- 1Design and Art Institute, Hunan University of Technology and Business, Changsha, China

- 2School of Economy and Trade, Hunan University of Technology and Business, Changsha, China

- 3Business College, Hong Kong Baptist University, Hong Kong, China

- 4Law School, Hunan University of Technology and Business, Changsha, China

How to effectively monitor and prevent volatile organic compounds (VOCs) in furniture manufacturing has become the key to solving the dilemma between furniture industry development and public health. Based on the combination of VOCs emission standards and prevention policies of China’s furniture manufacturing, this article explores the path of dynamic monitoring, intelligent prevention, and control of VOCs embedded in furniture manufacturing with big data and IoT and puts forward feasible VOCs control technologies in the whole process of China’s furniture manufacturing, including source, process, and end. Herein, dynamic monitoring, intelligent prevention, and control of VOCs in furniture manufacturing have important reference significance for the prevention and control of VOCs in other industries, such as coal chemical industry, rubber products, engineering machinery, and coiled materials.

Introduction

Human beings spend about 87% of their time indoors. Therefore, indoor air quality directly affects human health (Wang et al., 2021). With the continuous advancement of economic and social development, people pay more and more attention to the aesthetic and visual enjoyment of furniture, which leads to the diversified and personalized demand for furniture products, making furniture manufacturing enterprises constantly seek new materials, new technologies, and new processes to innovate furniture manufacturing. However, because furniture production is inseparable from adhesive and coating, a large number of irritating or toxic VOC gases will be generated in the production process, forming precursors of PM2.5 and ozone, which will aggravate atmospheric pollution such as haze and photochemical smog. Therefore, how to effectively monitor and prevent VOCs in furniture production has become an important means to solve the dilemma between the development of the furniture manufacturing industry and public health (Menghi et al., 2018). With the continuous maturity of new generation information technologies, such as big data and Internet of things (IoT), people began to explore the application of big data and IoT to VOCs dynamic monitoring and intelligent prevention in furniture production. They achieved certain results (Kaginalkarab et al., 2021). Since China overtook the United States to become the world’s largest furniture producer in 2010, it has always ranked first in the world. Therefore, taking China as an example, this article summarizes the evolution of VOCs monitoring and prevention policies and the application of big data and IoT technology in China’s furniture manufacturing from historical and practical logic, so as to provide scientific basis and technical support for the country to promote VOCs pollution prevention and control in furniture manufacturing industry.

The Carding of VOCs Emission Standards and Policies of China’s Furniture Manufacturing

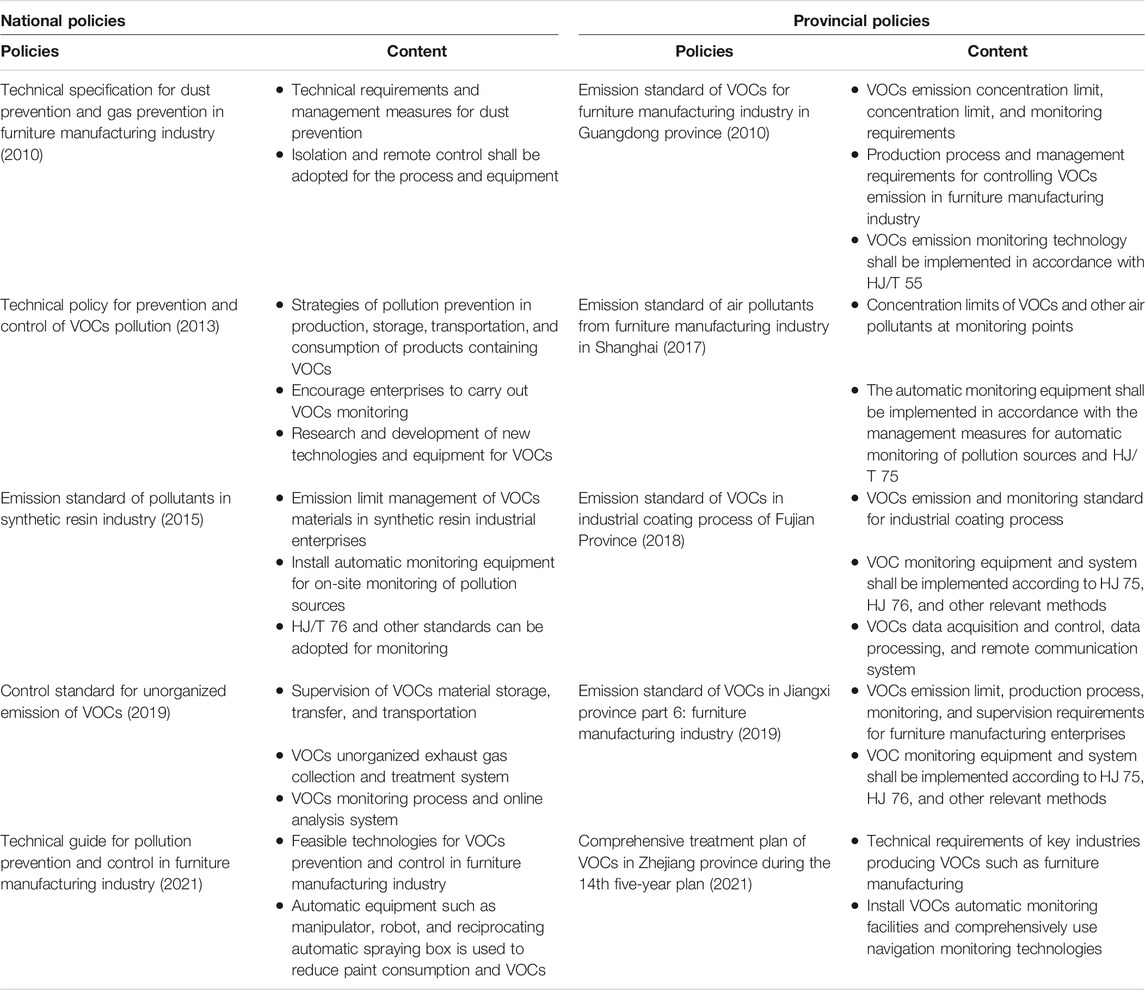

Chinese governments at all levels have issued a series of policies on the standards, monitoring, and prevention of VOCs emission from the furniture manufacturing industry (Table 1). From the national level, in September 2010, the State Administration of Work Safety distributed “Technical Specification for Dust Prevention and Gas Prevention in Furniture Manufacturing Industry,” which put forward normative requirements for pollution prevention and control in the furniture manufacturing industry for the first time. However, the specification does not put forward hard constraint requirements in technology but recommends that relevant enterprises adopt isolation and remote control operations. In 2013, the Ministry of Natural Resources of the People’s Republic of China issued “Technical Policy for Prevention and Control of VOCs Pollution” to encourage relevant enterprises to carry out VOCs monitoring, prevention, and control by themselves and develop new technologies and equipment in the form of suggestions. In 2015, the Ministry of Ecology and Environment of the People’s Republic of China issued the “Emission Standard of Pollutants in Synthetic Resin Industry,” requiring enterprises associated with furniture manufacturing to install corresponding automatic monitoring equipment for various pollution sources, including VOCs materials. On May 24, 2019, the Ministry of Ecology and Environment of the People’s Republic of China and the State Administration for Market Regulation jointly issued “Control Standard for Unorganized Emission of VOCs” and proposed an online sampling and analysis system for VOCs control. On May 12, 2021, the Ministry of Ecology and Environment of the People’s Republic of China issued the latest “Technical Guide for Pollution Prevention and Control in Furniture Manufacturing Industry,” which put forward guiding suggestions on the use of automatic and intelligent equipment and technologies such as manipulator, robot, and Internet of things for production in terms of equipment and process innovation technology for the first time.

At the provincial level, Guangdong, Shanghai, Zhejiang, Jiangxi, Fujian, and other major furniture manufacturing provinces have issued corresponding policies for VOCs emission monitoring and prevention. For example, on October 22, 2010, Guangdong issued the “Emission Standard of VOCs for Furniture Manufacturing Industry,” which put forward specific requirements for instrument use and technological innovation of VOCs emission monitoring in furniture production. In June 2017, Shanghai issued the “Emission Standard of Air Pollutants from Furniture Manufacturing Industry,” which required that the automatic monitoring equipment shall be implemented in accordance with the management measures for automatic monitoring of pollution sources and HJ/T 75. Moreover, the “Emission Standard of VOCs in Industrial Coating Process” issued by Fujian province in 2018 clearly stipulates the VOCs emission limit of furniture manufacturing industry and requires manufacturers to establish a variety of monitoring units such as gaseous pollutants, as well as data acquisition and control system, data processing and remote communication system, fixed source monitoring system, and pollution control facility operation monitoring system. On July 17, 2019, Jiangxi province had formulated technical requirements consistent with those of Shanghai and Fujian for VOCs pollution control policies for the furniture manufacturing industry, such as “Emission Standard of VOCs in Part 6: Furniture Manufacturing Industry.” In 2021, Zhejiang issued the “Comprehensive Treatment Plan of VOCs in Zhejiang Province during the 14th Five-Year Plan,” which prospectively proposed that furniture manufacturing needs to install VOCs automatic monitoring facilities and strengthen the application of intelligent technologies such as navigation monitoring.

In conclusion, it can be seen that a series of policies have been issued for VOCs emission, monitoring, and prevention in furniture manufacturing at both the national and provincial levels. Moreover, with the development and deepening of the new generation of information technology, government departments began to encourage furniture manufacturing enterprises to seek emerging technical means such as IoT and big data to improve the efficiency of VOCs monitoring and prevention.

Application Scenarios of Big Data and IoT in VOCs Emission From China’s Furniture Manufacturing

Evolution of Big Data and IoT

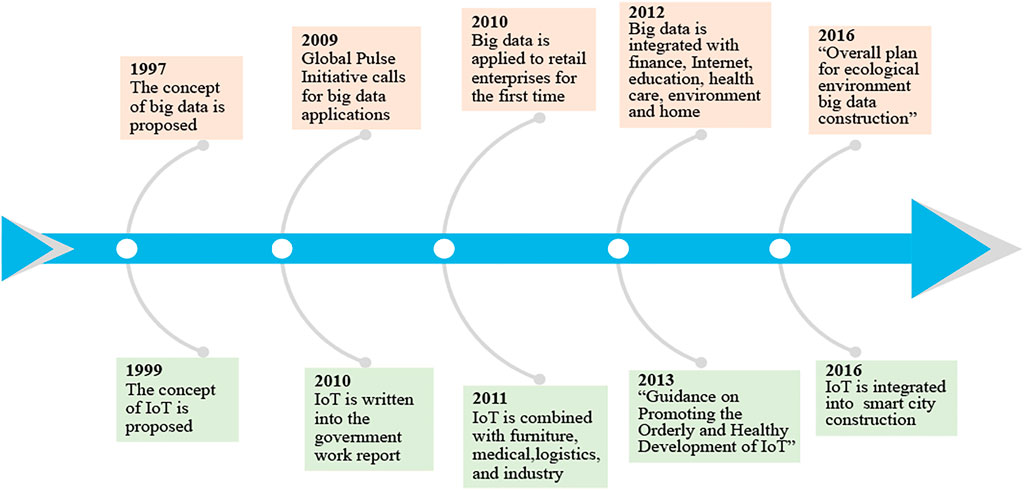

At present, the new generation of information technology represented by big data and IoT is developing rapidly, gradually accelerating its penetration into new materials, intelligent medicine, intelligent manufacturing, and other fields (Figure 1). Looking back on history, both big data and IoT were initiated in the late 20th century and flourished in the early 21st century. Among them, the concept of big data was first proposed by Michael and David Ellsworth in 1997. The concept of IoT was first proposed by the Auto-ID laboratory in 1999 and formally proposed at the World Summit on the Information Society (WSIS) in 2005. As big data and IoT become gradually known and recognized, they begin to enter people’s vision of life and production, which has changed the life and production mode and its inherent thinking to a certain extent. In 2009, the United Nations issued the “Global Pulse Plan,” calling for big data and IoT as the driving force to promote the economic development of a country or region. Therefore, big data and IoT began to be rapidly promoted and applied in China, India, and other countries. Meanwhile, Wen Jiabao, then Chinese Premier of the State Council, inspected and delivered an important speech at Wuxi Micro Nano Sensor Network Engineering Technology R&D Center, saying that China should seize the opportunity and vigorously develop Internet of things technology.

At the national two sessions held in March 2010, it was clearly pointed out that the use of big data and IoT to promote the transformation of economic development mode, and the IoT was established as one of the strategic pillars of national economic and technological development. In addition, in the “12th Five Year Plan for the development of the IoT” issued by the Ministry of Industry and Information of the People’s republic of China in 2011, the Ministry further defined the direction and focus of the development of the IoT, and promoted the interactive development of IoT technology and medical, logistics, home, industry, agriculture and other fields. In 2013, the State Council of China issued the guiding opinions on promoting the orderly and healthy development of the IoT, defined the guiding ideology, development objectives and main tasks of the development of the Internet of things, and proposed to promote the construction of a new smart city based on the classification of IoT technologies. In 2016, the Ministry of Ecology and Environment of the People’s Republic of China also issued the overall plan for the construction of ecological and environmental big data, which clearly pointed out the use of big data and IoT to monitor air pollution, environmental governance and life health, marking the formal integration of big data and Internet of things technology into all fields of life and production.

Application Scenarios and Platform Architecture for Big Data and IoT

1) Big data and IoT implanted furniture manufacturing link

The development of IoT is based on the extension and expansion of the Internet. Its ultimate development goal is to realize comprehensive perception, reliable transmission, and intelligent processing with the help of big data technology. With the continuous integration and application of IoT and big data technology. They are more and more respected in VOCs monitoring and control of furniture manufacturing. As we all know, the constituent materials of furniture mainly fall into two categories: one is dry materials, which mainly refers to all kinds of wood panels (solid wood panels, man-made panels, PVC panels, etc.), and soft materials (mattresses, sofa mattresses, etc.). One is wet materials (Wu et al., 2021), which mainly refer to paints, wood colorants, adhesives, and so on. As the base material of the furniture, the wood board itself will release a variety of aldehydes and pinenes. In the process of furniture manufacturing, the use of adhesives, paints, and other materials will introduce new organics, such as esters, ketones, and aromatic hydrocarbons. Therefore, the intelligent monitoring system based on IoT and big data technology is embedded into the important links and modules of furniture manufacturing, which helps collect VOCs monitoring data from time to time, and supports the intelligent and green selection of materials and production process of furniture manufacturing.

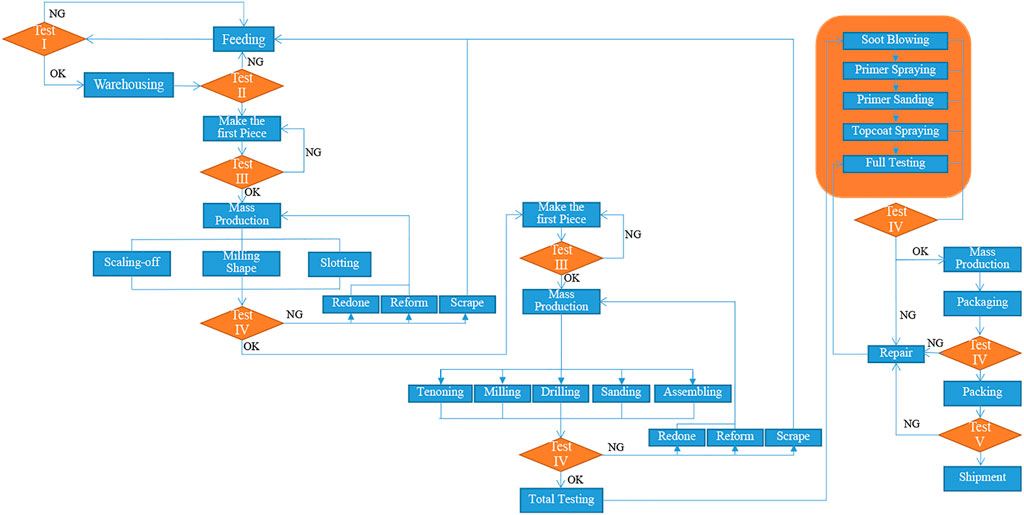

Figure 2 reports the production process of furniture manufacturing and the implantation of big data and IoT. See the orange shaded module in the figure for details. It can be seen that the IoT intelligent perception system and big data technology are mainly applied to VOCs detection and collection before material warehousing (Test I); VOCs detection and collection when material warehousing (Test II); VOCs detection and collection of the first product produced (Test III); VOCs detection and collection after various production links in mass production (Test IV); VOCs detection and collection after packaging of furniture parts (Test V); VOCs detection and collection in paint production; and so on. Among them, the paint manufacturing process includes soot blowing, primer spraying, primer sanding, topcoat spraying, paint full inspection, and other modules, which are the main links of VOCs generation and emission.

2) Platform architecture for big data and IoT in furniture manufacturing

FIGURE 2. Big data and IoT in furniture manufacturing. Note: the IoT intelligent perception system and big data technology are embedded in the module with orange shadow.

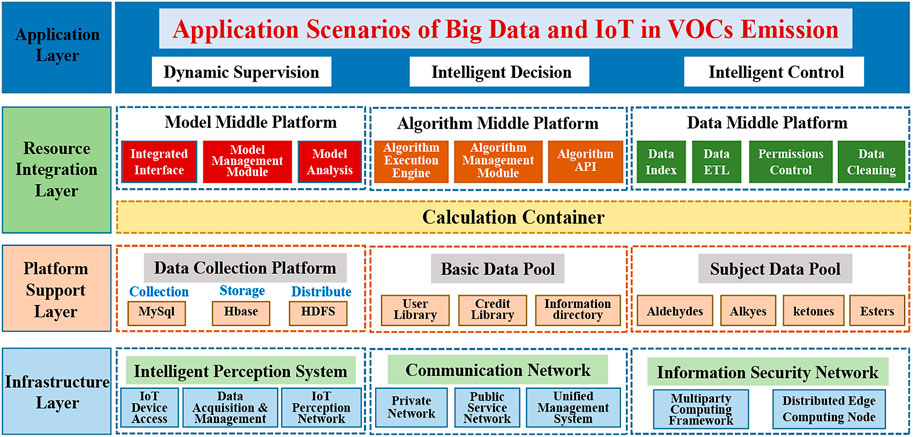

The design of infrastructure platform architecture is the key to solving the intelligent monitoring system of big data and IoT. From Figure 3, the basic platform architecture for VOCs dynamic monitoring, intelligent decision-making, and control in furniture manufacturing is mainly composed of four layers, namely, application layer, resource integration layer, platform support layer, and infrastructure layer. Among them, the application layer mainly solves the dynamic monitoring, intelligent decision-making, and control of VOCs emission data. The resource integration layer includes modules such as model platform, data platform, algorithm platform, and computing container. The platform support layer includes three modules: data collection platform (collection, storage, distribution), basic data pool (user library, credit library, information directory), and subject data pool (such as aldehydes, alkies, ketones, and esters). The infrastructure layer consists of three modules: intelligent sensing system, communication integrated network, and information security network.

Concluding Remarks

The furniture manufacturing industry is a typical industry with high pollution and low added value. The VOCs produced in furniture manufacturing seriously affect people’s health. Based on big data and IoT and combining the VOCs emission standards and prevention policies of China’s furniture manufacturing, we explore the path and mode of dynamic monitoring and intelligent prevention and control of VOCs embedded in furniture manufacturing by big data and IoT and put forward the feasible VOCs control technology of the whole process of China’s furniture manufacturing industry, including source, process, and end. In short, the prevention and control of VOCs in furniture manufacturing are not achieved overnight. In addition to the implementation of key technology and production process innovation in important links such as raw material selection, production adhesive, and coating, it is also necessary to combine emerging technologies such as big data and IoT to improve the efficiency of VOCs monitoring, prevention, and control in the whole process of furniture production. In addition, in reality, there are many industries involving VOCs emission, including coal chemical industry, rubber products, engineering machinery, steel structure, and coiled materials. These industries all need to carry out more refined monitoring, prevention, and control research. In this article, the dynamic monitoring, intelligent prevention, and control of VOCs in furniture manufacturing have important reference significance for the prevention and control of VOCs in other industries mentioned above.

Author Contributions

Z-GC: conceptualization, writing—original draft, and supervision. W-PW: writing—original draft and methodology. JL: software, writing—review and editing. Y-HZ: Methodology, writing—review and editing.

Funding

This research was supported by the National Natural Science Foundation of China (no. 71903056), National Science Foundation for Post-Doctoral Scientists of China (no. 2020M672464), Natural Science Foundation of Hunan Province in China (nos. 2020JJ5104 and 2020JJ4259), Project of Hunan Social Science Achievement Appraisal Committee (no. XSP21YBZ094), Scientific Research Project of Hunan Education Department in China (nos. 19C1038 and 21B0573).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Kaginalkar, A., Kumar, S., Gargava, P., and Niyogi, D. (2021). Review of Urban Computing in Air Quality Management as Smart City Service: An Integrated IoT, AI, and Cloud Technology Perspective. Urban Clim. 39, 100972. doi:10.1016/j.uclim.2021.100972

Menghi, R., Ceccacci, S., Papetti, A., Marconi, M., and Germani, M. (2018). A Method to Estimate the Total VOC Emission of Furniture Products. Proced. Manuf. 21, 486–493. doi:10.1016/j.promfg.2018.02.148

Wang, Y., Wang, H., Tan, Y., Liu, J., Wang, K., Ji, W., et al. (2021). Measurement of the Key Parameters of VOC Emissions from Wooden Furniture, and the Impact of Temperature. Atmos. Environ. 259 (7), 118510. doi:10.1016/j.atmosenv.2021.118510

Keywords: VOCs emission, furniture manufacturing, big data, IoT, dynamic supervision

Citation: Chen Z-G, Wu W-P, Li J and Zeng Y-H (2022) Dynamic Supervision and Control of VOCs Emission From China’s Furniture Manufacturing Based on Big Data and IoT. Front. Environ. Sci. 10:807216. doi: 10.3389/fenvs.2022.807216

Received: 01 November 2021; Accepted: 03 January 2022;

Published: 01 February 2022.

Edited by:

Tsun Se Cheong, Hang Seng University of Hong Kong, ChinaReviewed by:

Vincent Chen, The University of Sheffield, United KingdomWen Zezhou, Huazhong University of Science and Technology, China

Copyright © 2022 Chen, Wu, Li and Zeng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wei-Ping Wu, d3V3ZWlwaW5nLjIwMDdAMTYzLmNvbQ==; Jing Li, Njk0MjgwNTE5QHFxLmNvbQ==

Zi-Gui Chen

Zi-Gui Chen Wei-Ping Wu

Wei-Ping Wu Jing Li3*

Jing Li3*