- 1Department of Mechanical Engineering, Quaid -e- Awam University of Engineering, Science, and Technology, Nawabshah, Pakistan

- 2Electrical Engineering Department, School of Engineering, Al-Baha University, Al-Baha, Saudi Arabia

- 3Wolfson Centre for Magnetics, School of Engineering, Cardiff University, Cardiff, United Kingdom

Recent studies suggest that the world is facing an energy crisis due to the depletion of fossil fuel reserves. To combat this issue, researchers have turned to biodiesel, a renewable bioenergy source made from vegetable oils, microalgae, and animal fats. A recent study analysed engine parts’ particulate matter emissions and carbon deposition during the long-term use of mustard biodiesel and clove oil as antioxidants in a compression ignition engine. Three samples of fuels: DF (diesel fuel), B30 (30% mustard biodiesel and 70% DF), and biodiesel blended fuel with 3000 PPM in a single-cylinder CI engine. The use of 30% biodiesel in diesel fuel (B30) for the endurance test was based on a good mix. The engine was run for 100 h to investigate the particulate matter emissions and carbon deposition. The particulate matter emission data was collected every 25 h, and for carbon deposition, the engine’s fuel injector was turned off after 100 h of engine running. The results showed a reduction in particulate matter emissions of about 9.97%, 13.367%, 7.24%, 14.64%, 5.3%, 12.32%, 1.88%, and 7.99% for PM1, PM2.5, PM7, and PM10 in biodiesel blended fuel and biodiesel blended fuel with clove oil, respectively. The deposition of clove oil added to biodiesel blended fuel in the fuel injector has been reduced compared with the other fuels. Carbon deposition of the fuel injector was analysed through SEM and EDX tests, and the results showed that the carbon content in biodiesel blended fuel was lower than in diesel fuel. The deposition of clove oil added to biodiesel blended fuel in the fuel injector has been reduced compared with biodiesel blended fuel.

1 Introduction

As a result of increased metropolitan expansion and industrialisation, global energy consumption is constantly growing. Currently, finite fossil fuels such as crude oil, natural gas, and coal are regarded as the primary energy sources. Petroleum prices have been highly volatile because of the heavy reliance on petroleum derivatives in energy generation and transportation (Sadaf et al., 2018; Kurowska et al., 2020). Both environmental and energy degradation are considered severe issues that may be alleviated using alternative green and sustainable energy sources. Bioenergy, wind, and solar energy are the primary renewable resources that might help reduce reliance on fossil fuels (Kurowska et al., 2020; Yaqoob et al., 2021). Because of the crucial need to lessen dependency on fossil fuels, technical improvements in the biofuel industry as an alternative to petroleum diesel has accelerated (Yaqoob et al., 2021). Biodiesel is mainly made from edible oils such as olive, sunflower, rapeseed, and palm oil. So far, the most significant impediment to the commercialisation of biodiesel production has been the high cost of feedstock (Poudel et al., 2017; Xie et al., 2020). WCO (waste cooking oil) has been proposed as a workable fuel for biodiesel generation. WCO application in biodiesel production offers various advantages, including lower biodiesel feedstock costs and less waste disposal (Aboelazayem et al., 2018; Hsiao et al., 2021). Diesel engines are a significant contributor to air pollution. Diesel engines, on the other hand, are appealing power units extensively employed in many industries due to substantial benefits over gasoline engines, such as reduced fuel consumption, fewer carbon monoxide emissions, greater torque characteristics, and improved durability (Ali et al., 2014; Ong et al., 2014; Yasin et al., 2014). Because of these features, diesel engines account for a significant share of the overall petroleum usage. Diesel engines, on the other hand, are the primary contributors to air pollution for many pollutants, particularly particulates and nitrogen oxides, due to their lean-burning nature and elevated temperatures and pressures in the combustion process (NOx). Thus, one of the most essential parts of current air quality management is the control of these emissions. According to research, diesel engines powered by palm oil can reduce emissions of smoke, particulate matter, hydrocarbons, sulphur oxide, and carbon monoxide (Kumar and Chauhan, 2013). As a result, several scientists and policymakers have collaborated to address challenges from different viewpoints. The epidemiological and toxicological effects of airborne contaminants were investigated. Diesel cars contribute significantly to the problem of particle air pollution, particularly in emerging Asian cities (Jin et al., 2014). Corn, starch, sugarcane, and other crops produce ethanol. Because ethanol has a high latent heat of vaporisation, it can reduce the intake in charge temperature inside the cylinder and greatly enhance volumetric efficiency (Sathiyamoorthi and Sankaranarayanan, 2017). Ethanol can be injected directly into the cylinder or blended with other fuels (Lei et al., 2012). At lower loads, one research found that a more significant proportion of ethanol with diesel reduced brake thermal efficiency (BTE) relative to diesel, but a lower ratio of ethanol with diesel boosted BTE (Kurre et al., 2015). This can be attributable to proper combustion diffusion. Over the whole load range, lower quantities of ethanol with Rice Bran Biodiesel (RBD) were evaluated (Venkata Subbaiah and Raja Gopal, 2011; Khan et al., 2019; Khan et al., 2020; Khan et al., 2021; Ullah et al., 2021; Raziq et al., 2022). Lean combustion and a lengthy ignition delay let ethanol blends burn more fuel in the premixed combustion zone, increasing BTE for all blends. Another research looked at the mixture of biodiesel with ethanol and methanol (Venu et al., 2020). Adding methanol to biodiesel resulted in greater brake-specific fuel consumption (BSFC) than adding ethanol to biodiesel. BSFC rose as the concentrations of both alcohols increased. In a similar study, coconut biodiesel with less ethanol was tested (Yilmaz, 2012). B20E5 has a 2.0%–2.7% increase in fuel consumption. Compared to diesel, additives such as n-butanol and diethyl ether have lower BSFC and greater BTE (How et al., 2014; Imtenan et al., 2014). The antioxidant ingredient BHA is more stable than BHT in mixed biodiesel (Roy et al., 2014). It has been found that adding antioxidants to biodiesel lowers CO and HC emissions while increasing NOx emissions (Xingcai et al., 2004; Tan et al., 2017). Blends of waste cooking oil and bioethanol from liquefied sago starch (LSS) reduced CO2 emissions by 57% (Aydın and Öğüt, 2017). With ethanol emulsions in various amounts, NOx emissions rose at lower and higher engine speeds (Labeckas et al., 2014). While running faster, CO emissions from ethanol and biodiesel emulsions decreased dramatically (Fattah et al., 2014).

The literature review reflects that significant studies have been conducted to investigate compression ignition engine emissions using different fuels. However, minimal studies have been reported in the literature to investigate compression ignition engine parameters using clove oil. In addition, the analysis is made on a short-term basis. Moreover, carbon deposition was also not reported. Therefore, investigation of carbon deposition during the endurance test of C. I use biodiesel and clove oil as additives to better explore the engine’s life.

2 Materials and method

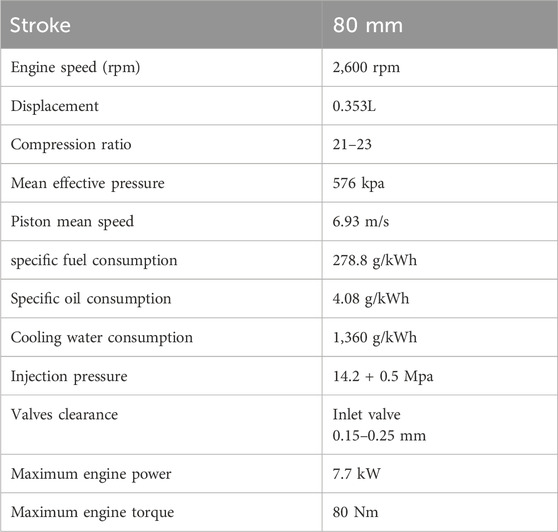

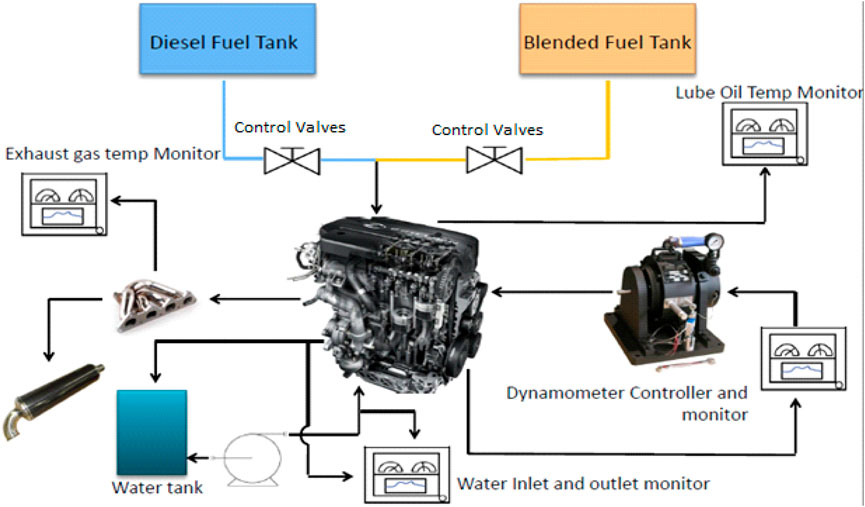

The objective of this study was to investigate the particulate matter (PM) emissions and carbon deposition in a four-stroke cylinder speed diesel engine when fueled with different blends of biodiesel and clove oil. The analysis was conducted under varying load conditions to assess the impact of fuel composition on engine performance and emissions the experimental setup shown in Table 1; Figure 1.

2.1 Particulate matter emissions

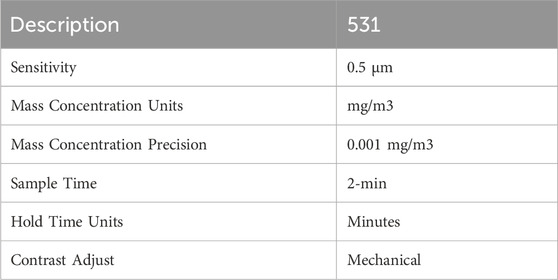

During a long-term analysis, PM (particulate matter) emissions from diesel engines were collected while running diesel, biodiesel, biodiesel, and clove oil blended fuels. The engine runs for 100 h. After completing 25 h, each date was collected from the engine. The particulate matter emission from the engine depends on speed, loads and fuel properties. This work analyses four particle sizes (PM 1.0, PM2.5, PM7.0 and PM10) using Diesel fuel and biodiesel blended with clove oil under the same speed and load conditions. The Aerocet 531S is a small, handheld, battery-powered, and completely portable unit that measures particle counts or mass PM in the form of stored data, logged values, real-time networked data, or printed results, specifications of the measuring device shown in Table 2.

2.1.1 Six mass ranges and four sizes

Six significant mass size ranges (PM1, PM2.5, PM7, PM10 and TSP) are displayed in mass mode and four popular (microns) in count mode. These six mass ranges results were obtained at the location, four feet from the source. The tests were made upon all the blends and various loads and found according to the specifications as desired.

2.2 Engine endurance test

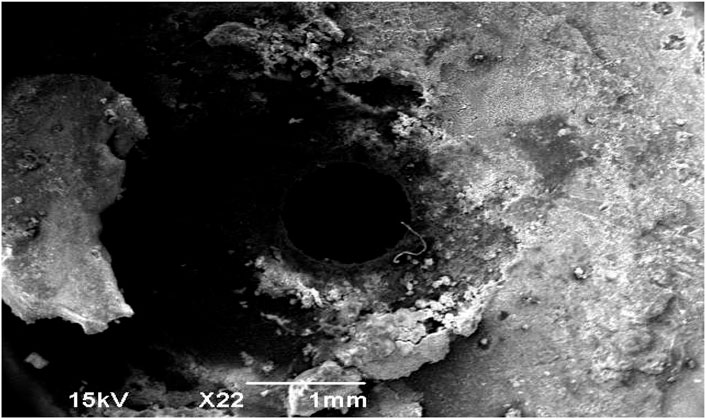

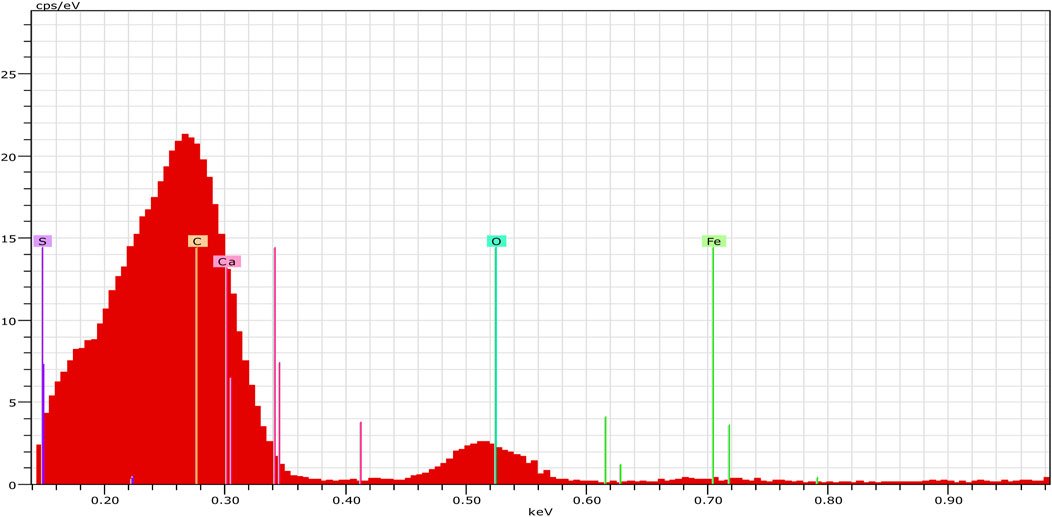

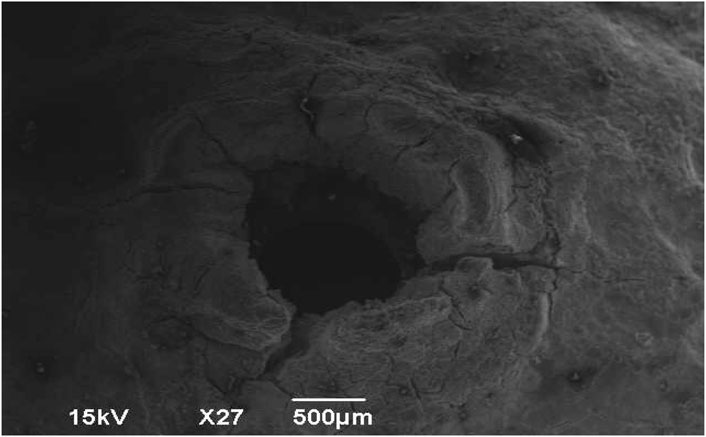

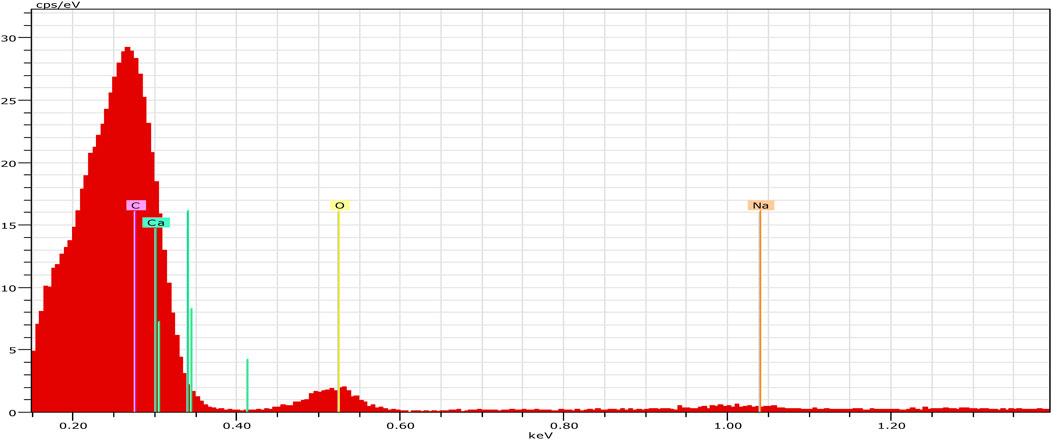

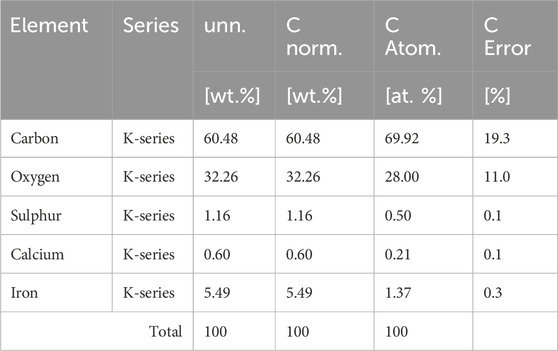

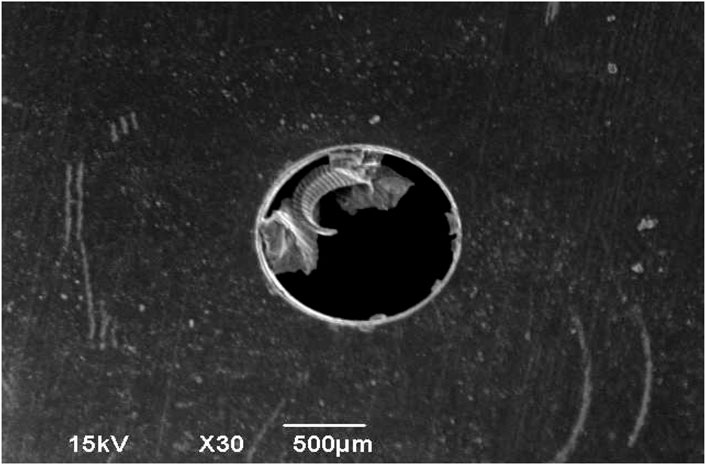

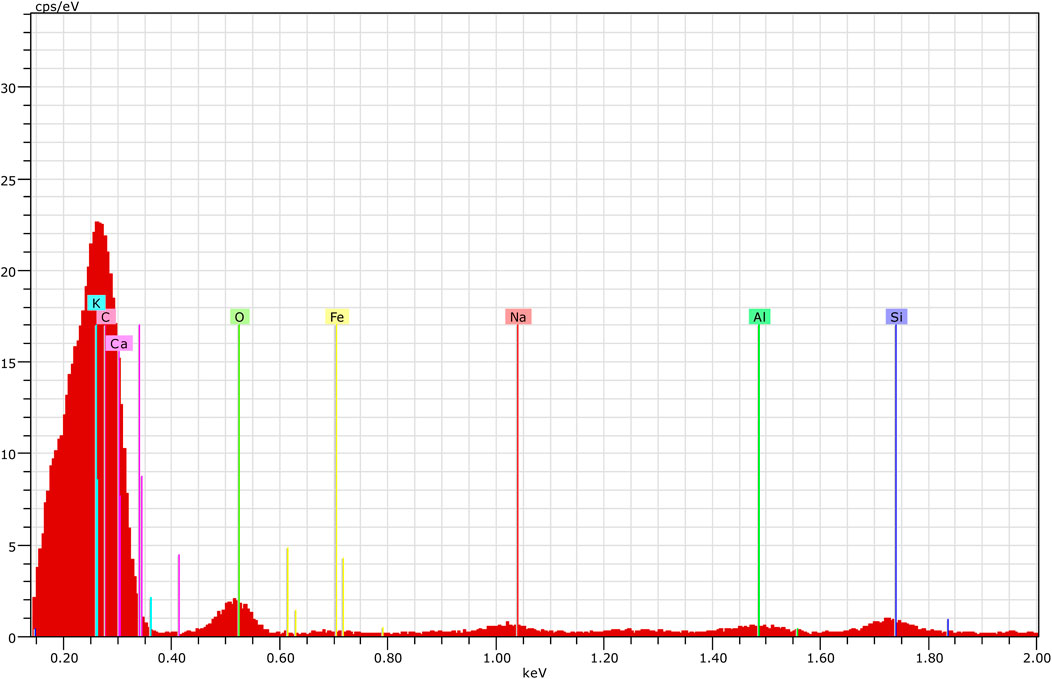

In this study, an endurance test was performed for 100 h at 1,500 rpm with a constant load. Three samples of fuels: DF (diesel fuel), B30 (30% mustard biodiesel and 70% DF), and biodiesel blended fuel with 3000 PPM in a single-cylinder CI engine. The use of 30% biodiesel in diesel fuel (B30) for the endurance test was based on a good mix. The engine was started on diesel fuel for 15 min daily and ran for 8 h during the test. The engine was shut down for the day after fuelling was switched back to diesel fuel for 15 min to purge the fuel pump and high-pressure fuel lines of biodiesel mixtures. To investigate the impact of using DF and biodiesel blends during the endurance test, a visual inspection of the injector nozzle was performed by photographing it. Deposit formations at and around the injector tip at various locations were examined using scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDS), as shown in Figure 2. To investigate the effects of Df, biodiesel blends, and biodiesel blended with clove oil on the engine. Moreover, during the endurance test, engine fuel economy and particulate matter emissions were investigated for all three fuel samples. The scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS) analysis, and equipment used for SEM-EDS analysis are shown in Figure 2. After partly dismantled and injector deposit formation studies were conducted by SEM-EDS analysis, a 100-h endurance test on DF, B30, and clove oil (3000 PPM), respectively.

3 Results and discussions

Particulate matter is a broad phrase that refers to a diverse array of air pollutants that vary in size and structure. Particulate matter is classified into coarse particles (more than 2.5 mm) and tiny particles (less than 2.5 mm). Soot is a small particulate matter (Kurien et al., 2018) Soot and soluble organic components comprise engine exhaust particulate matter (Bermúdez et al., 2015). Soot particles develop in the cylinder with high fuel and a low oxygen concentration, and soot absorbs soluble organic fractions on its surface (Serrano et al., 2016; Kurien et al., 2018). Several phases Fuel pyrolysis produces precursors or the fundamental building blocks for soot by changing the molecular structure of organic molecules in fuel at high temperatures in the presence of low oxygen concentrations (Mohankumar and Senthilkumar, 2017). The fuel’s carbon and hydrogen content also influences the soot formation rate, i.e., a higher carbon content in fuel leads to a higher soot formation rate and vice versa. (Trubetskaya et al., 2018). Adding biodiesel and clove oil could reduce particulate matter emissions from the engine (Rusli et al., 2022). This research aimed to see how different fuelling alternatives, such as pure diesel, biodiesel mixed, and biodiesel blended with clove oil, affected particle matter emissions significantly in standard diesel engines with little or no modification. Figure 1, PM1.0 displays the findings of average percentages of particulate matter emission as D100 (39.46%), B30 (29.97%), and B30+CL (26.093%), showing that PM1.0 is greater in diesel fuel than in biodiesel mixed with clove oil. Figure 2 depicts PM2.5 outcomes such as (40.62%), (33.38%), and (25.98%) respectively, lower values in biodiesel and antioxidants. Figure 3 PM7 results (39.20%), (33.90%), and (26.88%) and Figure 4 PM10 results of average percentages of particulate matter emission such as (36.66%), (34.78), and (28.67%) D100, B300, and B30 +CL, respectively, from the results show that particulate matter emission level of PM1, PM2.5, PM7, and PM10 higher in diesel fuel to compare with Furthermore, added clove oil to biodiesel as an antioxidant improves the oxidative stability of the biodiesel. Compared to mixed biodiesel diesel, when antioxidants are added to biodiesel blends, the percentage of particulate matter emissions is lowered.

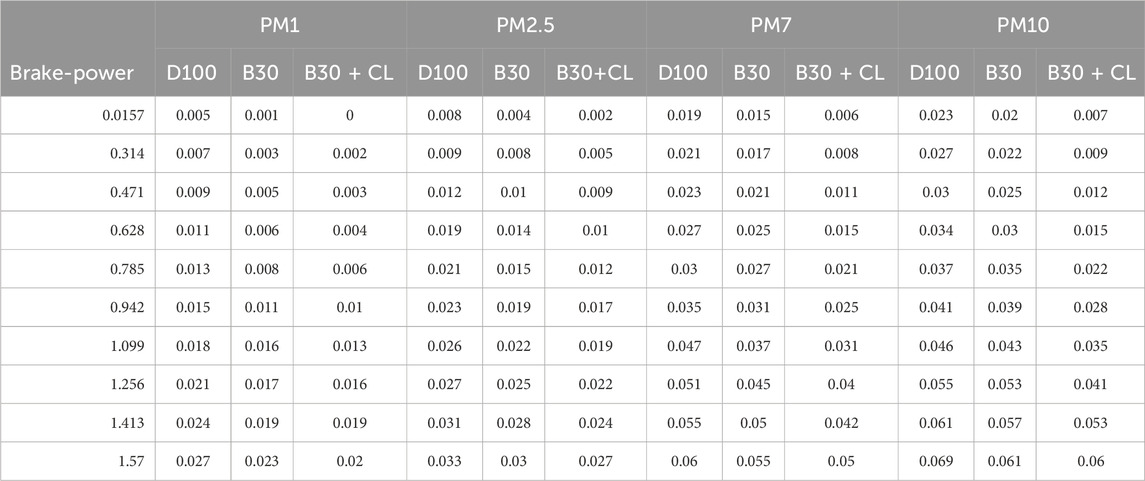

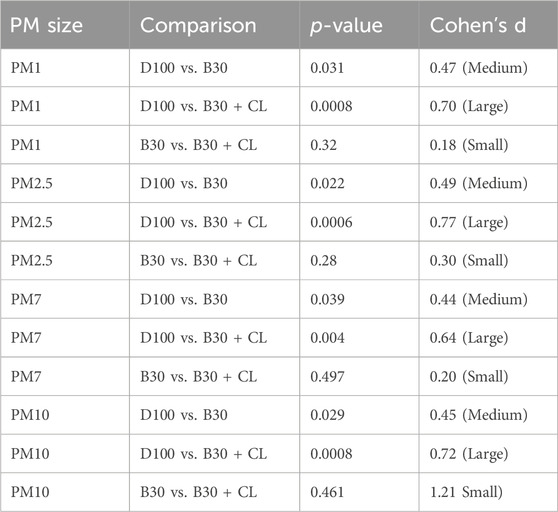

Table 3 shows the particulate emissions from compression ignition engine using biodiesel and clove oil as a blended fuel, when operated for 25 and 50 h.

3.1 Particulate matter emission

3.1.1 When engine run for 25 h

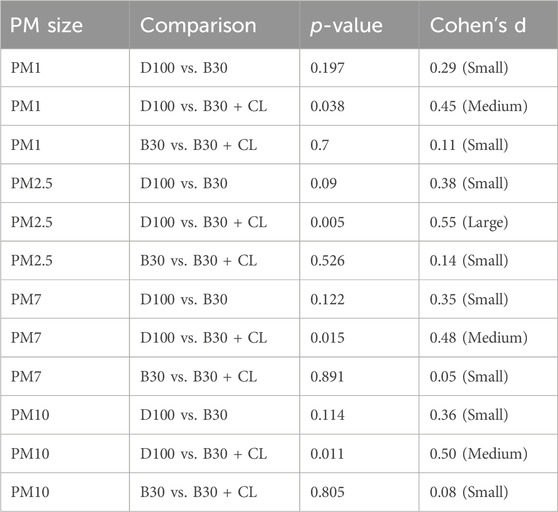

PM emissions data for different particle sizes were collected from an experiment involving different fuels (D100, B30, and B30+CL), when engine run for 25 and 50 h, respectively, under controlled conditions. For each PM size, paired t-tests were conducted to compare the PM emissions between different fuel pairs. Paired t-tests are appropriate when you have repeated measurements on the same subjects under different conditions, as is the case with different fuels in the same engine. Calculation of p-values and Cohen’s d: The p-values and Cohen’s d effect sizes were calculated from the results of the t-tests. The Tables 3, 4 show the key findings from the t-tests, highlighting statistically significant differences and effect sizes for each PM size and fuel comparison.

Across all particle sizes analysed (PM1, PM2.5, PM7, and PM10), both B30 and B30+CL significantly reduced emissions compared to D100. However, the degree of reduction varied based on particle size, with smaller particles experiencing greater benefits: B30+CL demonstrated the most significant reduction across all sizes, with large effect sizes for PM1, PM2.5, and PM10. This suggests the cerium-based catalyst in B30+CL effectively targets various PM emissions. The reduction effect decreased slightly as particle size increased, with PM7 showing a lower effect size compared to PM1 and PM2.5. This might indicate limitations in the catalyst’s efficacy for larger particles. B30 alone also significantly reduced emissions for all sizes, except for PM7 where the difference compared to D100 wasn’t statistically significant. This suggests B30’s inherent properties contribute to reducing PM, but B30+CL offers an additional advantage, particularly for smaller particles. No statistically significant difference was observed between B30 and B30+CL for any size, implying the primary benefit of B30+CL lies in its enhanced reduction of smaller PM.

This analysis suggests that both B30 and B30+CL are promising fuels for mitigating PM pollution, with B30+CL offering a clear advantage for reducing finer, potentially more harmful PM1 and PM2.5 particles. Further research with larger datasets and potentially investigating emission mechanisms could provide even deeper insights into the effectiveness of these fuels across different particle sizes.

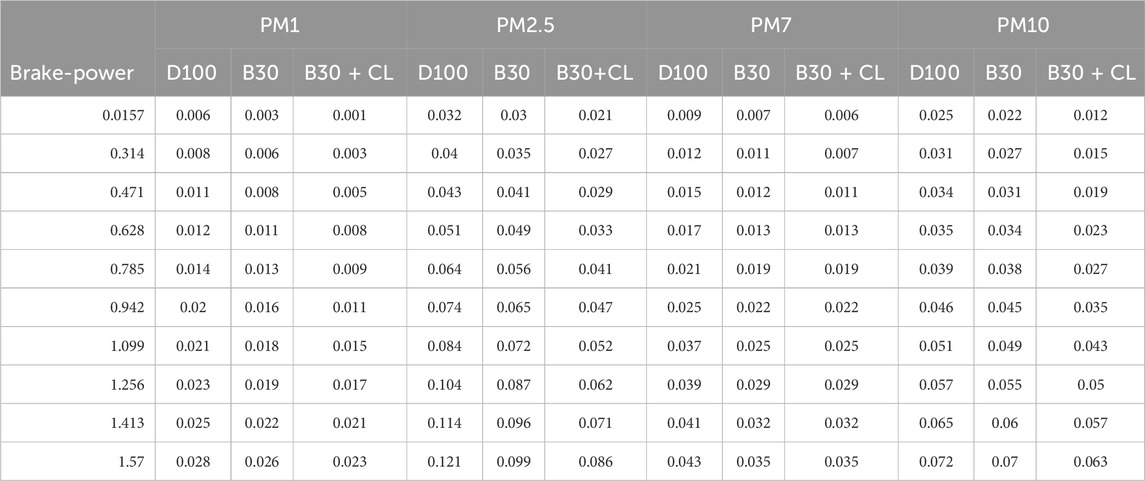

3.1.2 When engine run for 50 h

Across all particle sizes analysed (PM1, PM2.5, PM7, and PM10) after 50 h of engine operation, both B30 and B30+CL significantly reduced emissions compared to D100, but the degree of reduction varied based on particle size.

B30 + CL demonstrated the most significant reduction across all sizes, with large effect sizes for PM1, PM2.5, and PM10. This suggests the cerium-based catalyst in B30 + CL effectively targets various PM emissions, even after engine wear and tear. The reduction effect decreased slightly as particle size increased, with PM7 showing a lower effect size compared to PM1 and PM2.5. This might indicate limitations in the catalyst’s efficacy for larger particles, possibly due to their different physical properties and formation mechanisms. B30 alone also significantly reduced emissions for all sizes, except for PM7 where the difference compared to D100 wasn't statistically significant. This suggests B30’s inherent biodiesel properties contribute to reducing PM, but B30 + CL offers an additional advantage, particularly for smaller particles. No statistically significant difference was observed between B30 and B30 + CL for any size, implying the primary benefit of B30 + CL lies in its enhanced reduction of finer, potentially more harmful PM1 and PM2.5 particles, these are shown in Tables 5, 6.

This analysis suggests that both B30 and B30 + CL are promising fuels for mitigating PM pollution after engine run-in, with B30 + CL offering a clear advantage for reducing finer PM1 and PM2.5 particles. Further research with larger datasets and potentially investigating emission mechanisms could provide deeper insights into the long-term effectiveness of these fuels across different particle sizes and engine operating conditions.

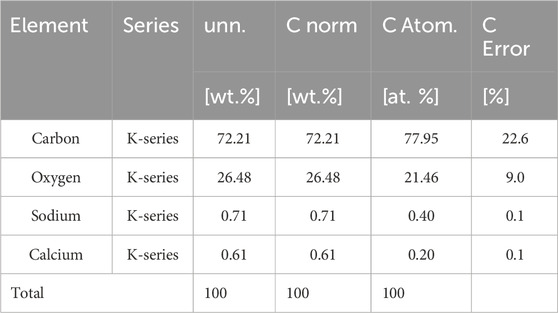

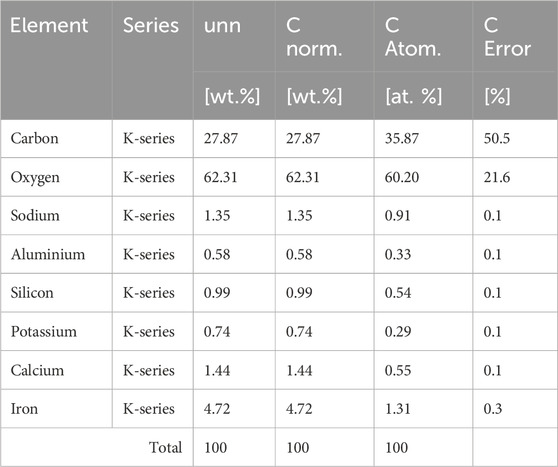

3.2 Analysis of carbon deposition of injector of engine

The engine was partly disassembled after completing the long-term 100-h endurance test on DF, B30, and clove oil (3000 PPM) blends, and the deposit formation on each injector tip was studied. Advanced diesel injector systems are characterised by a higher tip in the injector tip that can lead to stubborn deposits around the injector tip (Kumar and Chauhan, 2013). Figures 5, 6 shows the SEM of deposition on injector tips fuelled with Df, B30, and clove oil (3000 PPM), respectively. Deposition rates with diesel fuel are substantially lower than those with B30 blended fuel. Furthermore, deposition is reduced when clove oil is blended with biodiesel-blend fuel compared to diesel and biodiesel-blend fuel. The results of D100 (60.48%), B30 (72.21%), and clove oil 3000 PPM (27.38%) show that. The B30 has higher carbon deposition than diesel. When clove oil is added to biodiesel blended fuel, the results show that it reduces carbon deposition during compression ignition of the engine and some other elements discovered during the EdX test. Carbon deposits are typically formed at higher temperatures via two distinct routes of hydrocarbon to the elements carbon and hydrogen which can be illustrated from Tables 7–9.

4 Conclusion

• Particulate Matter Emissions: Were highest with pure diesel fuel (D100), reduced with biodiesel blended fuel (B30), and lowest with the addition of clove oil to the biodiesel blend.

• Carbon Deposition: Was moderate with diesel fuel, higher with biodiesel blended fuel, and significantly reduced when clove oil was added to the biodiesel blend.

The addition of clove oil at 3000 PPM to biodiesel blends offers a promising approach to improving combustion efficiency, reducing particulate emissions, and minimizing carbon deposition in compression ignition engines. These findings highlight the potential environmental and operational benefits of using clove oil as an additive in biodiesel fuels shown in (Figures 7, 8).

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

SB: Conceptualization, Writing–original draft, Writing–review and editing. ML: Methodology, Writing–original draft, Writing–review and editing. GW: Formal Analysis, Writing–original draft, Writing–review and editing. TA: Formal Analysis, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

C.I, Compression ignition; PM, Particulate matter; PPM, Part per millions; B30, 30% biodiesel; Cl. O, Clove oil; EDX, Energy Dispersive X-ray Spectroscopy; SEM, Scanning Electron Microscopy.

References

Aboelazayem, O., El-Gendy, N. S., Abdel-Rehim, A. A., Ashour, F., and Sadek, M. A. (2018) Biodiesel production from castor oil in Egypt: process optimisation, kinetic study, diesel engine performance and exhaust emissions analysis. Energy 157, 843–852. doi:10.1016/j.energy.2018.05.202

Ali, O. M., Yusaf, T., Mamat, R., Abdullah, N., and Abdullah, A. (2014). Influence of chemical blends on palm oil methyl esters’ cold flow properties and fuel characteristics. Energies (Basel). 7 (7), 4364–4380. doi:10.3390/en7074364

Aydın, F., and Öğüt, H. (2017) Effects of using ethanol-biodiesel-diesel fuel in single cylinder diesel engine to engine performance and emissions. Renewable Energy, 103, 688–694. doi:10.1016/j.renene.2016.10.083

Bermúdez, V., Serrano, J. R., Piqueras, P., and García-Afonso, O. (2015) Pre-DPF water injection technique for pressure drop control in loaded wall-flow diesel particulate filters. Applied Energy, 140, 234–245. doi:10.1016/j.apenergy.2014.12.003

Fattah, I. R., Masjuki, H., Kalam, M., Mofijur, M., and Abedin, M. (2014). Effect of antioxidant on the performance and emission characteristics of a diesel engine fueled with palm biodiesel blends. Energy Convers. Manag. 79, 265–272. doi:10.1016/j.enconman.2013.12.024

How, H., Masjuki, H., Kalam, M., and Teoh, Y. (2014). Engine performance, emission and combustion characteristics of a common-rail diesel engine fuelled with bioethanol as a fuel additive in coconut oil biodiesel blends. Energy Procedia 61, 1655–1659. doi:10.1016/j.egypro.2014.12.185

Hsiao, M.-C., Liao, P. H., Lan, N. V., and Hou, S. S. (2021). Enhancement of biodiesel production from high-acid-value waste cooking oil via a microwave reactor using a homogeneous alkaline catalyst. Energies (Basel). 14 (2), 437. doi:10.3390/en14020437

Imtenan, S., Masjuki, H. H., Varman, M., Arbab, M. I., Sajjad, H., Rizwanul Fattah, I. M., et al. (2014) Emission and performance improvement analysis of biodiesel-diesel blends with additives. Procedia Engineering, 90, 472–477. doi:10.1016/j.proeng.2014.11.759

Jin, T., Qu, L., Liu, S., Gao, J., Wang, J., Wang, F., et al. (2014) Chemical characteristics of particulate matter emitted from a heavy duty diesel engine and correlation among inorganic and PAH components. Fuel, 116, 655–661. doi:10.1016/j.fuel.2013.08.074

Khan, K., Tao, X., Shi, M., Zeng, B., Feng, Z., Li, C., et al. (2020). Visible-light-driven photocatalytic hydrogen production on Cd0.5Zn0.5S nanorods with an apparent quantum efficiency exceeding 80%. Adv. Funct. Mater. 30 (42), 2003731. doi:10.1002/adfm.202003731

Khan, K., Tao, X., Zhao, Y., Zeng, B., Shi, M., Ta, N., et al. (2019). Spatial separation of dual-cocatalysts on one-dimensional semiconductors for photocatalytic hydrogen production. J. Mater. Chem. A 7 (26), 15607–15614. doi:10.1039/c9ta03090e

Khan, K., Xu, L., Shi, M., Qu, J., Tao, X., Feng, Z., et al. (2021). Surface assembly of cobalt species for simultaneous acceleration of interfacial charge separation and catalytic reactions on Cd0. 9Zn0. 1S photocatalyst. Chin. J. Catal. 42 (6), 1004–1012. doi:10.1016/s1872-2067(20)63717-2

Kumar, N., and Chauhan, S. R. (2013). Performance and emission characteristics of biodiesel from different origins: a review. Renew. Sustain. Energy Rev. 21, 633–658. doi:10.1016/j.rser.2013.01.006

Kurien, C., and Srivastava, A. K. (2018). Advancement in the design of automotive catalytic filter for meeting environmental emission norms. Nature Environment and Pollution Technology 17 (2), 433–438.

Kurowska, K., Marks-Bielska, R., Bielski, S., Kryszk, H., and Jasinskas, A. (2020). Food security in the context of liquid biofuels production. Energies (Basel). 13 (23), 6247. doi:10.3390/en13236247

Kurre, S. K., Pandey, S., Garg, R., and Saxena, M. (2015). Experimental study of the performance and emission of diesel engine fueled with blends of diesel–ethanol as an alternative fuel. Exp. study Perform. Emiss. diesel engine fueled blends diesel–ethanol as Altern. fuel 6 (3-4), 209–216. doi:10.1080/17597269.2015.1078561

Labeckas, G., Slavinskas, S., and Mažeika, M. (2014). The effect of ethanol–diesel–biodiesel blends on combustion, performance and emissions of a direct injection diesel engine. Energy Convers. Manag. 79, 698–720. doi:10.1016/j.enconman.2013.12.064

Lei, J., Shen, L., Bi, Y., and Chen, H. (2012) A novel emulsifier for ethanol–diesel blends and its effect on performance and emissions of diesel engine. Fuel, 93, 305–311. doi:10.1016/j.fuel.2011.06.031

Mohankumar, S., and Senthilkumar, P. (2017) Particulate matter formation and its control methodologies for diesel engine: a comprehensive review. Renewable and Sustainable Energy Reviews, 80, 1227–1238. doi:10.1016/j.rser.2017.05.133

Ong, H. C., Masjuki, H., Mahlia, T., Silitonga, A., Chong, W., and Yusaf, T. (2014) Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy Reports. 69, 427–445.doi:10.1016/j.energy.2014.03.035

Poudel, J., Karki, S., Sanjel, N., Shah, M., and Oh, S. (2017). Comparison of biodiesel obtained from virgin cooking oil and waste cooking oil using supercritical and catalytic transesterification. Energies (Basel). 10 (4), 546. doi:10.3390/en10040546

Raziq, F., Khan, K., Ali, S., Ali, S., Xu, H., Ali, I., et al. (2022). Accelerating CO2 reduction on novel double perovskite oxide with sulfur, carbon incorporation: synergistic electronic and chemical engineering. Chem. Eng. J. 446, 137161. doi:10.1016/j.cej.2022.137161

Roy, M. M., Wang, W., and Alawi, M. (2014). Performance and emissions of a diesel engine fueled by biodiesel–diesel, biodiesel–diesel-additive and kerosene–biodiesel blends. Energy Convers. Manag. 84, 164–173. doi:10.1016/j.enconman.2014.04.033

Rusli, M. S., Septyan, M. A., and Farobie, O. (2022). Effect of bio-additive derived from essential oils on particulate matter and water content of B30 (30% of biodiesel blended fuel). IOP conference series: earth and environmental science 1034(1), 012057. doi:10.1088/1755-1315/1034/1/012057

Sadaf, S., Iqbal, J., Ullah, I., Bhatti, H. N., Nouren, S., Rehman, H., et al. (2018) Biodiesel production from waste cooking oil: an efficient technique to convert waste into biodiesel. Sustain. Cities Soc., 41, 220–226. doi:10.1016/j.scs.2018.05.037

Sathiyamoorthi, R., and Sankaranarayanan, G. (2017) The effects of using ethanol as additive on the combustion and emissions of a direct injection diesel engine fuelled with neat lemongrass oil-diesel fuel blend. Renewable Energy, 101, 747–756. doi:10.1016/j.renene.2016.09.044

Serrano, J. R., Climent, H., and Angiolini, E. (2016) Filtration modelling in wall-flow particulate filters of low soot penetration thickness. Energy, 112, 883–898. doi:10.1016/j.energy.2016.06.121

Tan, Y. H., Abdullah, M. O., Hipolito, C. N., Zauzi, N. S. A., and Abdullah, G. W. (2017) Engine performance and emissions characteristics of a diesel engine fueled with diesel-biodiesel-bioethanol emulsions. Energy Conversion and Management, 132, 54–64.

Trubetskaya, A., Brown, A., Tompsett, G. H., Timko, M. T., Kling, J., Broström, M., et al. (2018) Characterization and reactivity of soot from fast pyrolysis of lignocellulosic compounds and monolignols. Applied Energy, 212, 1489–1500. doi:10.1016/j.apenergy.2017.12.068

Ullah, K., Khan, K., and Ullah, A. (2021). Synthesis and structural characterization of energy crop peelu methyl esters, using hybrid metallic nano-particles. A step forward to bioenergy industry. Fuel 300, 119241. doi:10.1016/j.fuel.2020.119241

Venkata Subbaiah, G., and Raja Gopal, K. (2011). An experimental investigation on the performance and emission characteristics of a diesel engine fuelled with rice bran biodiesel and ethanol blends. Int. J. Green Energy 8 (2), 197–208. doi:10.1080/15435075.2010.548539

Venu, H., Raju, V. D., Subramani, L., and Appavu, P. (2020). Experimental assessment on the regulated and unregulated emissions of DI diesel engine fuelled with Chlorella emersonii methyl ester (CEME). Exp. Assess. Regul. unregulated Emiss. DI diesel engine fuelled Chlorella emersonii methyl ester (CEME) 151, 88–102. doi:10.1016/j.renene.2019.11.010

Xie, W., Gao, C., and Wang, H. (2020). Biodiesel production from low-quality oils using heterogeneous cesium salts of vanadium-substituted polyoxometalate acid catalyst. Catalysts 10 (9), 1060. doi:10.3390/catal10091060

Xingcai, L., Zhen, H., Wugao, Z., and Degang, L. (2004). The influence of ethanol additives on the performance and combustion characteristics of diesel engines. Combust. Sci. Technol. 176 (8), 1309–1329. doi:10.1080/00102200490457510

Yaqoob, H., Teoh, Y. H., Sher, F., Farooq, M. U., Jamil, M. A., Kausar, Z., et al. (2021). Potential of waste cooking oil biodiesel as renewable fuel in combustion engines: a review. Energies (Basel). 14 (9), 2565. doi:10.3390/en14092565

Yasin, M. M., Yusaf, T., Mamat, R., and Fitri Yusop, A. (2014). Characterization of a diesel engine operating with a small proportion of methanol as a fuel additive in biodiesel blend. Appl. Energy 114, 865–873. doi:10.1016/j.apenergy.2013.06.012

Keywords: biodiesel, clove oil, compression ignition engine, PM and carbon depositions, biodiese

Citation: Bhangwar S, Luhur MR, Walasai GD and Alghamdi TAH (2024) Impact of mustard biodiesel and clove oil additives on particulate matter emission and carbon deposition in diesel engines. Front. Energy Res. 12:1395545. doi: 10.3389/fenrg.2024.1395545

Received: 04 March 2024; Accepted: 28 June 2024;

Published: 29 July 2024.

Edited by:

Kifayat Ullah, COMSATS University, Islamabad Campus, PakistanReviewed by:

Rehana Masood, Shaheed Benazir Bhutto Women University, PakistanManoj Kumar Jena, RMIT University, Australia

Khakemin Khan, University of Trento, Italy

Copyright © 2024 Bhangwar, Luhur, Walasai and Alghamdi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sajjad Bhangwar, c2FqamFkYmhhbmd3YXJAcXVlc3QuZWR1LnBr; Thamer A. H. Alghamdi, YWxnaGFtZGl0MUBjYXJkaWZmLmFjLnVr

Sajjad Bhangwar

Sajjad Bhangwar Muhammad Ramzan Luhur1

Muhammad Ramzan Luhur1 Thamer A. H. Alghamdi

Thamer A. H. Alghamdi