114074. doi:10.1016/j.envpol.2020.114074

Keywords: material type, heavy metals, express delivery, plastic packaging bags, Rm samples

Citation: Jiang Y, Song G and Zhang H (2023) Material identification and heavy metal characteristics of plastic packaging bags used in Chinese express delivery. Front. Environ. Sci. 11:1253108. doi: 10.3389/fenvs.2023.1253108

Received: 04 July 2023; Accepted: 18 September 2023;

Published: 03 October 2023.

Edited by:

Tania Martellini, University of Florence, ItalyReviewed by:

Vimalkumar Krishnamoorthi, New York University, United StatesCopyright © 2023 Jiang, Song and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Guanghan Song, c29uZ3F1aWxsQHRvbmdqaS5lZHUuY24=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.