- 1Department of International Trade and Logistics, Chung-Ang University, Seoul, South Korea

- 2The Graduate School of Technology Management, Kyunghee University, Yongin, South Korea

- 3Department of Logistics, Service and Operations Management, Korea University Business School, Seoul, South Korea

- 4Department of Economics, Sejong University, Seoul, South Korea

In recent years, suppliers’ sustainability has been the primary source of conflict in multinational supply chains. How suppliers from developing nations may accomplish sustainable development and competitive advantage goals has become a tough issue inside the multinational supply chain, particularly in the agri-food cold chain. Using an integrated theory-based perspective, this paper analyzes how sustainable logistics service providers’ supply chain cooperation (MSCC) might drive the sustainable transformation of suppliers in developing nations. Between 1 June 2020 and 15 January 2021, we gathered feedback from 215 Chinese vendors and analyzed and discussed possible models using structural equation modeling. This study demonstrates that the sustainable practices of logistics service providers are the foundation for influencing the collaboration of suppliers in developing nations with regard to sustainability. In addition, the five-stage transnational supply chain cooperation based on the theory of innovation diffusion is an efficient strategy for ensuring the sustainable development of suppliers in developing nations. This paper examines the theoretical framework at the forefront of multinational supply chain sustainability development. This presents the most recent experience and policy application for suppliers from emerging nations to acquire a competitive advantage.

1 Introduction

In a globalized economic context, supply chains have shifted their competitive emphasis to sustainability. Sustainability as a differentiated approach enables supply chain internal companies to remain competitive in the current business climate (Magazzino et al., 2022; Sun et al., 2022). Despite the growing interest of businesses in sustainable practices, multinational agri-food cold chains still face challenges in protecting the global environment (Weber et al., 2021). In fact, agri-food systems are relevant to all Sustainable Development Goals (SDGs), which makes their transition to holistic sustainability (ecological, economic, and social) imperative (Tochtrop et al., 2022). Many large enterprises in developed countries benefit from multinational agri-food supply chains by outsourcing their functions or products to agri-food cold chain suppliers in developing countries (Menke et al., 2021; Fan et al., 2022). However, policies and laws in emerging countries are not only less stable than those in developed countries, but social and environmental standards may also be lower, which leads to social reputation and environmental protection issues for stakeholders in developed countries (Cassani and Gomez-Zavaglia, 2022). As environmental and social issues in developing countries become increasingly prominent, there is an urgent need to discover solutions for the sustainability of multinational supply networks as a whole (Rehman Khan et al., 2022).

The sustainable practice of multinational logistics service providers (MLSP) is an effective means of achieving the sustainable transformation of supply chains in the context of sustainable development (Li G. et al., 2021). With the further expansion of transnational supply chains, the enhancement of MLSP sustainable practices will further optimize the transnational supply networks’ sustainable environment (Fan et al., 2022). In actuality, sustainable logistics service providers take into account multiple links (transportation, warehousing, packaging, distribution processing, information management, waste management, etc.) to physically and virtually combine production and consumption links in multinational supply chains (Tochtrop et al., 2022). Therefore, it is vital to maximize the active engagement of sustainable MLSP in the mechanism of sustainable supply chain management. Because MLSP can promote sustainable development-related supply chain cooperation among multinational supply chain participants, provide developing country suppliers with sustainable development experience, and assist them in enhancing their competitive advantages (Cassani and Gomez-Zavaglia, 2022). In conclusion, to meet the overall sustainability objectives of the entire transnational agri-food cold chain, the importance of transnational supply chain cooperation (MSCC) and sustainable MLSP should be reevaluated (Centobelli et al., 2021; Donkor et al., 2021; Fan et al., 2022).

In the field of sustainable agri-food supply chain management, researchers have adopted a variety of theories and methods, such as literature review, system network design, performance management, and risk models (Ali et al., 2018; Cassani and Gomez-Zavaglia., 2022; Tochtrop et al., 2022; Yontar and Ersoz, 2020). Fan et al. (2022), constructed a sustainable logistics performance index using the entropy method. And experimentally analyzing the impact of partner countries’ sustainable logistics performance on export trade using the extended trade gravity model. Cassani and Gomez-Zavaglia, (2022) propose sustainable technologies for agri-food cold chains, such as those for fruits and vegetables, based on a literature review. Sun et al. (2022) employed quantitative techniques (e.g., discriminant validity analysis, measurement model evaluation, comprehensive reliability and validity analysis.) to investigate the relationship between sustainable supply chain management strategies and sustainable competitive advantage. Tochtrop et al. (2022) created a sustainable urban food supply chain system based on the concepts of regional collaboration and emphasized the logistics sector’s participation in the study. Yontar and Ersoz, (2020) determine the parameters that influence sustainable food supply chain management in the food industry through quantitative analysis, and evaluate the performance of supply chain parameters. Few studies have, however, addressed the formation mechanism of the sustainable development of agricultural supply chains from the perspective of logistics service providers, resulting in the following many research gaps: First, as a new trend in the evolution of modern logistics, there are relatively few academic studies on the impact of sustainable MLSP on multinational supply chains sustainability, whereas the majority of the literature focuses on the impact of sustainable logistics performance on multinational supply chains (Fan et al., 2022). Second, the impact of MLSPs’ sustainable practices on multinational supply chain cooperation (MSCC) in developing countries is unclear (Multaharju et al., 2017). At last, the impact of sustainable MLSP on the sustainable production and competitive advantage of suppliers in developing countries is not sufficiently clear (Soltanmohammadi et al., 2021). These considerations lead to the following research questions:

RQ1: What effect do MLSPs’ sustainable practices have on the multinational supply chains cooperative operation of suppliers in developing countries?

RQ2: Do and how do MLSPs’ sustainable practices affect the sustainable production and competitiveness of suppliers in developing countries?

To answer the aforementioned research questions, this paper takes the MSCC of China’s agricultural cold chain suppliers (CAFSs) led by MLSPs as the research background. Combined with contingency theory, innovation diffusion theory and resource advantage theory, a research model is established to analyze the impact of inter-firm collaboration on sustainable production and competitive advantage. Between 1 June 2020 and 15 January 2021, we obtained feedback from 215 Chinese agri-food providers and analyzed and discussed hypothetical models using structural equation modeling. The findings imply that sustainable logistics service providers can encourage cooperation between members of multinational supply chains to accomplish sustainable development goals and competitive benefits for developing country suppliers. This study explores the causes and effects of the influence of MSCCs dominated by sustainable logistics service providers on CAFS sustainable production and competitive advantage using a theory-driven methodology. This study also explores the actual situation of Chinese agri-food providers in a particular region (Northeast Asia). This work contributes to the existing body of knowledge in multiple ways.

This study first demonstrates that the climate of unpredictability and creativity produced by sustainable MLSPs is a major factor driving developing nation suppliers to collaborate in the supply chain. Second, this study expands both the theoretical and practical literature on the topic of sustainable MLSPs for promoting developing nation partners’ fulfillment of the SDGs. From the standpoint of multinational supply chain cooperation, this study concludes with a strategy for achieving the overall sustainable development of multinational supply chains. This provides a theoretical and practical approach for developing country cold chain food suppliers to practice sustainable production and competitive advantage goals.

The remaining sections of the research are as follows: First, a theoretical model presenting describing a hypothetical network and related theories is introduced. Following this, we investigated each hypothesis. Next, an approach to measurement is developed to make the theoretical model operable. Survey data were collected from CAFS. Structural equation modeling (SEM) was used to test the theoretical model, and the results were obtained and discussed. Finally, conclusions were drawn from the investigation results.

2 Literature review and theoretical framework

2.1 Literature review

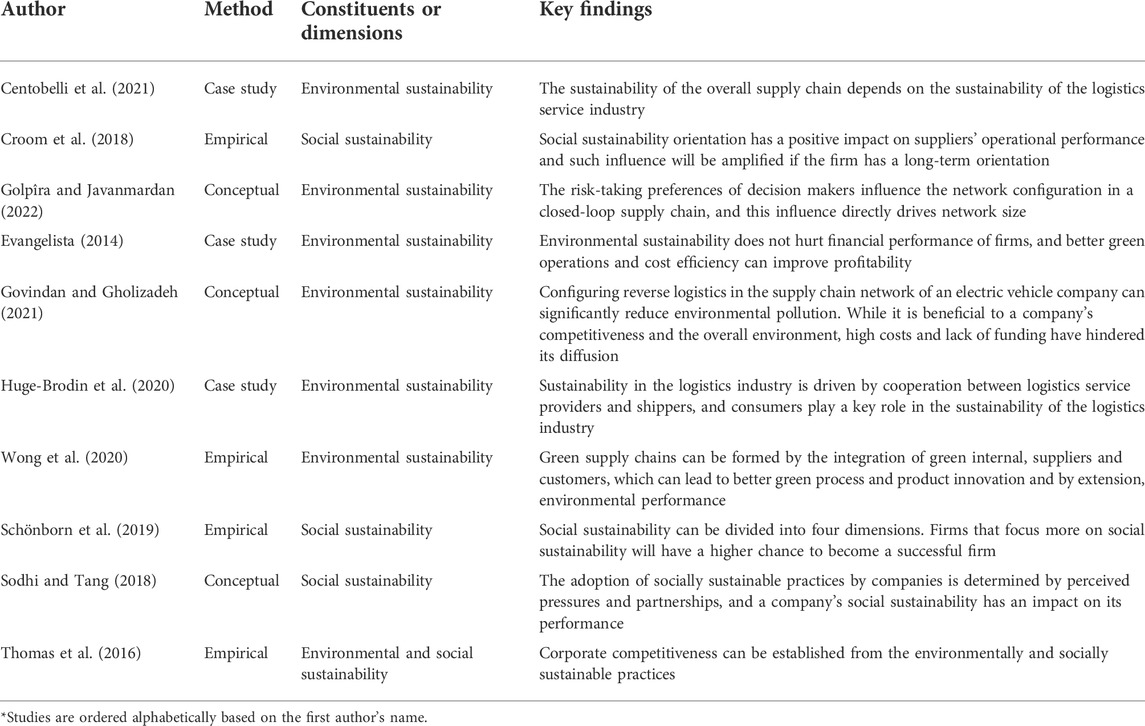

This study is closely associated with two streams of literature: the literature on sustainable management of logistics service providers and the literature on the SDG of suppliers. Due to the short product life cycle, the agricultural food cold chain requires a highly complex cold chain logistics system (Liu A. et al., 2021), which sometimes exacerbates the difficulty of sustainable management compared to the manufacturing industry (Centobelli et al., 2017). Previous research has highlighted the importance of logistics for a sustainable cold chain (Shashi et al., 2018; Niu and Wu, 2020; Froio and Bezerra, 2021), and logistics management plays a central role in enabling greater sustainability in the food value chain (Jabbour et al., 2015). In this regard, many researchers from different disciplines have conducted studies on the sustainable practices of logistics service providers (Pullman et al., 2009; Dam and Petkova, 2014; Thomas et al., 2016; Sodhi and Tang, 2018). However, most of the current research has been focused on the area of environmental sustainability (Table 1). For example, Evangelista (2014) conducted a case study on 13 Italian logistics service providers to investigate the drivers of environmental sustainability. Similarly, Centobelli et al. (2020) concluded that the environmental sustainability of the logistics service industry is of critical important for the supply chain-wide green development. Huge-Brodin et al. (2020) reported that the relationship between logistics service providers and shippers drives the green development of the logistics industry. Although our study has some similarities to these recent advances, our analysis proposes that the sustainable practice of logistics service providers should focus on not only the environmental perspective, but also on the economic and social sustainable perspectives. Previous studies have argued that a sustainable MLSP should promote sustainable development by simultaneously providing economic, social and environmental benefits (Norman and MacDonald, 2004), which highlights the importance of protecting the environment and safeguarding the social rights of all company stakeholders while pursuing profits (Touboulic and Walker, 2015; Kumar and Anbanandam, 2020). In the context of sustainable development, MLSPs’ sustainable practices have created an external sustainable environment in three aspects: economy, environment, and society for CAFS (Klumpp and Zijm, 2019; Tsao and Thanh, 2019).

The other relevant literature stream is on the SDG of suppliers. In recent years, numerous studies have been conducted to examine the success factors of suppliers’ SDGs. Su et al. (2022a) revealed that stakeholder pressure is the most significant factor influencing the suppliers’ sustainable development, followed by strategic positioning, sustainable policy, and the commitment of the top management team. Danese. (2011) emphasized that the alignment between the sustainable development project and plant goals determines the supplier’s sustainability practices. Scholars have also argued that the pressure from the customers, employees, governments, and trade partners are important antecedents of suppliers’ SDG (Danese, 2011; Ghadge et al., 2021). However, the impact of MLSP on the sustainable practice of the cold chain is still controversial. Particularly, in the multinational cold chain food industry, organizations have faced important sustainability challenges, including personnel management, short shelf life, food loss and waste, and high greenhouse gas emissions (Mangla et al., 2019). Even though some MLSPs with long-term vision have begun to implement more sustainable practices and cooperation and have committed to establishing a sustainable supply chain through cooperation. Few studies have noticed that MLSPs’ sustainable practical knowledge is transferred to source suppliers in developing countries through MSCC. The focus is on integrating the cooperation between MLSP and CAFS and achieving suppliers’ ecological, social, and financial goals through inter-organizational trade processes (Singh and Shabani, 2016).

2.2 Theoretical framework

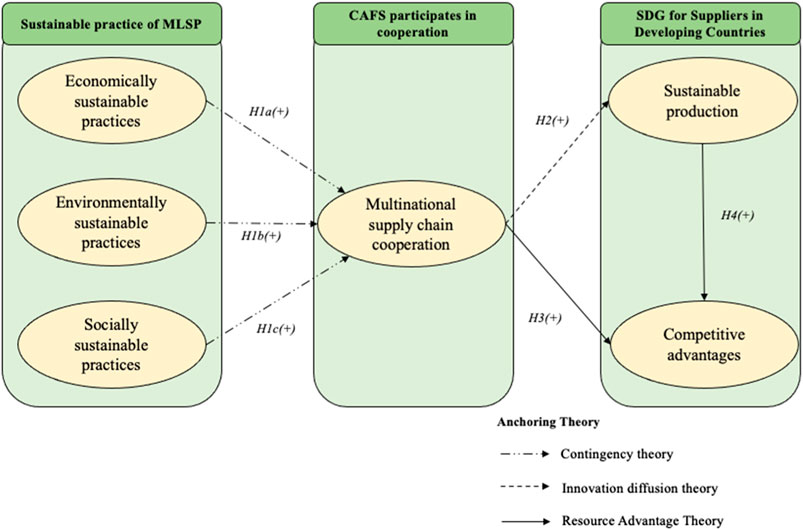

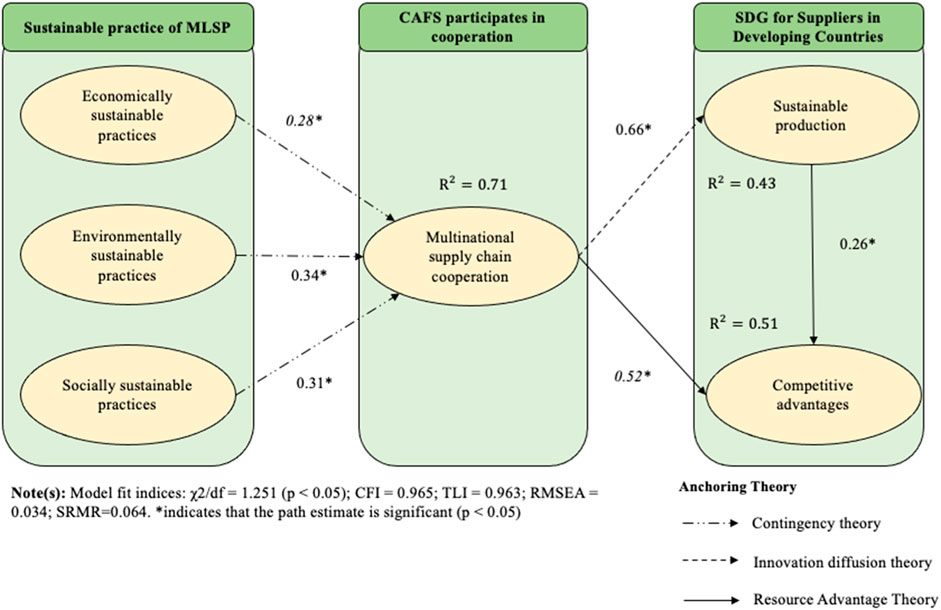

To reiterate, our central argument of this research is twofold: 1) the sustainable practice of MLSPs can positively influence the suppliers’ MSCC from developing countries; 2) suppliers from developing countries can achieve sustainable development goals through MSCC while gaining a competitive advantage. Therefore, we proposed a theoretical model and the hypotheses for this study (Figure 1). We root our research in the contingency theory, innovation diffusion theory (IDT), and resource advantage theory. Contingency theory holds that the external environment of enterprises brings much uncertainty to the supply chain, and supply chain cooperation can reduce this uncertainty (Pagell and Wu, 2009). In addition, the cooperation is not static but is affected by the external environment of the company (Wong and Boon-Itt, 2008). The operating processes of the organization also should be consistent with the external environment (Flynn et al., 2016). This provides a theoretical basis for CAFS to realize SDG through cooperation (H1).

Next, we apply IDT and resource advantage theory to support the hypothesis that CAFSs help achieve sustainable production and competitive advantage processes through MSCC and that improved sustainable production of suppliers can lead to better competitive advantages. Improving sustainable production requires profound changes in the organization, and this is mainly achieved through learning and innovation (Szopik-Depczyńska et al., 2018). Scholars recognized that sustainable practices should be based on an innovation-centric approach (Basu et al., 2015). According to IDT, innovations are dynamic in nature and will spread along certain channels over time (Zhu et al., 2012), which entails suppliers seeking collaborations to funnel the required resources (H2). In fact, since performance improvement is closely related with technological innovation (Magazzino et al., 2021), firms who are seeking superior performance should pursue innovations in their operations. If organizations can achieve innovations successfully, the firm will have superior competitiveness as it has better efficiency and operational capabilities (H3). Further, following resource advantage theory, the competitive advantages of a company come from the heterogeneity of resources within the supply chain (Griffith and Yalcinkaya, 2010). As Grewal and Tansuhaj (2001) indicated, when the resources obtained by the CAFS from the MSCC are deployed to provide unique capabilities, such as sustainable practice capabilities, and a lasting comparative advantage is obtained, superior competitive value is obtained (H4).

2.3 Hypothesis development

According to contingency theory, the sustainable practices of MLSPs have led to a novel sustainable development environment for CAFS. First, in terms of environmentally sustainable practices, cold chain MLSPs use clean energy in transportation, rationally plan routes, and monitor pollution from logistics emissions, which can reduce carbon dioxide emissions and the total carbon footprint (Kengpol et al., 2014). In addition, the reduction of waste in logistics packaging and the use of more effective reuse and recycling design also improves the performance of the cold chain environmental sustainability practice. The socially sustainable transportation activities of MLSPs and the construction of infrastructure have created new jobs and reduced poverty, hunger and local crime rates (Abbasi and Nilsson, 2016). Due to the sustainable practice of MLSP, safer warehousing and transportation activities have improved the working conditions of employees and reduced the health and safety costs of employees. This also reduces turnover and recruitment costs. Most importantly, social sustainable practices have improved employee motivation and productivity while reducing absenteeism (Carter and Easton, 2011). The social practice of MLSPs in organizing charity activities and community-oriented initiatives has also received good social responsibility performance (Multaharju et al., 2017; Muzaffar et al., 2019). In terms of economic sustainable practice, MLSPs implements the ISO 14000 standard and adopts detachable and reusable innovative technologies to reduce costs, shorten lead times, improve cold chain product quality (Carter and Easton, 2011). Then these saved costs can be used for infrastructure construction and innovative technology investment to produce a sustainable circular economy.

Thus, the sustainable practices of the above-mentioned MLSPs not only improve the organizational reputation of the MLSPs but also create a good sustainable practice environment within the supply chain. This is more attractive to CAFS (Carter and Rogers, 2008). This is because according to the contingency theory, the sustainable practice environment created by the MLSP is unknown and uncertain for CAFS which lacks sustainable practice knowledge and technology (Govindan and Gholizadeh, 2021). Previous research has shown that supply chain participants pursuing sustainable development often work in an unpredictable and dynamic environment. In an unpredictable climate, businesses are more likely to collaborate at a deeper/higher level to anticipate and address the client’s wants (Donkor et al., 2021). The study of supply chain cooperation is usually supported by path dependence theory. This theory seems to indicate that cooperation has nothing to do with the external environment of the enterprise and only depends on the experience and knowledge acquired by the company over time. However, cooperation can be severely negatively affected by background and environmental factors (Danese, 2011). Contingency theory indicates that uncertainty in the environment is generally regarded as the basic driving factor for supply chain cooperation (Sari, 2008). CAFS must consider the applicability of supply chain cooperation plans based on the specific background of the cooperation. When cooperation is being implemented, the most appropriate action is selected by analyzing the environment in which the collaboration should be implemented (Danese, 2011). By considering the environmental factors emphasized in contingency theory, CAFS accepts MSCC to reduce uncertainty. Therefore, we propose the following assumptions:

H1a: MLSPs’ sustainable economic practices have a positive impact on MSCC.

H1b: MLSPs’ environmentally sustainable practices have a positive impact on MSCC.

H1c: MLSPs’ socially sustainable practices have a positive impact on MSCC.

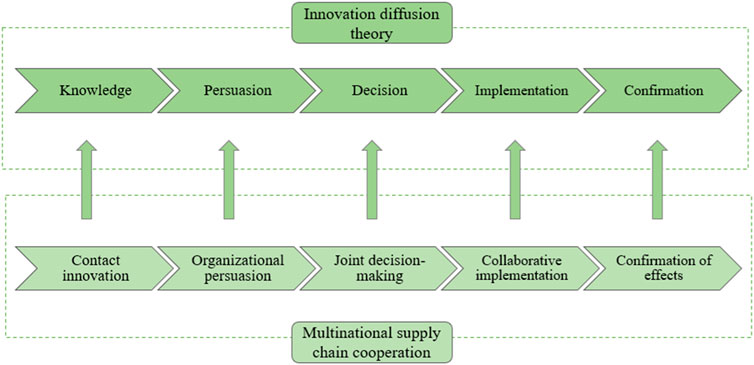

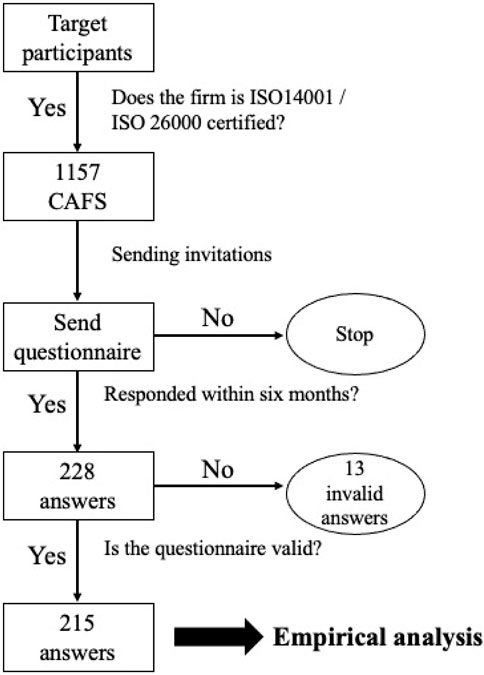

The literature recognizes that enhanced sustainability performance cannot be achieved without innovation (Silvestre, 2015). Given that MLSP improves existing or develops new products, technologies, and processes through sustainable practices, it is critical to a firm’s innovation in dynamic business development as well as its survival and growth (Gosling et al., 2016). Taking into account the skills, needs, and expectations of sustainable organizations in a dynamically changing world, the sustainable MLSP studied in this article is also understood as an innovative organization, and the organization’s sustainable knowledge is also regarded as an innovation (Szopik-Depczyńska et al., 2018). IDT was developed to explain the conditions and processes of an organization or individual accepting an innovation (Yuen et al., 2021). The theory showed that innovation spreads among the members of a social system through specific channels (Zhu et al., 2012), and argued a holistic set of innovation attributes emphasizing the essential attributes of services and products, it proposes that there are five main factors that influence the adoption of an innovation: relative advantage, compatibility, complexity, observability, and testability. These properties directly affect the outcome of the end acceptance (Su et al., 2022a). This theory can be applied in the context of this study, as the sustainable practices of logistics service providers are considered as an innovation that revolutionizes sustainable production in supply chains. Although some studies use innovation attributes in this theory to indicate the possibility of innovation being accepted (Wang et al., 2018), few studies mention the specific process by which organizations accept innovation. Therefore, we do not intend to emphasize the five attributes that influence innovation acceptance in this study but focus on the specific process of accepting innovation. According to this theory, the decision on whether an organization accepts innovation in a particular channel depends on five stages (Figure 2) (Rogers, 1995; Wani and Ali, 2015; Wang et al., 2018).

According to innovation diffusion theory, the process of MLSP spreading sustainable innovation knowledge to a CAFS, involving contact innovation, organizational persuasion, joint decision-making, collaborative implementation, and confirmation of effects. With the continuous increase of business contacts between the MLSP and the CAFS. Opportunities for MLSP to demonstrate sustainable development concepts and technologies to partners are also increasing. This allows the CAFS to be exposed to knowledge of sustainable practices. CAFS showed interest but knew little about it. At this point, the MLSP shares more innovations on sustainable practice through persuasion, and this helps partners consider their own needs as they formulate sustainable practice implementation plans. Then the CAFS decides to adopt this sustainable practice innovation through cooperation. Finally, the CAFS confirms whether the sustainable production result is in line with its own situation. Through the above five stages of cooperation, sustainable knowledge was successfully transferred from the MLSP to the CAFS. We put forward the following hypotheses:

H2: MSCC has a positive impact on the sustainable production of a CAFS.

Innovation diffusion theory shows that by introducing innovative practices at the right time, manufacturers can obtain a competitive advantage (Gilbert and Birnbaum-More, 1996). However, this theory does not explain the formation process of competitive advantages, so we propose to use resource advantage theory to compensate for this. Unlike resource dependence theory, resource advantage theory conceptualizes enterprises as operating in a larger environment (Hunt and Lambe, 2000) and recognizes that many enterprise resources in the same industry are significantly heterogeneous and relatively immobile (Griffith and Yalcinkaya, 2010). Resource advantage theory provides an explanation for understanding a company’s embeddedness in MSCC. The most obvious of these is that differences in customers, competitors, public policy, social resources, and institutions in different countries have led to differences in external environmental factors. This creates a unique background for the effective allocation of SDG-related resources in developing countries. Through MSCC, CAFSs have developed and utilized heterogeneous and incompletely flowing resources of enterprises in developed countries to achieve higher efficiency and gain competitive advantage (Chang et al., 2021; Donkor et al., 2021). This deepens our understanding of developing countries’ suppliers gaining competitive advantage from MSCC. In addition, it is noteworthy that Resource advantage theory is an evolutionary and unbalanced theory of competition. It emphasizes innovation and organizational learning, whether active or passive. Both active and passive innovation can be termed radical or progressive, and they both help to increase the vitality of corporate competition (Hunt and Morgan, 1995). Thus, we put forward the following hypotheses:

H3: MSCC can improve a CAFS’s competitive advantage.

H4: A CAFS can improve its competitive advantage through sustainable production.

3 Methodology

3.1 Research design

The research design is developed to meet the following goals:

Assessing the influence of MLSPs’ sustainable business practices on cross-border supply chain collaboration.

To investigate the mechanism by which MLSPs’ sustainable practices affect sustainable production and the competitiveness of suppliers in developing nations.

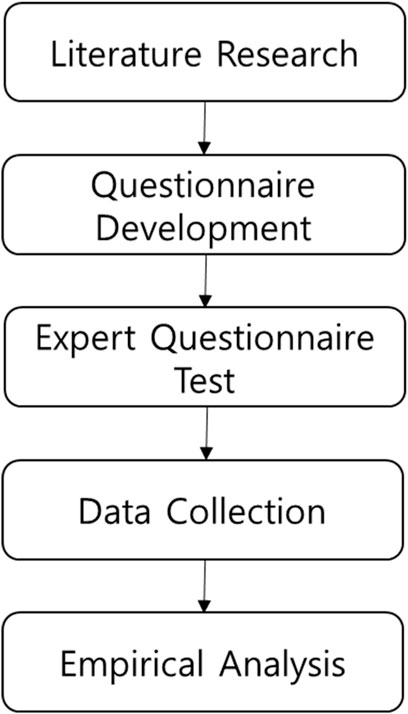

Through a questionnaire survey, this research obtains pertinent data about CAFSs. The majority of the CAFSs included in this research sell agricultural products to South Korea and Japan and work closely with developed country MLSPs such as those in South Korea and Japan. It is worth noting that the developed countries in Northeast Asia are responding to the challenges of sustainable development more actively than anywhere else in the world. These nations have been collaborating to improve the use of environmentally friendly supply chain methods (Hafezalkotob, 2017). Therefore, the annual Sustainable Asia Conference is also held continuously. This provides a perfect background for studying MSCC between developed countries (Japan, Korea) and developing countries (China). After collecting data from CAFS, we used structural equation modeling to carry out analysis to achieve the goal of this research. Figure 3 depicts the methodology flowchart for this investigation.

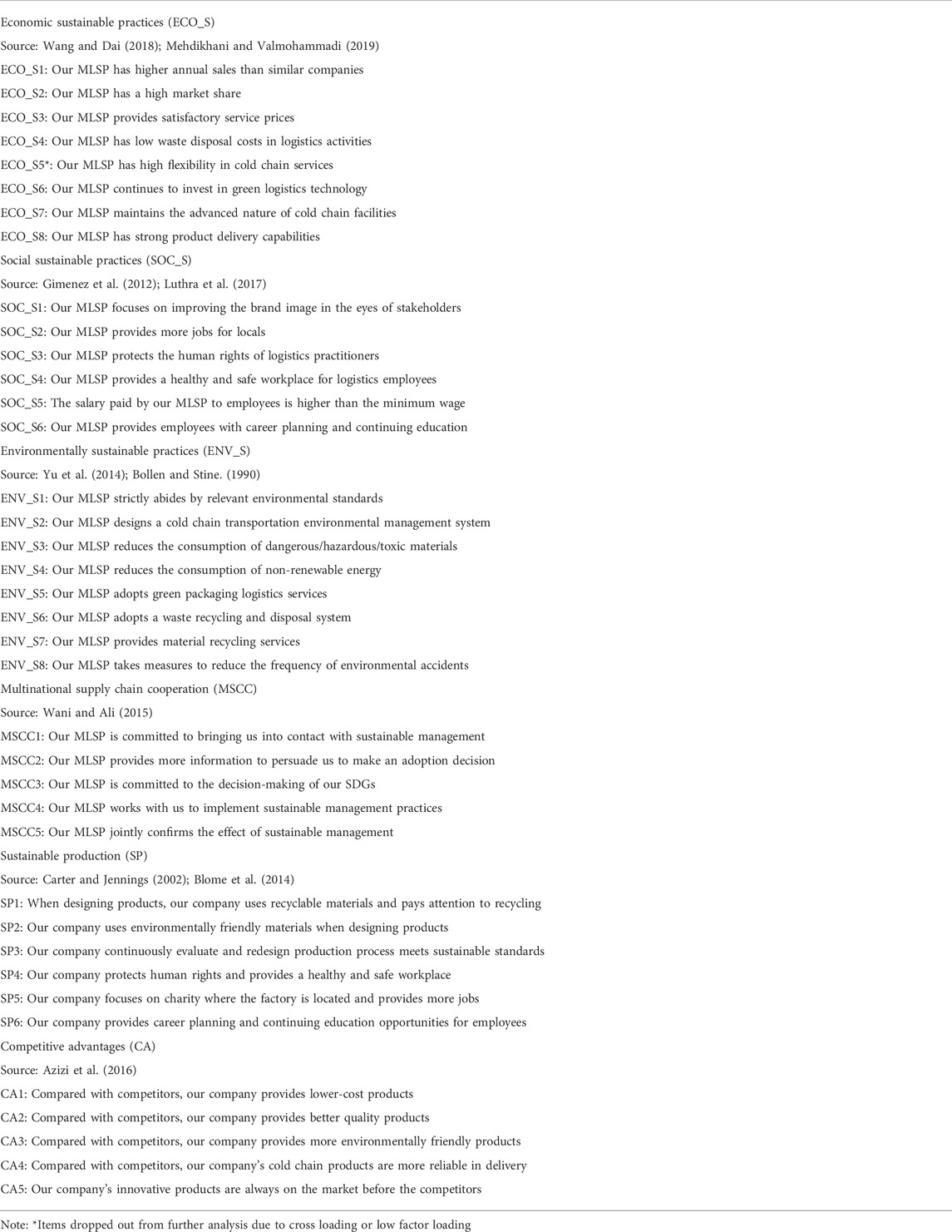

3.2 Determination of indicators

Since this study involves examining the relationship between the underlying structures of related variables, we consider measuring based on existing verified variables (Table 2). To adapt to the research background of this research, these structures have been adapted. To investigate the sustainable practices of MLSPs, this study developed 22 measurement items from the perspective of CAFSs. These 22 measurement items mainly measure the sustainable practices of MLSPs from the three dimensions of the environment, society, and the economy. In addition, the selected projects have been tested and are reliable and effective in the multinational cold chain transportation environment. Because the modified metrics have never been used in the setting of MSCC in underdeveloped countries, we performed pre-tests to confirm their relevance to this research. We asked eight academics and cold chain sector executives to pre-test the questionnaire prior to its formal publication. We asked for feedback on the questionnaire’s length, the scale format, the structure’s validity, and any ambiguity in the questionnaire. After some changes, we obtained 30 first survey responses and conducted sample tests and adjustments.

3.3 Sampling and data collection

The sampling frame for CAFSs is listed on the homepage of the General Administration of Customs of the People’s Republic of China, Shandong Provincial Department of Agriculture and Rural Affairs, China Federation of Logistics & Purchasing, Korea Trade Association, and Japan International Trade Promotion Association. After we determined the sample framework, we identified China’s agricultural food export suppliers. Finally, from these suppliers, 1,157 CAFS for export to South Korea and Japan were identified. For eligibility, suppliers must participate in ISO14001 and ISO 26000 standard certification and incorporate environmental and ethical standards into their cooperative activities (Zineldin and Bredenlöw, 2003).

The questionnaire includes three sections. The first section explains the research background, significance, and goals. The second asks the respondents to evaluate the degree of MLSP sustainable practice implementation. Then, respondents evaluate the actual state of MLSPs in the MSCC process. In addition, they were asked to evaluate their own sustainable production capacity and competitive advantages. To better operationalize the data, for each item, we employed the 7-point Likert scale, anchored at strongly disagree (1) and strongly agree (7) from the perspective of the supplier, as is commonly one (Schreck, 2009). The third part of the questionnaire collected basic information on the respondents and the company.

Data collection took place from 1 June 2020, to 15 January 2021 (Figure 4). First, together with a specialized questionnaire survey agency in China, an invitation was sent to the CAFS sample group via email, asking them to participate. The recipient of the email was also asked to forward it to 3–5 colleagues who are responsible for company logistics, strategy, or corporate social responsibility in similar roles. Determine the only and most accurate response through joint discussions within the enterprise. It should be noted that some enterprises are self-employed due to their small scale. Some general staffs are both managers and basic employees, and these employees also have a good understanding of the company’s business. We also paid attention to giving certain cash rewards to the respondents and sharing research results and shared information on the buyers of agricultural products from South Korea and Japan. Compensation was supplied to assure the survey data’s authenticity and the constancy of the time needed of participants to complete the survey (Goodman et al., 2013). Due to the low response rate, our team sent a bi-weekly reminder to multiple email addresses of companies that have not responded.

4 Results

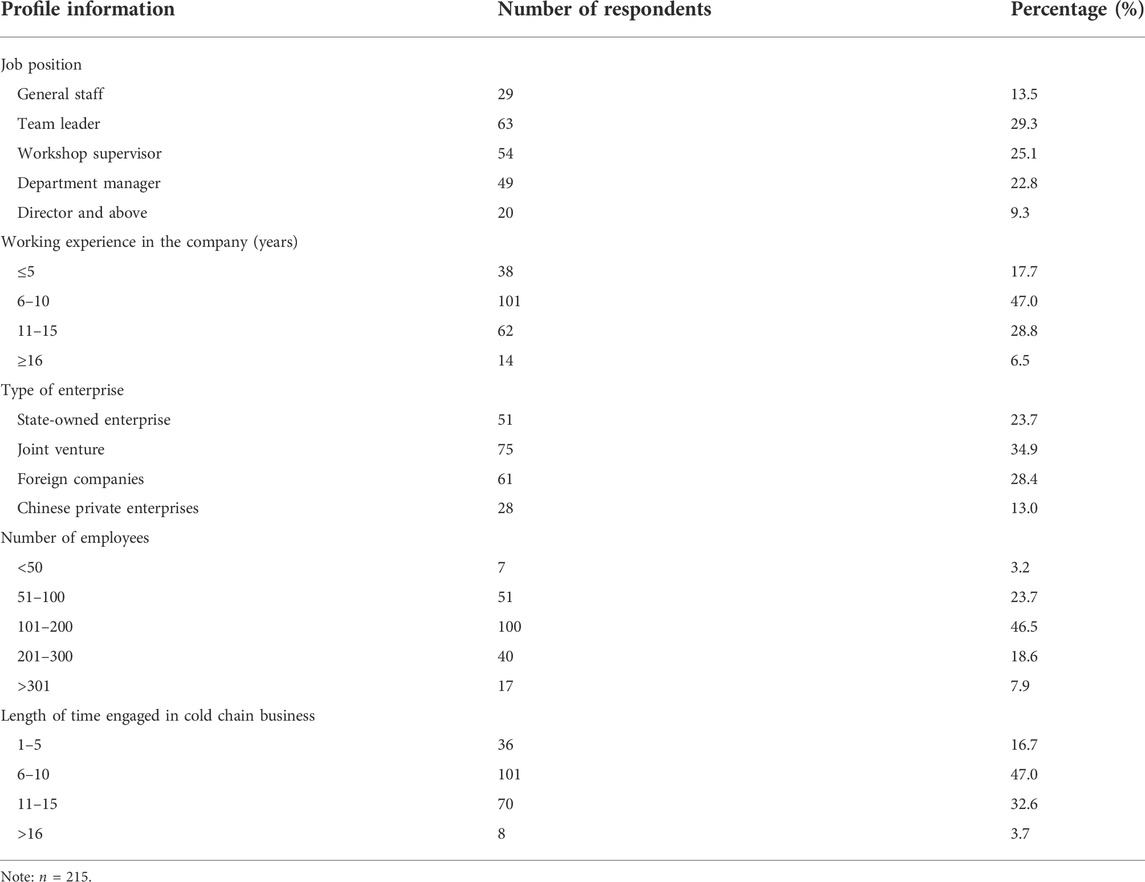

4.1 Sample statistics

As of 15 January 2021, our team had received 228 responses from CAFS. After removing 13 invalid questionnaires, 215 valid responses were finally obtained. According to statistics, the filling time of each questionnaire is about 6 min, which is basically the same as the filling time of the previous expert test, which indirectly supports the data quality (Wang et al., 2019). The respondent demographics are given in Table 3. Around 82% of the respondents had more than 5 years of professional experience, and 67% of them held managerial positions. The results suggest that respondents were appropriately competent to reply to survey questions on their companies’ behalf.

To test the non-respondent bias in the sample, we divided the received responses into early and late respondents using September 1 as the cut-off point and performed a t-test on the mean difference of each item. The insignificant results indicate that nonresponse bias is unlikely to be a problem in this study. In addition, several procedures were conducted to minimize the occurrence of common method bias (CMB) that may arise of the self-report questionnaire used in data collecting. First, reminders stating that there are no correct or incorrect answers to the questions were inserted in multiple places throughout the questionnaire to remind the participants to be as honest as possible in all of their answers. Second, to avoid the respondents’ biased “straight line” responses, the order of our measurement items was randomized, and the scaling of several explanatory variables was reversed. Third, we checked the possibility of CMB by employing Harman’s singe factor test (Podsakoff et al., 2003). The results suggested six factors with eigenvalues greater than one and the total variance of the first factor was 40.96%, which confirmed the absence of CMB in our study.

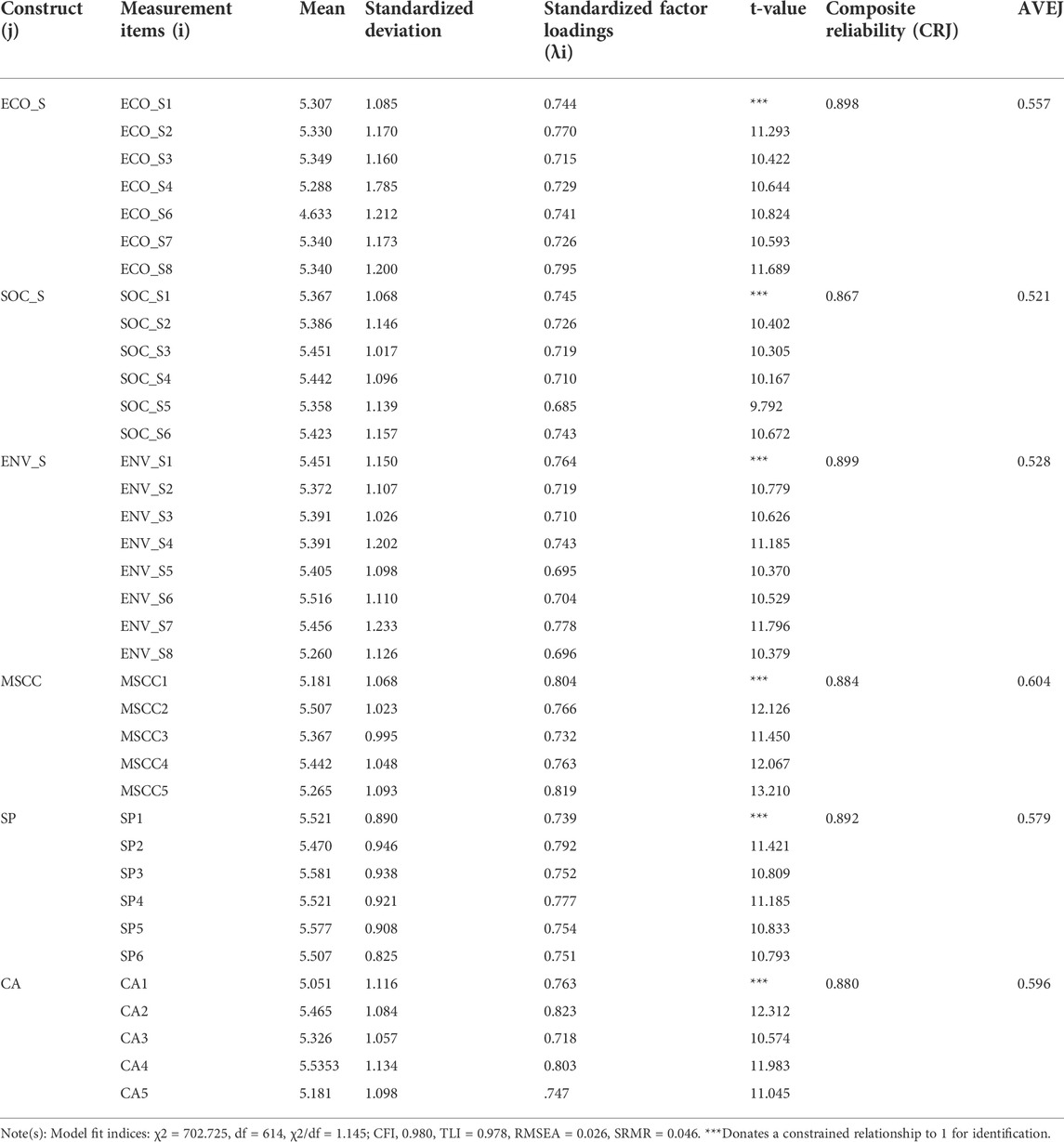

4.2 Reliability and measurement validity

Confirmatory factor analysis (CFA) was conducted to determine the fit of the measurement model. Due to low factor load, we deleted one item (ECO_S5). Another CFA test was performed using modified measurement items. The findings indicated that each project was weighted on its own structure, as predicted, and that the combined load of all variables exceeded 0.5 (Hair et al., 2010). Cronbach’s Alpha was also determined for each structure, and all measures demonstrated good dependability, with all values larger than 0.70. As seen by the CFA findings (Table 3), the fitting indicators indicate that the measurement model well fits the data. (χ2 = 702.725, df = 614, χ2/df = 1.145; CFI = 0.980, TLI = 0.978, RMSEA = 0.026, SRMR = 0.046). Table 4 also shows that the composite reliability (CR) of the four structures is higher than 0.7, indicating that the measurement is reliable (Hair et al., 2010).

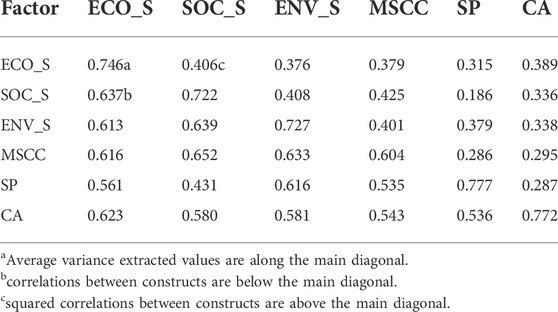

Additionally, we evaluated the convergence validity by analyzing the standardized factor loading and the average variance extracted (AVE) (Hair et al., 2010). The findings indicated that all standardized factor loadings and AVE values are greater than 0.5, suggesting good convergence of the construct. Discriminant validity was evaluated by comparing the AVE value and the squared correlation (Hair et al., 2010). The results (Table 5) showed that all AVE values were higher than the squared correlation value. Therefore, discriminative validity was also supported. The variance inflation factors (VIFs) on the items have also been examined, and the results show that the VIF for all indicators is far below 10 (ranging from 1.374 to 2.86), suggesting the absence of multicollinearity issues.

4.3 Model estimation

Structural equation modeling was employed to empirically test the proposed theoretical model, and the results are graphically described in Figure 5. Generally, our model’s goodness of fit is supported (χ2/df = 1.25, p < 0.05; CFI = 0.97; TLI = 0.96; RMSEA = 0.034; SRMR = 0.064), and is reinforced by the variance explanation for endogenous variables (ranging from 43 to 71%).

The economic, social, and environmental sustainability practices of MLPS had a significant positive impact on MSCC (β = 0.28, 0.34, 0.31, p < 0.05). Therefore, conclude that H1a, H1b, and H1c are all accepted. The sustainable supply chain environment created by the sustainable management of MLSP increased the MSCC value and explains about 70% of the difference. This finding is consistent with contingency theory, which emphasizes the importance of different forms of cooperation in different environmental contexts (Danese, 2011). Suppliers should develop a form of cooperation that is consistent with the sustainable environment to enhance cooperation effectiveness of cooperation. In addition, supplier operations should also take actions consistent with the external environment (Flynn et al., 2016). At the same time, MSCC had a significant positive impact on the sustainable production of CAFS (β = 0.66, p < 0.05). Therefore, it is assumed that H2 also holds.

In addition, the MSCC and the sustainable production capacity of suppliers both have a significant positive impact on the competitive advantage of CAFS (β = 0.52, p < 0.05; β = 0.26, p < 0.05). As a result, both H3 and H4 are believed to be validated. These results agree with the resource advantage theory. Namely, both passive and active innovation may help firms improve their competitiveness. CAFS obtain higher effectiveness and efficiency through the cooperative development and utilization of MLSP heterogeneous and incompletely flowing sustainable development resources and achieve sustainable goals to improve their competitive advantage.

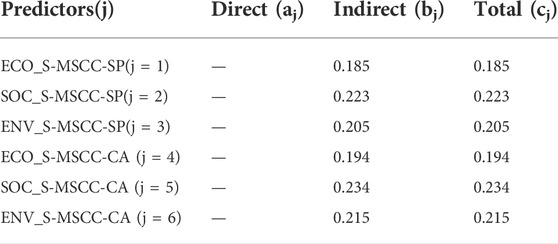

4.4 Analysis of direct, indirect and total effects

The bootstrapping method proposed by Bollen and Stine (1990) was used to explore the correlation between other overlooked structures. The immediate consequences of MLPS’ sustainable practices on partner sustainable production and competitive advantage are summarized in Table 6. After correcting the two-tailed significance test, the sustainable practice of MLSP was found to have significant direct effects on MSCC (p < 0.05). In addition, the sustainable practice of MLSP had a statistically significant indirect impact on the sustainable production and competitive advantage of CAFS (p < 0.05). This shows that MSCC played a full mediation role in the process of achieving sustainable goals in CAFS. At the same time, the results also show the indispensable role of MSCC in achieving competitive advantage of CAFS.

4.5 Robustness checks

4.5.1 Model comparison

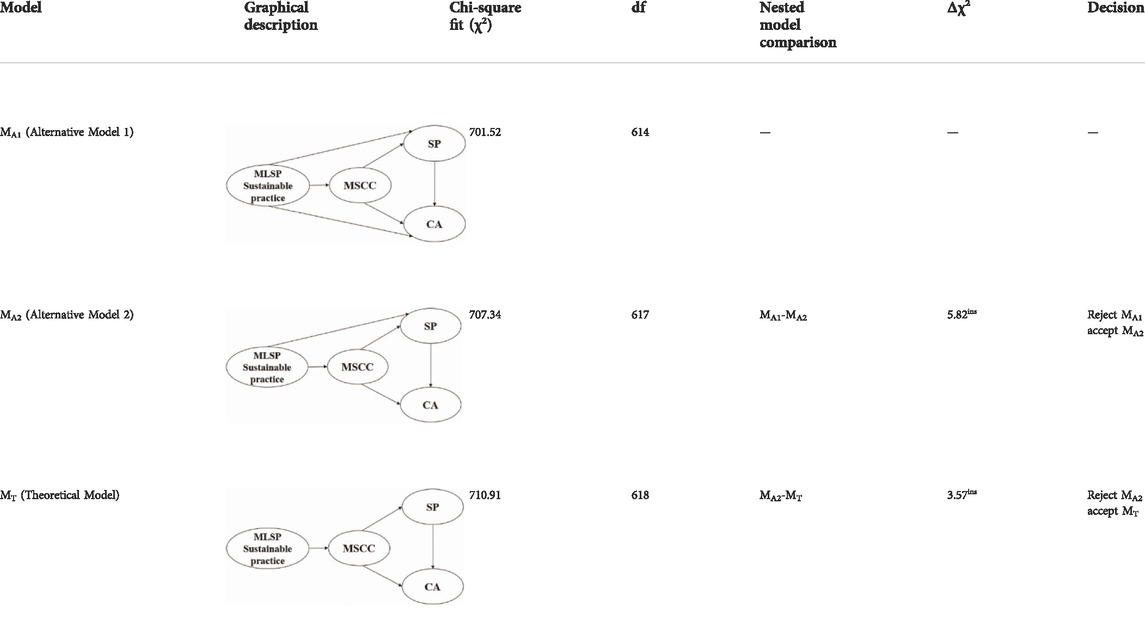

To assess the robustness of the theoretical relationships in our model, we created two alternative models for comparison, following the guidelines of the existing literature (Table 7). The chi-variance test can be used to test the superiority of the model (Kline, 2015). A chi-variance test compares pairs of nested models sequentially, starting with the model with the fewest degrees of freedom and progressing to the one with the most. When the comparative result is insignificant, the model that is more frugal is accepted, while the one that is less frugal is rejected. As can be seen in Table 5, due to the fact that the two alternative models (MA1 and MA2) have very few degrees of freedom, they are compared first. Their chi-variance test (Δχ2 = 5.82, Δdf = 3) is insignificant (p > 0.05), showing that the loss of model fit due to the deletion of the linkage between MLSP’s sustainable practices and CAFS’s competitive advantage is marginal. Following that, we compared MA2 to MT. A chi-square test (Δχ2 = 3.57, Δdf = 1) revealed that the relationship between sustainable MLSP practices and sustainable CAFS production is not significant (p > 0.05), suggesting that the loss of model fit as a result of deleting the connection between sustainable MLSP practices and sustainable CAFS production is not a concern. Collectively, the findings demonstrate that model MT is the optimal one among the three models.

4.5.2 Endogenous test

In addition, MSCC is found to positively affect sustainable production, however, there may be endogenous problems with this result. For example, reverse causality may exist between MSCC and sustainable production. To address this issue, a two-stage least squares regression (2SLS) using instrumental variable approach was performed (Greene, 2009). In addition, to ensure the validity of the selection of instrumental variables and the estimation results, a weak identification test is carried out for instrumental variables (Zhu et al., 2021). To perform 2SLS regression, the instrumental variables of MSCC must be determined. In this study, the number of employees and the length of the company’s cold chain business were identified as instrumental variables. Because it is reported that they have a significant correlation with supply chain cooperation, and the significant correlation with the sustainable production practices of CAFS has not been verified (Minguela-Rata et al., 2014). Subsequently, in the first stage of the 2SLS model, MSCC was regressed on the number of employees and the length of time engaged in cold chain business, and the regression coefficient are 0.45 and 0.54, respectively (p < 0.01). For the second stage of 2SLS regression, sustainable production is regressed based on the adjusted MSCC. The results show that the coefficient is significantly positive (β = 0.45, p < 0.01). In addition, the Cragg-Donald Wald F statistic is 652.25, which significantly exceeds the critical value of the Stock-Yogo weak ID test. This shows that our instrumental variables do not have weak instrumental variables (Zhu et al., 2021). After 2SLS regression, this study performed Durbin-Wu-Hausman post-estimation test for endogeneity. The result showed that the null hypothesis was rejected (χ2 = 0.63, p > 0.05). In summary, the results and conclusions of this study are unlikely to be affected by endogeneity (Yuen et al., 2017).

4.5.3 Non-linearity test

Non-linearity test Nonlinear effects are a relationship that cannot be proved by structural equation models. Therefore, in order to assess the stability of the theoretical model of this study, we also ran a normal P-P plot and residual scatter plot analysis on the study data. The normal distribution of the residuals supports that the data samples in this investigation are linearly associated. Following (Yuen et al., 2019), this study also constructed an alternative model with the quadratic value of MLSP sustainable practice as a control variable in hierarchical regression models to investigate the possible nonlinear relationship between MLSP sustainable practice and MSCC. The results show that the squared terms of the economic, social, and environmental sustainability practices of MLPS are not statistically significant, and our findings still hold with their inclusion into the model. Thus, the linear effects of MLSP sustainable practice on MSCC were validated, and it can be concluded that the original setting of the model is robust.

5 Discussion

The outcomes of the data analysis confirm the paper’s central argument, to begin, this study establishes that the sustainable climate of unpredictability and innovative fostered by sustainable logistics service providers is a critical factor motivating developing country suppliers to participate in supply chain collaboration Specifically, this study examines the internal mechanism of sustainable logistics service providers and supply chain cooperation in order to fulfill the goal of sustainable production and supplier competitive advantage in developing nations. Little study has been conducted on the relationship between logistics service providers’ sustainable practices and supply chain collaboration (Danese, 2011), this study is consistent with earlier research on supply chain partnership management in the face of dramatic environmental changes. In an uncertain sustainable climate, businesses in developing countries may leverage their supply chain partners to implement more sustainable technologies or processes (Mitręga and Choi, 2021). As a result, this work contributes to the development of a framework for supply chain collaboration in unpredictable sustainable contexts.

Additionally, there are two primary mechanisms for managing collaboration partnership relationships: formal tools (governance models and formal contracts) and informal mechanisms (relationship norms and trust) (Mitręga and Choi, 2021). However, few studies have studied the supply chain staged cooperation mechanism based on the innovation diffusion theory (contact, persuasion, planning, adoption, and confirmation). Different from past research (Su et al., 2022b), this study’s theoretical model represents different objects in the process of sustainable practical knowledge transfer and acquisition and the results of complex cooperation that work together at different times. By applying the innovation diffusion process to the context of supply chain collaboration, we may further enrich the research of innovation diffusion theory in the field of sustainable supply chain management. Taken together, this study complements prior research on supply chain collaboration in the context of sustainable environmental asymmetry by establishing a supply chain partnership led by a logistics service provider to improve the supply chain’s sustainability.

Second, through supply chain collaboration, sustainable logistics service providers help developing country partners reach sustainable production and competitive advantage targets. This study is consistent with earlier findings on management research, indicating adopting a partnership strategy with supply chain partners can improve supplier sustainability and boost suppliers’ competitive advantage (Niu and Mu, 2020; Liu Z. et al., 2021; Davis-Sramek et al., 2022; Guo et al., 2022). In reality, this study provides a deeper jurisprudential understanding of the interaction between supply chain parties. The findings support and imply that the sustainable practices of logistics service providers are favorable to the growth of sustainable production of partners and the increase of competitive advantage. In today’s business environment, suppliers cannot achieve a competitive advantage on their own (Ali et al., 2018). Our findings corroborate Niu and Mu’s (2020) findings that responsible logistics service providers participating in supply networks via sustainable practices have the potential to influence the sustainability and market potential of supply chain members. Simultaneously, this study complements the research of Guo et al. (2022) by providing empirical evidence on the relationship between sustainable supply chain environment, supply chain collaboration, and competitive advantage. Consistent with prior research findings, collaboration within the context of sustainable supply chains can help firms increase their competitive advantage and reduce environmental uncertainty.

Finally, this study advances the integration research of sustainable supply chain management theory by incorporating the contingency theory, innovation diffusion theory, and resource advantage theory into the theoretical model. These three theories, which are based on three theoretical lenses: Organizational management, social interaction, and trade economics, provides a theoretical framework for developing nation suppliers to meet their production sustainability and competitive advantage objectives. According to the research model, the theory proposed in this study can account for approximately 43% of the difference in the sustainable production of suppliers in developing nations and approximately 51% of the difference in competitive advantage. In contrast to prior studies assessing the sustainable performance of logistics service providers, we emphasize the driving role of sustainable logistics service providers in global supply chains. Indeed, our research builds on and expands on Donkor et al.’s (2021) perspective by highlighting the uncertain external sustainable environment in contingency theory in order to evaluate how logistics service providers may support sustainable production and competitive advantage for developing-country suppliers in multinational supply chains.

6 Conclusion

6.1 Summary

The purpose of this study is to assess and define the role of sustainable logistics service providers in supply chain collaboration, as well as the relationship between logistics service providers’ sustainable practices and the sustainable production and competitive advantage of suppliers in developing countries. This paper introduces and unifies three theoretical frameworks in order to accomplish this goal: contingency theory, innovation diffusion theory, and resource advantage theory. Based on theoretical integration and literature research, this study proposes the positive impact of sustainable practices of multinational logistics service providers in economic, social and environmental aspects on sustainable production and competitive advantage of developing country partners. This study used structural equation modeling to examine survey data from 215 agri-food providers in China. The data corroborate the hypothesis above, demonstrating a direct effect of logistics service providers’ sustainable practices on multinational supply chain collaboration. Additionally, the findings demonstrate that multinational supply chain collaboration completely mediates the positive effects of logistics service providers on sustainable production and supplier competitiveness in developing nations. This paper examines the theoretical framework at the forefront of multinational supply chain sustainability development. This presents the most recent experience and policy application for suppliers from emerging nations to acquire a competitive advantage.

6.2 Managerial implications

This study offers valuable Managerial implications. MLSPs should be aware that sustainable value growth of upstream suppliers has a significant beneficial effect on the value growth of downstream supply chains (Singh and Shabani, 2017). We highly advise MLSP managers to build a five-stage collaboration mechanism based on the findings of this research and diffusion theory of innovation. First of all, in the first stage (contact) of cooperation, MLSPs should optimize their own logistics and transportation techniques such as using renewable energy, improving the cold chain logistics and transportation networks, and reducing the pollution produced by cold chain logistics operations. Meanwhile, they should also recognize the importance of staff health and welfare, and continue to deepen the reform of socially sustainable practices in the cold chain business. To improve supplier exposure to sustainable development methods, MLSPs could communicate current knowledge and technology about sustainable logistics with suppliers through sustainability reports, web pages, stakeholder meetings, written bids, or bid presentations (Yuen et al., 2018) Additionally, MLSPs may provide sustainable technical support to suppliers, encourage suppliers to attend sustainable production seminars, and involve suppliers early in the sustainable product development process. In the second stage (persuasion) of cooperation, MLSPs should integrate sustainable practices into production, distribution, and transportation activities throughout the supply chain. Persuading developing country suppliers to respond to the growing demands for environmental, social and economic sustainability, ensuring that More members in the supply chain are involved in collaboration (Guo et al., 2022). This will not only result in a greater degree of collaboration, but also in increased supply chain advantages.

During stage 3 (Decision) and stage 4 (Implementation) of the collaboration, we recommend that MLSPs strengthen their communication with suppliers to identify their specific needs. Because high levels of openness and appropriate information exchange not only promote sustainable improvements in goods and services, but also expedite transactions and delivery (Li X. et al., 2021; Donkor et al., 2021). MLSPs can also provide the necessary sustainable support in the form of training suppliers to engage in sustainable activities. This type of training can take the form of sustainable design and implementation of new effective sustainable practices/methods, with the goal of maximizing the construction of a supplier-appropriate sustainability program (Donkor et al., 2021). Finally, in the collaboration’s fifth step (validation), the MLSP must verify the collaboration’s outcome. Implementing sustainable practices is not sufficient; we encourage MLSPs to also evaluate the sustainability performance of developing country suppliers, assist suppliers in obtaining sustainability-related certifications, and enhance the supply chain’s overall competitive advantage. Most importantly, MLSPs should always establish their role as a bridge between buyers in developed countries and suppliers in developing countries. Pay attention to the establishment of its own image and reputation in the supply chain and share the responsibility and obligation with suppliers to achieve the overall sustainable development goals of the supply chain.

Developing country suppliers uses the sustainable expertise of its partners to counter the pressure of stakeholders, not only helping companies achieve sustainable production goals, but also bringing them a competitive advantage (Shashi et al., 2018). This requires developing country suppliers to realize the importance of cooperation in sustainable supply chain management (Pagell and Wu, 2009; Sandra Marcelline et al., 2022). In addition, in view of the 5-stage issues of Supply Chain Cooperation discussed in this study, developing country suppliers should focus on seamlessly creating a collaborative process across the entire supply network (Sahin and Robinson, 2005). Developing country suppliers should regularly measure and evaluate the sustainable practices of MLSP partners to access the most advanced sustainable knowledge and technologies (Shashi et al., 2018). In established partnerships, developing country suppliers need to clearly communicate environmental and social sustainability requirements with multinational logistics service providers, and agree on appropriate sustainability practices (Multaharju et al., 2017). Developing country suppliers must also prepare for the ever-changing business environment. Cooperate with MLSPs to develop new sustainable logistics solutions and processes and allocate resources for sustainable development planning and capacity building cooperation (Multaharju et al., 2017; Sreekumar and Rajmohan, 2019). Developing country suppliers also need to share relevant results of sustainable practices in real time, and measure and control the sustainable practice process together with multinational logistics service providers.

6.3 Policy implications

The research offers crucial policy implications. In transnational supply chains, government agencies play a key role. First, the government implements support and preferential programs to encourage the growth of sustainable global logistics service providers. In order to secure the economic, social, and environmental sustainability of logistics service providers, government agencies should also enhance sustainable logistics policies (Fan et al., 2022). Second, governments should understand that supply chain collaboration has a direct impact on sustainable production practices and provides a competitive advantage to developing nation suppliers. The government should implement more favorable policies and pick international logistics service providers with a stronger commitment to sustainability for settlement in local export parks. Second, government agencies should construct bridges to promote information transparency throughout the supply chain and enhance cooperation between export suppliers from developing nations and international logistics service providers (Weber et al., 2021). The government should also assist suppliers in identifying the requirements they must achieve in order to be approved as potential long-term partners by international logistics service providers, and promote knowledge sharing across the supply chain in order to address sustainability concerns.

6.4 Limitations and recommendations

Although this research has made some contributions, it also has certain limitations. First of all, this research is aimed at the specific background of the multinational agri-food cold chain in China. Therefore, the results may only apply to this region. Future research may consider cross-validating the results in other types of supply chains and other regions to expand the universality of the results. In addition, we will perform follow-up surveys in underdeveloped nations, to use panel data to corroborate our findings, and to address study methodology restrictions. Moreover, this study only examines the supply chain cooperation among members of society from the perspective of how CAFS diffuses innovation through specific channels. Future research can investigate the impact of MSCC on the realization of SDGs in developing countries by focusing on other perspectives that are not currently considered in this research. These perspectives may include fairness theory, transaction cost theory, and resource gift theory. Finally, this article only examines the influence of cooperation within the supply chain on suppliers in developing countries from the perspective of a multinational supply chain and lacks the influence of the power of the public sector (government, non-profit organization) on cooperation. In the future, we can try to research the cooperation between suppliers and the public sector. Finally, carbon emission schemes are crucial in a circular economy (Hêriş Golpira and Javanmardan, 2022). Future studies should prioritize efforts such as creating optimal carbon emissions systems in sustainable closed-loop supply chains. We must be aware that the logistics Internet of things (IoT) delivers efficient logistics service solutions and is the primary driver of sustainable supply chain operations (Golpîra et al., 2021). In this regard, it is recommended to concentrate on mathematical modeling and design techniques for IoT-based systems to develop a low-carbon logistics system based on IoT.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Ethics statement

Ethics review and approval/written informed consent was not required as per local legislation and institutional requirements.

Author contributions

MS: Conceptualization, Methodology, Writing—original draft, Writing review and editing. MF: Software, Formal analysis, Writing review and editing. QP: Investigation, Resources, Data curation. K-sP: Funding acquisition, Project administration, Investigation.

Funding

This research was funded by 4th Maritime Port Logistics Training Project of the Ministry of Oceans and Fisheries, Korea.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abbasi, M., and Nilsson, F. (2016). Developing environmentally sustainable logistics: Exploring themes and challenges from a logistics service providers’ perspective. Transp. Res. Part D Transp. Environ. 46, 273–283. doi:10.1016/j.trd.2016.04.004

Ali, I., Nagalingam, S., and Gurd, B. (2018). A resilience model for cold chain logistics of perishable products. Int. J. Logist. Manag. 29, 922–941. doi:10.1108/ijlm-06-2017-0147

Azizi, R., Maleki, M., Moradi-Moghadam, M., and Cruz-Machado, V. (2016). The impact of knowledge management practices on supply chain quality management and competitive advantages. Manag. Prod. Eng. Rev. 7, 4–12. doi:10.1515/mper-2016-0001

Basu, R. J., Bai, R., and Palaniappan, P. K. (2015). A strategic approach to improve sustainability in transportation service procurement. Transp. Res. Part E Logist. Transp. Rev. 74, 152–168. doi:10.1016/j.tre.2014.10.015

Blome, C., Hollos, D., and Paulraj, A. (2014). Green procurement and green supplier development: Antecedents and effects on supplier performance. Int. J. Prod. Res. 52 (1), 32–49. doi:10.1080/00207543.2013.825748

Bollen, K. A., and Stine, R. (1990). Direct and indirect effects: Classical and bootstrap estimates of variability. Sociol. Methodol. 20, 115–140. doi:10.2307/271084

Carter, C. R., and Easton, P. L. (2011). Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distribution Logist. Manag 41 (1), 46–62. doi:10.1108/09600031111101420

Carter, C. R., and Jennings, M. M. (2002). Logistics social responsibility: An integrative framework. J. Bus. Logist. 23 (1), 145–180. doi:10.1002/j.2158-1592.2002.tb00020.x

Carter, C. R., and Rogers, D. S. (2008). A framework of sustainable supply chain management: Moving toward new theory. Int. Jnl. Phys. Dist. Log. Manage. 38, 360–387. doi:10.1108/09600030810882816

Cassani, L., and Gomez-Zavaglia, A. (2022). Sustainable food systems in fruits and vegetables food supply chains. Front. Nutr. 9, 829061. doi:10.3389/fnut.2022.829061

Centobelli, P., Cerchione, R., and Esposito, E. (2017). Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Transp. Res. Part D Transp. Environ. 53, 454–470. doi:10.1016/j.trd.2017.04.032

Centobelli, P., Cerchione, R., and Esposito, E. (2020). Pursuing supply chain sustainable development goals through the adoption of green practices and enabling technologies: A cross-country analysis of LSPs. Technol. Forecast. Soc. Change 153, 119920. doi:10.1016/j.techfore.2020.119920

Centobelli, P., Cerchione, R., Oropallo, E., Ei-Garaihy, W. H., Farag, T., and Shehri, K. H. A. (2021). Towards a sustainable development assessment framework to bridge supply chain practices and technologies. Sustain. Dev. 30, 647–663. doi:10.1002/sd.2262

Chang, C. H., Lu, C. S., and Lai, P. L. (2021). Examining the drivers of competitive advantage of the international logistics industry. Int. J. Logist. Res. Appl. 1, 19. doi:10.1080/13675567.2021.1915263

Croom, S., Vidal, N., Spetic, W., Marshall, D., and McCarthy, L. (2018). Impact of social sustainability orientation and supply chain practices on operational performance. Int. J. Operations Prod. Manag. 38, 2344–2366. doi:10.1108/ijopm-03-2017-0180

Dam, L., and Petkova, B. N. (2014). The impact of environmental supply chain sustainability programs on shareholder wealth. Int. Jrnl. Op. Prod. Mnagemnt. 34, 586–609. doi:10.1108/ijopm-10-2012-0482

Danese, P. (2011). Towards a contingency theory of collaborative planning initiatives in supply networks. Int. J. Prod. Res. 49 (4), 1081–1103. doi:10.1080/00207540903555510

Davis-Sramek, B., Hopkins, C. D., Richey, R. G., and Morgan, T. R. (2022). Leveraging supplier relationships for sustainable supply chain management: Insights from social exchange theory. Int. J. Logist. Res. Appl. 25 (1), 101–118. doi:10.1080/13675567.2020.1797654

Donkor, F., Papadopoulos, T., and Spiegler, V. (2021). The supply chain integration–supply chain sustainability relationship in the UK and Ghana pharmaceutical industry: A stakeholder and contingency perspective. Transp. Res. Part E Logist. Transp. Rev. 155, 102477. doi:10.1016/j.tre.2021.102477

Evangelista, P. (2014). Environmental sustainability practices in the transport and logistics service industry: An exploratory case study investigation. Res. Transp. Bus. Manag. 12, 63–72. doi:10.1016/j.rtbm.2014.10.002

Fan, M., Wu, Z., Qalati, S. A., He, D., and Hussain, R. Y. (2022). Impact of green logistics performance on China’s export trade to regional comprehensive economic partnership countries. Front. Environ. Sci. 10, 879590. doi:10.3389/fenvs.2022.879590

Flynn, B. B., Koufteros, X., and Lu, G. (2016). On theory in supply chain uncertainty and its implications for supply chain integration. J. Supply Chain Manag. 52 (3), 3–27. doi:10.1111/jscm.12106

Froio, P. J., and Bezerra, B. S. (2021). Environmental sustainability initiatives adopted by logistics service providers in a developing country–an overview in the Brazilian context. J. Clean. Prod. 304, 126989. doi:10.1016/j.jclepro.2021.126989

Ghadge, A., Er Kara, M., Mogale, D. G., Choudhary, S., and Dani, S. (2021). Sustainability implementation challenges in food supply chains: A case of UK artisan cheese producers. Prod. Plan. Control 32 (14), 1191–1206. doi:10.1080/09537287.2020.1796140

Gilbert, J. T., and Birnbaum-More, P. H. (1996). Innovation timing advantages: From economic theory to strategic application. J. Eng. Technol. Manag. 12 (4), 245–266. doi:10.1016/0923-4748(95)00017-8

Gimenez, C., Sierra, V., and Rodon, J. (2012). Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 140 (1), 149–159. doi:10.1016/j.ijpe.2012.01.035

Golpîra, H., and Javanmardan, A. (2022). Robust optimization of sustainable closed-loop supply chain considering carbon emission schemes. Sustain. Prod. Consum. 30, 640–656. doi:10.1016/j.spc.2021.12.028

Golpîra, H., Khan, S. A. R., and Safaeipour, S. (2021). A review of logistics internet-of-things: Current trends and scope for future research. J. Industrial Inf. Integration 22, 100194. doi:10.1016/j.jii.2020.100194

Goodman, J. K., Cryder, C. E., and Cheema, A. (2013). Data collection in a flat world: The strengths and weaknesses of Mechanical Turk samples. J. Behav. Decis. Mak. 26 (3), 213–224. doi:10.1002/bdm.1753

Gosling, J., Jia, F., Gong, Y., and Brown, S. (2016). The role of supply chain leadership in the learning of sustainable practice: Toward an integrated framework. J. Clean. Prod. 137, 1458–1469. doi:10.1016/j.jclepro.2014.10.029

Govindan, K., and Gholizadeh, H. (2021). Robust network design for sustainable-resilient reverse logistics network using big data: A case study of end-of-life vehicles. Transp. Res. Part E Logist. Transp. Rev. 149, 102279. doi:10.1016/j.tre.2021.102279

Greene, W. H. (2003). Models for discrete choice. Econometric Analysis. 5th ed.. Hoboken, NJ: Prentice Hall, 473–556.

Grewal, R., and Tansuhaj, P. (2001). Building organizational capabilities for managing economic crisis: The role of market orientation and strategic flexibility. J. Mark. 65 (2), 67–80. doi:10.1509/jmkg.65.2.67.18259

Griffith, D. A., and Yalcinkaya, G. (2010). Resource-advantage theory: A foundation for new insights into global advertising research. Int. J. Advert. 29 (1), 15–36. doi:10.2501/s0265048709201014

Guo, Y., Yu, J., Allaoui, H., and Choudhary, A. (2022). Lateral collaboration with cost-sharing in sustainable supply chain optimisation: A combinatorial framework. Transp. Res. Part E Logist. Transp. Rev. 157, 102593. doi:10.1016/j.tre.2021.102593

Hafezalkotob, A. (2017). Competition, cooperation, and coopetition of green supply chains under regulations on energy saving levels. Transp. Res. Part E Logist. Transp. Rev. 97, 228–250. doi:10.1016/j.tre.2016.11.004

Hair, J., Anderson, R., Babin, B., and Black, W. (2010). Multivariate data analysis: A global perspective. Upper Saddle River. NJ: Pearson.

Huge-Brodin, M., Sweeney, E., and Evangelista, P. (2020). Environmental alignment between logistics service providers and shippers–a supply chain perspective. Int. J. Logist. Manag. 31, 575–605. doi:10.1108/ijlm-04-2019-0101

Hunt, S. D., and Lambe, C. J. (2000). Marketing’s contribution to business strategy: Market orientation, relationship marketing and resource‐advantage theory. Int. J. Manag. Rev. 2 (1), 17–43. doi:10.1111/1468-2370.00029

Hunt, S. D., and Morgan, R. M. (1995). The comparative advantage theory of competition. J. Mark. 59 (2), 1–15. doi:10.2307/1252069

Jabbour, C. J. C., Jugend, D., de Sousa Jabbour, A. B. L., Gunasekaran, A., and Latan, H. (2015). Green product development and performance of Brazilian firms: Measuring the role of human and technical aspects. J. Clean. Prod. 87, 442–451. doi:10.1016/j.jclepro.2014.09.036

Kengpol, A., Tuammee, S., and Tuominen, M. (2014). The development of a framework for route selection in multimodal transportation. Int. J. Logist. Manag. 25, 581–610. doi:10.1108/ijlm-05-2013-0064

Kline, R. B. (2015). Principles and practice of structural equation modeling. New York, NY: Guilford publications.

Klumpp, M., and Zijm, H. (2019). Logistics innovation and social sustainability: How to prevent an artificial divide in human–computer interaction. J. Bus. Logist. 40 (3), 265–278. doi:10.1111/jbl.12198

Kumar, A., and Anbanandam, R. (2020). Assessment of environmental and social sustainability performance of the freight transportation industry: An index-based approach. Transp. Policy 124, 43–60. doi:10.1016/j.tranpol.2020.01.006

Li, G., Fang, X., and Liu, M. (2021a). Will digital inclusive finance make economic development greener? Evidence from China. Front. Environ. Sci. 9 (762231). doi:10.3389/fenvs.2021.762231

Liu, A., Zhu, Q., Xu, L., Lu, Q., and Fan, Y. (2021b). Sustainable supply chain management for perishable products in emerging markets: An integrated location-inventory-routing model. Transp. Res. Part E Logist. Transp. Rev. 150, 102319. doi:10.1016/j.tre.2021.102319

Liu, Z., Zheng, X.-X., Li, D.-F., Liao, C.-N., and Sheu, J.-B. (2021a). A novel cooperative game-based method to coordinate a sustainable supply chain under psychological uncertainty in fairness concerns. Transp. Res. Part E Logist. Transp. Rev. 147, 102237. doi:10.1016/j.tre.2021.102237

Luthra, S., Govindan, K., Kannan, D., Mangla, S. K., and Garg, C. P. (2017). An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 140, 1686–1698. doi:10.1016/j.jclepro.2016.09.078

Magazzino, C., Alola, A. A., and Schneider, N. (2021). The trilemma of innovation, logistics performance, and environmental quality in 25 topmost logistics countries: A quantile regression evidence. J. Clean. Prod. 322, 129050. doi:10.1016/j.jclepro.2021.129050

Magazzino, C., Mele, M., and Schneider, N. (2022). A new artificial neural networks algorithm to analyze the nexus among logistics performance, energy demand, and environmental degradation. Struct. Change Econ. Dyn. 60, 315–328. doi:10.1016/j.strueco.2021.11.018

Mangla, S. K., Sharma, Y. K., Patil, P. P., Yadav, G., and Xu, J. (2019). Logistics and distribution challenges to managing operations for corporate sustainability: Study on leading Indian diary organizations. J. Clean. Prod. 238, 117620. doi:10.1016/j.jclepro.2019.117620

Mehdikhani, R., and Valmohammadi, C. (2019). Strategic collaboration and sustainable supply chain management. J. Enterp. Inf. Manag. 32, 778–806. doi:10.1108/jeim-07-2018-0166

Menke, C., Hüsemann, M., and Siems, E. (2021). Stakeholder influence on sustainable supply chain management: A case study of a German apparel frontrunner. Front. Sustain. 2. doi:10.3389/frsus.2021.735123

Minguela-Rata, B., Fernández-Menéndez, J., and Fossas-Olalla, M. (2014). Cooperation with suppliers, firm size and product innovation. Industrial Manag. Data Syst. 114 (3), 438–455. doi:10.1108/IMDS-08-2013-0357

Mitręga, M., and Choi, T.-M. (2021). How small-and-medium transportation companies handle asymmetric customer relationships under COVID-19 pandemic: A multi-method study. Transp. Res. Part E Logist. Transp. Rev. 148, 102249. doi:10.1016/j.tre.2021.102249

Multaharju, S., Lintukangas, K., Hallikas, J., and Kähkönen, A.-K. (2017). Sustainability-related risk management in buying logistics services: An exploratory cross-case analysis. Int. J. Logist. Manag. 28, 1351–1367. doi:10.1108/ijlm-05-2016-0134

Muzaffar, A., Khurshid, A., Malik, M. N., and Azhar, A. (2019). Sustainable development across the supply chain: The missing link of socio-environmental effect. Sustain. Dev. 27 (5), 976–981. doi:10.1002/sd.1988

Niu, B., and Mu, Z. (2020). Sustainable efforts, procurement outsourcing, and channel co-opetition in emerging markets. Transp. Res. Part E Logist. Transp. Rev. 138, 101960. doi:10.1016/j.tre.2020.101960

Norman, W., and MacDonald, C. (2004). Getting to the bottom of “triple bottom line”. Bus. Ethics Q. 14 (2), 243–262. doi:10.5840/beq200414211

Pagell, M., and Wu, Z. (2009). Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars. J. Supply Chain Manag. 45 (2), 37–56. doi:10.1111/j.1745-493x.2009.03162.x

Podsakoff, P. M., MacKenzie, S. B., Lee, J.-Y., and Podsakoff, N. P. (2003). Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 88 (5), 879–903. doi:10.1037/0021-9010.88.5.879

Pullman, M. E., Maloni, M. J., and Carter, C. R. (2009). Food for thought: Social versus environmental sustainability practices and performance outcomes. J. Supply Chain Manag. 45 (4), 38–54. doi:10.1111/j.1745-493x.2009.03175.x

Rehman Khan, S. A., Hassan, S., Khan, M. A., Khan, M. R., Godil, D. I., and Tanveer, M. (2022). Nexuses between energy efficiency, renewable energy consumption, foreign direct investment, energy consumption, global trade, logistics and manufacturing industries of emerging economies: In the era of COVID-19 pandemic. Front. Environ. Sci. 10 (880200). doi:10.3389/fenvs.2022.880200

Rogers, E. M. (1995). Diffusion of innovations: Modifications of a model for telecommunications, Die diffusion von innovationen in der telekommunikation. Heidelberg: Springer, 25–38.

Sahin, F., and Robinson, E. P. (2005). Information sharing and coordination in make-to-order supply chains. J. Operations Manag. 23 (6), 579–598. doi:10.1016/j.jom.2004.08.007

Sandra Marcelline, T. R., Chengang, Y., Ralison Ny Avotra, A. A., Hussain, Z., Zonia, J. E., and Nawaz, A. (2022). Impact of green construction procurement on achieving sustainable economic growth influencing green logistic services management and innovation practices. Front. Environ. Sci. 9, 815928. doi:10.3389/fenvs.2021.815928

Sari, K. (2008). On the benefits of cpfr and vmi: A comparative simulation study. Int. J. Prod. Econ. 113 (2), 575–586. doi:10.1016/j.ijpe.2007.10.021

Schönborn, G., Berlin, C., Pinzone, M., Hanisch, C., Georgoulias, K., and Lanz, M. (2019). Why social sustainability counts: The impact of corporate social sustainability culture on financial success. Sustain. Prod. Consum. 17, 1–10. doi:10.1016/j.spc.2018.08.008

Schreck, P. (2009). The business case for corporate social responsibility. Heidelberg: Physica-Verlag.

Shashi, S., Cerchione, R., Singh, R., Centobelli, P., and Shabani, A. (2018). Food cold chain management: From a structured literature review to a conceptual framework and research agenda. Int. J. Logist. Manag. 29, 792–821. doi:10.1108/ijlm-01-2017-0007

Silvestre, B. S. (2015). Sustainable supply chain management in emerging economies: Environmental turbulence, institutional voids and sustainability trajectories. Int. J. Prod. Econ. 167, 156–169. doi:10.1016/j.ijpe.2015.05.025

Singh, R., and Shabani, A. (2016). The identification of key success factors in sustainable cold chain management: Insights from the Indian food industry. J. Operations Supply Chain Manag. 9 (2), 1–16.

Singh, R., and Shabani, A. (2017). Value‐adding practices in food supply chain: Evidence from Indian food industry. Agribusiness 33 (1), 116–130. doi:10.1002/agr.21478

Sodhi, M. S., and Tang, C. S. (2018). Corporate social sustainability in supply chains: A thematic analysis of the literature. Int. J. Prod. Res. 56 (1-2), 882–901. doi:10.1080/00207543.2017.1388934

Soltanmohammadi, A., Ardakani, D. A., Dion, P. A., and Hettiarachchi, B. D. (2021). Employing total quality practices in sustainable supply chain management. Sustain. Prod. Consum. 28, 953–968. doi:10.1016/j.spc.2021.07.013

Sreekumar, V., and Rajmohan, M. (2019). Supply chain strategy decisions for sustainable development using an integrated multi-criteria decision-making approach. Sustain. Dev. 27 (1), 50–60. doi:10.1002/sd.1861

Su, M., Fang, M., Kim, J., and Park, K. S. (2022a). Sustainable marketing innovation and consumption: Evidence from cold chain food online retail. J. Clean. Prod. 340, 130806. doi:10.1016/j.jclepro.2022.130806

Su, M., Woo, S. H., Chen, X., and Park, K. S. (2022b). Identifying critical success factors for the agri‐food cold chain's sustainable development: When the strategy system comes into play. Bus. Strategy Environ ahead-of-print. doi:10.1002/bse.3154

Sun, J., Sarfraz, M., Khawaja, K. F., and Abdullah, M. I. (2022). Sustainable supply chain strategy and sustainable competitive advantage: A mediated and moderated model. Front. Public Health 10, 895482. doi:10.3389/fpubh.2022.895482

Szopik-Depczyńska, K., Kędzierska-Szczepaniak, A., Szczepaniak, K., Cheba, K., Gajda, W., and Ioppolo, G. (2018). Innovation in sustainable development: An investigation of the EU context using 2030 agenda indicators. Land Use Policy 79, 251–262. doi:10.1016/j.landusepol.2018.08.004

Thomas, R. W., Fugate, B. S., Robinson, J. L., and Tasçioglu, M. (2016). The impact of environmental and social sustainability practices on sourcing behavior. Int. J. Phys. Distribution Logist. Manag. 46, 469–491. doi:10.1108/ijpdlm-02-2015-0041

Tochtrop, C., Bickel, M., Hennes, L., Speck, M., and Liedtke, C. (2022). Principles and design scenarios for sustainable urban food logistics. Front. Sustain. Cities 4, 896313. doi:10.3389/frsc.2022.896313

Touboulic, A., and Walker, H. (2015). Love me, love me not: A nuanced view on collaboration in sustainable supply chains. J. Purch. Supply Manag. 21 (3), 178–191. doi:10.1016/j.pursup.2015.05.001

Tsao, Y.-C., and Thanh, V.-V. (2019). A multi-objective mixed robust possibilistic flexible programming approach for sustainable seaport-dry port network design under an uncertain environment. Transp. Res. Part E Logist. Transp. Rev. 124, 13–39. doi:10.1016/j.tre.2019.02.006

Wang, J., and Dai, J. (2018). Sustainable supply chain management practices and performance. Industrial Manag. Data Syst. 31 (5), 1147–1182. doi:10.1108/MEQ-04-2019-0079

Wang, X., Yuen, K. F., Wong, Y. D., and Teo, C.-C. (2019). Consumer participation in last-mile logistics service: An investigation on cognitions and affects. Int. J. Phys. Distribution Logist. Manag. 49, 217–238. doi:10.1108/ijpdlm-12-2017-0372

Wang, X., Yuen, K. F., Wong, Y. D., and Teo, C. C. (2018). An innovation diffusion perspective of e-consumers’ initial adoption of self-collection service via automated parcel station. Int. J. Logist. Manag. 29, 237–260. doi:10.1108/ijlm-12-2016-0302

Wani, T. A., and Ali, S. (2015). Innovation diffusion theory. J. General Manag. Res. 3 (2), 101–118.

Weber, H., Loschelder, D. D., Lang, D. J., and Wiek, A. (2021). Connecting consumers to producers to foster sustainable consumption in international coffee supply-a marketing intervention study.. J. Mark. Manag. 37 (11-12), 1148–1168. doi:10.1080/0267257X.2021.1897650

Wong, C. Y., and Boon-Itt, S. (2008). The influence of institutional norms and environmental uncertainty on supply chain integration in the Thai automotive industry. Int. J. Prod. Econ. 115 (2), 400–410. doi:10.1016/j.ijpe.2008.05.012