- School of Management, Harbin University of Commerce, Harbin, Heilongjiang, China

China is currently undergoing a phase of high-quality development, with increasing emphasis on the circular economy, energy conservation, and environmental protection by both the government and enterprises. This paper examines a secondary supply chain comprising manufacturers and retailers, focusing on three supply chain decision-making models: one where the manufacturer is the channel leader, one where the retailer is the channel leader, and one where both parties have equal power. The study investigates the impact of manufacturers misrepresenting their Corporate Social Responsibility (CSR) information and the challenges associated with recycling efforts on the optimal performance of the supply chain. The findings reveal that when manufacturers lead the supply chain, they do not misrepresent their private information. However, when retailers dominate, manufacturers tend to underreport their CSR levels and the difficulty of recycling efforts. In scenarios where manufacturers and retailers have equal power, manufacturers do not misreport the difficulty of recycling but do underreport their CSR levels. This misreporting benefits the manufacturers at the expense of retailers and overall supply chain profitability, while also discouraging the recycling of used products. Across all three power structures, the study shows that retailers’ marketing efforts decrease as the misrepresentation of recycling difficulty increases, and increase as the misrepresentation of CSR levels increases. To mitigate the effects of manufacturers’ misreporting under information asymmetry, the paper proposes revenue-sharing contracts and two-part pricing contracts to coordinate the closed-loop supply chain under different power structures. Both contracts are shown to achieve Pareto improvements within the supply chain. This research provides valuable insights for enterprises operating within closed-loop supply chains, highlighting the importance of enhancing communication and cooperation to bridge information gaps and ensuring the coordina.

1 Introduction

Under the background of rapid development of social economy and technology, closed-loop supply chain management has gradually become the focus of attention of enterprises. Under the leadership of China’s “dual-carbon” strategic goal, how to better practice the environmental and social responsibility of closed-loop supply chain member enterprises, promote the recycling - remanufacturing - sales process of recycled products, and then realize the green and low-carbon transformation has become one of the hot issues nowadays (Xia and Niu, 2021). Recycling strategies for used and end-of-life products, as well as marketing services, have attracted widespread attention from all sectors of society as key elements driving the sustainability of closed-loop supply chains (Du et al., 2019). China’s National Development and Reform Commission (NDRC) and other departments have jointly issued relevant guidelines, clearly proposing that by 2025, about 60 large and medium-sized cities should take the lead in building a basically perfect recycling system for waste materials, vigorously developing the recycling economy and remanufacturing of waste products, and actively promoting the mechanism of recycling waste products. In this situation, focusing on the impact of marketing efforts of remanufactured products on the optimization of closed-loop supply chain operation and the environment from the perspective of CSR has significant practical guidance value for promoting the development of low-carbon industry and accelerating the construction of a recyclable and low-carbon consumption system.

On the one hand, with the aggravation of resource depletion and environmental degradation, the continuous upgrading of consumer demand, the environmental pollution caused by improper waste disposal and the increasing number of used products have brought great challenges to the development of circular economy in the country (Murthy and Ramakrishna, 2022). Promoted by the national extended producer responsibility system and other policies, many enterprises have realized the reduction and remanufacturing of waste products through the closed-loop supply chain, and have actively undertaken the ecological responsibility in corporate social responsibility (Cheng et al., 2023). Undertaking corporate social responsibility (CSR) refers to the fact that in the process of production and operation, enterprises should not only consider their own interests, but also integrate their contributions to the environment, consumers and society into their daily business activities. In the 1980s, CSR behaviors began to emerge in developed countries in Europe and the United States, and spread rapidly to other countries in the world with the expansion of multinational corporations’ capital. According to the data released by CSR China (www.csr.China.net), the number of enterprises disclosing social responsibility information in China has increased from 739 in 2009 to 2,115 in 2023. By the end of April year 2024, more than 2,000 listed companies disclosed their 2023 sustainability reports or social responsibility reports, and about 3,000 companies disclosed measures taken to reduce carbon emissions and their effects, indicating that CSR has received unprecedented attention in China in recent years.

On the other hand, information asymmetry is prevalent in closed-loop supply chains. Information asymmetry refers to the fact that when firms have an information advantage, they may use the strategy of false information to gain more profits. Therefore, the information asymmetry problem brings a series of new problems to the closed-loop supply chain that are different from those of the traditional supply chain: the information asymmetry greatly hampers the coordination of the closed-loop supply chain and the optimization of remanufacturing decisions (Jian et al., 2021). The problem of information asymmetry arises mainly due to the lack of information exchange and market economic activities between different members of the closed-loop supply chain, especially when one party holds private information that is not held by other members of the closed-loop supply chain, the impact of information asymmetry on the decision-making of remanufacturing in the closed-loop supply chain is more obvious. The increasing trend of economic globalization has led to intensified market competition, which makes members of closed-loop supply chains pay more attention to cooperation and coordination among supply chains.

In summary, the study of the two factors of CSR and information asymmetry in the closed-loop supply chain has important theoretical and practical significance. It not only helps enterprises to optimize decision-making and improve supply chain efficiency, but also provides reference for the government to formulate relevant policies and promotes the sustainable development of the whole society and economy.

Based on this, this paper investigates the problem of manufacturers’ misrepresentation of CSR information and recycling effort information in the supply chain, explores manufacturers’ misrepresentation strategies under different channel power structures, and introduces two coordination mechanisms to coordinate the supply chain, which is of great theoretical significance and practical value to promote the sustainable development of closed-loop supply chains.

The next part of this paper is organised as follows. In the second part, the related literature is reviewed. In the third part, we introduce the problem and hypotheses. Then, in Part IV, we establish the basic model. In Part V, we propose two coordination strategies. In Part VI, we analyse the given theorems numerically accordingly. Finally, we present the conclusions of this paper in Section 7.

2 Literature review

In this section, we review studies that are highly relevant to the work of this paper. These studies include, among others, recent research trends in closed-loop supply chains, studies related to corporate social responsibility, studies related to information asymmetry in supply chains, studies related to channel power structures in supply chains, and studies related to marketing efforts in supply chains.

2.1 Research on closed loop supply chain

At present, scholars’ research on the operation of closed-loop supply chains mainly focuses on issues such as recycling channel selection, pricing decisions, government rewards and punishments, and coordination mechanisms, etc.

In fact, scholars have explored a lot about product recycling and remanufacturing under closed-loop supply chains (Van Engeland et al., 2020; MahmoumGonbadi et al., 2021; Yang et al., 2020). Under the trend of transformation of traditional economy to the development mode of circular economy, product recycling and remanufacturing is an inevitable choice for enterprises (Ming-ge et al., 2021). In the product recycling process, the recycler usually bears heavy recycling costs and obtains low profits. However, research has shown that through recycling cooperation and sharing, the overall efficiency of the closed-loop supply chain is improved, and the profits of each member of the supply chain are also increased (Hosseini-Motlagh et al., 2020). Wang et al. (2019a) and He et al. (2019) constructed a two-level supply chain recycling decision-making model consisting of manufacturers and retailers to analyse, and found that cooperative mechanisms are the main way to improve recycling efficiency. In the current product recovery and remanufacturing environment, it is more common for producers to recycle through third parties. Xiao-gang et al. (2024) examined closed-loop supply chain decision-making under different recycling channels, considering mixed recycling channels of manufacturers, retailers, and third-party recyclers, as well as the fair concern behavior of retailers versus third-party recyclers. Four mixed recycling channel models are compared and it is found that recycling competition reduces the total amount of used products recycled and that the optimal recycling model changes when the level of fairness concerns of retailers and third-party recyclers changes. Qiankai et al. (2024) investigated the impact of e-commerce platforms opening second-hand markets on closed-loop dual-channel supply chain decisions. The study found that whether or not an e-commerce platform opens a second-hand market does not affect a company’s product pricing decisions, but increases the recycling price of a manufacturer’s used products.

Pricing decisions in closed-loop supply chains have also been thoroughly explored by scholars. Fengmin et al. (2021) studied and analysed the impact of CSR behaviours on sales behaviours and pricing strategies in closed-loop supply chains. Subsequently, Fengmin et al. (2022) investigated the impact of socially responsible behaviours of different member firms on the pricing decisions of closed-loop supply chains under different channel power structures. Shan and Dongyan (2021), Shan and Dong (2022) incorporated CSR behaviours into closed-loop supply chain pricing decisions and found that moderate competition among recyclers reduces product prices and increases scrap recycling rates.

In terms of government incentives and penalties, government subsidies to guide the closed-loop supply chain in waste recycling and remanufacturing play an important role in the establishment and effective operation of the closed-loop supply chain (Guo et al., 2019). Some scholars have studied the combination of subsidy policy and other policies, such as (Min and Zhen, 2019) derived the product recovery price and retail price under the four conditions of government non-intervention, government adopting reward and punishment mechanism, subsidy mechanism, and dual mechanism of reward and punishment and subsidy. In addition, the Government has taken measures to subsidise third-party recyclers to ensure that a certain amount of waste is recycled. Zheng et al. (2021) considered the impact of dynamic government penalty and subsidy strategies on the recycling of used and end-of-life products and finds that the government can increase the probability of firms choosing recycling strategies by increasing fines or decreasing subsidies, thereby reducing environmental pollution. Dao-ping et al. (2022) considered the dynamic stochastic situation of WEEE recycling rate and found that the implementation of reward and punishment mechanisms by the government can increase the recycling rate but is not conducive to mitigating the double marginal effect.

For the coordination problem in closed-loop supply chains, most of the studies have improved on individual contracts or multiple individual contracts, such as designing benefit-cost sharing contracts (Fang et al., 2020), price contracts (Fei and Maozeng, 2019), profit compensation mechanisms (Chuan and Yu-xiao, 2021), quantity discounts CSR cost sharing contracts (Xinran and Gang, 2020), etc. To achieve supply chain coordination.

2.2 Research on corporate social responsibility

In recent years, more and more enterprises are actively undertaking corporate social responsibility while pursuing economic benefits. Enterprises that actively undertake social responsibility are more likely to win the favour of consumers and shape a better brand image. Nearly 70 per cent of consumers indicate that they are willing to pay for the products and services of companies with a reputation for social responsibility (Minli et al., 2023).

In the supply chain level social responsibility literature, relevant studies can be divided into two categories: one category of literature, when examining CSR behavior, considers CSR behavior as an endogenous variable in the study of corporate decision-making behavior. Modak et al. (2019) explored the impact of CSR investments on closed-loop supply chain recycling decisions and coordination through social giving. Yan et al. (2019) examined CSR incentives under different channel power structures and showed that suppliers fulfil their social responsibilities at a higher level when retailers act as channel leaders. Liu et al. (2019) investigated the impact of government subsidies on retailer-led socially responsible supply chains, noting that a certain range of government subsidies can stimulate the overall effectiveness of the supply chain. Wang et al. (2019b) found that increasing CSR investment co-operation can effectively improve the level of retailers’ CSR investment, increase market share and gain more supply chain profits.

Another category of literature treats CSR as an exogenous variable and considers the impact of CSR as consumer surplus, which is directly added to the firm’s profit function. Yu-hui et al. (2024) constructed a green supply chain model to explore the incentive effects of different coordination contracts on product greenness and the impact of CSR preferences. The study finds that an increase in CSR preferences can help improve product greenness, etc., that two-part pricing contracts can harmonize the supply chain, and that CSR preferences can widen the range of their transfer payments. Feng-min et al. (2022) analyzed the operation and coordination of a closed-loop supply chain for third-party recycling in the context of manufacturers’ awareness of CSR behaviours and retailers’ CSR investments. Jian-yi Qi-chao (2022), in their study of fresh produce supply chains, found that CSR behaviors have a positive impact on the supply chain, and that the effect of stimulating demand when supply chain members share CSR is better than the effect of suppliers undertaking CSR alone.

In supply chain research that considers social responsibility, most studies assume that market demand is related to price or the extent to which firms fulfil their social responsibility, while fewer studies have explored the joint impact of social responsibility and marketing efforts. In addition, there is little existing research on misrepresentation of the level of corporate social responsibility.

2.3 Research on information asymmetry in supply chains

Information asymmetry is a common phenomenon in supply chains, and when a firm has an information advantage, it may seek to make more profits by concealing key information or even misrepresenting it. Existing related studies can be broadly categorized into three areas: (1) misrepresentation of product quality information; (2) misrepresentation of cost information; (3) misrepresentation of demand information.

In terms of misrepresentation of product quality information, being in a market with product differentiation makes it easy for there to be asymmetry of product quality information between firms and consumers. Consumers often judge product quality based on price, which provides an opportunity for companies to exploit false quality information. Based on vertical product differentiation, Xiong-wei et al. (2020) investigated whether monopoly firms have incentives to adopt false quality strategies in the presence of asymmetric information about product quality, and the results of the study showed that firms have incentives to adopt false quality strategies for high-quality and low-quality products, respectively. Gang and Xiao-yi (2024) have examined the impact of suppliers’ CSR disclosure on customer stability using a sample of listed companies’ data from 2011–2019. The results show that disclosure quality is positively related to customer stability, more pronounced in voluntary disclosure and private firms, and that stability is enhanced by increasing information transparency and improving corporate governance.

In terms of misrepresentation of cost information, the cost information of supply chain node firms is private, and it is difficult to achieve complete sharing of cost information due to the drive of firms’ self-interest and the independence of their decision-making. Minxing et al. (2024) have explored policy inefficiencies in emission reduction policies due to information asymmetry between governments and enterprises. Studies have shown that: when information is not updatable, hybrid policies are superior to quantity and price policies, with bilateral price-constrained hybrid policies being the best; and when information is updatable, the three are equivalent in terms of efficiency. Fang et al. (2019) investigated the impact of recycling operating cost information asymmetry on differential pricing in a closed-loop supply chain. The results of the study show that retailers report higher information on recycling operating costs to gain more profit. Qin and Shao (2019) and Fang et al. (2019) considered only unilateral cost information asymmetry. Xinhui et al. (2021) explored the impact of true sharing and false reporting of supply chain information on efficiency under bilateral information asymmetry and find that both supply and sales parties tend to exaggerate their private information.

For many manufacturers, continually improving the quality of their products is the key to competitiveness in the marketplace, and obtaining accurate information about market demand is critical in this process. In practice, retailers are closer to market demand than manufacturers and thus have access to private information about market demand, which can have a significant impact on both the pricing decisions of manufacturers and the inventory strategy decisions of retailers. Liang-liang and Pan (2022) used refined Bayesian theory and the Stackelberg game model to investigate the retailer’s demand information sharing strategy and the manufacturer’s optimal innovation model for process and product innovation in the supply chain when demand forecasting information is asymmetric. You-guo et al. (2022) investigated a two-stage dynamic game problem between a manufacturer and a retailer considering that market demand information is private to the retailer. By comparing and analyzing the game equilibrium decisions of different pricing contracts and the profits of supply chain parties under two scenarios of information disclosure and non-disclosure, it is found that the retailer discloses the demand information when the actual market size is smaller than its mean, whereas the retailer does not disclose the demand information when the actual market size is larger than its mean.

In closed-loop and reverse supply chains, information asymmetry between members is also common due to factors such as industry monopoly, trade barriers or conflicts of interest. For example, the information asymmetry problem of recycling costs is particularly prominent in Midea and Haier, which are engaged in recycling manufacturing business. Pan and Zhong-kai (2019) studied closed-loop supply chain decision making with asymmetric cost recovery information among manufacturers and showed that retailers can use two-part pricing contracts to enable manufacturers to share true cost information.

There are many studies on supply chain members’ false reporting behaviours and supply chain coordination strategies under information asymmetry, but little literature has considered optimal decision making and channel selection in closed-loop supply chains under different channel power structures. Due to the complexity of closed-loop supply chains, manufacturers’ CSR levels are often private information that is difficult for retailers to accurately observe (Zhibing, 2022). Based on this, this paper investigates the impact of channel information asymmetry on the performance of closed-loop supply chains under different power structures in the context of manufacturers’ misrepresentation of the difficulty of recycling and the level of corporate social responsibility (CSR) to provide a theoretical basis for the decision-making of firms in closed-loop supply chains.

2.4 Research on channel power structures in supply chains

Research on channel power structure is crucial to this paper. Wenwei et al. (2024) have explored the effects of manufacturer overconfidence and power structure differences on supply chain decisions and profits. The study shows that the total supply chain profit is highest when both parties have equal power; the impact of manufacturer overconfidence on its own and supply chain profit is related to the power level. Feng et al. (2021) focused on the impact of expected regret (AR) on closed-loop supply chain decisions. They investigated how expected regret affects original equipment manufacturers’ (OEMs’) remanufacturing strategies and pricing decisions in OEMs’ competition with third-party remanufacturers (TPRs) under different power structures. Fuan et al. (2024) have explored the impact of trading models and channel power structures on the pricing decisions of electronic closed-loop supply chains under carbon trading mechanisms. It is found that the optimal pricing and service decisions of electronic closed-loop supply chains vary according to the trading model and channel power structure; the choice of supply chain dominant player and trading model affects revenue and carbon emissions from both economic and environmental perspectives. Fengmin et al. (2022) investigated the impact of CSR behaviors of different member firms on pricing decisions of closed-loop supply chains under three different channel power structures. They found that when a channel leader exists in a closed-loop supply chain, channel followers’ assumption of CSR is more favorable to the overall development of the closed-loop supply chain than that of the leader. Xing-hua et al. (2023) found that channel power structure not only affects the product durability and selling effort decisions of a durable goods supply chain, but also relates to the optimal profits of member firms by constructing a decision-making model for a durable goods supply chain under different channel power structures. It can be seen that there is a lot of research in the existing literature on supply chains under channel power structure, but the research on channel power structure and information asymmetry is not yet in-depth.

2.5 Research on marketing efforts in supply chains

With the development of economy and science and technology, the life cycle of products is gradually shortening and market competition is becoming increasingly fierce. In order to successfully sell their products, increase market demand and expand their market share, enterprises must achieve their goals through advertising, discount promotions, product exhibitions, training of sales staff and other sales tactics. Currently, a large number of scholars have conducted relevant research on marketing effort, mainly focusing on the supply chain coordination problem under marketing effort and the relationship between marketing effort and firm performance. Zhang et al. (2023) investigated selling effort in a low-carbon supply chain and found that selling effort improves the efficiency of the supply chain and that the level of selling effort is positively related to supply chain profit. Jie and Yu (2023) considered the sales effort behaviour of retailers and constructed a supply chain decision model based on the WCVaR method, discussing the optimal decision of retailers’ order quantity and sales effort level. It was found that as the retailer’s risk tolerance increases, its order quantity and profit increases. Tong et al. (2021a) considered the assumption of CSR by different members and analyzed the impact of retailers’ selling effort behaviour and social responsibility awareness on the decision-making and profitability of member firms of a closed-loop supply chain. They found that retailers’ selling effort not only reduces the wholesale price of products, but also increases product demand. Ren and Luo (2024) studied the decision-making and coordination of product quality and marketing efforts in e-commerce supply chains under different power structures. Comparing the profit relationships of different decision-making models, the sensitivity coefficients of profit and product quality and marketing effort are positively correlated. Fu-hai et al. (2024) explored the effects of the shop-in-shop model on the optimal production decisions, sales effort levels and expected profits of supply chain member firms. They found that the shop-in-shop model can effectively incentivise producers to increase production and sales effort when the sales revenue commission ratio and bank loan interest rate satisfy certain conditions, thus increasing the expected profits of producers and the supply chain system. In short, retailers’ marketing behavior and sales efforts are key to gaining market share. In fact, advertising and marketing can help supply chain members streamline the sales process and capture the consumer market. Pongen et al. (2024) mentioned the role of the level of marketing effort on product collection and recycling rates, arguing that the collection and marketing efforts of different channel members affect the collection and recycling rates of discarded products, and that firms can increase consumer awareness of recycling participation through incentive programs. In addition, through proper advertising in the recycling and remanufacturing market, consumers will become more aware of the benefits of recycling and remanufacturing. Currently, there is limited literature considering retailer marketing efforts in closed-loop supply chains, which warrants research.

To summarize, previous studies on closed-loop supply chains have mainly focused on the selection of recycling channels and the influence of the power structure of supply chain channels. By summarizing previous studies, we find that few scholars have considered the problem of closed-loop supply chain information decision-making based on CSR. Therefore, based on summarizing previous studies, this paper explores the impact of information symmetry and channel power structure on closed-loop supply chains. By studying the impacts of channel power structure and manufacturers’ misrepresentation behavior on closed-loop supply chains and proposing corresponding coordination strategies, this paper provides corresponding theoretical support for communication and cooperation among enterprises in closed-loop supply chains, eliminating the information gap, and enhancing information disclosure.

3 Problem description and assumptions

This paper takes a closed-loop supply chain consisting of a single manufacturer and a single retailer as the object of study. In the forward supply chain, the manufacturer is responsible for producing new products and wholesaling them to the downstream retailer, who sells the products to the end of the market; in the reverse supply chain, it is assumed that the manufacturer is responsible for the recycling and remanufacturing of used products, and that the remanufactured products are identical to the new products in terms of function and quality, and that the two products enter the consumer market in the same way, with the same market acceptance and sales price (Savaskan et al., 2004b).

Without loss of generality, the unit production cost of a remanufactured product is lower than the production cost of a new product. Let the unit cost of the new product be

Analysed from a macro perspective, the recycling and remanufacturing of products in closed-loop supply chains can be viewed as an act of socially responsible corporate investment. However, when analysed from the point of view of business operation strategy, the decision to recycle waste products and the decision to invest in corporate social responsibility are independent of each other. Apple has implemented the “trade-in” strategy to recycle products, save costs and improve the efficiency of resource utilisation, while at the same time implementing a number of large-scale social welfare activities and actively donating to the community in order to fulfil its corporate social responsibility. In terms of the nature of the two, the implementation of remanufacturing of used products by enterprises is aimed at saving production costs, with the goal of improving economic efficiency; whereas the CSR input of enterprises is aimed at fulfilling their corporate social responsibility, and ultimately realising the improvement of social efficiency. In order to portray the CSR input behaviour of the manufacturer, the CSR behaviour was expressed in the form of consumer surplus with reference to Panda’s study (Panda et al., 2017):

Under information asymmetry, the difficulty of recycling efforts and the level of corporate social responsibility are private information of the manufacturer, driven by corporate self-interest, the manufacturer may benefit from its own information advantage and misrepresent its private information to the retailer, which makes the retailer deviate from the optimal decision-making in the process of the game, so as to make more profits for itself. The decision variables for manufacturers are the recovery effort difficulty misrepresentation coefficient

Assumption 1. All information in the supply chain is symmetric except for information on the difficulty of the manufacturer’s recycling effort and the level of CSR.

Assumption 2. The total amount of new and remanufactured goods produced by manufacturers is equal to the market demand, i.e., the market can be cleared completely.

Assumption 3. The fact that the coefficient of difficulty of the recovery effort,

Assumption 4. The difficulty of a manufacturer’s recycling effort to a retailer’s announcement is

Assumption 5. Market demand is linearly related to the retail price of the product by setting

4 Modelling and solving models

In order to explore manufacturers’ misreporting behaviour under different rights structures, three scenarios will be modelled and analysed separately. Equation 1 represents the market demand for the product:

Equations 2–4 represents the manufacturer’s actual profit, manufacturer’s disclosed profit and retailer’s profit function:

4.1 Manufacturer-led supply chain

The manufacturer-led Stackelberg game supply chain structure represents a supply chain consisting of a few large manufacturers and many relatively small retailers, e.g., firms such as Huawei and Apple with their core retailers. In this case, the manufacturer first determines the misrepresentation coefficients

The game sequence of a manufacturer-dominated two-stage closed-loop supply chain is solved using a backward recursive approach. It is easy to see that the retailer’s profit function is strictly concave with respect to

According to Equations 5, 6:

Since the recycling rate of used products satisfies

Theorem 1. When the manufacturer does not misrepresent private information, the optimal decisions of the manufacturer and the retailer are

Proof: Bringing

Theorem 2. When a manufacturer dominates the supply chain, the manufacturer does not misrepresent its private information.

Proof: Let

4.2 Retailers -led supply chain

The retailer-dominated Stackelberg gaming supply chain structure represents a supply chain consisting of a number of large retailers (e.g., mega-retail giants such as Metro, Walmart, Carrefour, etc.) and manufacturers that have greater market influence compared to manufacturers. In this case, the manufacturer first determines the misrepresentation coefficients

Similarly, in order to make the decision information consistent with the misreported information, the manufacturer should set the optimal wholesale price

Equations 12–15 represent the wholesale price, the recycling rate of used products, the level of marketing effort and the retail price of the product:

Equations 16–18 can be derived from Equations 12–15

Since the recycling rate of used products satisfies

Theorem 3. When the manufacturer does not misrepresent private information, the optimal decisions of the manufacturer and the retailer are

Proof: by bringing

Theorem 4. When retailers dominate the supply chain, manufacturers understate the level of CSR and the difficulty of recycling efforts.

Proof: Let

Corollary 1 When retailers dominate the supply chain, manufacturers’ misreporting behaviour increases wholesale prices, retail prices, marketing effort levels and their own profits, while at the same time decreasing the recycling rate of used products, retailers’ profits and the total profits of the supply chain.

From Corollary 1, it can be seen that when manufacturers report a low level of recycling of used products, this will lead to lower demand in the secondary market, which will lead to a lower rate of recycling of used products; at the same time, meanwhile manufacturers underreport levels of corporate social responsibility, it is actually a case of the manufacturer shifting the focus of its production to the market for new products, which will increase the demand for the market for the new products out of thin air, thus intentionally increasing the wholesale price of the product, and the retailer will then increase the retail price of the product and the level of marketing effort to sell it to the consumer. The retailer then increases the retail price and marketing effort of the product and sells it to the consumer. Ultimately, the manufacturer’s profits increase, the retailer and the supply chain as a whole suffer, and the consumer is required to pay a higher price for the new product, which is also detrimental to the consumer’s interests and not conducive to building the product’s brand image in the long term.

4.3 Power equalization supply chain

Manufacturers and retailers Nash equilibrium game supply chain structure represents a class of manufacturers and retailers of comparable strength to form the supply chain structure, for example, Haier, Lenovo, Huawei and other manufacturers of electrical appliances and retailers such as Suning, Gome, etc. In the market mutual checks and balances evenly matched, which are not able to become a leader in the supply chain. In this case, the manufacturer first determines the manufacturer first determines the misrepresentation coefficients

Let

Expressions (Equations 23–25) can be found by bringing Equations 19–22 into Equations 2–4.

Since the recycling rate of used products satisfies

Theorem 5. When the manufacturer does not misrepresent private information, the optimal decision of the manufacturer and the retailer is

Proof: Bringing

Theorem 6. When manufacturers and retailers have equal power, manufacturers do not misreport the difficulty of recycling efforts but underreport the level of CSR.

Proof: Let

From Theorem 6, it can be seen that in the power-equal supply chain, the manufacturer does not obtain absolute leadership, and driven by its own interests, the manufacturer still adopts the strategy of misrepresentation in order to obtain profits.

Corollary 2 When manufacturers and retailers have equal power, manufacturers’ misrepresentation leads to higher wholesale and retail prices of products, lower recycling rates and marketing levels of used products, as well as higher profits for manufacturers as a result of their own misrepresentation and lower profits for retailers and the supply chain in general.

Proof: Bringing

From Corollary 2, a manufacturer’s misrepresentation of CSR information affects consumer purchasing power, i.e., market demand, and lower market demand leads to higher wholesale and retail prices, lower consumer and recycling markets, and lower recycling and marketing of used and end-of-life products. Manufacturers’ misrepresentation only benefits themselves and directly harms retailers, the supply chain and consumers as a whole.

Corollary 3 When the manufacturer and retailer have equal power, the manufacturer’s misreporting behaviour makes the supply chain optimal decision the same as when the manufacturer dominates, and the manufacturer, the retailer and the supply chain as a whole are equally profitable.

Proof: It is easy to prove that

From Corollary 3, it can be seen that in a supply chain with equal power, the manufacturer can bring itself back to a dominant position by misrepresenting its behaviour, and in the context of information asymmetry, the power of each member of the supply chain is no longer equal.

5 Closed-loop supply chain coordination

5.1 Centralised decision-making

When information in the supply chain is perfectly symmetric, the overall profit function of the supply chain under centralised decision making is:

Let

Bringing Equations 27–29 into Equation 26

5.2 Revenue-sharing contract

If the upstream and downstream parties of the supply chain reach a co-operation, they follow the relevant agreement, i.e., at the beginning of the sales period, the manufacturer provides the retailer with a relatively low wholesale price

Combining the above description and bringing it to Equations 2–4 leads to Equations 31–33:

Joint first-order condition

In order for the supply chain under the coordination of the revenue sharing contract to achieve the same effect of centralised decision making, for this purpose it is necessary to satisfy

Introducing

After coordination using the revenue sharing contract, manufacturers do not misrepresent the difficulty of recycling efforts, while both manufacturers’ and retailers’ profit expressions are independent of the CSR misrepresentation coefficients, i.e., manufacturers do not engage in misrepresentation behaviour after coordination using the revenue sharing contract. The validation leads to

5.3 Two-part pricing contract

From the analysis in Section 4, it can be seen that when there is information asymmetry in the supply chain, the manufacturer’s misrepresentation can harm the overall profitability of the supply chain. Due to the existence of double marginal effects in the closed-loop supply chain under decentralised decision making, the decisions of the supply chain are not optimal. Therefore, this section adopts a two-part pricing contract to coordinate the closed-loop supply chain under information asymmetry.

Under a two-part pricing contract, the manufacturer sets a waste product recycling rate

Therefore, the manufacturer’s actual profit, open profit and retailer’s profit functions when the supply chain uses a two-part pricing contract are:

Theorem 7. When the parameters in the two-part pricing contract satisfy

Proof: Taking the supply chain when the manufacturer is dominant as an example, the expression for the retailer’s optimal retail price and level of marketing effort with respect to the wholesale price w can be derived by using the backward induction method:

The above equation can be obtained by conjunction:

From Theorem 7, the retail price of the product, the recycling rate of the used product, and the level of marketing effort under the two-part pricing contract are the same as the optimal decision under centralised decision making, while the manufacturer and the retailer agree on the wholesale price of the product so that the parameters of the open decision making of both the manufacturer and the retailer are determined. Even if the manufacturer has information about the person, it cannot change its decision through misrepresentation, so a two-part pricing contract can achieve profit coordination among closed-loop supply chain members under information asymmetry while avoiding misrepresentation by the manufacturer. In a two-part pricing contract, retailers can obtain a higher profit share by increasing their negotiation skills or by obtaining patents and exclusivity to obtain lower transfer fees.

6 Numerical analysis

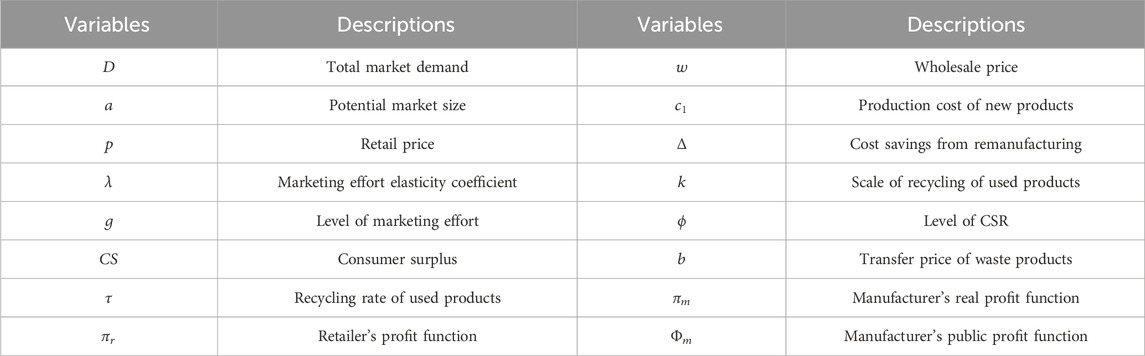

In order to verify the reasonableness of the conclusions and dig deeper into the management insights behind the model, numerical simulation experiments are conducted in this section. At the heart of this paper is the study of the impact that manufacturer misrepresentation brings to the closed-loop supply chain, considering three different decision models with different channel power structures. The arithmetic analysis consists of two parts: on the one hand, it is to analyse the coordination performance of the supply chain and verify the coordination effect of the revenue sharing contract and the two-part pricing contract on the closed-loop supply chain; on the other hand, it is to analyse the impact of the sensitivity of the manufacturer’s misrepresentation strategy on the equilibrium of the supply chain and the optimal profit under different channel power structures. Considering the practical significance of the model and combining the relevant literature (Tong et al., 2021b; Juan et al., 2023), the experimental data were standardized and selected as follows:

6.1 Analysis of contractual coordination mechanisms

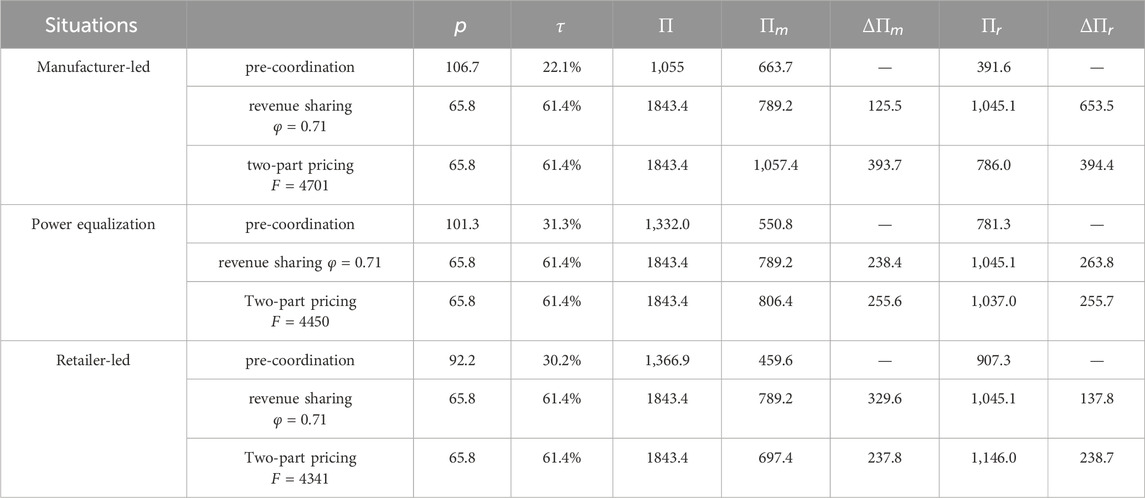

In order to verify the effectiveness of the coordination mechanism, before and after the coordination of the closed-loop supply chain, the optimal decision-making and profit-related situation of each member are compared, as shown in Table 3. As shown in Table 2, no matter which channel power structure is adopted, the optimal retail price of products in the closed-loop supply chain after co-ordination is significantly reduced, and the recycling rate of used products as well as the profits of each member of the supply chain are significantly increased, realising the Pareto improvement of the supply chain, which indicates that the revenue sharing contract and the two-part pricing contract can achieve better supply chain co-ordination and make it reach the level of centralised decision-making, and this also further argues the conclusion of this paper.

6.2 Sensitivity analysis of two-factor misreporting coefficients

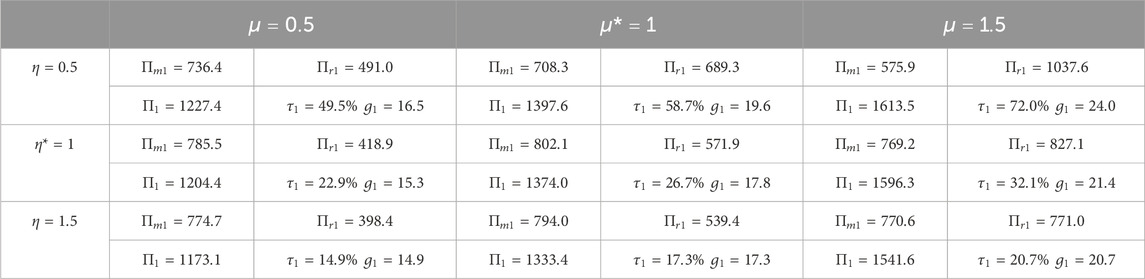

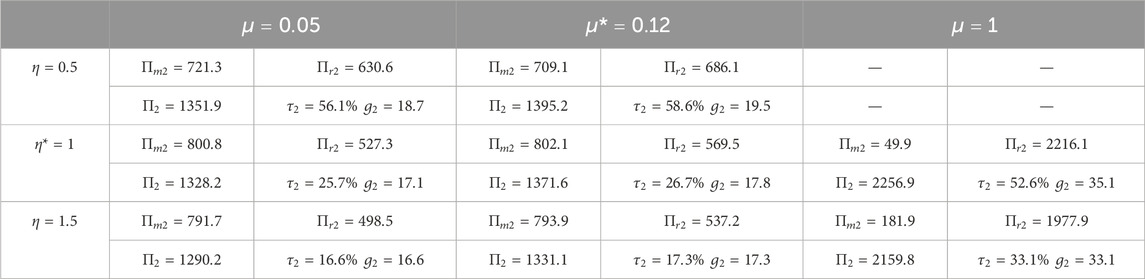

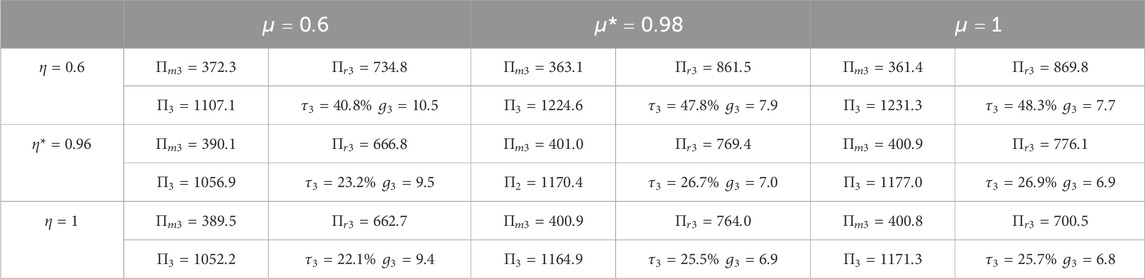

As can be seen from Tables 3–5, the manufacturer’s profit shows a trend of increasing and then decreasing with the increasing misrepresentation factor

As can be seen in Tables 3–5, retailers’ marketing effort decreases as the misrepresentation coefficient of recall difficulty increases, while it increases as the CSR misrepresentation coefficient increases. It means that when the coefficient of misrepresentation of recycling difficulty increases, the recycling market is not prosperous, and retailers are not willing to invest more advertising and marketing in the promotion of used products; when the coefficient of misrepresentation of CSR increases, the remanufacturers show a higher level of social responsibility in the quality of products, environmental protection, brand image, etc., and therefore, retailers are willing to provide a higher level of advertising and marketing to promote the remanufactured products.

7 Conclusion and policy implications

7.1 Conclusion

This paper investigates the closed-loop supply chain coordination problem considering CSR and information asymmetry, and analyses manufacturers’ misreporting strategies and their impacts on the supply chain in three scenarios: manufacturer-dominated supply chains, retailer-dominated supply chains, and power-parity supply chains under the asymmetry of information on the difficulty of manufacturers’ recycling efforts and the level of CSR. The paper draws the following conclusions.

(1) Manufacturers do not misrepresent their private information when the manufacturer dominates the supply chain; When retailers dominate the supply chain, manufacturers underreport the level of CSR and the difficulty of recycling efforts; and when there is equal power between the manufacturer and the retailer, the manufacturer does not misrepresent the difficulty of the recycling effort, but understates the level of CSR.

(2) Manufacturers’ misreporting behaviors only benefit themselves, always harming retailer and total supply chain profits, and also discouraging the recycling of used products. When the manufacturer adopts a two-factor misreporting strategy, it keeps retailer profits, total supply chain profits, and used product recycling lower than they would be without the manufacturer’s misreporting strategy.

(3) The manufacturer’s two-factor misrepresentation strategy converges the manufacturer’s profit to the level when the manufacturer is dominant under an equal-power supply chain, i.e., the manufacturer’s adoption of a two-factor misrepresentation strategy enables the manufacturer to regain its market position when the manufacturer and the retailer have equal power.

(4) Under all three supply chain models with different channel power structures, retailers’ marketing effort decreases with the increase in the recall difficulty misrepresentation coefficient and increases with the increase in the CSR misrepresentation coefficient.

To address manufacturers’ misreporting behavior under information asymmetry, this paper designs a revenue-sharing contract and a two-part pricing contract to coordinate a closed-loop supply chain under different power structures, and finds that both contracts can achieve Pareto improvement in the supply chain.

7.2 Policy implcations

The relevant management implications of this paper are as follows.

(1) The security and stability of the supply chain is the basis for building a Dual circulation. Large manufacturers should continue to improve their sustainable development management capabilities, meet the management needs of customers for sustainable development, build a sustainable development system of the supply chain, and organize material suppliers to exchange information to ensure the transparency of channel information in the supply chain.

(2) Enterprises in the supply chain should implement the concept of sustainable development management, effectively fulfill social responsibility in the supply chain management process, and transmit social responsibility information to upstream partners and core suppliers to ensure the effective implementation of social responsibility requirements in supply chain management, strengthen cooperation to alleviate supply chain risks, and promote sustainable development of the supply chain.

(3) When manufacturers have information advantages, retailers should actively communicate and cooperate with manufacturers to eliminate the information gap; When formulating coordination contracts, retailers can enhance their bargaining power by obtaining patents and exclusive rights, in order to obtain more share of profit distribution.

(4) The government should improve the information disclosure mechanism, strengthen information disclosure, create a fair, just, and open market environment, and ensure the healthy development of the market.

Overall, there are still some shortcomings in this article. This article only focuses on the social responsibility behavior of manufacturers. In fact, with the development and growth of the retail industry, the social responsibility behavior of retail enterprises should also be considered. The model in this article is based on the assumption of demand determination, and future research will be conducted under uncertain demand.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

HH: Writing–original draft, Writing–review and editing. YC: Writing–original draft, Writing–review and editing. RW: Methodology, Conceptualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. We appreciate the financial support of the Natural Science Foundation of Heilongjiang Province (Grant No. LH 2022G014) and the Social Science Foundation of Heilongjiang Province (Grant No. 22GLD356).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Cheng, W., Li, W., and Dai, L. (2023). Fulfilling corporate social responsibility in a Closed-loop supply chain–Evidence from alternative remanufacturing models. J.Computers and Industrial Eng. 179, 109154. doi:10.1016/J.CIE.2023.109154

Chuan, Z., and Yu-Xiao, C. (2021). Decision and coordination of cascade utilization power battery closed-loop supply chain with economies of scale under government subsidies. J.Operations Manag. Res. 30, 72–91. doi:10.12005/orms.2021.0386

Dao-Ping, W., Ke, Z., and Yu, Z. (2022). Different game of closed-loop supply chain with dynamic stochastic recovery rate under reward-penalty mechanism of government. J.Chinese J. Manag. Sci., 1–15. doi:10.16381/j.cnki.issn1003-207x.2021.1138

Du, S., Wang, L., Hu, L., and Zhu, Y. (2019). Platform-led green advertising: promote the best or promote by performance. J.Transportation Res. Part E Logist. Transp. Rev. 128, 115–131. doi:10.1016/j.tre.2019.05.019

Fang, L., Xin, M., and Jia, H. (2020). Research on contract coordination of dual channel closed loop supply chain considering quality uncertainty. J.Statistics and Decis. 36, 176–180. doi:10.13546/j.cnki.tjyjc.2020.09.038

Fang, L., Xin, M., Jia, H., et al. (2019). Pricing decision research of closedloop supply chain under asymmetric information on government regulation. J.Chinese J. Manag. Sci. 27, 116–126. doi:10.16381/j.cnki.issn1003-207x.2019.07.011

Fei, T., and Maozeng, X. (2019). Decision and coordination of dual-channel closed-loop supply chain with remanufacturing considering patent protection and channel preference. J.Operations Manag. Res. 28, 61–69. doi:10.12005/orms.2019.0129

Feng-Min, Y., Ying-Luo, Y., and Chun-Xian, T. (2022a). Operational coordination for closed loop supply chain considerating corporate social responsibility behavior consciousnes. J.Chinese J. Manag. Sci. 30, 52–63. doi:10.16381/j.cnki.issn1003-207x.2019.1734

Fengmin, Y., Yingluo, Y., and Chunxian, T. (2022b). Pricing decision for closed-loop supply chain considering corporate social responsiility and Channel Power structure. J.Business Rev. 34, 283–294. doi:10.14120/j.cnki.cn11-5057/f.2022.01.014

Fengmin, Y., Yue, W., Shan, L., et al. (2021). Sales effort and pricing decision for closed-loop supply chain under different CSR sharing modes. J.Journal Industrial Eng./Engineering Manag. 35, 210–219. doi:10.13587/j.cnki.jieem.2021.01.019

Feng, Y., Manman, W., and Sheng, A. (2021). Optimal remanufacturing decisions in supply chains considering consumers’ anticipated regret and power structures. J.Transportation Res. Part E 148, 102267–102287. doi:10.1016/J.TRE.2021.102267

Fuan, Z., Hongxin, Z., and Qingli, D. (2024). E-Closed-Loop supply chain decision making considering trading modes and power structures. J.Chinese J. Manag. Sci., 1–18. doi:10.16381/j.cnki.issn1003-207x.2023.1578

Fu-Hai, N., Dian-Sheng, L., and Ting-Ting, X. (2023). Effects of the store-within-a-store mode on production and sale effort strategy of a capital constrained supply chain. J.Chinese J. Manag. Sci. 31, 141–151. doi:10.16381/j.cnki.issn1003-207x.2020.1349

Gang, L., Xiao-Yi, Y., Wei-Ke, W., et al. (2024). Supplier' corporate social responsibility InformationDisclosure and customer stability. J.Journal of Central University of Finance and Economics, 78–91. doi:10.19681/j.cnki.jcufe.2024.04.004

Guo, J., He, L., and Gen, M. (2019). Optimal strategies for the closed-loop supply chain with the consideration of supply disruption and subsidy policy. J.Computers and Industrial Eng. 128, 886–893. doi:10.1016/j.cie.2018.10.029

He, Q., Wang, N., Yang, Z., He, Z., and Jiang, B. (2019). Competitive collection under channel inconvenience in closed-loop supply chain. J.European J. Operational Res. 275, 155–166. doi:10.1016/j.ejor.2018.11.034

Hosseini-Motlagh, S.-M., Nouri-Harzvili, M., Johari, M., and Sarker, B. R. (2020). Coordinating economic incentives, customer service and pricing decisions in a competitive closed-loop supply chain. J.Journal Clean. Prod. 255, 120241. doi:10.1016/j.jclepro.2020.120241

Jian, L., Lan, Y., and Yao, X. (2021). Research on information sharing mechanism of emission reduction in supply chain based on blockchain under information asymmetry. J.Chinese J. Manag. Sci. 29, 131–139. doi:10.16381/j.cnki.issn1003-207x.2020.1076

Jian-Yi, L., Qi-Chao, S., Zhong-Wei, F., et al. (2022). Research on corporate social responsibility sharing strategy selection in fresh E-commerce supply chain. J.Chinese J. Manag. Sci., 1–15. doi:10.16381/j.cnki.issn1003-207x.2021.1781

Jie, D., and Yu, W. (2023). Research on risk- and ambiguity-averse behavior using a newsvendor model with retailer′s sales effort. J.Journal Industrial Eng. Eng. Manag. 37, 118–128. doi:10.13587/j.cnki.jieem.2023.03.011

Juan, T., Bang-Yi, L., Ben-Gang, G., et al. (2023). Decision and coordination of the retailer recycling closed-loop supply chain considering corporate social responsibility. J.Chinese J. Manag. Sci. 31, 228–237. doi:10.16381/j.cnki.issn1003-207x.2020.1809

Liang-Liang, Z., and Pan, Z. (2022). Research on selection of process and product innovation modes in supply chains under asymmetric demand information. J. Operations Res. Manag. Sci. 31, 128–134. doi:10.12005/orms.2022.0295

Lingrong, Z., Xiaoyan, L., Feng, W., et al. (2023). Research on misreporting strategies and coordination of closed-loop supply chain under cap-and-trade policy. J.Journal Industrial Eng./Engineering Manag. 37, 196–205. doi:10.13587/j.cnki.jieem.2023.04.017

Liu, Y., Quan, B.-T., Xu, Q., and Forrest, J. Y. L. (2019). Corporate social responsibility and decision analysis in a supply chain through government subsidy. J.Journal Clean. Prod. 208, 436–447. doi:10.1016/j.jclepro.2018.10.121

Mahmoumgonbadi, A., Genovese, A., and Sgalambro, A. (2021). Closed-loop supply chain design for the transition towards a circular economy: a systematic literature review of methods, applications and current gaps. J.Journal Clean. Prod. 323, 129101. doi:10.1016/j.jclepro.2021.129101

Ming-Ge, Y., Yang, W., and Xiao-Zhen, L. (2021). Research on decision of remanufacturing entry for manufacturers and distributors. J.Industrial Eng. Manag. 26, 82–91. doi:10.19495/j.cnki.1007-5429.2021.01.011

Minli, X., Yongjian, N., and Huiyun, J. (2023). Decision making of reverse supply chain considering value Co-creation and corporate social responsibility. J.Business Rev. 35, 301–310. doi:10.14120/j.cnki.cn11-5057/f.2023.06.010

Min, X., and Zhen, Z. (2019). A study of closed-loop supply chain with reward-penalty and subsidy mechanism considering consumers' environmental preference. J.Industrial Eng. Manag. 24, 53–68. doi:10.19495/j.cnki.1007-5429.2019.03.007

Minxing, J., Yijiang, H., and Bangzhu, Z. (2024). Intertemporal dynamic hybrid policy design for emissions control with information uncertainty. J.Systems Eng. — Theory and Pract. 44, 2213–2226.

Modak, N. M., Kazemi, N., and CáRDENAS-BarróN, L. E. (2019). Investigating structure of a two-echelon closed-loop supply chain using social work donation as a Corporate Social Responsibility practice. J.International J. Prod. Econ. 207, 19–33. doi:10.1016/j.ijpe.2018.10.009

Murthy, V., and Ramakrishna, S. (2022). A review on global E-waste management: urban mining towards a sustainable future and circular economy. J. Sustain. 14, 647. doi:10.3390/SU14020647

Panda, S., Modak, N. M., and CáRDENAS-BarróN, L. E. (2017). Coordinating a socially responsible closed-loop supply chain with product recycling. J.International J. Prod. Econ. 188, 11–21. doi:10.1016/j.ijpe.2017.03.010

Pan, Z., and Zhong-Kai, X. (2019). Designing incentive contract for a retailer under asymmetric information of manufacturer′s collection cost. J.Journal Industrial Eng. Eng. Manag. 33, 144–150. doi:10.13587/j.cnki.jieem.2019.04.017

Pongen, I., Ray, P., and Govindan, K. (2024). Creating a sustainable closed-loop supply chain: an incentive-based contract with third-party E-waste collector. J.Journal Clean. Prod. 462, 142351. doi:10.1016/J.JCLEPRO.2024.142351

Qiankai, Q., Wenhu, W., Yuan, S., et al. (2024). Decision-making in dual-channel closed-loop supply chains considering secondary market introduced by E-commerce platform. J.Journal Syst. and Manag., 1–21.

Qin, SHAO, and Shao, Y. (2019). Supply chain decisions under asymmetric information with cost and fairness concern. J.Enterprise Inf. Syst. 13, 1347–1366. doi:10.1080/17517575.2019.1638974

Ren, H., and Luo, Z. (2024). Decisions and coordination of E-commerce supply chain considering product quality and marketing efforts under different power structures. J. Sustain. 16, 5536. doi:10.3390/SU16135536

Savaskan, R. C., Bhattacharya, S., and Van Wassenhove, L. N. (2004a). Closed-loop supply chain models with product remanufacturing. J.Management Sci. 50, 239–252. doi:10.1287/mnsc.1030.0186

Savaskan, R. C., Bhattacharya, S., and Wassenhove, L. N. V. (2004b). Closed-loop supply chain models with product remanufacturing. J.Management Sci. 50, 4451–4469. doi:10.1287/mnsc.1030.0186

Shan, L., and Dongyan, C. (2021). The recycling partner selection for manufacturer and coordination of closed-loop supply chain considering CSR investment. J.Journal Industrial Eng. Eng. Manag. 35, 163–175. doi:10.13587/j.cnki.jieem.2021.06.014

Shan, L., Feng-Min, Y., Dong-Yan, C., et al. (2022). Pricing and coordination stategies of closed-loop supply chain considering CSR behavior under recycling competition. J.Chinese J. Manag. Sci. 30, 205–217. doi:10.16381/j.cnki.issn1003-207x.2019.0584

Tong, S., Jianqian, Z., Shou, C., et al. (2021a). Pricing decision of CSR closed-loop supply chain considering retailer's sale effort. J.Business Rev. 33, 303–315. doi:10.14120/j.cnki.cn11-5057/f.2021.12.022

Tong, S., Jiaqian, Z., Shou, C., et al. (2021b). Pricing decision of CSR closed-loop supply chain considering retailer’s sales effort. J.MANAGEMENT Rev. 33, 303–315. doi:10.14120/j.cnki.cn11-5057/f.2021.12.022

Van Engeland, J., BeliëN, J., De Boeck, L., and De Jaeger, S. (2020). Literature review: strategic network optimization models in waste reverse supply chains. J. Omega 91, 102012–102022. doi:10.1016/j.omega.2018.12.001

Wang, N., He, Q., and Jiang, B. (2019a). Hybrid closed-loop supply chains with competition in recycling and product markets. J.International J. Prod. Econ. 217, 246–258. doi:10.1016/j.ijpe.2018.01.002

Wang, Z., Wang, M., and Liu, W. (2019b). To introduce competition or not to introduce competition: an analysis of corporate social responsibility investment collaboration in a two-echelon supply chain. J.Transportation Res. Part E 133, 101812–101818. doi:10.1016/j.tre.2019.11.006

Wenwei, G., Meng, X., Fan, D., et al. (2024). Dynamic decisions of dual-channel green supply chain considering power structures under manufacturer’s overconfidence J.Computer Integr. Manuf. Syst.: 1–17. doi:10.13196/j.cims.2023.0480

Xia, J., and Niu, W. (2021). Carbon-reducing contract design for a supply chain with environmental responsibility under asymmetric information. J. Omega 102, 102390. doi:10.1016/J.OMEGA.2020.102390

Xiao-Gang, C., Bo-Wei, C., and Hui, W. (2024). Closed-loop supply chain decision of hybrid recycling channels considering fairness concerns. J.Chinese J. Manag. Sci., 1–21. doi:10.16381/j.cnki.issn1003-207x.2023.0619

Xing-Hua, W., Xing-Zheng, A., and Si-Huan, L. (2023). A study on the decision models and the equilibriums comparing of the durable consumer products supply chain under different Channel Power structures. J.Journal of Central University of Finance and Economics, 116–128. doi:10.19681/j.cnki.jcufe.2023.08.010

Xinhui, W., Yingsheng, S., Hongmei, G., et al. (2021). Telling truth or lying:Bilateral information incentive and supply chain efficiency. J.Journal Industrial Eng. Eng. Manag. 35, 167–176. doi:10.13587/j.cnki.jieem.2021.02.015

Xinran, L., and Gang, L. (2020). Study on coordination mechanism of two-period closed-loop supply chain considering CSR exhibiting. J.Chinese J. Manag. Sci. 28, 77–86. doi:10.16381/j.cnki.issn1003-207x.2019.1235

Xiong-Wei, Z., Zhi-Long, S., and Yan-Ju, Z. (2020). False quality strategy of monopoly enterprises based on vertical product differentiation. J.Control Decis. 35, 2252–2260. doi:10.13195/j.kzyjc.2018.1656

Yang, L., Hu, Y., and Huang, L. (2020). Collecting mode selection in a remanufacturing supply chain under cap-and-trade regulation. J.European J. Operational Res. 287, 480–496. doi:10.1016/j.ejor.2020.04.006

Yan, Y., Yan-Pei, C., and Shou, C. (2019). Stimulatingcorporate social responsibility in supply chain in different dominated modes. J.Chinese J. Manag. Sci. 27, 144–156. doi:10.16381/j.cnki.issn1003-207x.2019.03.015

You-Guo, J., Jian, S., and Zhen, L. (2022). Information disclosure and contract selection under asymmetric information with strategic inventory. J.Chinese J. Manag. Sci. 30, 47–58. doi:10.16381/j.cnki.issn1003-207x.2019.1666

Yu-Hui, L., Bing-Shu, X., Fa-Ming, Z., et al. (2024). Incentive research on green supply chain with corporate social responsibility preference. J.Soft Sci. 38, 111–117. doi:10.13956/j.ss.1001-8409.2024.04.16

Zhang, S., Ding, J., and Ding, Q. (2023). Retailer-led low-carbon supply chain coordination considering sales effort. J. Sustain. 15, 10556. doi:10.3390/su151310556

Zheng, L., Lingling, L., Lingling, L., Zhao, Y., and Shi, L. (2021). Evolutionary game analysis on the recycling strategy of household medical device enterprises under government dynamic rewards and punishments. J.Mathematical Biosci. Eng. MBE 18, 6434–6451. doi:10.3934/MBE.2021320

Keywords: corporate social responsibility, channel power structures, misreporting behaviour, information asymmetry, revenue-sharing contract, two-part pricing contract

Citation: Huo H, Chen Y and Wu R (2024) Closed-loop supply chain decision making and coordination considering channel power structure and information symmetry. Front. Energy Res. 12:1411248. doi: 10.3389/fenrg.2024.1411248

Received: 02 April 2024; Accepted: 05 September 2024;

Published: 24 September 2024.

Edited by:

Slawomir Wycislak, Jagiellonian University, PolandReviewed by:

Aravind C. K., Vellore Institute of Technology (VIT), IndiaFengmin Yao, Harbin University of Science and Technology, China

Copyright © 2024 Huo, Chen and Wu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Rong Wu, d3Vyb25nX2pzdGNAMTYzLmNvbQ==

†These authors have contributed equally to this work

Hong Huo†

Hong Huo† Yuqiu Chen

Yuqiu Chen