- Sichuan University, Chengdu, China

The efficient use of associated petroleum gas with combined heat and power (CHP) systems in oil extraction sites has proven to be technically feasible, but its economic inefficiency continues to deter oil companies from using CHP, given that simple fuel cost reductions do not yield significant positive returns in the face of large investments in purchasing and maintaining CHP. This research constructs a cost-benefit analysis model, which includes the monetized environmental benefits generated by CHP. A pilot experiment operated in a certain oilfield in Shandong province shows that the annual difference between the reduction in fuel costs and the investment in purchase and maintenance of CHP is only about ¥210,000 per device. However, when environmental benefits including health benefit and low-carbon benefit are included in the model, the annual environmental benefits of a single equipment update can be about ¥760,000, and the overall annual net benefits will reach about ¥970,000. It is concluded that the application of CHP in oil extraction sites is economically efficient, taking into account the environmental benefit it can produce. The research results will help oil companies use CHP to make more contributions to carbon and air pollutant emission reduction. However, considering that a large number of CHP systems can form a distributed energy structure, the proposed model still has limitations.

1 Introduction

Oil extraction sites in oilfields are ideal scenarios for applying combined heat and power (CHP) systems. It is because a) Oil extraction sites have both electricity and heat needs. There is a large amount of electrical equipment at the site, and the temperature of the freshly extracted crude oil once it enters the site needs to be maintained at around 70°C for subsequent transportation (Osintsev et al., 2019); b) CHP can use associated petroleum gas as fuel, which reduces the cost of fuel. Previously, oil extraction sites burned associated petroleum gas directly into the atmosphere through torches (Rajović et al., 2016); c) The use of CHP can reduce the emission of carbon dioxide, nitrogen oxide, and PM2.5 (Shi et al., 2022). It is because the source of electricity has changed from a coal-fired thermal power plant to CHP fueled by associated petroleum gas (Ekaterina et al., 2017; Zhu et al., 2019), meanwhile the source of heat has changed from the original heating equipment to CHP with a higher process level (Berg et al., 2019). However, previous studies have only focused on discussing whether it is technically feasible to use CHP to achieve efficient use of associated petroleum gas, neglecting whether the scheme is economical.

Regarding the application of CHP in other application scenarios (e.g. school, shopping mall, and office building), previous studies have shown that considering the high cost of purchasing and maintaining CHP, making them economical requires stringent conditions, including low operating power and low fuel prices (Ghorbani et al., 2016; Amber et al., 2018; Yang et al., 2019; Hossein et al., 2021). Although oil extraction sites can use low-cost associated petroleum gas as fuel for CHP, it is still difficult to offset the investment cost by reducing fuel costs alone, leaving oil companies unable to operate CHP at normal power levels to fully meet the sites’ thermal and electrical needs. In short, if only fuel cost reduction and investment in purchase and maintenance of CHP are included in the cost-benefit calculation, it is difficult for CHP to be economical at normal power.

Previous studies have demonstrated that CHP is eco-friendly (Maurovich-Horvat et al., 2016; Perea et al., 2016; Cora et al., 2019). At the same time, China’s “Dual Carbon” goals put forward higher requirements for enterprises’ contribution to carbon emission reduction (Guo et al., 2022). Therefore, the environmental benefits of CHP cannot be ignored. This research monetizes the environmental benefit arising from the use of CHP and incorporates it into the cost-benefit analysis model. Through this model, this research analyzes whether the use of CHP in oil extraction sites can be economically operated at the required operating power in the face of high investment in purchase and maintenance of CHP, considering its environmental benefits and fuel cost reduction. To prove that the total benefits of using CHP are significantly higher than the investment in purchase and maintenance of CHP, a pilot experiment from an oilfield in Shandong Province is used as a case study.

This article is organized as follows: theoretical models to quantify the benefits and costs of applying CHP are presented in Section 2; empirical results are presented in Section 3; the conclusion proved by empirical findings and discussions on potential extensions and limitations of the theoretical models are presented in Section 4.

2 Theoretical models

A model for quantitative analysis of the economic benefits of using CHP is expressed as follows:

where

2.1 Monetary quantification of health benefit

Switching from coal-fired power plants to CHP that burns associated petroleum gas has resulted in lower PM2.5 emissions and lower rates of respiratory and cardiovascular disease caused by an excessive level of PM2.5 in the air, resulting in health benefit. According to the environmental health value assessment theory (Huang et al., 2013; Du et al., 2021a), the following model is built:

where

The change in health risk is based on the epidemiological “exposure-response relationship” and combined with the relative risk model using Poisson regression. Thus, the following formula is constructed:

where

For the economic loss caused by the premature death of residents caused by PM2.5, this research adopts the Value of a Statistical Life Method (VSL) to evaluate. Xie’s method based on the choice experiment estimated the VSL of Beijing residents in 2010 (Xie, 2011). It is denoted as

by adjusting

For outpatient and inpatient expenses, this research uses the cost of disease method to estimate the formula as follows:

where

2.2 Monetary quantification of low-carbon benefit

Using CHP to generate electricity, the power generation energy is changed from coal to associated petroleum gas, and carbon dioxide emissions are reduced, hence low-carbon benefit is generated (Maurovich-Horvat et al., 2016; Cora et al., 2019).

The product of reduced greenhouse gas emissions and carbon trading price is used as the monetized low-carbon benefit. It is calculated as follows:

where

The formula for calculating CO₂ emission reduction in the pilot experiment is as follows:

where

The critical emission temperature of nitrogen oxides is 1,400 °C, and the higher the temperature, the more nitrogen oxides will be produced. While the original heating equipment burns at temperatures above 1,400 °C, CHP uses low-temperature combustion technology. It can control the combustion temperature at around 1,300°C (Yao et al., 2022). Therefore, compared with the original heating equipment, CHP reduces the emission of nitrogen oxides and produces low-carbon benefit. The formula for calculating NOx emission reduction is as follows:

where

2.3 Cost reduction due to the use of oil associated petroleum gas

The emission standards of air pollutants in various regions of China are becoming increasingly strict. Considering that the new pollutant emission standards have been implemented, even oil companies have not opted for the plan to introduce CHP (i.e. the “renewal plan”), it is also necessary for oil companies to apply the plan that using low nitrogen burner and flue gas treatment equipment to meet emission standards (i.e. the “improvement plan”). Therefore, the formula for calculating the cost reduction is as follows:

where

2.4 Investment in purchase and maintenance of CHP

The initial investment cost of CHP is higher than that of existing heating equipment. At the same time, the operation stability of CHP is less than that of the existing heating equipment, the maintenance cost of its operation is also higher than that of the existing heating equipment. Therefore, this research analyzes the increased investment cost of energy supply plan renewal from two directions: equipment investment cost and operation cost:

where

Given that most of the equipment investment cost is a one-time investment at the beginning of the period, this research uses the following formula to amortize the equipment investment cost for each year according to the service life of the project or equipment and the social discount rate:

where EIC represents the annual discounted value of the equipment investment cost, R is the social discount rate, and T is the service life of the equipment. IIC is the one-time initial investment cost of purchasing equipment. Hence:

where

where

3 Case analysis

Since 2021, a pilot experiment about CHP has been conducted at an oil extraction site in an oilfield in Shandong province. The pilot experiment continued for more than a year until mid-2022. After obtaining 1-year data from the pilot experiment and other publicly available data, this research introduced the data into the model constructed in Section 2 and obtained the following results.

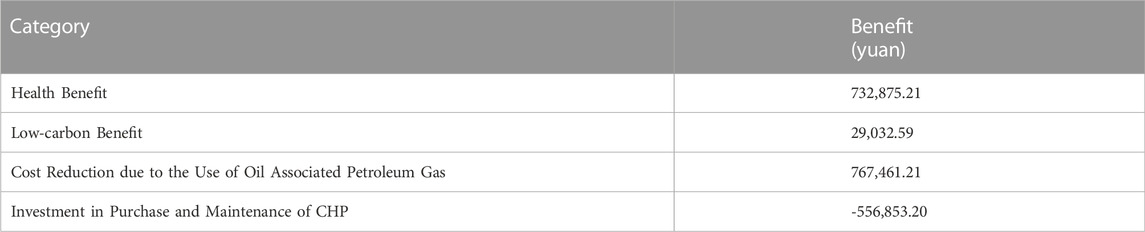

To operate CHP continuously for 1 year at an oil extraction site to replace the previous heat and electricity supply system requires an investment of about ¥560,000 in purchase and maintenance. Correspondingly, CHP can generate about ¥730,000 in health benefit, about ¥30,000 in low-carbon benefit, and about ¥770,000 in fuel cost reductions over a year (Table 1).

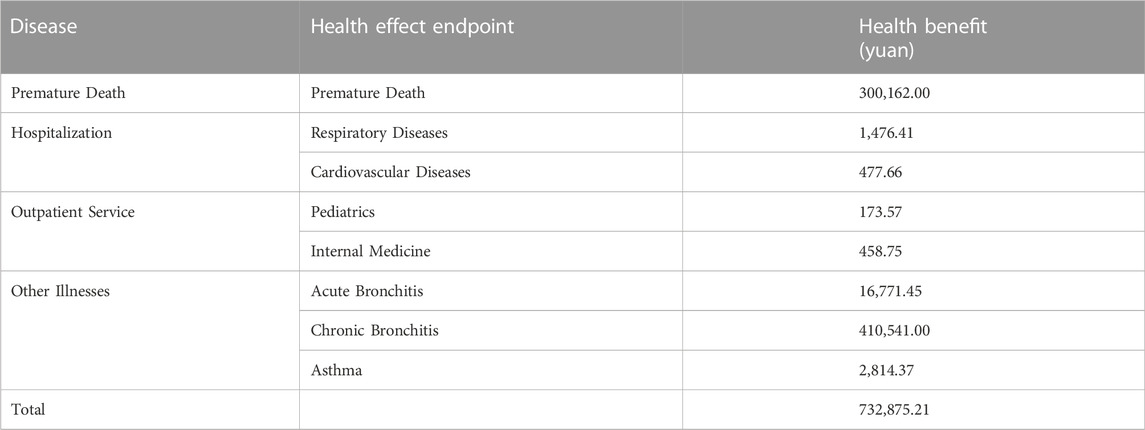

Table 2 shows the details of the health benefit.

In the face of high investment in purchase and maintenance of CHP, if only the fuel cost reduction is counted as the benefit, the application of CHP can only generate a net benefit of ¥210,000, that is, a net interest rate of 27.3%. However, if the environmental benefits produced by CHP are taken into account in the cost-benefit analysis, the overall net benefit can reach ¥970,000, with a net interest rate of 63.4% (Figure 1).

In conclusion, the pilot experiment in an oilfield in Shandong Province has demonstrated that it is economical to replace the previous heat and electricity supply system with CHP at an oil extraction site after incorporating environmental benefits into the cost-benefit analysis.

4 Discussion

Previous studies on the prospect of combined heat and power for public use have shown that the high investment in purchase and maintenance of combined heat and power causes stringent conditions to make it economical, including low operating power and low fuel price. Although low fuel price can be achieved by using associated petroleum gas as fuel for oil extraction sites, keeping combined heat and power operating at low power is not acceptable for oil extraction sites. Therefore, if combined heat and power is operating at normal power at oil extraction sites, oil companies are concerned about whether the simple reduction in fuel cost can make the use of combined heat and power profitable.

This research provides a model that includes monetized health and low-carbon benefits, cost reduction value, and investment in purchase and maintenance of combined heat and power. In Sections 2.1, 2.2, this research provides the idea of monetizing the economic benefits generated by combined heat and power. Using data on reductions in the number of respiratory and cardiovascular diseases and deaths among residents, this research calculates the economic benefits of reducing air pollutants (i.e. health benefit). At the same time, from the perspective that oil companies can make profits in the carbon trading market through greenhouse gas emission reduction, this research calculates the economic benefits generated by greenhouse gas emission reduction (i.e. low-carbon benefit). The calculation methods of fuel cost reduction and investment in purchase and maintenance of combined heat and power are presented in Sections 2.3, 2.4, respectively.

The model in this research helps oil companies verify whether the following conclusion holds in a specific oilfield area: When applying combined heat and power to oil extraction sites, if environmental benefits are taken into account in the cost-benefit analysis, combined heat and power can be economical at normal power operating conditions. To verify the feasibility of the model, a pilot experiment of combined heat and power in an oilfield in Shandong Province is used as a case, which successfully proves that the above conclusion is valid in the oilfield in Shandong Province. In sum, the model in this research can guide oil companies when analyzing whether to use combined heat and power in an oilfield. While promoting the reduction of air pollutant emission, the use of combined heat and power as a thermal and power supply solution for oil extraction sites will also help oil companies slow down global warming in terms of deep decarbonization to meet the 1.5°C–2°C target. Moreover, with the expansion of urbanized areas, more oil field facilities that emit pollutants that were originally far away from urban residential areas will directly affect the surrounding residents. In this case, the application of combined heat and power will not only make the oil field facilities that emit pollutants directly profit from the equipment renewal, but also alleviate the tension between them and the surrounding residents due to the emission of pollutants.

This research’s model still has limitations. Considering the wide distribution and a large number of oil extraction sites in the entire oilfield area, if the number of sites using combined heat and power is large enough, the economy of scale will be formed (Carvajal et al., 2019), which makes the model in this research need to be revised. Moreover, when the site’s heat and power needs are met, there is still a lot of associated petroleum gas left over (Valentin et al., 2020). The ability to integrate combined heat and power at different sites into the same power network, which could provide power not only for the site itself but also for other industrial and even civil facilities nearby (Stoltmann et al., 2019), would also generate additional benefits. Finally, the power network composed of a large number of combined heat and power belongs to a distributed energy structure. Compared with the power network from a single source, the power network with distributed energy structure has a stronger anti-risk ability in the face of power failure (Zeng et al., 2020; Chin et al., 2021; Marcos et al., 2022). The corresponding benefits will also be generated as the number of unexpected production interruptions due to power outages decreases (Kayoung Kim et al., 2017; Karyn Morrissey et al., 2018; Tensay Hadush Meles et al., 2021). For oil companies that want to use combined heat and power on a wider scale, the model needs to be revised.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

The author confirms being the sole contributor of this work and has approved it for publication.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Amber, K. P., Day, T., Ratyal, N. I., Kiani, A., and Ahmad, R. (2018). Techno, economic and environmental assessment of a combined heat and power (CHP) system—a case study for a university campus. Energies 11 (5), 1133. doi:10.3390/en11051133

Berg, I. A., Porshnev, S. V., Medvedev, M. A., and Melnichenka, D. A. “Control of nitrogen oxides content in torch combustion products based on system analysis approach[C],” in Proceedings of the AIP Conference Proceedings, Rhodes, Greece, September 2019 (Melville, NY: AIP Publishing LLC), 430019.21161

Carvajal, Carmen Ramos, García-Muñiz, Ana Salomé, Moreno Cuartas, Blanca, and Moreno Cuartas, B. (2019). Assessing socioeconomic impacts of integrating distributed energy resources in electricity markets through input-output models. Energies 12 (23), 4486. doi:10.3390/en12234486

Chin, J. X., and Hug, G. (2021). Formation of ad hoc microgrids for prompt critical load pickup during blackouts by leveraging stochastic distributed energy resources. J. Eng. 2021 (11), 705–714. doi:10.1049/tje2.12057

Cora, M. G., and Hung, Y. T. (2019). Increasing business value: Combined heat and power systems, the way of future or the way now take the initiative and develop a sustainable strategic approach. Int. J. Environ. Waste Manag. 23 (3), 257–273. doi:10.1504/ijewm.2019.099005

Du, P., and Wang, J. (2021a). Health benefit assessment of PM2.5 pollution control in beijing. Environ. Sci. 42 (03), 1255–1267. doi:10.13227/j.hjkx.202005225

Du, P., and Wang, J. (2021b). Health benefit assessment of PM2.5 pollution control in beijing. Environ. Sci. 42 (03), 1255–1267. doi:10.13227/j.hjkx.202005225

Ekaterina, Lysova, Oksana, Paramonova, and Oksana, Gurova (2017). Simulation of the process and system of power plants exhaust gases purification during construction and re-construction of housing and utilities infrastructure of urban areas. MATEC Web Conf. 129, 05016. doi:10.1051/matecconf/201712905016

Faisya, A. F., Malaka, T., Zulkifli, H., and Zulkarnain, M. (2018). Environmental health risk assessment of inhaled dust exposure on workers at industry crumb rubber palembang city 2016. Ind. Jour. Publ. Health Rese. Dev. 9 (2), 201. doi:10.5958/0976-5506.2018.00119.5

Gentry, E. P., and Viscusi, W. K. (2016). The fatality and morbidity components of the value of statistical life. J. Health Econ. 46, 90–99. doi:10.1016/j.jhealeco.2016.01.011

Ghorbani, N. (2016). Combined heat and power economic dispatch using exchange market algorithm. Int. J. Electr. Power & Energy Syst. 82, 58–66. doi:10.1016/j.ijepes.2016.03.004

Guo, Xiaojia, Wang, Xin, Wu, Xueling, Chen, Xingpeng, and Li, Ya (2022). Carbon emission efficiency and low-carbon optimization in shanxi province under “dual carbon” background. Energies 15 (7), 2369. doi:10.3390/en15072369

Hossein, Ranjbar, Hamid, Hosseini Seyed, and Hamidreza, Zareipour (2021). Resiliency-oriented planning of transmission systems and distributed energy resources. IEEE Trans. Power Syst. 36 (5), 4114–4125. doi:10.1109/tpwrs.2021.3065395

Huang, D., and Zhang, S. (2013). Health benefit assessment of PM_(2.5) pollution control in Beijing-Tianjin-Hebei region [J]. China Environ. Sci. 33 (01), 166–174.

Jung, J. H., Shon, B. H., and Yoo, K. S. (2010). “Effects of air pollutants on the environmental health risk assessment of gyeongju and pohang in South Korea[C],” in Abstracts of papers of the AMERICAN chemical society (1155 16TH ST, NW, WASHINGTON, DC 20036 USA, 240.doi:AMER CHEMICAL SOC

Kan, H., Chen, B., and Wang, H. (2004). Economic evaluation of the health hazards of residents from atmospheric particulate matter pollution in urban areas of Shanghai[J]. China Health Econ. 23 (2), 8–11.

Kim, Kayoung, and Cho, Youngsang (2017). Estimation of power outage costs in the industrial sector of South Korea. Energy Policy 101, 236–245. doi:10.1016/j.enpol.2016.11.048

Kim, Y. E., and Loayza, N. V. (2022). Economic loss from COVID-19 fatalities across countries: A VSL approach. Appl. Econ. Lett. 29 (7), 644–650. doi:10.1080/13504851.2021.1883521

Lu, Lingkey, and Li, Hongyuan (2016). Health economic evaluation of PM10 and PM2.5 pollution in Beijing-Tianjin-Hebei region[J]. J. Nankai Univ. Nat. Sci. Ed. 49 (1), 69–77.

Marcos, F. P., Domingo, C. M., and San Román, T. G. (2022). Improving distribution network resilience through automation, distributed energy resources, and undergrounding. Int. J. Electr. Power & Energy Syst. 141, 108116. doi:10.1016/j.ijepes.2022.108116

Maurovich-Horvat, L., Rocha, P., and Siddiqui, A. S. (2016). Optimal operation of combined heat and power under uncertainty and risk aversion. Energy Build. 110, 415–425. doi:10.1016/j.enbuild.2015.11.009

Mori, R., Sakamoto, N., Nakajima, K., Ohno, E., Morisugi, M., Tomoda, G., et al. (2019). Measurement of multi-attribute VSL considering constant relative risk aversion based on happiness survey in Japan[J]. J. Jpn. Soc. Civ. Eng. Ser. G Environ. Res. 75 (5), I_201–I_209.

Morrissey, Karyn, Plater, Andrew, and Dean, Mary (2018). The cost of electric power outages in the residential sector: A willingness to pay approach. Appl. Energy 212, 141–150. doi:10.1016/j.apenergy.2017.12.007

Osintsev, K. V., and Prikhodko, I. S. (2019). Application of mathematical modeling to optimize the operation of a tubular oil heating furnace. IOP Conf. Ser. Mater. Sci. Eng. 560 (1), 012081. doi:10.1088/1757-899x/560/1/012081

Perea, E., Ruiz, N., Cobelo, I., Lizuain, Z., and Carrascal, A. (2016). A novel optimization algorithm for efficient economic dispatch of Combined Heat and Power devices. Energy Build. 111, 507–514. doi:10.1016/j.enbuild.2015.11.025

Putri, K. R., Achmadi, U. F., Arminsih, R., and Ramdhan, D. H. (2019). An environmental health risk assessment of workers’ ambient exposure to particulate matter of 2.5 microns or less at a concrete batching plant. Ind. Jour. Publ. Health Rese. Dev. 10 (2), 479–484. doi:10.5958/0976-5506.2019.00337.1

Rajović, Vuk, Kiss, Ferenc, Maravić, Nikola, and Bera, Oskar (2016). Environmental flows and life cycle assessment of associated petroleum gas utilization via combined heat and power plants and heat boilers at oil fields. Energy Convers. Manag. 118, 96–104. doi:10.1016/j.enconman.2016.03.084

Sandra, Pérez, Catherine, German-Labaume, Sébastien, Mathiot, Sylvaine, Goix, and Philippe, Chamaret (2022). Using Bayesian networks for environmental health risk assessment. Environ. Res. 204, 112059. doi:10.1016/j.envres.2021.112059

Shi, Xiaoliang, Zhang, Jiayi, Lu, Shuaiyu, Wang, Tielong, and Zhang, Xinyue (2022). China carbon neutralization research status and research frontier tracking. Front. Environ. Sci. 10. doi:10.3389/fenvs.2022.896524

Stoltmann, A., Jaskólski, M., and Bućko, P. (2019). Optimization of combined heat and power (CHP) market allocation: The case of Poland. IOP Conf. Ser. Earth Environ. Sci. 214 (1), 012036. doi:10.1088/1755-1315/214/1/012036

Tensay, Hadush Meles, Alemu, Mekonnen, Beyene, Abebe D., Hassen, Sied, Pattanayak, Subhrendu K., Sebsibie, Samuel, et al. (2021). Households' valuation of power outages in major cities of Ethiopia: An application of stated preference methods. Energy Econ. 102, 105527. doi:10.1016/j.eneco.2021.105527

Thu, Ngo Hien Thi, Pensri, Watchalayann, NguyenBich, Diep, DoanNgoc, Hai, and Liang, Li (2021). Environmental health risk assessment of heavy metal exposure among children living in an informal e-waste processing village in Viet Nam. Sci. Total Environ. 763, 142982. doi:10.1016/j.scitotenv.2020.142982

Valentin, Morenov, Ekaterina, Leusheva, George, Buslaev, and Gudmestad Ove, T. (2020). System of comprehensive energy-efficient utilization of associated petroleum gas with reduced carbon footprint in the field conditions[J]. Energies 13 (18).

Viscusi, W. K., Magat, W. A., and Huber, J. (1991). Pricing environmental health risks: Survey assessments of risk-risk and risk-dollar trade-offs for chronic bronchitis. J. Environ. Econ. Manag. 21 (1), 32–51. doi:10.1016/0095-0696(91)90003-2

Xie, P., Liu, X. Y., Liu, Z. R., Liu, X. Y., Li, T. T., Bai, Y. H., et al. (2009). Study on the relationship between exposure and response to atmospheric particulate matter pollution among the population in my country[J] Chinese. Environ. Sci. 29 (10), 1034–1040.

Xie, X. (2011). The value of health: Environmental benefit assessment methods and urban air pollution control strategies [J]. Beijing: Peking University.

Yang, X., Li, Y., Niu, D., and Sun, L. (2019). Research on the economic benefit evaluation of combined heat and power (CHP) technical renovation projects based on the improved factor analysis and incremental method in China. Sustainability 11 (19), 5162. doi:10.3390/su11195162

Yao, Qian, Zhang, Yu, Wang, Xinjie, Zhou, Tian, Hu, Guihua, and Du, Wenli (2022). Investigation of NOx emission under different burner structures with the optimized combustion model. Neurocomputing 482, 224–235. doi:10.1016/j.neucom.2021.11.051

Zeng, B., Li, X., Fang, W., Zhu, Z., and Zhao, C. (2020). Evaluating potential benefits of distributed energy resources for improvement of distribution system resiliency[J]. J. Electr. Syst. 16 (3).

Keywords: cost-benefit analysis, associated petroleum gas, combined heat and power (CHP) system, environmental benefit, health benefit, low-carbon benefit

Citation: Chen M (2022) Whether it is economical to use combined heat and power (CHP) system for the efficient utilization of associated petroleum gas in oil extraction sites in China: A cost-benefit analysis considering environmental benefits. Front. Environ. Sci. 10:984872. doi: 10.3389/fenvs.2022.984872

Received: 02 July 2022; Accepted: 28 November 2022;

Published: 13 December 2022.

Edited by:

Ruidong Chang, University of Adelaide, AustraliaReviewed by:

Elchin Suleymanov, Baku Enginering University, AzerbaijanMuhammad Kamran Khan, Bahria University, Pakistan

Copyright © 2022 Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mingjian Chen, MTcxNDE2MDQ1OUBxcS5jb20=

Mingjian Chen

Mingjian Chen