- 1Institute of Mineral Resources, Chinese Academy of Geological Sciences, Beijing, China

- 2China University of Geosciences (Beijing), Beijing, China

- 3Research Center for Strategy of Global Mineral Resources, Chinese Academy of Geological Sciences, Beijing, China

A great demand for lithium, cobalt, nickel, and other critical metals by power batteries has been increasing with the explosive development of the new energy industry, which further exacerbated the contradiction between the supply and demand of critical metals. In addition, two key factors, including an imbalance of government reward and punishment and a low degree of cooperation between manufacturers and recycling enterprises, have hindered the recovery and utilization of critical metals in power battery with the expansion of the power battery recycling market. A three-party evolutionary game model, including power battery manufacturers, third-party recycling enterprises, and the government, was constructed in this study to analyze the evolutionary stability of the strategy selection of each participant. Also, the influence of each factor on the three-party strategy selection and verifying the reliability of the results through simulation were also discussed. The results show that 1) both government incentives and punishments are beneficial for promoting cooperation between power battery manufacturers and recycling enterprises. The cost of cooperation will be the key factor affecting power battery recycling. 2) Increasing the probability of cooperation is an effective way to ensure the increase in income of both parties after cooperation. Further suggestions, including the establishment of a dynamic reward and punishment mechanism by the government and strengthening the cooperation to cope with the continued tight supply of critical metals by the manufacturers and recyclers, were also put forward in this research.

Introduction

The development of energy vehicles (EVs) is an effective way to achieve carbon emission reduction and carbon neutrality (Li et al., 2022). As an important component of EVs, power batteries are crucial to the manufacturing and development of EVs. Critical metals such as lithium, cobalt, and nickel, as essential constituents of active cathode materials and anode active materials of power batteries, have become indispensable raw materials in power battery manufacturing (Gu et al., 2017). By 2030, China’s lithium-ion battery (LIB) demand for lithium, cobalt, and nickel will be 11 times, 9 times, and 62 times higher than that in 2020, respectively (Shafique et al., 2022), and the tight supply and demand situation for critical metals in China is expected to intensify in the future. Power battery will enter the end-of-life stage after their capacity decays to a certain level, and recycling of retired power batteries can effectively increase the supply of key materials and reduce the initial production cost of power batteries (Idjis and Costa, 2017). In addition, battery recycling and reusing will achieve a win-win situation for both resource recovery and environmental protection impact, compared to new battery manufacturing (Gu et al., 2018). It will become increasingly important as lithium batteries increase (Alipanah et al., 2021). It is expected that by 2025, recycled lithium in China will account for 9% of the total lithium supply from lithium batteries and cobalt will account for nearly 20% (Pagliaro and Meneguzzo, 2019), which will go some way to alleviating the tight supply and demand for critical metals in power battery production.

Government supervision plays a major role in power battery recycling. On the one hand, a rational design of the layout, pricing strategy, and utilization to the power battery recycling industry is the key to realizing the efficient use of recycled power batteries (Lyu et al., 2021). On the other hand, supervision and subsidies for power battery recycling, gradient utilization, and resource reuse recycling systems are important to realize resource recycling (Tang et al., 2019; Liu and Wang, 2021; Wang, 2022). Lack of supervision will lead to the occurrence of corporate fraud and other situations. The Chinese government has introduced a series of regulations to guide and regulate the recycling of used batteries (Sun et al., 2021). Nevertheless, there are still phenomena such as regulatory imbalances and unsound recycling networks, which seriously hinder the healthy development of recycling market and incur huge environmental governance costs (He and Sun, 2022).

The cooperation cost is also one of the factors that both production enterprises and recycling enterprises must be considered when cooperating. Although extended producer responsibility (EPR) policies hold producers responsible for the entire life cycle of their products (Lindhqvist, 2000), especially the recycling and disposal of products designated by consumers as no longer useful (Gaur et al., 2022), producers usually cannot completely rely on their own power to achieve waste recycling. According to Gu et al. (2016), subjects involved in waste recovery can be divided into hawkers, collection stations, distributors, and middlemen, of which middlemen are second-level recyclers, and the other three are directly connected with consumers and belong to first-level recyclers (Chi et al., 2011). Although the number of recycling enterprises is very large, most of which are small and medium-sized enterprises, no special recycling network has been formed (Wang and Wu, 2017). Both power battery manufacturers and recycling enterprises need to pay a certain cost to seek recycling cooperation. For recycling enterprises, capabilities with high dismantling capabilities and strong technical have to pay less such costs. Power battery manufacturers can achieve win-win cooperation by signing risk-equivalent contracts and establishing advantages in the recycling power battery recycling market (Zhu and Yu, 2019). For recyclers, the amount of investment under different investment models and the recycling rate will also influence its decisions (You et al., 2014).

There are many studies on various aspects of power battery recycling, such as policies and regulations on power battery recycling (Xu et al., 2017; Choi and Rhee, 2020; He and Sun, 2022), power battery recycling subjects (Schultmann et al., 2003), recycling channels (Chuang et al., 2014; Tang et al., 2018), and recycling mode (Hong and Yeh, 2012). Game theory is simulated decision interactions among rational decision-makers by using mathematical methods and has many applications in political science, economics, and sociology (Fang et al., 2021). Compared with traditional engineering methods, game theory pays more attention to the social and personal behaviors of stakeholders (Yuan et al., 2022). Luo et al. (2019) used a dynamic game to optimize subsidy policy for autonomous vehicles. Gu et al. (2021) constructed a game model of the impact of government subsidies on the utilization of electric vehicle batteries from the perspective of the closed-loop supply chain. Li X. et al. (2020) conducted an evolutionary game analysis on the behavior of the main participants in the electric vehicle battery deposit refund scheme launched by the Shenzhen Municipal Government of China. Li J. et al. (2020) built a non-cooperative game model that considers the battery recycling rate and consumers’ environmental awareness and includes three game subjects, namely, EVs manufacturers, fuel vehicle manufacturers, and the government, and further verify the efficiency of dual credit policy over subsidy one. Using an evolutionary game model among consumers, EVs manufacturers, and the government under the EPR system, He and Sun (2022) found that the government’s dynamic reward and punishment mechanism encourage consumers and 97% of EVs enterprises to participate in power battery recycling; the cost of recycling is the biggest influencing factor that hinders the recycling of power batteries by EVs manufacturers, and the change of recycling price of third-party recycling enterprises will affect the development of recycling industry.

There are many literatures on government policy research, but there is a lack of research on the design of power battery recycling network at the enterprise level (Wang et al., 2020). In order to improve the efficiency of power battery recycling and the utilization rate of recycled power batteries, it seems difficult to rely only on the government, and the roles and interactions between different players must be considered (Kong et al., 2020). Specifically, the cooperation between recycling enterprises and power battery stakeholders can promote a mutually beneficial win-win situation (Ding and Zhong, 2018; Sopha et al., 2022). Therefore, it is necessary to study the cooperation between interest groups in the battery recycling industry in China (Zhou et al., 2007).

In summary, this study structures an evolutionary game model of three responsible parties in the power battery recycling chain to address 1) the influence of the initial selection probability of production enterprises, recycling manufacturers, and the government on the evolutionary game process and results in power battery recycling. 2) The impact on the game subject is analyzed from the perspectives of cooperation cost, supervision cost, and the amount of rewards and penalties; furthermore, the mitigation effect of power battery recycling on the supply shortage of critical metal resources is analyzed. Compared with previous studies, the model scenario of this study is more practical and the analysis of the scenario is richer. First, this study considers the participation willingness of both power battery manufacturers and recycling enterprises; second, the model of three-party game is introduced to analyze the evolution process of the three-party game under the reward and punishment mechanism. Third, this study introduces the optimization behavior of the dynamic reward and punishment mechanism for the three game subjects. Finally, this study analyzes the influence of key factors on group behavior and provides policy suggestions for power battery recycling to alleviate the supply shortage of critical metals. This can help policy makers to make better policies and help alleviate the tight supply and demand situation of critical metals. The rest of the article is structured as follows: Section 2 constructs a three-party evolutionary game model, Section 3 provides a stability analysis of the game subjects, Section 4 conducts simulations, and the last section gives conclusions and policy recommendations.

Tripartite evolutionary game modeling

Research framework

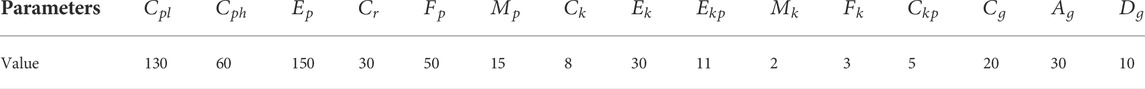

This study adopts the evolutionary game method for research, and the specific research framework (Figure 1) can be obtained as follows: first, the game model is hypothesized based on the actual situation, including determining the game subject, setting the game relationship between the subjects and the parameters in the game relationship, and constructing the pure strategy game matrix. Second, we analyzed the stability of game models and evolutionary stable strategy (ESS), including the calculation of the dynamic replication equation under different pure game strategies, phase diagram of strategy evolution, and Jacobian matrix of the stable system. Third, the model parameters are assigned to the actual situation, and a simulation analysis is carried out to observe the influence of the change in the initial selection probability of the subject and the change in related parameters on the evolution process of all parties in the evolutionary game. Finally, the related results are described by images.

FIGURE 1. Framework for studying the evolution of a tripartite game for recycling critical metals in power batteries.

Game model assumption

The reduction in the supply of critical metals has exacerbated the tension of the contradiction between supply and demand, resulting in increased production costs for power battery manufacturers. The government has strengthened its supervision of power battery recycling enterprises, which makes it difficult for them to sell recycled power batteries to unqualified enterprises. Under the guidance of the government, power battery manufacturers and third-party recycling enterprises are willing to cooperate and spend some cost to seek cooperation. Therefore, the government, power battery manufacturers, and recycling enterprises are the main participants of power in battery recycling.

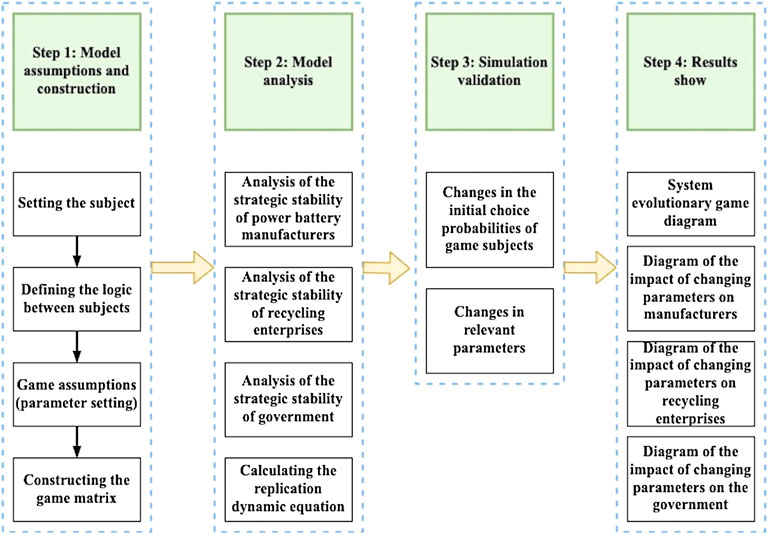

Based on the aforementioned scenarios, this study constructs a three-party evolutionary game system (Figure 2) and puts forward the following reasonable assumptions:

FIGURE 2. Evolutionary game model among power battery manufacturers, recycling enterprises, and government.

Assumption 1: The power battery manufacturer is participant 1, the third-party recycling enterprise is participant 2, and the government regulatory department is participant 3. The three parties are rational subjects with limited participation, and the choice of strategy gradually evolves over time and stabilizes at the optimal strategy. This study only considers the scenario that power battery manufacturers and recycling enterprises cooperate to recycle power batteries. Power battery manufacturers are not directly involved in power battery recycling. Third-party recycling enterprises do not include manufacturers.

Assumption 2: The strategy space for power battery manufacturers is

Assumption 3: The production cost of power battery manufacturer is

Assumption 4: The cost of the third-party recycling enterprises is

Assumption 5: When the government regulates recycling behavior, the regulatory cost that the government pays is

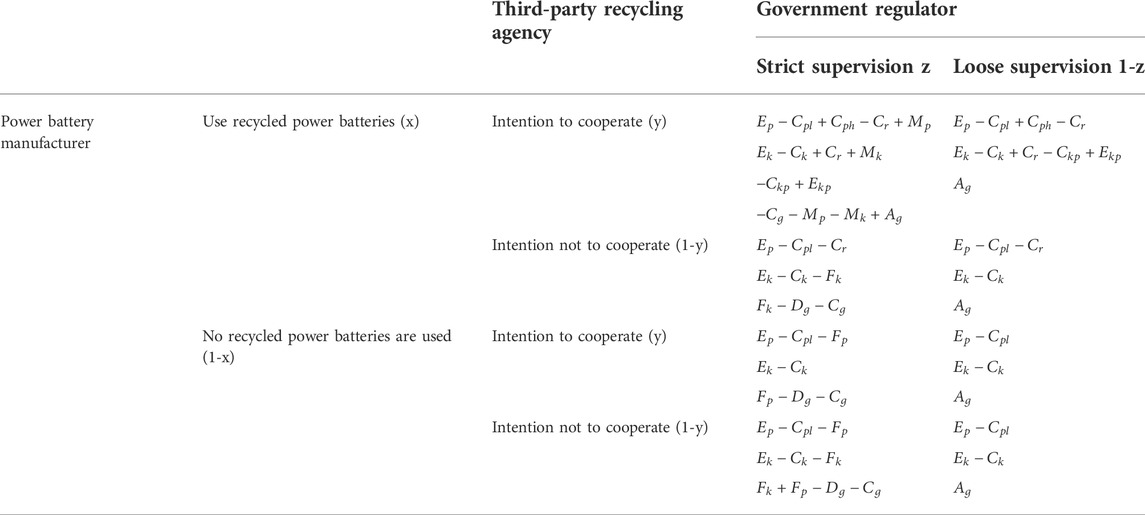

According to the aforementioned assumptions, the mixed strategy game matrix of the power battery manufacturer, third-party recycling enterprises, and government can be obtained, as shown in Table 1.

Evolution model construction and stability analysis

In this section, we calculate the mathematical expectations and probabilities of the strategic choices of power battery producers, recycling enterprises, and governments, and the factors that influence the evolution of the game between the parties can be obtained and analyzed.

Strategy stability analysis of power battery manufacturers

The mathematic expectation that power battery manufacturers using recycled power batteries

The dynamic replication equation of the power battery manufacturer’s strategy selection is as follows:

The first derivative of

making

According to the stability theorem of the ordinary differential equation, the probability of power battery production enterprises choosing to use recycled batteries in a stable state must satisfy

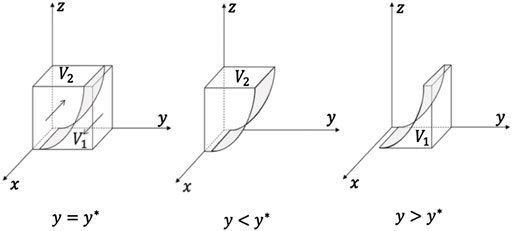

As shown in Figure 3,

Corollary 1:. The willingness of power battery manufacturers to use recycled power batteries

Stability analysis of third-party recovery enterprises

The mathematic expectation that third-party recycling enterprises intend to cooperate with power battery manufacturers

The dynamic replication equation of the power battery manufacturer’s strategy selection is as follows:

The first derivative of

making

According to the stability theorem of ordinary differential equations, the probability of the third-party recycling enterprises choosing cooperation in a stable state must meet

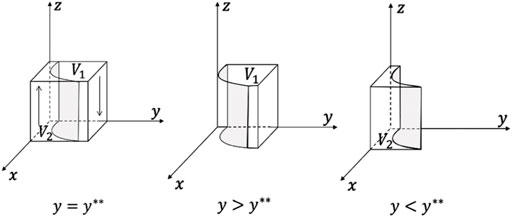

As shown in Figure 4,

Corollary 2:. The probability of third-party recycling enterprises choosing cooperation

Stability analysis of government

The mathematic expectation that power battery manufactures using recycled power batteries

The dynamic replication equation of the power battery manufacturer’s strategy selection is as follows:

The first derivative of

making

According to the stability theorem of ordinary differential equations, the probability of strict government supervision in a stable state must meet

As shown in Figure 5,

Corollary 3. The probability of the government’s strict supervision

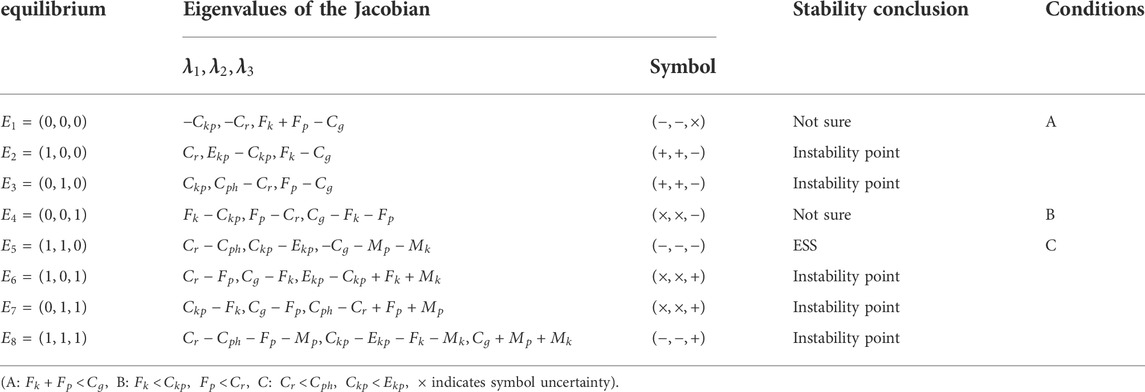

Stability analysis of ESS

According to Lyapunov’s first rule: all eigenvalues of the Jacobian matrix have negative real parts, then the equilibrium point is asymptotically stable. If at least one of the eigenvalues of the Jacobian matrix has a positive real part, the equilibrium point is not stable. Make

Corollary 4:. When

Simulation analysis

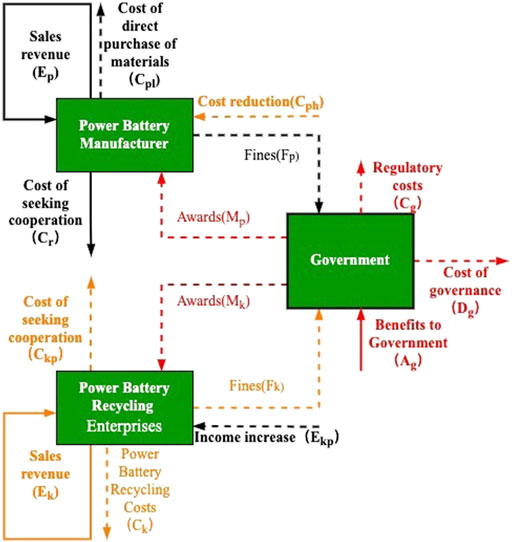

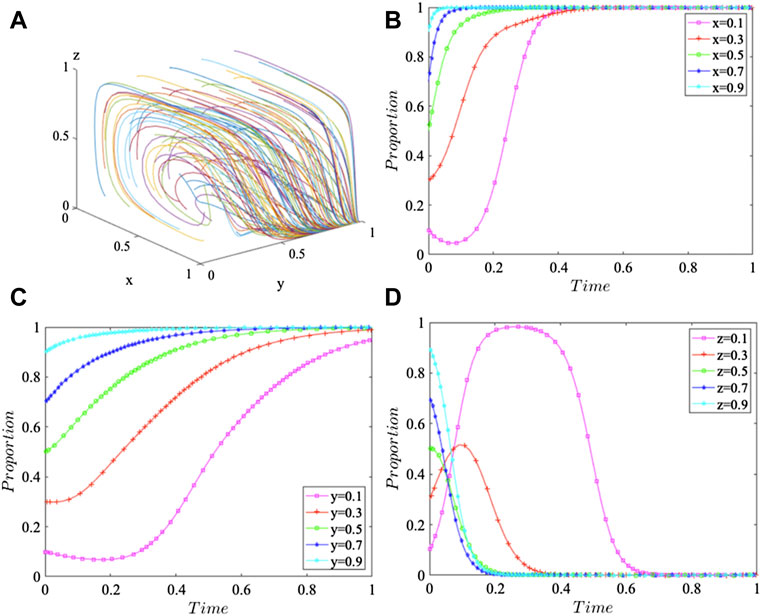

In order to intuitively observe the dynamic evolution of the behavior of the three stakeholders in the power battery recycling model and verify the validity of the aforementioned analysis, the model parameters were assigned and simulated based on Corollary 4. The parameters are assigned according to Lander et al. (2021) and the actual situation. Table 3 illustrates the initial game values of the three stakeholders.

Each parameter value in Table 2 satisfies the stability conditions, and 50 groups of different initial strategy points of

FIGURE 6. Results of three parties with different initial selection probabilities. (A) Results of ESS with different initial selection probabilities, (B) evolutionary game results of power battery manufacturers under different initial selection probabilities, (C) evolutionary game results of recycling enterprise under different initial selection probabilities, (D) evolutionary game results of government under different initial selection probabilities.

Compared with the evolution process of power battery manufacturers and third-party recycling enterprises, it takes a long time for third-party recycling enterprises to reach

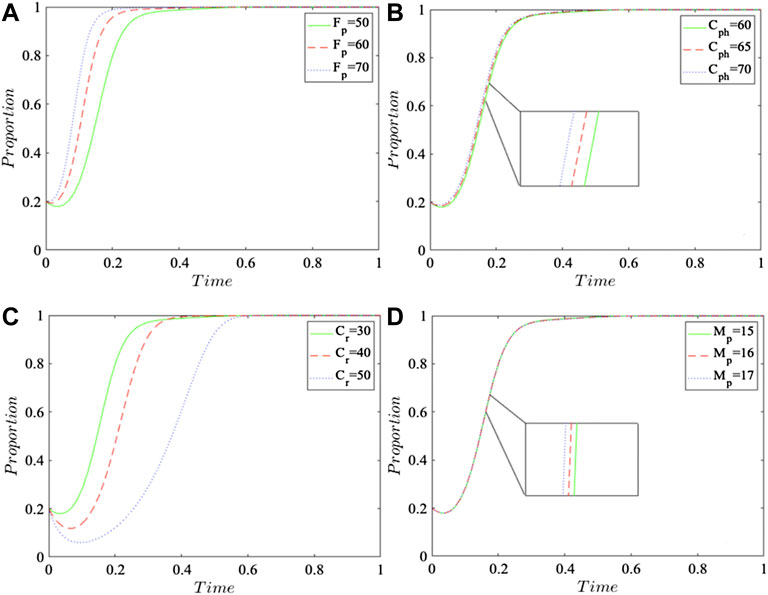

To analyze the cost saved by enterprises, the government’s rewards and punishments for enterprises, and the impact of cooperation cost changes on power battery manufacturers, assign 50, 60, and 70 to

With the amount of government reward

FIGURE 7. Influence of changing parameters on power battery manufacturers. (A) Impact of changes in the amount of punishment, (B) impact of changes in profits from using power batteries, (C) impact of changes in collaboration costs, (D) impact of changes in the amount of reward.

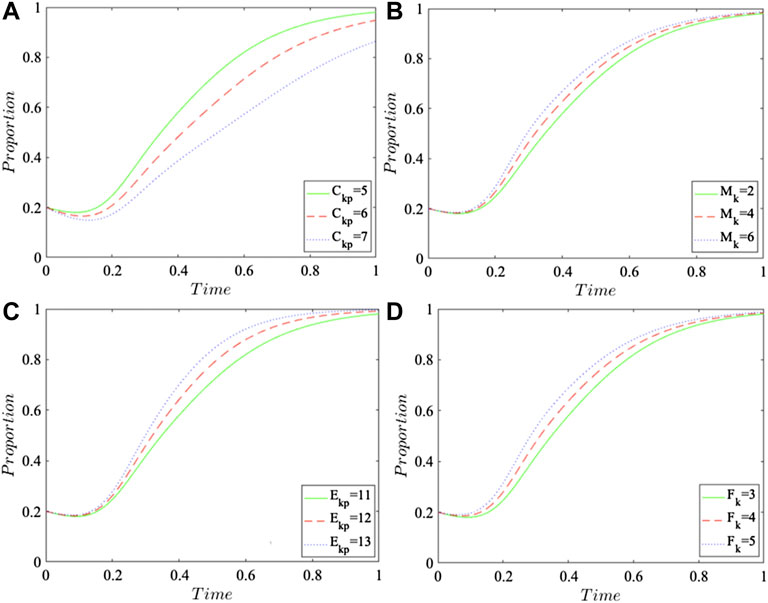

To analyze the increased sales revenue after cooperation, the government’s rewards and punishments, and seek the impact of changes in cooperation costs on recycling enterprises, assign 5, 6, and seven to

When the government reward amount

FIGURE 8. Influence of changing parameters on third-party recycling enterprises. (A) Impact of changes in collaboration costs, (B) impact of changes in the amount of reward, (C) impact of changes in profits in increase profits, (D) impact of changes in the amount of punishment.

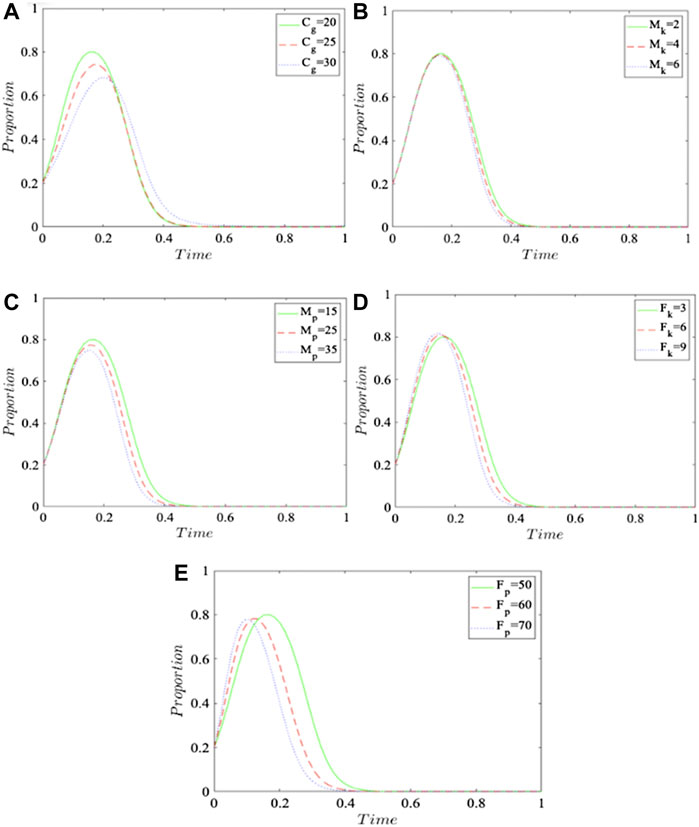

To analyze the effects of increasing government regulatory cost

With the increase in

FIGURE 9. Influence of changing parameters on the government. (A) Impact of changes in monitoring costs, (B) impact of changes in rewards for recycling enterprises, (C) impact of changes in rewards for power battery manufacturers, (D) impact of changes in punishments for recycling enterprises, (E) impact of changes in punishments for power battery manufacturers.

The aforementioned simulation results show that, under the assignment conditions of Table 2, the system only has one combination of evolutionarily stable strategies (use recycled power battery, cooperation, loose supervision), which is consistent with the conclusion of inference 4. The simulation results are consistent with the analysis results, which have certain practical guiding significance for the development of the critical metal recycling market.

Conclusion and policy recommendations

With the rapid growth of the demand for EVs critical metals and the continuous contradiction between the supply and demand of critical metals, the efficient recycling of power batteries plays an increasingly prominent role in alleviating the tight supply of critical metals and protecting the environment. As stakeholders, the production manufacturers, recycling enterprises and the government have a great impact on this process. Therefore, this study considers the impact of recycling cooperation between power battery manufacturers and recycling enterprises under government supervision on the contradiction between the supply and demand of critical metals used in power battery production, and constructs a three-party evolutionary game model between them. The stability of each strategy choice, the system stability, and the influence of each factor on the main body of the game are analyzed. The effectiveness of the results is verified by simulation. The main conclusions and policy recommendations are included as follows:

(1) The initial probability of selection strategy does not change the decision only affects the process of

(2) The effective way to promote cooperation between power battery manufacturers and recycling enterprises is to ensure an increase in both sides’ income after cooperation. In the case of a shortage of critical metals in the power battery production process, power battery manufacturers must increase the use of recycled power battery to reduce the consumption of primary resources to reduce the manufacturing cost of power battery. For production enterprises, it is better to suggest that the government strengthen market supervision rather than spending much on negotiating with third-party recycling enterprises. Recycling enterprises need to appropriately increase recycling efforts and technical input according to their own economic conditions. With the expansion of the recycling scale and the increase in government subsidies, recycling enterprises need to choose appropriate development strategies according to their own conditions. Continuing to increase cooperation is a good development direction for recycling enterprises to increase profits while maintaining the same cost.

(3) Government rewards and punishments are conducive both to promote cooperation between power battery manufacturers and recycling enterprises and to encourage the recovery and utilization of critical metals. The cost of cooperation between both parties will be the key factor affecting the recovery of power battery. The government should pay close attention to the trend of the recycling market, increase the communication between manufacturers and recycling enterprises, and do a good job of publicizing policies to reduce the cost of cooperation so that both sides can gain certain benefits under the cooperation mode. The government needs to pay attention to the cost changes of market supervision and adjust the rewards and punishments mechanism according to the constant changes in the market. Static rewards and punishments mechanism will lead to rigid behavior patterns of participants in power battery recycling. Dynamic rewards and punishments will make power battery manufacturers more actively participate in recycling. Government rewards for power battery manufacturing enterprises cannot be too high, and the optimal battery recycling rate may be reduced by increased government rewards. In both model analysis and simulation analysis, government subsidies for power battery recycling enterprises and third-party recycling enterprises play a positive role in the decision-making of both parties. Relevant studies also show that government subsidies for manufacturers and third-party recycling enterprises promote the closed-loop development of the supply chain of EVs. The intensity of subsidies is the issue that the government needs to focus on when making policies. In the setting of the punishment amount, the punishments for noncooperation of third-party testing enterprises should be higher than that of power battery manufacturers.

Future work

This study only considers the game behavior among the three players of power battery recycling under the premise of bounded rationality and does not consider the influence of consumer behavior and other parameter changes on power battery production. Therefore, expanding the system boundary, combining system dynamics with game theory to draw more quantitative conclusions, and introducing consumers as game subjects will be our next research direction.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

Conceptualization, SG and GL; methodology, SG and YW; software, SG; validation, SG and GL, and XG; formal analysis, SG; investigation, SG and GL; resources, SG; data curation, SG; writing—original draft preparation, SG; writing—review and editing, SG, GL, and XG; visualization, SG and YW; supervision, GL and XG; project administration, GL; funding acquisition, GL. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by grants from the National Natural Science Foundation of China (Grant No. 71991485 and 71991480) and Basic Science Center Project for National Natural Science Foundation of China (No. 72088101, the Theory and Application of Resource and Environment Management in the Digital Economy Era).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alipanah, M., Saha, A. K., Vahidi, E., and Jin, H. (2021). Value recovery from spent lithium-ion batteries: A review on technologies, environmental impacts, economics, and supply chain. Clean Technol. Recycl. 1 (2), 152–184. doi:10.3934/ctr.2021008

Chi, X., Streicher-Porte, M., Wang, M. Y., and Reuter, M. A. (2011). Informal electronic waste recycling: A sector review with special focus on China. Waste Manag. 31 (4), 731–742. doi:10.1016/j.wasman.2010.11.006

Choi, Y., and Rhee, S.-W. (2020). Current status and perspectives on recycling of end-of-life battery of electric vehicle in Korea (Republic of). Waste Manag. 106, 261–270. doi:10.1016/j.wasman.2020.03.015

Chuang, C.-H., Wang, C. X., and Zhao, Y. (2014). Closed-loop supply chain models for a high-tech product under alternative reverse channel and collection cost structures. Int. J. Prod. Econ. 156, 108–123. doi:10.1016/j.ijpe.2014.05.008

Ding, X., and Zhong, J. (2018). Power battery recycling mode selection using an extended MULTIMOORA method. Sci. Program., 1–14. doi:10.1155/2018/7675094

Fang, F., Liu, S., Basak, A., Zhu, Q., Kiekintveld, C. D., and Kamhoua, C. A. (2021). Introduction to game theory. Hoboken: Game Theory and Machine Learning for Cyber Security, 21–46. doi:10.1002/9781119723950.ch2

Gaur, A., Gurjar, S. K., and Chaudhary, S. (2022). “22 - circular system of resource recovery and reverse logistics approach: Key to zero waste and zero landfill,” in Advanced organic waste management. Editors C. Hussain, and S. Hait (Elsevier), 365–381. doi:10.1016/B978-0-323-85792-5.00008-3

Gu, F., Guo, J., Yao, X., Summers, P. A., Widijatmoko, S. D., and Hall, P. (2017). An investigation of the current status of recycling spent lithium-ion batteries from consumer electronics in China. J. Clean. Prod. 161, 765–780. doi:10.1016/j.jclepro.2017.05.181

Gu, X., Ieromonachou, P., Zhou, L., and Tseng, M.-L. (2018). Developing pricing strategy to optimise total profits in an electric vehicle battery closed loop supply chain. J. Clean. Prod. 203, 376–385. doi:10.1016/j.jclepro.2018.08.209

Gu, X., Zhou, L., Huang, H., Shi, X., and Ieromonachou, P. (2021). Electric vehicle battery secondary use under government subsidy: A closed-loop supply chain perspective. Int. J. Prod. Econ. 234, 108035. doi:10.1016/j.ijpe.2021.108035

Gu, Y., Wu, Y., Xu, M., Wang, H., and Zuo, T. (2016). The stability and profitability of the informal weee collector in developing countries: A case study of China. Resour. Conservation Recycl. 107, 18–26. doi:10.1016/j.resconrec.2015.12.004

He, L., and Sun, B. (2022). Exploring the EPR system for power battery recycling from a supply-side perspective: An evolutionary game analysis. Waste Manag. 140, 204–212. doi:10.1016/j.wasman.2021.11.026

Hong, I.-H., and Yeh, J.-S. (2012). Modeling closed-loop supply chains in the electronics industry: A retailer collection application. Transp. Res. Part E Logist. Transp. Rev. 48 (4), 817–829. doi:10.1016/j.tre.2012.01.006

Idjis, H., and Costa, P. d. (2017). “Is electric vehicles battery recovery a source of cost or profit?,” in The automobile revolution (Springer), 117–134. doi:10.1007/978-3-319-45838-0_8

Kong, D., Xia, Q., Xue, Y., and Zhao, X. (2020). Effects of multi policies on electric vehicle diffusion under subsidy policy abolishment in China: A multi-actor perspective. Appl. Energy 266, 114887. doi:10.1016/j.apenergy.2020.114887

Lander, L., Cleaver, T., Rajaeifar, M. A., Nguyen-Tien, V., Elliott, R. J. R., Heidrich, O., et al. (2021). Financial viability of electric vehicle lithium-ion battery recycling. iScience 24 (7), 102787. doi:10.1016/j.isci.2021.102787

Li, J., Ku, Y., Liu, C., and Zhou, Y. (2020a). Dual credit policy: Promoting new energy vehicles with battery recycling in a competitive environment? J. Clean. Prod. 243, 118456. doi:10.1016/j.jclepro.2019.118456

Li, X., Mu, D., Du, J., Cao, J., and Zhao, F. (2020b). Game-based system dynamics simulation of deposit-refund scheme for electric vehicle battery recycling in China. Resour. Conservation Recycl. 157, 104788. doi:10.1016/j.resconrec.2020.104788

Li, X., Xiao, X., and Guo, H. (2022). A novel grey Bass extended model considering price factors for the demand forecasting of European new energy vehicles. Neural comput. Appl. 34, 11521–11537. doi:10.1007/s00521-022-07041-7

Lindhqvist, T. (2000). Extended producer responsibility in cleaner production: Policy principle to promote environmental improvements of product systems. Lund: Lund University.

Liu, K., and Wang, C. (2021). The impacts of subsidy policies and channel encroachment on the power battery recycling of new energy vehicles. Int. J. Low-Carbon Technol. 16 (3), 770–789. doi:10.1093/ijlct/ctab006

Luo, Q., Saigal, R., Chen, Z., and Yin, Y. (2019). Accelerating the adoption of automated vehicles by subsidies: A dynamic games approach. Transp. Res. Part B Methodol. 129, 226–243. doi:10.1016/j.trb.2019.09.011

Lyu, X., Xu, Y., and Sun, D. (2021). An evolutionary game research on cooperation mode of the NEV power battery recycling and gradient utilization alliance in the context of China’s NEV power battery retired tide. Sustainability 13 (8), 4165. doi:10.3390/su13084165

Pagliaro, M., and Meneguzzo, F. (2019). Lithium battery reusing and recycling: A circular economy insight. Heliyon 5 (6), e01866. doi:10.1016/j.heliyon.2019.e01866

Schultmann, F., Engels, B., and Rentz, O. (2003). Closed-loop supply chains for spent batteries. Interfaces 33 (6), 57–71. doi:10.1287/inte.33.6.57.25183

Shafique, M., Rafiq, M., Azam, A., and Luo, X. (2022). Material flow analysis for end-of-life lithium-ion batteries from battery electric vehicles in the USA and China. Resour. Conservation Recycl. 178, 106061. doi:10.1016/j.resconrec.2021.106061

Sopha, B. M., Purnamasari, D. M., and Ma’mun, S. (2022). Barriers and enablers of circular economy implementation for electric-vehicle batteries: From systematic literature review to conceptual framework. Sustainability 14 (10), 6359. doi:10.3390/su14106359

Sun, S., Jin, C., He, W., Li, G., Zhu, H., and Huang, J. (2021). Management status of waste lithium-ion batteries in China and a complete closed-circuit recycling process. Sci. Total Environ. 776, 145913. doi:10.1016/j.scitotenv.2021.145913

Tang, Y., Zhang, Q., Li, Y., Li, H., Pan, X., and Mclellan, B. (2019). The social-economic-environmental impacts of recycling retired EV batteries under reward-penalty mechanism. Appl. Energy 251, 113313. doi:10.1016/j.apenergy.2019.113313

Tang, Y., Zhang, Q., Li, Y., Wang, G., and Li, Y. (2018). Recycling mechanisms and policy suggestions for spent electric vehicles' power battery -A case of Beijing. J. Clean. Prod. 186, 388–406. doi:10.1016/j.jclepro.2018.03.043

Wang, L., Wang, X., and Yang, W. (2020). Optimal design of electric vehicle battery recycling network – from the perspective of electric vehicle manufacturers. Appl. Energy 275, 115328. doi:10.1016/j.apenergy.2020.115328

Wang, S. (2022). “Multi-angle Analysis of electric vehicles battery recycling and utilization,” in IOP conference series: Earth and environmental science. Philadelphia: (IOP Publishing), 012027.

Wang, W., and Wu, Y. (2017). An overview of recycling and treatment of spent LiFePO4 batteries in China. Resour. Conservation Recycl. 127, 233–243. doi:10.1016/j.resconrec.2017.08.019

Xu, C., Zhang, W., He, W., Li, G., Huang, J., and Zhu, H. (2017). Generation and management of waste electric vehicle batteries in China. Environ. Sci. Pollut. Res. 24 (26), 20825–20830. doi:10.1007/s11356-017-9890-8

You, J., Duan, C., Huang, Z., and Zhong, Z. (2014). Environmental quality cost control modeling based on power battery recycling. J. Tongji Univ. Nat. Sci. 42 (6), 969–975.

Yuan, M., Li, Z., Li, X., Li, L., Zhang, S., and Luo, X. (2022). How to promote the sustainable development of prefabricated residential buildings in China: A tripartite evolutionary game analysis. J. Clean. Prod. 349, 131423. doi:10.1016/j.jclepro.2022.131423

Zhou, L., Naim, M. M., and Wang, Y. (2007). Soft systems analysis of reverse logistics battery recycling in China. Int. J. Logist. Res. Appl. 10 (1), 57–70. doi:10.1080/13675560600717847

Keywords: critical metals, recycling, cooperation, tripartite evolutionary game model, simulation analysis

Citation: Guo S, Liu G, Guo X and Wang Y (2022) Game evolution and simulation analysis of power battery recycling in China under conflicting supply and demand of critical metals. Front. Energy Res. 10:984437. doi: 10.3389/fenrg.2022.984437

Received: 02 July 2022; Accepted: 29 July 2022;

Published: 15 September 2022.

Edited by:

Xiaoqi Sun, Shenzhen University, ChinaReviewed by:

Yawen Han, Zhejiang Sci-Tech University, ChinaYunjie Wei, Institute of Systems Science (CAS), China

Copyright © 2022 Guo, Liu, Guo and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Guwang Liu, bGd3MTEwQDEyNi5jb20=

Shaobo Guo

Shaobo Guo Guwang Liu1,3*

Guwang Liu1,3*