- School of Economics, Nanjing Audit University, Nanjing, China

Once the world’s largest waste importer, China alleviated the shortage of raw materials in its related industries; however, such activity incited more prominent ecological and environmental problems. Based on several major sample databases from 2003 to 2006—including the China Industry Business Performance Data, Customs Trade Database, and scrap metal commodity data from Harmonized System code catalogues—this paper establishes a city-level panel data model and a mediation effect model to examine the impact of scrap metal imports on industrial wastewater discharge in China as well as the mechanism of this impact. Furthermore, this paper analyses the impact of scrap metal imports on Chinese enterprises’ pollution fees from the perspective of enterprises to ensure the robustness of results based on the China Industry Business Performance Data in 2004. Results show that scrap metal imports significantly increase industrial wastewater discharge in China and exacerbate environmental pollution. Specifically, results indicate that if scrap metal imports increase by 1%, wastewater discharge will significantly increase by approximately 0.015–0.198 percentage points. In terms of the impact mechanisms, by driving the development of metal smelting, scrap metal imports have increased both the metal smelting rate in total industrial output and cities’ reliance on metal smelting, which has significantly increased industrial wastewater discharge in China. Finally, the robustness test demonstrates that increasing metal waste imports will significantly increase the discharge of pollutants by Chinese industrial enterprises, thereby increasing their pollution fees. Specifically, the results of the Ordinary Least Square and IV 2SLS model indicate that if scrap metal imports increase by 1%, industrial enterprises’ pollution fees will significantly increase by 1.081–11.3 million yuan. On the premise of protecting the environment, the Chinese government can import recyclable scrap metal commodities such as high-grade waste copper and aluminium that can meet the product quality standards for enterprises. Additionally, the Chinese government should raise the standards of the metal smelting and recycling industries, reduce the discharge of industrial waste water, and strive to improve the ecological environment.

1 Introduction

In the 1980s, China began to import solid waste for use as raw materials to alleviate raw material shortages. China is currently the world’s largest importer of waste (Sun, 2019). Per the World Trade Statistics, in 2006, China imported 56% of the world’s total plastic waste and more than 50% of the world’s total copper and paper waste (Sina News, 2018). Further, according to China’s Ministry of Ecology and Environment, China imported a total of 46.58 million tonnes of solid waste in 2016, ranking first in the world. Among these imports, 88.9% comprise waste paper, plastic, and metal products (Sohu News, 2018). These imported solid wastes, especially scrap copper, aluminium, and iron, have reduced the shortage of raw materials in China to some extent.

With the increase in solid waste imports, environmental pollution is becoming an increasingly severe problem (Yoshida, 2022). First, the stock, decomposition, and secondary processing of solid waste pollute the air, water, and soil. Additionally, after secondary processing, they produce toxic and hazardous substances that can be very difficult to handle. Even generalized recyclable solid waste is normally mixed with some highly polluted and hazardous waste with high environmental risks. Second, most enterprises that process and recycle solid waste as raw materials are polluted and poorly managed, with weak pollution treatment capabilities. Many do not have pollution treatment facilities, and their emissions seriously damage the local ecological environment. In July 2017, to protect the environment and promote sustainable economic development, China adjusted its policy on solid waste imports (Sohu News, 2017). By the end of 2017, China completely banned the import of environmentally harmful solid waste. By the end of 2019, China gradually stopped importing solid waste that can be replaced by domestic resources. Although solid waste imports seem to have a negative impact on the environment, there are not enough studies on solid waste imports and environmental pollution in China. To this end, using scrap metal imports as an example, this paper aims to empirically analyse the impact of metal waste imports on industrial wastewater discharge in China and its impact mechanisms.

The main contributions of this study are as follows: First, this paper not only empirically analyses the impact of metal waste imports on industrial wastewater discharge, but also investigates its reasons from the perspective of the development of metal smelting. Second, this paper employs several major sample databases from 2003 to 2006, including the China Industry Business Performance Data, Customs Trade Database, and scrap metal commodity data under Harmonized System (HS) code catalogues. Hence, the scientific merit and robustness of the study’s conclusions are guaranteed.

The paper is organised as follows. Section 2 highlights the literature review and states the research hypothesis. Section 3 lists the data sources and key variables included in the study, and the steps involved in data processing. Section 4 presents the empirical model applied, and Section 5 conveys the results of the empirical model. Lastly, Section 6 concludes the study.

2 Literature review and research hypothesis

2.1 Solid waste and environmental pollution

To date, there has been considerable research on solid waste and environmental pollution. Many researchers believe that solid waste has a negative impact on environmental protection and exacerbates environmental pollution (Li and Chen, 2019). Various countries or regions directly bury solid waste, such as plastic and waste paper, polluting soil and groundwater (Vasanthi et al., 2008; Chae and An, 2018), whereas others incinerate them, which pollutes the air (Ni et al., 2016; Verma et al., 2016). Additionally, various countries or regions smelt and process solid waste such as scrap metals, which consumes a high amount of fossil fuels and cooling water and discharges a large quantity of industrial exhaust and wastewater, causing air and water pollution (Huan et al., 2018). Thus, the increase in solid waste has a negative impact on environmental protection and worsens pollution.

2.2 Solid waste imports and industrial development

Under the global division of production, solid waste has been traded as a commodity (Wang, 2018; Qu et al., 2019; Huang et al., 2020). In developed countries, large amounts of solid waste such as plastic, waste paper, and scrap metal are generated by consumer and industrial production. Due to constraints in these countries, they export large amounts of solid waste to developing countries for processing (Brooks et al., 2018; Wang W. et al., 2019). Additionally, some developing countries that import solid waste are paid to dispose of waste by developed countries (Wang et al., 2020). Various solid waste, such as scrap metals, are also used as important materials in metal smelting. This reduces mining costs, transportation, and smelting resources such as iron and aluminium ore, advances the development of metal smelting to a certain extent, and stimulates employment (Liao et al., 2019). Wang J. et al. (2019) reported that China has a high demand for copper. However, due to shortages in domestic copper supplies, China must rely heavily on imports. According to the United Nations Commodity Trade Statistics Database (UNCTSD), 22.4% of China’s copper came from waste copper imported from the US in 2016. Similarly, many developing countries also have a demand for imported solid waste. Therefore, the industrial chain for the import and treatment of solid waste has gradually emerged.

2.3 Metal waste smelting and wastewater discharge

As for the impact of metal smelting on industrial wastewater discharge and pollution, many studies have shown that metal smelting also produces a substantial amount of industrial wastewater during the smelting process due to the consumption of copious amounts of industrial cooling water (Yuan et al., 2017; Xie and Zhu, 2020). At the same time, the industrial wastewater produced by metal smelting contains numerous heavy metals, which have a significant impact on aquatic organisms, crops, and soil (Okereke et al., 2016; Fiorentino et al., 2019; Ilyas et al., 2019). Moreover, if a metal smelting enterprise has limited capital and low metal smelting wastewater treatment technology, the industrial wastewater produced by metal smelting will not be recycled or degraded, leading to the direct discharge of industrial wastewater and resulting in serious environmental pollution problems (Younis and Sundarakani, 2019; Ajiboye et al., 2021).

In China, enterprises engaged in scrap metal smelting often have limited business scale, and frequently use traditional smelting methods to engage in scrap metal smelting. This requires a substantial amount of industrial cooling water, resulting in excessive industrial wastewater (Pan et al., 2014; Zhang et al., 2022). At the same time, due to less investment in wastewater treatment technology and poor wastewater treatment capacity, these enterprises prefer to discharge industrial wastewater directly, resulting in increased local industrial wastewater discharge and significant environmental pollution (Lyu et al., 2016; Li et al., 2021).

2.4 Research hypothesis

First, as solid waste, scrap metal imports consume a substantial amount of cooling water during the smelting process, thus producing a high quantity of industrial wastewater. Therefore, we propose the following basic research hypothesis:

2.4.1 Basic research hypothesis

Increased scrap metal imports can significantly increase industrial wastewater discharge in China.

Second, scrap metal commodities are mainly imported as production materials and are smelted and processed later, which can significantly drive the development of metal smelting. The higher a city’s scrap metal imports, the higher its rates of metal smelting and industrial wastewater production. Hence, we posit the following mechanism research hypothesis:

2.4.2 Mechanism research hypothesis

By driving the development of metal smelting, scrap metal imports can increase both the metal smelting rate’s total industrial output and a city’s dependence on it, thereby significantly increasing industrial wastewater discharge in China.

Finally, numerous heavy metals can be found in industrial wastewater (Ilyas et al., 2018; Ishfaq et al., 2019). Consequently, the increase of industrial wastewater discharge will lead to serious environmental pollution, which will have a serious impact on the ecological environment and people’s health (Chen et al., 2019; Srivastava et al., 2020). To reduce the heavy metal pollution of industrial wastewater, enterprises must increase their expenditure on pollution fees, so as to reduce the adverse impact of environmental pollution (Wang and Yang, 2016; Sattar et al., 2019; Ilyas et al., 2020). Therefore, if the import of scrap metal leads to a substantial increase in the pollution cost of enterprises, the basic research hypothesis of this paper is further verified.

2.4.3 Robustness research hypothesis

Scrap metal imports will lead to an increase in pollution fees to solve the problem of environmental pollution, because increased scrap metal imports can significantly increase industrial wastewater discharge in China.

3 Data sources and key variables

3.1 Data sources

First, data on all state and private enterprises larger than a designated size and encompassing all manufacturing sectors in China was obtained from the China Industry Business Performance Data from 2003 to 2006 (Yu, 2022). The indexes included more than 100 variables, such as the name, code, and year of the enterprise; product information; sales volume; industrial sales output; gross industrial output value; paid-up capital; fixed assets; total assets; total liabilities; annual average number of employees; and financial indicators such as total payable wages (Tian and Yu, 2020). We processed the data to improve the accuracy. Specifically, we omitted missing values, outliers, and obvious error samples of the related variables. Using Yu and Tan’s method (2012), we removed the observed values that met one of the following conditions: 1) the number of employees was missing or less than eight; 2) one item in total assets or product sales was missing or not positive; 3) one item in current assets, fixed assets, gross fixed assets, or gross industrial output value was missing or negative; 4) current assets were greater than total assets; 5) fixed assets were greater than total assets; and 6) gross fixed assets were greater than total assets.

Second, we used the Chinese customs’ import and export data from 2003 to 20061, which included information on the products imported and exported through customs clearance companies, including many basic trade variables such as trade volume, trade status (import or export), product quantity, destination countries or regions of export and import, type of trade (processing trade or general trade), and other information including tax codes and names of enterprises, ownership of enterprises (foreign/private/state), HS codes, and cities (Yu, 2015; Tian and Yu, 2019).

Third, we used the data on scrap metal from the HS commodity category, which can be accessed at http://tariffdata.wto.org/. This database contains comprehensive information on the Most-Favoured-Nation (MFN) applied and bound tariffs at the standard codes of the Harmonized System (HS) for all WTO Members. In addition, it provides data at the HS subheading level on non-MFN applied tariff regimes which a country grants to its export partners. This information is sourced from the submissions made to the WTO Integrated Data Base (IDB) for applied tariffs and imports and from the Consolidated Tariff Schedules (CTS) database for the bound duties of all WTO Members. We collected all the information on HS scrap metal codes as specified in Chapters 72 to 83, including product names, product codes, units of measurement, import tax rebate rates, supervision conditions, inspection, and quarantine.

Lastly, the data on industrial wastewater discharge, industrial structures, industrial power consumption, and scientific expenditures was procured from the China City Statistical Yearbook (https://data.stats.gov.cn/easyquery.htm?cn=C01), from 2003 to 2006 at the city level.

3.2 Data processing

The steps of consolidating and merging the data involved in this paper were as follows. First, we merged the data on China’s industrial enterprises and customs export trade. Using Yu and Tian (2012), we merged the companies with the same year and name. After deleting the missing postal codes and telephone numbers, we merged the companies with the same postal codes and the same last seven digits of their telephone numbers. Second, according to the HS codes, we matched the scrap metal data to the industrial enterprise-customs database. We used eight digits from the HS codes in the scrap metal database and merged and consolidated the data to obtain a micro database at the ‘enterprise-product’ level. Third, according to the codes and business names and codes and city names, we merged and combined the China Industry Business Performance Data, China’s Customs import and export database, and scrap metal data in the HS commodity category from 2003 to 2006 with relevant data in the China City Statistical Yearbook to obtain the city level panel data.

4 Empirical model

4.1 Modelling

4.1.1 The impact of metal waste imports on industrial wastewater discharge in China

As previously mentioned, we established a city level panel data model to empirically study the impact of scrap metal waste imports on industrial wastewater discharge in China:

where c is the city, t is the time, and the dependent variable, i.e.

As an estimation method, we first adopted fixed- and random effects models as benchmark models to empirically analyse and produce preliminary results. Moreover, to address the issue of exogeneity and obtain unbiased and effective results, we also used an instrumental variable regression model for the empirical analysis and conducted robustness tests on the preliminary results to determine the impact.

4.1.2 Mechanism test: Analysis of mediation effects on metal smelting

After analysing the impact of metal waste imports on industrial wastewater discharge in China, we further explored the influence mechanism from the perspective of metal smelting in various cities. By introducing the mediator variable of the metal smelting rate (metal_smelt_rate), we established a mediation effect model to examine the influence mechanism of scrap metal imports.

To build the mediation effect model, we estimated the dependent variable (

4.1.3 Robustness test: The impact of metal waste imports on Chinese enterprises’ pollution fees

Furthermore, we also analysed the impact on Chinese enterprises’ pollution fees from the perspective of enterprises to further examine whether scrap metal imports have an impact on pollution and whether they represent a key factor affecting industrial wastewater discharge in China to ensure the robustness of results. Because the China Industry Business Performance Data only recorded pollution fees data in 2004, the robustness test used the micro data at the ‘enterprise-product’ level for analysis.

where lnwaste_im_firm is the logarithm of the total scrap metal imports; lnpollutfee is the logarithm of the pollution fees; j is the firm;

4.2 Index variables

4.2.1 Scrap metal imports

In selecting the import variable based on the HS code, the China Industry Business Performance Data, and import and export trade data from China’s customs, we merged and consolidated the micro data at the ‘enterprise-product’ level from 2003 to 2006 and the city level panel data. Next, we conducted the measurements using the total value of scrap metal imports from 2003 to 2006 (unit: RMB 1,000). In the robustness test, we used the total volume of scrap metal imports (unit: RMB 1,000) processed from the China Industry Business Performance Data, import and export trade data of China’s customs, and the 2004 HS code for the tests.

4.2.2 Industrial wastewater discharge and pollution fees

The city level data on industrial wastewater discharge (wastewater) were obtained from the China City Statistical Yearbook (unit: 10,000 tons). Statistics on businesses’ pollution fees were obtained from (pollutfee) the 2004 China Industry Business Performance Data (unit: RMB 1,000).

4.2.3 Mediator variable

In terms of index measurement, based on the China Industry Business Performance Data, we calculated the rates of ferrous (CIC 32 sector) and non-ferrous metal smelting (CIC 33 sector) in the total industrial output to measure the metal smelting rate.

4.2.4 Control variables in the city level panel data model

4.2.4.1 The rate of industrial output (industry_rate, unit: %)

Based on the study’s objective, the rate of industrial sectors is a key factor in industrial wastewater discharge. Therefore, we conducted an empirical analysis using the logarithm of the rate of the secondary industry in the total GDP of various cities.

4.2.4.2 The rate of scientific expenditures (science_rate, unit: %)

Many studies suggest that science and technology are essential to green economic development and play an important role in reducing pollutant discharge. The higher the rate of scientific expenditures, the more advanced the science and technology, and the lower the industrial wastewater discharge. Therefore, we measured the development of science with the rate of scientific expenditures in the total financial expenditures of different cities and used their logarithms for the empirical analysis.

4.2.4.3 The rate of industrial electricity (elec_rate, unit: %)

Many studies suggest that electricity consumption is a key indicator of energy consumption and businesses’ production activity. High electricity consumption suggests that production is thriving. In return, the increase in power consumption will also produce more pollutants, including industrial wastewater. Thus, we measured the rate of industrial electricity in different cities and used their logarithms for the empirical analysis.

4.2.5 Control variables in the robustness test

1) Metal smelting dummy (smelt_dummy, unit: o or 1).

If a business engages in metal smelting, it will have higher pollution fees. Thus, we introduced the metal smelting rate (1 means CIC 32 or CIC 33 sector, and 0 means negative) for analysis.

2) The age of enterprises (age, unit: year).

The production capacity and scale of enterprises vary considerably at different stages of development. As the age of a business increases, its production capacity and scale also increase, as do the pollution fees. To this end, we introduced the age of enterprises.

3) Capital labour ratio (kl).

Enterprises with high capital labour ratios normally engage in heavy industry, which produces significant discharges of pollutants, such as industrial wastewater, and generates higher pollution fees. Therefore, we also introduced this variable, which is the amount of capital (unit: 10 million yuan) that can be used by the enterprise per employee.

4) Ownership of enterprises (ownership, unit: o or 1).

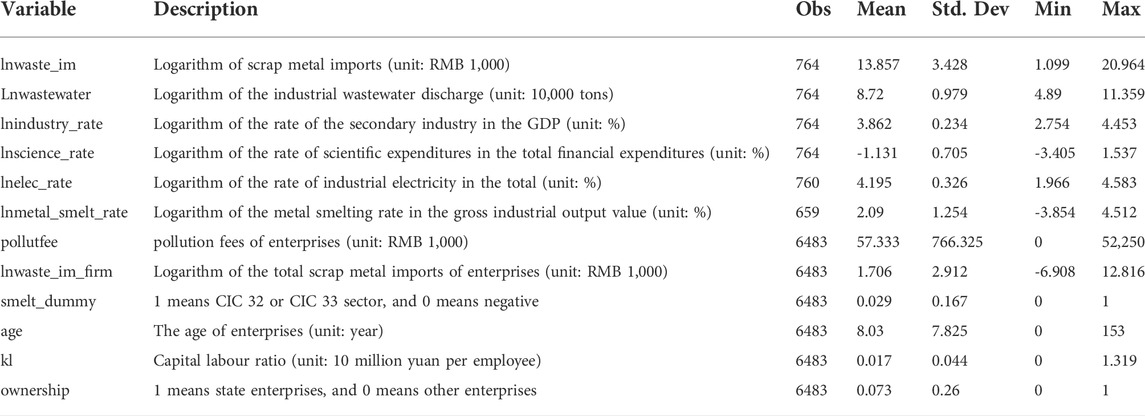

In China, enterprises with different forms of ownership demonstrate considerable differences in terms of technical level, production efficiency, industry characteristics, and energy consumption. They also discharge varying amounts of pollutants, such as industrial wastewater, and generate different pollution fees. Thus, we also introduced the ownership of enterprises for analysis (1 means state enterprises, and 0 means other enterprises). The descriptive statistics for the above variables are presented in Table 1.

5 Empirical results analysis

5.1 The impact of metal waste imports on industrial wastewater discharge in China

5.1.1 Analysis of the basic estimation results

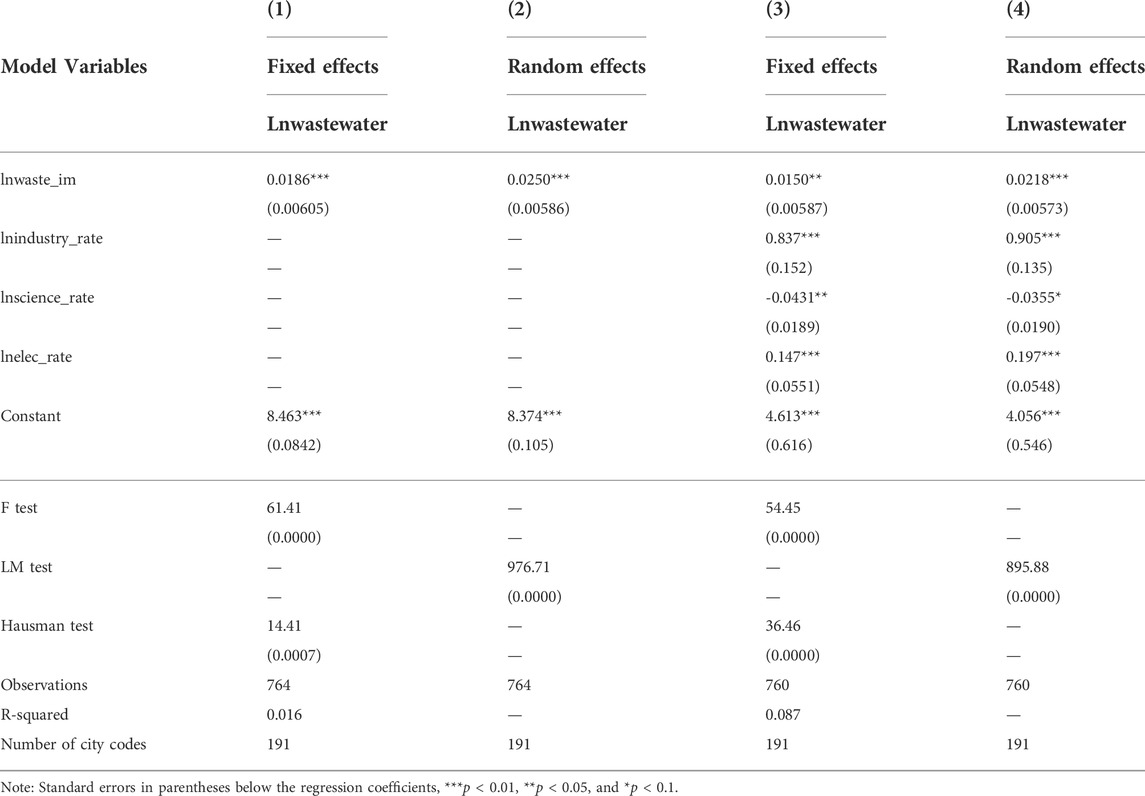

Table 2 presents the results of the panel data model. Both the F test in the fixed effects model and the LM (Langrange Multiplier) test in the random effects model suggested that the OLS (Ordinary Least Square) results were biased, so we did not include them. Although the Hausman test indicated that the results of the fixed effects model were more efficient than the random effects model, we still included the results of the latter to ensure the robustness of the estimation results. Table 2 shows that the results of both the fixed effects and random effects models suggest that scrap metal imports have a significant impact on industrial wastewater discharge in China, significantly increasing industrial wastewater discharge and exacerbating environmental pollution, confirming our basic research hypothesis. Specifically, the fixed effects model results indicated that if scrap metal imports increase by 1%, wastewater discharge will significantly increase by approximately 0.015 percentage points.

The regression results of the control variables suggest that the rate of industrial output (lnindustry_rate) is positively correlated with industrial wastewater discharge, implying that cities with high ratios of industrial output in their total GDP will discharge more industrial wastewater, thus aggravating environmental pollution. The rate of scientific expenditures (lnsicence_rate) has a significant negative impact on wastewater discharge, suggesting that increasing scientific expenditures can boost technology levels, reduce the discharge of pollutants, including industrial wastewater, and mitigate environmental pollution. The results demonstrate that the rate of industrial electricity (lnelec_rate) has a significantly positive impact on industrial wastewater discharge, indicating that in regions with high industrial electricity consumption, production is higher, with higher energy consumption and more pollutants, such as industrial wastewater.

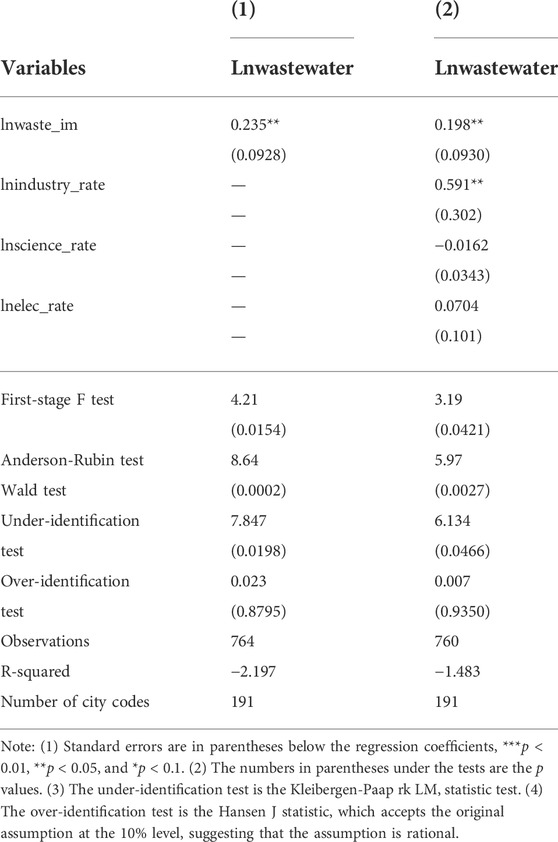

5.1.2 Instrumental variable (IV) regression results

To avoid interference from endogenous factors and ensure the impartiality and efficacy of the estimated results, based on the outcomes of the Hausman test, we conducted deviation transformation based on the fixed effects model, and an empirical analysis using IV estimation and the generalized method of moments (GMM). In terms of instrument variables, we analysed the import tariffs on intermediate goods during the current and lag periods. As an intermediate input in production, scrap metal is closely related to import tariffs on intermediate goods. Furthermore, as tariffs are relatively exogenous, they have little impact on industrial wastewater discharge during the current period. According to Yu (2015), and Amiti and Konings (2007), we used the following method to calculate the equation of import tariffs on intermediate goods:

where

As shown in Table 3, the F and Anderson-Rubin Wald tests conducted in stage 1 indicate there is no issue of a weak IV, nor of the under-identification test. This suggests that the IV can be estimated and identified, whereas the over-identification test demonstrates that the IV has sound exogeneity. Therefore, the estimated results of the IV are unbiased and effective. The instrument variable results in Table 3 indicate that, regardless of whether other variables are controlled, scrap metal imports (lnwaste_im) have a significantly positive impact on industrial wastewater discharge in China (lnwastewater), further supporting our hypothesis that increased metal waste imports have significantly increased both industrial wastewater discharge in China and environmental pollution.

5.2 Test of influence mechanisms: Analysis of the mediation effects of metal smelting

5.2.1 Preliminary analysis

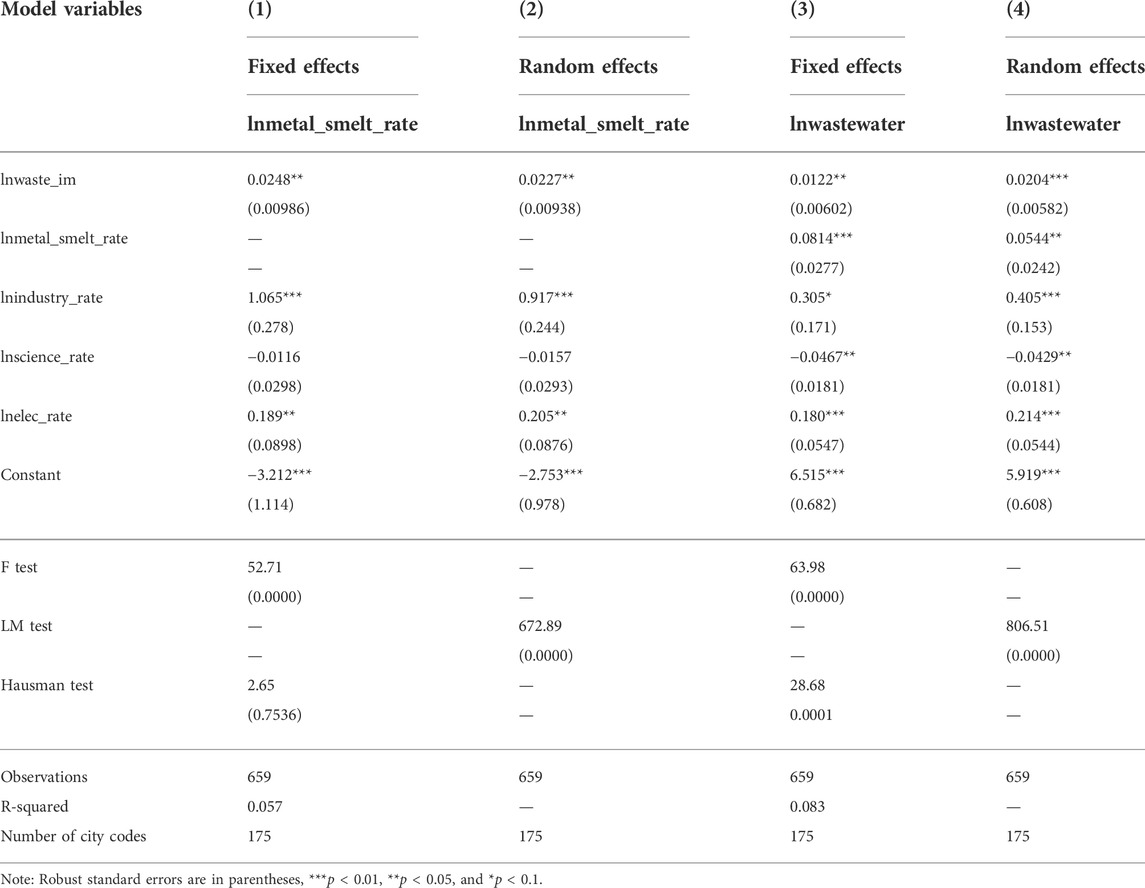

As previously mentioned, from the perspective of the development of metal smelting, we established the mediation effects model to empirically study the impact mechanisms. The estimation results in Eq. 2 are the estimation results in Table 2. The results show that coefficient

As shown in columns (3) and (4) in Eq. 4, coefficient

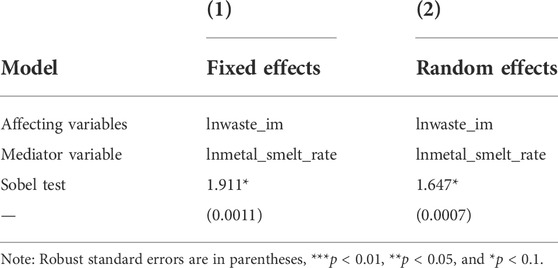

5.2.2 Sobel test

More stringent tests are needed to further test whether metal smelting is the channel. From the result,

We first employed Sobel’s method 1987) to calculate the deviation of the product term

where s represents the standard deviation of the relevant estimated coefficient, and

According to the method by Sobel (1987), we derived Eq. 7:

We also conducted the Sobel test on the significance of Z. As presented in Table 5, the metal smelting rate (lnmetal_smelt_rate) is indeed the channel through which metal waste imports affect industrial wastewater discharge in China. By increasing the metal smelting rate in industrial output, scrap metal imports increase cities’ dependence on metal smelting, thus, significantly increasing industrial wastewater discharge.

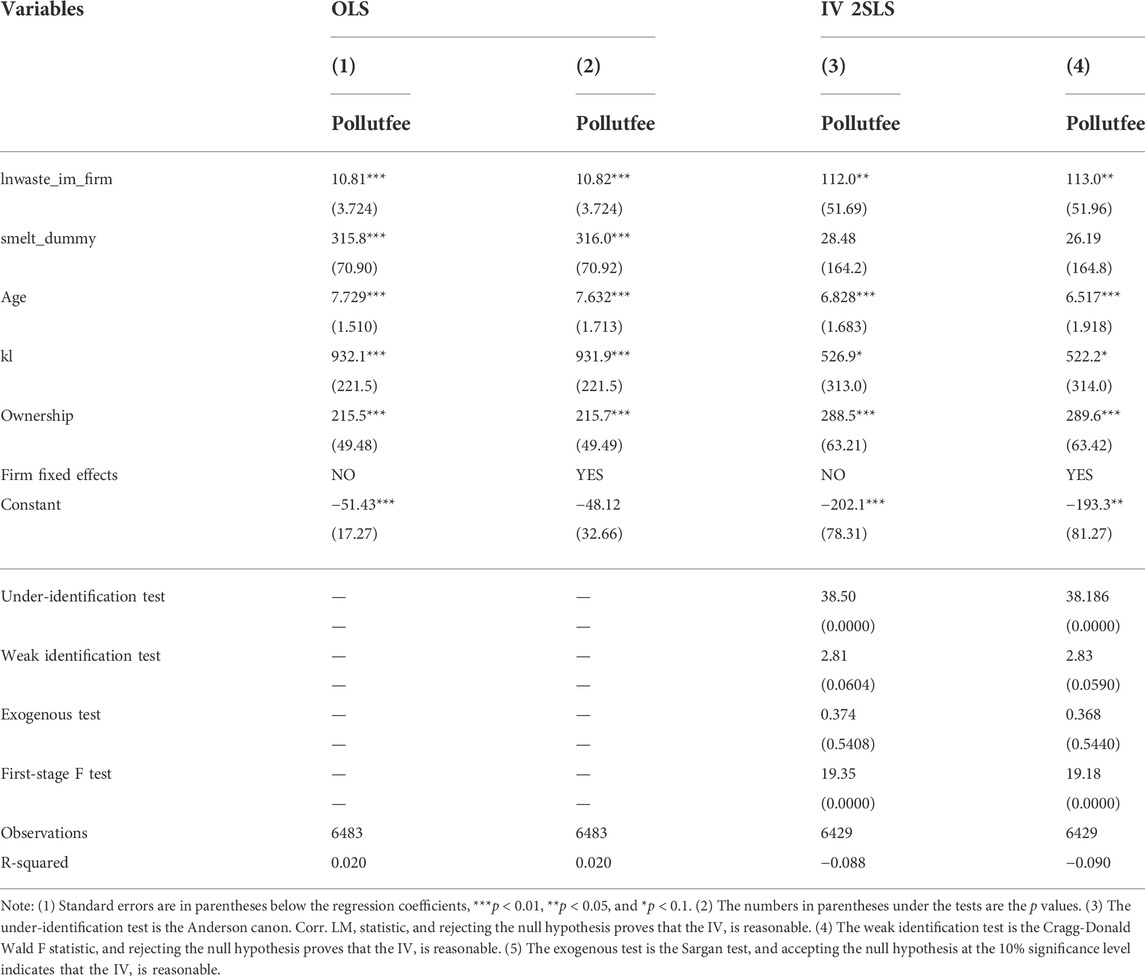

5.3 Robustness test: The impact of metal waste imports on Chinese industrial enterprises’ pollution fees

To further test the study’s conclusions, we also analysed the impact at the business level. As presented in Table 6, both the OLS and IV 2SLS results indicate that scrap metal imports are significantly positively correlated with pollution fees. This suggests that increasing metal waste imports will significantly increase Chinese industrial enterprises’ pollutant discharge, thus, increasing their pollution fees. Specifically, the results of the OLS and IV 2SLS models demonstrated that if scrap metal imports increase by 1%, industrial enterprises’ pollution fees will significantly increase by 1.081–11.3 million yuan. This again proves that results are robust regarding scrap metal imports being an important factor for increasing both environmental pollution and Chinese industrial enterprises’ wastewater discharge.

In terms of the influence of the other control variables, the OLS results indicated that metal smelting has a significantly positive impact on pollution fees. This suggests that metal smelting businesses’ pollution fees are higher and, thus, confirms this study’s mechanisms. The age of enterprises and capital labour ratios also have a significant positive impact on pollution fees, demonstrating that enterprises with greater longevity and higher capital labour ratios have higher pollution fees. Finally, in terms of ownership, state enterprises’ pollution fees are higher.

6 Research conclusions and suggestions

China is the world’s largest importer of scrap and waste. Increasing waste imports has damaged China’s ecological environment. Against this background, we explored the impact of scrap metal on industrial wastewater discharge in China, as well as its impact mechanisms. The study showed that increased metal waste imports have significantly increased industrial wastewater discharge in China and aggravated environmental pollution. Specifically, the results indicated that if scrap metal imports increase by 1%, wastewater discharge will significantly increase by approximately 0.015–0.198 percentage points. In terms of the impact mechanisms, by driving the development of metal smelting, scrap metal imports have increased both the metal smelting rate in total industrial output and cities’ reliance on metal smelting, which has significantly increased industrial wastewater discharge in China. Finally, the robustness test demonstrated that increasing metal waste imports will significantly increase the discharge of pollutants by Chinese industrial enterprises, thus increasing their pollution fees. Specifically, the results of the OLS and IV 2SLS model showed that if scrap metal imports increase by 1%, industrial enterprises’ pollution fees will significantly increase by 1.081–11.3 million yuan.

Based on these conclusions, we propose the following suggestions. First, the study’s conclusions suggest that it is appropriate for China to ban solid wastes, which can significantly reduce environmental pollution and improve the ecological environment. Second, China’s waste import catalogues must be further improved. To protect the environment, China should import only high-quality recyclable scrap metals such as high-quality scrap copper and aluminium to provide materials with low production costs. Third, China should mandate more stringent industry standards for metal smelting and recycling and reduce industrial wastewater discharge to improve the ecological environment. Fourth, China should reduce its dependence on the metal smelting industry and actively adjust the industrial structure, so as to reduce the discharge of industrial wastewater and environmental pollution.

First, future studies should further expand the research on the impact of scrap metal commodity import on the environment and resource utilisation. Second, they should also analyse the impact of different scrap metal commodity imports on the environment and resource utilisation, especially the beneficial impact of high quality recyclable scratch on the sustainable utilisation of resources. Third, research on the mechanism of the impact of scrap metal commodity import on the environment and resource utilisation should also be expanded, so as to provide a basis for formulating various policies. Fourth, the formulation of industrial standards for scrap metal smelting and recycling should also be studied, which can promote the effective utilisation of resources. Lastly, due to data limitations, this paper cannot further enrich the research conclusions based on the environmental Kuznets curve (EKC) model. In the future, if sufficient research data can be obtained, the EKC model can be used in future research to further expand the analysis, so as to further enhance the research value of this topic.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

WC: Conceptualization, Writing, Theoretical Analysis, Data Analysis, Policy Implications; WY: Conceptualization, Literature Review, Writing, Empirical Model Analysis, Data Analysis.

Funding

This work was supported by Six Talent Peaks Project in Jiangsu Province (2018-JY-017) to WC, and General project of universities’ philosophy and social science researches in Jiangsu province(2022SJYB0367) to WY.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

1At present, due to limited data access, the most recent customs trade data commonly used in academic research is 2003–2006, which is also the most recent data available to academia (Tian and Yu, 2019; Yu, 2022). Therefore, the other databases we used for merging are also from 2003 to 2006

References

Ajiboye, T. O., Oyewo, O. A., and Onwudiwe, D. C. (2021). Simultaneous removal of organics and heavy metals from industrial wastewater: A review. Chemosphere 262, 128379. doi:10.1016/j.chemosphere.2020.128379

Amiti, M., and Konings, J. (2007). Trade liberalization, intermediate inputs, and productivity: Evidence from Indonesia. Am. Econ. Rev. 97 (5), 1611–1638. doi:10.1257/aer.97.5.1611

Brooks, A. L., Wang, S., and Jambeck, J. R. (2018). The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 4 (6), eaat0131. doi:10.1126/sciadv.aat0131

Chae, Y., and An, Y. J. (2018). Current research trends on plastic pollution and ecological impacts on the soil ecosystem: A review. Environ. Pollut. 240, 387–395. doi:10.1016/j.envpol.2018.05.008

Chen, B., Wang, M., Duan, M., Ma, X., Hong, J., Xie, F., et al. (2019). In search of key: Protecting human health and the ecosystem from water pollution in China. J. Clean. Prod. 228, 101–111. doi:10.1016/j.jclepro.2019.04.228

Fiorentino, A., Di Cesare, A., Eckert, E. M., Rizzo, L., Fontaneto, D., Yang, Y., et al. (2019). Impact of industrial wastewater on the dynamics of antibiotic resistance genes in a full-scale urban wastewater treatment plant. Sci. Total Environ. 646, 1204–1210. doi:10.1016/j.scitotenv.2018.07.370

Huan, H., Xu, J., Wang, J., and Xi, B. (2018). “Industrial and economic analysis of groundwater pollution,” in Groundwater pollution risk control from an industrial economics perspective (Singapore: Springer), 15–24.

Huang, Q., Chen, G., Wang, Y., Chen, S., Xu, L., and Wang, R. (2020). Modelling the global impact of China’s ban on plastic waste imports. Resour. Conservation Recycl. 154, 104607. doi:10.1016/j.resconrec.2019.104607

Ilyas, M., Ahmad, W., Khan, H., Yousaf, S., Yasir, M., and Khan, A. (2019). Environmental and health impacts of industrial wastewater effluents in Pakistan: A review. Rev. Environ. health 34 (2), 171–186. doi:10.1515/reveh-2018-0078

Ilyas, N., Ilyas, S., Sajjad-ur-Rahman, S. U. R., Yousaf, S., Zia, A., and Sattar, S. (2018). Removal of copper from an electroplating industrial effluent using the native and modified spirogyra. Water Sci. Technol. 78 (1), 147–155. doi:10.2166/wst.2018.226

Ilyas, S., Srivastava, R. R., and Kim, H. (2020). Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 749, 141652. doi:10.1016/j.scitotenv.2020.141652

Ishfaq, A., Ilyas, S., Yaseen, A., and Farhan, M. (2019). Hydrometallurgical valorization of chromium, iron, and zinc from an electroplating effluent. Sep. Purif. Technol. 209, 964–971. doi:10.1016/j.seppur.2018.09.050

Li, C., and Chen, J. (2019). The significance of restrictions on waste import in promoting green development in China. Am. J. Environ. Prot. 8 (1), 5–16. doi:10.11648/j.ajep.20190801.12

Li, Y., Wang, Z., and Wei, Y. (2021). Water lock-in within China’s economic industry based on the input–output method and social network analysis. Environ. Sci. Pollut. Res. 29, 22391–22403. doi:10.1007/s11356-021-17463-w

Liao, M. I., Shih, X. H., and Ma, H. W. (2019). Secondary copper resource recycling and reuse: A waste input–output model. J. Clean. Prod. 239, 118142. doi:10.1016/j.jclepro.2019.118142

Lyu, S., Chen, W., Zhang, W., Fan, Y., and Jiao, W. (2016). Wastewater reclamation and reuse in China: Opportunities and challenges. J. Environ. Sci. 39, 86–96. doi:10.1016/j.jes.2015.11.012

Ni, H. G., Lu, S. Y., Mo, T., and Zeng, H. (2016). Brominated flame retardant emissions from the open burning of five plastic wastes and implications for environmental exposure in China. Environ. Pollut. 214, 70–76. doi:10.1016/j.envpol.2016.03.049

Okereke, J. N., Ogidi, O. I., and Obasi, K. O. (2016). Environmental and health impact of industrial wastewater effluents in Nigeria-A Review. Int. J. Adv. Res. Biol. Sci. 3 (6), 55–67.

Pan, X., Sha, J., Zhang, H., and Ke, W. (2014). Relationship between corporate social responsibility and financial performance in the mineral Industry: Evidence from Chinese mineral firms. Sustainability 6 (7), 4077–4101. doi:10.3390/su6074077

Qu, S., Guo, Y., Ma, Z., Chen, W. Q., Liu, J., Liu, G., et al. (2019). Implications of China’s foreign waste ban on the global circular economy. Resour. Conservation Recycl. 144, 252–255. doi:10.1016/j.resconrec.2019.01.004

Sattar, R., Ilyas, S., Bhatti, H. N., and Ghaffar, A. (2019). Resource recovery of critically-rare metals by hydrometallurgical recycling of spent lithium ion batteries. Sep. Purif. Technol. 209, 725–733. doi:10.1016/j.seppur.2018.09.019

Sina News (2018). China stops importing “foreign garbage”. Available at: http://k.sina.com.cn/article_5654253203_151050e930010039hd.html (Accessed February 9, 2018).

Sohu News (2017). General Office of the State Council of China: Completely ban the import of solid waste with great environmental hazards by the end of the year. Available at: https://www.sohu.com/a/160508421_114986 (Accessed July 28, 2017).

Sohu News (2018). Ministry of ecology and environment of China: Comprehensively tighten the environmental protection standards for solid wastes such as scrap steel and waste non-ferrous metals. Available at: https://www.sohu.com/a/216763766_200899 (Accessed January 15, 2018).

Srivastava, R. R., Ilyas, S., Kim, H., Tri, N. L. M., Hassan, N., Mudassir, M., et al. (2020). Liquid–liquid extraction and reductive stripping of chromium to valorize industrial effluent. JOM 72 (2), 839–846. doi:10.1007/s11837-019-03948-0

Sun, M. (2007). The effect of border controls on waste imports: Evidence from China’s Green Fence campaign. China Econ. Rev. 54, 457–472.

Tian, W., and Yu, M. (2020). Distribution, outward FDI, and productivity heterogeneity: China and cross-countries’ evidence. J. Int. Financial Mark. Institutions Money 67, 101218. doi:10.1016/j.intfin.2020.101218

Tian, W., and Yu, M. (2019). Input trade liberalization and import switching: Evidence from Chinese firms. Rev. Int. Econ. 27 (4), 1002–1020. doi:10.1111/roie.12410

Vasanthi, P., Kaliappan, S., and Srinivasaraghavan, R. (2008). Impact of poor solid waste management on ground water. Environ. Monit. Assess. 143 (1-3), 227–238. doi:10.1007/s10661-007-9971-0

Verma, R., Vinoda, K. S., Papireddy, M., and Gowda, A. N. S. (2016). Toxic pollutants from plastic waste-a review. Procedia Environ. Sci. 35, 701–708. doi:10.1016/j.proenv.2016.07.069

Wang, C., Zhao, L., Lim, M. K., Chen, W. Q., and Sutherland, J. W. (2020). Structure of the global plastic waste trade network and the impact of China’s import Ban. Resour. Conservation Recycl. 153, 104591. doi:10.1016/j.resconrec.2019.104591

Wang, J., Ju, Y., Wang, M., and Li, X. (2019a). Scenario analysis of the recycled copper supply in China considering the recycling efficiency rate and waste import regulations. Resour. Conservation Recycl. 146, 580–589. doi:10.1016/j.resconrec.2019.02.008

Wang, J. (2018). Solid wastes import control in China: Recent developments. Asia-Pac. J. Ocean. Law Policy 3 (1), 116–125. doi:10.1163/24519391-00301006

Wang, Q., and Yang, Z. (2016). Industrial water pollution, water environment treatment, and health risks in China. Environ. Pollut. 218, 358–365. doi:10.1016/j.envpol.2016.07.011

Wang, W., Themelis, N. J., Sun, K., Bourtsalas, A. C., Huang, Q., Zhang, Y., et al. (2019b). Current influence of China’s ban on plastic waste imports. Waste Dispos. sustain. Energy 1 (1), 67–78. doi:10.1007/s42768-019-00005-z

Xie, W., and Zhu, Q. (2020). Wastewater emission reduction by China’s industrial imports of and its influencing factors IOP conference series: Materials science and engineering. IOP Conf. Ser. Mat. Sci. Eng. 730 (1), 012060. doi:10.1088/1757-899x/730/1/012060

Yoshida, A. (2022). China’s ban of imported recyclable waste and its impact on the waste plastic recycling industry in China and Taiwan. J. Mater. Cycles Waste Manag. 24 (1), 73–82. doi:10.1007/s10163-021-01297-2

Younis, H., and Sundarakani, B. (2019). The impact of firm size, firm age and environmental management certification on the relationship between green supply chain practices and corporate performance. Benchmarking Int. J. 27 (1), 319–346. doi:10.1108/bij-11-2018-0363

Yu, M. (2022). “Managerial efficiency and product decision: Evidence from Chinese firms,” in China’s miracle in foreign trade (Singapore: Springer), 155–204.

Yu, M. (2015). Processing trade, tariff reductions and firm productivity: Evidence from Chinese firms. Econ. J. 125 (585), 943–988. doi:10.1111/ecoj.12127

Yu, M., and Tian, W. (2012). China’s firm-level processing trade: Trends, characteristics, and productivity. Report.

Yuan, Y., Xiang, M., Liu, C., and Theng, B. K. (2017). Geochemical characteristics of heavy metal contamination induced by a sudden wastewater discharge from a smelter. J. Geochem. Explor. 176, 33–41. doi:10.1016/j.gexplo.2016.07.005

Keywords: metal waste, solid waste, industrial wastewater, environmental pollution, economic development (ED), China

Citation: Chen W and Yan W (2022) The impact of metal waste imports on industrial wastewater discharge in China. Front. Environ. Sci. 10:911497. doi: 10.3389/fenvs.2022.911497

Received: 02 April 2022; Accepted: 04 July 2022;

Published: 23 August 2022.

Edited by:

Vassilis Inglezakis, University of Strathclyde, United KingdomReviewed by:

Marco Schiavon, University of Trento, ItalySadia Ilyas, Jeonbuk National University, South Korea

Copyright © 2022 Chen and Yan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Weitao Chen, Y3d0QG5hdS5lZHUuY24=

Weitao Chen

Weitao Chen Weitao Yan

Weitao Yan