- 1Department of Mechanical/Biomedical Engineering, Bells University of Technology, Ota, Nigeria

- 2Department of Mechanical Engineering, Federal University of Agriculture, Abeokuta, Nigeria

- 3Department of Mechanical Engineering, University of Calabar, Calabar, Nigeria

- 4Department of Mechanical Engineering, Covenant University, Ota, Nigeria

- 5Department of Mechanical Engineering, Federal University of Petroleum Resources, Effurun, Nigeria

- 6Department of Mechanical Engineering, University of South Africa, Science Campus, Florida, South Africa

- 7Department of Chemical Engineering, University of Strathclyde, Glasgow, United Kingdom

- 8Department of Chemical and Metallurgical Engineering, Tshwane University of Technology, Pretoria, South Africa

Given the increased natural resource consumption of contemporary energy conversion systems, as well as the emissions, waste disposal, and climate changes that accompany them, a critical review of new techniques - known as thermo-economic and thermo-environmental analyses - has been carried out for the evaluation and optimization of energy conversion processes, from the perspectives of thermodynamics, economics, and the environment. Such a review study is essential because of the energy system’s impacts on sustainability and performance management requirements, and more importantly, it is crucial to understand the whole picture of performance evaluation of energy systems from the sustainability perspective. The study evaluated the performance and optimization of energy systems and examined the different approaches that integrate the economic, environmental, and second law of thermodynamics for sustainable development. Moreover, to assess the technical, economic, and environmental worth of energy systems and guarantee that the chosen designs are well-suited to a sustainable development framework, a mix of thermodynamic, economic, and environmental indicators is taken into consideration. In this regard, thirteen sustainability indicators for the design, analysis, and performance improvement of energy systems from the viewpoints of thermodynamics, economics, and the environment are presented and discussed. The outcome of this study shows that (i) the sustainability of energy conversion systems can be enhanced with the use of exergy techniques assessment; (ii) by reducing energy losses, exergy efficiency initiatives can lessen their adverse effects on the environment; (iii) the best methods for efficient use of energy resources, low energy production costs, and less environmental impact can be provided by hybrid energy systems; and (iv) use of a single performance metric to optimize the energy process results in improbable outcomes. Hence, multi-criteria techniques should be utilized, allowing for a more comprehensive optimization and planning of sustainable energy systems. Researchers and field engineers working on energy systems’ design, modeling, assessment, and performance optimization would find great value in this comprehensive review study.

1 Introduction

Today, scientists and engineers are developing new technologies and more effective energy-harvesting systems to maximize the use of available energy resources. Because of this, studying and improving energy conversion systems is important from a scientific standpoint and is also necessary for the effective use of available energy resources (Oyedepo, 2014a). Any country’s ability to grow economically depends on its supply of energy. Social developments impact the energy system in various ways, but society is also affected by the energy system (Oyedepo, 2014b). The production and availability of energy significantly influence global economic and political development. A strong energy sector is essential for success in other socioeconomic domains. The link between natural resource availability and security for energy consumption is known as energy security. These days, having access to economically priced energy is crucial to the functioning of modern economies. The attainment of the Sustainable Development Goals (SDGs) is contingent upon every individual having access to modern, adequate, and efficient energy (Bishoge et al., 2020). Since then, a vast array of technical applications for energy have been created, making energy availability a crucial concern for civilization (Huggins, 2016).

Sustainable development has recently been recognised as the utmost task of this new age (Annamalai et al., 2018). The latter leads to several transnational consequences, particularly environmental contamination, climate change, reduction of natural deposits, natural decimation, and international injustice (Akbari et al., 2020). Human activities have added undesirably to sustainable growth. Additionally, it is known that a transformation to economic sustainability requires substantial variations in energy demands and resources (Mulvihill et al., 2011). However, in recent times, the lack of adequate energy supply and limited capital, followed by efforts to alleviate the hazard posed by contamination of the environment, has resulted in the growth of feasible engineering science (Das et al., 2019).

The prime objective of sustainable technology is to attain economic feasibility for scenic surroundings. Sustainable technology has a principal goal in environmental disciplines and the development of worldwide economies, generally linked alongside the design layout and breakdown of multifaceted, unified energy processes and economic sustainability. Lessening material and energy supply and minimising misuse is a significant environmental objective (Srebrenkoska et al., 2013). Sustainable energy is necessary for any strategies for global sustainability due to (i) the generality of energy usage, (ii) its demand in economic growth and standards of living, and (iii) the significant effects of energy processes and systems on the environment and its continued influence (Oyedepo, 2012). Increasing environmental issues and limited available non-renewable conventional energy resources have engendered new impulses in modern sustainable energy technologies. This is because resources for energy and their utilisation closely have to do with sustainable developments. The development of cleaner energy systems is one of the significant advances of this advanced century. Most forecasts demonstrate that combustion type of energy conversion systems remains the prime method for most energy consumption (Lieuwen and Yang, 2013). Hence, to accomplish sustainable progress, it is crucial to increase the efficiencies of energy processes that utilize sustainable energy (Hepbasli, 2008).

In the next 20 years, energy use worldwide is projected to rise considerably worldwide, with developing countries having the highest growth rates. Fossil fuels are anticipated to deliver a big part of the world’s energy, up to 75% of overall energy utilization in 2040 (Rao, 2015). Following the massive expansion in petroleum derivative use around the world, the ozone-depleting substance CO2 emanations to the environment are relied upon to increment by an average yearly development of 1.29% within the range of the years 2010–2040 or by as far as 45.8% by 2040 from 2010. Notwithstanding this ozone-harming substance, the tackling of the energy trapped inside a fuel by incineration generates contaminations like oxides of sulphur, nitrogen, and partly combusted fossil fuels that are brought into the air, the quantity dependent upon the effectiveness and efficiency of the technology utilized for transformation. A challenge emanates between raising the quality of life (assessed by gross national product per capita), and energy use per capita that can directly influence the surroundings provided sustainable energy conversion systems and operations are followed up.

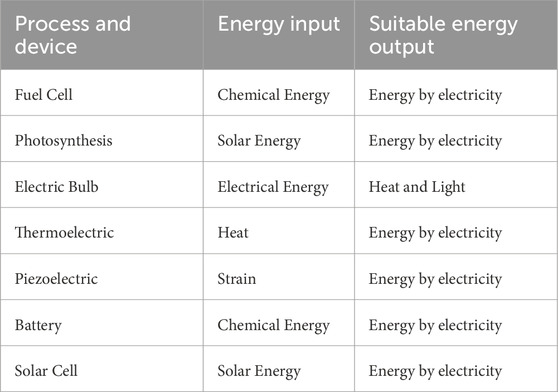

Research in generating alternative energy sources has made more energy available to consumers. Different equipment and processes convert energy into different forms, as shown in Table 1. An IC engine converts the chemical energy from gasoline into heat, which in turn creates mechanical energy that moves a vehicle. The energy passes through a device that converts it, which produces another energy source. The output energy is always less than the input energy. However, the quantity of energy is conserved (Demirel, 2012). Figure 1 depicts a representation of the energy use and its conversion process.

Table 1. Processes/devices for energy conversion (Demirel, 2012).

Figure 1. Diagram of energy use and its conversion process (Demirel, 2012).

The different forms of energy are grouped into three general categories: (i) primary energy (hydropower, fossil fuel, hydraulic energy, wind energy and solar energy), (ii) secondary energy (gasoline, diesel, and kerosene. Others are, ethanol fuel and biodiesel derived from biomass, thermal energy from solar collectors, and district heating from geothermal fluids), (iii) tertiary energy (electric energy, nuclear energy, gas, coal, and most of the different renewable energy source of energy, which are categorised as primary energy sources, contribute to the supply of tertiary energy when they are used to produce electricity). The processing and transformations that produce secondary and tertiary energy forms always involve energy losses, which are often significant for tertiary energy (Khartchenko and Kharchenko, 2014). The first two laws of thermodynamics control the energy dissipation during such transformations. The efficiency of the transformation process indicates how well the primary resource’s original energy can be converted to the secondary form (Michaelides, 2018).

Thermal efficiencies of energy transformation are typically far less than 100% because of inefficiencies caused by friction, heat loss, and other factors. For example, in a steam power station, only 35%–40% of the thermal energy can be transformed into electrical current. A typical gasoline automobile engine operates at about 25% efficiency. Energy is always conserved, according to the first law of thermodynamics. But some of the energy that was initially available is lost during energy transformations as waste heat that is not needed or used by human society.

Due to different energy conversion technologies based on differences in economic and environmental factors, energy utilization should be guided by principles whose validity has been proven beyond doubt (Giovanni, 2014). Hence, analysis and optimisation of energy systems are logical and vital for humanity from the socio-economic and environmental points of view.

Furthermore, the past 2 decades have witnessed tremendous transformation in energy technology, now a focal field for research and development studies. Extensive studies were carried out in energy system research to optimize energy conversion efficiency and advance the technologies that promote other energy sources. The main objective of such studies was to determine the degradation effect of exergy resources. To complement this drive, the research area of thermo-economic and thermo-environmental involves combining thermodynamic, economic and environmental issues in design, assessment and enhanced optimal performance of energy conversion systems and industrial process efficiencies without jeopardizing an energy system’s financial feasibility. The resulting improvement in efficiency has further decreased environmental impact due to improved system efficiency (von Spakovsky and Frangopoulos, 2011).

The sustainable utilization of energy is inherently connected to the systems’ effectiveness in transforming crude materials into useful products. The technology of these energy converters straightforwardly impacts the value and amount of their energy consumption, services, and the effluent dispersed to the atmosphere. In this regard, the consumption of sources of fuel, paying little mind to fossil fuel or the supposed renewable energy, should be led by utilizing an effective conversion system during its final use as well as in the entire process of energy transformation measures starting from the fuel source, through the energy conversion process till the waste disposal stage. Assessing each stage of energy usage is imperative in determining the extent of energy quality (de Oliveira, 2013).

In view of the above, the energy conversion system is recognised as a device that consumes fuel and other scarce natural resources. Consequently, it has an adverse effect on the atmosphere in the course of operation. Hence, the study on assessing and optimising energy systems must consider sustainability matters quantifiably. Accordingly, this paper focuses on the critical review of the enhancement and sustainability of energy systems from thermodynamic, thermo-economic and thermo-environmental perspectives, considering selected performance indicators as signposts of sustainability for energy conversion systems.

2 Thermodynamics assessment of energy conversion systems

Thermodynamics plays a vital role in dissecting frameworks and equipment where energy transformation occurs. Thermodynamics’ significance is across the board of human initiative (Dincer and Cengel, 2001). Thermodynamics science follows two central natural laws, the first and second (Oyedepo, 2014a). The thermodynamic first law emphasizes that energy as a thermodynamic property interacts and can transform from state to state. However, the energy is conserved. The first law is conventionally used to analyze energy consumption and plant operation. Unfortunately, it does not consider the energy quality, which is now remedied by the second law of thermodynamics. The thermodynamic second law affirms that energy has quantity and quality and that real processes exist in the path of reducing the quality of energy called exergy.

The energy system is designed to provide energy services to consumers by continuously evaluating its exergy performance (Granet and Bluestein, 2000). Exergy studies have been used to extract the maximum amount of useful work or performance of an operation as it moves from one equilibrium state to another (Ahmadi et al., 2011a). It is also considered the elementary notion by which the thermodynamic cycle is modelled and analyzed by the applications of the laws of thermodynamics (Zare and Hasanzadeh, 2016). Moreover, it thoroughly analyzed energy systems’ efficiencies, optimal performance and irreversibility sources (Saidur et al., 2007).

Surprisingly, the various means of generating and supplying power are unsustainable and costly, leading to an upsurge in energy demand; if appropriate actions are not taken, this increase in energy demand will be truncated with more energy waste, resulting in environmental pollution. Therefore, if carried out sustainably, increased energy demand, efficient energy systems, improved technologies, and environmental preservation dictate improvement in a nation’s industrial development (Saidur et al., 2010).

2.1 Analysis of energy and exergy of an energy systems

Presently, humankind faces incredible economic, environmental, and energy difficulties. A solid essential exists to more readily configure, investigate, evaluate and enhance energy measures, systems and utilization (Dincer et al., 2014). Accordingly, energy and exergy analysis are the two essential tools for designing and optimising energy systems to use effectively resource-constrained fossil fuels (Oyedepo et al., 2018). Researchers have delved into using exergy analysis to overcome the shortcomings of the first and foremost law of thermodynamics.

Moreover, studies reveal a correlation between sustainable development and exergy. Both will establish that the energy system is cost-effective, steady and non-threat to the environment. Hence, exergy analysis is broadly employed in the design of our energy equipment (Hepbasli, 2008). The exergy idea is dependent on the first two thermodynamic laws. Exergy assessment shows the positions of energy deterioration in a procedure and can result in enhanced technology. Exergy analysis mainly detects energy losses in a system and the magnitude of such loss. It also identifies energy efficiency to optimize the system (Zare, 2020).

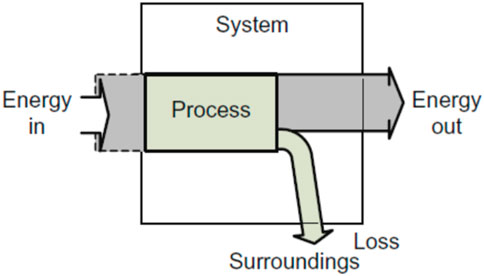

With the exergy analysis concept, it is possible to gauge energy transformation operation processes on a thermodynamics aspect and the eco-environmental impact of the process in the study. This inclusive approach to energy conversion is essential for sustainable energy resource utilization (de Oliveira, 2013). Exergy methods can help improve the sustainability of energy systems. Studies have indicated that enhancing the exergy efficiency of energy systems can reduce environmental impacts by cutting down on energy wastage (Oyedepo, 2014a; Rao, 2015; Ahmadi et al., 2011a; Zare and Hasanzadeh, 2016). A measure to assess the relationship between exergy efficiency and environmental sustainability is the Exergetic Sustainability Index (ESI). This indicator helps to determine the capacity and effective utilization and preservation of energy resources (Dincer et al., 2014; Oyedepo et al., 2018; Rosen, 2021). Figure 2 illustrates this qualitatively by demonstrating how, as exergy efficiency increases, sustainability increases and environmental impact decreases. Exergy efficiency becomes closer to 100%, sustainability approaches infinity since the process approaches reversibility, while environmental impact approaches zero because exergy is converted from one form to another without any loss. Exergy efficiency approaches 0% since exergy resources are used to accomplish nothing, hence, sustainability approaches zero. On the other hand, environmental impact approaches infinity because increasing resources must be used and increasing exergy wastes are emitted for a fixed service (Rosen, 2021).

Figure 2. Qualitative depiction of relation of environmental impact and sustainability with exergy efficiency (Rosen, 2021).

Environmental pollution from fossil fuels has led to numerous studies on energy-efficient conversion and eco-friendly renewable energy sources (Rosen, 2021). An energy-efficient system assures sustainable development. A deliberate improved system as a function of exergy analysis will usher in reliability, sustainability and cost-effectiveness (Hepbasli, 2008). A correlation exists among exergy analysis, sustainable development, and ecological and environmental management (Rosen, 2009). The analysis of exergy aids in projecting thermodynamics into ecological and environmental impact on devices in consideration. The essence of exergy analysis investigates the useful energy that does work on the system. It looks into the primary source of irreversibility in the cycle and improves it to prevent exergy destruction.

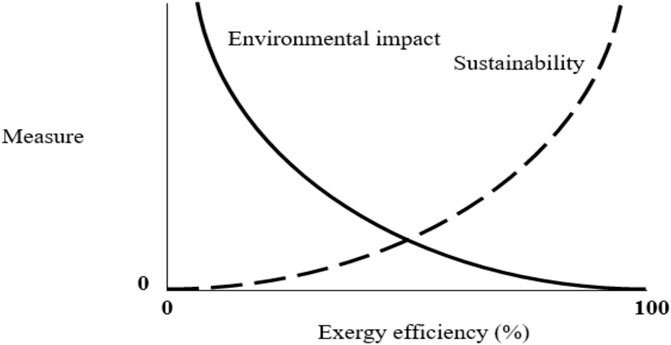

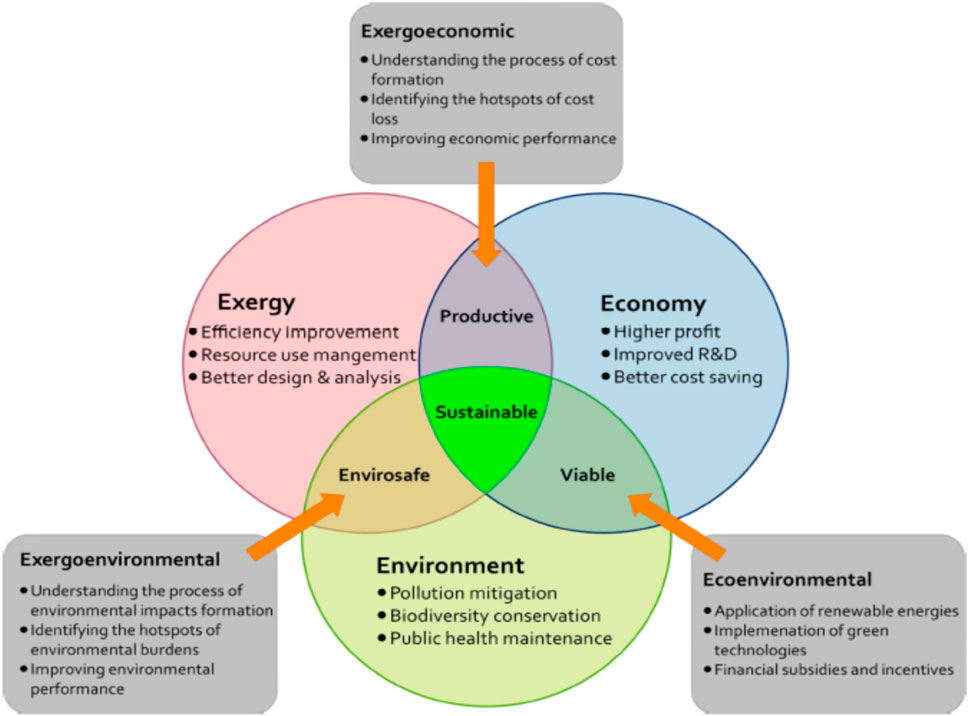

Another essential feature of the second law of thermodynamic (exergy) concept is its capability to be integrated with economic and environmental constraints. These integrated methods, called “thermo-economic and thermo-environmental” approaches, are powerful tools to identify, quantify, and interpret economic losses and environmental burdens of energy systems at the component level. Precisely, the thermo-economic method can effectively address the shortcomings of techno-economic analysis by accounting for thermodynamic losses (Al-Qayim, 2019). In addition, the thermo-environmental method can reliably cope with the drawbacks of Life Cycle Assessment (LCA) analysis in the sustainability assessment of energy systems by allocating the environmental burdens at the component level and measuring the environmental burdens of intermediate products. This unique combination of exergy, economy, and environment can reliably assess the thermodynamic productivity, economic viability, environmental safety, and overall sustainability of energy and material conversion processes (Figure 3) (Aghbashlo et al., 2022).

Figure 3. Opportunity interactions among exergy, economy, and environment (Aghbashlo et al., 2022).

Additionally, numerous studies on the exergy assessment of energy operations have been carried out to study the variability of energy systems for power generation or industrial processes. Among the explored studies are gas turbines (Rosen, 2021; Aghbashlo et al., 2022), steam power plants, combined cycle power plants, refrigeration systems, ORC and Kalina cycles, wind energy and solar energy systems, among others (Ahmadi et al., 2011a; Saidur et al., 2010; Rosen, 2021; Aghbashlo et al., 2022; Waheed et al., 2018).

2.1.1 Gas turbine engine

The demand for gas turbine engines is increasing due to their low cost, high flexibility, high reliability without complexity, short delivery time, and fast starting and loading but low efficiency. Several analyses have therefore been conducted to improve the low thermal efficiency in Simple Gas Turbine (SGT) (Rosen, 2009). In recent times, efforts to improve the power generation efficiency of SGTs have been through gas-to-gas recuperation, steam injection (STI), evaporation cycle, chemical recuperation, inlet air cooling (IAC) and combined cycle. These efforts have led to an increase in output power, thermal efficiency and work-back ratio (Waheed et al., 2018).

A typical gas turbine unit comprises a low-pressure turbine (LPT) and a high-pressure turbine (HPT). The LPT consist of four segments with an effectual blade for cooling and negligible leak. The HPT is positioned within two combustors possessing a single stage. During the initial expansion, most of the exhaust gases diffuse to the second combustor (Aghbashlo et al., 2022). Numerous researchers have worked on the thermodynamic assessment of different gas turbines (Wang and Chiou, 2004; Farzaneh-Gord and Deymi-Dashtebayaz, 2009). The thermodynamic investigation of gas turbines revealed that ambient temperature, humidity, pressure ratio, turbine inlet temperature (TIT) (around 500°C) and nature of fuel are the essential factors affecting gas turbine performance. The enormous exhaust temperature shows that energy is being flared uncontrollably into the environment. In the work of Sulaiman et al. (2017), the effect of decreasing entry air cooling of the compressor with energy wasted in the gas pressure drop station on a basic gas turbine power plant was studied. They proposed recuperating misused energy within exhaust through the heat-regaining steam generator and adding steam into the combustion compartment. The least specific fuel consumption of 0.15 kg/kWh, the highest energetic efficiency of 47.35%, and high-enhanced capacity in thermal efficiency along with power output were reported. Fagbenle et al. (2014) applied an exergy study to numerous gas turbine power equipment in Nigeria. They stated that the energetic efficiency improved as the turbine inlet temperature increased.

Oyedepo et al. (2015c) evaluated a selection of gas turbine performance in Nigeria utilizing energy and exergy analyses. The study revealed that the maximum proportion of energy loss happened in the combustion channel, ranging from 33.30% to 39.94%. The exergy investigation additionally confirmed the combustion compartment as the utmost exergy critical part contrasted with other cycle constituents. The exergy ruin in the fire chamber ranged from 86.04% to 94.66%. Its energetic proficiency is lesser than other workings. A rise in the entry turbine temperature increased the exergetic effectiveness in response to an upsurge in the turbine’s outlet power and losses in the combustion chamber.

Zhang et al. (2018) suggested eight arrangements of gas turbines fuelled by biomass gasification and simulated their performance. They described that exergy effectiveness ranged between 22.2% and 37.2%. De Souza-Santos also investigated the functioning of a gas turbine fuelled by syngas from the environment and the pressurized gasifying of sugarcane bagasse (De Souza-Santos, 1999). They reported that the syngas obtained from pressurised vaporization produce greater effectiveness than the climatic one. Gümüş (Gümüş and Atmaca, 2013) investigated the exergy effect on mixed fuel and diesel in a diesel engine. Exergy, energy and irreversibility increase as engine speeds increase for both energy sources. Mixed fuel proved to possess a higher exergy efficiency than diesel fuel. The operation of some gas turbine devices was studied by Almutairi et al. (Granet and Bluestein, 2000) on diverse load requirements and weather circumstances applying two configurations. The reheat systems boosted output power and reduced exergy efficiency compared to the elementary gas turbo. Athari et al. (2015a) conducted an exergy analysis on a simple gas turbine. It was observed that the combustor’s improved exergy efficiency was achieved once the compressor pressure ratio was increased. The compressor pressure ratio is seen as a focal factor determining both energy and exergy efficiencies of both steam injection gas turbines alone and steam injection gas turbines with inlet fogging cooler.

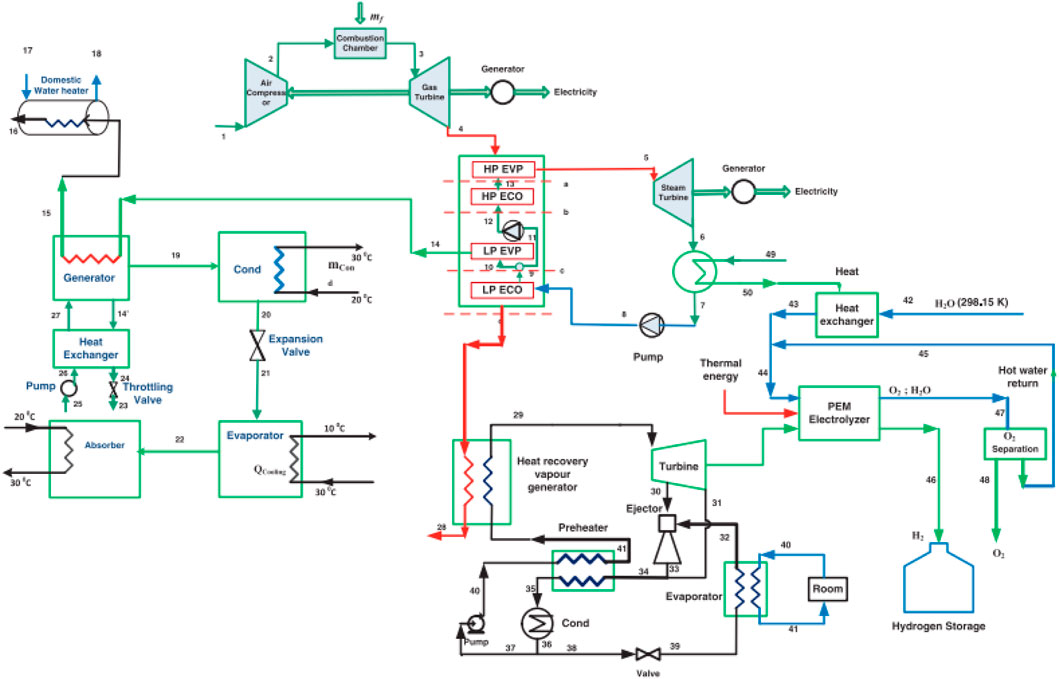

Ahmadi et al. (2013) performed an all-inclusive thermodynamic simulation and multipurpose optimisation of a multi-operational system comprising an absorption chiller, ejector refrigeration system, heat regain steam generator, and an electrolyser that gives numerous products: energy, hot water boiler, refrigeration, and hydrogen (Figure 4). Exergy and environmental studies were performed. A multipurpose optimisation method based on a rapid and elite non-dominant categorization genomic process was applied to assess the system’s optimal design factors. The two goals tasks used across the streamlining study were the framework’s complete expense rate, which shaped the expense related to fuel, part procuring and environmental effect, and the system’s exergy effectiveness. The framework’s all-out expense rate was scaled down while the cycle exergy effectiveness was expanded utilizing a developmental calculation (evolutionary algorithm). A shut structure condition about the connection amid exergy proficiency and the overall cost was inferred. A sensitivity investigation was also accomplished to evaluate the impacts of a few plan boundaries’ total exergy destruction rate on the system, carbon dioxide discharge, and exergy effectiveness. The major conclusions made were that an increase in heat recovery steam generator pressures increased exergy efficiency of the system and decreased the system’s rate of total cost. In contrast, a rise in heat recovery steam generator throttle point temperatures reduced the exergy efficiency of the system.

Figure 4. Multigeneration energy system (Ahmadi et al., 2013).

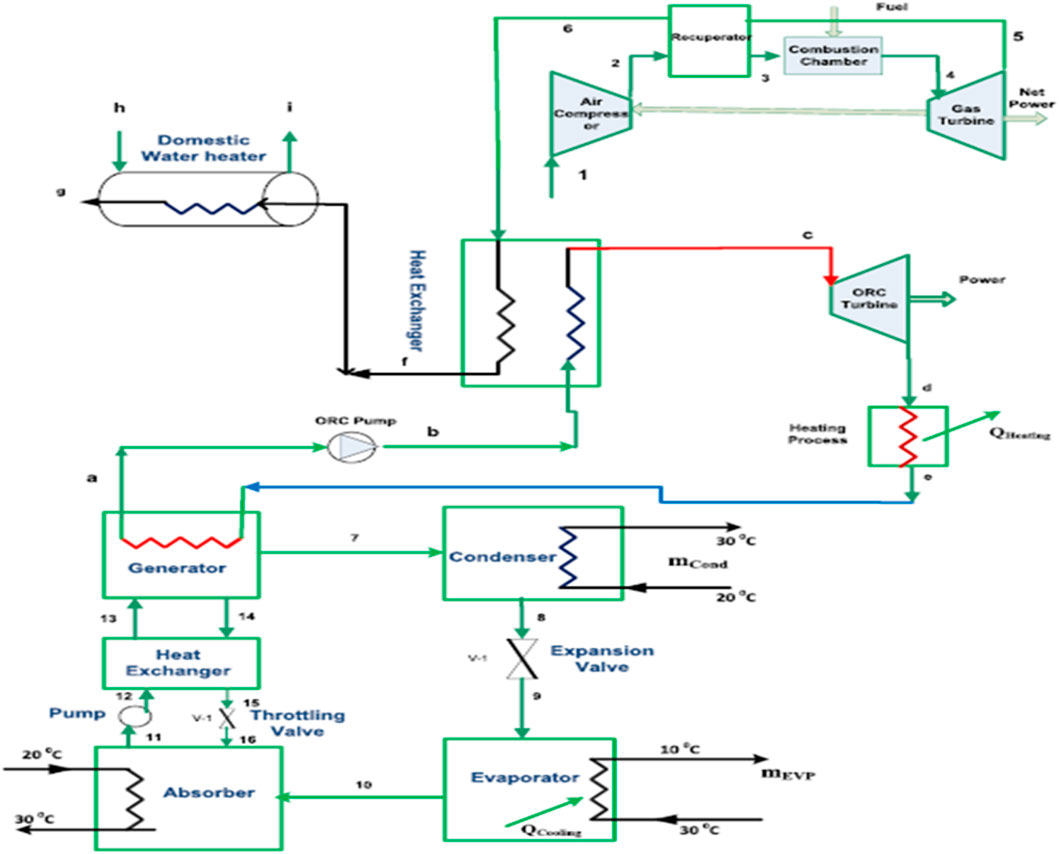

Ahmadi et al. (2012) executed an all-inclusive thermodynamic modelling of a trigeneration operation for heating system, chilling, and energy generation. The trigeneration operation comprises a gas turbine cycle, an ORC, a single-effect absorption chiller and a native water boiler (Figure 5). An exercise-based environmental analysis was undertaken, and parameters that assessed ecological effect and sustainability were gauged. The trigeneration system’s exergy efficiency was discovered to be greater than classic mixed heating and power systems. The outcome also shows that the trigeneration system’s CO2 emissions are less than those mentioned above. The exergy results revealed that the exergy obliteration was most elevated in the combustion chamber because of the temperature contrast between the working fluid and combustion temperature. The study concludes that the entry temperature of the turbine, the pressure proportion of the compressor, and the turbine’s isentropic efficiency significantly affect the system’s performance. Moreover, raising the inlet temperature of the turbine diminishes the expense of the surrounding effect, basically by lessening the concentration transfer rate of the combustion chamber.

Figure 5. Representation of a Multigeneration system for steaming, refrigeration plus power generation (Ahmadi et al., 2012).

2.1.2 Steam power plant

Steam injection technology enhances the functioning of a basic gas turbine. Ghazikhani et al. (2005) studied the impact of steam injection at the Mashhad Power Plant with a gas turbine, GE-F5. They observed an increase of 10% in the system’s thermal efficiency while the back-work ratio improved by 15%. Bouam et al. (2008) enhanced a gas turbine under Sahara conditions by injecting steam into the combustion chamber when the efficiency of the steam gas turbine was held constant at 50% while the ambient temperature was varied from ISO conditions to 50°C. This study shows that steam injection makes it possible to achieve high efficiency. Ziółkowski et al. (2012) also investigated the effects of steam injection on a gas turbine performance at the PGE Gorzow power plant using COM-GAS code and Aspen plus software. Agarwal and Mishra, (2011) reviewed current and future sustainable gas turbine technologies by comparing their thermodynamic characteristic and concluded that mixed air steam technologies offered superior performances compared to other technologies. Comparative exergoeconomic analysis of a steam injection gas turbine fuelled with biomass gasification was also studied to assess the influences and performance of operating variables with and without fogging inlet cooling (Jana and De, 2014).

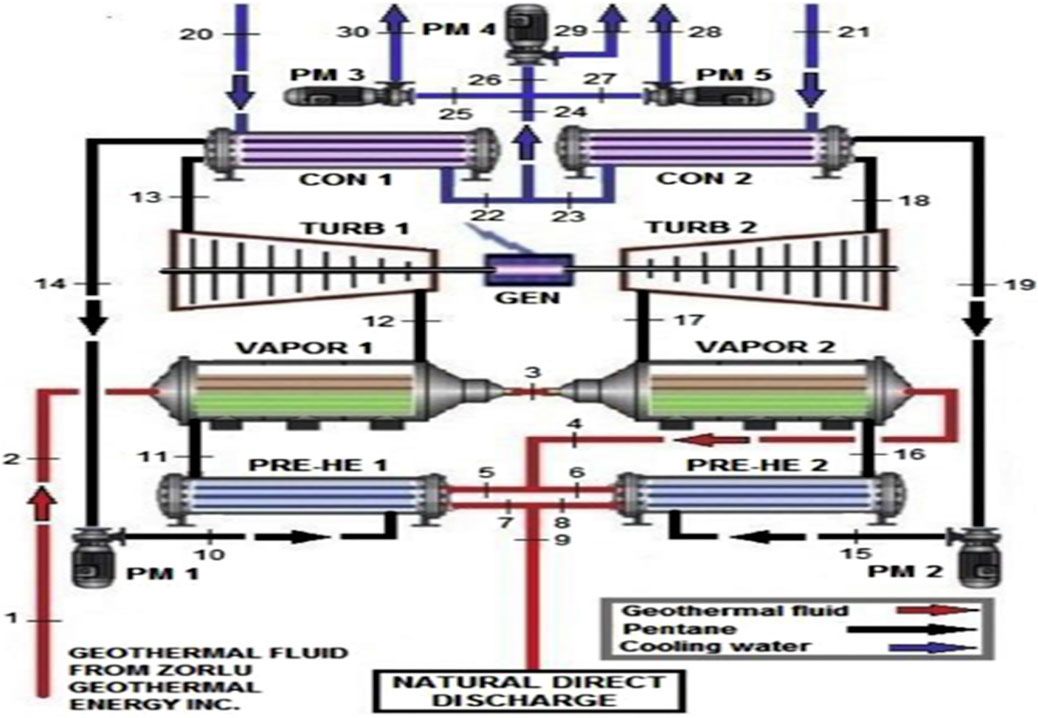

Keçebaş and Gokgedik (2015) performed conventional and advanced exergy analyses of an existing geothermal binary power system for power generation (Figure 6). Details about the exergy destruction in the system and its parts were analysed through advanced analysis to investigate the interactions between the system components and the actual performance of the reasonable improvements. The obtained results showed that the primary improved components were in the order of CON 1, TURB 1 and VAP 2 for the conventional analysis, as shown in the schematic, while for the advanced exergy analysis, the order of improvement was CON 1, CON 2 and PRE-HE 1. From the study, the conventional exergy analysis results were found to be more qualified than the conventional exergy analysis. Following the improvements made to the system, the modified exergy efficiency increased to 18.26%. However, the total system efficiency was found to be about 9.60% in the real conditions.

Figure 6. Geothermal binary power system for power generation (Keçebas and Gokgedik, 2015).

2.1.3 Combined cycle power plant

Recently, attempts to advance the capacity and effectiveness of simple gas turbine power generators were carried out through different combined heat and power cycle (CHP) methods (Ahmadi et al., 2011b). For instance, Boonnasa et al. (2006) improved a mixed cycle power plant in Bangkok using a steam absorption chiller to chill inlet air to 16°C and 100% humidity. This gives a 14% increase in the plant’s power output. Traverso and Massardo (2002) evaluated the function of four diverse combined cycle types of machinery. Humid air-water injection turbine was found to be more attractive than other technologies.

Moreover, some studies were focused on biomass-fuelled gas turbine systems for improved performance. For instance, Vera et al. (2011a) studied a CHP-gas turbine system with a capacity of 70 kWe and 150 kWth for an olive mill. Vera et al. (2011b) reported that there is higher thermal efficiency for the externally fuel gas turbine (EFGT) in comparison to the internally fuel gas turbine (IFGT) on a 30 kWe CHP system due to the extra required work for syngas compression in IFGT. Iora and Silva (2013) studied a biomass-fuelled 50 kWe CHP-EFGT and obtained an efficiency of 21%. Also, the CHP-EFGT system is fuelled by wastes from poultry, with a part at the turbine exit planned to dry the fuel and another for steam generation (Bianchi et al., 2006). For instance, biomass gasification fuelled on EFGT-Rankine combined cycle with steam injection and fog inlet cooling was investigated by (Athari et al. (2016a), Athari et al. (2016b). Besides, Gholamian et al. (2016) used a biomass-fuelled mutual cycle involving a conventional EFGT and a supercritical CO2 cycle. They reported an increase from 26.95% to 38.18% for exergy efficiency through EFGT combined with a supercritical CO2 cycle. Almutairi et al. (2015) observed the combustion chamber in a mixed-cycle power plant as the primary source of irreversibility due to poor air-fuel mixing and fuel oxidation. Therefore, adding an air preheater and reducing the air-fuel ratio were recommended to solve the cycle’s high exergy destruction. Doseva and Chakyrova, (2015) investigated the cogeneration system’s exergy efficiency of an internal combustion engine for use with biogas from a wastewater treatment plant. It was observed that the focal cause of irreversibility in the cogeneration plant emanated from the combustion chamber due to friction, temperature variation and chemical reaction.

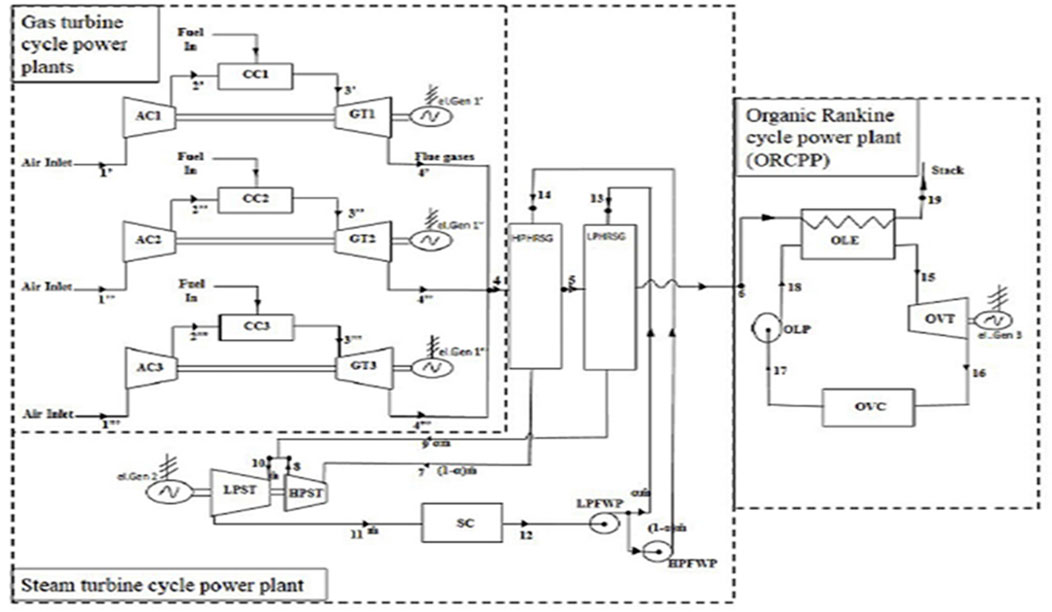

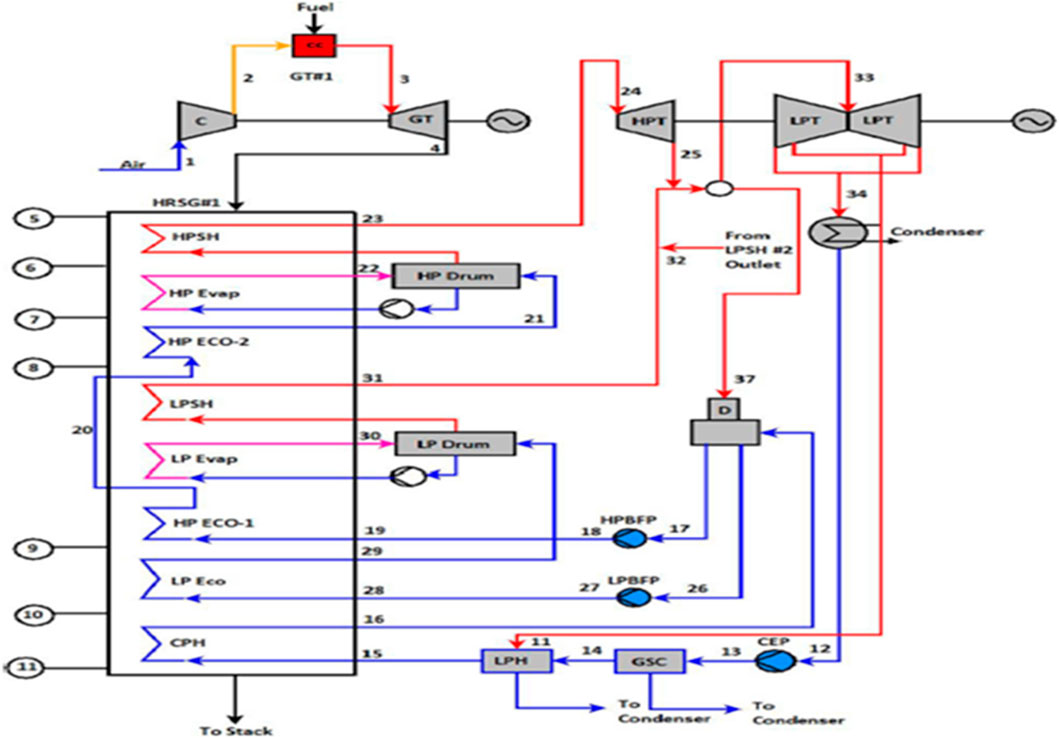

Oko and Njoku (2017) explored the thermodynamic viability of upgrading an existing 650 MW combined thermal power plant (Figure 7) by adding an organic Rankine cycle unit. Energy and exergy methods were utilised to thermodynamically analyse the performance of the integrated gas, steam, and organic fluid-cycle power plant. The choice of organic refrigerant greatly enhanced the system’s performance.

Figure 7. Schematic layout of Integrated Combined Thermal Power Plant with Organic Rankine Cycle (Oko and Njoku, 2017).

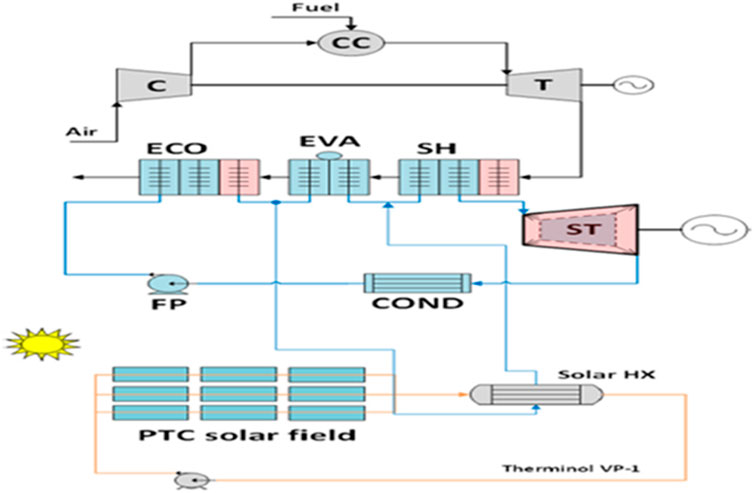

Manente, (2016) built a detailed off-design model of a 390 MW three-pressure level natural gas combined cycle (Figure 8) to assess the different integration schemes of solar energy, which keep the equipment of the combined cycle unchanged or include new equipment which comprises the steam turbine and heat recovery steam generator. Power-boosting and fuel-saving operation strategies were analysed to search for the highest annual efficiency and solar share. The results showed that without modifying the existing equipment, the maximum incremental power output from solar at design solar irradiance is limited to 19 MW. Depending on solar share and extension of tube banks in the heat recovery steam generator, high solar radiation-to-electrical efficiencies in the 24%–29% range were achievable in the integrated solar combined cycle. Compared to power-boosting, the fuel-saving strategy shows lower thermal efficiencies of the integrated solar combined cycle due to the efficiency drop of the gas turbine at reduced loads.

Figure 8. Schematic layout of integrated solar combine cycle (Manente, 2016).

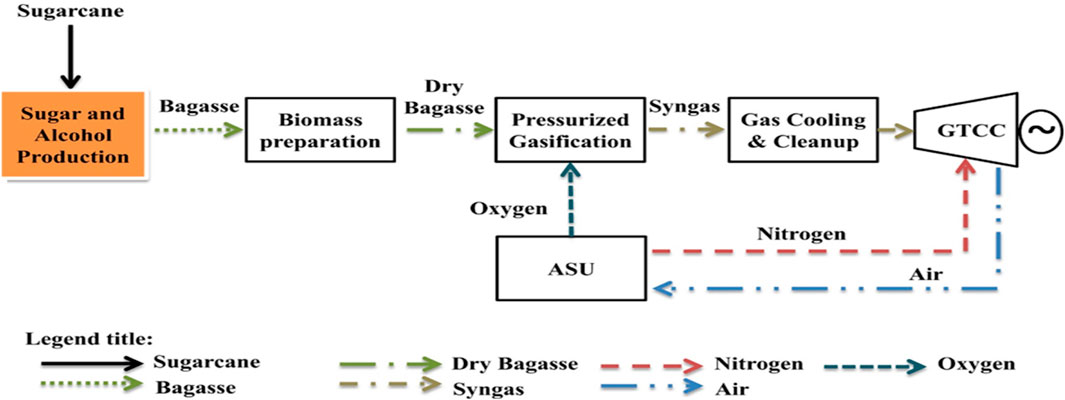

Another form of integrated combined cycle is a biomass integrated gasification combined cycle (BIGCC). The BIGCC, as a power generation process, incorporates a biomass gasification system with a combined cycle power plant. This process is an attractive alternative for power generation compared to the conventional CHP processes due to high thermal efficiency and energy output, smaller production of greenhouse gases, and reduced generation of solid wastes. Moreover, A BIGCC process without carbon capture and storage (CCS) may contain four central operating units: an air separation unit (ASU), a gasifier, a syngas cooling and clean-up system, and a combined cycle power plant (Santos et al. (2016)]. Figure 9 shows a simplified scheme of a BIGCC process without CCS. Due to the promising benefits of BIGCC over the firing-based conventional power plants and coal-firing-based IGCC plants, several types of research from the second law of thermodynamics perspectives have been conducted to improve its performance. Bhattacharya et al. (Santos et al., 2016) investigated a 50 MWe BIGCC system integrated to supplement biomass firing. The study showed Second law (exergetic) efficiency of 36.86% for the entire power plant. Khanmohammadi et al. (Bhattacharya et al., 2011) studied integrating combined EFGT, ORC and biomass gasifier for CHP applications. Zhang et al. (Oyedepo et al., 2015c) used an IFGT-based CHP combined cycle powered by biomass gasification and coupled with a ground source heat pump. A Second law (exergetic) efficiency of 13.6% was obtained. A novel BIGCC based on IFGT, and oxy-fuel combustion was proposed by Xiang et al. (Khanmohammadi et al., 2019).

Figure 9. Simplified diagram of the Biomass Integrated Gasification Combined Cycle (B-IGCC) [Santos et al. (2016)].

2.1.4 Refrigeration systems

Refrigeration systems are widely used for cooling purposes in industrial and residential sectors. These systems have been recognised to consume a high proportion of energy. Because of climate change resulting from the greenhouse effect and depletion of the ozone layer many world unions have recommended decreasing climate effects by improving the system’s efficiency and changing the existing refrigerants with ozone-friendly and eco-friendly ones (Xiang et al., 2019; Bolaji, 2010; Gill and Singh, 2018).

Lugo-Leyte et al. (Borokinni et al., 2018) studied the refrigeration cycle’s energy and exergetic analysis via R134a as the operating fluid. The equipment’s irreversibilities, the temperature of the refrigerated spaced and the exergetic operation cost in function of the environmental temperature were reported. The energy and exergy analysis of R502, R404A and R507 was also investigated by Arora and Kaushik (Lugo-Leyte et al., 2013). They computed the exergy destruction, exergetic efficiency, coefficient of performance and efficiency defects in the system. Based on exergy concept, Ahamed et al. (Keçebas and Gokgedik, 2015) stated that the major parameters that affect a vapour compression system are evaporating and condensation temperatures, undercooling and compressor pressure. Kizilkan et al. (Arora and Kaushik, 2008) presented that major irreversibility happened in the compressor and then the condenser, the evaporator, and the throttling valve for diverse compressor frequencies. Similarly, the exergy study of plant refrigeration with R407C, R507 and R417A as the working fluids by varying the compressor speed was examined by Aprea et al. (Kizilkan et al., 2010). The result obtained indicated that the compressor contributed better to the overall irreversibility, while R407C performed better than R507 and R417A. The total energy and exergy performance of a domestic refrigeration cycle working with R413A is consistently better than that of R12 when the performance of R413A in an unmodified R12 system was evaluated by Padilla et al. (Aprea et al., 2003).

Kalaiselvam and Saravan (Padilla et al., 2010) also investigated the total exergy losses on different scroll compressors using R22, R417A and R407C as the working fluid. They suggested that R417A, being eco-friendly, can be used as an alternative to other refrigerants. Agarwal et al. (Kalaiselvam and Saravan, 2009) investigated the performance of mechanically subcooled simple vapour compression refrigeration systems based on energy and exergy analysis. Compatibility of alternative low GWP and zero ODP HFOs R1234yf and R1234ze were investigated to replace the HFC 134a. Results of the study revealed that R1234ze was the best alternate refrigerant considered in the analysis and can replace R134a as the COP and exergetic efficiency of R1234ze were 1.87% and 1.88% higher than that of R134a for 30°C of sub-cooling. On the other hand, R1234yf offered lower performance than R134a. According to the study, the condenser and evaporator components had the highest and lowest exergy destruction sites, respectively (Agarwal et al., 2021).

Al-Sayyab and Abdulwahid (Yataganbaba et al., 2015) used R1234yf, R1234ze, R245fa, and R227ea as alternative refrigerants to R134a for exergy study of ten vapour compression cycles. The study results revealed that the maximum no-reversibility among the system mechanisms happened in the compressor, followed by the throttling valve, flash tank, and condenser. At the same time, the evaporator possessed the least no-reversibility. R245fa possessed the least exergy destruction with high exergetic efficiency and high COP with respect to other refrigerants. Hence, this refrigerant has the potential to serve as an alternative refrigerant to R134a. From the study by (Al-Sayyab and Abdulwahid, 2019), R454B was found to be the satisfactory fluid for use in the ground source heat pump. Menlik et al. (Bobbo et al., 2019) presented the second law of thermodynamic analysis, the potential of R22, and its alternatives, R407C and R410A, in a VCRS. Results of the study revealed that R407C was a better alternative to R22 than R410A. The highest exergy-destroyer component of VCRS was the condenser. Gill and Singh (Menlik et al., 2013) experimentally inspected a vapour compression refrigeration framework’s thermodynamic performance utilizing a combination of R134a and LPG refrigerant as a swap for R134a. From the investigation, the proposed combination of R134a and LPG performed in a way that is better than R134a from insightful exergy and energy examinations.

2.1.5 Organic Rankine Cycle (ORC) and Kalina Cycle (KC)

Organic Rankine Cycle (ORC) and Kalina Cycle (KC) are new energy conversion technologies. These technologies convert low-temperature waste heat from industries (or solar energy sources) into useful energy (heat or power) (Kim et al., 2013). Based on the desire for effective energy utilization and preservation of the environment from pollution, various researchers have worked on performance improvement and economic assessment of ORC and KC.

Gill and Singh, (2017) and Kim et al. (2012) investigated the energy and exergy system performance characteristics of the ammonia-water Rankine cycle using low-temperature heat sources and ammonia-water mixture heat exchangers with and without regenerator. Similarly, Kim et al. (2012) reported the pinch point characteristics in heat exchangers and ammonia-water-based power cycle condensers. Moreover, studies on integrating ORC/KC with other heat sources were studied. For instance, (Lolos and Rogdakis, 2009; Kim et al., 2014) studied a Kalina cycle’s performance with solar energy as a heat source. Ogriseck, (2009) analysed the integration of Kalina power in a combined heat and power plant in Germany.

Ogriseck, (2009) compared and analysed the Kalina Cycle’s performance and bottoming transcritical organic Rankine cycle in the cryogenic cogeneration system for engine exhaust heat recovery. Yue, et al. (2015) and Sun et al. (2012) carried out energy, and exergetic analysis for solar-boosted KC with an auxiliary superheater to utilise low-grade heat sources. Sun et al. (2014) investigated a 150 kWe EFGT system fuelled by a downdraft gasifier and combined with an ORC to maximise the electrical energy generation. They reported an electrical efficiency, generated power and biomass consumption of 20.7%, 200 kWe and 217 kg/h. Vera and Jurado, (2018) compared ORC and KC’s low-temperature waste heat recovery performance. At the expense of higher pressure, KC generated more power with higher efficiency.

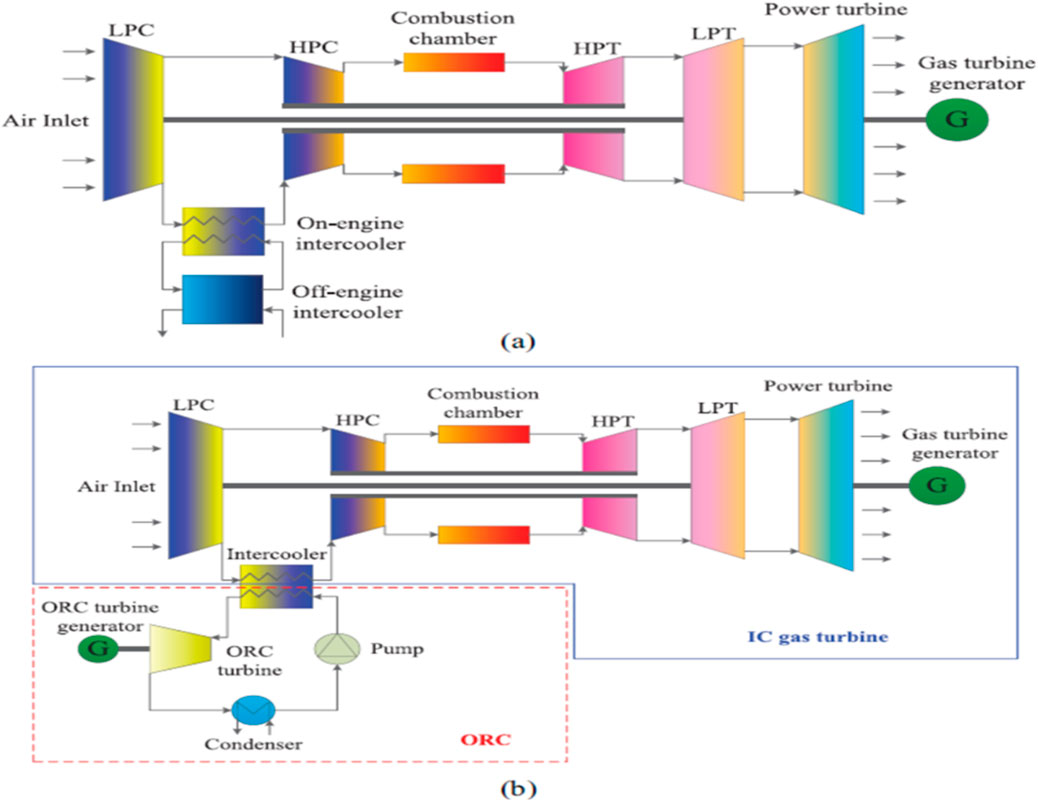

Furthermore, an investigation on KC driven by low-grade geothermal energy integrated with thermoelectric generators to convert heat into electricity directly has been carried out (Varga and Palotai, 2017). The study enhanced the net power by 7.3%, with efficiencies comparable to the conventional KCs. Zare and Palideh, (2018) developed a novel Organic Rankine cycle (ORC) (see Figure 10). The ORC system’s thermodynamic performance was investigated to study the system’s operational improvement. The study results indicated that ORC integration and intercooled cycle gas turbines could recover waste heat. From the study, the maximum enhancements of output power and thermal efficiency were 6.08% and 2.14%, respectively. Based on the outcome of the investigation, it was established that both room temperature and operating conditions of gas turbines are principal factors influencing the operating performances of the ORC system. Koç et al. (Liu et al., 2018) performed energy, exergy, and parametric analysis on the Organic Rankine Cycle (ORC) with a simple and recuperative ORC case study using a gas turbine-based combined cycle. The study showed high power output at quasi 9 MW for simple ORCs that employed methanol and recuperative ORCs using trans-2-butane as working fluids. Recuperative ORC was observed to have the potential for reduction in CO2 emission.

Figure 10. Schematic diagram of the IC gas turbine (A) without and (B) with ORC power generation system (Zare and Palideh, 2018).

2.1.6 Renewable energy systems

Renewable energy systems are gaining users’ attention as an incomplete or total substitution of fossil fuel-based sources. Numerous studies have been conducted on using renewable sources to replace fossil fuels. The superior substitutes are solar and biomass energy, which replace power generation’s thermal energy because of their carbon-neutral nature and environmental beneficence (Koç et al., 2020). Moreover, these renewable energy resources are easily accessible to humanity worldwide and also available in abundance (Seyam et al., 2020). In his study, Hepbasli, (2008) presented a comprehensive review of exergetic analysis and performance evaluation of different renewable energy resources (RERs). The RERs studied are solar, wind, geothermal, and biomass energy systems. The paper concluded that such a study is of great importance and relevant to engineers and scientists applying the second law of thermodynamics in the design, simulation and performance improvement of RERs.

This section presents a thermodynamic performance assessment of the selected renewable energy systems based on energy and exergy analyses. The focus is on integrated renewable energy sources with the conventional energy system.

2.1.6.1 Integrated solar energy system

Solar energy is a form of renewable energy that converts the sun entering the earth’s surface into heat or electricity. Integrated solar-assisted polygeneration systems have emerged as an effective and sustainable alternative for meeting thermal, cooling, power and freshwater demands (Khani et al., 2022). Because of this, numerous studies on integrated solar-assisted plants with conventional thermal power plants have been carried out (Alta et al., 2010; Oztop et al., 2013; Akyuz et al., 2012). Assareh et al. (2023) proposed an innovative power generation system based on solar and biomass energy resources. The system consists of a biomass unit, a solar unit, a waste heat recovery unit, and a hydrogen liquefaction unit. The power was generated by two gas turbines and two Rankine cycles. Results of the study showed that solar energy with waste-heat recovery reduces CO2 emissions by 30.5% while increasing the system’s electrical power output by 44%. Roshanzadeh et al. (2023) conducted a study focusing on utilizing solar cooling systems to achieve low inlet air temperature and generate high electricity yields. The study simulated the thermodynamic behavior of a combined cycle power plant with integrated solar-driven inlet air cooling for Tehran, Phoenix, and Houston during warm-hot seasons. Results of the study revealed that a considerable reduction in the output power was realized during hot ambient conditions due to the lower density of the air and lower mass flow rate to the turbines. The output power decreased from 306.6 to 260.8 MW as the ambient temperature increased from 15 to 45°C.

Moreover, Ghorbani et al. (Ratlamwala et al., 2011) developed and analysed an integrated system capable of producing 65.2 MW of heating, 1.87 MW of power and 83.2 kg/s of freshwater. Servam et al. (Koç et al., 2020) assessed the performance of a novel integrated large-scale combined cycle power plant (CCPP). This system depends on renewable sources such as solar radiation and seawater from the Atlantic Ocean to provide clean and sustainable energy. The integrated power plant consists of six subsystems: solar farm, Gas turbine cycle, Rankine cycle, multi-effect desalination, electrolyser, and hydrogen liquefaction subsystem. The combined cycle was studied thermodynamically to investigate thermal and exergy performance. The integrated system’s overall thermal efficiency was 88.12%, while the exergetic efficiency was 23.05%. The combined system has the energy cost of 14.59 $/MWh, which was found to be economical due to the system’s multiple services. Also, the emissions were significantly low, making this power plant environmentally benign. Alibaba et al. (Ghorbania et al., 2018) developed an optimal thermodynamic, exergo-economic and exergo-environmental design for the geothermal power plant used as a complement to concentrated solar power (CSP) and then combined energy-exergy-economic-environmental analysis was conducted. In the study, a standalone geothermal cycle and hybrid Geothermal-Solar cycle were investigated to generate the heating/cooling power. The study revealed that the exergo-economic analysis of the hybrid power plant has the highest investment cost when related to the solar power plant. It also had the lowest exergy degradation cost with zero environmental impact. The highest environmental rate was associated with the solar power plant. However, its environmental destruction rate was minimal because it does not consume fuel. Sarhaddi et al. (Alibaba et al., 2020) did an exhaustive energy and exergy investigation to assess a commonplace PV cluster’s electrical performance, componentwise exergy destruction, and exergy efficiency. The consequences of the investigation demonstrated that the PV exhibit temperature greatly affects the exergy efficiency. The investigation reasoned that a PV cluster’s exergy proficiency could be improved if the heat could be eliminated from the PV array surface.

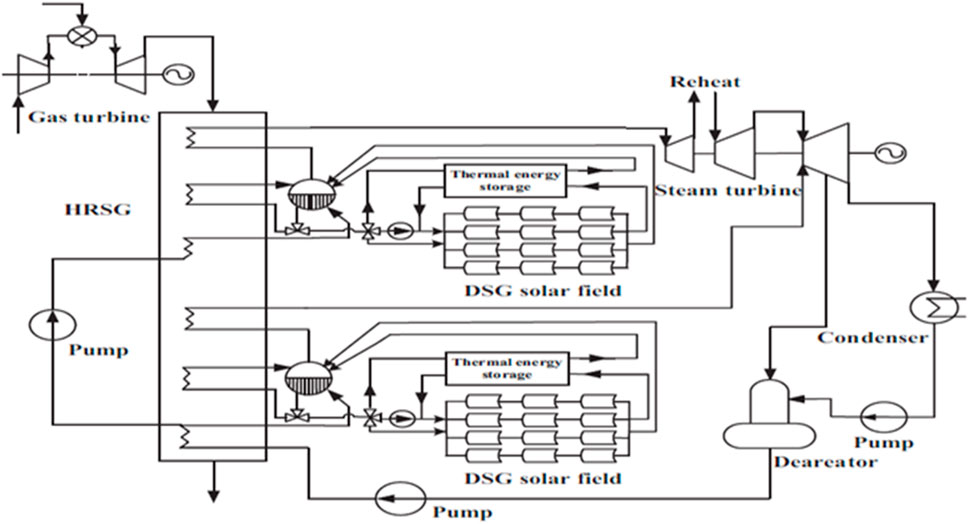

Yuanyuan and Yongping (Sarhaddi et al., 2009) presented a thermodynamic and economic analysis for an integrated solar combined cycle (ISCC) system with two pressure-level DSG solar fields (ISCC–2DSG) (Figure 11). The impacts of solar multiples on the system’s performance with or without consideration of thermal storage were studied. In that order, the solar thermal energy produced from two solar fields in the ISCC–2DSG system was only used to supply latent heat for low and high-pressure water vaporisation. The analysis characterised several such ISCC–2DSG systems’ annual thermodynamic performances, using different solar multiple values but identical design parameters in the power subsystem. The results showed that the capacity factor increases with a more significant solar multiple due to more outstanding electricity production for ISCC–2DSG systems without thermal storage. The capacity factors were more substantial than those without thermal storage for the systems with thermal storage, following the effective utilisation of the surplus solar thermal energy generated. The results concluded that the system’s levelized electricity cost with thermal storage was considerably higher for a given solar multiple than without thermal storage.

Figure 11. Schematic diagram of an ISCC system with two DSG solar fields with thermal storage (Sarhaddi et al., 2009).

Al-Ali and Dincer (Yuanyuan and Yongping, 2015) proposed a thermodynamic analysis of a multi-generation integrated geothermal-solar (GS) system that consists of the geothermal-solar cycle, organic Rankine cycle 1, organic Rankine cycle 2 and a single absorption chiller that produces electricity, space heating, hot water, industrial process heat and cooling. Results obtained show the energy efficiencies for single-generation and multi-generation systems were 16.4% and 78%, respectively. The exergy efficiencies yield 26.2% and 36.6%, respectively. Adibhatla and Kaushik (Al-Ali and Dincer, 2014) performed energy, exergy and economic analyses of a conceptual power plant cycle formed by adding solar energy to the steam cycle of a natural gas-based combined cycle power plant (Figure 12). The solar integration idea was made at a moderate temperature level using a direct steam generation technique with parabolic trough collectors. The simulated results showed that the solar field’s energy and exergy efficiencies were 53.79% and 27.39%, respectively. The results have indicated that the plant output was increased by 7.84%, with the solar field operating at the design point for a 50 MW nominal solar field-rated capacity. The results showed that the levelized cost of electricity generation decreased from 7.4 to 6.7 cents/kW.

Figure 12. Integrated solar direct steam generation combined cycle power plant (Al-Ali and Dincer, 2014).

2.1.6.2 Integrated biomass energy system

Reducing natural resources for fossil fuel has shifted attention to sustainable renewable energy integrated systems (Gholamian et al., 2016). The economic policy international bodies support research into utilizing renewable energy to minimize environmental pollution posed by fossil fuel. Biomass is being explored as renewable energy. With the increase in the depletion of fossil fuels and greenhouse gas (GHG) emissions, highly efficient energy utilisation systems have drawn increasing attention, especially renewable and sustainable energy integration systems (Gholamian et al., 2016). The current global energy policies promote research to enhance the utilisation of renewable energy sources, largely to minimise environmental problems and improve the national energy security of countries dependent on the use of imported fossil fuels. Biomass is currently one of the most popular renewable energy sources. This is because biomass has great potential as a clean, renewable feedstock for producing modern energy carriers (Adibhatla and Kaushik, 2017).

Buentello-Montoya and Zhang (2019) analysed the thermodynamic efficiencies of biomass gasification from char-activated char catalysts. The work introduced an equilibrium model for the thermodynamic analysis and assessed the effect of the reactor temperature, reaction time and equivalence ratio based on the gas quality. The result showed that there is a thermodynamic advantage and reduction in exergy destruction due to high reforming temperature. The result is in tandem with Echegaray et al. (Adibhatla and Kaushik, 2017) as the exergetic efficiency of the gasification process lessened when all measured working parameters were increased.

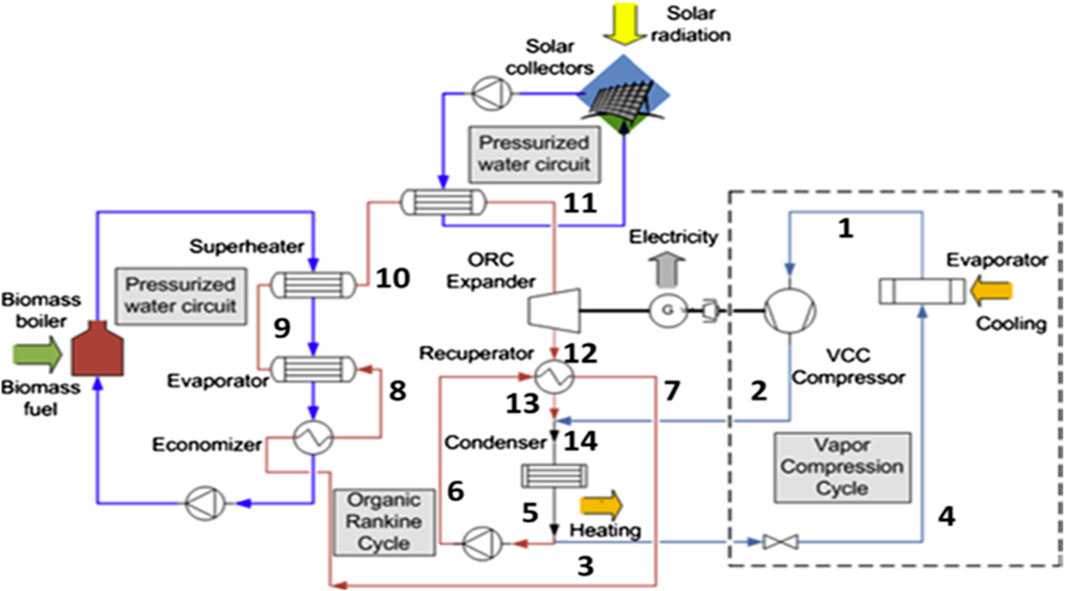

There was also the attempt to generate electricity through a combination of solar heat and biomass-fired power systems (Khalid et al., 2015). Thermodynamic performance of the hybrid solar heat–biomass-fired plant was carried out, which resulted in an improved efficiency of 20%. The exergetic conversion efficiency of the combined heat power plant was estimated to attain 21% (Buentello-Montoya and Zhang, 2019) (Figure 13). A cost assessment of the system was investigated for a case study considering a typical apartment block on a Greek Island, assuming Parabolic Trough Collector (PTC) area of 50 m2. The savings in fuel oil and electricity consumption accounted for an Internal Rate of Return (IRR) of around 12%, with a payback period of 7 years (Asim et al., 2020).

Figure 13. The combined ORC–VCC cycle and biomass boiler and PTC heating water circuits (Buentello-Montoya and Zhang, 2019).

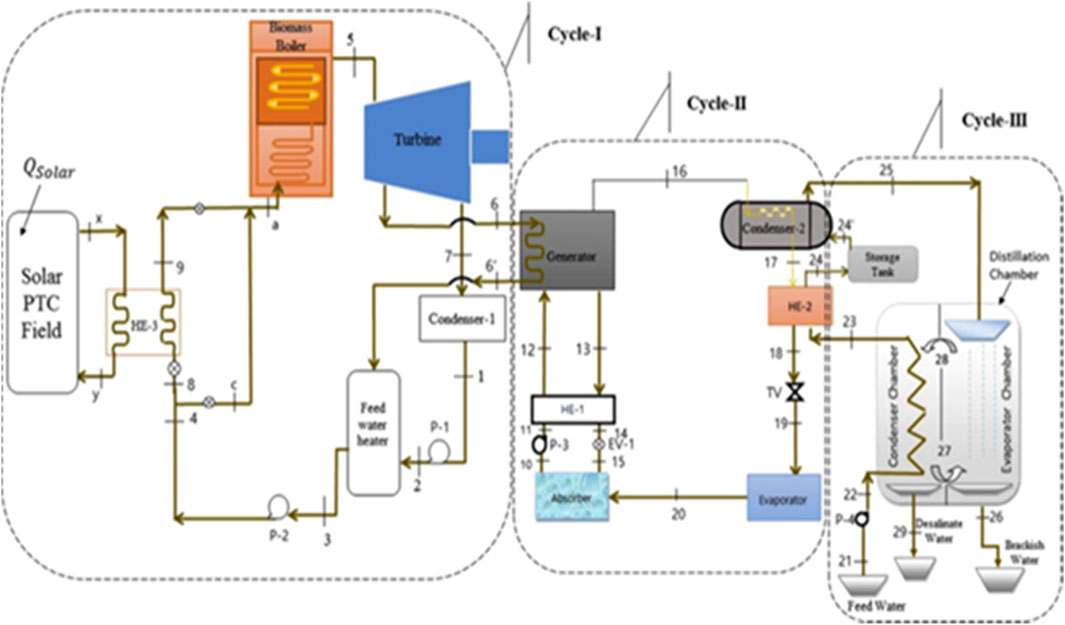

A thermodynamic evaluation and optimisation of a hybrid solar-biomass (HSB) system in a polygeneration process for combined power, cooling and desalination (Figure 14) was investigated by Sahoo et al. (2017) purposely to identify the effects of various operating parameters. Primary energy savings (PES) of the polygeneration process in the HSB system was achieved to 50.5%. The energy output from this system was increased to 78.12% compared to that of simple power plants (Chen et al., 2020).

Figure 14. Schematic diagram of hybrid solar-biomass power plant with cooling and desalination in polygeneration process (Karellas and Braimakis, 2016).

2.2 Thermodynamic optimisation of energy systems

In order to improve the performance of an energy conversion system, thermodynamic analysis of energy systems offers a comprehensive, systems-based approach that offers a methodological scientific framework for arriving at realistic, integrated solutions to complex energy systems problems. Modern energy systems are evolving quickly and exhibit increasingly complex features. This is mostly because modern energy systems have other purposes in addition to energy conversion and supply. Aside from providing energy, energy systems should also secure their resources to ensure long-term operation, minimize their effects on the environment and ecology during construction and operation, provide energy at a reasonable cost to maximize benefits to a larger population, and help mitigate carbon emissions that contribute to global warming. In an effort to meet some of the aforementioned goals, new energy technologies are always developing. With the implementation of these technologies, renewable energy has been increasingly exploited and used, the energy efficiency of conventional power generation has been continuously improved, and energy end-consumers have become more energy-efficient and environmentally benign (Sahoo et al., 2017). According to Benja et al. (Kopanos et al., 2017), a thermodynamic optimization aims to minimise the thermodynamic inefficiencies: exergy destruction and loss in energy system components.

Many researchers have contributed valuable publications on the thermodynamic optimisation of a variety of energy systems via hybrid systems or waste heat recovery technology. These endless sustainable energy technologies can reduce fossil fuel consumption and decrease carbon emissions when its operations are optimised and controlled. Vera et al. (Sun et al., 2014) reported a value of 15.6% for exergy efficiency at base case operating conditions, which was increased to 18% by optimisation. They also reported a parametric optimisation result for a pilot system that generates power, exergy and energy efficiencies reaching up to 491 kW, 35.6% and 6.48%, respectively. Not too long ago, Prananto et al. (Bejan et al., 1996) investigated the electricity-generating performance of a KC by recovering the heat of the unused brine discharged from a geothermal power plant. In an optimised condition, 48 kg/s of unused brine was reported to generate up to 1.66 MW of electricity. In addition, Ghaebi et al. (Prananto et al., 2018) proposed and assessed geothermal power by combining KC with an ejector refrigeration cycle. In optimised conditions, the cycle has the potential to produce 2.3 MW of net power and 1.1 MW of refrigeration. Ahmadi et al. (Ghaebi et al., 2018; Ahmadi et al., 2015) optimised a transcritical CO2 power cycle operated by a geothermal energy source with LNG as its heat sink and an irreversible Carnot refrigerator. Ahmadi et al. (2016a) also studied the exergetic and sustainable multi-objective optimisation on a nano-scale Braysson cycle operating with Maxwell–Boltzmann gas. A solar-geothermal combined cooling, heating and power plant, becoming more popular as an efficient alternative to fossils, was optimised using multiple criteria by Boyaghchi and Chavoshi (Ahmadi et al., 2016b). Boyaghchi and Sabaghian, (2017) also wrote a similar work optimising the Kalina power cycle on a parabolic trough solar collector. Ahmadi and Dincer (Boyaghchi and Sabaghian, 2016) also optimised the cogeneration of a combined cooling, heating and power plant using exergo environmental principles through a Multimodal Genetic Algorithm. Ahmadi and Dincer, (2010) made significant contributions to the multi-objective optimisation of gas turbine power plants for increased efficiency of the thermodynamic system. Further studies by Barzeger et al. (Ahmadi and Dincer, 2011) focused on a closely related study investigating the multi-objective optimisation of a gas turbine power plant with a preheater using evolutionary algorithms. Shamoushaki et al. (Barzegar- Avval et al., 2011) built on this work by applying multiple objective optimisations of gas turbine power plants in Aliabad Katoul by evolutionary algorithms to improve efficiency.

3 Thermoeconomic assessment of energy systems

Economic studies of an energy system allow using costing equations, elaboration of estimation and optimisation algorithms, cost optimisation and low-cost energy systems and operations for thermoeconomic evaluation (Ahmadi and Dincer, 2011; Shamoushaki et al., 2017; Palazzo, 2013). Thermoeconomic studies, on the other hand, provide a balance between system efficiency and cost. Therefore, in designing and evaluating an energy system, the oil price, yearly equipment purchase cost (EPC), and functioning and management are valuable indicators for economic benefit analysis of energy systems by assessing several energy generation devices (Khanmohammadi et al., 2019; Goncalves and Arrieta, 2010; Boukelia et al., 2016). Hence, thermoeconomics is the art of saving natural resources that connects engineering and costing accounts through the Second Law of Thermodynamics. Energy systems are obtained from a set of sub-assemblies that network with one another environment and consume external resources that are transformed into products (Bakhshmand et al., 2015). Almutairi et al. (Valero and Cuadra, 2002) stated that the thermos-economic impact analysis of some power plants shows that the cost of destroying exergy is reduced. The suitability of thermo-economic study ranges to alternative energy areas of usefulness, such as heat engines, dewatering plants, refrigeration systems, etc. (Almutairi et al., 2016; Esen et al., 2007).

3.1 Thermoeconomic analysis and optimisation of energy systems

Thermoeconomics combines thermodynamics with principles of analytical accounting, and the main aim is minimising cost. In contrast to typical fiscal study, thermoeconomic provides a choice to examine and advance the operation of individual parts in the energy system (Taner, 2015). Hence, thermoeconomic appeared as a vital instrument to optimise the work of energy systems from both thermodynamic and economic perspectives. In thermoeconomics, the individual cost of part and stream is connected to its exergy subject. Capital expenditure of the mechanisms and the ecological influence are considered methodically for thermoeconomic optimisation of energy systems (Jamil et al., 2020). For energy transformation operations, accounting as a practice studies unit costs as it relates to energy. In view of this, several authors have suggested that budgets are preferably spread amid turnouts if management accounting is built on the thermodynamic exergy quantity. This is justified because exergy, but not energy, is often assigned economic value (Kopanos et al., 2017).

Numerous research studies on the relationship between thermodynamic (exergy) and economics analysis to evaluate quality output and optimisation of energy systems are stated in the literature. Pellegri (Dincer and Rosen, 2007) carried out a thermoeconomic and environmental study on sugarcane and ethanol for electricity generation in cogeneration plants. It was observed that a reduction in entropy resulted in a more efficient cogeneration operation, a reduction in exergy destruction and a better thermoeconomic and environmental operation. Oyedepo et al. (Pellegrini and de Oliveira Junior, 2011) conducted exergy estimation and quality assessment of carefully chosen gas turbine energy stations in Nigeria. From the study, the unit cost of electricity produced in the carefully chosen power plants varied from cents 1.98/kWh to cents 5.66/kWh. The result confirms that the combustion chamber had the highest exergy destruction cost in comparison to other components, as further confirmed by (Oyedepo et al., 2015a). Imran et al. (Athari et al., 2015b) introduced the thermo-economic improvement of fundamental ORC and regenerative ORC for waste heat recovery systems at consistent heat source conditions. In the examination, optimization was performed for five distinctive working fluids. The after-effects of the examination demonstrated that R245fa was the best working fluid under considered conditions, and basic ORC has a low explicit investment cost and thermal efficiency, which is in contrast to regenerative ORC. The sensitivity analysis revealed that evaporation pressure has promising effects on thermal efficiency and specific investment costs (Imran et al., 2014).

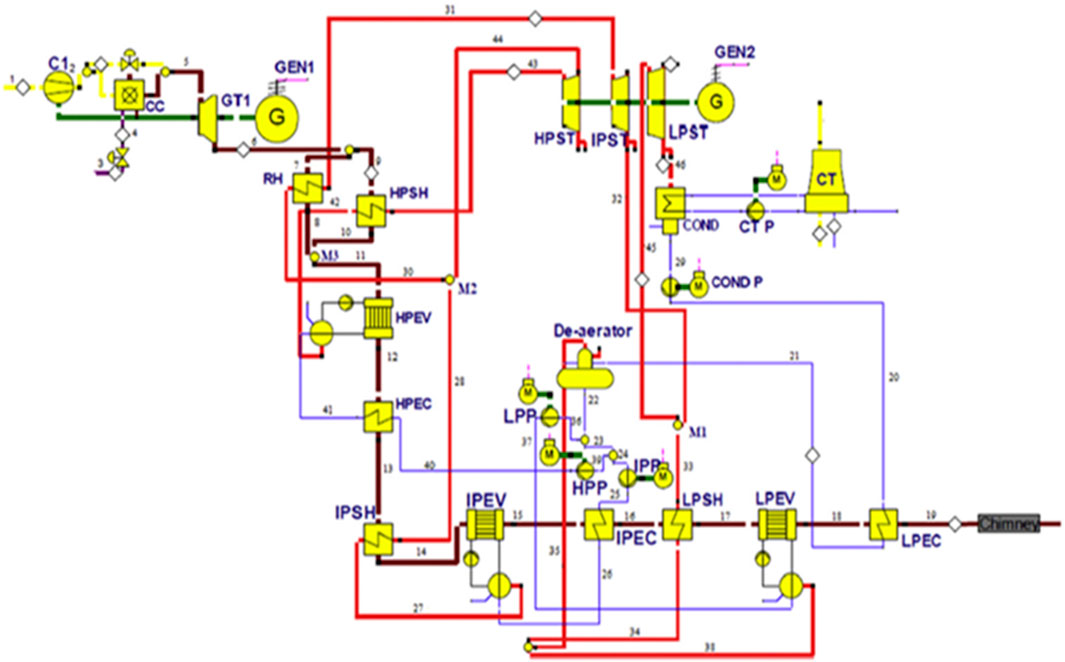

Bakhshmand et al. (Singh and Kaushik, 2014) investigated the thermos-economic analysis and optimisation of a triple-pressure combined cycle power station with one reheat stage (Figure 15). The total cost rate of the plate formed the optimisation objective function. The results showed that the optimisation process brought an increase of about 2.9% in energetic and exergetic efficiencies and a reduction of about 8.9% in the total thermos-economic cost.

Figure 15. Schematic diagram of combined power plant with triple-pressure levels and one reheating stage (Singh and Kaushik, 2014).

4 Thermo-environmental analysis of energy systems

Recently, the environmental effects of unsustainable ways of energy consumption have been a serious concern, and the Second Law of thermodynamic analysis has been employed as an improvement method to (i) reduce atmospheric discharges and increase the life span of natural means through improving effectiveness and (ii) evaluate the probable influences of emissions. Thermo-environmental analysis combines the first two laws of thermodynamic examination and environment estimation to analyse thermodynamic efficiency and environmental impacts of energy systems components [Oyedepo et al. (Bakhshmand et al., 2015)]. The amalgamation of exergy and environmental studies unveils the interconnections among thermodynamic actions and environmental influences amid energy systems’ constituents (Oyedepo et al., 2018).

Environmental impact for energy utilisation results in climate change, acid rain and ozone depletion. Carbon dioxide emissions cause harmful environmental effects when the resources are used. In this regard, estimating carbon dioxide emissions is a substantial part of making an environmental assessment. At the point when the exergy efficiency, overall cost of the equipment and CO2 emissions are utilized for the improvement of mixed cycle power generation station with accompanying burning, the outcomes show that the cost of exergy destruction and losses diminished as the turbine inlet temperature expanded alongside burning compartment, the significant source of irreversibility (Keçebas and Gokgedik, 2015). The CO2 discharge could be limited by upgrading the efficiency of the components and bringing down the fuel rate of flow. Almutairi et al. (Granet and Bluestein, 2000) also stated that variation in ambient temperature demonstrates climatic circumstances about the location of a gas turbine. They further noted that the rise in ambient temperature reduces both exergetic efficiency and overall power outflow.

4.1 Thermo-environmental analysis and optimisation of energy systems

Research has shown that global warming is the utmost ecological task confronting the globe these days. Energy systems play a chief part in the emission of greenhouse gases. For example, about 21.2% of greenhouse gases are solely released by power stations (Oyedepo et al., 2015b). The need to understand the linkages between the first two laws of thermodynamics (energy and exergy) analysis and the ecological effect becomes more noteworthy due to the relations between exergy and the environment revealing the causal forms impacting environmental transformation. Recently, it has been shown that raising the exergy efficiency will reduce conditions for energy capacity and emissions. Moreover, exergy has been linked to ecological influence, as such a proportion from departing from the condition of a framework from the surrounding (Oyedepo et al., 2016; Baumgärtner and Arons, 2003).

The environmental analysis looks into the costs related to the movements of contaminants as well as the exergetic and economic costs of mass concentration and energy flows in energy devices (Jørgensen and Svirezhev, 2004). The rise of the exergy efficiency of these developments can decrease the environmental effect of energy transformation progressions. An increase in exergy efficiency will lessen the consumption of resources and consequently reduce the waste and the noxious discharge to the environment. This infers an enhancement in the ecological efficiency of these operations (de Oliveira, 2013).

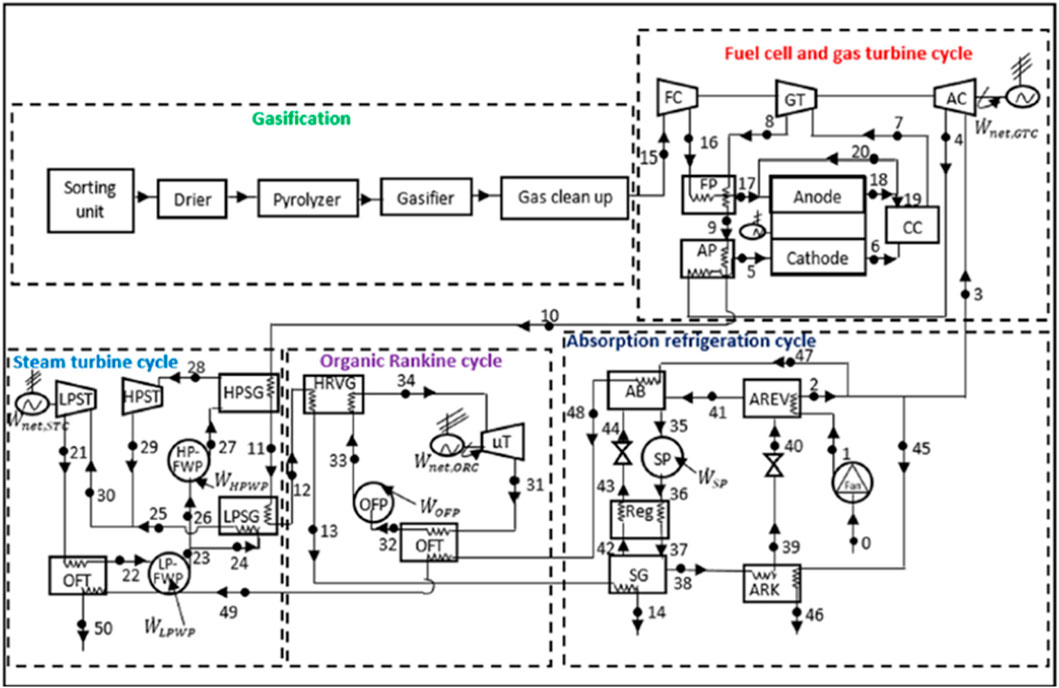

Numerous studies related to the linkages between the first and second laws of thermodynamic analysis (exergy), and environmental impacts to assess the performance and optimisation of energy systems are reported (Pellegrini and de Oliveira Junior, 2011; Oyedepo et al., 2015b; Ahmadi and Dincer, 2010; Ahmadi and Dincer, 2011; Ameri et al., 2016). Owebor et al. (Amrollahi et al., 2011) carried out an energy, thermo-environmental and fiscal study for a projected municipal waste-propelled power station. The projected plant consisted of vaporization, solid oxide fuel cells, gas and steam turbines, absorption refrigeration, and organic Rankine cycles (Figure 16). Results of the study revealed that the fuel noxious release factor, explicit CO2 discharge and sustainability exponent were 0.00097, 148.23 kgCO2/MWh and 6.56, correspondingly. Moreover, the energy-economic sustainability exponent was shown, which considered the efficiency of the energy change progressions and its commercial effect on the people in terms of cost and social, economic state. Oyedepo et al. (2015b) presented an all-inclusive thermodynamic simulation and exergoenvironomic performance analysis for Nigeria’s designated gas turbine power station. In the study, the exergo-environomic parameters computed were carbon (IV) oxide emission in kg per MWh of power generated, sustainability index, consumption number, price flow rate of environmental effects in $/h and overall rate of cost of products in $/hr. Results of the study revealed that the combustion chamber was the utmost exergy-damaging section linked to other cycle components. However, the exergy ruin of this module is lessened by the growing gas turbine inlet temperature (GTIT). Moreover, it was observed that the thermodynamic inefficiency was responsible for the environmental power of gas turbine components. Hence, the study showed that CO2 discharges and the cost of environmental impact decreased with increasing GTIT.

Figure 16. Schematics of an integrated gasification, SOFC, GT, ST, ORC and AR cycles (Amrollahi et al., 2011).

Ameri et al. (Jørgensen and Svirezhev, 2004) presented the exergoeconomic and ecological maximization of a selected huge steam generating station. The impact of additional air on exergy efficiency and noxious emissions were studied. Furthermore, the optimization process was presented by exergetic efficiency, standardized CO2 emissions of the plant, and three diverse cost functions, including electricity costs, environmental impacts, and total plant costs. Aftereffects of the study revealed that the cost of electricity generation and the cost of environmental impacts diminished by 20.25% and 49.6%, respectively, at the optimum operating conditions of the plant. A thorough thermoeconomic and thermoenvironomic modeling and analysis of selected gas turbine power plants in Nigeria were presented by Oyedepo et al. (Pellegrini and de Oliveira Junior, 2011) utilizing the first and second laws of thermodynamics (exergy) principle. The consequences of the study uncovered that CO2 emissions varied somewhere in the range of 100.18 and 408.78 kg CO2/MWh for the selected power plants, while the cost rate of the green effect varied from 40.18 $/h to 276.97 $/h. It was additionally shown that CO2 discharges and the consequence of environment influence diminished with growing GTIT. Meanwhile, the sustainability index of the plants increased with increasing GTIT.

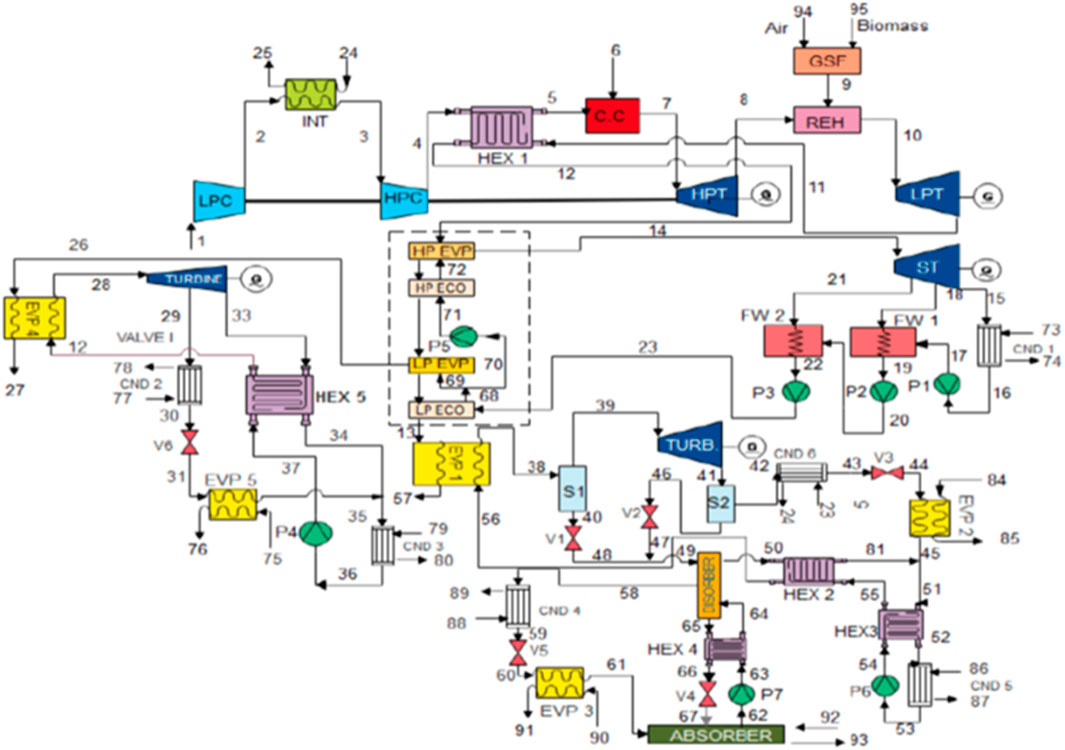

Maraver et al., (2014) showed the thermodynamic streamlining of ORCs, combined alongside absorption or adsorption refrigeration components, for consolidated CCHP production from biomass burning. In the study, system modelling with the prime objective of proffering optimization procedures with the condition of operation of such systems was carried out. Furthermore, the energy and ecological execution of the distinctive ideal CCHP machine were explored. The study established that the trigeneration plant is capable of being designed in an energy-environmentally effective route with an n-pentane restorative ORC and a volumetric sort expander. Ahmadi et al. (Keçebas and Gokgedik, 2015) investigated exergoeconomic and environmental analyses for a mixed cycle and examined the impacts of additional burning on the effectiveness of bottoming cycle and CO2 discharges. Memon et al. (2015) performed parametric-based thermoenvironmental and exergoeconomic analyses of a combined cycle power plant. Abam et al. (Memon et al., 2015) proposed an in-service turbine gas device, burned by gas to be modified with a steam turbine (ST), organic Rankine cycle (ORC), gas turbine (GT) for refrigeration and electricity generation, an adapted Kalina cycle (KC) for electricity development and refrigeration, and a vapour absorption system (VAS) for refrigeration (Figure 17). The integrated multi-generation plant (IMP) was to be burned by biomass-based syngas as a supplementary firing source. Exergoeconomic and environmental analysis was carried out on the IMP. The after-effects of the study demonstrated that the planned system could propel the existing energy evolution predicament in the energy sector of Nigeria and workable energy approach to match the Agreement of Paris and Sustainable Development Goals (SDGs) strategy.

Figure 17. The proposed integrated multi-generation plant (Memon et al., 2015).

5 Assessment of sustainability indices (indicators) of energy systems

One of the fundamental ideas of sustainable development is sustainable energy development (SED). It ensures affordable, accessible energy for all while adhering to social and economic development requirements and the environment. Increasing the share of alternative energy sources in the energy mix, such as renewables, improving energy efficiency, and lowering greenhouse gas and air pollution emissions, are some of the actions that help implement the SED (Abam et al., 2020a). The evaluation criteria for the energy system’s sustainability must consider the resource, environmental, social, and economic facets.

The process of converting energy from sources like fossil fuels and renewables into easily utilised forms, like electrical energy, propulsive energy, heating, and cooling, is known as energy conversion. The primary goal of the energy conversion systems sustainability evaluation is to ensure that options have been thoroughly considered and assessed for their potential short- and long-term impacts on the environment, economy, society, and other factors (Deng et al., 2022). In other words, when new and innovative energy systems are introduced for transportation, electric power generation, or industrial operations, it is prudent and essential to conduct a thorough sustainability assessment before moving forward with the execution of these innovative concepts. This is so because sustainability refers to an energy supply that is affordable, readily available, and likely has little to no impact on the environment (Chamchine et al., 2022).

Establishing a strong and comprehensive set of indicators to track the advancement of sustainable energy development is now essential, as sustainable development has made sustainable energy development a key goal of international policy. United Nations Sustainable Development Goal (SDG 7) calls for support in ensuring everyone can access affordable, clean energy (UN, 2015). This demonstrates the dedication to clean energy and sustainability. Affordable and sustainable electricity is essential for the growth of business, communications, agriculture, healthcare, education, and transportation. Energy constraints impede human development and economic growth, especially in developing countries.

Setting up various suitable performance indicators is a prerequisite for measuring the effectiveness of energy conversion systems. A mix of thermodynamic, economic, and environmental indicators is considered to assess the technical, financial, and societal worth of the energy systems and guarantee that the chosen designs are well-suited to a sustainable development framework. Numerous general energy system performance indicators and new ones are included in the performance indicators below (Spelling, 2013). The sustainability indices of the energy systems listed below are examined based on the economic, environmental, and first and second laws of thermodynamics.

5.1 Enthalpic efficiency indicator (thermal efficiency)

Enthalpic change values (ΔH) are used to quantify “heat content,” which is how the indicator gauges the efficiency of the process inputs and outputs. For every process, the enthalpic efficiency ratio can be calculated by dividing the ΔH value of the process’s useable output by its inputs’ ΔH value. Equation 1 can be used to compute enthalpic efficiency (Patterson, 1996):

where,

ηΔH = enthalpic efficiency

For instance, a basic gas turbine has an enthalpic efficiency of roughly 33%. The enthalpic efficiency indicator evaluates the “useful” output. The conversion rate of chemical energy (ΔH) into electricity in this process is only 33%; the remaining 67% is lost as “waste” heat to the environment. When computing energy in enthalpic terms, the total output equals the total inputs if each activity’s “waste” output is combined with the “useful” output from all processes. This is essentially another way of saying the first law of thermodynamics, which states that energy cannot be generated or destroyed during any type of conversion. Because of this, enthalpic efficiency is frequently referred to as first-law efficiency.

5.2 Thermal discharge index (TDI)

The number of thermal energy units released into the environment for every unit of electrical energy generated by a plant is known as the thermal discharge index of the power system. The following can be used to express it in power units (Ofodu and Abam, 2002).

Every thermal power plant must have an index that is not zero to comply with the second law of thermodynamics; however, the index should be as low as feasible to maximize plant efficiency and maintain low pollution levels (Rajput, 2003; Labele-Alawa and Asuo, 2011; Abam et al., 2012). The thermal discharge index can be described as follows in terms of thermal efficiency, a crucial determinant of the index (Ofodu and Abam, 2002).

where Pth is the thermal energy input and

5.3 Overall exergetic efficiency (OEE)

Exergy plays a significant role in identifying efficiency improvements and decreases in thermodynamic losses related to energy conversion processes. By lowering energy losses, exergy efficiency initiatives can lessen their adverse effects on the environment. Naturally, minimizing irreversibility or exergy loss results in an energy conversion process’s most significant increase in exergy efficiency (Inoussah et al., 2017).