- 1Development Research Center of Shandong Provincial People’s Government, Jinan, China

- 2School of Management, Ocean University of China, Qingdao, China

- 3Olin Business School, Washington University in St. Louis, St. Louis, MO, United States

- 4School of Economics, Peking University, Beijing, China

- 5School of Public Finance and Taxation, Capital University of Economics and Business, Beijing, China

- 6The Center for Economic Research, Shandong University, Jinan, China

The organizational development following the philosophy of sustainability is becoming the prerequisite for companies, which urges and emphasizes them to incorporate social, economic, and environmental aspects into their manufacturing and operations. Despite plethora of researches exploring lean practices as the solution for improving productivity, it is limited to the operational aspects only, thus ignoring the other aspects of sustainability. Moreover, there is a dearth of studies that explored the combined effect of sustainable innovation, process innovation, and lean practices on the three aspects of sustainability. The current study is an attempt and contribution in the existing literature through the sample of 431 respondents from ISO 14001 certified Chinese organizations during COVID-19 pandemic conditions. The estimations were performed through the Partial Least Squares–Structural Equation Modeling. The results revealed a positive association among the proposed hypothesis of aforementioned studied phenomena. In addition, the current study explores the role of sustainable innovation as a mediator between lean and three dimensions of the sustainability, which is reportedly found to be a partial mediator as both direct and indirect effects are found to be statistically significant. Through the findings of the current study, the managers and decision makers can comprehend the potential of the possible benefits which can be reaped by incorporating both lean and sustainability within their operations.

1 Introduction

The concept of sustainability has jolted and startled the world since its inception in late 1980s by the “World Commission of Environment and Development” (WCED) (Khodeir and Othman, 2018). The concept of sustainability predominately covers three aspects that include economic, social, and ecology (Dagar et al., 2021; Tang et al., 2022). The ecological aspects cover and address the concerns caused to the environment because of the non-environment friendly operations including manufacturing, transportation, and so on (Liu et al., 2020; Bhardwaj et al., 2022). The social aspects cover the concerns that are related to the welfare of the stakeholders including employees, customers, strategic partners, and all stakeholders (Hao et al., 2021; Elavarasan et al., 2021a; Elavarasan et al., 2021b; Razzaq et al., 2021; Irfan et al., 2022). The economic aspects cover the concerns through which the excessive and unnecessary wastage of financial resources are controlled and accordingly invested into profitable avenues (Resta et al., 2016; Khan et al., 2021; Rauf et al., 2021; Huang et al., 2022; Islam et al., 2022).

A recent study by The United Nation Global Compact (2016) recommended that through the improvement in the environmental-oriented performance, the supply chain of an organization will become capable to improve their processes, whereas this will also result in reduction in costs, enhancement of productivity, and improvement in the outcomes that includes financial as well as societal. Therefore, achieving sustainable innovation through which the cost to the environments is reduced as well as societal wellbeing is ensured is the need of the time (Chen et al., 2006; Burki et al., 2018). Moreover, through the integration of the operations and processes that are environment friendly, organizations can become greener and sustainable (Burki et al., 2018; Wu et al., 2021). The sustainable objectives can be achieved, through mutual collaboration among the related stakeholders, which is beneficial not only for the organization itself but also for the whole supply chain partners and the society (Thoo et al., 2013; Yumei et al., 2021).

Apart from sustainability, there are various management principles and philosophies that have urged to have maximum utilization of resources either by specialization of labor or by improving the productivity (Ahmad et al., 2021; Ali et al., 2021; Abbasi et al., 2022). One of the most studied, followed, and implemented solution is the philosophy of lean that was originated from the assembly line of automobile industry. Initially it was proposed to improve the level of productivity in the production operations by reducing different kind of non-value-added activities and wastes (Herron and Hicks, 2008). Despite the similarity within the philosophies of lean and sustainability, they are in contrast with certain aspects. For instance, lean is focused on improving the level of productivity by reducing the excess resources including inventory, whereas the theme of sustainability revolves around the efficiency without compromising the responsiveness (Jum’a et al., 2022). Similarly, the exploration of both these philosophies is conventionally limited to operational efficiency only, thus ignoring the aspects of environment and social wellbeing (Stamenkov and Dika, 2019; De et al., 2020), which however need equal attention and exploration (Piercy and Rich, 2015).

In addition, despite the similarities between lean and sustainability, there is dearth of researchers that have explored the integration of both of these philosophies within the manufacturing operations at the same time (Reich-Weiser and Dornfeld, 2009; Hartini and Ciptomulyono, 2015). The few evidences that have explored this stream include Dey et al. (2020) who as explored an integrated model covering the aspects of lean, corporate social responsibility, and innovation; however, they have integrated for exploring the economic performance only. Similarly, Ikram et al. (2019) also assessed the role of sustainability exclusive certification including SA8000, ISO 9001, and ISO 14001 in enhancing the level of exports and economic development. Similarly, different researchers have explored different performance outcomes, including Bandehnezhad et al. (2012) exploring environmental outcome, Hofer et al. (2012) exploring financial performance, Yang et al. (2011) exploring organizational performance, and Iranmanesh et al. (2019) and De et al. (2020) exploring sustainability performance.

Furthermore, the exploration of the linkage between lean practices with the any single aspect of sustainability has been reported by numerous researchers (Iranmanesh et al., 2019; Dieste et al., 2020). In addition, the relationship between sustainable innovation with the performance of the sustainability is also being documented (Adams et al., 2016; Khurana et al., 2021). In addition, the role of innovation based on the principles of sustainability is considered integral for bringing change in the existing operations and play the role of a connector in establishing linkage between advancement and sustainability without creating excessive financial burden (Adams et al., 2016). On the other hand, the integration of lean and sustainability can create synergy and harmony in achieving the objectives of the sustainability, although being explored by the researchers; however, their findings are either limited to a certain aspect of sustainability (as mentioned earlier) or the conclusions drawn are inconclusive. In addition, a systematic review by Carvajal-Arango et al. (2019) covering 117 research articles revealed that only 16% of these studied are based on the exploration of the phenomena through interviews and survey methodology. This is one of the potential contributions that the current study intends to fill by exploring the relationships among the studied phenomena through following the survey methodology (discussed in greater detail in Section 3).

Therefore, the current study is an attempt to search for the answers to the following research questions:

RQ1: To what extent sustainable innovation and lean manufacturing practices enhance the levels of the three sustainability aspects (environment, social, and economic)?

RQ2: To what extent sustainable innovation mediates the association between lean manufacturing practices and the three sustainability aspects (environment, social, and economic)?

For drawing the conclusions for the aforementioned research questions, the section comprised the literature review, followed by the methodology, statistical estimations, and outcome, whereas in the end the recommendations are proposed.

2 Literature Review

2.1 Aspects of Sustainability

As already mentioned, through the phenomena of sustainability, the world has been taken by storm since its proposition in 1987 by the “World Commission of Environment and Development” (WCED) (Khodeir and Othman, 2018). Moreover, in accordance with the objectives of the studies, the researchers have been using different aspects of it. For instance, in the context of construction, the findings of Carvajal-Arango et al. (2019) had listed around 27 dimensions, which should be covered within the umbrella of sustainability. However, the majority is of the researchers who categorize, operationalize, consider, and cover only three aspects of sustainability which are social, economic, and environmental, which are also referred as the triple bottom line (TBL) (Elkington, 2013), as validated by numerous researchers (Martínez-Jurado and Moyano-Fuentes, 2014; Resta et al., 2016; Ikram et al., 2021). At the business level, among the available conceptualizations, the concise definition of sustainability is presented by Martínez-Jurado and Moyano-Fuentes (2014); according to them, the sustainability is “meeting the needs of a firm’s direct and indirect stakeholders, without compromising its ability to meet the needs of future stakeholders.” Considering the three predominately studied aspects, the environmental aspect of sustainability covers reduction in the obliteration cause to the ecology by efficient management of resources, waste disposal, energy consumption, and safeguarding of natural resources (Martínez León and Calvo-Amodio, 2017). In addition, the economic aspect covers efficient management and utilization of financial resources, whereas the social aspect covers welfare, wellbeing, and prosperity of all the internal and external stakeholders including employees, customers, society, and so on (Martínez León and Calvo-Amodio, 2017). Despite the consensus among the researchers regarding the three predominately aspects of sustainability, there is still a presence of vacuum in terms of exploration of all these aspects hence required further exploration (Burawat, 2019; Iranmanesh et al., 2019; Singh et al., 2020).

2.2 Process Innovation

Innovation has been considered as an integral element and prerequisite in order to improve value of the organization as well as its performance (Montes et al., 2005; Bowen et al., 2010). However, within the innovation, it is also essential at which level innovation is required so that it tickles down the expenses and expedite the economic condition of the organization (Li et al., 2007). Among them, the level where innovation can be far more beneficial is in the process termed as process innovation (PIN) as through this other innovation can also be triggered, for instance at the product level (Li et al., 2007; Camisón and Villar-López, 2014). Moreover, Oke (2007) also considered PIN as the driving force, which has the capability to improve the manufacturing and related operations resulting in improving the product offerings. Organizations that are progressive and proactive heavily strive in bringing in the PIN so that they can not only just improve their product offerings (Ahmed et al., 2020) but also such offerings tend to improve the other aspects of sustainability (Burki et al., 2018; Jum’a et al., 2022). Hence based on these discussions, it is assumed that when there is PIN it will reduce overconsumption and costs to the environment through which the environmental aspect is improved, reduces the excessive resources through which the financial aspect is improved, and improved the distribution of the all tangible and intangible resources through which the social aspects are improved. Therefore, it is anticipated that

H1: Process innovation enhances the environmental aspect of sustainability;

H2: Process innovation enhances the economic aspect of sustainability;

H3: Process innovation enhances the social aspect of sustainability.

2.3 Lean Manufacturing Practices

The inception of lean manufacturing and its practices was originally made in the automobile industry by the Toyota production system (TPS); however, its benefits and contribution toward profits makes it a standard for every organization to be followed (Jum’a et al., 2022). By the help of this philosophy, the organizations are stimulated to improve their level of productivity within their manufacturing operations and processes (Lee and Jo, 2007). Therefore, researches have listed different practices covering the LMP through which the overall productivity of the organizations can be improved. For instance, according to Vinodh et al. (2011), for LMP, the major processes include implementation of the 5S framework, manufacturing design that follows the cellular layout, maintenance at preventive level, demand management through pull approach, and continuous improvement such as Kaizen, sig sigma, perceptual mapping of the value stream, and so on. On the other hand, Bandehnezhad et al. (2012) have emphasized on the incorporation of human element in it. They urge to include employee engagement, customer satisfaction, supplier integration, and all other relevant sustainable practices that cover the human resources.

Similarly, Godinho Filho et al. (2016), Resta et al. (2016), Iranmanesh et al. (2019), and Dey et al. (2020) have explored different practices that are covered within the philosophy of LMP. Among all of them, the common practices that are validated by majority of the researchers include just-in-time flow, quality management, and employee involvement as they are true representation of maximization of the efficiency during production and the regular elimination of waste (Yang et al., 2011; Jum’a et al., 2022). Precisely, the just-in-time flow is the set of interrelated activities which ensure that only right quantity of material and products are made available, which enables reduction of excessive inventory, elimination of inventory waste, and improves the overall product flow across the manufacturing facility (Yang et al., 2011; Jum’a et al., 2022). In addition, quality management not only just covers the government and monitoring and maintenance of the quality but also assists in improving the processes and operation through the continuous improvement program, which assists in reducing the non-value-added activities (Yang et al., 2011; Jum’a et al., 2022). On the other hand, employee involvement covers the aspect related to human resource, which is actually the back bone of any organization and entails the needs of training, development of procedures that assist in creating systems and processes, development of groups for problem solving, and so on (Yang et al., 2011; Jum’a et al., 2022). Therefore, when all these practices are implemented, it is assumed that there will be a reduction in costs to the environment through which the environmental aspect is improved, reduction in the excessive resources through which the financial aspect is improved, and improvement in the distribution of the all tangible and intangible resources through which the social aspects are improved. Hence, it is anticipated that

H4: Lean manufacturing practices enhances the sustainability-oriented innovation;

H5: Lean manufacturing practices enhances the environmental aspect of sustainability;

H6: Lean manufacturing practices enhances the economic aspect of sustainability;

H7: Lean manufacturing practices enhances the social aspect of sustainability.

2.4 Sustainability-Oriented Innovation

SOI has been explained as the combination of operations and processes that are involved in the development of the product following the principles of sustainability, with an objective to meet the objectives of the organization that covers ecological, financial, and social aspects (Klewitz and Hansen, 2014). In addition, SOI also highlight the areas where an organization need to made changes through the incorporation of practices that are aligned with sustainability, which leads to environmental, financial, and social wellbeing (Adams et al., 2016; Ikram et al., 2020a). Despite the potential benefits brought in by following the principles of sustainability, it is in contrast in terms of its nature when compared with the lean philosophy (De et al., 2020). For instance, in lean, the organization emphasizes on productivity and efficiency, whereas in SOI, it strives for improving responsiveness (Jum’a et al., 2022). However, if they both are implemented within the organization, then the synergy and harmony that is created through the integration can reap multiple sustainable benefits (Dey et al., 2020). In addition, an attempt was made by multiple researchers in explaining the level of association between the SOI and three studied aspects of sustainability (Klewitz and Hansen, 2014; Adams et al., 2016). Therefore, when there is a presence and incorporation of SOI, it is assumed that there will be a reduction in costs to the environment through which the environmental aspect is improved, reduction in the excessive resources through which the financial aspect is improved, and improvement in the distribution of the all tangible and intangible resources through which the social aspects are improved. Hence, it is anticipated that

H8: Sustainability-oriented innovation enhances the environmental aspect of sustainability;

H9: Sustainability-oriented innovation enhances the economic aspect of sustainability;

H10: Sustainability-oriented innovation enhances the social aspect of sustainability.

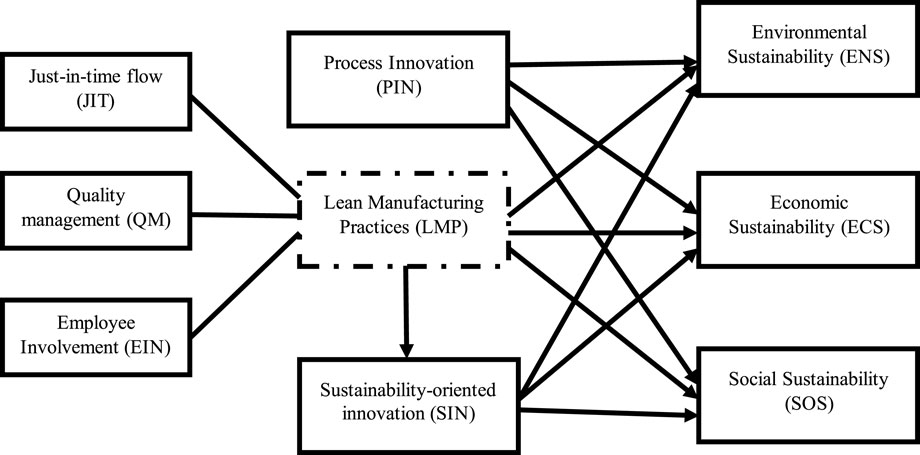

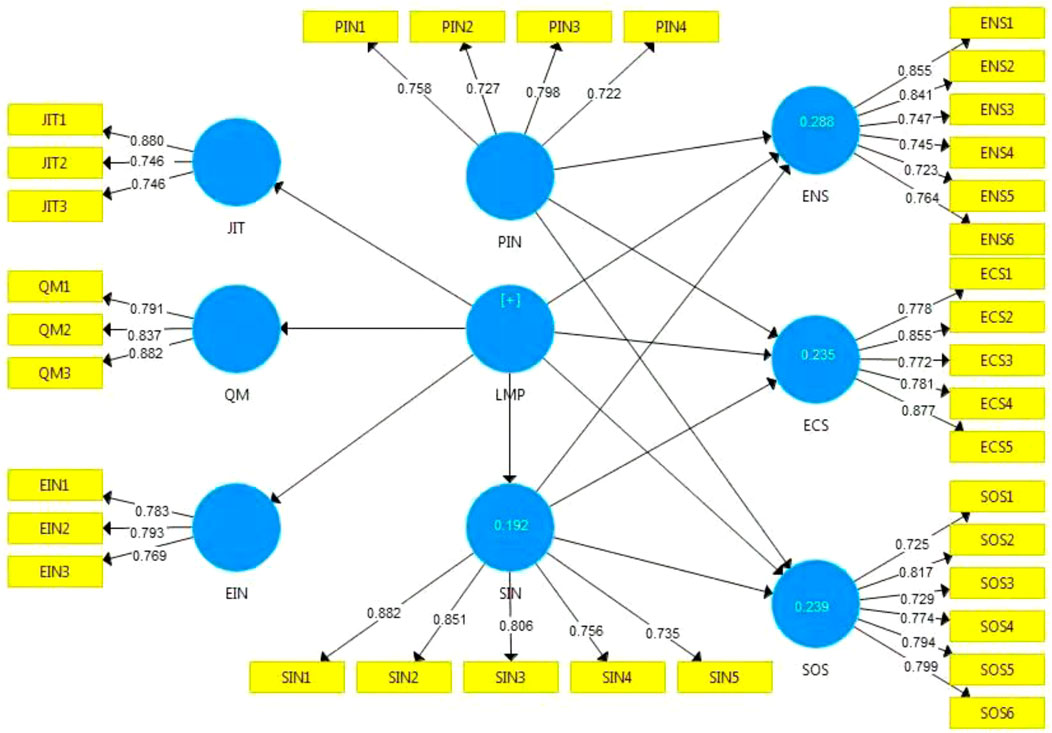

The proposed hypotheses in terms of their relationships are graphically illustrated in Figure 1.

3 Methodology

In the light of the discussed objectives and proposed hypotheses, the most suitable and relevant research approach is the quantitative research approach. This research enables the researchers to reach the logical conclusion from the collected numerical data through the application of statistical analysis, which are relatively more objective when compared to the qualitative methodologies that are extremely subjective. Moreover, within the quantitative research approaches, there are multiple research designs, whereas for the current study, the researchers have chosen a survey research design. This research design enables the researchers to have the data collected through a structured research questionnaire. Through the help of collected data, which is relatively small compared to the whole population, the findings can be generalized to the larger portion of the population (Cooper et al., 2006).

In addition, the quality of the research and the collected data is highly dependent on the research questionnaire that has been used for the data collection purpose. If such research questionnaire contains any ambiguity or errors, the same will be reflected in the outcome generated from the collected data. Therefore, the development of questionnaire is the crucial phase and hence need to be conducted with due care and diligence. Hence, for employing the survey methodology, the guidelines discussed by Hulland et al. (2018) were followed. The developed questionnaire predominantly comprises two sections: section 1, which comprises the questions that are intended to measure the studied phenomena that are shown in Figure 1, whereas the second section comprises questions that are intended to ask for gauging the demographic profiles of the respondents.

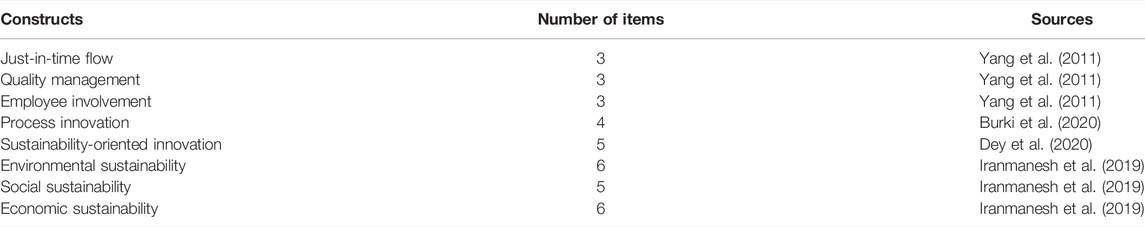

Regarding Section 1, the questions that were asked to measure the studied phenomena were based on the questions that are adapted from the existing literature. As these questions are crucial enough to determine the outcome, it is important to have those scales that have justified their validity in any other geographical context. Hence, the sources and details of the adapted scales are listed in Table 1. It should be noted that all of these questions were measured on the Likert Scales having five points in which “1 represents Strongly Disagree,” “2 represents Disagree,” “3 represents neither Disagree nor Agree,” “4 represents Agree,” and “5 represents Strongly Agree.”

Despite validation being made in the other studied, the face and content validity of these adapted questions were again ensured by a panel of five experts. The panel includes both linguistics and subject experts. The reason for ensuring the face and content validity again is that the current study is conducted on the manufacturing companies of China, where English is not easily understood by the masses. However, since the nature of the study demands to have responses from the qualified professional, a questionnaire being designed in the simple and easy to understand English language, could serve the purpose. Nevertheless, the panel validated the questionnaire as simple and easy to understand and recommended go-ahead data collection.

On the other hand, since environment is the most important aspect of sustainability, therefore for the current study, only those professionals are suited that belong to the manufacturing companies being ISO 14001 certified. This requirement serves as a pre-requisite to qualify for the sample of the current study. Moreover, around 1,000 questionnaire were mailed to the respondents that fit within the objectives of the current study due to the ongoing COVID-19 situation. Therefore, sending questionnaire through email is the best way of data collection. Among them, 490 were returned, which reached the response rate of 49% that is extremely good in the context of studies involving survey methodologies. Among those 490, 59 responses were eliminated as they were identified as univariate and multivariate outliers, following the procedures discussed by Hair et al. (2010). Comrey and Lee (1992) recommended the following scale to determine the adequacy of sample size: (very poor—50), (poor—100), (fair—300), (very good—500), and (excellent—1000 or more). According to this scale, the size of our study sample (431 respondents) falls under the “very good” category, ensuring that the sample is representative for this research.

Among the collected 431 responses, 241 that form 56% of the data were collected from males, whereas the rest 190 that forms 44% of the data were collected from females. The division of data in terms of age includes 141 responses that forms 33% were collected from the group of people having age 30 or less years, 164 responses that forms 38% were collected from the group of people having age 31–40 years, 81 responses that forms 19% were collected from the group of people having age 41–50 years, and 45 responses that forms 10% were collected from the group of people having age 51 and above. In terms of scale and size of the organization in terms of employees, 123 responses that forms 29% were collected from the group of organizations having employees less than 100, 142 responses that forms 33% were collected from the group of organizations having employees between 101–250, 94 responses that forms 22% were collected from the group of organizations having employees between 251–450, and 72 responses that forms 17% were collected from the group of organizations having employees more than 450. In terms of the industry from where the company belongs, 89 responses that forms 21% were collected from the group of the organizations from automobile industry, 161 responses that forms 37% were collected from the group of the organizations from electronics industry, 74 responses that forms 17% were collected from the group of the organizations from chemical industry, 64 responses that forms 15% were collected from the group of the organizations from pharmaceutical industry, and 43 responses that forms 10% were collected from the group of the organizations other than mentioned earlier. The demographic list of final samples is mentioned in Table 2.

In addition, there are certain biases which usually arise in the quantitative studies, and hence need to be ascertained. Such biases lead to inflated variance which can easily deteriorate the quality of generated outcome (Podsakoff et al., 2003). Therefore, following the operational remedies proposed by Podsakoff et al. (2012), the possibility of having the method variance is reduced. In addition, the presence of method variance was also assessed statistically through Harman (1967) single factor test and through the values of correlations among the construct as highlighted in Najmi and Ahmed (2018). Both of the measure negates the presence of method variance. Thus, the current data are apparently found to be free from the methodological unwanted variances.

4 Estimations and Results

In the researches involving complex research frameworks and the objective of maximum explanation of the variance, as the case of the current study is, the application of Partial Least Squares–Structural Equation Modeling (PLS-SEM) is highly recommended (Hair et al., 2019). This is because of the fact that PLS-SEM belongs to the category of second-generation techniques and has the capability to incorporate multiple predictors and criteria in one go. Hence, through the help of SmartPLS software, which is the easiest to handle software having simple interface, the application of PLS-SEM was made possible. In addition, Hair et al. (2016) suggested that the application of PLS-SEM must be done in a dual-step method. In this dual step, the first step covers the assessment of the outer model in which the relationships of the observed variables with the latent variables are being assessed. The second step covers the assessment of the inner model in which the relationships between latent variables are assessed. Once both assessments are done, then the researchers will be in a position to evaluate the proposed hypotheses and their respective relationships. The assessment is discussed in the following sections.

4.1 Assessment of Outer Model

As already discussed, the assessment of the outer model covers the relationships of the observed variables with the latent variables. Within the outer model, the assessment of the relationships between the observed variables with their respective latent variables is termed as convergent validity, whereas the assessment of the relationships between the observed variables of a latent variable with the other latent variables is termed as discriminant validity (Mehmood and Najmi, 2017).

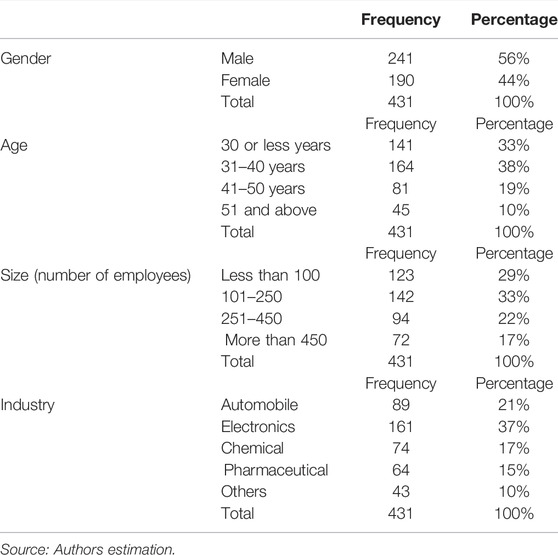

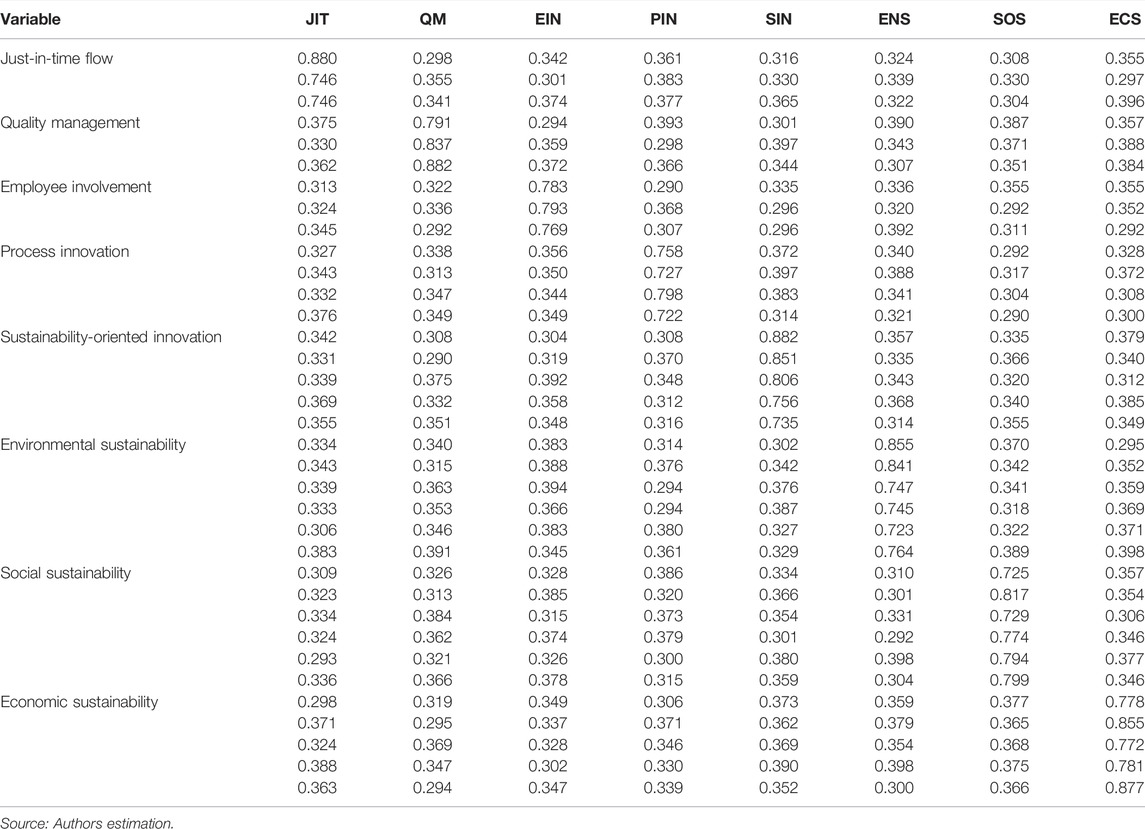

Considering the convergent validity, the current study ensures the presence of convergence by the help of three different parameters, which includes factor loadings, internal consistency (through Cronbach’s Alpha and Composite Reliability), and through the value of average variance extracted (AVE). For factor loadings, the recommendations by Hair et al. (2016) is that it should be larger than 0.7. The values listed in Table 3 clearly shows that the observed values of factor loadings are larger than 0.7. For internal consistency, which is further assessed through Cronbach’s Alpha and Composite Reliability, the recommendations by Hair et al. (2016) is that these should be larger than 0.7. The values listed in Table 3 clearly shows that the observed values of Cronbach’s Alpha and Composite Reliability are larger than 0.7. For AVE, the recommendations by Hair et al. (2016) is that it should be larger than 0.5. The values listed in Table 3 clearly shows that the observed values of AVE are larger than 0.5.

Considering the discriminant validity, this is assessed by three different criteria including cross loadings, Fornell–Larcker criterion, and “Heterotrait–Monotrait ratio of correlations” (HTMT). Cross loading is the representation of a factor loading within a particular construct along with the loadings of this factor into other constructs. Theoretically and statistically, a factor loading of a construct should be highly loaded into its own construct. Moreover, Gefen and Straub (2005) have stated the acceptable difference of a factor loadings into other constructs which is the cross loadings. According to them, the acceptable difference should be higher than 0.1, which is found in the current study as the outcome listed in Table 4.

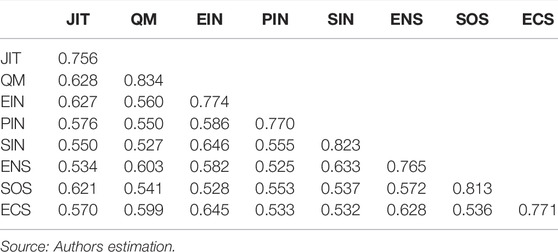

The second criterion is the one which is most commonly applied in the researches assessing discriminant validity and is known as the Fornell and Larcker (1981) criterion proposed by the authors in their own name. As per them, a particular factor’s square root of AVE should be much higher while comparing it with the values of the correlations among the constructs. The outcome mentioned in Table 5 outlines the meeting of the said proposition as the diagonal values are the factor’s square root of AVE, whereas all other values represents correlations among the constructs. The outcome outlined in Table 5 clearly satisfies the meeting of the Fornell and Larcker (1981) criterion.

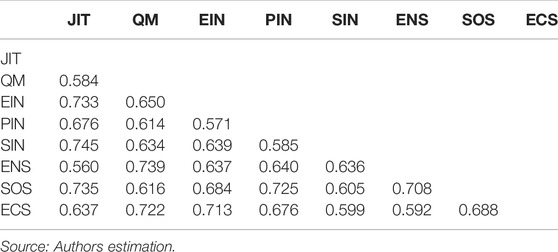

The third and the most recent criteria by which the discriminant validity is assessed in the present study is of HTMT proposed by Henseler et al. (2015). As per this criterion, the value of the HTMT at which there is the establishment of discriminant validity is 0.85; however, any value below one is also considered as acceptable. The outcome outlined in Table 6 clearly satisfies the meeting of the HTMT criterion.

4.2 Assessment of Inner Model

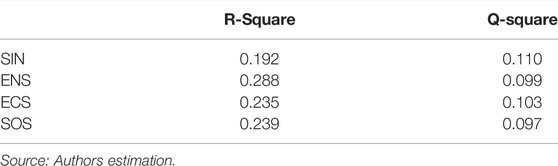

After the assessment of outer model, the second step involves the assessment of inner model in which the relevancy and predictability of the model which is the reflection of the exploration of variance from the dependent variable through the independent variables. The assessment was done through “coefficient of determination” and “Cross-Validated Redundancy” which is gauged through R-Square and Q-Square. Particularly for R-Square, Cohen (1988) stated that it is highly rely on the nature and attributional quality of the independent variable that successfully explain the dependent variable; however, if the value of R-Square is found to be below 0.02 then it is considered as low, whereas if it is found between 0.02 and 0.25 then it is moderate and will be termed as substantial if it is higher than 0.26. On the other hand, for Q-Square which is the reflection of “Cross-Validated Redundancy” is computed through the methodological framework of Stone–Geisser’s value. According to this criterion, any value beyond the number of zero is acceptable for it. The outcome outlined in Table 7 shows the assessment of R-Square and Q-Square criterion.

4.3 Hypotheses Testing

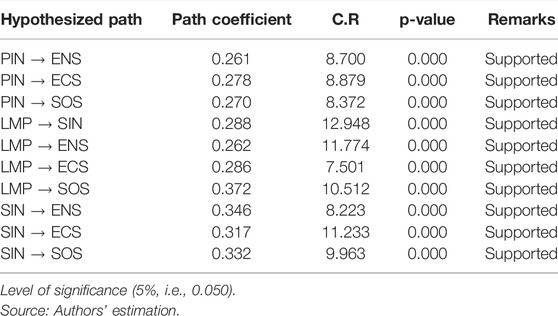

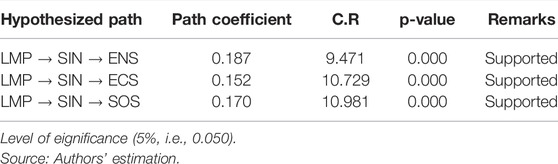

For the computation of significance of the relationship among the variables, the application of PLS-SEM is used because of an edge on the comparative statistical analysis (Figure 2). The edge is because of the significance computation following the framework of bootstrapping. In this methodology, the significance is computed after drawing multiple subsamples from the data set of which Hair et al. (2016) have recommended the number of 5,000 subsamples. Nevertheless, through computing significance after drawing 5,000 subsamples, the legitimacy and reliability of the outcomes is ascertained which is outlined in Table 8.

First, about the relationships of process innovation with the different criterion variables reflecting three aspects of sustainability. For environmental aspect of sustainability, process innovation is reported to affect environmental aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion environmental aspect of sustainability can have by 26.1%, through the level of expansion in the process innovation. This relationship is explained as when organizations improve the processes through the innovation, there will be optimization of the resources and minimization of the waste. As an outcome, there will be a comparatively lesser effect to the environment as process innovation will lead to less consumption of resources causing least possible cost to the environment. For economic aspect of sustainability, process innovation is reported to affect economic aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion economic aspect of sustainability can have by 27.8%, through the level of expansion in the process innovation. This relationship is explained as when organizations improve the processes through the innovation, there will be optimization of the resources and minimization of the waste. As an outcome, there will be a comparatively lesser level of consumption of financial resources. Through this, firms can save the finances which can further be invested in other possible profitable avenues when needed. For social aspect of sustainability, process innovation is reported to affect social aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion social aspect of sustainability can have by 27%, through the level of expansion in the process innovation. This relationship is explained as when organizations improve the processes through the innovation, there will be optimization of the resources and minimization of the waste. As an outcome, firms can realign those resources for the welfare of the society through which firms can improve the social aspect of sustainability.

Second, the relationships of lean manufacturing practices are reflected by three criteria, namely, involvement of the employees, just-in-time flow of the products, and quality management across the manufacturing processes, with the different criterion variables reflecting three aspects of sustainability and sustainable innovation. For sustainable innovation, lean manufacturing practices are reported to affect sustainable innovation positively and significantly at level of significance of 1%. This is the reflection of the level of expansion sustainable innovation can have by 28.8%, through the level of expansion in the lean manufacturing practices. This is because when there is higher level of involvement by the employees and quality management across all of the manufacturing practices, followed by lesser level of inventory due to following the just-in-time approach, organization can have enough room of improvement in terms of sustainable innovation, which is also reflected though the outcome estimated. These findings validate the outcome reported by earlier researchers (Piercy and Rich, 2015; De et al., 2020). For environmental aspect of sustainability, lean manufacturing practices are reported to affect environmental aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion environmental aspect of sustainability can have by 26.2%, through the level of expansion in the lean manufacturing practices. This is because when there is higher level of involvement by the employees and quality management across all of the manufacturing practices, followed by lesser level of inventory due to following the just-in-time approach, organization can reduce the possible environment costs which lead to increase the environmental aspect of sustainability. These findings validate the outcome reported by earlier researchers (Bandehnezhad et al., 2012; Baliga et al., 2019; Dieste et al., 2020).

Moreover, for economic aspect of sustainability, lean manufacturing practices are reported to affect economic aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion economic aspect of sustainability can have by 28.6%, through the level of expansion in the lean manufacturing practices. This is because when there is higher level of involvement by the employees and quality management across all of the manufacturing practices, followed by lesser level of inventory due to following the just-in-time approach, organization can reduce the possible economic costs through taking out the unnecessary finances which lead to increase the economic aspect of sustainability. These findings validate the outcome reported by earlier researchers (Hofer et al., 2012; Dey et al., 2020). Furthermore, for social aspect of sustainability, lean manufacturing practices are reported to affect economic aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion social aspect of sustainability can have by 37.2%, through the level of expansion in the lean manufacturing practices. This is because when there is higher level of involvement by the employees and quality management across all of the manufacturing practices, followed by lesser level of inventory due to following the just-in-time approach, organization can reduce the possible social costs through taking out the unnecessary finances which will be available to be invested for social wellbeing for the employees, society and other relevant stakeholders. These findings validate the outcome reported by earlier researchers (Dey et al., 2020; Singh et al., 2020).

Third about the relationships of sustainable innovation with the different criterion variables reflecting three aspects of sustainability. For environmental aspect of sustainability, sustainable innovation is reported to affect environmental aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion environmental aspect of sustainability can have by 34.6%, through the level of expansion in the sustainable innovation. This relationship is explained as when organizations improves the processes through the innovation keeping in mind the social, ecological and financial aspects, there will be optimization of the resources and minimization of the waste. As an outcome, there will be a comparatively lesser effect to the environment as sustainable innovation will lead to less consumption of resources causing least possible cost to the environment. For economic aspect of sustainability, sustainable innovation is reported to affect economic aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion economic aspect of sustainability can have by 31.7%, through the level of expansion in the sustainable innovation. This relationship is explained as when organizations improves the processes through the social, ecological and financial aspects of innovation, there will be optimization of the resources and minimization of the waste. As an outcome, there will be a comparatively lesser level of consumption of financial resources. Through this, firms can save the finances which can further be invested in other possible profitable social, ecological and financial aspects and avenues when needed. For social aspect of sustainability, sustainable innovation is reported to affect social aspect of sustainability positively and significantly at level of significance of 1%. This is the reflection of the level of expansion social aspect of sustainability can have by 33.2%, through the level of expansion in the sustainable innovation. This relationship is explained as when organizations improves the processes through the social, ecological and financial aspects of innovation, there will be optimization of the resources and minimization of the waste. As an outcome, firms can realign those resources for the welfare of the society through which firms can improve the social aspect of sustainability.

Considering the relationship of sustainable innovation as mediator between lean practices and the three dimensions of sustainability, the sustainable innovation was found to act as the mediator in all of the proposed relationships. In addition, since the both direct and indirect relationships are reportedly found statistically significant therefore, the kind of mediation is said to be partial between predictors, mediator and criterion variables. It means that the presence of sustainable innovation will play a beneficial role for lean practices while transforming them in enhancing all the dimensions of sustainability.

5 Conclusion and Recommendations

Despite plethora of researches exploring lean as the solution for improving productivity, it is limited to the operational aspects only, thus ignoring the other aspects of sustainability. The current study is an attempt and contribution in the existing literature through the sample of 431 respondents from ISO 14001 certified Chinese organizations. The estimations were performed through the Partial Least Squares–Structural Equation Modeling whereas the outcome reported a positive association among the proposed hypothesis of aforementioned studied phenomena. The findings of the present study draw the conclusion that implementation of lean and innovation that comply to the principles of sustainability can significantly enhance all the three levels of sustainability (including environmental, social and economic) among the Chinese firms. Since the SIN is also reported as the partial mediator, it draws the in the presence of LMP, the SIN can enhance the aspects of sustainability.

Considering the LMP which in present study is measured through three subdimensions, which are employee engagement, quality management and just-in-time flow, there are multiple recommendations. For employee engagement, organizations need to look into means by which the level of engagement can be increased. This includes implementation of incentive and reward systems where additional rewards are awarded to the employee contributing to the sustainability of the organizations. Moreover, provision of educational trainings and certifications can also act as the catalyst whereas taking employees on board even at the stage of the product development can also enhance their level of engagement. For quality management, implementation of quality programs like being accredited by internal certifications like ISO 9001 and compliance to the Total Quality Management policies can also make the difference. For just-in-time flow, implementation of systems like Kanban can improve the product flow by reducing the excessive inventory and lead times. For innovation, implementation of green initiatives can increase the level of compliance toward sustainability. This includes implementation of green procurement, green transportation, green warehousing and green logistics. In addition, organizations need to invest in the research and development of the initiatives that comply to the principles of lean as well as sustainability.

In terms of limitations, following are the future research recommendations. Firstly, current study only explores the three subdimensions of lean however, there are several other dimensions as well which includes like 5S, six sigma, value stream mapping and so on. In addition, the current study though based on the sample size which is large but it is based on the companies from China only, hence the generalizability will be issue. Lastly, the current study is among the few limited studies that explores the synergy between lean and sustainability, more empirical survey methodology-based studies are required in order to broaden the literature further.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding authors.

Ethics Statement

The studies involving human participants were reviewed and approved by the Institutional Review Board of Ocean University of China (protocol code 674-3 on 18 October 2021). The patients/participants provided their written informed consent to participate in this study.

Author Contributions

GL: conceptualization, writing—original draft, and methodology. YD: supervision. CW: formal analysis. KG: variable construction. TW: funding acquisition. RS: data handling. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Chinese Society for Technical and Vocational Education. “Research on the History and Contribution of China’s Industrial Development from the Perspective of Industrial Economics” (SZ21D003) and “Research on Increasing Human Capital Investment and Improving the Contribution Rate of Vocational Education” (SZ21D004).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

The authors acknowledge the support of Shandong Academy of Social Sciences for collaborative innovation research on major theoretical and practical issues of social science planning in the Shandong Province in 2020 “Research on the High-Quality Development of Economy Promoted by Finance” (20CCXJ24).

References

Abbasi, K. R., Shahbaz, M., Zhang, J., Irfan, M., and Alvarado, R. (2022). Analyze the Environmental Sustainability Factors of China: The Role of Fossil Fuel Energy and Renewable Energy. Renew. Energ. 187, 390–402. doi:10.1016/j.renene.2022.01.066

Adams, R., Jeanrenaud, S., Bessant, J., Denyer, D., and Overy, P. (2016). Sustainability-Oriented Innovation: A Systematic Review. Int. J. Manag. Rev. 18 (2), 180–205. doi:10.1111/ijmr.12068

Ahmad, B., Da, L., Asif, M. H., Irfan, M., Ali, S., and Akbar, M. I. U. D. (2021). Understanding the Antecedents and Consequences of Service-Sales Ambidexterity: A Motivation-Opportunity-Ability (MOA) Framework. Sustainability 13 (17), 9675. doi:10.3390/su13179675

Ahmed, W., Najmi, A., and Ikram, M. (2020). Steering Firm Performance through Innovative Capabilities: A Contingency Approach to Innovation Management. Technol. Soc. 63, 101385. doi:10.1016/j.techsoc.2020.101385

Ali, S., Yan, Q., Sajjad Hussain, M., Irfan, M., Ahmad, M., Razzaq, A., et al. (2021). Evaluating Green Technology Strategies for the Sustainable Development of Solar Power Projects: Evidence from Pakistan. Sustainability 13 (23), 12997. doi:10.3390/su132312997

Baliga, R., Raut, R. D., and Kamble, S. S. (2019). Sustainable Supply Chain Management Practices and Performance. Manag. Environ. Qual. Int. J. 31 (5), 1147–1182. doi:10.1108/meq-04-2019-0079

Bandehnezhad, M., Zailani, S., and Fernando, Y. (2012). An Empirical Study on the Contribution of Lean Practices to Environmental Performance of the Manufacturing Firms in Northern Region of Malaysia. Int. J. Value Chain Manag. 6 (2), 144. doi:10.1504/ijvcm.2012.048379

Bhardwaj, A., Dagar, V., Khan, M. O., Aggarwal, A., Alvarado, R., Kumar, M., et al. (2022). Smart IoT and Machine Learning-Based Framework for Water Quality Assessment and Device Component Monitoring. Environ. Sci. Pollut. Res., 0123456789. doi:10.1007/s11356-022-19014-3

Bowen, F. E., Rostami, M., and Steel, P. (2010). Timing Is Everything: A Meta-Analysis of the Relationships between Organizational Performance and Innovation. J. Bus. Res. 63 (11), 1179–1185. doi:10.1016/j.jbusres.2009.10.014

Burawat, P. (2019). The Relationships Among Transformational Leadership, Sustainable Leadership, Lean Manufacturing and Sustainability Performance in Thai SMEs Manufacturing Industry. Int. J. Qual. Reliab. Manag. 36 (6), 1014–1036. doi:10.1108/ijqrm-09-2017-0178

Burki, F., Roger, A. J., Brown, M. W., and Simpson, A. G. (2020). The New Tree of Eukaryotes. Trends Ecol. Evol. 35 (1), 43–55.

Burki, U., Ersoy, P., and Dahlstrom, R. (2018). Achieving Triple Bottom Line Performance in Manufacturer-Customer Supply Chains: Evidence from an Emerging Economy. J. Clean. Prod. 197, 1307–1316. doi:10.1016/j.jclepro.2018.06.236

Camisón, C., and Villar-López, A. (2014). Organizational Innovation as an Enabler of Technological Innovation Capabilities and Firm Performance. J. Bus. Res. 67 (1), 2891–2902. doi:10.1016/j.jbusres.2012.06.004

Carvajal-Arango, D., Bahamón-Jaramillo, S., Aristizábal-Monsalve, P., Vásquez-Hernández, A., and Botero, L. F. B. (2019). Relationships between Lean and Sustainable Construction: Positive Impacts of Lean Practices over Sustainability during Construction Phase. J. Clean. Prod. 234, 1322–1337. doi:10.1016/j.jclepro.2019.05.216

Chen, Y.-S., Lai, S.-B., and Wen, C.-T. (2006). The Influence of Green Innovation Performance on Corporate Advantage in Taiwan. J. Bus. Ethics 67 (4), 331–339. doi:10.1007/s10551-006-9025-5

Cohen, J. (1988). Statistical Power Analysis for the Behavioral Sciences 2nd ed. New York: Academic Press.

Comrey, A. L., and Lee, H. B. (1992). A First Course in Factor Analysis. 2nd ed. Hlilsdale, NJ, USA: Lawrence Erlbaum Associates. ISBN 0805810625.

Cooper, D. R., Schindler, P. S., and Sun, J. (2006). Business Research Methods, 9. New York: McGraw-Hill, 1–744.

Dagar, V., Khan, M. K., Alvarado, R., Rehman, A., Irfan, M., Adekoya, O. B., et al. (2021). Impact of Renewable Energy Consumption, Financial Development and Natural Resources on Environmental Degradation in OECD Countries with Dynamic Panel Data. Environ. Sci. Pollut. Res. 29 (12), 18202–18212. doi:10.1007/s11356-021-16861-4

De, D., Chowdhury, S., Dey, P. K., and Ghosh, S. K. (2020). Impact of Lean and Sustainability Oriented Innovation on Sustainability Performance of Small and Medium Sized Enterprises: A Data Envelopment Analysis-Based Framework. Int. J. Prod. Econ. 219, 416–430. doi:10.1016/j.ijpe.2018.07.003

Dey, P. K., Malesios, C., De, D., Chowdhury, S., and Abdelaziz, F. B. (2020). The Impact of Lean Management Practices and Sustainably‐Oriented Innovation on Sustainability Performance of Small and Medium‐Sized Enterprises: Empirical Evidence from the UK. Br. J. Manag. 31 (1), 141–161. doi:10.1111/1467-8551.12388

Dieste, M., Panizzolo, R., and Garza-Reyes, J. A. (2020). Evaluating the Impact of Lean Practices on Environmental Performance: Evidences from Five Manufacturing Companies. Prod. Plann. Control. 31 (9), 739–756. doi:10.1080/09537287.2019.1681535

Elavarasan, R. M., Leoponraj, S., Dheeraj, A., Irfan, M., Sundar, G. G., and Mahesh, G. K. (2021a). PV-Diesel-Hydrogen Fuel Cell Based Grid Connected Configurations for an Institutional Building Using BWM Framework and Cost Optimization Algorithm. Sustain. Energy Technol. Assess. 43, 100934. doi:10.1016/j.seta.2020.100934

Elavarasan, R. M., Pugazhendhi, R., Shafiullah, G. M., Irfan, M., and Anvari-Moghaddam, A. (2021b). A Hover View over Effectual Approaches on Pandemic Management for Sustainable Cities - The Endowment of Prospective Technologies with Revitalization Strategies. Sustain. Cities Soc. 68, 102789. doi:10.1016/j.scs.2021.102789

Elkington, J. (2013). “Enter the Triple Bottom Line,” in The Triple Bottom Line: Does it All Add up, 1–16.

Fornell, C., and Larcker, D. F. (1981). Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 18 (1), 39–50. doi:10.1177/002224378101800104

Gefen, D., and Straub, D. (2005). A Practical Guide to Factorial Validity Using PLS-Graph: Tutorial and Annotated Example. Commun. Assoc. Inf. Syst. 16 (1), 91–105. doi:10.17705/1cais.01605

Godinho Filho, M., Ganga, G. M. D., and Gunasekaran, A. (2016). Lean Manufacturing in Brazilian Small and Medium Enterprises: Implementation and Effect on Performance. Int. J. Prod. Res. 54 (24), 7523–7545. doi:10.1080/00207543.2016.1201606

Hair, J. F., Black, B., Babin, B., and Anderson, R. E. (2010). Multivariate Data Analysis: Global Edition, 7th Edition. Upper Saddle River, NJ: Pearson Prentice Hall.

Hair, J. F., Hult, G. T. M., Ringle, C., and Sarstedt, M. (2016). A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM). Sage Publications.

Hair, J. F., Risher, J. J., Sarstedt, M., and Ringle, C. M. (2019). When to Use and How to Report the Results of PLS-SEM. Eur. Business Rev. 31 (1), 2–24. doi:10.1108/ebr-11-2018-0203

Hao, Z., Liu, C., and Goh, M. (2021). Determining the Effects of Lean Production and Servitization of Manufacturing on Sustainable Performance. Sustainable Prod. Consumption 25, 374–389. doi:10.1016/j.spc.2020.11.018

Hartini, S., and Ciptomulyono, U. (2015). The Relationship between Lean and Sustainable Manufacturing on Performance: Literature Review. Proced. Manufacturing 4, 38–45. doi:10.1016/j.promfg.2015.11.012

Henseler, J., Ringle, C. M., and Sarstedt, M. (2015). A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 43 (1), 115–135. doi:10.1007/s11747-014-0403-8

Herron, C., and Hicks, C. (2008). The Transfer of Selected Lean Manufacturing Techniques from Japanese Automotive Manufacturing into General Manufacturing (UK) through Change Agents. Robot. Comput. Integrated Manuf. 24 (4), 524–531. doi:10.1016/j.rcim.2007.07.014

Hofer, C., Eroglu, C., and Rossiter Hofer, A. (2012). The Effect of Lean Production on Financial Performance: The Mediating Role of Inventory Leanness. Int. J. Prod. Econ. 138 (2), 242–253. doi:10.1016/j.ijpe.2012.03.025

Huang, W., Saydaliev, H. B., Iqbal, W., and Irfan, M. (2022). Measuring the Impact of Economic Policies on Co2 Emissions: Ways to Achieve Green Economic Recovery in the Post-Covid-19 Era. Clim. Change Econ., 2240010. doi:10.1142/s2010007822400103

Hulland, J., Baumgartner, H., and Smith, K. M. (2018). Marketing Survey Research Best Practices: Evidence and Recommendations from a Review of JAMS Articles. J. Acad. Mark. Sci. 46 (1), 92–108. doi:10.1007/s11747-017-0532-y

Ikram, M., Sroufe, R., Rehman, E., Shah, S. Z. A., and Mahmoudi, A. (2020a). Do quality, Environmental, and Social (QES) Certifications Improve International Trade? A Comparative Grey Relation Analysis of Developing vs. Developed Countries. Phys. Stat. Mech. Appl. 545, 123486. doi:10.1016/j.physa.2019.123486

Ikram, M., Zhang, Q., Sroufe, R., and Ferasso, M. (2021). Contribution of Certification Bodies and Sustainability Standards to Sustainable Development Goals: An Integrated Grey Systems Approach. Sustain. Prod. Consum. 28, 326–345. doi:10.1016/j.spc.2021.05.019

Ikram, M., Zhou, P., Shah, S. A. A., and Liu, G. Q. (2019). Do Environmental Management Systems Help Improve Corporate Sustainable Development? Evidence from Manufacturing Companies in Pakistan. J. Clean. Prod. 226, 628–641. doi:10.1016/j.jclepro.2019.03.265

Iranmanesh, M., Zailani, S., Hyun, S., Ali, M., and Kim, K. (2019). Impact of Lean Manufacturing Practices on Firms' Sustainable Performance: Lean Culture as a Moderator. Sustainability 11 (4), 1112. doi:10.3390/su11041112

Irfan, M., Elavarasan, R. M., Ahmad, M., Mohsin, M., Dagar, V., and Hao, Y. (2022). Prioritizing and Overcoming Biomass Energy Barriers: Application of AHP and G-TOPSIS Approaches. Technol. Forecast. Soc. Change 177, 121524. doi:10.1016/j.techfore.2022.121524

Islam, M. M., Irfan, M., Shahbaz, M., and Vo, X. V. (2022). Renewable and Non-renewable Energy Consumption in Bangladesh: the Relative Influencing Profiles of Economic Factors, Urbanization, Physical Infrastructure and Institutional Quality. Renew. Energ. 184, 1130–1149. doi:10.1016/j.renene.2021.12.020

Jum'a, L., Zimon, D., Ikram, M., and Madzík, P. (2022). Towards a Sustainability Paradigm; the Nexus between Lean green Practices, Sustainability-Oriented Innovation and Triple Bottom Line. Int. J. Prod. Econ. 245, 108393. doi:10.1016/j.ijpe.2021.108393

Khan, I., Hou, F., Irfan, M., Zakari, A., and Le, H. P. (2021). Does Energy Trilemma a Driver of Economic Growth? The Roles of Energy Use, Population Growth, and Financial Development. Renew. Sustain. Energ. Rev. 146, 111157. doi:10.1016/j.rser.2021.111157

Khodeir, L. M., and Othman, R. (2018). Examining the Interaction between Lean and Sustainability Principles in the Management Process of AEC Industry. Ain Shams Eng. J. 9 (4), 1627–1634. doi:10.1016/j.asej.2016.12.005

Khurana, S., Haleem, A., Luthra, S., and Mannan, B. (2021). Evaluating Critical Factors to Implement Sustainable Oriented Innovation Practices: An Analysis of Micro, Small, and Medium Manufacturing Enterprises. J. Clean. Prod. 285, 125377. doi:10.1016/j.jclepro.2020.125377

Klewitz, J., and Hansen, E. G. (2014). Sustainability-Oriented Innovation of SMEs: A Systematic Review. J. Clean. Prod. 65, 57–75. doi:10.1016/j.jclepro.2013.07.017

Lee, B.-H., and Jo, H.-J. (2007). The Mutation of the Toyota Production System: Adapting the TPS at Hyundai Motor Company. Int. J. Prod. Res. 45 (16), 3665–3679. doi:10.1080/00207540701223493

Li, Y., Wang, J., Li, X., and Zhao, W. (2007). Design Creativity in Product Innovation. Int. J. Adv. Manuf. Technol. 33 (3), 213–222. doi:10.1007/s00170-006-0457-y

Liu, C. C., Niu, Z. W., and Li, Q. L. (2020). The Impact of Lean Practices on Performance: Based on Meta-Analysis and Bayesian Network. Total Qual. Manag. Bus. Excel. 31 (11–12), 1225–1242. doi:10.1080/14783363.2018.1471352

Martínez León, H. C., and Calvo-Amodio, J. (2017). Towards Lean for Sustainability: Understanding the Interrelationships between Lean and Sustainability from a Systems Thinking Perspective. J. Clean. Prod. 142, 4384–4402. doi:10.1016/j.jclepro.2016.11.132

Martínez-Jurado, P. J., and Moyano-Fuentes, J. (2014). Lean Management, Supply Chain Management and Sustainability: A Literature Review. J. Clean. Prod. 85, 134–150. doi:10.1016/j.jclepro.2013.09.042

Mehmood, S. M., and Najmi, A. (2017). Understanding the Impact of Service Convenience on Customer Satisfaction in Home Delivery: Evidence from Pakistan. Int. J. Electron. Cust. Relatsh. Manag. 11 (1), 23–43. doi:10.1504/ijecrm.2017.10007745

Montes, F. J. L., Moreno, A. R., and Morales, V. G. (2005). Influence of Support Leadership and Teamwork Cohesion on Organizational Learning, Innovation and Performance: An Empirical Examination. Technovation 25 (10), 1159–1172. doi:10.1016/j.technovation.2004.05.002

Najmi, A., and Ahmed, W. (2018). Assessing Channel Quality to Measure Customers' Outcome in Online Purchasing. Int. J. Electron. Cust. Relatsh. Manag. 11 (2), 179–201. doi:10.1504/ijecrm.2018.10011240

Oke, A. (2007). Innovation Types and Innovation Management Practices in Service Companies. Int. J. Operations Prod. Manage. 27 (6), 564–587. doi:10.1108/01443570710750268

Piercy, N., and Rich, N. (2015). The Relationship between Lean Operations and Sustainable Operations. Int. J. Oper. Prod. Manag. 35 (2), 282–315. doi:10.1108/ijopm-03-2014-0143

Podsakoff, P. M., MacKenzie, S. B., Lee, J.-Y., and Podsakoff, N. P. (2003). Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 88 (5), 879–903. doi:10.1037/0021-9010.88.5.879

Podsakoff, P. M., MacKenzie, S. B., and Podsakoff, N. P. (2012). Sources of Method Bias in Social Science Research and Recommendations on How to Control it. Annu. Rev. Psychol. 63, 539–569. doi:10.1146/annurev-psych-120710-100452

Rauf, A., Ozturk, I., Ahmad, F., Shehzad, K., Chandiao, A. A., Irfan, M., et al. (2021). Do Tourism Development, Energy Consumption and Transportation Demolish Sustainable Environments? Evidence from Chinese Provinces. Sustainability 13 (22), 12361. doi:10.3390/su132212361

Razzaq, A., Ajaz, T., Li, J. C., Irfan, M., and Suksatan, W. (2021). Investigating the Asymmetric Linkages between Infrastructure Development, Green Innovation, and Consumption-Based Material Footprint: Novel Empirical Estimations from Highly Resource-Consuming Economies. Resour. Pol. 74, 102302. doi:10.1016/j.resourpol.2021.102302

Reich-Weiser, C., and Dornfeld, D. A. (2009). A Discussion of Greenhouse Gas Emission Tradeoffs and Water Scarcity within the Supply Chain. J. Manuf. Syst. 28 (1), 23–27. doi:10.1016/j.jmsy.2009.04.002

Resta, B., Dotti, S., Gaiardelli, P., and Boffelli, A. (2016). “Lean Manufacturing and Sustainability: an Integrated View,” in Advances in Production Management Systems. Initiatives for a Sustainable World. Editors I. Nääs, O. Vendrametto, J. Mendes Reis, R.F. Gonçalves, M.T. Silva, G. von Cieminskiet al. (Cham: Springer International Publishing), 488, 659–666. doi:10.1007/978-3-319-51133-7_78

Singh, J., Singh, H., and Kumar, A. (2020). Impact of Lean Practices on Organizational Sustainability through green Supply Chain Management – an Empirical Investigation. Int. J. Lean Six Sigma 11 (6), 1049–1082. doi:10.1108/ijlss-06-2017-0068

Stamenkov, G., and Dika, Z. (2019). Quo Vadis, (e-)Service Quality? Towards a Sustainability Paradigm. Total Qual. Manag. Bus. Excel. 30 (7–8), 792–807. doi:10.1080/14783363.2017.1338521

Tang, C., Irfan, M., Razzaq, A., and Dagar, V. (2022). Natural Resources and Financial Development: Role of Business Regulations in Testing the Resource-Curse Hypothesis in ASEAN Countries. Resour. Pol. 76, 102612. doi:10.1016/j.resourpol.2022.102612

The United Nation Global Compact (2016). EY and UN Collaborate on Climate Change and Supply Chain Study. Available at: http://www.scmr.com/article/ey_and_un_collaborate_on_climate_change_and_supply_chain_study (Accessed February 22, 2022).

Thoo, A. C., Abdul Hamid, A. B., Rasli, A., and Zhang, D. W. (2013). The Moderating Effect of Enviropreneurship on Green Supply Chain Management Practices and Sustainability Performance. Adv. Mater. Res. 869-870, 773–776. doi:10.4028/www.scientific.net/amr.869-870.773

Vinodh, S., Arvind, K. R., and Somanaathan, M. (2011). Tools and Techniques for Enabling Sustainability through Lean Initiatives. Clean. Technol. Environ. Pol. 13 (3), 469–479. doi:10.1007/s10098-010-0329-x

Wu, H., Ba, N., Ren, S., Xu, L., Chai, J., Irfan, M., et al. (2021). The Impact of Internet Development on the Health of Chinese Residents: Transmission Mechanisms and Empirical Tests. Socio-Economic Plann. Sci., 101178. doi:10.1016/j.seps.2021.101178

Yang, M. G., Hong, P., and Modi, S. B. (2011). Impact of Lean Manufacturing and Environmental Management on Business Performance: An Empirical Study of Manufacturing Firms. Int. J. Prod. Econ. 129 (2), 251–261. doi:10.1016/j.ijpe.2010.10.017

Keywords: lean practices, innovation, sustainability, environment, economic, social

Citation: Liu G, Ding Y, Wen C, Gao K, Wang T and Sun R (2022) Understanding the Role of Sustainable-Oriented and Process Innovation With Lean Practices in Achieving Sustainability Paradigm: A Chinese Perspective. Front. Environ. Sci. 10:905112. doi: 10.3389/fenvs.2022.905112

Received: 26 March 2022; Accepted: 12 April 2022;

Published: 10 May 2022.

Edited by:

Muhammad Irfan, Beijing Institute of Technology, ChinaReviewed by:

Kiran Batool, North China Electric Power University, ChinaArooj Fatima, Yanshan University, China

Copyright © 2022 Liu, Ding, Wen, Gao, Wang and Sun. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yuan Ding, NDk3MDY3MTNAcXEuY29t; Ke Gao, Y2hlbi53ZW5Ad3V0bC5lZHU=; Chen Wen, Z2tmbHlAMTI2LmNvbQ==

Guodong Liu1

Guodong Liu1 Ke Gao

Ke Gao