95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res. , 13 October 2022

Sec. Bioenergy and Biofuels

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.979217

A. K. M. Aminul Islam1,2*

A. K. M. Aminul Islam1,2* Zahira Yaakob1

Zahira Yaakob1 Jaharah A. Ghani3

Jaharah A. Ghani3 Azza Alareefy4

Azza Alareefy4 Nisreen M. Abdulsalam5

Nisreen M. Abdulsalam5 Najla A. Khateeb6

Najla A. Khateeb6 Nahla Zidan7

Nahla Zidan7 Mahmoud A. Abdelazi8

Mahmoud A. Abdelazi8 Ayman El Sabagh9*

Ayman El Sabagh9* Mohamed I. Sakran10

Mohamed I. Sakran10 Awatif Omran10

Awatif Omran10 Ahmad El Askary11

Ahmad El Askary11 Mohamed El-Sharnouby12

Mohamed El-Sharnouby12 Marzough Aziz albalawi13

Marzough Aziz albalawi13 A. K. M. Mominul Islam14

A. K. M. Mominul Islam14Jatropha curcas, has been established as a plant whose seeds contain a relatively high percentage of oil that is suitable for biodiesel production, among other industrial applications. Seed oil properties of J. curcas may vary depending on soils, age of plant, genotype of the plant, and agro-climatic conditions of a specific geographical region. Studies under such conditions have not yet been conducted. The present study was aimed at investigating the effects of genotype and age of the plant on the physicochemical properties of its seed oil. The seed oil was extracted using n-hexane as a solvent in the Soxhlet extraction apparatus from seed kernel collected from different genotypes and plants of different ages. Oil content in the kernel ranged from 49.78–53.75% (w/w) among the seed samples depending on genetic materials and plant age. The oil content showed very little but significant differences in density and specific gravity among the samples. The highest free fatty acid (FAA) was produced by the kernel oil of 3-year-old plants (7.78%), and 7- and 10-year-old plants gave the lowest FAA (1.26 and 1.31%, respectively). The kernel oil of 7-year-old plants produced the highest iodine value (93.60 mg/g oil) and the kernel oil of 3-year-old plants produced the lowest iodine value (61.10 mg/g oil). Kernel oil of 10-year-old plants gave the lowest (172.98 mg KOH/g) saponification value and 4-year-old Hybrid-3 gave the maximum value (209.97 mg KOH/g oil). The seed oil of Jatropha accessions showed very little difference (39.88–40.85 MJ/kg) for high heating values irrespective of their age. On the other hand, the cetane number varied from 55.32 to 59.58 in the oil samples. The age of plant and seed sources had a significant effect on seed oil content and the physio-chemical properties of Jatropha.

Recent studies have indicated that fossil fuel as a petrochemical energy stock is non-renewable and can be exhausted with time as a result of continuous and various utilizations (Demirbas, 2009; Oyekunle et al., 2019). . Over 90% of the world population directly or indirectly depends on fossil fuel for their source of energy supply. . To solve the problem, biofuel is being believed to be a good alternative to fossil fuels and is produced from vegetable oil and animal fats. Biofuel causes less environmental pollution (lower greenhouse effect) due to its low Sulphur content compared to fossil fuel (Wang et al., 2006). On the other hand, biofuel production from edible vegetable oils (rapeseed, corn, palm oil, soyabean etc.) creates a burden on the world food supply. Augmented natural apprehension and expected attenuation of fossil fuel reserves are the principal cause of searching for non-edible sources as an alternative feedstock for the production of biofuels (Charlene et al., 2004). In recent times, the utilization of non-edible oil such as jatropha as feedstock for biodiesel production has received more attention and is anticipated to play down the crisis for vegetable oil (FAO, 2009). Since non-edible oil is underutilized it can be a potential feedstock for biodiesel by reducing the dependency on crude oil import.

The plant parts (leaves, seeds etc.) of J. curcas are toxic to humans and animals. The toxicity of seeds is largely due to the existence of diterpine and curcin (Openshaw, 2000; Kureel, 2006; Kaushik et al., 2007; Achten et al., 2010). The seed oil of Jatropha comprises a high proportion (78–84%) of fatty acids which contains one or more carbon-carbon double/triple bonds (Heller, 1996). The properties of kernel oil of Jatropha obtained from parental accessions, their hybrids, and different age level are still scarce (Sirisomboon et al., 2007; Salimon and Abdullah, 2008; Sirisomboon and Kitchaiya, 2009). The properties of kernel oil are specific gravity (SG), density, refractive index (RI), viscosity, FFA content, iodine value (IV), acid value (AV), saponification value (SV), high heating value (HHV) and cetane number (CN). The biodiesel properties produced through transesterification are also affected by the seed oil properties of Jatropha (Emil et al., 2010; Kumar et al., 2011). The constituents of seed oil vary to a great extent with the genotype, climatic condition, soil, and management practices (irrigation, weeding, use of fertilizer, crop density, use of pesticide, and inter-cropping). Variation also occurs when marginal farming is changed to commercial farming with irrigation facilities (Kumar et al., 2011). Seed oil properties are important attributes for biodiesel production, which affects several parameters of biodiesel from Jatropha. The seed oil content of Jatropha and its physio-chemical properties are considerably influenced by the type of genetic materials and age of the plant. Therefore, the present study aims to estimate kernel oil content, and physical and chemical characteristics of kernel oil collected from plants of different genotypes and ages.

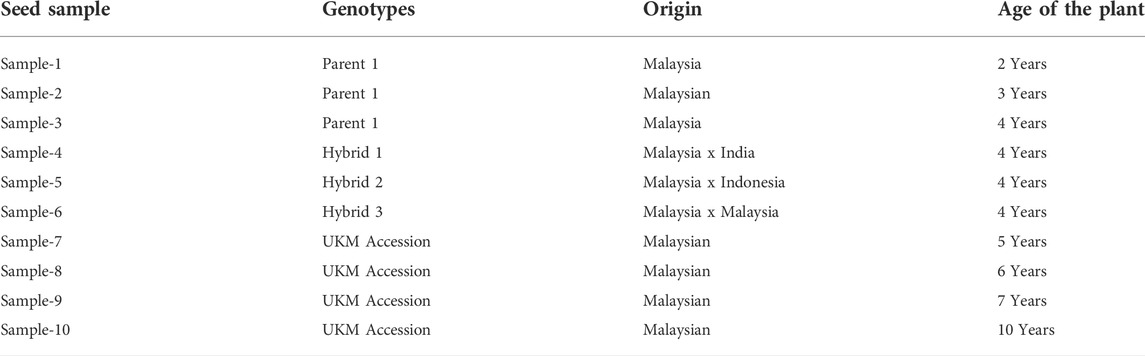

Ten seed samples (Table 1) were collected from the Jatropha genotypes/accessions (parents, hybrids, or accessions) planted at Biofuel Research Station, National University of Malaysia (UKM), Malaysia. The experimental area was under tropical climate which is mostly experienced in Malaysia (McGinley and Clough, 2010) and the soil belongs to marginal land previously under tropical rain forest. Seeds were collected from yellow to dark brown fruits of healthy plants and de-hulled after drying under sunlight to lessen the amount of moisture. To get kernels, the fruits were de-shelled followed by de-hulled the seeds of the parents and hybrids. Seed kernels were dried at 100–105°C for 30 min in the oven drier to reduce moisture content following Sirisomboon et al. (2007) before oil extraction (Sirisomboon and Kitchaiya, 2009) as the seed kernels of Jatropha contain a high amount (34%) of moisture (Emil et al., 2010).

TABLE 1. Seed sample with their source, origin and age of the plant from which seeds were collected.

Jatropha seed kernels were ground to powder prior to oil extraction by solvent extraction method using n-hexane (Sayyar et al., 2009). Analytical grade chemicals were used in the extraction process without additional refinement. Solvent extraction with n-hexane (b.p. 60–70°C, 6 h by gentle heating) was used to extract oil from the samples of known weight without any interruption. The oil sample extracted using n-hexane was evaporated on a rotary water bath evaporator until hexane remain. The amount of extracted oil was calculated as the percent of the kernel powder used.

A total of 120 ml n-hexane was used as solvent to extract oil from a 10 g sample placed in the Soxhlet extraction apparatus (Sayyar et al., 2009). The seed kernel powder was placed in the thimble before setting in the Soxhlet extraction apparatus. The remaining n-hexane from extracted oil was removed at 40°C by using a rotary water bath evaporator. Finally, the amount of extracted oil was determined as the percentage of oil in seed kernel powder of Jatropha curcas. The oil sample was then stored in the refrigerator at −2°C for further analysis of oil properties.

The oil density and specific gravity were determined by Anton-Paar DMA 4500 density meter at 20 C in the laboratory.

The refractive index (RI) of the seed oil was determined by the transfer of a few drops of oil into the prism of the refractometer and determination was done at 40°C. RI determination was technically equivalent to ISO 6320:1995.

Several chemical properties of kernel oil such as % free fatty acid (FAA) content, iodine value, acid value, and saponification value were estimated by following Standard Tentative Methods of Analysis (AOCS, 1991).

The gross calorific or gross energy value known as high heating value (HHV) represents the amount of heat released by the oxidation of oil in the air as fuel. HHV is the amount of energy generated by the full burning of a unit amount of oil. The high heating value of kernel oil of Jatropha was calculated using an equation adopted from Demirbas (1998) using the derived amount of IV and SV:

SV = Soponification value.

IV = iodine value.

CN of the seed oil was estimated by using the equation suggested by Bose (2009).

SV = Saponification value.

IV = Iodine value.

Data were collected for each sample and replicated thrice for all parameters. SAS 9.2, a standard statistical package was used to analyze the data (SAS, 2010).

The percentage of seed kernel oil was extracted using the solvent extraction method from 10 different samples and the results are presented in Figure 1. Kernel oil extracted from different seed samples through n-hexane solvent extraction varied from 46.56 to 53.75 by %w.

The highest kernel oil content (53.75%) was obtained from the seed sample-9 of seven-year-old plants originating from Malaysia and the lowest (46.56%) in the seed sample-1 (2 years old plant) from Malaysia. The oil extracted from the seeds kernel of plants aged 4 years onward yielded maximum kernel oil content of >50% (Figure 1). On the other hand, hybrids produced higher amounts of seed oil compared to parental genotypes.

Irrespective of plant age, density of seed oil, SG, and RI index revealed non-significant variances among the samples (Table 2). Light yellow color of oil was observed for all the extracted samples. Seed oil density ranged from 0.898 to 0.945 amongst all seed samples. The seed sample-7 showed the highest oil density and seed sample-1 showed the lowest oil density.

The suitability of oil as feedstock for biodiesel production depends on the biochemical characteristics of seed oil of J. curcas. Pre-treatment of seed oil samples before alkaline transesterification is determined by biochemical characteristics of seed oil. FFA value, AV, IV SV of ten seed samples are presented in Table 3. Biochemical characteristics of the seed kernel oil of jatropha varied significantly irrespective of the age of the plant. Seed oil from sample-2 contained higher FFA content (7.78%) followed by sample-6 (6.34%) and sample-8 (6.00%) than other samples with FFA content between 1.26 and 4.69% (Table 3). None of the seed samples had FFA content <1% and only three seed samples (sample-1, sample-9, sample-10) obtained FFA content below 2% (1.68, 1.26, 1.31%).

The highest IV (104.45 mg/g oil) was observed in the kernel oil of sample-1 (2-year-old) and the lowest IV (99.10 mg/g oil) was found in sample 2 (3-year-old) (Table 3). Iodine value represents the content of unsaturated fatty acid.

The saponification value of seed oil among seed samples varied from 172.98 (sample-10) to 209.97 (sample-6) mg KOH/g and the average value for this study was 190.55 mg KOH/g (Table 3).

HHV and CN ranged significantly among the seed samples (Figures 2, 3). The high heating value varied (39.88–40.99 MJ/kg) among the oils of the seed samples depending on the genetic material and age of the plant (Figure 2). The seed sample-7 (5-year-old plant) stored at room temperature 6 months after harvest gave the highest HHV (40.99 MJ/kg) and the seed sample-6 (4-year-old hybrid 3) gave the minimum HHV (39.88). Most of the oil crops showed similar HHVs (39–40 MJ/kg) except castor oil (37.27 MJ/kg).

FIGURE 2. Effect of age of the plant and Jatropha genotype on high heating value (HHV) of the kernel oil sample.

The seed oil sample-8 (6-year-old plant) gave the highest CN (59.58) followed by the sample-5 (59.41), sample-2 (59.36) and the lowest (52.24) by the sample-1 (Figure 3).

The results obtained from seed kernel of Jatropha curcas in the current research follow the array of the oil percentage of 46–54% by weight found in the report (Pramanik, 2003; Azam et al., 2005). EL Kinawy (2010) also reported 43% oil in the seed kernel of Jatropha. Punia (2007) reported that seed oil content is expected to be maximum in 6-year-old plants. Jatropha seed kernel contains higher oil than the kernel of linseed, soybean, and palm oil (Gunstone, 2004). A significant increase in seed oil content was noted in Jatropha plants at the age above 4 years depending on genetic materials. Selected genotypes (parents and hybrids) contained a higher percentage of oil in their kernel compared to wild sources (Islam, 2011; Islam et al., 2012). Storage time also affects the kernel oil content in Jatropha seed and may be due to loss of water and physiological changes that occurs in the seed kernel during storage. The higher amount of seed kernel oil of Jatropha indicated its suitability as non-edible vegetable oil as feedstock for biodiesel production and other oleo-chemical industries. Jatropha curcas plantation yields 2000 L of oil per annum per hectare of land (Azam et al., 2005).

More energy is released from the oil with high density compared to oil with low density. The density of a material is defined as the measurement of its mass per unit volume (e.g., in g/ml). The density of vegetable oil is lower than water and the differences between vegetable oils are quite small, particularly among the common vegetable oils. Generally, the density of oil decreases with molecular weight, yet increases with unsaturation level (Gunstone, 2004). Specific gravity varied from 0.900 (sample-1) - 0.956 (sample-7) amongst the seed oil samples. Density and specific gravity are the most important factors in the injection systems of diesel fuel. For complete combustion, optimum or tolerable limits needs to be maintained to allow ideal air-to-fuel ratio. A high flow of air may lead to partial combustion of biodiesel fuel or its blend (Azam et al., 2005).

Free fatty acid (FFA) content is one of the most essential characteristics that represent oil quality. A higher FFA value exhibited a higher acid value in the oil sample. The suitability of Jatropha seed oil as feedstock for biodiesel production depends on its FFA content and high FFA content makes Jatropha oil unsuitable as feedstock. The transesterification process becomes complex if the oil sample contains a high amount of FFA due to the formation of soap with an alkaline catalyst (Canakci, 2007; Tiwari et al., 2007). This soap inhibits the separation process of biodiesel from glycerin (Demirbas, 2003). Canakci (2001) and Tiwari et al. (2007) recommended base transesterification to overcome bubbles (soap) formation from the oil with less (<1%) FFA content. Pretreatment with acid before transesterification was also suggested for feedstock with high FAA (>1%) values (Canakci and Gerpen, 2001; Dorado et al., 2002). The esterification reaction of the oil with an acid catalyst is an alternative (Crabbe et al., 2001), but it is 4,000 times slower than the transesterification with an alkaline catalyst. The acid-catalyzed process does not have the same acceptability as alkaline transesterification in industrial applications due to slow transesterification. Two-step esterification was also reported as another alternative process for the feedstock having high FFA content (Ghadge and Raheman, 2005; Veljkovic´ et al., 2006).

The age and quality of seed oil depend on acid value. The acid value of the present study ranged from 1.78 to 11.06 mg NaOH/g which indicated high FFA content but the value was relatively low compared to previous results obtained by other researchers (Emil et al., 2009; Belewu et al., 2010). The maximum acid value was observed in seed sample-2 (3-years-old) and minimum in seed sample-9 (7-years-old). The results indicated that oil properties are not affected by the age of the Jatropha plant but rather by genotype.

A higher amount of unsaturated fatty acid has been reflected by a higher iodine number in the oil sample (Knothe, 2005). Jatropha seed oil contains high iodine which is due to its high content of unsaturated fatty acids such as oleic and linoleic acid. Emil et al. (2009) reported 78.5% unsaturated fatty acid in the seed oil of Jatropha curcas. The high iodine value of Jatropha seed oil showed its suitability in the production of alkyle resin, shoe polish, and varnishes (Akintayo, 2004).

Jatropha seed oil has a high saponification value (Emil et al., 2009; Maricela Rodriguez et al., 2010; Antony Raja, 2011). A high saponification value indicates that Jatropha curcas seed oil contains typical triglycerides (Emil et al., 2009). The oil with a high saponification value required more base catalyst to neutralize existing FFA in the oil samples. The oils with high saponification value contain normal triglycerides which can be used in the shampoo and liquid soap industries.

High saponification values indicate the existence of a high proportion of FFA in the oil sample. The oil with a high saponification value infers the possibility of the formation of soap and problems in the separation of glycerin products during biodiesel production. This condition leads to a very low yield of biodiesel (methyl ester) using the oil sample with a high saponification value. Salimon and Abdullah (2008) described a similar characteristic of Jatropha seed oil of Malaysian origin.

Fatty acid methyl ester composition considerably influenced the cetane number (CN) of biodiesel fuels (Geller and Goodrum, 2004). Biodiesel fuel quality, especially ignition quality depends on CN of Jatropha seed oil (Bamgboye and Hansen, 2008). Cetane number quantify the suitability of the oil to automobile ignition after injection into the engine (Knothe, 2005). The cetane number of the biodiesel derived from soybean oil varied from 45 to 60 whereas biodiesel derived from canola oil varied from 48 to 61.2 (Demirbas, 2003; Bamgboye and Hansen, 2008). High cetane number accompanied by complete ignition and low cetane number were related to a reduced ignition value of the oil sample.

The current research was carried out to evaluate how genotype and plant age of an industrial plant, Jatropha curcas, affect the physico-chemical properties of seed kernel oil. It was observed that seed oil content varied among the genotype and is influenced by the age of the plant. The fatty acid content was observed higher in the plants with younger age compared to older ones, which affects the transesterification process during biodiesel production. The highest iodine value was found in the seed oil of a seven-year-old plant and the lowest in a three-year-old plant. The seed oil of a 10-year-old plant gave the lowest saponification value and Hybrid-3 (four-year-old) plants gave the highest value. It could be concluded based on the above findings that the physico-chemical properties are greatly influenced by the age and genotype of the Jatropha curcas plant.

The original contributions presented in the study are included in the article/supplementary materials, further inquiries can be directed to the corresponding authors.

All authors contributes: Conception or design of the work Data collection Data analysis and interpretation Drafting the article Critical revision of the article Final approval of the version to be published.

The authors acknowledge the support of Taif University Researches Supporting Project number: (TURSP-2020/82), Taif University, Taif, Saudi Arabia. The project is financed by the Universiti Kebangsaan Malaysia, under the Grants UKM-AP-2012–008 and UKM-DPP-2013–108.

The authors would like to thank the university authority for financial support. The authors thanks to (TURSP-2020/82), Taif University, Taif, Saudi Arabia. The authors also would like to acknowledge their gratitude towards the university authority for the support from Bangabandhu Sheikh Mujibur Rahman Agricultural University, Gazipur 1706, Bangladesh.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Achten, W. M. J., Nielsen, L. R., Aerts, R., Lengkeek, A. G., Kjær, E. D., Trabucco, A., et al. (2010). Towards domestication of Jatropha curcas. Biofuels 1, 91–107. doi:10.4155/bfs.09.4

Akintayo, E. T. (2004). Characteristics and composition of Parkia biglobbossa and Jatropha curcas oils and cakes. Bioresour. Technol. 92, 307–310. doi:10.1016/s0960-8524(03)00197-4

Antony Raja, S., Robinson Smart, D. S., and Lindon Robert Lee, C. (2011). Biodiesel production from Jatropha oil and its characterization. Res. J. Chem. Sci. 1, 81–87.

Aocs (1991). “Official test method Ca 14-56 for total, free and combined glycerol (Iodometric-Periodic acid method,” in Proceedings of the Official Methods and Recommended Practices of the American Oil Chemists Society. Champaign, IL: AOCS.

Azam, M., Waris, A., and Nahar, N. M. (2005). Prospects and potential of fatty acid methyl esters of some non-traditional seed oils for use as biodiesel in India. Biomass Bioenergy 29, 293–302. doi:10.1016/j.biombioe.2005.05.001

Bamgboye, A. I., and Hansen, A. C. (2008). Prediction of cetane number of biodiesel fuel from the fatty acid methyl ester (FAME) composition. Int. Agrophys. 22, 21–29.

Belewu, M. A., Adekola, F. A., Adebayo, O. M., Ameen, N. O., Muhammad, A. M., et al. (2010). Physico-chemical characteristic of oil and biodiesel from Nigerian and Indian, Jatropha curcas seeds. Int. J. Biol. Chem. Sci. 4, 524–529. doi:10.4314/ijbcs.v4i2.58169

Bose, P. K. (2009). Retracted article: Empirical approach for predicting the cetane number of biodiesel. Int. J. Automot. Technol. 10, 421–429. doi:10.1007/s12239-009-0048-7

Canakci, M., and Gerpen, J. V. (2001). Biodiesel production from oils and fats with high free fatty acids. Trans. ASAE 44, 1429–1436.

Canakci, M. (2007). The potential of restaurant waste lipids as biodiesel feedstocks. Bioresour. Technol. 98, 183–190. doi:10.1016/j.biortech.2005.11.022

Charlene, A., Markolwsi, W., Kichere, A., and Saling, P. (2004). Using eco-efficiency analysis to assess renewable-resource-based technologies. Environ. Prog. 23, 329–333. doi:10.1002/ep.10051

Crabbe, E., Nolasco-Hipolito, C. N., Kobayashi, G., Sonomoto, K., and Ishizaki, A. (2001). Biodiesel production from crude palm oil and evaluation of butanol extraction and fuel properties. Process Biochem. 37, 65–71. doi:10.1016/s0032-9592(01)00178-9

Demirbas, A. (2003). Biodiesel fuels from vegetable oils via catalytic and non-catalytic supercritical alcohol transesterifications and other methods: A survey. Energy Convers. Manag. 44, 2093–2109. doi:10.1016/s0196-8904(02)00234-0

Demirbas, A. (1998). Fuel properties and calculation of higher heating values of vegetable oils. Fuel 77, 1117–1120. doi:10.1016/s0016-2361(97)00289-5

Demirbas, A. (2009). Progress and recent trends in biodiesel fuels. Energy Convers. Manag. 50, 14–34. doi:10.1016/j.enconman.2008.09.001

Dorado, M. P., Ballesteros, E., Almeida, J. A., Schellert, C., Lohrlein, H. P., and Krause, R. (2002). An alkali-catalyzed transesterification process for high free fatty acid waste oils. Trans. ASAE 45, 525–529. doi:10.13031/2013.8849

El Kinawy, O. S. (2010). Characterization of Egyptian jatropha oil and its oxidative stability. Energy Sources Part A Recovery Util. Environ. Eff. 32, 119–127. doi:10.1080/15567030802089102

Emil, A., Yaakob, Z., Kamarudin, S. K., Ismail, M., and Salimon, J. (2009). Characteristics and composition of Jatropha curcas oil seed from Malaysia and its potential as biodiesel feedstock. Eur. J. Sci. Res. 29, 396–403.

Emil, A., Yaakob, Z., Kumar, M. N. S., Jahim, J. M., and Salimon, J. (2010). Comparative evaluation of physicochemical properties of jatropha seed oil from Malaysia, Indonesia and Thailand. J. Americ. Oil Chem. Soc. 87, 689–695. doi:10.1007/s11746-009-1537-6

Fao (2009). World cropped area, yield and production of oil bearing crops. Available at: http://www.fao.org/economic/ess/chartroom-and-factoids/chartroom/36-world-cropped-area-yield-and-production-of-oil-bearing-crops/en/.

Geller, D. P., and Goodrum, J. W. (2004). Effects of specific fatty acid methyl esters on diesel fuel lubricity. Fuel 83, 2351–2356. doi:10.1016/j.fuel.2004.06.004

Ghadge, S. V., and Raheman, H. (2005). Biodiesel production from mahua (Madhuca indica) oil having high free fatty acids. Biomass Bioenergy 28, 601–605. doi:10.1016/j.biombioe.2004.11.009

Gunstone, F. D. (2004). Rapeseed and canola oil: Production, processing, properties and uses. London: Blackwell Publishing Ltd.

Heller, J. (1996). Physic nut (Jatropha curcas L.). Promoting the conservation and use of underutilized and neglected crop. Institute of Plant Genetics and Crop Plant Research, Gatersleben/International Plant Genetic Resources Institute, Rome.

Islam, A. K. M. A. (2011). Improvement of biodiesel production through genetic studies of Jatropha curcas. Ph D Thesis. Malaysia, Bangi: Department of Chemical and Process Engineering, Universiti Kebangsaan, 43600.

Islam, A. K. M. A., Yaakob, Z., Anuar, N., Primandari, S. R. P., and Osman, M. (2012). Physiochemical properties of Jatropha curcas seed oil from different origins and candidate plus plants (CPPs). J. Americ. Oil Chem. Soc. 89, 293–300. doi:10.1007/s11746-011-1908-7

Kaushik, N., Kumar, K., Kumar, S., Kaushik, N., and Roy, S. (2007). Genetic variability and divergence studies in seed traits and oil content of jatropha (Jatropha curcas L.) accessions. Biomass Bioenergy 31, 497–502. doi:10.1016/j.biombioe.2007.01.021

Knothe, G. (2005). Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process. Technol. 86, 1059–1070. doi:10.1016/j.fuproc.2004.11.002

Kumar, S., Shukla, S. D., Gautam, P. K., Kato, S., and Kojima, T. (2011). Effect of climate and soil condition on oil content of jatropha plants grown in arid areas of India. J. Arid. Land Stud. 21, 51–55.

Kureel, R. S. (2006). “Prospect and potential of Jatropha curcas for biodiesel production,” in Biodiesel – towards energy independence. Editors B Singh, R. Swaminathan, and V. Ponraj (New Delhi: Rashtrapathi Bhawan), 374.

Maricela Rodriguez, A., Jesus Santival, R., and Reyna Zeferino, D. (2010). Extraction and characterization of oils from three Mexican Jatropha Species. J. Mex. Chem. Soc. 54, 88–91.

McGinley, M., and Clough, L. D. (2010). Climate of Malaysia. In: Encyclopedia of earth. Eds. Cutler J. Cleveland (Washington, D.C.: Environmental Information Coalition, National Council for Science and the Environment.

Openshaw, K. (2000). A review of Jatropha curcas: An oil plant of unfulfilled promise. Biomass Bioenergy 19, 1–15. doi:10.1016/s0961-9534(00)00019-2

Oyekunle, J. A. O., Elugoke, S. E., Adekunle, A. S., Ojo, O. S., Oyinloye, A. J., Fakoya, O. T., et al. (2019). Biodiesel potentials and lubricating properties of citrus sinensis seed oil. Int. J. Bioorg. Chem. 4 (2), 84–92. doi:10.11648/j.ijbc.20190402.11

Pramanik, K. (2003). Properties and use of Jatropha curcas oil and diesel fuel blends in compression ignition engine. Renew. Energy 28, 239–248. doi:10.1016/s0960-1481(02)00027-7

Punia, M. S. (2007). Cultivation and use of jatropha for bio-diesel production in India. Status Paper on different aspects of Jatropha plantation and processing, Natl. Oilseeds Veg. Oils Dev. Board, Ministry Agric. Govt India, 86, Sector-18, Gurgaon -122015, Haryana, India.

Salimon, J., and Abdullah, R. (2008). Physicochemical properties of Malaysian Jatropha curcas seed oil. Sains Malays. 37, 379–382.

SAS, . (2010).SAS/STAT user installation guide for SAS® 9.2 Foundation for Microsoft® Windows®”, SAS Institute Inc., Copyright® 2003, Cary, North Carolina, USA.

Sayyar, S., Abidin, Z., Yunus, R., and Muhammad, A. (2009). Extraction of oil from jatropha seeds-optimization and kinetics. Am. J. Appl. Sci. 7, 1390–1395. doi:10.3844/ajassp.2009.1390.1395

Sirisomboon, P., Kitchaiya, P., Pholpho, T., and Mahuttanyavanitch, W. (2007). Physical and mechanical properties of Jatropha curcas L. fruits, nuts and kernels. Biosyst. Eng. 97, 201–207. doi:10.1016/j.biosystemseng.2007.02.011

Sirisomboon, P., and Kitchaiya, P. (2009). Physical properties of Jatropha curcas L. kernels after heat treatments. Biosyst. Eng. 102, 244–250. doi:10.1016/j.biosystemseng.2008.11.003

Tiwari, A., Kumar, A., and Raheman, H. (2007). Biodiesel production from Jatropha oil (Jatropha curcas) with high free fatty acids: An optimized process. Biomass Bioenergy 31, 569–575. doi:10.1016/j.biombioe.2007.03.003

Veljkovic´, V. B., Lakicevic, S. H., Stamenkovic, O. S., Todorovic, Z. B., and Lazic, K. L. (2006). Biodiesel production from tobacco (Nicotiana tabacum L.) seed oil with a high content of free fatty acids. Fuel 85, 2671–2675. doi:10.1016/j.fuel.2006.04.015

Keywords: jatropha, seed kernel, oil content, age of plant, hybrids, renewable energy, biofuel

Citation: Islam AKMA, Yaakob Z, Ghani JA, Alareefy A, Abdulsalam NM, Khateeb NA, Zidan N, Abdelazi MA, El Sabagh A, Sakran MI, Omran A, El Askary A, El-Sharnouby M, Aziz albalawi M and Mominul Islam AKM (2022) Genotype and age of industrial plant Jatropha curcas L. affect physico-chemical properties of seed oil. Front. Energy Res. 10:979217. doi: 10.3389/fenrg.2022.979217

Received: 29 June 2022; Accepted: 06 September 2022;

Published: 13 October 2022.

Edited by:

Eriola Betiku, Obafemi Awolowo University, NigeriaReviewed by:

John Oyekunle, Obafemi Awolowo University, NigeriaCopyright © 2022 Islam, Yaakob, Ghani, Alareefy, Abdulsalam, Khateeb, Zidan, Abdelazi, El Sabagh, Sakran, Omran, El Askary, El-Sharnouby, Aziz albalawi and Mominul Islam. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: A. K. M. Aminul Islam, YW1pbnVsZ3BiQGJzbXJhdS5lZHUuYmQ=; Ayman El Sabagh, YXltYW4uZWxzYWJhZ2hAYWdyLmtmcy5lZHUuZWc=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.