- 1Sustainable Real Estate Research Center, Hong Kong Shue Yan University, North Point, Hong Kong SAR, China

- 2Yulu Region Company, Jinke Property Group Co., Ltd, Zhengzhou, China

- 3Chakrabongse Bhuvanarth International Institute for Interdisciplinary Studies, Rajamangala University of Technology Tawan-Ok, Bangkok, Thailand

- 4College of Civil Engineering, Jiujiang University, Jiujiang, China

- 5Faculty of Economics, Srinakharinwirot University, Bangkok, Thailand

- 6School of Literature and Media, Pass College of Chongqing Technology and Business University, Chongqing, China

One major change in the modern construction industry worldwide in recent years is moving toward prefabricated buildings (offsite construction) to achieve sustainable development. Despite an increase in attention to ESG due to global stock markets’ requirements and prefabricated buildings aid industries in achieving the ESG goal, few or even no research investigated the ESG attributes of the prefabricated buildings. Additionally, ESG subitems in different industries receive varying attention. Developed countries are primarily subject to ESG rules, but ESG laws in developing countries are at their infant stages. No study examined the effects of economic progress on prefabricated buildings’ ESG attributes. The research gaps are filled by visualising and clustering the WoS and Scopus articles’ keywords, themes, and authors’ locations. This article also studied the evolution of this field. Based on the science map modularity cluster analysis, cost control is the most concerned issue in developed and developing countries. There are far more articles related to sustainability and environmental aspects of prefabricated buildings. Although the governance aspects of prefabricated buildings have not been thoroughly studied, inadequate governance increases bond yields. Therefore, future research on prefabricated buildings may expand to governance aspect to benefit industry and academia.

1 Introduction

The rapid development of urbanisation in developing countries, policy guidance, digital technology, and building information model (BIM) technology has fastened the development of prefabricated buildings in recent years (Abanda et al., 2017). Building construction has increased to almost 4 billion square meters annually since 2013, and it is anticipated that this rapid growth will continue for decades, with 33 billion more square meters added by 2040 and another 17 billion by 2060 (Abergel et al., 2017). The traditional methods of building design and construction are changed to prefabricated, which mainly depends on in-plant manufacturing and site assembly of building components (Chang et al., 2018). Due to its standardised architectural design, high-quality building part production, quick onsite building assembly, easy disassembly, and appropriate building reuse, the prefabricated building holds promise for the sustainable transformation of the construction sector (Chang et al., 2018).

Besides, the construction industry is always perceived as a traditional labour-intensive industry with high energy consumption, low efficiency, low digitalisation and industrialisation (Barbosa et al., 2017). Countries like the United States (Razkenari et al., 2020), Europe (Pan and Sidwell, 2011), and China have labour force shortages. Prefabricated or offsite buildings, semi-finished components made by offsite construction and combined onsite to form complete buildings (Jiang et al., 2019), can solve the abovementioned problems by reducing the use of materials, energy, and construction time (Razkenari et al., 2020), improving the construction environment and quality (Hanafi et al., 2018), and minimising the negative impact of traditional construction activities on the environment and society (Li et al., 2014). As the prefabricated building is part of the supply chain in buildings and infrastructures’ production, its performance also affects a company’s governance. Indeed, developing prefabricated buildings has important implications for construction industry companies’ environmental, social and governance (ESG) performance.

Because of the high environmental and social awareness (especially in developed countries), customers expect businesses, including construction firms, to invest time and resources in sustainable practices. A focus on the impact of ESG disclosures on corporate financial performance has caused an overall increase in ESG disclosures and reporting globally. Disclosure of non-financial information is now required in many European nations. Other nations were inspired to adopt obligatory ESG disclosure policies for sustainable development by this change from voluntary to required disclosure. Disclosing non-financial information has become more popular worldwide in all industries for several reasons, including raising awareness, educating consumers, mitigating risks related to corporate performance, and achieving sustainability (Singhania and Saini, 2021).

While there is an increase in attention to ESG due to listed companies’ requirements in many stock markets Worldwide, prefabricated buildings help industries achieve ESG, few studies or even no research investigated the ESG attributes of the prefabricated buildings per previous research. Furthermore, different levels of economic development pay extra attention to various ESG subitems in various industries; therefore, environmental performance, social performance, and financial performance are different (Wang et al., 2016). It is expected that the coverage of ESG and prefabricated building in different levels of economic development research may be higher in developed countries due to more financial resources for research and ESG regulations mainly covered by developed countries (Singhania and Saini, 2021). Nevertheless, no research investigates the impact of economic development on ESG coverage in prefabricated building research.

Bibliometric analysis is a widely used and rigorous technique for investigating and analysing many pieces of literature published worldwide. As quantitative research of bibliographic material (Merigó and Yang, 2017), bibliometric analysis enables the exploration of the subtleties of a particular field’s evolutionary history while illuminating its emerging areas (Donthu et al., 2021). In bibliometric analysis, a knowledge map is a graph showing the many entities and concepts in the real world and their connections. This study utilised CiteSpace per previous research (Wang and Lu, 2020) to systematically explore the ESG attributes in the prefabricated building industry. It visualised the knowledge map of prefabricated buildings for ESG-relevant academic research with the aims to:

(1) Compare the research productivity of prefabricated buildings in developed and developing countries.

(2) Review the existing research in prefabricated buildings that threw light on the environment, social and governance (ESG), and suggest future academic research direction.

This research found that developed countries have far more prefabricated buildings research (except China), echoing the results of (Singhania and Saini, 2021). The findings of the environmental aspect of the prefabricated building are more than the social and governance aspect. In the following sections, Section 2 lists the literature review, Section 3 is the research method, Section 4 sheds light on the research results, Section 5 is the discussion, and Section 6 concludes the article.

2 Literature review

2.1 Prefabricated building

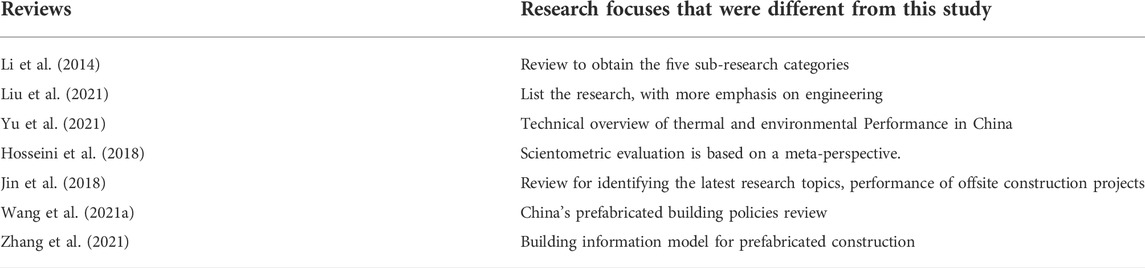

Jaillon and Poon (2009) defined prefabrication as a building that could be delivered in pieces and assembled or that needed to be built entirely in a factory. Li et al. (2014) stated that prefabricated buildings refer to “various materials joined together to form a component of the final installation procedure“. Navaratnam et al. (2019) emphasised modular volumetric units. Taylor (2010) listed most of the definitions for offsite construction before 2009. The most commonly cited definition is by Goodier and Gibb (2007), which described the process of manufacturing and preassembly of a certain number of building components, modules, and elements before their shipment and installation on construction sites. Hosseini et al. (2018) traced the early development process of “offsite construction” and did not distinguish between the two concepts in critical literature reviews. This study analysed prefabricated buildings (or offsite construction) by throwing light on ESG. While these two concepts sound different, we critically comment on the related review studies in prefabricated buildings or offsite construction in Table 1.

TABLE 1. Research that reviewed prefabricated buildings (note: ESG were not included in all these studies).

From Table 1, previous relevant critical comments focus on prefabricated building, rarely on its relationship to ESG, providing a new research gap.

2.2 Environmental, social, and governance and sustainable development of construction management

The sustainable business emphasises global and local environmental, community, societal, and economic responsibilities at the industry and corporate levels. The idea has been highlighted as a new way for a successful business. Approximately 2/3 of institutional investors anticipate that environmental, social, and governance (ESG) issues will become the industry standard (Managers, 2019). ESG refers to the “configuration of principles of environmental, social, and governance responsibility; processes of environmental, social, and governance responsiveness, and politics, programs, and observable outcomes as they relate to the firm’s society relationships” (Velte, 2019).

Environmental governance is creating and implementing policies and procedures to protect the environment from damages caused by enterprises’ activities and ongoing environmental performance monitoring. It is composed of a solution to carbon emission, resource depletion, climate change and ecosystem pollution (Patil et al., 2021). Businesses that use ESG put more emphasis on growing their marketing and profitability while giving the public’s environmental concerns and the reduction of environmental consequences equal weight.

Social governance refers to the regulations and rules that business organisations adopt to improve relations with the stakeholders while ensuring the companies’ prosperity, rights, wellbeing, employee and animal welfare, good community relation and protection of the interests of shareholders (Patil et al., 2021). How businesses are governed may be affected by institutional (business in society) and organisational (individual firm-level activities) nexus. Corporate governance could be described as “the creation of institutions that promote trust among stakeholders (including employees, consumers, suppliers, and communities).

All management and the board issue relevant to management, including agenda issues, board meetings, attendance, board diversity, and corruption, are all included in the governance factor (Sharma et al., 2020). Governance at the organisational level addresses the principal-agent problem that results from the separation of management and capital. Governance effectiveness aids in lowering sovereign bond yield spreads; nations that are more corrupt must pay higher yields when issuing bonds (Crifo et al., 2017).

Construction companies’ environmental, social, and governance (ESG) elements are frequently assessed by aggregating project sustainability performance. The construction industry has been developing a future strategy for improving their ESG scores, emphasising ESG integration, despite controversies on ESG factors’ practical impact on the organisation’s performance or profits (Siew, 2017). However, stakeholders’ needs for information on ESG management are not satisfied in the construction industry (Hadro et al., 2022). Evidence from Italy shows that the construction industry scored the highest ESG when it disaggregates the accrual and real earnings management proxies (Gavana et al., 2022). In construction management and operations, construction companies should emphasise collaborative ESG activities to gain favourable public business reputations, for example, lowering CO2 emissions and construction waste and improving safety and health (Butković et al., 2021). While there are quite a number of research on ESG, there is still a research gap that review the prior research about prefabricated building’s contribution on ESG.

2.3 Developed countries and developing countries

Economists usually adopt United Nations’ Human Development Index (HDI) to measure human development in a country. Any score of 0.80 or higher is classified as a developed country, and any lower is developing (Center, 2021). Developed countries are countries that are developed in terms of economy and industrialisation. Developed countries have better housing and living conditions and industrial, infrastructural, and technological advancements. One finance research found that existing empirical articles mainly focus on environmental factors when examining industrialised countries and on social or governance aspects only when analysing underdeveloped or rising nations (Crifo et al., 2017). It is sensible to speculate that there are different levels of studies on ESG attributes in the development of prefabricated buildings or offsite construction and most only study one aspect of ESG only. If most research comes from the developed countries, we speculate that most research focuses on environmental aspect only, similar to the abovementioned finance research.

3 Research methods

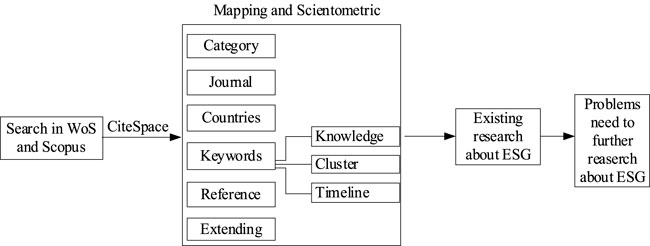

A systematic literature review provides an in-depth understanding of a research domain. The literature review process is listed in Figure 1. We adopted the bibliometric science map modularity cluster analysis approach for this research. Similar approach was adopted to study construction safety research (Zeng and Li, 2022) and tourism (Zeng et al., 2022). Pritchard (1969) pioneered the concept of bibliometrics. Historically, bibliometric research has mainly focused on intelligence, archives, and other fields. Big data bibliometric tools have become popular in various disciplines recently, assisting researchers in tracking and analysing research foci and development over time (Chen, 2014; Jie, 2016). CiteSpace knowledge visualisation software has become one of the most popular knowledge map-drawing tools. Chen (2006) explained its basic principles: “a picture is worth thousands of words, clear at a glance.” It is considered a knowledge-map tool with a high level of information visualisation (Chen and Chen, 2003).

CiteSpace extracted titles, keywords, abstracts, and references of the articles and performed statistical and cluster analysis of all the information. We excluded the review article to avoid having a review label appear in the cluster analysis, which often overrides the display of other research information. It is an excellent tool for reviewing research in specific fields. While the Web of Science (WoS) covers the most important and influential academic research results worldwide (Hosseini et al., 2018), Scopus is the world’s largest abstract and indexing academic database. Scopus and WoS are two central databases covering the best journals worldwide and complement each other as neither resource is all-inclusive (Burnham, 2006). Merging the two databases and removing the duplicates allowed us to include the best articles related to prefabricated buildings and offsite construction.

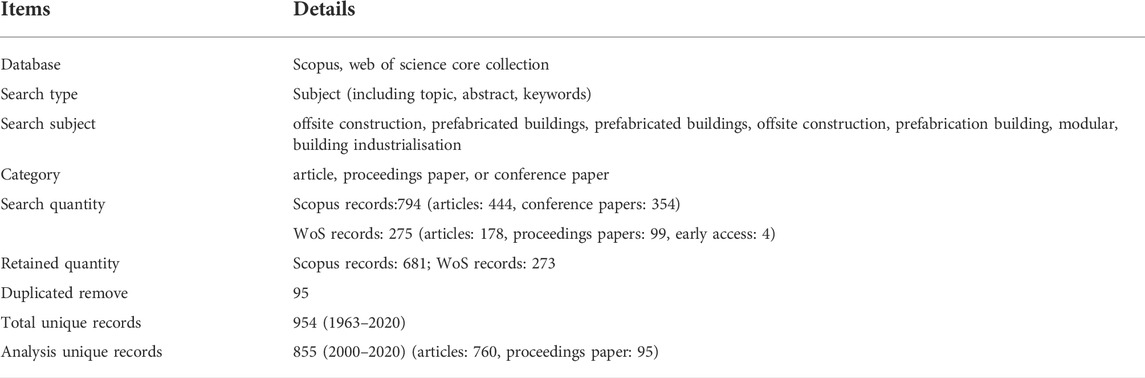

For papers published in the WoS and Scopus, we searched for subjects such as “offsite construction,” “offsite construction,” “prefabricated buildings,” “prefabricated building,” and “prefabrication building, “modular building” and “building industrialisation.” All search terms are in double quotation marks. In the WoS core collection, we checked the boxes for articles, proceeding papers, and early access and obtained 275 terms. We checked the boxes for articles and conference papers in Scopus and got 794 items. We obtained 1069 records from the two databases. We cleaned the data and removed duplicates by using CiteSpace. We obtained 954 unique records and observed a significant increase in articles from 2000 onwards. From 2000 to 2020 (the search date is 28 October 2020), there were 855 prefabricated building articles, all shown in Table 2. As in most fields, the number of studies has increased yearly since 2015, 647 from 2015 to 2020. (CiteSpace identifies all data.)

In the result maps, we obtained two parameters, modularity and silhouette, according to Chen (2014) and Li and Chen (2016): The Modularity (Q) value is an evaluation index of network modularity. The higher the value, the better the clustering effect. The value range of Q is (0, 1); Q > 0.3 means that the structure of the network community is significant (Li and Chen, 2016). Silhouette (S) is a parameter used to assess clustering homogeneity; the closer the value is to 1, the higher the homogeneity; S > 0.7 has high reliability, and S > 0.5 can be considered good clustering (Li and Chen, 2016). In addition, the betweenness of centrality or centrality is an essential parameter. The node is crucial if the centrality value is more significant than 0.1. The higher the centrality value, the greater the node circle, and the article is critical in this field. On the science map, nodes represent keywords, articles, categories, countries, journals, authors, or other information. The larger the circle is, the more influential the node is. The line indicates that there is a specific connection between these nodes.

4 Research results

4.1 Research category, journals and countries

Regarding the research results of knowledge mapping of research category analysis, this study found no results per WoS database for topic words such as “prefabricated building or offsite construction and ESG” (Figure 2). Most of the results concentrated on construction and building technology, engineering, environmental, Environmental sciences & ecology, and science and technology. Among the three areas of ESG, most focus on the environmental (E). For example, Green and sustainable science and technology, environmental sciences, energy and fuels, and environmental studies. Social (S) includes architecture, and urban studies, while G (governance) includes management.

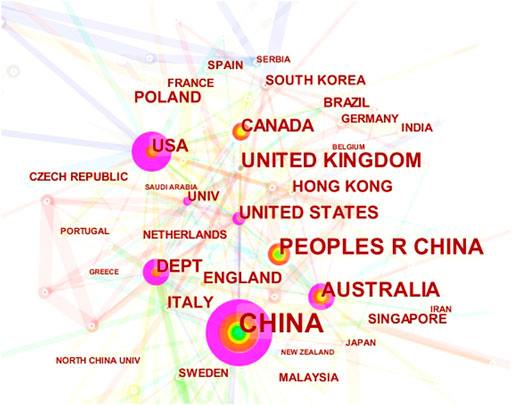

Figure 3 is a knowledge mapping of journals, showing the prominent journals in this field, excluding the engineering technology journal. The Journal of Cleaner Production and Building Environment may be the most concerned the environmental or social studies, and the Journal of Construction Engineering and Management is most concerned with prefabricated buildings. Figure 4 shows that developed countries and regions, such as the United States, Australia, the United Kingdom, Canada, and Hong Kong, had more prefabricated research. China, Brazil, India, and Malaysia are developing countries with the most prefabricated research. Details about countries of top centrality are shown in Table 3.

4.2 Keywords analysis

4.2.1 Keywords knowledge mapping

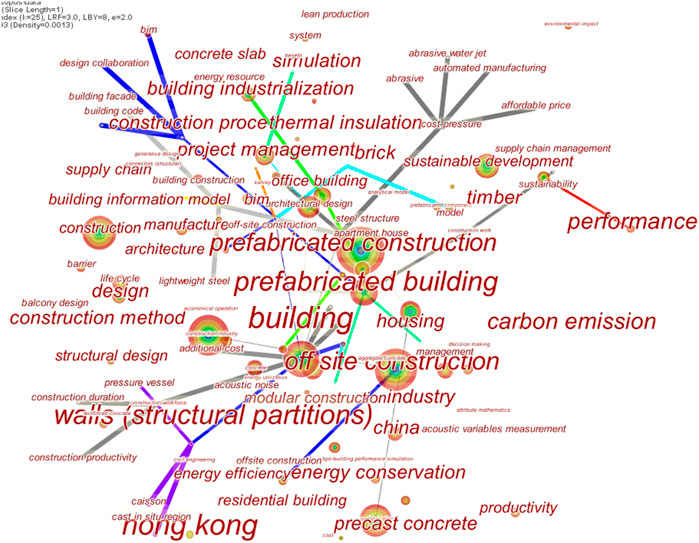

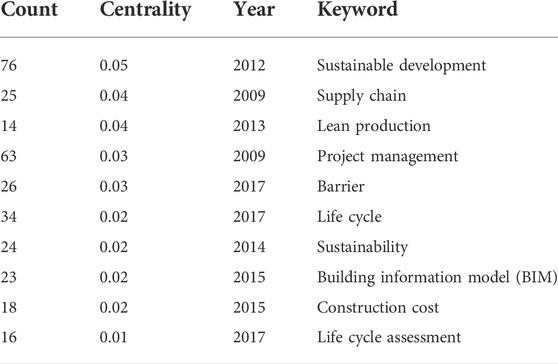

In Figure 5, the keyword nodes “prefabricated building” and “offsite construction” display high centrality. Many studies on engineering technology, such as “walls,” “timber,” “brick,” and “thermal insulation” are relevant to management in the top 100 keywords, as shown in Table 4. Others include “supply chain,” “residential building,” “housing,” and “productivity.” We may consider these as the social aspect-related keywords. The environment aspect-related keywords include “carbon emission,” “energy conservation,” sustainable development, “life cycle assessment,” and “building information model”. There is a lack of governance-related studies.

4.2.2 Keywords clusters analysis

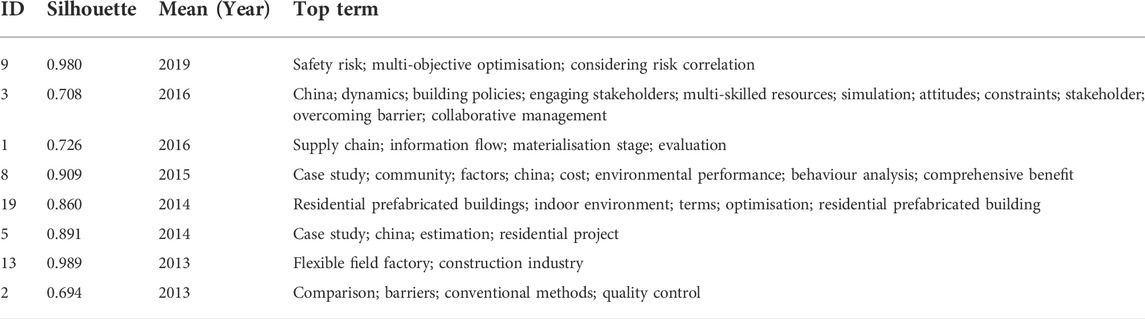

The keyword cluster mapping analysis is shown in Figure 6. In this cluster analysis, the modularity (Q) value is 0.677 > 0.3, and the silhouette (S) value is 0.827 > 0.7. That means the cluster is significant. According to the results of this significant clustering, we can screen out the literature and main research topics that need to be reviewed. The top terms are calculated and listed in Table 5. The terms “prefabricated building” and “offsite construction” or similar keywords used for the retrieval were removed manually.

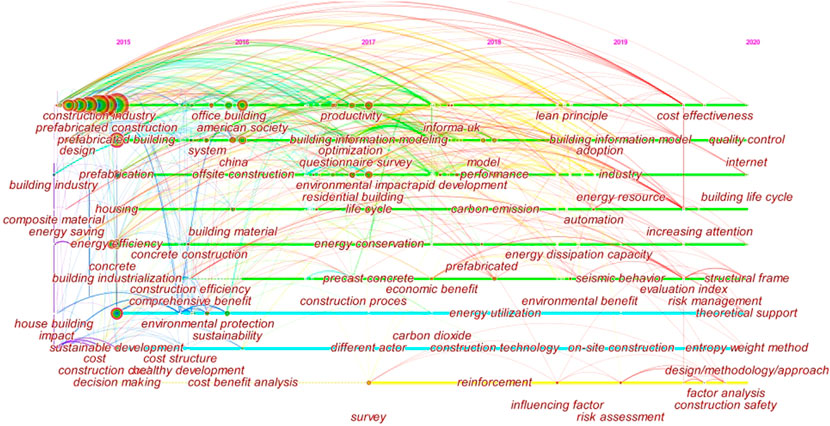

4.2.3 Evolution of the prefabricated building studies

This study reviewed articles from 2015 to 2020; the total number of articles was 647 for 2015–2020, accounting for 75.6% of the total volume of 855 from 2000 to 2020 (Figure 7). Most shed light on the technology. For management, “life cycle assessment” appeared in 2012, and “offsite construction” focused on the research of “model” and “design”. In 2016, research on “prefabrication concrete” appeared. The concepts of “sustainability building industries” and “cost-benefit analysis” were proposed in several articles, and research on “developing” and “barriers in China” appeared almost simultaneously, cited more frequently as the “capital cost” in 2017. After 2018, research directions became more diverse, such as “preformation,” “optimisation,” “BIM,” “environmental benefit,” “influencing factor,” “simulation,” and “implementation.” However, researchers have concentrated on other aspects of prefabricated buildings, such as “energy consumption,” “carbon emission,” “benefit evaluation,” “policies,” and “risk assessment” or “risk management” since 2019.

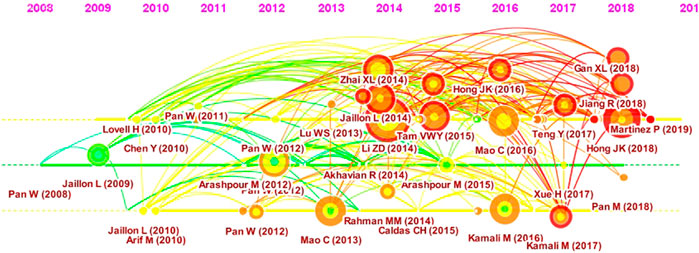

4.3 Reference analysis

The research source and evolution can be carried out through the analysis of reference information. The total number of terms cited by 855 papers is 18972, including some of their citations. According to the time evolution of the primary references (Figure 8), we can obtain the citation relationship and the evolution process of the research in this field. Pan, Gibb (2012) proposed strategies for building companies’ management using offsite technology. Mao et al. (2013) compared greenhouse gas emissions between offsite prefabrication and conventional construction methods in two cases. Zhang et al. (2014) discussed the challenges faced by industrialised residential buildings in China.

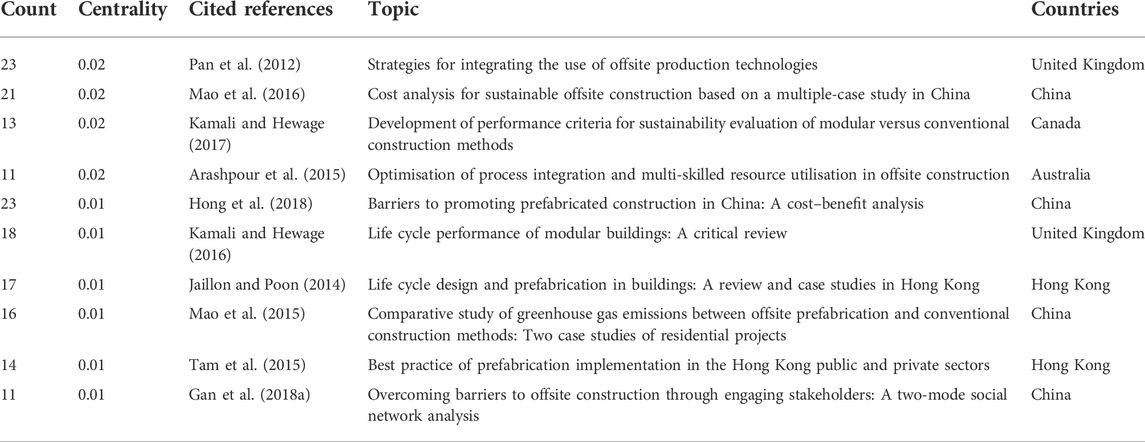

The top co-cited reference is in Table 6, and we obtained the top topic in this field. Jaillon and Poon (2014) studied the life cycle design of prefabricated buildings in Hong Kong. Tam et al. (2015) studied prefabrication implementation in Hong Kong. Arashpour et al. (2015) discussed the optimisation of process integration and multi-skilled resource utilisation in offsite construction. For example, Mao et al. (2016) analysed the cost, and Kamali and Hewage (2017) studied the performance criteria for the sustainability evaluation of offsite construction. These are highly cited papers related to management.

4.4 Extending research

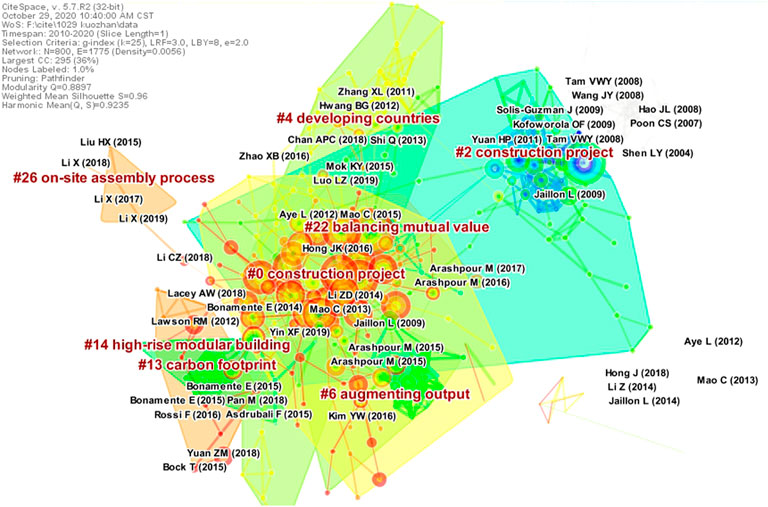

According to the expansion method (Chen et al., 2012), the first group papers (855) were cited by the second group papers. Then we analysed the second group of papers to find the trend of the first group and obtained a new research point. So, based on the 855 papers (first group), we got the citing papers in WoS and Scopus. By removing duplicates, 3022 records (second group) were obtained. The second group paper reference analysis is shown in Figure 9. The modularity (Q) value was 0.8897 > 0.3, and the silhouette (S) value was 0.96 > 0.7. That means the cluster was extremely significant.

The nodes were the articles of the first group papers. According to the cluster analysis results, the label of cluster #4 in Figure 9 was “developing countries.” That means developing countries, especially China, published so much research in the 2010s. Clusters #6 and #13 indicated that developed countries’ extending research focused more on “carbon footprints” and “augmenting output.”

Goodier and Gibb (2007) from the United Kingdom, Pan et al. (2007) from the United Kingdom, Tam et al. (2007) from Australia, Jaillon and Poon (2009) from Hong Kong, Blismas and Wakefield (2009) from Australia, Aye et al. (2012) from Australia, Mao et al. (2013) China, Li et al. (2014) China, Jaillon and Poon (2014) from Hong Kong, Mao et al. (2015) China, Hong et al. (2016) from China, and Arashpour et al. (2017) from Australia had high citations, implying that these studies received increased attention. That is to say, in developed countries and regions (Australia, Hong Kong), the research on offsite construction was conducted earlier, while developing countries (China) are rapidly promoting such buildings as a form of building in the 2010s.

5 Discussion

5.1 Environmental, social, and governance in prefabricated building industry

5.1.1 Environment

There is a high expectation of prefabricated buildings concerning sustainability. Most articles have mentioned this keyword, highlighting it in the literature analysis. Gallo et al. (2021) investigate the evaluation of sustainable parameters in Hong Kong. Arashpour et al. (2017) compared the environmental, economic, and social aspects of traditional site construction and preassembly life cycle sustainability. Wasim et al. (2020) studied industry management techniques that promote sustainable development. For “sustainability”, most studies concern applications of sustainable technology, so the research on the product management features was not too much. Pham et al. (2020) also mentioned sustainable construction development in Vietnam. Wu et al. (2021a) summarised that the sustainability of prefabricated buildings or offsite construction must be combined with environmental, economic, social, and technological development.

5.1.2 Social

“Supply chain management” is a top topic of management research. Xue et al. (2018) revealed the stakeholders’ collaborative management in the supply chain. Luo et al. (2020) analysed the problems and experiences of prefabricated building production, transportation, and supply chain management in Hong Kong. Arashpour et al. (2017) studied the theorised supply chain configurations in offsite construction. Liu et al. (2018) studied the establishment of the maturity model of the industrial supply chain relationship for prefabricated buildings. Wang et al. (2020) studied a blockchain-based framework for improving supply chain traceability and information sharing for a prefabricated building. Government guidance plays a significant role in the supply chain (Steinhardt and Manley, 2016; Jing et al., 2020; Wang et al., 2021a). The supply chain for prefabricated buildings is still developing; it is not a mature industrial chain in most countries, and collaborative stakeholder management goes a long way.

“Barriers” are the top centrality keyword related to management, a critical study topic. Prefabricated buildings are still concentrated in low-rise buildings (O'Neill and Organ, 2016), and the high cost is an obstacle to developing prefabricated buildings in the United Kingdom (Goodier et al., 2005). Mao et al. (2015) revealed that “government regulations and policies,” “technological innovation,” “industry supply chain,” “cost,” and “market demand” are the main obstacles to the development of prefabricated buildings in China. They continue to find the driving path of development in China (Mao et al., 2018). Yuan et al. (2020) studied the design process’s obstacles to solving technical, economic, and management barriers. Liu et al. (2018) studied Chinese policies, knowledge, and standardisation barriers in China. Developers are not actively promoting prefabricated buildings (Wang et al., 2021b), and stakeholders play games (Zhang et al., 2020) (Wu et al., 2021b), even in the USA, where they also face those barriers (Razkenari et al., 2020). At present, the development of prefabricated buildings in developing countries still mainly relies on the government’s strong push and needs the cooperation of stakeholders. Researchers in developing and developed countries still study how to overcome those barriers.

“Safety risk” is one main topic in 2019. In this cluster, Darko et al. (2020) found that technology application is the most critical factor in reducing construction risk in prefabricated buildings. Chang et al. (2020) studied the system to avoid the safety risks of prefabricated construction. Ahn et al. (2020) explained why offsite construction can help reduce safety risks on construction sites. Many researchers, as well as industry practitioners, believed that offsite construction methods are associated with a lower level of worker safety risks than traditional onsite construction methods. Zhao et al. (2020) analysed projects’ impacts on environmental protection in China. He suggested that the degree to which benefits of offsite construction help reduce safety risks at construction sites needs future study in all countries.

5.1.3 Governance

Among the three elements in ESG, there is a lack of governance study linked to prefabricated buildings. Given the scale and complexity of contracts, competitive bidding procedures, the need to interact with both public and private players, and the need to prevent bribery, corruption, and anti-competitive behaviour, governance has long been a hot topic in the sector (Roberts, 2021). Nevertheless, it is pretty surprising that governance almost disappeared in literature. Prefabricated construction governance issues have not yet been properly investigated, yet bad governance in all businesses may raise bond yields. Future studies on prefabricated buildings may be applied to other academic fields, leading to real-world implications.

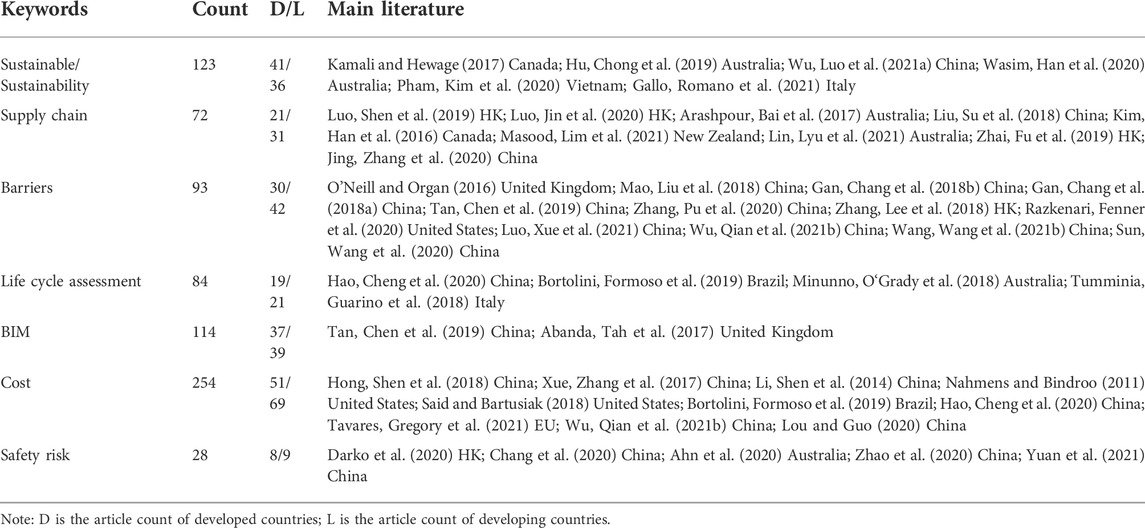

According to the keyword knowledge maps, cluster analysis maps, and timeline analysis maps, we obtained the primary top keywords and studied issues for prefabricated buildings, or offsite construction of their product management attributes to get the primary information about ESG. In Table 7, we summed up the total research in the core collection of WoS (all search terms are in double quotation marks, 2016.1.1–2021.12.31); the count referred to the article numbers; the country attributes of the paper were calculated according to WoS automatic classification, and the relevant country numbers were obtained. Some articles belong to more than one country, so the sum of developed and developing countries is greater than the count.

According to Table 7, we can see that in recent years, developed countries have been a bit more concerned about sustainability than developing countries, and both conducted more cost-benefit analyses that showed developed countries attach greater importance to the environmental and social benefits of ESG more than developing countries. Developing countries studied more about the barriers and supply chain than developed ones, which means more concern about governance. Most studied BIM technology did not focus on safety risks. We list the primary and latest research literature about management and discuss the details in Table 8.

5.2 Prefabricated buildings, building information model and costs saving

Though “BIM” is still in its infancy, it can combine building information model (BIM) with safety risk data to automatically evaluate construction safety concerns and aid architects in making speedy design decisions (Luo et al., 2022). BIM technology supports the development of prefabricated buildings, and to some degree, the development of prefabricated buildings is inseparable from BIM technical assistance (Yin et al., 2019; Akbarieh et al., 2020). BIM is currently critical in driving other innovative techniques and is being pushed by the government to improve building industrialisation (Abanda et al., 2017). However, whether BIM technology is the main factor restricting the development of prefabricated buildings still needs further research, and the quantitative benefits of BIM for prefabricated buildings need to be further studied. In “life cycle assessment” research, Bortolini et al. (2019) considered that building information model (BIM) could solve the complex problem of scheduling and reduce costs. BIM and digital technology are the ultimate solutions to the development of the construction industry (Akbarieh et al., 2020). Hammad et al. (2019) demonstrated prefabricated buildings’ improved social, environmental, and economic benefits. Hao et al. (2020) studied the life cycle carbon emissions of prefabricated buildings with BIM. Therefore, BIM technology has always been associated with the life cycle assessment of prefabricated buildings and is an essential factor in the promotion of the development of prefabricated buildings. Yet, one of the previous research suggested that BIM is not economically feasible for usage in China’s prefabricated buildings (Xu et al., 2019). A summary of the top research is shown in Table 8.

“Construction cost” is the top centrality keyword related to management. It is about governance. Based on the construction industry conditions in Japan and the United Kingdom, Barlow et al. (2003) concluded that information technology significantly reduces construction costs. Li et al. (2014) revealed strengthening construction management and problem-solving efficiency. Hong et al. (2018) considered the benefits of prefabricated buildings, established a cost analysis framework, analysed the actual cases, and put forward countermeasures. Nahmens and Bindroo (2011) concluded that the existing system in the United States had not formed a large-scale business. Said and Bartusiak (2018) concluded that local businesses have certain advantages in the regional competition for industrialised housing in the United States. Currently, the costs of prefabricated buildings are not lower than those of traditional buildings, which have limited their large-scale business in both developed and developing countries. Whether the carbon emission of prefabricated buildings (concrete) is better than that of traditional buildings still needs to control the transportation distance parameter (Hao et al., 2020, Almashaqbeh and El-Rayes, 2021). Moreover, cost control remains a research focus, and how to reduce the cost still needs more research under different countries’ situations.

6 Conclusion

ESG report has become one major requirement for many listed companies. Whether these companies comply with these requirements might affect the stock prices. While many listed construction companies operated their plants and made their prefabricated units and bibliometrics have been done in many research areas, bibliometrics study on prefabricated buildings’ attributes of ESG is rare, not to mention systematic review on this area. This study fills the academic void and figures out prefabricated buildings and offsite research knowledge map and proposes further research about prefabricated buildings that achieve the goal of ESG. Besides, while developed countries are more concerned with the environmental aspect than developing countries, there were substantially less research on the governance aspect. The results might have managerial implications that we may research on the means to motivate the prefabricated industry to work more on the governance aspect of ESG.

Prefabricated building is not mature in the construction supply chain in most countries, especially developing countries and is dependent on government policies and collaborative stakeholder management. As most of these developing countries have immature legal and management systems, more studies about governance in prefabricated buildings are needed. A similar rationale is needed for the safety aspects of prefabricated units. While technical, economic, and management barriers might be related to ESG, a lack of comprehensive study implies that there is room for improvement. Developing a future strategy for ESG rating improvements and integrating ESG in prefabricated buildings may be one of the future directions that academia has not yet studied, but worth to do so in the future to enhance industry awareness in this area where the financial sector has already taken action long ago.

This research also has practical implications. Given the current listed companies’ requirements in ESG reporting in the financial sector, this study suggests the construction industries to enhance governance aspects that could benefit industry practitioners who might list their companies in the stock market. A similar idea holds for academia. The current review is limited to the selected literature sample published in WoS and Scopus, and only English journal articles were included. It might have excluded some of the latest studies published in other languages. As one of our research indicated that local language research might allow us to see other angles in housing price research (Li et al., Forthcoming 2022), similar research might be conducted to study prefabricated buildings. Detailed focus groups and surveys may be taken to see the professionals’ perspectives on ESG and prefabricated buildings in the future. So that we may also know more about practitioners’ extrinsic and intrinsic motivations in ESG and prefabricated buildings knowledge sharing (Li and Poon, 2011).

Author contributions

RL: Conceptual idea, write, review and edit the manuscript. BL: Conceived and designed the study, completed the paper in English. XZ: Conceived and designed the study, revised the important intellectual content. JZ: Gave valuable research advice and revised the manuscript. RP: Provided a comprehensive English revision. LS: Part of literature review, proof and editing.

Conflict of interest

Author Bo Li is/was employed by Jinke Property Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abanda, F., Tah, J., and Cheung, F. (2017). BIM in off-site manufacturing for buildings. J. Build. Eng. 14, 89–102. doi:10.1016/j.jobe.2017.10.002

Abergel, T., Dean, B., and Dulac, J. (2017). Towards a zero-emission, efficient, and resilient buildings and construction sector: Global Status Report 2017, 22. Paris, France: UN Environment and International Energy Agency.

Ahn, S., Crouch, L., Kim, T. W., and Rameezdeen, R. (2020). Comparison of worker safety risks between onsite and offsite construction methods: A site management perspective. J. Constr. Eng. Manag. 146 (9), 05020010. doi:10.1061/(asce)co.1943-7862.0001890

Akbarieh, A., Jayasinghe, L. B., Waldmann, D., and Teferle, F. N. (2020). BIM-based end-of-lifecycle decision making and digital deconstruction: Literature review. Sustainability 12 (7), 2670. doi:10.3390/su12072670

Almashaqbeh, M., and El-Rayes, K. (2021). Minimizing transportation cost of prefabricated modules in modular construction projects. Eng. Constr. Archit. Manag. doi:10.1108/ECAM-11-2020-0969

Arashpour, M., Bai, Y., Aranda-mena, G., Bab-Hadiashar, A., Hosseini, R., and Kalutara, P. (2017). Optimizing decisions in advanced manufacturing of prefabricated products: Theorizing supply chain configurations in off-site construction. Automation Constr. 84, 146–153. doi:10.1016/j.autcon.2017.08.032

Arashpour, M., Wakefield, R., Blismas, N., and Minas, J. (2015). Optimization of process integration and multi-skilled resource utilization in off-site construction. Automation Constr. 50, 72–80. doi:10.1016/j.autcon.2014.12.002

Aye, L., Ngo, T., Crawford, R., Gammampila, R., and Mendis, P. (2012). Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 47, 159–168. doi:10.1016/j.enbuild.2011.11.049

Barbosa, F., Woetzel, J., and Mischke, J. (2017). Reinventing construction: A route of higher productivity. Washington: McKinsey Global Institute.

Barlow, J., Childerhouse, P., Gann, D., Hong-Minh, S., Naim, M., and Ozaki, R. (2003). Choice and delivery in housebuilding: Lessons from Japan for UK housebuilders. Build. Res. Inf. 31 (2), 134–145. doi:10.1080/09613210302003

Blismas, N., and Wakefield, R. (2009). Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 9, 72–83. doi:10.1108/14714170910931552

Bortolini, R., Formoso, C. T., and Viana, D. D. (2019). Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Automation Constr. 98, 248–264. doi:10.1016/j.autcon.2018.11.031

Burnham, J. F. (2006). Scopus database: A review. Biomed. Digit. Libr. 3 (1), 1. doi:10.1186/1742-5581-3-1

Butković, L. L., Tomšić, D., and Kaselj, S. (2021). Collaborative strategic view in corporate social responsibility–construction industry case. Bus. Syst. Res. J. 12 (1), 144–163. doi:10.2478/bsrj-2021-0010

Center, U. N. H. D. D. (2021). Developed countries list. Available from https://worldpopulationreview.com/country-rankings/developed-countries.

Chang, C., Wu, X., and Yan, X. (2020). Multiobjective optimization of safety risk of prefabricated building construction considering risk correlation. Math. Problems Eng. 2020, 3923486. doi:10.1155/2020/3923486

Chang, Y., Li, X., Masanet, E., Zhang, L., Huang, Z., and Ries, R. (2018). Unlocking the green opportunity for prefabricated buildings and construction in China. Resour. Conservation Recycl. 139, 259–261. doi:10.1016/j.resconrec.2018.08.025

Chen, C. (2006). CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 57 (3), 359–377. doi:10.1002/asi.20317

Chen, C., Hu, Z., Liu, S., and Tseng, H. (2012). Emerging trends in regenerative medicine: A scientometric analysis in CiteSpace. Expert Opin. Biol. Ther. 12 (5), 593–608. doi:10.1517/14712598.2012.674507

Chen, C. (2014). The CiteSpace manual. Available at: http://cluster.ischool.drexel.edu/∼cchen/citespace/CiteSpaceManual.pdf.

Crifo, P., Diaye, M.-A., and Oueghlissi, R. (2017). The effect of countries’ ESG ratings on their sovereign borrowing costs. Q. Rev. Econ. Finance 66, 13–20. doi:10.1016/j.qref.2017.04.011

Darko, A., Chan, A. P., Yang, Y., and Tetteh, M. O. (2020). Building information modeling (BIM)-based modular integrated construction risk management – critical survey and future needs. Comput. Industry 123, 103327. doi:10.1016/j.compind.2020.103327

Donthu, N., Kumar, S., Mukherjee, D., Pandey, N., and Lim, W. M. (2021). How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 133, 285–296. doi:10.1016/j.jbusres.2021.04.070

Gallo, P., Romano, R., and Belardi, E. (2021). Smart green prefabrication: Sustainability performances of industrialized building technologies. Sustainability 13 (9), 4701. doi:10.3390/su13094701

Gan, X., Chang, R., and Wen, T. (2018). Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 201, 735–747. doi:10.1016/j.jclepro.2018.07.299

Gan, X., Chang, R., Zuo, J., Wen, T., and Zillante, G. (2018). Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 197, 8–18. doi:10.1016/j.jclepro.2018.06.184

Gavana, G., Gottardo, P., and Moisello, A. M. (2022). Related party transactions and earnings management: The moderating effect of ESG performance. Sustainability 14 (10), 5823. doi:10.3390/su14105823

Goodier, C., and Gibb, A. (2007). Future opportunities for offsite in the UK. Constr. Manag. Econ. 25 (6), 585–595. doi:10.1080/01446190601071821

Goodier, C. I., and Gibb, A. G. (2005). “Barriers and opportunities for offsite in the UK,” in Systematic innovation in the management of projects and processes. Cib Helsinki international joint symposium. Editor Abdul Samad Kazi (USA: Citeseer).

Hadro, D., Fijalkowska, J., Daszynska-Zygadlo, K., Zumente, I., and Mjakuskina, S. (2022). What do stakeholders in the construction industry look for in non-financial disclosure and what do they get? Meditari Account. Res. 30 (3), 762–785. doi:10.1108/medar-11-2020-1093

Hammad, A. W., Akbarnezhad, A., Wu, P., Wang, X., and Haddad, A. (2019). Building information modelling-based framework to contrast conventional and modular construction methods through selected sustainability factors. J. Clean. Prod. 228, 1264–1281. doi:10.1016/j.jclepro.2019.04.150

Hanafi, M. H., Farrell, P., Yusoff, M. N., Abdullah, S., and Abdul Razak, A. (2018). Installation systems of on-site prefabricated concrete components: A qualitative approach. Int. J. Constr. Manag. 18 (5), 343–350. doi:10.1080/15623599.2017.1326297

Hao, J. L., Cheng, B., Weisheng, L., Jun, X., and Wang, J. (2020). Carbon emission reduction in prefabrication construction during materialization stage: A BIM-based life-cycle assessment approach. Sci. Total Environ. 25, 137870. doi:10.1016/j.scitotenv.2020.137870

Hong, J. K., Shen, G. Q., Mao, C., Li, Z., and Li, K. (2016). Life-cycle energy analysis of prefabricated building components: An input-output-based hybrid model. J. Clean. Prod. 112, 2198–2207. doi:10.1016/j.jclepro.2015.10.030

Hong, J., Shen, G. Q., Li, Z., Zhang, B., and Zhang, W. (2018). Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 172, 649–660. doi:10.1016/j.jclepro.2017.10.171

Hosseini, M. R., Martek, I., Zavadskas, E. K., Aibinu, A. A., Arashpour, M., and Chileshe, N. (2018). Critical evaluation of off-site construction research: A scientometric analysis. Automation Constr. 87, 235–247. doi:10.1016/j.autcon.2017.12.002

Hu, X., Chong, H.-Y., and Wang, X. (2019). Sustainability perceptions of off-site manufacturing stakeholders in Australia. J. Clean. Prod. 227, 346–354. doi:10.1016/j.jclepro.2019.03.258

Jaillon, L., and Poon, C. (2014). Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Automation Constr. 39, 195–202. doi:10.1016/j.autcon.2013.09.006

Jaillon, L., and Poon, C. S. (2009). The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Automation Constr. 18 (3), 239–248. doi:10.1016/j.autcon.2008.09.002

Jiang, W., Luo, L., Wu, Z., Fei, J., Antwi-Afari, M. F., and Yu, T. (2019). An investigation of the effectiveness of prefabrication incentive policies in China. Sustainability 11 (19), 5149. doi:10.3390/su11195149

Jie, L. (2016). CiteSpace: Science and technology text mining and visualization. China: Capital University of Economics and Business Press.

Jin, R., Gao, S., Cheshmehzangi, A., and Aboagye-Nimo, E. (2018). A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 202, 1202–1219. doi:10.1016/j.jclepro.2018.08.195

Jing, S. W., Zhang, Z. Y., and Yan, J. A. (2020). Government supervision mode selection in the promotion period of prefabricated construction using evolutionary game. Math. Problems Eng. 2020, 11. doi:10.1155/2020/7105617

Kamali, M., and Hewage, K. (2017). Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. J. Clean. Prod. 142, 3592–3606. doi:10.1016/j.jclepro.2016.10.108

Kamali, M., and Hewage, K. (2016). Life cycle performance of modular buildings: A critical review. Renew. Sustain. energy Rev. 62, 1171–1183. doi:10.1016/j.rser.2016.05.031

Kim, Y.-W., Han, S. H., Yi, J. S., and Chang, S. (2016). Supply chain cost model for prefabricated building material based on time-driven activity-based costing. Can. J. Civ. Eng. 43 (4), 287–293. doi:10.1139/cjce-2015-0010

Li, J., and Chen, C. (2016). CiteSpace: Text mining and visualization in scientific literature. Beijing, China: Capital University of Economics and Business Press, 149–152.

Li, N., Li, R. Y. M., and Nuttapong, J. (Forthcoming 2022). Factors affecting housing prices in china: A systematic review of papers indexed in chinese science citation database. Prop. Manag.. doi:10.1108/PM-11-2020-0078

Li, R. Y. M., and Poon, S. W. (2011). Using web 2.0 to share knowledge of construction safety: The fable of economic animals. Econ. Aff. 31 (1), 73–79. doi:10.1111/j.1468-0270.2010.02053.x

Li, Z., Shen, G. Q., and Xue, X. (2014). Critical review of the research on the management of prefabricated construction. Habitat Int. 43, 240–249. doi:10.1016/j.habitatint.2014.04.001

Lin, T., Lyu, S., and Tivendale, L. (2021). Offsite construction in the Australian low-rise residential buildings application levels and procurement options. Eng. Constr. Archit. Manag. doi:10.1108/ECAM-07-2020-0583

Liu, K., Su, Y., and Zhang, S. (2018). Evaluating supplier management maturity in prefabricated construction project-survey analysis in China. Sustainability 10 (9), 3046. doi:10.3390/su10093046

Liu, W., Zhang, H., Wang, Q., Hua, T., and Xue, H. (2021). A review and scientometric analysis of global research on prefabricated buildings. Adv. Civ. Eng. 2021, 1–18. doi:10.1155/2021/8869315

Lou, N., and Guo, J. (2020). Study on key cost drivers of prefabricated buildings based on system dynamics. Adv. Civ. Eng. 2020, 8896435. doi:10.1155/2020/8896435

Luo, F., Li, R. Y. M., Crabbe, M. J. C., and Pu, R. (2022). Economic development and construction safety research: A bibliometrics approach. Saf. Sci. 145, 105519. doi:10.1016/j.ssci.2021.105519

Luo, L., Jin, X., Shen, G. Q., Wang, Y., Liang, X., Li, X., et al. (2020). Supply chain management for prefabricated building projects in Hong Kong. J. Manage. Eng. 36 (2), 05020001. doi:10.1061/(asce)me.1943-5479.0000739

Luo, L., Qiping Shen, G., Xu, G., Liu, Y., and Wang, Y. (2019). Stakeholder-associated supply chain risks and their interactions in a prefabricated building project in Hong Kong. J. Manage. Eng. 2019 (2), 35. doi:10.1061/(asce)me.1943-5479.0000675

Luo, T., Xue, X., Wang, Y., Xue, W., and Tan, Y. (2021). A systematic overview of prefabricated construction policies in China. J. Clean. Prod. 280, 124371. doi:10.1016/j.jclepro.2020.124371

Managers, N. I. (2019). Looking for the best of both worlds. Available from www.im. natixis.com/us/resources/esg-investing-survey-2019.

Mao, C., Liu, G., Shen, L., Wang, X., and Wang, J. (2018). Structural equation modeling to analyze the critical driving factors and paths for off-site construction in China. KSCE J. Civ. Eng. 22 (8), 2678–2690. doi:10.1007/s12205-017-1705-4

Mao, C., Shen, Q., Pan, W., and Ye, K. (2015). Major barriers to off-site construction: The developer’s perspective in China. J. Manage. Eng. 31 (3), 04014043. doi:10.1061/(asce)me.1943-5479.0000246

Mao, C., Shen, Q., Shen, L., and Tang, L. (2013). Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 66, 165–176. doi:10.1016/j.enbuild.2013.07.033

Mao, C., Xie, F., Hou, L., Wu, P., Wang, J., and Wang, X. (2016). Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 57, 215–222. doi:10.1016/j.habitatint.2016.08.002

Masood, R., Lim, J. B. P., and Gonzalez, V. A. (2021). Performance of the supply chains for New Zealand prefabricated house-building. Sustain. Cities Soc. 64, 102537. doi:10.1016/j.scs.2020.102537

Merigó, J. M., and Yang, J.-B. (2017). A bibliometric analysis of operations research and management science. Omega 73, 37–48. doi:10.1016/j.omega.2016.12.004

Minunno, R., O’Grady, T., Morrison, G., Gruner, R., and Colling, M. (2018). Strategies for applying the circular economy to prefabricated buildings. Buildings 8 (9), 125. doi:10.3390/buildings8090125

Nahmens, I., and Bindroo, V. (2011). Is customization fruitful in industrialized homebuilding industry? J. Constr. Eng. Manag. 137 (12), 1027–1035. doi:10.1061/(asce)co.1943-7862.0000396

Navaratnam, S., Ngo, T., Gunawardena, T., and Henderson, D. (2019). Performance review of prefabricated building systems and future research in Australia. Buildings 9 (2), 38. doi:10.3390/buildings9020038

O'Neill, D., and Organ, S. (2016). A literature review of the evolution of British prefabricated low-rise housing. Struct. Surv. 34, 191–214. doi:10.1108/SS-08-2015-0037

Pan, W., Gibb, A. G., and Dainty, A. R. (2012). Strategies for integrating the use of off-site production technologies in house building. J. Constr. Eng. Manag. 138 (11), 1331–1340. doi:10.1061/(asce)co.1943-7862.0000544

Pan, W., Gibb, A. G. F., and Dainty, A. R. J. (2007). Perspectives of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 25 (2), 183–194. doi:10.1080/01446190600827058

Pan, W., and Sidwell, R. (2011). Demystifying the cost barriers to offsite construction in the UK. Constr. Manag. Econ. 29 (11), 1081–1099. doi:10.1080/01446193.2011.637938

Patil, R. A., Ghisellini, P., and Ramakrishna, S. (2021). “Towards sustainable business strategies for a circular economy: Environmental, social and governance (ESG) performance and evaluation,” in An introduction to circular economy (Germany: Springer), 527–554.

Pham, H., Kim, S. Y., and Luu, T. V. (2020). Managerial perceptions on barriers to sustainable construction in developing countries: Vietnam case. Environ. Dev. Sustain. 22 (4), 2979–3003. doi:10.1007/s10668-019-00331-6

Razkenari, M., Fenner, A., Shojaei, A., Hakim, H., and Kibert, C. (2020). Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 29, 101138. doi:10.1016/j.jobe.2019.101138

Roberts, E. (2021). The current state of ESG reporting in the engineering and construction industry. Available from https://www.ey.com/en_us/real-estate-hospitality-construction/esg-reporting-and-construction-industry.

Said, H. M., and Bartusiak, J. (2018). Regional competition analysis of industrialized homebuilding industry. J. Constr. Eng. Manag. 144 (2), 04017108. doi:10.1061/(asce)co.1943-7862.0001424

Sharma, P., Panday, P., and Dangwal, R. C. (2020). Determinants of environmental, social and corporate governance (ESG) disclosure: A study of Indian companies. Int. J. Discl. Gov. 17 (4), 208–217. doi:10.1057/s41310-020-00085-y

Siew, R. Y. J. (2017). Critical evaluation of environmental, social and governance disclosures of Malaysian property and construction companies. Constr. Econ. Build. 17 (2), 81–91. doi:10.5130/AJCEB.v17i2.5328

Singhania, M., and Saini, N. (2021). Quantification of ESG regulations: A cross-country benchmarking analysis. Vision. 26 (2), 163–171. doi:10.1177/09722629211054173

Steinhardt, D. A., and Manley, K. (2016). Adoption of prefabricated housing-the role of country context. Sustain. CITIES Soc. 22, 126–135. doi:10.1016/j.scs.2016.02.008

Sun, Y., Wang, J., Wu, J., Shi, W., Ji, D., Wang, X., et al. (2020). Appl. Sci. (Basel). 10 (20), 7159. doi:10.3390/app10207159

Tam, V. W., Fung, I. W., Sing, M. C., and Ogunlana, S. O. (2015). Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 109, 216–231. doi:10.1016/j.jclepro.2014.09.045

Tam, V. W., Tam, C., Zeng, S., and Ng, W. C. (2007). Towards adoption of prefabrication in construction. Build. Environ. 42 (10), 3642–3654. doi:10.1016/j.buildenv.2006.10.003

Tan, T., Chen, K., Xue, F., and Lu, W. (2019). Barriers to Building Information Modeling (BIM) implementation in China's prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. Prod. 219, 949–959. doi:10.1016/j.jclepro.2019.02.141

Tavares, V., Gregory, J., Kirchain, R., and Freire, F. (2021). What is the potential for prefabricated buildings to decrease costs and contribute to meeting EU environmental targets? Build. Environ. 206, 108382. doi:10.1016/j.buildenv.2021.108382

Taylor, M. D. (2010). A definition and valuation of the UK offsite construction sector. Constr. Manag. Econ. 28 (8), 885–896. doi:10.1080/01446193.2010.480976

Tumminia, G., Guarino, F., Longo, S., Ferraro, M., Cellura, M., and Antonucci, V. (2018). Life cycle energy performances and environmental impacts of a prefabricated building module. Renew. Sustain. Energy Rev. 92, 272–283. doi:10.1016/j.rser.2018.04.059

Velte, P. (2019). The bidirectional relationship between ESG performance and earnings management – empirical evidence from Germany. J. Glob. Responsib. 10 (4), 322–338. doi:10.1108/jgr-01-2019-0001

Wang, H., Lu, W., Ye, M., Chau, K., and Zhang, X. (2016). The curvilinear relationship between corporate social performance and corporate financial performance: Evidence from the international construction industry. J. Clean. Prod. 137, 1313–1322. doi:10.1016/j.jclepro.2016.07.184

Wang, W., and Lu, C. (2020). Visualization analysis of big data research based on Citespace. Soft Comput. 24 (11), 8173–8186. doi:10.1007/s00500-019-04384-7

Wang, Y. J., Wang, F., Sang, P., and Song, H. (2021). Analysing factors affecting developers' behaviour towards the adoption of prefabricated buildings in China. Environ. Dev. Sustain. 23 (10), 14245–14263. doi:10.1007/s10668-021-01265-8

Wang, Y., Xue, X., and Yu, T. (2021). Mapping the dynamics of China’s prefabricated building policies from 1956 to 2019: A bibliometric analysis. Build. Res. Inf. 49 (2), 216–233. doi:10.1080/09613218.2020.1789444

Wang, Z., Wang, T., Hu, H., Gong, J., Ren, X., and Xiao, Q. (2020). Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Automation Constr. 111, 103063. doi:10.1016/j.autcon.2019.103063

Wasim, M., Han, T. M., Huang, H., Madiyev, M., and Ngo, T. D. (2020). An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 32, 101474. doi:10.1016/j.jobe.2020.101474

Wu, H. J., Qian, Q. K., Straub, A., and Visscher, H. (2021). Stakeholder perceptions of transaction costs in prefabricated housing projects in China. J. Constr. Eng. Manag. 147 (1), 15. doi:10.1061/(asce)co.1943-7862.0001947

Wu, Z. Z., Luo, L., Li, H., Wang, Y., Bi, G., and Antwi-Afari, M. F. (2021). An analysis on promoting prefabrication implementation in construction industry towards sustainability. Int. J. Environ. Res. Public Health 18 (21), 11493. doi:10.3390/ijerph182111493

Xu, Z., Wang, S., and Wang, E. (2019). Integration of BIM and energy consumption modelling for manufacturing prefabricated components: A case study in China. Adv. Civ. Eng. 2019, 1–18. doi:10.1155/2019/1609523

Xue, H., Zhang, S., Su, Y., and Wu, Z. (2017). Factors affecting the capital cost of prefabrication-A case study of China. Sustainability 9 (9), 1512. doi:10.3390/su9091512

Xue, H., Zhang, S., Su, Y., Wu, Z., and Yang, R. J. (2018). Effect of stakeholder collaborative management on off-site construction cost performance. J. Clean. Prod. 184, 490–502. doi:10.1016/j.jclepro.2018.02.258

Yin, X., Liu, H., Chen, Y., and Al-Hussein, M. (2019). Building information modelling for off-site construction: Review and future directions. Automation Constr. 101, 72–91. doi:10.1016/j.autcon.2019.01.010

Yu, S., Liu, Y., Wang, D., Bahaj, A. S., Wu, Y., and Liu, J. (2021). Review of thermal and environmental performance of prefabricated buildings: Implications to emission reductions in China. Renew. Sustain. Energy Rev. 137, 110472. doi:10.1016/j.rser.2020.110472

Yuan, M. Q., Li, Z., Li, X., and Luo, X. (2021). Managing stakeholder-associated risks and their interactions in the life cycle of prefabricated building projects: A social network analysis approach. J. Clean. Prod. 2021, 129102. doi:10.1016/j.jclepro.2021.129102

Yuan, Z., Ni, G., Wang, L., Qiao, Y., Sun, C., Xu, N., et al. (2020). Research on the barrier analysis and strength measurement of a prefabricated building design. Sustainability 12 (7), 2994. doi:10.3390/su12072994

Zeng, L., and Li, R. Y. M. (2022). Construction safety and health hazard awareness in Web of Science and Weibo between 1991 and 2021. Saf. Sci. 152, 105790. doi:10.1016/j.ssci.2022.105790

Zeng, L., Li, R. Y. M., Nuttapong, J., Sun, J., and Mao, Y. (2022). Economic development and mountain tourism research from 2010 to 2020: Bibliometric analysis and science mapping approach. Sustainability 14 (1), 562. doi:10.3390/su14010562

Zhai, Y., Fu, Y., Xu, G., and Huang, G. (2019). Multi-period hedging and coordination in a prefabricated construction supply chain. Int. J. Prod. Res. 57 (7), 1949–1971. doi:10.1080/00207543.2018.1512765

Zhang, S., Li, Z., Li, T., and Yuan, M. (2021). A holistic literature review of building information modeling for prefabricated construction. J. Civ. Eng. Manag. 27 (7), 485–499. doi:10.3846/jcem.2021.15600

Zhang, W., Lee, M. W., Jaillon, L., and Poon, C. S. (2018). The hindrance to using prefabrication in Hong Kong's building industry. J. Clean. Prod. 204, 70–81. doi:10.1016/j.jclepro.2018.08.190

Zhang, X., Skitmore, M., and Peng, Y. (2014). Exploring the challenges to industrialized residential building in China. Habitat Int. 41, 176–184. doi:10.1016/j.habitatint.2013.08.005

Zhang, Y., Pu, S., Li, R. Y. M., and Zhang, J. (2020). Microscopic and mechanical properties of undisturbed and remoulded red clay from Guiyang, China. Sci. Rep. 10 (1), 18003. doi:10.1038/s41598-020-71605-7

Keywords: prefabricated building, science mapping, modularity cluster analysis, construction management, ESG, economic development

Citation: Li RYM, Li B, Zhu X, Zhao J, Pu R and Song L (2022) Modularity clustering of economic development and ESG attributes in prefabricated building research. Front. Environ. Sci. 10:977887. doi: 10.3389/fenvs.2022.977887

Received: 25 June 2022; Accepted: 23 August 2022;

Published: 26 October 2022.

Edited by:

Lu Yang, Shenzhen University, ChinaReviewed by:

Mário Nuno Mata, Instituto Politécnico de Lisboa, PortugalIoannis Vardopoulos, Harokopio University, Greece

Copyright © 2022 Li, Li, Zhu, Zhao, Pu and Song. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Rita Yi Man Li, ymli@hksyu.edu; Bo Li, bo.li@rmutto.ac.th; Xiaoe Zhu, xiaoe.zhu@rmutto.ac.th

†These authors share first authorship

Rita Yi Man Li

Rita Yi Man Li Bo Li

Bo Li Xiaoe Zhu

Xiaoe Zhu Jingjing Zhao

Jingjing Zhao Ruihui Pu

Ruihui Pu Lingxi Song

Lingxi Song