- 1Belt and Road Initiative Institute for Chinese-European Studies (BRIICES), Guangdong University of Petrochemical Technology, Maoming, China

- 2Department of Economy and Economic Cybernetics, Dnipro University of Technology, Dnipro, Ukraine

- 3Department of Mining Engineering and Education, Dnipro University of Technology, Dnipro, Ukraine

- 4Branch for Physics of Mining Processes, Institute of Geotechnical Mechanics Named by N. Poljakov, Dnipro, Ukraine

The purpose of this paper is to propose a new methodological approach to complex assessment of coal-mining enterprises basing on the evaluation of technological schemes from the viewpoint of their susceptibility to innovations. To solve the specified problems, a complex method has been used. The method involves geometrical interpretation of a task of determining boundary parameters of technological schemes, application of criteria-based estimations for determining a level of production efficiency, and use of complex index of economic re liability. For the first time, optimality criteria for innovation management in coal industry have been proposed; they take into consideration a level of organization of innovations, organization of innovative production system, and organization of innovative production process. A complex index “internal potential of technological networks” has been developed, being one of the essential parameters for evaluating coal mine conditions. It has been identified that its formation is the result of the influence of certain factors determining the underground mining efficiency and, first of all, the coal mine property—spatial development. According to the represented concept, a policy of optimal control for maintaining the operating mine capacities is based on the evaluation of remained reserves, substantiated planning of a stoping line, and correspondence of extraction equipment to the operating conditions. It is possible to increase the concentration of production by redistributing the remained reserves and integration of mines by mining operations; that makes it possible to concentrate resources within those parts of a mine field where the effect will show its maximum. Modelling of such problems is based on a system of constraints without any requirements for providing the planned mine loading, obligatory in the past. Analysis of the indices of efficiency of coal-mining technological schemes and accounting of the developed factual system of indices have helped elaborate recommendations concerning the use of optimality criteria in the organizational tasks of assessment of the potential of technological scheme of mines. Further application of graphs and network models will allow optimizing the mining production parameters. Consequently, the carried out research has resulted in a new system as for innovation management in a mining complex.

Introduction

The mining of mineral resources is considered an important issue to natural resources management and resource-saving sustainability (Kashan et al., 2022; Koval et al., 2021; Tampubolon et al., 2021). At the same time using non-traditional and renewable energy sources are extremely important nowadays (Gawusu et al., 2022; Ostapenko et al., 2022), especially in modern terms of decarbonization (Savina et al., 2021; Vatalis et al., 2022; Ćorović et al., 2022). The energy sector of industry development needs more mineral resources for energy generation that is, mined out from Earth subsoil. At the same time, the innovative development of mining technologies is also driven by the need for saturation of the long-term demand for raw materials (IlyashovDiedich et al., 2019; Zhironkin and Cehlár, 2021).

Nowadays, fuel and energy complex of Ukraine is facing certain crises: grown prime costs, worn-out main facilities, unsatisfactory infrastructure conditions—all these negative phenomena have resulted in the uncontrolled closure of production facilities (Melnyk, 2018; Koveria et al., 2019; Dergachova et al., 2020; Petrochenko et al., 2021). The majority of enterprises have already worked out their working lifespan. Besides, today we observed inadequate technological conditions as no levels were opened in 1990s; as a result, a network of mine workings is rather long that influences the time of mineral transportation to the surface and mining prime cost. In other words, purchase of more advanced means of mechanization or improvement of mining techniques do not lead to the improved economic activity of an enterprise (Conteh and Maconachie, 2021; Rozin, 2021). There is a problem of “heritage,” i.e., general technical and economic indices depend on decision-making at all historical stages of development (Ursul et al., 2017; Haiko et al., 2019; Bazaluk, 2021; Brovender et al., 2021). There is also no scientifically substantiated system of decision making at the design stage (Dychkovskyi et al., 2018a; Kopacz et al., 2019; Dychkovskyi et al., 2020).

Decisions are usually made on the basis of previous experience (Fedorov et al., 2020; Kryshtanovych et al., 2021). In addition, crisis phenomena are stipulated by very unprofitable enterprises in the structure of associations or ministries. Currently, there is a practice when there is one effective and three-four very unprofitable mines within one association (Pavlenko et al., 2007; Dychkovskyi et al., 2013). The “effective” mine activity supports the life of the “ineffective” ones. “Effective” means totality of technical and economic indices of the company operation, in terms of which it has a breakeven production level. In the context of current paper, we analyze the mines from the viewpoint of economic effectiveness. Effectiveness is the ratio of the consumed resources to the obtained effect. Thus, we understand “effective” mine as such indices of economic activity of an enterprise, at which a breakeven production level is possible. “Ineffective” mine is the one, which costs for mineral mining are higher than the earned profit. Basing on the previous studies carried out by the authors of this paper, it has been determined that under Ukrainian conditions the breakeven production level is about 1000 thousand t/day from one production unit.

Due to military actions at the territory of Donbas, Ukraine has lost 63% of coal-mining enterprises. The companies being at the territory controlled by Ukraine are in the unsatisfactory technical and economic state: operating period of 28% of enterprises is more than 70 years; 84% of enterprises operate without any reconstruction. All that has resulted in the fact that 56% of mines are very unprofitable, 10%—rather unprofitable, 16%—unprofitable, 10%—breakeven, and 8%—profitable. State-owned enteprises bring output to the design figures only by 59.5%; private-ownership enterprises—by 80.7%. Average annual mine production is 258 thousand t/year that corresponds to the lower limit, at which uncontrolled phasedown of production facilities is observed (Petlovanyi et al., 2018; Nehrii et al., 2019; Horoshkova et al., 2020; Kobylianskyi and Mуkhalchenko, 2020).

Analysis of negative tendencies occurred in the national fuel and energy complex (Bondarenko et al., 2010; Pivniak et al., 2012; Gorova et al., 2013; Petlovanyi et al., 2018) helps conclude that currently there is no system for complex evaluation of coal mines. This situation is peculiar not only for Ukraine but also for a coal-mining complex in all countries. That is, why the indicated study is of certain interest. That is, explained by multifactor nature of the parameters that should be considered as well as by different origin and degree of influence of the parameters on the overall process efficiency. Thus, it is required to consider comprehensively the parameters and develop the approaches. Irrespective of the country, there are certain negative tendencies peculiar for a coal-mining complex. They are manifested in wear of main production assets, increasing capital costs for production, reducing costs for mineral transportation (due to growing distance between mine workings). In the long-term prospects, these tendencies result in the increased prime cost of mining and reduced labour productivity per one worker. The tendencies arisen in the country show that there is a transition to stimulation of the most efficient enterprises as there is certain lack of finances for supporting the obsolete facilities; thus, it is necessary to develop a complex methodology for evaluating the coal mine state. Innovation management of enterprises is the basis for solving these problems that will help overcome crisis phenomena (Saik et al., 2018; Petrov et al., 2021). As indicated in references (Galiyev et al., 2019; Galiyev et al., 2020; Uteshov et al., 2021) the digitalization of technological and organizational processes of mining operations due to the implementation of the installation system and accounting the key indicators is more than important.

Consequently, stabilization of the field situation requires answering several questions: What is the efficiency index of a technological scheme? What parameters determine the production efficiency? What are the criteria of optimality of innovation management for organizational tasks? How can we evaluate comprehensively the enterprise activity and transfer to the distribution of investment level? Our study is devoted to the answers for these questions. Solution of the mentioned problems will allow developing a new approach to the evaluation of the efficiency of current company conditions. Use of the research results will help carry out complex estimation of the production conditions, single out the most promising enterprises requiring state support, and identify a subsidy level. Consequently, development of a new approach to the innovation management at coal mines basing on the evaluation of technological schemes and their susceptibility to innovations is rather a topical scientific problem requiring certain solutions.

Basing on the research topicality, it is necessary to analyze main scientific papers concerning innovative activity in the sphere of mining management. It should be noted that we consider innovation management as an instrument for the increase in investment allocation efficiency, optimization of technological processes, and improvement of production reliability that is, impossible without integrated enterprise assessment. Final results of the innovation management will be represented by complex involvement of the available enterprise resources as well as growth of production efficiency from the raised investment.

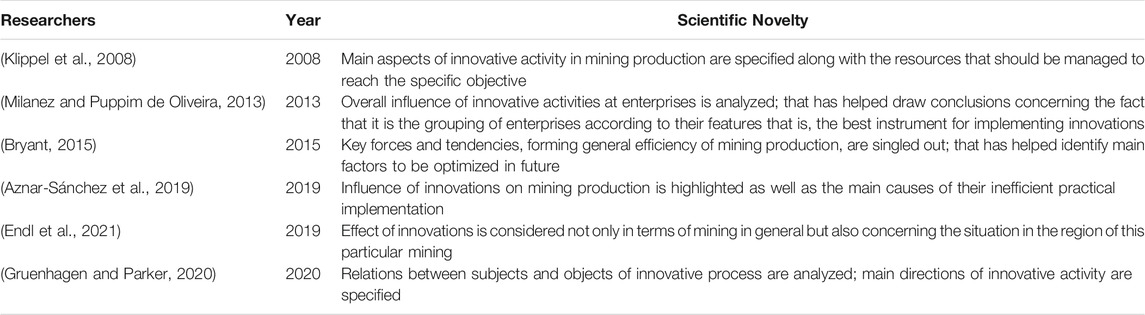

Table 1 represents integrated analysis of the publications dealing with innovation management in mining industry. It should be stressed that analysis of these papers is used to identify main factors and criteria to be optimized.

TABLE 1. Analysis of publications dealing with innovation management and influence of innovations on the mining efficiency.

Analysis of papers (Klippel et al., 2008; Milanez and Puppim de Oliveira, 2013; Bryant, 2015; Aznar-Sánchez et al., 2019; Gruenhagen and Parker, 2020; Endl et al., 2021) makes it possible to elaborate the main methodological approaches for solving a problem of effective representation of innovative activity in mining:

– key “moving forces” and factors determining the efficiency of mining production should be identified; —main constraints effecting the total production efficiency should be defined; —while studying the effect of innovations on final production efficiency, all factors should be considered holistically; —it is necessary to take into account a degree of enterprise involvedness into the regional economy as well as the relation between the enterprises, which extract the similar raw material; —one should propose a comprehensive method for estimating the coal enterprise conditions.

It is clear that integrated and, what is more important, real assessment of the operating enterprises, is the key for effective implementation of innovations. Analyze the main approaches to the evaluation of coal enterprises (Table 2). That will help formulate the key requirements for the development of the own assessment.

Conditionally, the main approaches to evaluation of coal-mining complexes are classified as for target function, i.e., end result of the method. According to it, approaches are divided into informative and optimization ones. Optimization approaches make it possible to minimize (maximize) a value of the parameter taken as the effectiveness criteria; informative approaches allow getting information on the behaviour (strategy) that results in the effectiveness growth. In other words, while applying optimization approaches, it is possible to obtain optimal solution from the viewpoint of a quantitative parameter; and while using informative approaches, it is a qualitative parameter. An optimization approach is characterized by application of quantitative criteria. An informative approach is peculiar by using estimations.

Before elaborating the requirements for decision-making instruments and moving on to the statement of the research methodology, an approach should be selected: optimization of informative one? The informative approach (MCDA, PROMETHEE, ELECTRE, VICOR) means application of evaluations. In this context, evaluation involves determination of the area of the decision being made. In other words, prior to decision making, one should identify the value of the parameter, at which decision is satisfactory (it is called a “prevailing” level). For instance, a mine will be effective, which mining indices are more than 1000 thousand t/day from one production unit. In this context, in Ukraine the mining indices are within the range of 500–3,000 t/day from one production unit. Therefore, while using the informative approach, 6 Lines 6% of the mining indices will be prevailing. Apart from that, these mining indices are characteristic only for Ukraine; in other countries they are a sequence higher (Poland—6000 thousand t/day, the USA—25 thousand t/day). Relying on the fact that the use of informative approaches does not allow getting unambiguous answer as for the operation indices and these approaches are not universal, they cannot be used for the operating enterprises. However, it should be noted that the informative methods are rather effective at the design stage. We believe that current coal-mining enterprise management should apply numerical indicators. That will help optimize the indices of production activities and make the approach universal—without relation to one specific country.

Thus, analysis of papers (Iphar and Goktan, 2006; Abdel Sabour and Dimitrakopoulos, 2011; Bakhtavar et al., 2012; Gonen et al., 2012; Betrie et al., 2013; Krzak, 2013; Hrinov and Khorolskyi, 2018; Zhang et al., 2018) has allowed formulating main requirements for the decision-making instruments:

– firstly, the indicated instruments should consider the parameters of mine working networks, operating conditions, and available constraints; —secondly, the specified instrument should be complex and dimensionless that will allow its using for a group of enterprises; —thirdly, reliability of production, i.e., ability of a coal-mining enterprise to provide the indicated production level in terms of preset constraints, is the main criterion responsible for the efficiency of innovation implementations (Khorolskyi et al., 2019); —fourthly, it is necessary to model the performance representation according to the raised investments.

Therefore, the performed analysis has helped identify that without involving of innovations, the industry is doomed to disappear. A key to overcome crisis is innovative activities in the sphere of mining production management; in its turn, that requires developing new instruments and approaches. To do that, one should elaborate complex assessment of a coal enterprise that will help identify the investment volumes and order of their financing into an enterprise. All that things form scientific and practical value of the research.

The proposed research is the first to put emphasis on the innovative activity in the process of mining production management that is, in identification of criteria and constraints concerning a solution of organizational problems. A characteristic feature of the identified approach is evaluation of a technological scheme that considers not only state of funds and operating conditions but also a level of concentration of operations and spatial development of a technological scheme. To do that, the criteria of production efficiency are developed as well as the ones of production management optimality. Solution of the mentioned problems will make it possible to propose an integral assessment of the level of coal mines and determine the level of investment allocation in terms of fuel and energy complex.

Consequently, the authors of the paper are trying to study the dependence of regularities of changes in mining growth on the innovative activity by attracting investments taking into account the level of economic reliability of a coal enterprise; that will allow developing an approach for determining the investment level for a group of mines in terms of one legal entity.

To solve the specified problem, it is necessary to:

1) Identify characteristics of production efficiency. Analysis of the efficiency indices of coal-mining technological schemes and accounting of actual system of the obtained parameters make it possible to elaborate recommendations for using optimality criteria in the organizational tasks aimed at estimating the potential of a technological scheme.

2) Propose a complex index that assesses a general level of concentration of company’s operations in space. It will be the basis for identifying optimal parameters, which common effect helps specify the boundary, up to which deterioration of technical and economic indices of mines is possible.

3) Develop a complex index for evaluating a level of raised investments that will help identify the most prospective enterprises in terms of one legal entity.

Methodology

Components of Forming the Potential of Technological Networks of Mines

Forming the potential of technological mine networks is a symbiosis of the factors of a level of concentration of mining operations, ventilation stability, and influence on the formation of company’s production flows. Each of the factors is characterized by one of the parameters: “ratio of the capacity of technological links,” “limitation of the capacity in terms of ‘ventilation’ criteria,” and “density of production flows,” respectively. Optimization of a target index “technical and economic stability of a mine’s technological network,” characterizing its potential to innovations, is the result of interaction of these factors and the second-order factors, which determine formation of several key parameters. It can be stated that the technological network stability is the ability to preserve its integrity and mission of coal product supplier and ability to function in the specified mode under uncertainty of internal and external factors, while preserving its capacity in terms of simple or expanded representation.

It is obvious that all factors influencing the level of technological network potential are synthetic, formed as a result of interaction of numerous manifestations of a natural component as well as production and economic activity of a mine. Practically all factors describing the mining-geological conditions (mostly, technological conditions of mining) depend on the specifics of mine activity and its branch belonging that stipulated the availability of not only functional relations between the factors, while forming a potential, but also the analytic ones, which are quite essential. Identification of those relations will make it possible to find out the internal components of technical potential that form immediately the technical potential of a topological mine network. Thus, one can argue that technical potential of a technological network of mines is stipulated by numerous simultaneous and interconnected factors of both first and second, third, and further orders.

Thus, we have identified that technical potential of a technological network of mines is formed by the set of parameters; and their effect on the potential should be determined by means of statistical analysis. Application of this method will help define the dependence between the technical potential index and a set of indices describing both production and economic activity of a mine. In this context, it should be pointed out that obtaining of analytical expression of the “technical potential” index requires determination of the effect of mining-geological, technological, and factorial features. That is, implemented by representing the indicated parameter in the form of integral assessment of the innovative level of a technological network of mines; approaches of optimal programming and criteria of decision-making under uncertainty are applied as the instruments.

The initial parameters forming “technical potential” are as follows: level of concentration of mining operations (L) characterizing a degree of mining concentration of the indicated mineral; labour productivity of a mining worker (P), monthly advance of a stope (longwall) (V), prime cost of mining 1t of a mineral (in our case, it is coal) (S).

To characterize a level of concentration of operations in the fields that manufacture one product type, natural indices are used. For instance, in the electric-power industry it is average specified power of electric stations in kilowatts, annual generation of electric energy—per one electric station, specific weight of electric energy generated by small and the largest electric stations—in general amount of electric energy generated by all stations per year. In our case, we mean production concentration as a level of development of production facilities of a mine. That is, a dimensionless criterion varying from 0 to 1. At value “1,” an enterprise uses its production facilities at 100%.

The “technological scheme potential” category is used mostly while considering certain regions. The increased mining and improved technical and economic indices can be reached differently: by constructing other mines and reconstructing or even closing the operating mines. For the region, the notion of “technological scheme potential” is getting its new meaning; in this case, we can speak about the development, one of which elements is modernization of some mines and concentration and intensification of production, closely connected with it.

As is known, main property of a coal mine determining all elements of its operations is its development in space. This feature is of objective nature as it is stipulated by fundamentality of coal property—its non-regenerability. The development rate is determined by human activity and depends on numerous factors, i.e., level of scientific and technical progress, but the necessity of development is natural and cannot be excluded or replaced by something, even if the technology of a production process is changed somehow.

Some definitions should be introduced:

Spatial development of mines is the change in mine working location, i.e., distancing from the central shafts along the strike and vertical lowering from the level. This parameter is necessary to describe changes of mine working configurations in all three dimensions. It should be noted that for a long time changes in configuration can take place mostly horizontally while vertically it remains the same; or it can change only in two directions.

Internal potential of a technological system is the integral index, which is the integral assessment of mine potential in terms of innovations.

Labour productivity of a worker, monthly advance of a stope, prime cost of 1t of extracted raw material were determined basing on the obtained data incoming from anthracite mines of DTEK Rovenkiantratsit PJSC, DTEK Sverdlovantratsit PJSC, Donbasantratsit SE. The time frame of the research is from 2010 up to the beginning of military actions on the East of Ukraine.

Developing an Economic and Mathematical Model of Technical Potential of a Coal Mine

Technical potential of a coal mine can be described by the equation of multiple regression (1). To construct the equation, a method of step-by-step inclusion of variables is applied:

where

It is clear that reaching a maximum value depends, above all, on the ratio of values

Physical sense of the proposed economic and mathematical model is reduced to the following—optimal value of a target function is possible in terms of minimal concentration of mining operations and minimal prime cost of mining; in this context, productivity and advance of a stope should reach their maximum. In other words, one should find a balance between the ratio of values

To solve a problem (2), one should apply simulation systems that can be determined by Pareto method (Dychkovskyi et al., 2018b). There is the following feature of these systems: it is impossible to determine extremum for them, but one can find “Pareto optimum” characterizing the situation improvement (Kursunoglu and Onder, 2015).

To set the priority of influencing the parameters of production and economic mine activity, it is required to compare the obtained (factual) values of indices with the optimal indices obtained while solving a system of Eqs 1, 2. Then, the essence of implementation of economic potential of a mine is in representation of the identified optimal technological parameters of coal mines. In other words, a technological scheme of a mine becomes susceptible to innovations in terms of reaching boundary (reference) values of optimizing parameters that characterizes complete fulfilment of economic potential.

When a model for technological potential assessment is developed, it is time to determine the factors favouring the implementation of the present level. Only after that one can go on to their optimization and regulation of a technological cycle.

After that, we can move on to determining the production.

Developing a Model of Production Efficiency Evaluation at a Coal Mine

In a general case, production is considered in the form of certain number of people M, who are involved in coal mining in A volume with the preset quality (in our case, ash content) α (Salli et al., 2014) with the help of machines N, during the determined time T in terms of attracted resources in K amount, funds for remuneration for workers, and machine operation S. Moreover, to represent the parameters, it is necessary to have favourable working conditions expressed by the ratio of general working capacity of personnel ∑R to general working capacity of machines ∑q.

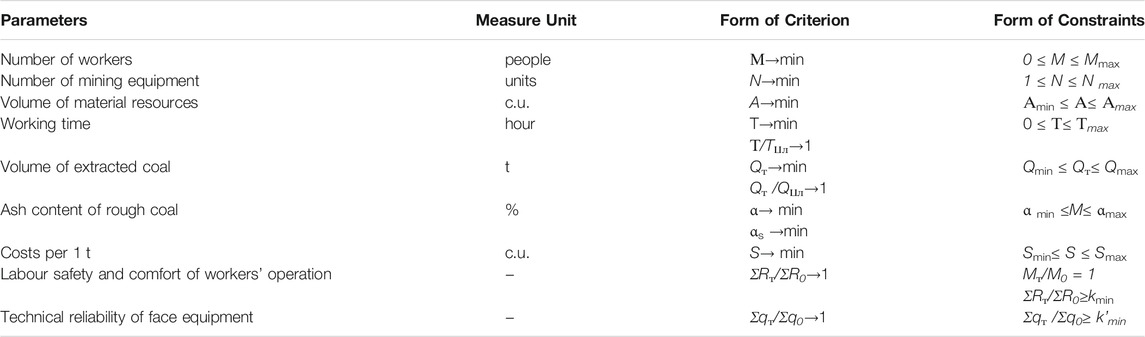

If the parameter depends on the operating conditions as well as on the problem purpose and if it can be optimized in this context, then it can be taken as the characteristic of coal mining efficiency (Table 3). It should be mentioned that the characteristics can be either constant or variable. If the characteristics fluctuate within some period of time, they are variable.

However, a series of clarifications while task setting should be given:

1. Number of workers, number of mining equipment, volume of material resources, working time (M, N, A, T) are the criteria that should be minimized; however, condition Qт≥Qп, should be met, i.e., the volume of extracted coal is more than the planned one. To reach that, one should save resources spent for extraction. Practically, this situation is possible when the stocks are transferred to other enterprise or when mines are united by mining operations.

2. Indices ΣR and Σq can be used as the criteria but they have no point in case of active coal mining operations.

3. Indices Qт, α, S can be applied as characteristics of production but they are cardinally different in their essence. Index of mining volumes Qт can be maximized only at the obtaining of required constraints with resources, ash content of coal, working cycle indices (technological reliability, coefficient of operation, labour safety). That is, when planning the production it is better to consider the index of planned (specified) volume of coal extraction Qпл. It should be also emphasized that coefficients of equipment use and technical reliability of equipment are better to be taken as constant values in case of a short-term period.

Coal quality is characterized by ash content, moisture, amount of harmful components (α→min). Coal quality is determined by the topology of mine workings, compliance with the extraction machines, and modes of seam occurrence. However, the practice shows that volume of commercial coal in the form of concentrate after its coming from a dressing work can be taken as the coal index. Thus, it is not always that the quality parameters can be used as substandard reserves can be mined as well.

A level of costs for production of the identified coal volume S derives from the number of workers, equipment, volumes of material resources, working time, and volume of extracted coal

If we set the fixed volume of extraction Q = const, then this value (3) can be used as the criterion of optimality. Nevertheless, it should be said that this parameter is hardly susceptible so it should be applied only for long-terms periods of time (a decade, a month); to solve operative problems, it is better to use derivative costs, e.g., prime cost c, then Qm≠const

Consequently, assessment of the coal mine potential includes analysis of technical and economic indices of operations, level of mechanization, topology of mining operations, and structure of production cycle. In this context, efficiency of a technological scheme is of deterministic nature, i.e., the general system efficiency depends on the efficiency at each production stage. Therefore, it is impossible to solve a problem of production efficiency increase without optimizing and ordering the relations at lower hierarchical levels: “stope,” “transportation system” etc.

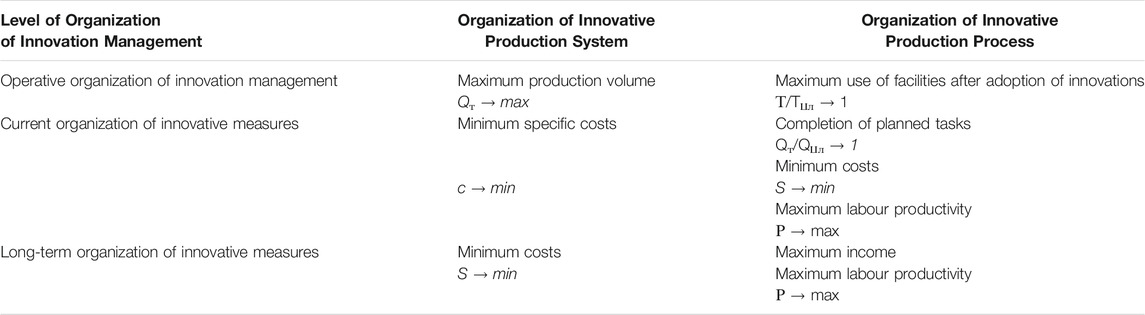

Indices of the Formation of Optimal Technological Parameters

Up to now, the only criterion of optimality of technological parameters at coal mines was completion of the coal mining plan in a current month. Indices of fuel quality and economic indices play mostly a role of constraints. In operative tasks, completion of a changeable task or better use of equipment is the main criterion. According to the purposes of this paper, it is necessary to develop a mechanism of ratio of the quality of technological scheme of a mine relative to innovations. Thus, it is essential to consider intensity of production flows formed while coal mining. In this context, these flows often have changeable intensity, whether it is changing coal demand or reducing volumes of rock transported to the surface. Analysis of the efficiency of technological coal-mining schemes and accounting of factual system of the developed indices make it possible to elaborate recommendations for using optimality criteria in the organizational tasks for assessing the potential of a technological scheme of a mine (Table 4). To interconnect the criteria effecting at different temporary levels, corresponding constraints should be applied.

The proposed criteria do not always allow considering some statements in strategic management, e.g., reduction of investment costs per each selected innovative project, and do not answer the question, which most efficient method can be used to move closer to the preset development goals. The criteria also do not take into account the most probable risks, which background is explained by the fact of involvement of new technologies under conditions of changing structure of seam occurrence in a mine field.

Analysis of source (Dychkovskyi et al., 2013) has shown that there are following essential factors preventing from efficient innovation management: danger of late introduction of innovations into the market, lack of contractors—project performers, problem of finding strategic partners for project implementation, and limited investment funds.

As a system of quantitative assessment of a technological network of coal mines, we have proposed the parameter of “internal potential of technological schemes.” The offered index has its peculiar feature—while selecting the solutions, it helps analyze them from the viewpoint of innovative advantages, not from the viewpoint of extensive representation. This index is based on the development of topological network of a coal mine in space.

Result and Discussion

As it has been mentioned before, innovations mean growth of coal-mining indices that requires quantitative estimation of the state of certain technological links. Total efficiency of the links determines general productive capacity of a coal mine. It should be highlighted that the indices can be calculated both for annual mining volume (5) and for one ton of extracted coal (6). This condition can be represented as follows:

where Ejz is jth calculation value of a specific index per unit of reserves;

Ejt is jth absolute value of the index during tth year of mine operation; Z is total reserves mined during all time of mine or level operation; EjWt is jth specific value in calculation per one unit of extraction in tth year; Wt is amount of the extracted coal at a mine or level in tth year.

It is of fundamental importance to eliminate intermediate production stages from the consideration. To do that, one should express the costs for labour subjects (that will come from the external suppliers) and internal consumption of primary resources by means of linear function of commercial “finite” volume of production of this enterprise. In this case, it is necessary to introduce the notions and conditions for defining a “production unit.” A production unit is an enterprise or group of sites, for which a set of conditions is met:

1) if there is a possibility for independent manufacturing of products of this type, no products are received from outside;

2) costs per production unit experience no changes depending on changes in the production volume.

Consequently, in terms of increasing production capacities if some products are brought from outside, it is not an enterprise-production unit anymore—now it is a complex of production units. This statement helps continue with studying the interaction between enterprises producing one and the same product type.

This definition of a production unit is required for effective equipment use. If we do not have such a definition, the problem will involve determination of specialization of a certain mine, groups of sites, and mine fields of the specified enterprise. As the problem solution, one should identify the volume of certain і-type products for their supplying to another region.

Then, the problem essence is reduced to determining the transformation indices, i.e., increase in company capacity depending on the level of arisen investment resources. In case of Donbas, this problem can be formulated in determination of homogeneous mine groups and definition of a certain level of costs required for growth of each ton of production capacity depending on mining and geological conditions and capital investments. However, due to diversity of mining and geological conditions and level of capital investment influence, it is hard to solve this problem for the operating enterprises. That was the reason of our analyzing the cost estimate documentation as for the costs for mine modernization. It has been identified that investments can be divided conditionally into three parts: investments that experience changes in direct proportion to the changes in production capacity of a mine; investments that are varied but staying behind the changes in mine capacity; and investments that do not depend on any changes in mine capacity. Depending on the enterprise (mine) capacity, costs for improvement of technological links across the enterprises vary as well. Then, to solve a problem of funds allocation between the enterprises producing one and the same product (in our case, it is coal), one should apply a function

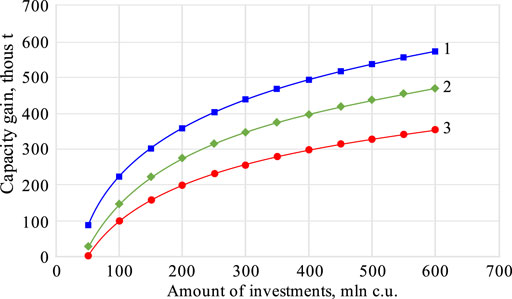

Function φn(X) can be also determined with the help of dynamic programming. We have developed a dependence of productivity changes on the attracted investments. In this context, investment volume experienced certain changes in terms of three mines. Not only volumes but also ratios varied. Figure 1 represents the modelling results.

FIGURE 1. Dependence of changes in mine capacities depending on the investment volumes in terms of three mines of State Coal Company SE: 1—Pivdennodonbaska #3; 2—Pivdennodonbaska #1, and Kapitalna.

Three mines of State Coal-Mining Company have been selected as the research objects. Our selection is explained as follows. These three mines are promising from the viewpoint of investments in the production activities; they have mineral reserves prepared for extraction and have potential for the output increase. During their operating activity, the mines had much greater production facilities and much higher level of annual coal extraction. Technical and economic indices of these mines are rather sensitive to the level of attracted investments. That is, why a task was set to study the gain of annual output depending on the investment level. Besides, it should be noted that these mines were always profitable or had minimum loss ratio compared to other mines in Ukraine, being unprofitable or very unprofitable.

That is, the basis to propose the following approach for determining the amount of investments that can be allocated for a specified number of enterprises:

– to increase the production volumes, it is required to arise investments in S amount;—to allocate the investments with maximum efficiency, it is necessary to identify how many xi investments from the indicated funds are used by ith enterprise to provide the production gain, which is determined by a value of nonlinear function fi(Xi).

All that helps apply the modelling results for allocating the funds in case of state support among the enterprises dealing with production of one and the same product type. However, as Figure 1 shows, the productivity gain is different in case of different enterprises. Depending on the amount of attracted investments, the capacity gain is defined by mining and geological conditions, operation technology, technological effectiveness of equipment, in other words—everything can be expressed by a generalized index “level of economic reliability.” In this context, several moments should be emphasized. A technological chain is improved at the expense of established rational relations between equipment in a production cycle. However, that also means purchase of more productive type of equipment. Thus, to increase the mine capacity, it is required to increase costs for purchasing more productive equipment, material, and auxiliary means of mechanization of production processes. However, growing capacity is impossible without improvement of relations in the technological links. Consider a concrete production situation. There are certain coal reserves prepared for mining. To increase productive capacity of a mine, one should extract more coal, which requires more productive types of equipment (coal shearers, powered supports, conveyors). In this context, the equipment purchase itself does not guarantee the capacity increase as one should also organize transportation of the extracted coal to a concentration plant. This example shows that mine capacity is defined not only by the equipment but by the length of mine workings, enterprise capacity, and production ties. That is, the reason why it is expedient to use the “economic reliability” criterion that considers not only production indices (productivity, value of daily output) but also productive characteristic of an enterprise (length of mine workings, preparation degree of reserves). Economic reliability can be defined using such formula as:

where Nенt is coefficient of economic reliability at the determined period of time t;

Nmt is coefficient of mine technological effectiveness at the determined moment of time t; Nbt is coefficient of economic level of operations at the determined moment of time t; Ngt is coefficient of the level of reserves remained at certain moment of time t.

Under “operation technology” of equipment, technological schemes etc. as the totality of characteristics representing both economic and operating indices. For instance, operation technology of equipment is a dimensionless indicator that expresses a degree of costs for equipment purchase, its operation, productivity, time spent for maintenance, nonproduction periods. Alternatively stated, technological effectiveness is a totality of characteristics representing economic and operational parameters of work but this indicator is dimensionless and relative. Generally, it is possible only to compare one equipment type with another; the same is about technological schemes. Technological effectiveness varies from 0 to 1. Value “1” corresponds to a reference value when, for instance, equipment has maximum productivity; time spent for maintenance is minimum. In terms of a mine, “coefficient of technological effectiveness” represents correspondence of the technological resource limits. In other words, if technological effectiveness of a mine is “1,” it meets the stated production capacity, i.e., its uses 100% of its potential, which brings the results of mine operation to a possible breakeven threshold.

Basing on study (Salli et al., 2014), it has been determined that mines with the level of economic reliability being more than 1.4 can operate in an unsubsidized mode; and to expand the production volume, the costs are to be increased by 500–800 c.u./t.

Physical value of economic reliability is determined by the totality of technical results of operations and economic indices of work. Specific feature of this evaluation is the fact that not only expert estimates but also indices of economic and technical activities are used. Moreover, this estimation makes it possible to identify a general level of mine funds along with determination of mine privatization order.

According to the data represented in Figure 1, Kapitalna mine has higher indices of economic reliability than mines Pivdennodonbaska #1 and Pivdennodonbaska #3, being the result of more effective capacity gain. When we have identified a mine with the highest level of economic reliability, we can start determining optimal and conditionally optimal investment allocation among the enterprises.

Before moving on to determination of investment volumes, it is necessary to mention a principle of dynamic modelling. A dynamic process is divided into the totality of successive stages or steps. Each step is optimized separately, and solution, according to which a system transfers from a current state into the new one, is selected considering its future aftereffects, and it does not always give the greatest effect at this stage. The last step involves decision making (solution is found) to provide the maximum effect. Basing on the aforementioned, optimization by a dynamic programming method starts from the end: first, the last step is planned. Basing on the known information cocnerning the end of the next-to-last step and relying on different hypotheses concerning its finishing, the control is selected at the final step. Such control is called conditionally optimal as it is found in terms of assumption that the previous step was taken according to one of possible hypotheses. Thus, the “conditionally optimal” volume of investments is understood as the limited (preset) investment allocation among the enterprises. “Conditionality” means the fact that a modelling process starts from the end, and the investment volume is already known. As a result of task performance, a conditionally optimal volume of investments from the general investment volume will be identified for one of the enterprises. It means that we will get the answer for a question—how much we should invest in an enterprise from the possible investment volume to reach maximum economic effect. The “conditionally optimal” volume differs from the “optimal” one only in the fact that a dynamic programming problem is solved in the reverse order, i.e., a value of general volume is already known.

The initial data were preset as follows: volume of investments—UAH 600 mln c.u.; three mines—Kapitalna, Pivdennodonbaska #1, and Pivdennodonbaska #3. The amount of capital investments into mining operations should be identified; it depends on the production volume of mines. The methods of dynamic programming are to be used to solve a reverse order problem. Here we start searching for optimal solution from the identification of optimal solution for a certain mine during the last year of a calculation period. Dynamic programming involves a principle of “R. Bellman optimum” when each further step it optimal, i.e. without determining an optimal solution at the previous step, it is impossible to go to the following one.

A calculation scheme is as follows: first, consider the expediency of investing into mine Pivdennodonbaska #1, then—into Pivdennodonbaska #3 and Kapitalna. To do that, the data of previous calculations are determined using formula

According to the modelling results, maximum production gain from the specified three mines is UAH 692.2 thousand in terms of equal distribution for each mine within a 6-year reconstruction period. In case of mine Kapitalna, conditionally optimal volume of investments was calculated (Table 5).

The represented results show the potential capacities of the State Coal Company mines. These assumptions are formed using both high indices of economic reliability of enterprises and data of dynamic modelling.

Further studies will be aimed at analyzing connections between enterprises in the generation of energy and metal that will help stabilize situations in the industrial regions. It will require development of a dynamic programming model that will make it possible to trace changes of reserves in time in such links as “coal—coke—metal” and “coal—dressing works—electrical energy.”

Conclusion

Solution of the problem of effective allocation of funds among company groups in terms of one legal entity should involve complex evaluation by the “economic reliability” parameter, which takes into account quality of reserves development and level of operation concentration. It has been identified that the most efficient variant of transforming mines of a coal-mining region is compensation of possible reduction of production volumes; they should grow at the expense of additional loading of the most efficient mines and, as a rule, with lower capital costs.

The following results have been obtained:

– level of concentration of operations and development of production-spatial relations are the parameter of efficiency of coal mine activities; —representation of company productivity is stipulated by the amount of raised investments; however, the efficiency of the used funds is determined by economic reliability of a mine that includes a degree of reserves preparation for extraction, length of mine workings, level of organization of operations at an enterprise, and degree of mechanization of operations.

The proposed approaches can be used for complex assessment of coal mines that will help determine a level of state support as well as predict a level of development and concentration of mining operations in space. All that will allow effective managing for the main production resources to increase the potential of technological mining schemes and reduce a level of unprofitability of state coal mines.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author Contributions

Conceptualization, OB, OA, and AK; methodology, OM and AK; software, VL and PS; validation, OA and OM; formal analysis, VL and PS; investigation, OA and AK; resources, OB and VL; data curation, OM and PS; writing-original draft preparation, OA and AK; writing-review and editing, OB, AK, and VL; visualization, VL and PS; supervision, OA and AK; project administration, OB and VL; funding acquisition, OB. All authors have read and agreed to the published version of the manuscript.

Funding

This study was carried out as part of the project “Belt and Road Initiative Institute for Chinese-European Studies (BRIICES)” and was funded by the Guangdong University of Petrochemical Technology.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

The team of authors expresses their gratitude to the reviewers for valuable recommendations that have been taken into account to improve significantly the quality of this paper.

References

Abdel Sabour, S. A., and Dimitrakopoulos, R. (2011). Incorporating Geological and Market Uncertainties and Operational Flexibility into Open Pit Mine Design. J. Min Sci. 47 (2), 191–201. doi:10.1134/S1062739147020067

Aznar-Sánchez, J. A., Velasco-Muñoz, J. F., Belmonte-Ureña, L. J., and Manzano-Agugliaro, F. (2019). Innovation and Technology for Sustainable Mining Activity: A Worldwide Research Assessment. J. Clean. Prod. 221, 38–54. doi:10.1016/j.jclepro.2019.02.243

Bakhtavar, E., Shahriar, K., and Mirhassani, A. (2012). Optimization of the Transition from Open-Pit to Underground Operation in Combined Mining Using (0-1) Integer Programming. J. South. Afr. Inst. Mining Metall. 112 (12), 1059–1064.

Bazaluk, O. (2021). The Philosophy of the Modern Age: The Issue of the Source of Meaningful Presence. w 18 (2), 28–36. doi:10.24234/wisdom.v18i2.460

Betrie, G. D., Sadiq, R., Morin, K. A., and Tesfamariam, S. (2013). Selection of Remedial Alternatives for Mine Sites: A Multicriteria Decision Analysis Approach. J. Environ. Manag. 119, 36–46. doi:10.1016/j.jenvman.2013.01.024

Bondarenko, V., Tabachenko, M., and Wachowicz, J. (2010). Possibility of Production Complex of Sufficient Gasses in Ukraine. New Tech. Tech. Mining, 113–119. doi:10.1201/b11329-19

Brovender, Y., Haiko, H., and Brovender, O. (2021). Mining under the Early Metal in the Context of Kartamysh Ore Occurrence of Ukrainian Donbas. Min. Miner. Depos. 15 (3), 45–53. doi:10.33271/mining15.03.045

Conteh, F. M., and Maconachie, R. (2021). Artisanal Mining, Mechanization and Human (In) Security in Sierra Leone. Extractive Industries Soc. 8 (4), 100983. doi:10.1016/j.exis.2021.100983

Ćorović, N., Urošević, B. G., and Katić, N. (2022). Decarbonization: Challenges for the Electricity Market Development - Serbian Market Case. Energ. Rep. 8, 2200–2209. doi:10.1016/j.egyr.2022.01.054

Dergachova, V., Kravchenko, M., Kuznietsova, K., and Kotsko, T. (2020). Ukraine's Energy Policy: Analysis and Development Strategy. Polityka Energetyczna - Energ. Pol. J. 23 (4), 67–90. doi:10.33223/epj/128598

Dychkovskyi, R., Falshtynskyi, V., Ruskykh, V., Cabana, E., and Kosobokov, O. (2018). A Modern Vision of Simulation Modelling in Mining and Near Mining Activity. E3s Web Conf. 60, 00014. doi:10.1051/e3sconf/20186000014

Dychkovskyi, R. O., Avdiushchenko, A. S., Falshtynskyi, V. S., and Saik, P. B. (2013). On the Is-Sue of Estimation of the Coal Mine Extraction Area Economic Efficiency. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu 4, 107–114.

Dychkovskyi, R., Shavarskyi, I., Saik, P., Lozynskyi, V., Falshtynskyi, V., and Cabana, E. (2020). Research into Stress-Strain State of the Rock Mass Condition in the Process of the Operation of Double-Unit Longwalls. Min. Miner. Depos. 14 (2), 85–94. doi:10.33271/mining14.02.085

Dychkovskyi, R., Vladyko, O., Vladyko, O., Maltsev, D., and Cáceres Cabana, E. (2018). Some Aspects of the Compatibility of mineral Mining Technologies. Mgpb 33 (4), 73–82. doi:10.17794/rgn.2018.4.7

Endl, A., Tost, M., Hitch, M., Moser, P., and Feiel, S. (2021). Europe's Mining Innovation Trends and Their Contribution to the Sustainable Development Goals: Blind Spots and strong Points. Resour. Pol. 74, 101440. doi:10.1016/j.resourpol.2019.101440

Fedorov, E., Kassymkanova, K.-K., Jangulova, G., and Miletenko, N. (2020). The Influence of Extensive Caving Zones on the State and Behavior of the Surface as a Result of Underground Mining Works. E3s Web Conf. 192, 03009. doi:10.1051/e3sconf/202019203009

Galiyev, D. A., Uteshov, E. T., and Tekenova, A. T. (2020). Digitalization of Technological and Organizational Processes of Mining Operations Due to the Implementation of the Installation System and Accounting the Key Indicators. Ser. Geology. Tech. Sci. 5 (443), 47–53. doi:10.32014/2020.2518-170x.103

Galiyev, S. Zh., Dovzhenok, A. D., Kol’ga, A. S., Galiyev, D. A., and Uteshov, E. T. (2019). Digitalization and the Potential for Improving the Design and Planning of Mining Operations in Open Cast Mining. News Natl. Acad. Sci. Republic Kazakhstan, Ser. Geology. Tech. Sci. 1 (439), 146–154.

Gawusu, S., Zhang, X., Ahmed, A., Jamatutu, S. A., Miensah, E. D., Amadu, A. A., et al. (2022). Renewable Energy Sources from the Perspective of Blockchain Integration: From Theory to Application. Sustainable Energ. Tech. Assessments 52, 102108. doi:10.1016/j.seta.2022.102108

Gonen, A., Malli, T., and Kose, H. (2012). Selection of Ore Transport System for a Metalliferous Underground Mine / Dobór Systemu Transportu Rud W Kopalni Podziemnej Rud Metalu. Arch. Mining Sci. 57 (3), 779–785. doi:10.2478/v10267-012-0050-1

Gorova, A., Pavlychenko, A., and Borysovs’Ka, O. (2013). The Study of Ecological State of Waste Disposal Areas of Energy and Mining Companies. Annu. Scientific-Technical Colletion, 169–172. doi:10.1201/b16354-29

Gruenhagen, J. H., and Parker, R. (2020). Factors Driving or Impeding the Diffusion and Adoption of Innovation in Mining: A Systematic Review of the Literature. Resour. Pol. 65, 101540. doi:10.1016/j.resourpol.2019.101540

Haiko, H., Saik, P., and Lozynskyi, V. (2019). The Philosophy of Mining: Historical Aspect and Future Prospect. P&C 22, 76–90. doi:10.29202/phil-cosm/22/6

Horoshkova, L., Khlobystov, I., and Volkov, V. (2020). Modelling of Resource Flows in the Coal Industry of Ukraine. Geoinformatics: Theor. Appl. Aspects 2020 (1), 1–6. doi:10.3997/2214-4609.2020geo069

Hrinov, V., and Khorolskyi, A. (2018). Improving the Process of Coal Extraction Based on the Parameter Optimization of Mining Equipment. E3S Web Conf.Ukrainian Sch. Mining Eng. 60, 00017–110. doi:10.1051/e3sconf/20186000017

IlyashovDiedich, M. I., Nazimko, V., Diedich, I., and Nazimko, V. (2019). Prospective Tendencies of Coal Mining Risk Management. Min. Miner. Depos. 13 (1), 111–117. doi:10.33271/mining13.01.111

Iphar, M., and Goktan, R. M. (2006). An Application of Fuzzy Sets to the Diggability index Rating Method for Surface Mine Equipment Selection. Int. J. rock Mech. mining Sci. 43 (2), 253–266. doi:10.1016/j.ijrmms.2005.07.003

Kashan, A. J., Lay, J., Wiewiora, A., and Bradley, L. (2022). The Innovation Process in Mining: Integrating Insights from Innovation and Change Management. SSRN Electron. J 76. doi:10.1016/j.resourpol.2022.102575

Khorolskyi, A., Hrinov, V., Mamaikin, O., and Demchenko, Y. (2019). Models and Methods to Make Decisions while Mining Production Scheduling. Min. Miner. Depos. 13 (4), 53–62. doi:10.33271/mining13.04.053

Klippel, A. F., Petter, C. O., and Antunes, J. A. V. (2008). Management Innovation, a Way for Mining Companies to Survive in a Globalized World. Utilities Policy 16 (4), 332–333. doi:10.1016/j.jup.2007.09.001

Kobylianskyi, B., and Mуkhalchenko, H. (2020). Improvement of Safety Management System at the Mining Enterprises of Ukraine. Min. Miner. Depos. 14 (2), 34–42. doi:10.33271/mining14.02.034

Kopacz, M., Kulpa, J., Galica, D., Dyczko, A., and Jarosz, J. (2019). Economic Valuation of Coal Deposits - the Value of Geological Information in the Resource Recognition Process. Resour. Pol. 63, 101450. doi:10.1016/j.resourpol.2019.101450

Koval, V., Mikhno, I., Udovychenko, I., Gordiichuk, Y., and Kalina, I. (2021). Sustainable Natural Resource Management to Ensure Strategic Environmental Development. TEM J., 1022–1030. doi:10.18421/tem103-03

Koveria, A., Kieush, L., Hrubyak, A., and Kotsyubynsky, V. (2019). Properties of Donetsk basin Hard Coals and the Products of Their Heat Treatment Revealed via Mossbauer Spectroscopy. Pet. Coal 61 (1), 160–168.

Kryshtanovych, M., Akimova, L., Akimov, O., Kubiniy, N., and Marhitich, V. (2021). Modeling the Process of Forming the Safety Potential of Engineering Enterprises. Ijsse 11 (3), 223–230. doi:10.18280/ijsse.110302

Krzak, M. (2013). The Evaluation of an Ore Deposit Development Prospect through Application of the "Games against Nature" Approach. Asia Pac. J. Oper. Res. 30 (6), 1350029. doi:10.1142/S0217595913500292

Kursunoglu, N., and Onder, M. (2015). Selection of an Appropriate Fan for an Underground Coal Mine Using the Analytic Hierarchy Process. Tunnelling Underground Space Techn. 48 (48), 101–109. doi:10.1016/j.tust.2015.02.005

Melnyk, T. (2018). Ukraine and its Future in a Globalised International Community. Up 3 (3), 17–28. doi:10.29202/up/3/3

Milanez, B., and Puppim de Oliveira, J. A. (2013). Innovation for Sustainable Development in Artisanal Mining: Advances in a Cluster of Opal Mining in Brazil. Resour. Pol. 38 (4), 427–434. doi:10.1016/j.resourpol.2013.07.003

Nehrii, S., Nehrii, T., Bachurin, L., and Piskurska, H. (2019). Problems of Mining the Prospective Coal-Bearing Areas in Donbas. E3s Web Conf. 123, 01011. doi:10.1051/e3sconf/201912301011

Ostapenko, O., Olczak, P., Koval, V., Hren, L., Matuszewska, D., and Postupna, O. (2022). Application of Geoinformation Systems for Assessment of Effective Integration of Renewable Energy Technologies in the Energy Sector of Ukraine. Appl. Sci. 12 (2), 592. doi:10.3390/app12020592

Pavlenko, I., Salli, V., Bondarenko, V., Dychkovskiy, R., and Piwniak, G. (2007). Limits to Economic Viability of Extraction of Thin Coal Seams in Ukraine. Thin-Seams Coal Mining Int. Mining Forum 2007, 129–132. doi:10.1201/noe0415436700.ch16

Petlovanyi, M. V., Lozynskyi, V. H., Saik, P. B., and Sai, K. S. (2018). Modern Experience of Low-Coal Seams Underground Mining in Ukraine. Int. J. Mining Sci. Techn. 28 (6), 917–923. doi:10.1016/j.ijmst.2018.05.014

Petrochenko, O., Zinich, P., Kubanov, R., Kushnir, S., and Nischuk, V. (2021). Ways to Ensure Energy Security of ukraine: Diversification of the Energy Market. Norwegian J. Develop. Int. Sci. 74, 21–23.

Petrov, N. I., Dimitrova, K. Y., and Baskanbayeva, D. D. (2021). On the Reliability of Technological Innovation Systems. IOP Conf. Ser. Mater. Sci. Eng. 1031, 012044. doi:10.1088/1757-899X/1031/1/012044

Pivniak, H. H., Pilov, P. I., Pashkevych, M. S., and Shashenko, D. O. (2012). Synchro-mining: Civilized Solution of Problems of Mining Regions' Sustainable Operation. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu 174 (3), 131–138.

Rozin, V. (2021). From Engineering and Technological Process to Post-Cultural Technology. Fhi 15, 99–109. doi:10.29202/fhi/15/9

Saik, P., Petlovanyi, M., Lozynskyi, V., Sai, K., and Merzlikin, A. (2018). Innovative Approach to the Integrated Use of Energy Resources of Underground Coal Gasification. Ssp 277 (277), 221–231. doi:10.4028/www.scientific.net/SSP.277.221

Salli, S., Pochepov, V., and Mamaykin, O. (2014). “Theoretical Aspects of the Potential Technological Schemes Evaluation and Their Susceptibility to Innovations,” in Progressive Technologies of Coal Coalbed Methane, and Ores Mining, 491–496. doi:10.1201/b17547-81

Savina, N., Sribna, Y., Pitel, N., Parkhomenko, L., Osipova, A., and Koval, V. (2021). Energy Management Decarbonization Policy and its Implications for National Economies. IOP Conf. Ser. Earth Environ. Sci. 915 (1), 012007. doi:10.1088/1755-1315/915/1/012007

Tampubolon, F. R. S., Yuwono, A. S., Tambunan, A. H., and Achsani, N. A. (2021). Coal Mining Energy Utilization and Environmental Impact Management Strategy Using the LCA Method. Nept 20 (5). doi:10.46488/nept.2021.v20i05.017

Ursul, A., Ursul, T., and Dugarova, M. (2017). Towards a Global Sustainable Future. Philos. Cosmology 18 (15), 37–50.

Uteshov, Y., Galiyev, D., Galiyev, S., Rysbekov, K., and Nаuryzbayeva, D. (2021). Potential for Increasing the Efficiency of Design Processes for Mining the Solid mineral Deposits Based on Digitalization and Advanced Analytics. Min. Miner. Depos. 15 (2), 102–110. doi:10.33271/mining15.02.102

Vatalis, K. I., Avlogiaris, G., and Tsalis, T. Α. (2022). Just Transition Pathways of Energy Decarbonization under the Global Environmental Changes. J. Environ. Manage. 309, 114713. doi:10.1016/j.jenvman.2022.114713

Zhang, L., Wang, J., and Feng, Y. (2018). Life Cycle Assessment of Opencast Coal Mine Production: a Case Study in Yimin Mining Area in China. Environ. Sci. Pollut. Res. 25 (9), 8475–8486. doi:10.1007/s11356-017-1169-6

Keywords: innovations, minimal costs, production volume, investment, economic reliability, efficiency, space

Citation: Bazaluk O, Ashcheulova O, Mamaikin O, Khorolskyi A, Lozynskyi V and Saik P (2022) Innovative Activities in the Sphere of Mining Process Management. Front. Environ. Sci. 10:878977. doi: 10.3389/fenvs.2022.878977

Received: 18 February 2022; Accepted: 09 March 2022;

Published: 23 March 2022.

Edited by:

Piotr Olczak, Mineral and Energy Economic Research Institute (PAN), PolandReviewed by:

Vlad Mihai Pasculescu, National Institute for Research and Development in Mine Safety and Protection to Explosion—INSEMEX, RomaniaKanay Rysbekov, Satbayev University, Kazakhstan

Copyright © 2022 Bazaluk, Ashcheulova, Mamaikin, Khorolskyi, Lozynskyi and Saik. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Vasyl Lozynskyi, bHZnLm5tdUBnbWFpbC5jb20=

Oleg Bazaluk

Oleg Bazaluk Oleksandra Ashcheulova

Oleksandra Ashcheulova Oleksandr Mamaikin

Oleksandr Mamaikin Andrii Khorolskyi

Andrii Khorolskyi Vasyl Lozynskyi

Vasyl Lozynskyi Pavlo Saik3

Pavlo Saik3