- School of Economics and Management, Yantai University, Yantai, China

Several countries and regions have adopted recycling subsidy policies to encourage recycling activities and enacted recycling laws to improve the recycling rate of waste electrical and electronic equipment (WEEE). These initiatives are designed to reduce the damage to the environment and natural resource consumption caused the enterprise. In this study, we analyze how government recycling regulations, value co-creation activities, and recycling subsidies influence the pricing and output decisions of members of a closed-loop supply chain. We develop a Stackelberg game model led by manufacturers and followed by retailers to explore the impact of value co-creation activities and recycling subsidies on the quantity of new and remanufactured products, recyclers’ prices and prices of recycled electronic parts, manufacturers’ capacity to recycle, and environmental performance in the context of government recycling regulations. Manufacturers can choose from three recycling modes: mandatory minimum remanufacturing (

1 Introduction

Waste electrical and electronic equipment (WEEE), commonly referred to as “e-waste,” is one of the fastest-growing sources of waste worldwide (Bernardes et al., 2023). The annual growth rate of its waste can reach 3%–5%, and the amount of e-waste is expected to reach 75 million tons by 2030 (Shittu et al., 2021). WEEE contains several valuable resources and materials, yet only about 20% of the total e-waste is recycled (Balla et al., 2022). According to statistics, Since 2000, recycling of municipal waste in the EU has increased by 84%, while the amount of waste sent to landfill has fallen by more than 50%. EU member states generated about 230 million tons of municipal waste in 2021, of which about 50% was recovered for recycling. Asian countries, by contrast, recycle less WEEE than EU. According to the data simulation, Shanghai’s total waste output will continue to rise between 2025 and 2050. By 2050, the city’s waste production will reach 16 million tons. However, Recycling rates in Shanghai are well below 50% (Chu et al., 2023). What’s even more noteworthy, harmful chemicals in WEEE can seriously affect the ecological environment and human health (Batoo et al., 2022). The seriously negative impact makes the recycling of WEEE become an urgent need. (Tang et al., 2022). In the context of cleaner production, Circular Economy is an important way to achieve a sustainable society. Nowadays, Circular Economy (CE) is emphasized as a solution for achieving the balance of economy and environment (Hosseini Dehshiri and Amiri, 2024). The remanufacturing industry is one of the components of the circular economy. Due to the high residual value of WEEE, there are huge economic and environmental benefits to recycle WEEE. Recycling WEEE can save about 80% of resources compared to manufacturing new products, which shows that remanufacturing offers greater cost advantages (Boone et al., 2012). Also as a part of the circular economy, the waste electrical and electronic equipment recycling industry can effectively promote low-carbon economy and sustainable development (Aranda-Usón et al., 2020). The remanufacturing industry has broad prospects for development, and when products are recycled, resources retain value through reuse, so the remanufacturing industry has become an important driving force for the implementation of circular economy (Agrawal et al., 2023). In 2017, Beijing actively responded to the extended producer responsibility initiative by adopting energy-saving supermarkets as a recycling pilot project and relying on the GSI coding technology to develop a two-dimensional code logo, and introduced a traceability system (“one device, one code”) to effectively manage the recycling of WEEE. In 2018, Amazon announced an investment in closed-loop infrastructure funds in the United States and the United Kingdom, with plans to collect 1 million tons of recyclable resources by 2028. The investment aims to effectively promote green consumption and green recycling to solve problems such as resource scarcity and pollution. Recycling of waste and the construction of a circular economy are regarded by many scholars as key factors for sustainable development (Liu et al., 2023).

Value co-creation has become an important measure to achieve green and low-carbon sustainability. The traditional concept of value co-creation considers enterprises as the sole subject of value creation (Vargo and Lusch, 2004). With the emergence of Internet technology, the modern theory of value co-creation suggests that value creation is accomplished by all stakeholders in the supply chain (e.g., manufacturers, recyclers, consumers, and non-profit organizations) (Vargo and Lusch, 2008). In the recycling sector, most recyclers have started to include consumers in the value co-creation process, tying the interests of recyclers and consumers to each other and promoting sustainable and deep cooperation up and down the supply chain, which has proven to be beneficial to value co-creation (Lacoste, 2016). Value co-creation brings relative fairness to supply chain members, and relative fairness is indeed beneficial to the decision-making of supply chain members and their cooperation in sustainable supply chain management (Zheng et al., 2019; Liu et al., 2021). Ongoing cooperation among all participants in the supply chain facilitates the development of value co-creation activities and the implementation of extended manufacturer responsibility programs (Jacobs and Subramanian, 2012). However, the formation of a sustainable economy does not depend only on value co-creation activities, but also on government regulation of recycling. The WEEE Directive was developed and adopted by EU member states in 2002 and was transposed into national law by 2014. In 2012, the Japanese Senate announced the implementation of the Scrap Small Appliances Recycling Law (SHARL). In 2013, the EU announced the implementation of the Ship Recycling Regulation (SRR) (Esenduran et al., 2016; Solakivi et al., 2021). These recycling regulations are designed to guide the economy toward a sustainable transition. However, the process of recycling WEEE is not always smooth and its associated operations are hampered by available funding; therefore, the government needs to facilitate the development of the recycling industry through subsidies. In 2011, the State Council of China passed the Regulations on the Recycling of WEEE, which provide subsidies for each WEEE dismantled by recyclers. There are still many countries in the world that lack management experience, investment funds, incentives and subsidies, and mandatory laws and regulations in the field of recycling (Abdulrahman et al., 2014). The promotion of sustainable development and the establishment of a circular economy require precise design, implementation planning, and measures. However, there is a lack of research on the factors that impact the closed-loop supply chain in the complex environment of government recycling regulations, recycling subsidies, and value co-creation behavior at the recycling stage. The interaction of multiple factors such as recycling constraints, recycling subsidy policies, and value co-creation activities increases the decision-making complexity of participants in closed-loop supply chains. For example, new products and remanufactured products compete for market share. Additionally, the remanufacturing industry is influenced by complex internal and external factors, such as the adequacy of recyclable resources and the level of value co-creation, which may positively or negatively affect remanufacturing, thus making it difficult for manufacturers and recyclers to make pricing and output decisions. Therefore, this study first investigates the impact of value co-creation and recycling subsidies on optimal output and pricing decisions of manufacturers and recyclers under government recycling regulations. The necessity of improving the mandatory legal framework and the importance of stakeholder responsibility are emphasized.

Optimizing the recycling capacity of manufacturers and promoting value co-creation activities at the recycling stage has the ultimate goal of promoting sustainable development, achieving a circular economy, and reducing environmental damage. Therefore, the most important innovations and contributions of this study are:

• Evaluating the output decision under complex scenarios of value co-creation, government regulation, and government subsidies.

• Evaluating three schemes of recycling capacity under the complex scenario of value co-creation, government regulation and government subsidy to obtain the sustainability of closed-loop supply chain.

• The value co-creation of consumers in the recycling phase is considered and the Closed-loop supply chain is involved to the model.

• Providing some solutions based on results for manager and government.

To achieve the above research objectives, three questions need to be addressed: 1) What are the optimal output and pricing decisions of manufacturers and recyclers, and what are the profits considering value co-creation behavior and recycling subsidy policies under government recycling regulations? 2) How do recycling subsidies affect manufacturers’ ability to recycle and the profits of supply chain participants? 3) How does the strength of government recycling regulations, environmental taxes, and recycling subsidies affect environmental performance?

To address the above research questions, a Stackelberg game model consisting of a manufacturer and a recycler is constructed in this study. The results of the analysis reveal several main findings. First, the manufacturer can choose from three recycling models: mandatory minimum remanufacturing (

The rest of the paper is organized as follows: Section 2 presents a review of the relevant literature. Section 3 introduces the modeling framework and develops the Stackelberg game model led by the manufacturer and followed by the recycler. Section 4 identifies the optimal output and pricing decisions of manufacturers and recyclers under different recycling capacities, the thresholds of the recycling capacity stage modes, and the impact of environmental taxes on environmental performance under more stringent recycling constraints. Section 5 analyzes the main results of the study using numerical examples. Finally, the results of this study are summarized and the conclusions and future research outlook are presented in Section 6.

2 Literature review

2.1 Government regulations

The improvement of government regulations has led many enterprises to take on more social and environmental issues, which deserve in-depth attention in the Closed-Loop supply chain (CLCS) (Dehshiri et al., 2023; Mirzaei et al., 2023). Several scholars have focused on closed-loop supply chains under different government regulations. For example, Xu et al. (Xu et al., 2021) used the Stackelberg game model to study the recycling channel choice of applying eco-design under government environmental regulation. Qu et al. (Qu et al., 2022) developed a dual-recycling channel supply chain decision model with “Internet + Recycling” and investigated the effects of consumer preferences, recycling efforts, and government regulations on the closed-loop supply chain participants. Wang et al. (Wang et al., 2019) investigated the recycling of used products under different regulatory scenarios based on the classical game theory, taking government regulation and social reputation into account in the Stackelberg game model. Tan and Guo (Tan and Guo, 2019) explored the impact of different regulatory environments on the logistics system in a closed-loop supply chain by considering the uncertainty of the quality of recycled products. In addition, some scholars have also studied closed-loop supply chains in terms of carbon trading and carbon quota regulation. For example, Chen et al. (Chen et al., 2018) considered government carbon regulation and recycling regulation in a game model and analyzed the impact of regulatory constraints on environmental performance. Sun et al. considered retailers and prefabricated building manufacturers (PBM) into a closed-loop supply chain game model and analyzed the optimal decision of manufacturers under carbon trading policy and low carbon emission reduction subsidy (CER) (Sun et al., 2023). Lyu et al. (Lyu et al., 2022) used game theory to consider manufacturers’ strategies for emission reduction and recycling, and studied the impact of different government regulations on the recycling decisions of manufacturers. At present, most countries in the world have formulated corresponding policies according to Extended Producer Responsibility (EPR) regulations, which provides a reference for government recycling regulation. Based on EPR regulations, Cao et al. (Cao et al., 2023) consider the impact of trade-in policy on manufacturers’ optimal strategy. Jiang et al. (Jiang et al., 2023) explored a multi-responsibility system in which the government regulates members of the closed-loop supply chain (producers, retailers, consumers, and recyclers) to achieve a shared responsibility for recycling, and have further explored the impacts of different responsibility ratios on the equilibrium outcomes of the supply chain members as well as on the welfare of the society. Mathew, G et al. made up for the gap in the study of used lithium-ion batteries (LIB) by means of a national online survey, and found that the harm of LIB could be mitigated through government-mandated laws and regulations (Mathew et al., 2023). However, few scholars have analyzed decision-making in closed-loop supply chains from the perspective of governmental recycling constraints.

2.2 Value co-creation

The “service-led logic,” a new form of value co-creation which is consumer-oriented and involves the joint participation of supply chain members in the value co-creation process, is more suitable for value production in modern society (Sugathan et al., 2017). Zhang et al. (Zhang et al., 2022a) introduced the concept of value co-creation rate and developed and optimized a quality risk control model for the new retail supply chain. Li et al. (Li et al., 2020) established three different types of value co-creation mechanisms based on game theory and studied the investment and profit-sharing strategies of closed-loop supply chain members. Zhang and Meng, and Zhang et al. (Zhang and Meng, 2021; Zhang et al., 2022b) investigated the effects of equity crowdfunding and cross-shareholding on value co-creation among external members (investors) and internal members (manufacturers, retailers, remanufacturers, and consumers) of the supply chain based on multilevel planning and Stackelberg game models. Some scholars have also analyzed the impact of value co-creation on supply chains from an empirical perspective. Ren et al. (Ren et al., 2015) studied the processes and operational mechanisms of value co-creation in the supply chain based on a sample of 110 manufacturers and consumers. From the perspective of marketing and tourism, Yang et al. (Yang et al., 2023) emphasized the importance of value co-creation in maintaining cultural facilities through regression and structural equation methods. Value co-creation is not only reflected in real products, but also in the virtual world. Tater, M et al. analyzed a game called “Mission BioHero,” which builds a platform that enables players to participate in bioeconomy. Not only are players entertained, but the ideas they interact with can be used to shape bioeconomic policy. Research shows that player participation design plays an important role in the production of game value (Tatar et al., 2023). However, few existing studies have considered the value co-creation behavior at the recycling stage, which is worth further research.

2.3 Recycling subsidy

Several scholars have studied the impact of recycling subsidies on effectively promoting the remanufacturing industry and sustainable development. Zhang et al. (Zhang et al., 2021) developed four types of single-channel game models based on the classical game theory considering government subsidies and recycling promotion, and explored the impact of different game strategies on the recycling of waste products. Tan et al. (Tan et al., 2023) developed a game model for the supply chain of building materials based on construction waste recycling, and explored the impact of different subsidy agents on the decision-making of supply chain members. Yu et al. (Yu et al., 2021) constructed a Stackelberg game model led by manufacturers and followed by recyclers to analyze the impact of four heterogeneous subsidy schemes on recycling efficiency. Wang et al. (Wang et al., 2023) developed an evolutionary game model for recyclers and consumers with and without government subsidies to study the decisions of recyclers and consumers under different scenarios. The impact of the recycling subsidy policy has also been analyzed from a system dynamics perspective. Wang et al. (Wang et al., 2022) analyzed the impact of recycling subsidies and tax policies on the recycling industry of used cell phones in China based on a system dynamics model. Li et al. (Li et al., 2019) used the system dynamics approach to model the recycling of used electric vehicle batteries and explored the impact of different recycling subsidy policies on the economic efficiency of recycling. However, few scholars have studied the impact of recycling subsidies on the recycling capacity of manufacturers, which will be investigated in depth in this study.

2.4 Research gap

On the basis of a comprehensive review of existing literature, many scholars have conducted in-depth research on government recycling regulations and value co-creation, which provides some references for this paper. But there are still some gaps. First of all, most of the existing studies on value co-creation are based on empirical analysis. How to analyze the impact mechanism of value co-creation on closed-loop supply chain from the perspective of model needs to be studied. Secondly, most studies on government remanufacturing subsidies and government recycling regulations are analyzed from a single perspective, and the impact of government regulation policies on closed-loop supply chain is not analyzed from the perspective of complex regulatory environment. Third, the existing participation methods of value co-creation are mainly based on consumers’ feedback on products and enterprises’ improvement of products, and the value co-creation methods in the recovery stage have not been deeply studied by scholars. The study of this paper fills the gap mentioned above.

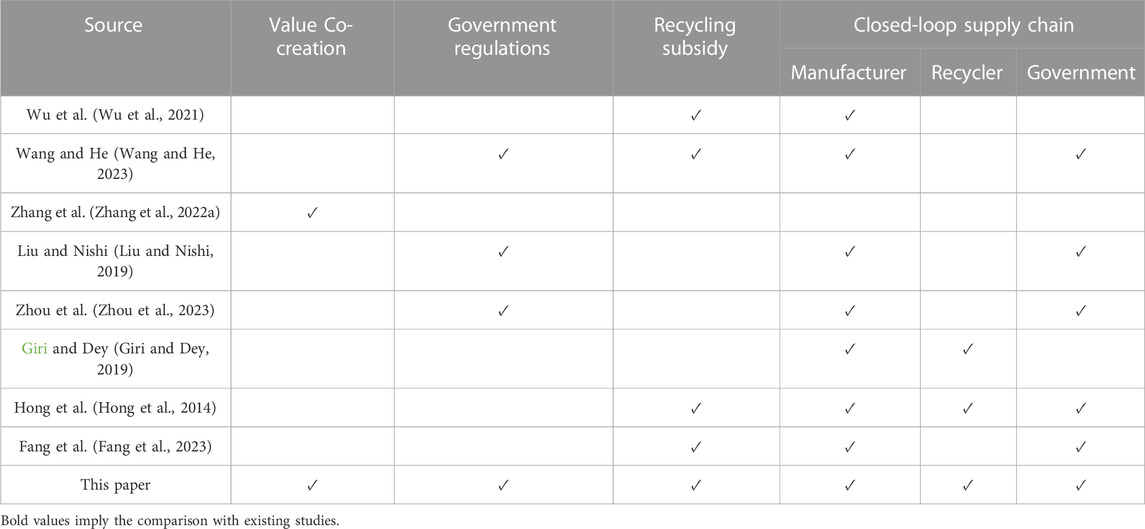

In order to highlight the differences between this paper and other literature, Table 1 lists some representative articles, which are compared and analyzed.

3 Model description

How to characterize the extent of producer recycling capacity? We develop a two-level closed-loop supply chain game model consisting of a manufacturer and a recycler. The model takes into account value co-creation activities and recycling subsidies under government recycling regulations. The recycler first recycles the WEEE in the market, and the value co-creation activity is represented by the participation of the recycler and the consumer in the recycling stage, and then the recycler dismantles the WEEE after the recycling activity. For every unit of WEEE recycled by the recycler, the government will give the recycler a recycling subsidy of

In this model, manufacturers can choose from three recycling modes: 1) mandatory minimum remanufacturing (

(1) The new product and the remanufactured product are homogeneous, and consumers have the same acceptance of the new product and the remanufactured product.

(2) The market demand function is

(3) The recycling quantity of WEEE is a linear function of the recycling price and value co-creation level of WEEE, i.e.,

(4) The recycler invests in value creation activities, which involve both the recycler and the consumer. For example, the recycler establishes a recycling service platform, broadens recycling channels, and designs a standardized recycling process. Consumers respond positively to recycling activities, participating in product recovery, feedback, and service to create value. The value co-creation investment cost of the recycler is a quadratic function, similar to Swami etc., (Swami and Shah, 2013),

(5) The sales price and production cost of new products are

(6) The quantity recycled by manufacturers satisfies the inequality constraint

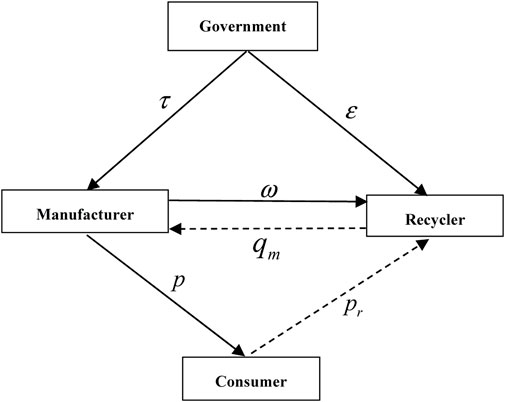

Additionally, Figure 1 shows the structure diagram for this article.

4 Closed-loop supply chain optimal decision analysis

The Stackelberg game model is based on the assumption that the manufacturer is the leader and the recycler is the follower, with both the manufacturer and the recycler aiming to maximize their own interests. In this case, the manufacturer first determines the sales price

According to the assumption, the manufacturer’s profit function is as follows:

The profit function of the recycler is as follows:

4.1 Optimal decision when the Manufacturer’s recycling capacity is

Proposition 1. Optimal decision-making in closed-loop supply chains when the manufacturer’s recycling capacity is

The proof is given in Supplementary Appendix SA.

4.2 Optimal decision when the Manufacturer’s recycling capacity is

Proposition 2. Optimal decision-making in closed-loop supply chains when the manufacturer’s recycling capacity is

The proof is given in Supplementary Appendix SA.

Proposition 3. There exists a threshold

According to Proposition 3, the recycling capacity of manufacturers is affected by government recycling subsidies. When

The proof is given in Supplementary Appendix SD.

Proposition 4. Optimal retail prices, value co-creation levels, and WEEE recycling prices under different recycling capacities satisfy the following relations:

Proposition 4 suggests that the level of value co-creation by the recycler is optimal when the manufacturer’s recycling capacity is at the stage

The proof is given in Supplementary Appendix SB.

Proposition 5. Optimal remanufacturing output for different recycling capacities satisfies the relation

Proposition 5 suggests that as manufacturers’ recycling capacity increases, it will increase the willingness of manufacturers to produce remanufactured products, and since new and remanufactured products are functionally similar, the increased production of remanufactured products will take market share away from the new products. Proposition 4 suggests that when the manufacturer’s recycling capacity is at the

Proposition 6. The boundary condition for manufacturers to enter the remanufacturing industry satisfies the relation

Proposition 6 suggests that manufacturers will choose to enter the remanufacturing market only when the parameters satisfy the equation

The proof is given in Supplementary Appendix SC.

4.3 Optimal decision when the Manufacturer’s recycling capacity is

Proposition 7. Optimal decision-making in closed-loop supply chains when the manufacturer’s recycling capacity is

The proof is given in Supplementary Appendix SA.

Proposition 8. There exists a threshold

According to Proposition 8, when government recycling subsidies reach the threshold

The proof is given in Supplementary Appendix SD.

Proposition 9. A threshold

Proposition 9 suggests that when the recycling rate

The proof is given in Supplementary Appendix SE.

Proposition 10. If

Proposition 10 suggests that the profit of the recycler does not always increase with the increase in the recycling subsidy. When

The proof is given in Supplementary Appendix SF.

Proposition 11. If

Proposition 11 suggests that carbon emissions are not always reduced by an increase in environmental taxes and fees. When

The proof is given in Supplementary Appendix SF.

5 Numerical analysis

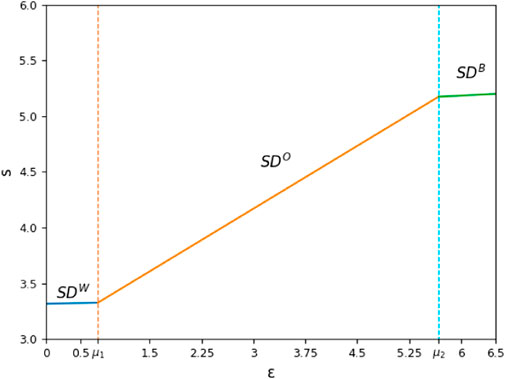

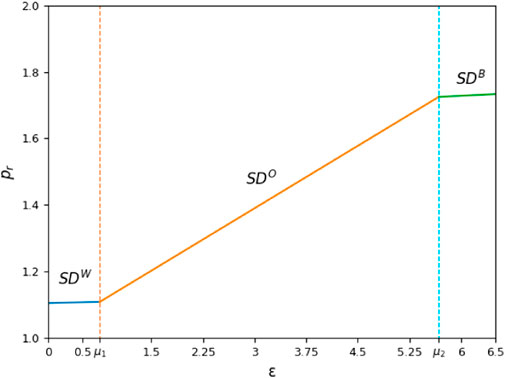

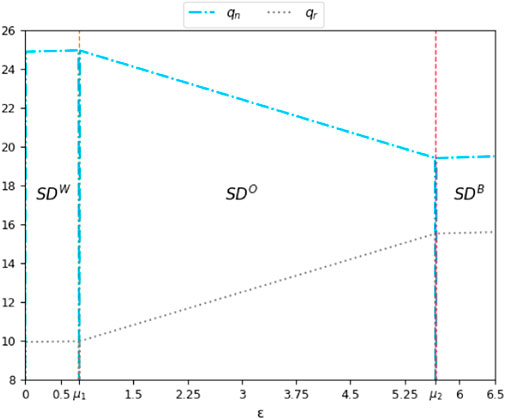

To visualize the differences in demand, value co-creation levels, and purchase prices of dismantled electronic parts for different recycling capacities, the following numerical calculations are performed.

Take

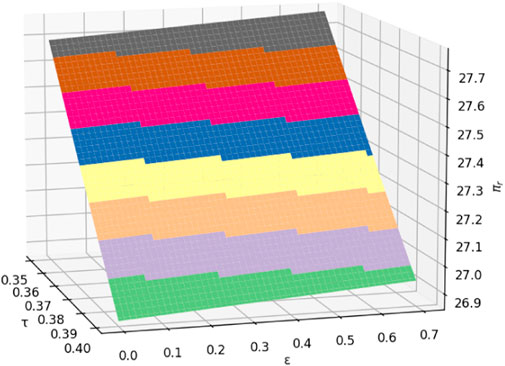

As shown in Figure 2, when the government increases the recycling subsidy, the level of value co-creation increases accordingly. Figure 3 shows that consumers are able to obtain more benefits from value co-creation activities and therefore actively participate in such activities, which increases the level of value co-creation.

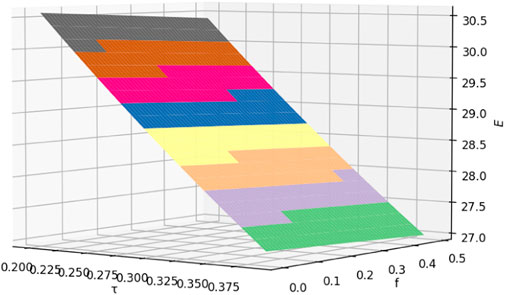

As shown in Figure 4, when the recycling subsidy is increased, the recycler actively reduces the price of recycled electronic parts which increases the purchasing capacity of the manufacturer. The reduction in the price of recycled electronic parts does not harm the profitability of the recycler; on the contrary, the combination of low price and high sales volume is more profitable for the recycler.

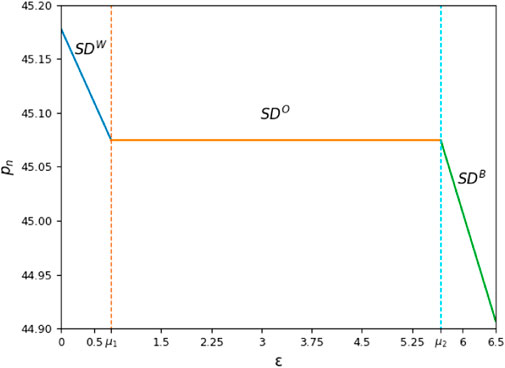

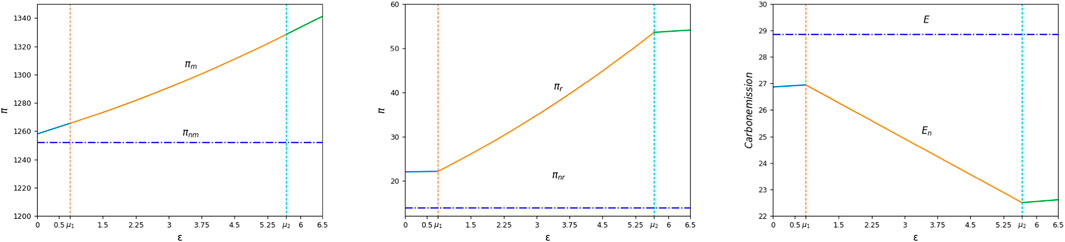

As can be seen from Figure 5, when recycling subsidies are increased to promote the recycling capacity of manufacturers, it promotes the sustainable development of the remanufacturing industry. Manufacturers become less motivated to produce new products and consumers become more willing to pay for remanufactured products, which eats into the market share of new products. The manufacturer is forced to reduce the price of the new product to ensure that the new product is sold at an optimal profit. As shown in Figure 6, the price of the new product decreases as the manufacturer’s recycling capacity increases.

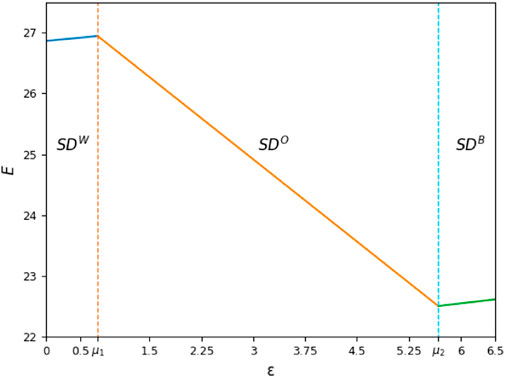

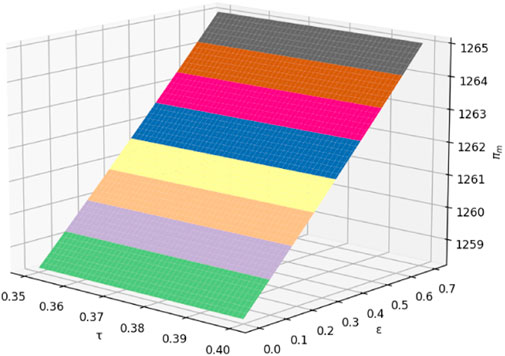

Figures 7, 8 reflect the changes in profits and carbon emissions of the members in the Stackelberg game model, respectively. Higher recycling subsidies benefit both recyclers and manufacturers. Figure 8 shows that higher recycling subsidies do not always reduce the environmental damage caused by production activities, and only when the government regulates recycling subsidies can carbon emissions be effectively reduced.

FIGURE 7. Impact of recycling subsidies on the profitability of parties in the closed-loop supply chain.

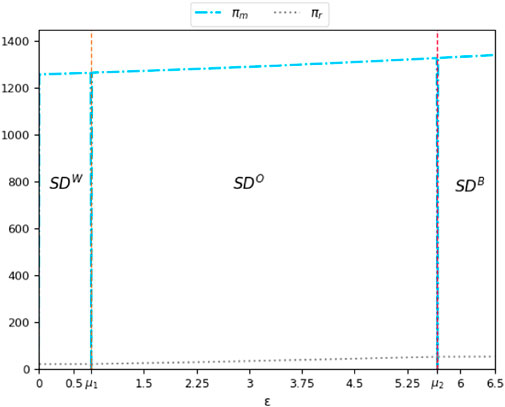

From Figures 9, 10, it can be seen that the profits of both manufacturers and recyclers tend to increase when the recycling constraints are weakened, and the increase in recycling subsidies is beneficial for the profits of both manufacturers and recyclers.

Figure 11 shows that carbon emissions can be reduced when the government imposes appropriate environmental taxes and fees or increases the minimum recycling rate constraint for manufacturers. A suitable combination of environmental taxes and minimum recycling rate constraints can effectively reduce carbon emissions from production activities. Figures 8, 11 together indicate that a reasonable layout of government policies remains an important means of reducing carbon emissions from production activities.

6 Discussion and implications

6.1 Compared with existing research

In this study, we considered Value Co-creation and Government policy applied to Closed-Loop Supply Chain. This is the difference from other existing literature. We use

As shown in Figure 12. By comparison, when the Value Co-creation and Government policy are applied to the Closed-Loop Supply chain, we found both manufacturers and recyclers have increased their profits while the manufacturer produces less carbon mission. The results of the numerical comparison show that this approach is positive.

6.2 Managerial and operational insights

This study provides some theoretical implication in the fields of green recycling and remanufacturing. Government regulations, recycling subsidy, and value co-creation were considered for Closed-Loop Supply Chain. WEEE harms the environment. The government, recycler, and consumer are vital in the CE network. In this regard, research in this paper provide insights for policymakers and managers. On the other hand, this paper analyzes all the possible recycling capacities. Business managers can utilize the outcomes of this research to make optimal decision. In this study, business managers, considering different scenarios of recycle capacity, can make decisions in the conditions relation to changes in the government subsidy, increase in production, changes in the difficulty of value co-creation, and stricter regulations.

This study proposes three remanufacturing schemes based on circular capabilities, which derive results through Stackelberg game theory while considering the closed-loop supply chain and all its members. Compared with previous studies, the decision-making results obtained in this paper are more in line with social reality. Since the method is the result of scientific calculation, it is more credible. In fact, achieving sustainable development requires the efforts of all parties. Without facilitating government regulations, environmental awareness of consumers, and active participation of all CLSC members, it is not possible to implement the sustainable development. Therefore, it’s essential to improve the legal system and promote cooperation among the participant. For managers and policymakers, a favourable business policy is necessity. However, the government can’t be unconditional support for the recycling industry and the manufacturing industry. Due to unconditional support, it is easy for the enterprise managers seek the interests of the government, which may lead to serious debts for government. The adverse effects will greatly affect the lives of citizens, such as inflation and financial crisis. Therefore, the results of this study also warn of the seriousness of this problem. On the other hand, This study also explores the impact of environmental tax on environmental performance. We find these policies are not necessarily more effective when they are more stringent. Governments should enhance consumer’s awareness of value co-creation and environmental protection through the media, in addition, appropriate regulations and incentive policies should be formulated to promote the development of CE. Managers and policymakers can utilize the findings of this study to face the development of CE, especially in countries with numerous challenges in the field of remanufacturing.

7 Conclusion and future research

Although the recycling industry has a long history, it is still in a low development stage today due to various factors. The goal of developing recycling industry is to exert the residual value of discarded products and reduce the waste of resources and the deterioration of the environment. A developed recycling industry can effectively achieve sustainable development. Therefore, more and more countries set up recycling legislation to improve recycling rates to achieve desired environmental and economic performance. However, the impact of complex regulations on closed-loop supply chains is not clear. In this paper, by analyzing a Stackelberg game model in which the manufacturer leads and the recycler follows. The results of the study show how environmental regulation and value co-creation affect the decisions of manufacturers. The main findings of this paper are as follows:

1. There are three recycling models: mandatory minimum remanufacturing (

2. The increase in government recycling subsidies will optimize the recycling capacity of manufacturers, which will lead to an increase in the number of remanufactured products, reducing the market share of new products, and the price of new products will suffer from the competition from remanufactured products. The results also show that it is not realistic to increase recycling rates only through high government subsidies, which will put huge financial pressure on the government. A more effective approach is to focus on increasing consumers’ awareness of value co-creation.

3. Higher recycling subsidies reduce the price of recycled electronic parts purchased by manufacturers, increase the bargaining power of consumers, increase the price of recyclers, promote the active participation of consumers in value co-creation activities, and increase the level of value co-creation.

4. Higher recycling subsidies help to increase the economic value of all parties in the closed-loop supply chain (manufacturers, recyclers, consumers). Stricter recycling constraints are not always beneficial to environmental performance. More stringent recycling regulation leads to a rise in total products (include new products and remanufactured products), which may have more serious environmental impacts. The results also show that recycling constraints above a certain threshold of environmental taxes can reduce the negative environmental impact of production activities.

The above findings can provide insights for government recycling regulation and for managers facing a more complex business environment. Policymakers should carefully analyze potential environmental impacts when designing policies.

For governments, recycling laws and recycling subsidy incentives can have a significant impact on the decision-making plans of manufacturers and recyclers. However, the subsidy mechanism of the government is affected by its financial situation, so it is not feasible to carry out high subsidies. Then, the environmental awareness of consumers is particularly important. The government can conduct publicity through the media to increase the willingness of consumers to participate in value co-creation, and finally achieve the policy goal.

For managers, the complexity of decision-making is increased by government regulations, and they must have the ability to make scientific and efficient management decisions based on the strength of recycling subsidies and recycling laws. In addition, producers and consumers communicate with each other through products. Producers and consumers communicate directly with each other through products, and there is no intermediate link between them. The goal of consumers is to obtain better products, and producers must meet the needs of consumers in time in order to obtain profits. They all have a common goal - better products, which is a natural advantage. Therefore, they can jointly create an organic ecosystem, in which participants divide labor and cooperate to create value together. This interdependent relationship can promote the healthy development of the ecosystem, and each member can share the value they create. In this case, managers should take the initiative to maintain the relationship with consumers and create higher value chain efficiency. This study provides some implications for managers to make practical decisions.

This study also has some shortcomings. First, there are many types of recovery subsidies, but this study only discusses cost subsidies and does not consider other scenarios. Secondly, this study only considers the value co-creation behavior in the recovery stage, and does not pay attention to the application of value co-creation in other aspects. Finally, random demand is more relevant to the actual situation of society, rather than just considering deterministic demand. In future studies, the author will focus on the following aspects: 1) There are two types of recycling subsidies: trade-in subsidies and cost subsidies. The influence of trade-in subsidies on the optimal decision-making of closed-loop supply chain will be discussed in the future’s study. 2) Focus on the application of other perspectives of value co-creation, such as participation in product design and green investment. 3) This study only considers the case of definite demand, and random demand is also worthy of further study. Author will refine these aspects in subsequent studies.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

BL: Writing–review and editing. YSh: Writing–original draft. YSu: Writing–review and editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This work was supported by Shandong Social Science Planning Project of China (Grant No. 21CJJJ32).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenrg.2023.1308800/full#supplementary-material

References

Abdulrahman, M. D., Gunasekaran, A., and Subramanian, N. (2014). Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Prod. Econ. 147, 460–471. doi:10.1016/j.ijpe.2012.08.003

Agrawal, R., Yadav, V. S., Majumdar, A., Kumar, A., Luthra, S., and Garza-Reyes, J. A. (2023). Opportunities for disruptive digital technologies to ensure circularity in supply Chain: a critical review of drivers, barriers and challenges. Comput. Ind. Eng., 178.

Aranda-Usón, A., Portillo-Tarragona, P., Scarpellini, S., and Llena-Macarulla, F. (2020). The progressive adoption of a circular economy by businesses for cleaner production: an approach from a regional study in Spain. J. Clean. Prod., 247.

Balla, P., Ginjupalli, S. R., Pothu, R., Boddula, R., and Perugopu, V. (2022). Book review: applications of ion exchange materials in chemical andFood industries. Curr. Anal. Chem. 18, (8), 926–929. doi:10.2174/1573411018666220428095001

Batoo, K. M., Pandiaraj, S., Muthuramamoorthy, M., Raslan, E. H., and Krishnamoorthy, S. (2022). Behavior-based swarm model using fuzzy controller for route planning and E-waste collection. Environ. Sci. Pollut. R. 29, (14), 19940–19954. doi:10.1007/s11356-021-12824-x

Bernardes, M., Moraes, F. T. F., Tanaka, K. H., and Lima, R. D. (2023). Engaging the end user in waste from electrical and electronic equipment management: an action research study. Syst. Pract. Act. Res., doi:10.1007/s11213-023-09646-y

Boone, T., Jayaraman, V., and Ganeshan, R. (2012). Sustainable supply chains: models, methods, and public policy implications. New York, NY, USA: Springer.

Cao, J., Gong, X., Lu, J. W., and Bian, Z. L. (2023). Optimal manufacturer recycling strategy under EPR regulations. Processes, 11.1

Chen, Y. Y., Li, B. Y., Bai, Q. G., and Liu, Z. (2018). Decision-making and environmental implications under cap-and-trade and take-back regulations. Int. J. Env. Res. Pub He 15, 678. doi:10.3390/ijerph150406784

Chu, Z., Li, Q., Zhou, A., Zhang, W., and Wang, J. (2023). Strategy formulation path towards zero-waste of municipal solid waste: a case study from Shanghai. J. Clean. Prod. 418, 138091. doi:10.1016/j.jclepro.2023.138091

Dehshiri, S. J. H., Amiri, M., Olfat, L., and Pishvaee, M. S. (2023). A robust fuzzy stochastic multi-objective model for stone paper closed-loop supply chain design considering the flexibility of soft constraints based on Me measure. Appl. Soft Comput., 134.

Esenduran, G., Kemahlioglu-Ziya, E., and Swaminathan, J. M. (2016). Take-back legislation: consequences for remanufacturing and environment. Decis. Sci. 47, (2), 219–256. doi:10.1111/deci.12174

Fang, Y. L., Ren, Z. Y., and Yang, F. (2023). The impact of carbon allowance allocation rules on remanufacturing decisions in a closed-loop supply chain. Mathematics-Basel, 11.13

Giri, B. C., and Dey, S. K. (2019). Game theoretic analysis of a closed-loop supply chain with backup supplier under dual channel recycling. Comput. Ind. Eng. 129, 179–191. doi:10.1016/j.cie.2019.01.035

Hong, I. H., Lee, Y. T., and Chang, P. Y. (2014). Socially optimal and fund-balanced advanced recycling fees and subsidies in a competitive forward and reverse supply chain. Resour. Conservation Recycl. 82, 75–85. doi:10.1016/j.resconrec.2013.10.018

Hosseini Dehshiri, S., and Amiri, M. (2024). Considering the circular economy for designing closed-loop supply chain under hybrid uncertainty: a robust scenario-based possibilistic-stochastic programming. Expert Syst. Appl. 238, 121745. doi:10.1016/j.eswa.2023.121745

Huang, M., Song, M., Lee, L. H., and Ching, W. K. (2013). Analysis for strategy of closed-loop supply chain with dual recycling channel. Int. J. Prod. Econ. 144, (2), 510–520. doi:10.1016/j.ijpe.2013.04.002

Jacobs, B. W., and Subramanian, R. (2012). Sharing responsibility for product recovery across the supply chain. Prod. Oper. Manag. 21, (1), 85–100. doi:10.1111/j.1937-5956.2011.01246.x

Jiang, X., Hu, Q., Lou, T. Y., Zuo, W. J., and Li, J. C. (2023). Impact of government environmental regulations on remanufacturing supply chain with multi-subject responsibility for recycling and disposal. Mathematics-Basel, 11.8

Lacoste, S. (2016). Sustainable value co-creation in business networks. Ind. Mark. Manag. 52, 151–162. doi:10.1016/j.indmarman.2015.05.018

Li, G. Z., Shi, X. L., Yang, Y. F., and Lee, P. K. C. (2020). Green Co-creation strategies among supply chain partners: a value Co-creation perspective. Sustainability-Basel, 12.10

Li, X., Du, J. B., Cheng, Y. W., Hanif, S., Mu, D., and Cui, Y. M. (2019). Electric vehicle battery recycling: system dynamics game based analysis for the influencing factors. Environ. Eng. Manag. J. 18, (5), 1123–1136. doi:10.30638/eemj.2019.108

Liu, Z., and Nishi, T. (2019). Government regulations on closed-loop supply chain with evolutionarily stable strategy. Sustainability-Basel, 11.18

Liu, Z., Zheng, X.-X., Li, D.-F., Liao, C.-N., and Sheu, J.-B. (2021). A novel cooperative game-based method to coordinate a sustainable supply chain under psychological uncertainty in fairness concerns. Transp. Res. Part E Logist. Transp. Rev. 147, 102237. doi:10.1016/j.tre.2021.102237

Liu, Z. W., Schraven, D., de Jong, M., and Hertogh, M. (2023). The societal strength of transition: a critical review of the circular economy through the lens of inclusion. Int. J. Sust. Dev. World 30, 826–849. doi:10.1080/13504509.2023.2208547

Lyu, R. X., Zhang, C. H., Li, Z. T., and Li, Y. T. (2022). Manufacturers' integrated strategies for emission reduction and recycling: the role of government regulations. Comput. Ind. Eng., 163.

Mathew, G., Teoh, W. H., Rahman, W. M. A. W. A., and Abdullah, N. (2023). Survey on actions and willingness towards the disposal, collection, and recycling of spent lithium-ion batteries in Malaysia. J. Clean. Prod., 421.

Mirzaei, M. G., Goodarzian, F., Mokhtari, K., Yazdani, M., and Shokri, A. (2023). Designing a dual-channel closed loop supply chain network using advertising rate and price-dependent demand: case study in tea industry. Expert Syst. Appl., 233.

Qu, Y., Zhang, Y. X., Guo, L. L., Cao, Y., and Zhu, P. P. (2022). Decision strategies for the WEEE reverse supply chain under the "Internet plus recycling" model. Comput. Ind. Eng. 36, 172–176. doi:10.13201/j.issn.2096-7993.2022.03.003

Ren, S. J., Hu, C. H., Ngai, E. W. T., and Zhou, M. J. (2015). An empirical analysis of inter-organisational value co-creation in a supply chain: a process perspective. Prod. Plan. Control 26, (12), 969–980. doi:10.1080/09537287.2014.1002022

Shittu, O. S., Williams, I. D., and Shaw, P. J. (2021). Global E-waste management: can WEEE make a difference? A review of e-waste trends, legislation, contemporary issues and future challenges. Waste Manage 120, 549–563. doi:10.1016/j.wasman.2020.10.016

Solakivi, T., Kiiski, T., Kuusinen, T., and Ojala, L. (2021). The European Ship Recycling Regulation and its market implications: Ship-recycling capacity and market potential. J. Clean. Prod., 294.

Sugathan, P., Ranjan, K. R., and Mulky, A. G. (2017). Atypical shifts post-failure: influence of Co-creation on attribution and future motivation to Co-create. J. Interact. Mark. 38, 64–81. doi:10.1016/j.intmar.2017.01.002

Sun, X. F., Wang, Y. Y., Li, Y. Y., Zhu, W. J., Yan, D. H., and Li, J. H. (2023). Optimal pricing and carbon emission reduction decisions for a prefabricated building closed-loop supply chain under a carbon cap-and-trade regulation and government subsidies. Plos One, 18.6

Swami, S., and Shah, J. (2013). Channel coordination in green supply chain management. J. Oper. Res. Soc. 64, (3), 336–351. doi:10.1057/jors.2012.44

Tan, R. W., Jin, H., Yu, M. J., Yang, J. S., and Zhang, J. (2023). Research on construction waste recycling subsidy model considering contractor's environmental awareness. Sustainability-Basel, 15.3

Tan, Y., and Guo, C. X. (2019). Research on two-way logistics operation with uncertain recycling quality in government multi-policy environment. Sustainability-Basel, 11.3

Tang, B., Chen, S. J., Zheng, J., Xiong, S. M., Yan, X., Luo, W. K., et al. (2022). Changes in human hair levels of organic contaminants reflecting China's regulations on electronic waste recycling. Sci. Total Environ., 806.

Tatar, M., Khrapunenko, M., Henahan, R. K., and Asser, A. (2023). Engaging citizens in the bioeconomy: insights from the Co-creation and Co-design in the development of the serious bioeconomy game "mission BioHero. Sustainability-Basel, 15.18

Vargo, S. L., and Lusch, R. F. J. J. o. M. (2004). Evolving to a new dominant logic for marketing. J. Mark. 68, 1–17. doi:10.1509/jmkg.68.1.1.24036

Vargo, S. L., and Lusch, R. F. J. J. o. t. A. o. M. S. (2008). Service-dominant logic: continuing the evolution. J. Acad. Mark. Sci. 36 ((1), 1–10. doi:10.1007/s11747-007-0069-6

Wang, E. C., Nie, J. Y., and Wang, Y. H. (2023). Government subsidy strategies for the new energy vehicle power battery recycling industry. Sustainability-Basel, 15.3

Wang, G. Z., Yuan, M. N., and Xu, H. (2022). The impact of subsidy and preferential tax policies on mobile phone recycling: a system dynamics model analysis. Waste Manage 152, 6–16. doi:10.1016/j.wasman.2022.08.004

Wang, J., and He, S. L. (2023). Government interventions in closed-loop supply chains with modularity design. Int. J. Prod. Econ., 264.

Wang, M. Y., Li, Y. M., Li, M. M., Wan, L., Miao, L., and Wang, X. W. (2019). A comparative study on recycling amount and rate of used products under different regulatory scenarios. J. Clean. Prod. 235, 1153–1169. doi:10.1016/j.jclepro.2019.06.320

Wu, Q. L., Xu, X. X., and Lin, R. H. (2021). Government incentive mechanism of closed-loop supply chain based on information asymmetry. Rairo-Oper Res. 55, (6), 3359–3378. doi:10.1051/ro/2021124

Xu, S. Q., Liu, H., and Xu, G. Y. (2021). Selection of recycling channels and product eco-design with take-back regulation. Sustainability-Basel, 13.16

Yang, Y. Z., Liu, S. J., and Song, X. T. (2023). The Co-creation of museum experience value from the perspective of visitor motivation. Sage Open 13, 13. doi:10.1177/215824402312021184

Yu, H., Chang, X. Y., and Liu, W. J. (2021). Cost-based subsidy and performance-based subsidy in a manufacturing-recycling system considering product eco-design. J. Clean. Prod., 327.

Zhang, C., Wang, X. P., Li, B. Y., Su, C., and Sun, L. H. (2022a). Analysis of quality risk transmission in the new retail service supply chain system with value Co-creation. Systems-Basel, 10.6

Zhang, F. F., Wang, H., and Wu, X. Y. (2021). The impact of government subsidies on single-channel recycling based on recycling propaganda. Energies, 14.23

Zhang, S., and Meng, Q. (2021). Electronics closed-loop supply chain value co-creation considering cross-shareholding. J. Clean. Prod. 278, 123878. doi:10.1016/j.jclepro.2020.123878

Zhang, S., Meng, Q. C., and Xie, J. C. (2022b). Closed-loop supply chain value co-creation considering equity crowdfunding. Expert Syst. Appl., 199.

Zheng, X. X., Li, D. F., Liu, Z., Jia, F., and Sheu, J. B. (2019). Coordinating a closed-loop supply chain with fairness concerns through variable-weighted Shapley values. Transp. Res. E-Log 126, 227–253. doi:10.1016/j.tre.2019.04.006

Keywords: closed-loop supply chain, recycling regulation, value co-creation, recycling subsidy, circular economy (CE)

Citation: Liao B, Shang Y and Sun Y (2023) Optimal decisions of closed-loop supply chain under government recycling subsidy and value co-creation. Front. Energy Res. 11:1308800. doi: 10.3389/fenrg.2023.1308800

Received: 07 October 2023; Accepted: 06 November 2023;

Published: 23 November 2023.

Edited by:

Shi-Tong Peng, Shantou University, ChinaReviewed by:

Jiajun Wu, Shantou University, ChinaSeyyed Jalaladdin Hosseini Dehshiri, Allameh Tabataba’i University, Iran

Copyright © 2023 Liao, Shang and Sun. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yuanchao Shang, MTU3NjM0MTczMjJAMTYzLmNvbQ==

Bifeng Liao

Bifeng Liao Yuanchao Shang

Yuanchao Shang Yangyi Sun

Yangyi Sun