95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

HYPOTHESIS AND THEORY article

Front. Environ. Sci. , 29 September 2022

Sec. Environmental Economics and Management

Volume 10 - 2022 | https://doi.org/10.3389/fenvs.2022.1012229

This article is part of the Research Topic The Role of Energy Efficiency and Transition Towards Clean Energy in Achieving the COP26 Commitments View all 22 articles

Yingjing Yu1

Yingjing Yu1 Junwei Shi2*

Junwei Shi2*Low-carbon technological progress is an important way to achieve energy conservation and emission reduction, as well as achieve the goal of peaking carbon emission and carbon neutrality. Due to the difference in energy input structure, the difficulty of attaining low-carbon technology progress in industries with different energy consumption levels will lead to different responses to environmental regulation, affecting energy efficiency. This paper demonstrates the theoretical mechanism of how environmental regulation affects energy-saving efficiency through low-carbon technological progress in industries with different energy consumption levels. By reconstructing energy consumption of different industries in each province, this paper estimates the low-carbon technology progress in high-energy-consuming industries and low-energy-consuming industries in 30 provinces and cities of China from 2000 to 2016. It carries out empirical tests using mediating effect model. The results show that nationwide, the impact of environmental regulation on energy efficiency through low-carbon technology progress is U-shaped. Low-carbon technology progress accelerates the inflection point, indicating that the progress of low-carbon technology is beneficial for strict environmental regulation policies to improve energy efficiency. It shows there is asymmetric regional heterogeneity in the impact of environmental regulation on energy efficiency through low-carbon technology progress in high-energy-consuming and low-energy-consuming industries: in the central-western region, the progress of low-carbon technology in high-energy-consuming industries is faster than that in low-energy-consuming industries; in eastern region, room for energy-saving through low-carbon technology in low-energy-consuming industries is more significant than that in high-energy-consuming industries. This paper provides empirical evidence and policy suggestions for China to implement differentiated environmental regulation policies in accordance with local conditions, promote green technology transformation, and conserve the ecological civilization.

China has stepped into the critical stage of growth model transformation. The improvement of energy efficiency has become one of the major problems to be solved to realize energy consumption reduction and green development, as well as the transition from the phase of rapid growth to a stage of high-quality development. The coal consumption is still on the rise. The total carbon emission has not yet reached its peak, and the difficulty in improving energy efficiency is aggravated. The report of the 19th National Congress of the Communist Party of China emphasized the improvement of a green, low carbon, and circular economic system; and the construction of a clean, low-carbon, safe and efficient energy system. China announced to the international community that “Aim to have CO2 emissions peak before 2030 and achieve carbon neutrality before 2060”, which is the “carbon peak and neutrality” goal. In the face of growing energy consumption demand and increasingly tighter carbon emission constraints, low-carbon technology progress has become an important way to improve energy efficiency, and the key to successfully achieving the “carbon peak and neutrality” goal, as well as a crucial driver for industrial carbon emission reduction and energy efficiency. With high energy consumption, long-term economic growth model gives market and profit advantages to non-cleaner production and high-energy consuming technology research and development. It offers insufficient incentives for innovations in cleaner production and low-carbon technology. Low-carbon technology will not be adopted and spread spontaneously over industries. It needs to be induced by environmental policies and appropriate incentives. (Popp, 2019). In this case, the environmental regulation, low-carbon technology progress, and energy efficiency in the same analysis framework are obviously beneficial to the more comprehensive research of the impact mechanism of environmental regulation policies on energy efficiency.

Industrial production does not only consume energy, but also requires the input of energy elements (Ye et al., 2020). The energy input structure of industries with different energy consumption levels is distinctive, which is the natural feather of energy-consuming industries that directly determines the impact of environmental regulation on low-carbon technology progress among industries. Industries with greater dependence on fossil fuels like coal, are facing greater pressure and resistance to low-carbon technology innovation. Low-carbon technology progress is more unlikely to be made. That is the relative size of front-end low-carbon technology innovation investment and back-end pollution control technology innovation investment. The impact of environmental regulation on energy efficiency depends on the direction and size of the impact of environmental regulation on low-carbon technology progress in high-energy-consumption industries and low-energy-consumption industries. Therefore, clarifying the relationship between investment distortion of technological innovation caused by differences in energy input structure and low-carbon technology progress, is the key to analyzing the impact of environmental regulation on energy efficiency. Energy consumption is not only the input for industrial production but also the source of environmental pollution emissions (Mavi and Mavi, 2019; Wu et al., 2020). The improvement of energy efficiency can reduce pollutant emissions and environmental economic losses (Li et al., 2020). With the gradual improvement of environmental quality and the implementation of environmental protection policies, the development of low-carbon technologies will help to promote the green and low-carbon development of energy and reduce energy consumption. The optimization of the path toward carbon emission reduction will be achieved, promoting the sustainable development of the economy and society.

Compared with the existing literature, the marginal contributions of this paper are mainly in the following four aspects:①Integrate environmental regulation, low-carbon technological progress, and energy efficiency into the analytical framework; Clarify the differentiated behavior mechanism of environmental regulation caused by the difference in energy input structure. Analysis the internal mechanism of how environmental regulation improves energy efficiency through low-carbon technology progress in industries of different levels of energy consumption, providing countermeasures for the implementation of environmental regulation policies and the achievement of energy conservation and emission reduction targets in China.②For the existing database, this paper makes up for energy consumption data of different industries in each province in the existing literature. It estimates the proportion adjustment coefficient of different provinces in the industry through industrial output value, reconstructs the energy consumption data of different industries in each province, enriches the existing energy data, and lays the foundation of data to construct low-carbon technology progress in two types of industries.③According to the existing literature on industrial classification in environmental research, most previous researches used pollution emission data to classify industries into pollution-intensive industries and clean industries. But energy data is more reliable than pollution emission data. This paper focuses on energy input and pollution control sources, using energy data with a smaller statistical bias than pollution emission data to classify industries into high-energy-consuming and low-energy-consuming industries. It uses Data Envelopment Analysis (DEA) to calculate Low-carbon technology progress in high-energy-consuming industries and low-energy-consuming industries.④Based on the regional features in China, this paper makes a comprehensive research of asymmetric regional heterogeneity, which is how environmental regulation in the eastern, central-western region affects energy efficiency through low carbon technology progress in high-energy-consuming industries and low-energy-consuming industries. This paper also finds out the technical factors and the differentiated behavior mechanism of environmental regulation that improve energy efficiency in different regions. It provides empirical evidence and policy suggestions for China to implement differentiated environmental regulation policies.

The rest are as follows: the second part is literature reviews and hypothesis proposal; the third part is theoretical analysis and research hypothesis; the fourth part is research design; the fifth part is the report of the empirical tests and a brief discussion; the last part is the conclusion and policy suggestion.

The research of environmental regulation and energy efficiency is a hot controversial issue in the energy economy and green development field, but the relationship has not yet reached a unanimous agreement. Existing researches are mainly the following two perspectives: one is the “inhibition theory,” which holds that environmental regulation burdens enterprises with additional pollution control investment and cost, therefore inhibiting the improvement of energy efficiency (Greenstone et al., 2012; Yu et al., 2019). The increasing environmental regulation intensity and the rising price of scarce energy resources will stimulate energy efficiency improvement. The “innovative offset” effect will be gradually replaced by the “compliance cost” effect which caused by the negative externalities of the enterprise’s end treatment. The second is “promotion theory.” It argues strict and appropriate environmental regulation impels enterprise to innovate green technology and improve energy efficiency (Metcalf, 2006; Wang and Feng, 2014). Some scholars have theoretically elaborated on environmental regulation and energy efficiency mechanisms, and found that the relationship between environmental regulation intensity and total factor energy efficiency is not linear but U- shaped (Li et al., 2019).

Most researches have shown that technological progress improves energy efficiency (Hu and Wang, 2006). In particular, the progress of low-carbon technology improves energy efficiency and help achieve emission reduction goals. A few researches believe there is an inverted U-shaped relationship between energy-oriented technology progress and energy consumption due to the energy rebound effect. (Qian, 2020). Therefore, the impact of low-carbon technology progress on energy efficiency remains controversial. There are few literatures discussed the relationship between low-carbon technological progress and energy efficiency through the differential behavior of environmental regulation in different energy consumption industries, from the perspective of energy input structure. The energy input structure is inherent in industry, which is difficult to change in a short time. It has an important impact on the decision-making of environmental protection and pollution control in industry. The following parts will focus on demonstrating the internal influence mechanism. There are significant gaps between the development of industries in different regions of China. The proportion of high-energy-consuming industries and low-energy-consuming industries in different regions varies is quite different. The role of low-carbon technology progress in these two industries differs in environmental regulation affecting energy efficiency, which is enlightening for formulating differentiated regional environmental policies. There are significant differences in environmental regulation intensity, technology R&D, and industrial development among different regions in China, which provides an ideal empirical environment for the following multi-dimensional regional heterogeneity tests.

There are few empirical researches on the transmission mechanism between environmental regulation and energy efficiency. Some scholars discussed the relationship of environmental regulation, technology innovation, and energy efficiency (Pan et al., 2017), but they did not analyze low-carbon technology as a mediating variable within the research framework. This paper researches how low-carbon technology progress in industries with different levels of energy consumption promote energy efficiency under the differential behavior mechanism of environmental regulation, from the perspective of energy input structure and empirical tests in different regions. By measuring the low carbon technology progress indexes of high-energy-consuming and low-energy-consuming industries, this paper investigates the influence mechanism of environmental regulation on energy efficiency, through low carbon technology progress in industries of different energy consumption with a mediating effect model.

The industry consumes a large number of energy resources and generates pollutants in production. As the intensity of environmental regulation increases, the industrial sector usually has two options, to avoid the government’s punishment for industrial pollutions and maintain high profits: one is to increase investment in back-end pollution treatment technology; the other is to increase investment in front-end low-carbon technology innovation. High-energy-consuming and low-energy-consuming industries realize low-carbon technology progress by increasing investment in low-carbon technology innovation. But these two types of industries have different degrees of difficulty in realizing low-carbon technological innovation in the face of environmental regulation. High-energy-consuming industries’ greater dependence on coal and other fossil fuels created more tremendous pressure and resistance to low carbon technology innovation. Their potential for technological energy conservation is promising, yet it is hard to achieve. Low-energy-consuming industries are exactly the opposite. With greater pressure and resistance to low-carbon technology innovation, the industries need more investment in it, and the environmental regulation intensity at the inflection point of the U-shaped curve of low-carbon technology progress is higher. The intensity level of environmental regulation corresponding to low-carbon technology progress in high-energy-consuming industries is higher than that in low-energy-consuming industries.

The low-carbon technology progress in the industrial sector is determined by the direction of environmental technology innovation caused by the difference in the energy input structure. The industries that rely more on coal and other fossil fuel energy consumption in the energy input structure spend more on low-carbon technology innovation. Faced greater pressure and resistance, their incentives to increase investment in pollution control innovation to offset the rising cost of environmental protection is stronger. Likewise, industries that rely less on coal and other fossil fuel energy consumption in the energy input structure spend less on low-carbon technology innovation. Faced less pressure and resistance, their incentives to increase investment in low-carbon technology innovation to reduce pollution emission is stronger. For high-energy-consuming industries, when the intensity of environmental regulation is low, they choose to increase investment in pollution control technology innovation due to the pressure and resistance of low carbon technology innovation, which occupies investment in low carbon technology innovation and restricts the progress of low carbon technology. When the intensity of environmental regulation increases, environmental costs will rise at an accelerated pace. The increasing investment in pollution control technology innovation in high-energy-consumption industries cannot offset the investment in environmental costs. They will turn to increase investment in low-carbon technology innovation to promote low-carbon technology progress, reducing pollution emission and avoiding rise of environmental costs. When the intensity of environmental regulation rises, the low-energy-consuming industries will also choose to increase the investment in pollution control technology innovation, due to the pressure and resistance of low-carbon technology innovation. It crowds out the investment in low-carbon technology innovation, and impedes the progress of low-carbon technology. However, when the intensity of environmental regulation rises, low-energy-consuming industries will take a faster step than high-energy-consuming industries to increase their input in low-carbon technology innovation, promoting low-carbon technology progress and reducing pollutant emission, so as to avoid the rise of environmental cost. Therefore, this paper proposes the following:

Hypothesis 1:. The impact of environmental regulation on energy efficiency through low-carbon technology progress in high-energy and low-energy consuming industries is U-shaped; In low-energy-consuming industries, the intensity of environmental regulation at the inflection point is higher than that of the high-energy-consuming industries.The impact of environmental regulation on energy efficiency depends on the direction and magnitude of the impact of environmental regulation on low-carbon technology progress in high-energy-consuming industries and low-energy-consuming industries. Specifically, if environmental regulation restricts the low-carbon technology progress in both industries, the energy efficiency is negatively affected. If the environmental regulation can boost low-carbon technology progress at the same time, the low-carbon technology progress in both industries can jointly improve energy efficiency with the incentives from environmental regulation. Under the circumstance where environmental regulation constraints the low-carbon technology progress in high-energy-consuming industries while promotes the low-carbon technology progress in low-energy-consumption industries: when the increase of low-carbon technology progress in low-energy-consuming industries is more considerable than the decrease of low-carbon technology progress in high-energy-consuming industries, environmental regulation improves energy efficiency; otherwise, the environmental regulation inhibits energy efficiency. But how environmental regulation influence low-carbon technology progress in both high and low-energy-consuming industries, depends on the difference in technology innovation investment orientation which is leaded by the difference in the energy input structure. There are two steps to explore the impact of environmental regulation policies on energy efficiency. The first step is to analyze the direction of the impact of environmental regulation on low-carbon technology progress in two types of industries. The second step is to analyze the relative size of the impact of environmental regulation on low-carbon technology progress in both high and low-energy-consuming industries.Specifically, when the intensity of environmental regulation rises, in the short term, enterprises are forced to increase their investment in low-carbon technology innovation to offset the rising cost of environmental protection, as the result of high pressure and resistance to low-carbon technological innovation. It crowds out low-carbon technology innovation, which restricts the progress of low-carbon technology, and has a negative impact on energy efficiency. In the long term, when enterprises fail to improve energy efficiency through end-of-pipe pollution control, they will increase their investment in low-carbon technology innovation instead and promote low-carbon technology progress, which has a positive impact on energy efficiency. Compared with high-energy-consuming industries, low-energy-consuming industries are less dependent on fossil fuel energy consumption. When the intensity of environmental regulation increases, the investment in innovation of pollution control technology occupies a dominant position in the short term. The investment in low-energy-consuming industries will be faster than that in high-energy-consuming industries in the long term, so the investment in low-carbon technology innovation will be increased to promote low-carbon technology progress. When the growth rate of low-carbon technology progress in low-energy-consuming industries is greater than that of high-energy-consuming industries, environmental regulation promotes the energy efficiency.

Hypothesis 2:. The impact of environmental regulation on energy efficiency is U-shaped, and low-carbon and high-carbon technological progress accelerated the arrival of the inflection point.As the development of industrial sectors in different regions of China is quite different, the proportion of high- and low-energy-consuming industries in different regions is different. The role played by low-carbon technology progress in different energy consumption industries may be different in the process of environmental regulation affecting energy efficiency. Since the Reform and Opening up, the eastern region is mainly in the late stage of industrialization. The industrial structure is gradually optimized. The proportion of low-energy-consuming industries has exceeded that of high-energy-consuming industries. The tolerance for environmental regulation is lower, and the demand for environmental governance through low-carbon technological innovation is more potent. It is more beneficial to the realization of low-carbon technological progress. The central-western region is mainly in the early and middle stages of industrialization. The resource utilization rate is not high, and the energy consumption structure is to be optimized. The proportion of high-energy-consuming industries greatly exceeds that of low-energy-consuming industries, the pressure for energy conservation and consumption reduction is higher, and the tolerance for environmental regulation intensity is stronger. Comparing the national samples, it shows that the intensity of environmental regulation in the eastern region is in the right half of the U-shaped curve. The intensity of environmental regulation in most provinces of central-western region is still far below the level of the inflection point, and is in the left half of the U-shaped curve. The proportion of the above regional industries is shown in Figures 1–4. The proportion of the total industrial output value of high energy consumption industries in the total industrial output value of industries accounts for an average of 0.4681 in eastern region, and 0.6457 in the central-western region.Since the proportion of the high-energy-consuming industries in the central-western region is much higher than the low-energy-consuming industries, and high-energy-consuming industries have low carbon technology spillover effect. The high-energy-consuming industries are more likely to exceed the inflection point of environmental regulation under the environmental regulation incentive effect, promoting the progress of low carbon technology. However, the proportion of low-energy industries in the central-western region is too low. The technology spillover effect brought by economies of scale has not appeared, and the inflection point of environmental regulation arrives later. Therefore, the high-energy-consuming industries in the central-western region realize the progress of low-carbon technology faster than the low-energy-consuming industries. The structural adjustment effect caused by the difference in industrial structure makes room for technological energy-saving of low-carbon technology progress in low-energy-consuming industries in eastern China, which significantly greater than that in high-energy-consuming industries. The gross value of industrial output of high-energy-consuming industries in the eastern region is relatively low, and the space for environmental regulation to promote energy efficiency through low carbon technology progress in high-energy-consuming industries through industrial structure adjustment is limited. The low-energy-consuming industries account for a large share of the total, there is more room for environmental policy to improve energy efficiency by promoting low-carbon technology progress through low-carbon technology innovation inputs and technology spillover effects. The energy-saving situations between the eastern region and the central-western region are quite different. Based on this, the empirical analysis of the whole country, the eastern region, and the central-western region is carried out to research the regional differences in the impact of environmental regulation on energy efficiency through low-carbon technological progress in different energy consumption industries, which has important reference value for the formulation of environmental policies in different regions.

Hypothesis 3:. There is asymmetric regional heterogeneity in the impact of environmental regulation on energy efficiency through low-carbon technological progress in high- and low-energy consuming industries.

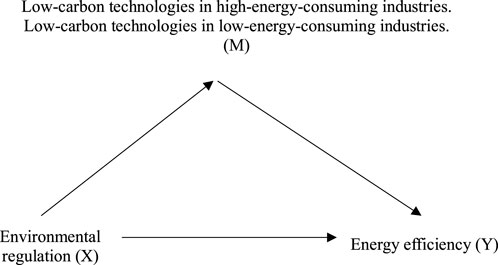

The mediating effect model (Baron and Kenny, 1986) is used to estimate the impact of environmental regulation on energy efficiency through low-carbon technological progress. There are three steps to estimate. First, verify whether explanatory variable X has a significant influence on explained variable Y. If the coefficient of X is substantial, it tests whether the mediating effect exists. Second, verify whether the explanatory variable X has a significant effect on the mediating variable M. Third, the coefficients of the explanatory variable X, the mediating variable M and the explanatory variable Y are tested, by adding the mediating variable M to the regression equation in the first step. If the coefficients of X and M are both significant, and there is a change in the coefficient of X relative to the first step, the effect is partially mediated. If the coefficient of M is significant, but the coefficient of X is not, the effect is fully mediated. The explanatory variable X is environmental regulation, the explanatory variable Y is energy efficiency, and the mediating variable M is low-carbon technology progress. The relationship between them is described in Figure 5. The mediating effect model is as follows:

FIGURE 5. Transmission mechanism of mediating effect between environmental regulation, low-carbon technology progress, and energy efficiency. Source: The author.

Here, i represents 30 provinces and municipalities in China (except Tibet), i = 1, 2,..., 30, t represents the year, t = 2000, 2004,..., 2016,

Benchmarking empirical model (1) is a nonlinear model equation, measuring the impact of environmental regulation on energy efficiency, and the square of environmental regulation intensity is included in the model. In order to reflect the time effect of environmental regulation, the environmental regulation variable is delayed by one period. If the coefficient of environmental regulation is significant, it indicates that environmental regulation has a significant impact on energy efficiency, and the impact of environmental regulation on low-carbon technology progress can be further studied. If the coefficient of environmental regulation in model (2) is significant, it indicates that environmental regulation has a significant impact on low-carbon technology progress, which means it meets the second condition of mediating effect test. Further research is needed to verify the third condition. Based on the benchmarking model (1), model (3) is added with low-carbon technology progress in high-energy-consuming

From the perspective of energy input, industrial sectors are classified as high-energy-consuming industries and low-energy-consuming industries. In comparison with some literature that classifies industries as polluting industries and clean industries on the basis of pollution emission, the classification method adopted in this paper can output more reliable outcomes. The reason is that, in consideration of data availability and research purpose, the energy consumption data has advantages in measurability, controllability, and high reliability.

The sample period by industry is from the year 2001–2015, because of the lack of environmental data for some years in 33 industrial sectors of China. Due to the differences in the classification of the industry sub-sector in the 2002 and 2011 versions of the Industrial Classification for National Activities, the data are divided and merged as necessary with the principle of maximizing the use of data. The classification is made with 33 industry sub-sectors which refers to the industry classification in China Industrial Economic Statistical Yearbook. The data of certain years in five sub-industries (handicraft and other industry; waste resources and materials recovery and process industries; other mining industries; gas production and supply industry; and water production and supply industry) are excluded because of missing, and the missing data of other industries are replaced by interpolation. To maintain the integrity of data and consistency of statistical criteria, we merged the plastic product industry, and rubber product industry into the plastic and rubber product industry; the automobile industry and rail, ship, aircraft, spacecraft and other transport equipment industry are merged into transportation equipment manufacturing industry. With the above adjustment, 33 industries are classified. Based on the median energy intensity by industry, the industrial sector is classified into low-energy-consuming and high-energy-consuming industries. If the ratio of energy consumption to total industrial output value is higher than average, it is classified as the high-energy-consuming industries. Otherwise, it is the low-energy-consuming industries. There are 17 low-energy-consuming industries and 16 high-energy-consuming industries (see Table 1).

The calculation of energy intensity (EP) is expressed by the ratio of the energy consumption to the gross value of industrial output, that is

The current technological progress measurement methods are Solow Residual Method and non-parametric DEA. The former is measured by regression residuals, while the latter calculates technological progress by production rate. According to the relevant definition of national policy documents, low-carbon technology, as a green technology, aims to reduce or eliminate carbon dioxide emissions through high-efficiency utilization of resources. Due to the lack of quantitative research on low carbon technology progress, this paper measures low carbon technology progress from the perspective of output, and undesirable output is carbon dioxide. It is measured similarly to green technology progress, and the non-parametric DEA is employed to measure the low-carbon technology progress.

Based on the input-output data of different industries in each province from 2000 to 2016, the ML index is calculated respectively with the computation value of the total-factor energy efficiency. As the ML index reflects the growth rate of low-carbon technology progress rather than the progress itself, the low-carbon technology progress in 2000 is assumed as 1. The low-carbon technology progress in high-energy-consuming industries and low-energy-consuming industries from 2000 to 2016 is obtained by multiplying the computation values of ML index. Considering the data availability, the research targets are industrial enterprises above the designated size. For the lack of the data of different industries in each province before 2000 in the China Industrial Economic Statistical Yearbook and China Environmental Statistical Yearbook, this paper actually researches the input-output data of 33 industries in 30 provinces (excluding Tibet for the lack of data in Tibet) from 2000 to 2016. Input indices include energy input, capital, and labor investment of different industries in each province. The expected output index is industrial added value of different industries in each province, and the industrial CO2 emission of different industries in each province measures the unexpected output index.

The processing of relevant index and data of input, expected, and unexpected output is described as follows:

Besides the capital and labor input, this paper considers the energy input, namely, the energy consumption. It assumed as the main source of the unexpected output. The data of total energy consumption by industry of industrial enterprises above the designated size, from the statistical table of total energy consumption by industry in China Energy Statistical Yearbook. It is converted into 10,000 tons of standard coal based on the conversion coefficient from the relevant appendix of the book. As the energy consumption data of different industries in each province have not yet been counted, this paper reconstructs it. The estimation is as follows.

The first step is to calculate the adjustment coefficient

The second step is to reconstruct

In order to reduce the data deviation in the estimation of capital stock as much as possible, it selects the annual average balance of net fixed assets of industrial enterprises above designated size of different industries in each province as an approximate estimate of the capital stock, and converts the fixed-asset investment price index by province into the constant price in 2000. As China Industry Economy Statistical Yearbook only offers the net fixed assets of different industries in each province instead of the annual average balance of net fixed assets in some years, the annual average balance of the net fixed assets of the current year is replaced by the average value of the net fixed assets of the current year and the previous year. In addition, it requires estimating the missing data of the net fixed assets of different industries in each province. The estimation method is: net fixed assets = original price of fixed assets - accumulated depreciation of fixed assets. Relevant data is from China Industry Economy Statistical Yearbook.

Working hours serve as a better measurement of measuring labor input than the number of workers, but those data are difficult to obtain. Like most of the literature, working hours is replace by the average number of employees of industrial enterprises above designated size of different industries in each province. The relevant data comes from China Industry Economy Statistical Yearbook, with the missing values estimated by the intermediate interpolation method.

This paper uses industrial added value as the expected output, and adjusts it to the constant price in 2000 with the “factory price index of industrial products by province” in China Urban (Town) Life and Price Yearbook. For the missing industrial added value of different industries in each province in “China Industry Economy Statistical Yearbook” in some years, the estimation is as follows. Industrial added value = gross industrial output value—industrial intermediate input + value-added tax payable in the current period. The industrial intermediate input is substituted with stock.

This paper estimates CO2 emissions with the amount of fuel burned and default emission factors, based on the calculation method of carbon emissions in the IPCC Guidelines for National Greenhouse Gas Inventory. This paper constructs the industrial CO2 data of different industries in each province in the same method of energy consumption. It assumes industrial CO2 emissions of different industries in each province as CNI, and industrial CO2 emissions by industry as CI. Other variables are also set in the above way, then CNI = CI*WNI.

The measurement of energy efficiency is single factor energy efficiency index and total factor energy efficiency index. The former is measured by the ratio of output to energy input (Desvallées, 2022); The latter measures the production relationship between multiple inputs, such as energy, labor force, capital, and is divided into parametric methods and non-parametric methods, namely SFA and DEA, which are classified based on the construction of production Frontier.

As the DEA model has been employed to measure the low-carbon technology progress, this paper adopts the ratio of the gross industrial output value to final energy consumption (10,000 tons of standard coal) as a gauge of energy efficiency. The higher the ratio, the higher the energy efficiency. Although only energy is considered as a single input factor, the method is simple to calculate and more convenient to understand in the analysis. It is the reciprocal of energy intensity (energy used per unit of output), and both are partial factors productivity indicators that reflect the relationship between energy consumption and output growth in economic activity.

Domestic and foreign scholars mainly measure environmental regulation from the following perspectives, including the proportion of total investment in industrial pollution control to industrial value added (Lanoie et al., 2008), the proportion of operating costs of pollution control facilities in industrial output (Gray et al., 2014), the number of inspections of enterprise emissions by policies on environmental regulatory agencies (Brunnermeier and Cohen, 2003), etc.

This paper selects two methods to measure the intensity of environmental regulation, in consideration of the availability of provincial panel data in different industries. First, the proportion of completed investment in pollution control projects to total industrial output value (ER) in each province is chosen as a proxy variable for the intensity of environmental regulation. Second, the proportion of operating costs of treatment facilities to total industrial output value in each province is chosen to conduct a robustness analysis of the empirical results. Since data on operating costs of treatment facilities for industrial solid waste are missing, the operating costs of treatment facilities include wastewater and waste gas. In the econometric model, the one-period lagged value of environmental regulation is used to measure the value of the dependent variable, taking into account the lagged factor of the policy effectiveness.

The degree of dependence on foreign trade (trad) is expressed by the proportion of total trade volume in GDP. The proportion of fiscal expenditure (gov) is expressed by the proportion of fiscal expenditure in GDP. Human capital (hc) is expressed by the average number of students enrolled in colleges and universities per 10,000 people. Patent ownership (pat) is expressed by the patent authorization per 10,000 people.

This paper conducts empirical analysis with the panel data of double-digit manufacturing industries in 30 provinces of China (excluding Tibet, Hong Kong, Macao, and Taiwan) from 2000 to 2016 for empirical analysis, with a sample size of 510. The sample data mainly come from China Environment Statistical Yearbook, China Energy Statistical Yearbook, China Industry Economy Statistical Yearbook and statistical yearbooks in different provinces. In order to eliminate the influence of price factors, this paper uses producer price index (PPI) in region to construct deflator by region, then converts the relevant indicator into the constant price in 2000.

Descriptive statistics for the variables are given in Table 2, and correlation coefficients of that in Table 3. The test results show that the correlation coefficient between variables is not large, indicating the independence of variables. The serious multicollinearity problems will not arise when they appear in the same econometric analysis model.

The regression analysis starts with a benchmark relationship between environmental regulation and energy efficiency, based on the fixed effect at provincial level. The estimated results are shown in Table 4. Column (1) is the regression model of control variables on energy efficiency. Explanatory variable environmental regulation is added in Column (2). The quadratic term of environmental regulation is added in Column (3), and the model’s explanatory power is significantly improved (△R2 = 0.031). At the 1% level, the coefficients of the linear term of environmental regulation are significantly negative, and that of the quadratic term are significantly positive. That indicates the impact of environmental regulation on energy efficiency is in a significant U-shaped characteristic. The corresponding intensity of environmental regulation at the inflection point of the U-shaped curve of the impact of environmental regulation on energy efficiency under the national sample is 44.0184. The mediating effect test can be continued.

Table 5 verifies the impact of environmental regulation on low-carbon technology progress in high-energy-consuming industries and low-energy-consuming industries respectively. Based on columns (1) and (3), the explanatory power of the model is significantly increased by adding the quadratic term of environmental regulation in columns (2) and (4) (△R2 = 0.011 in Column (2) and △R2 = 0.008 in Column (4)). The coefficients of the environmental regulation with primary term are significantly negative, and the coefficients of the quadratic term are significantly positive at the 1% level, which indicates that the impact of environmental regulation on the low-carbon technological progress in both high-energy and low-energy consuming industries has a U-shaped characteristic. When the environmental regulation intensity rises, the pressure and resistance of low-carbon technological innovation increases. The enterprises tend to substitute low-carbon technological innovation input by increasing pollution control technological innovation input to offset the rising environmental protection cost, which inhibits the low-carbon technological progress in industry. As the environmental regulation intensity rises, in order to avoid the surge of environmental regulation cost, industrial enterprises try to reduce pollution emission by increasing low-carbon technological innovation input. When the environmental regulation intensity crosses the inflection point, the low-carbon technological progress shows an increasing trend on the right side of the U-shaped curve. This also indicates the relationship between environmental regulation and technological progress in the existing literature.

It shows that the environmental regulation intensity corresponding to the U-shaped curve inflection point of the impact of environmental regulation on low-carbon technological progress in high- and low-energy-consuming industries under the national sample is 50.9615 and 47.1530, respectively. It indicats that the level of environmental regulation intensity corresponding to the U-shaped curve inflection point of the impact of environmental regulation on low-carbon technological progress in low-energy-consuming industries is much lower than that in high-energy-consuming industries. This is determined by the differential behavior of industry environmental regulation caused by differences in energy input structures. Compared to high-energy-consuming industries, low-energy-consuming industries rely less on fossil fuels such as coal, and face less pressure and resistance to low-carbon technological innovation. When the intensity of environmental regulation rises sharply, to circumvent the increase in environmental protection costs, low-energy-consuming industries will increase low-carbon technological innovation inputs and reduce technological innovation inputs for pollution control faster than high-energy-consuming industries. It promotes low-carbon technological progress in the industry, and reduces environmental protection costs. The above conclusions have certified Hypothesis 1.

The low-carbon technological progress in high-energy-consuming industries and low-energy-consuming industries is added to test the impact of environmental regulation on it. The estimated results are in Table 6. Based on Column (1) and Column (3), the quadratic term of environmental regulation is added in Column (2) and Column (4), significantly improving the explanatory power of the model (△R2 = 0.027 in model 2, △R2 = 0.023 in model 4). At the level of 1%, the coefficients of the linear term of environmental regulation are significantly negative, and that of the quadratic term is significantly positive. On the baseline regression in Table 4, the coefficients of the linear term of environmental regulation increase while that of the quadratic term decreases. It indicates a partial mediating effect, namely a U-shaped effect of environmental regulation on energy efficiency through low-carbon technological progress. The intensity of environmental regulation corresponding to the inflection points of the U-shaped curve at this time are 43.6102 and 43.5540, respectively, which are lower than the intensity of environmental regulation corresponding to the inflection points in the baseline regression model. It indicates that low-carbon technological progress accelerates the arrival of the inflection points.

When the intensity of environmental regulation rises, both industries will experience a distortion effect of technological innovation inputs. That is technological innovation inputs for pollution control dominate in the short term. In the long term, given the differences of energy input structure, low-energy-consuming industries will increase low-carbon technological innovation inputs faster than high-energy-consuming industries to achieve low-carbon technological progress. When the low-carbon technological progress in low-energy-consuming industries increases more significantly than the decreases in high-energy-consuming industries, environmental regulation promotes energy efficiency. The above conclusions have certified Hypothesis 2.

Since the huge differences in the development of industrial sectors in different regions of China, it is necessary to examine whether there is regional heterogeneity in the above conclusions. Considering that only six provinces are in the central region, we merged them into the western region. As a benchmark model analysis by region, the impact of environmental regulation by region on energy efficiency is still in U shape, as shown in Column (1) and Column (2) of Table 7.

The environmental regulation intensity is 31.6361 and 46.1140, respectively, corresponding to the inflection point of U-shaped curve in eastern and central-western region. By comparing Column (3) of Table 4, it shows that the intensity of environmental regulation in the eastern region has exceeded the level of the inflection point. It is in the right half of the curve, indicating that the enhancement of environmental regulation will promote the energy efficiency. However, the environmental regulation intensity of most provinces in the central-western regions is still lower than the inflection point. It is in the left half of the U-shaped curve, indicating that the enhancement of environmental regulation will hinder the energy efficiency.

Column (3)-(6) of Table 7 shows that the impact of environmental regulation by region on low-carbon technology progress in high-energy-consuming and low-energy-consuming industries are still in U shape. For the high-energy-consuming industries, the intensity of environmental regulation corresponding to the inflection point of the U-shaped curve of the impact of environmental regulation on low-carbon technology progress in eastern and central-western region is 34.5628 and 51.5533, respectively. For the low-energy-consuming industries, the intensity of environmental regulation corresponding to the inflection point of the U-shaped curve of the impact of environmental regulation on low carbon technology progress in eastern and central-western region is 31.9658 and 53.6117, respectively. A comparison of the national sample in Table 5 shows that, the affordability of environmental regulation differs between high- and low-energy consuming industries in different regions. This is because the proportion of low-energy-consuming industries in the eastern region has exceeded that of high-energy-consuming industries. The eastern region has a lower tolerance for environmental regulation, and more robust demand for environmental governance through low-carbon technological innovation, which is more beneficial to achieving low-carbon technological progress. The proportion of high-energy-consuming industries in the central-western region greatly exceeds that of low-energy-consuming industries, with higher pressure on energy conservation and consumption reduction. The central-western region has a stronger tolerance for environmental regulation intensity.

In the central-western region, the environmental regulation intensity of the inflection point of the impact of environmental regulation on low-carbon technological progress in high-energy-consuming industries is lower than that in low-energy-consuming industries. That’s probably because the central-western region is mainly covered by high-energy-consuming industries. It is more likely to break through the inflection point of environmental regulation and promote low-carbon technology progress under the combined effect of environmental regulation and technology spillover effects. Low-energy-consuming industries account for a relatively low proportion. The technology spillover effects brought by economies of scale have not yet emerged, so the corresponding inflection point of environmental regulation comes later. The above conclusions have certified Hypothesis 3.

The regional heterogeneity characteristics of environmental regulation to promote energy efficiency through low-carbon technology progress are validated and shown in Table 8. Columns (2) and (4) show that for the central-western region, the impact of environmental regulation on energy efficiency through low-carbon technology progress is still U-shaped. Moreover, the intensity of environmental regulation corresponding to the inflection point of the U-shaped curve is 44.5205 and 44.5860, respectively. This shows that in the central-western region, low-carbon technological progress has accelerated the arrival of the inflection point, and environmental regulation promotes energy efficiency through low-carbon technological progress.

However, it should be noted that in Column (1), the coefficient of low-carbon technological progress in high energy-consuming industries is not significant in the eastern region. It may be because the total industrial output value of high-energy-consuming industries in the eastern region is relatively low. The environmental regulation promote energy efficiency through low-carbon technological progress in high-energy-consuming industries has limited room with industrial restructuring, as shown in Figure 1. In contrast, the high energy-consuming industries in the central-western region account for a high percentage of the total. It has been on a significant downward trend since 2008, with a large decline and a solid structural adjustment effect. As the intensity of environmental regulation increases, the high energy-consuming industries are transformed and upgraded to low energy-consuming industries through low-carbon technological progress, with a greater potential for energy efficiency improvement, as shown in Figures 2–4. There are noticeable regional differences in the impact of environmental regulation on energy efficiency through low-carbon technological progress in high energy-consuming industries. The role played by structural adjustment and low-carbon technological progress in energy efficiency improvement must be fully explored. The coefficient of low-carbon technological progress in low-energy-consuming industries in Column (3) is positive and significant, which indicates that in the eastern region, the impact of environmental regulation on energy efficiency through low-carbon technological progress in low-energy-consuming industries presents a U-shaped characteristic. The above conclusions have verified Hypothesis 3.

In order to test the robustness of the regression results, we use the method of replacing the measures of environmental regulation. After comparing the test results with that in the above tables, it indicates that the estimation results of the two proxy variables of environmental regulation are generally consistent. Therefore, the theoretical and empirical conclusions of this paper are robust.

There may be a two-way causal relationship between environmental regulation and energy efficiency in the econometric model, and the regression results may be biased. This paper uses the mean value of the environmental regulation intensity of neighboring provinces as an instrumental variable (IVER) to solve the endogeneity existing in the model. The test results show that the choice of instrumental variables is generally adequate.

Based on the perspective of energy input structure, this paper clarifies the mechanism of differentiated behavior of environmental regulation triggered by differences in energy input structure, and provides insight into the mechanism of how environmental regulation promote energy efficiency through low-carbon technological progress in different energy-consuming industries. By reconstructing energy consumption of different industries in each province, we measure the low-carbon technological progress of high- and low-energy consuming industries separately. It uses a mediating effects model to empirically test the internal logic of energy efficiency promoted by differences in environmental regulation behavior between industries. It in turn provides empirical evidence and policy insights for China to implement differentiated environmental regulation policies according to local conditions, successfully achieving energy conservation and emission reduction targets.

The main findings are as follows:①the impact of environmental regulation on low-carbon technological progress in high- and low-energy industries presents U-shaped characteristic. The level of environmental regulation intensity at the inflection point of low-carbon technological progress in low-energy-consuming industries is much lower than that in high-energy-consuming industries.②The impact of environmental regulation on energy efficiency presents U-shaped characteristics, and the low-carbon technological progress of high- and low-energy-consuming industries accelerates the arrival of the inflection point.③It shows there is asymmetric regional heterogeneity in the impact of environmental regulation on energy efficiency through low-carbon technological progress in high- and low-energy-consuming industries: in the central-western region, the development of low-carbon technology in high-energy-consuming industries is faster than that in low-energy-consuming industries; in eastern region, room for energy-saving through low-carbon technology in low-energy-consuming industries is more significant than that in high-energy- consuming industries.

To accelerate the progress of low-carbon technology in industry and promote energy efficiency, this paper puts forward the following three policy suggestions:

(1) Establish and improve the energy conservation and environmental protection policy system, including laws and regulations. Use environmental policies to promote and apply advanced low-carbon technologies. Play the incentive mechanism of environmental and technical standards, and promote industrial enterprises to adopt energy-saving and environmental protection technologies. Eliminate backward and high-energy-consuming technologies, and ensure the low-carbon energy structure from the source. Form an operating mechanism conducive to energy saving and environmental protection, achieving a win-win situation of energy saving and pollution reduction.

(2) Improve the credit policy for financing green and low-carbon technology, and reduce the financing threshold and cost of low-carbon technological innovation of industrial enterprises. Although low-carbon technology innovation helps low-carbon technology progress and energy-saving efficiency improvement, it is difficult to achieve due to R&D financial constraints. Financial institutions need to be guided to accurately invest in energy-saving technology projects, accelerate low-carbon technology innovation, reduce the cost of energy structure transformation, and improve the market competitiveness of low-carbon technology.

(3) Formulate differentiated regional and industrial environmental regulation policies, and focus on implementing differentiated management by regions and classifications. For example, the high energy-consuming industries in the central-western region account for a relatively large share of the energy saving and consumption reduction tasks, and the foundation for low-carbon energy transformation is weak. The financial transfer payments of central government need to be strengthened to accelerate the reform process of industrial structure transformation, optimization and upgrading and low-carbon technologies in the central-western region, promoting the overall level of industrial green and low-carbon development.

Publicly available datasets were analyzed in this study. This data can be found here: China Environment Statistical Yearbook, China Energy Statistical Yearbook, China Industry Economy Statistical Yearbook and statistical yearbooks in different provinces.

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

This research was funded by the National Social Science Foundation “Research on Multi-level System and Policy of Technological Innovation in China’s Manufacturing Industr” (Project No. 21FJYB033).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenvs.2022.1012229/full#supplementary-material

1Considering the length, the estimation results of robustness test and the treatment results of endogeneity problem are not given in the main body of this paper. Please see the appendix for details.

Baron, R. M., and Kenny, D. A. (1986). The moderator-mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Personality Soc. Psychol. 51 (6), 1173–1182. doi:10.1037/0022-3514.51.6.1173

Brunnermeier, S. B. (2003). Determinants of environmental innovation in US manufacturing industries. J. Environ. Econ. Manag. 45, 278–293. doi:10.1016/s0095-0696(02)00058-x

Desvallées, L. (2022). Low-carbon retrofits in social housing: Energy efficiency, multidimensional energy poverty, and domestic comfort strategies in southern europe. Energy Res. Soc. Sci. 85, 102413. doi:10.1016/j.erss.2021.102413

Fisher-vanden, K., Jefferson, G. H., Liu, H. M., and Tao, Q. (2004). What is driving China’s decline in energy improvement? Resour. Energy Econ. 26 (3), 2287–2295. doi:10.1016/j.reseneeco.2003.07.002

Gray, W. B., Shadbegian, R. J., Wang, C., and Meral, M. (2014). Corrigendum to: Do EPA regulations affect labor demand? Evidence from the pulp and paper industry. J. Environ. Econ. Manag. 68 (1), 188–202. doi:10.1016/j.jeem.2014.06.002

Greenstone, M., and List, J. A. (2012). Syverson C. The effects of environmental regulation on the competitiveness of U.S. manufacturing. NBER Work. Pap. 9, 18392. doi:10.2139/ssrn.2145006

Hu, J. L., and Wang, S. C. (2006). Total-factor energy efficiency of regions in China. Energy Policy 34 (17), 3206–3217. doi:10.1016/j.enpol.2005.06.015

Lanoie, P., Patry, M., and Lajeunesse, R. (2008). Environmental regulation and productivity: Testing the porter hypothesis. J. Product. Anal. 30, 121–128. doi:10.1007/s11123-008-0108-4

Li, Y., Chiu, Y. H., Wang, L. H., Zhou, Y., and Lin, T. Y. (2020). Dynamic and network slack-based measure analysis of China’s regional energy and air pollution reduction efficiencies. J. Clean. Prod. 251, 119546. doi:10.1016/j.jclepro.2019.119546

Li, Y., Xu, X., and Zheng, Y. (2019). An empirical research of environmental regulation impact on China’s industrial total factor energy efficiency: Based on the data of 30 provinces from 2003 to 2016. Manag. Rev. 31 (12), 40–48. doi:10.14120/j.cnki.cn11-5057/f.2019.12.004

Mandal, S. K. (2010). Do undesirable output and environmental regulation matter in energy efficiency analysis? Evidence from Indian cement industry. Energy Policy 38, 6076–6083. doi:10.1016/j.enpol.2010.05.063

Mavi, N. K., and Mavi, R. K. (2019). Energy and environmental efficiency of OECD countries in the context of the circular economy: Common weight analysis for malmquist productivity index. J. Environ. Manag. 247 (7), 651–661. doi:10.1016/j.jenvman.2019.06.069

Pan, X. F., Ai, B. W., Li, C. Y., Pan, X. Y., and Yan, Y. B. (2017). Dynamic relationship among environmental regulation, technological innovation and energy efficiency based on large scale provincial panel data in China. Technol. Forecast. Soc. Change 144 (7), 428–435. doi:10.1016/j.techfore.2017.12.012

Popp, D. (2019). Environmental policy and innovation: A decade of research, 3. NBER Working Paper, 25631.

Qian, J. (2020). The threshold effect of energy-saving bias-oriented technological progress on industrial energy saving and emission reduction. Sci. Res. Manag. 41 (01), 223–233. doi:10.19571/j.cnki.1000-2995.2020.01.022

Wang, Z., and Feng, C. (2014). The impact and economic cost of environmental regulation on energy utilization in China. Appl. Econ. 46 (27), 3362–3376. doi:10.1080/00036846.2014.929629

Wu, H., Xu, L. N., Ren, S. Y., Hao, Y., and Yan, G. Y. (2020). How do energy consumption and environmental regulation affect carbon emissions in China? New evidence from a dynamic threshold panel model. Resour. Policy 67 (8), 101678. doi:10.1016/j.resourpol.2020.101678

Ye, P., Xia, S., Xiong, Y., Liu, C., Li, F., Liang, J., et al. (2020). Did an ultra-low emissions policy on coal-fueled thermal power reduce the harmful emissions? Evidence from three typical air pollutants abatement in China. Int. J. Environ. Res. Public Health 17 (22), 8555. doi:10.3390/ijerph17228555

Keywords: environmental regulation, low-carbon technology progress, energy efficiency, mediating effect, energy input structure

Citation: Yu Y and Shi J (2022) Environmental regulation, low-carbon technology progress and energy efficiency. Front. Environ. Sci. 10:1012229. doi: 10.3389/fenvs.2022.1012229

Received: 05 August 2022; Accepted: 29 August 2022;

Published: 29 September 2022.

Edited by:

Atif Jahanger, Hainan University, ChinaReviewed by:

Wenyun Xu, Jiangxi University of Finance and Economics, ChinaCopyright © 2022 Yu and Shi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Junwei Shi, andzaGlAenVlbC5lZHUuY24=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.