- School of Management, Guangzhou University, Guangzhou, China

Recycling and remanufacturing waste electrical and electronic equipment (WEEE) can promote the comprehensive utilization of resources and promote the development of the circular economy. However, there are associated risks involved. This study explored the effectiveness of risk control in the WEEE closed-loop supply chain to provide decision support in the sustainable development of WEEE. The catastrophe progression method was used for risk evaluation, and the WEEE risk control model was constructed using system dynamics to analyze the influence of risk control strategies. The results show that adopting risk control strategies positively promotes risk control. Risk mitigation is most pronounced when both the fund subsidy and the green and low-carbon strategies are adopted. When only one approach is implemented, the green and low-carbon strategy has a more considerable effect. When the intensities of the mitigation measures are improved to the same extent, the risk control effect generated by the fund subsidy strategy was found to have a greater impact. The findings provide a useful reference for formulating subsequent risk control strategies in the WEEE closed-loop supply chain.

1 Introduction

The development of science and technology and the progress of society have prompted the continuous innovation of electronic products. In particular, notebook computers and mobile phones are being improved, upgraded, and updated at very fast rates. Because of this, many electronic and electrical products are being disposed of or discarded. In China, according to a white paper on the Waste Electrical and Electronic Equipment (WEEE) recycling industry, the theoretical amount of scrap TV sets, refrigerators, washing machines, air conditioners, and microcomputers in 2020 was about 189 million and is estimated to grow at an annual rate of 3%–5% (Shittu et al., 2021). By 2030, global e-waste is expected to reach 74.7 million tons (Houessionon et al., 2021).

WEEE has a tremendous recycling value. For example, the medals for the 2020 Tokyo Olympic Games were made of raw materials extracted from discarded electronic products. But if not properly disposed of or discarded, WEEE can harm the environment and the human body. For example, several heavy metals, especially Cd, Cu, Pb, and Zn, were found to exceed acceptable levels in the farmland soils near an e-waste removal area in Qingyuan, Guangdong province. Cadmium (Cd) and copper (Cu), even at low-level exposures, may pose significant health risks (Zhang et al., 2015; Wu et al., 2018). In another study, the heavy metals (e.g., Cd, Ni, Pb, Cu, Zn, and Cr) in the surface sediments of nearby river outlets exceeded China’s third-level environmental quality standards for soils (GB15618-1995) (Lin et al., 2015).

In the recycling and dismantling of electronic waste, useful substances are extracted through acid-base soaking, incineration, heating, and melting. But due to atmospheric deposition and rainwater runoff, huge quantities of broken particles, fly ash, residues, and pickling wastewater are produced from the processing of electronic waste. High amounts of toxic and harmful heavy metals and organic pollutants are directly introduced into the environment and pollute the local ecology (Lin et al., 2015; Zhang et al., 2015).

The closed-loop supply chain refers to a completely closed-loop system formed by considering reverse logistics based on the traditional forward supply chain. The closed-loop supply chain of waste electrical and electronic products comprises various processes, such as recycling and remanufacturing. Proper recycling and disposal of WEEE promotes the comprehensive utilization of resources and the development of a circular economy and protects the environment and human health. However, there are numerous complexities and associated risks in the recycling process.

First, the source channels of recycling WEEE are complex and are mainly divided into formal and informal recycling. When recycling through formal channels has considerably fewer safety risks, its proportion is minuscule. According to the latest survey of WEEE processing enterprises by the China Household Electric Appliance Research Institute, among the waste products processed in 2020, the recycling through formal channels of TV sets accounted for 2.7%, refrigerators 2.6%, washing machines 2.7%, room air conditioners 8.3%, and microcomputer 8.9%. In comparison, the recycling from informal channels of TV sets, refrigerators, washing machines, room air conditioners, and microcomputers accounted for 78.0%, 78.2%, 77.7%, 77.0%, and 75.4%, respectively.

Second, the WEEE recycling process is complicated and includes recycling, disassembly, and classification, among others. The process has many links, scattered management, and weak points.

Third, informal dismantling activities are extremely harmful. The dismantling process of WEEE for reuse needs corresponding technical support. In China, the dismantling of WEEE is mainly a combination of manual dismantling and mechanical processing. Informal dismantling activities can adversely affect the environment and cause physical harm to the dismantling personnel. According to professionals, WEEE contains a large number of polluting elements, which can be toxic to the human body. For example, making a computer requires more than 700 kinds of chemical materials, of which more than 300 are harmful to human beings. At the same time, WEEE generally contains Pb, Cd, Hg, and other harmful materials. These elements will not cause damage to the human body when using electronic products normally but will cause a lot of pollution to the informal disassembly of WEEE.

To address these concerns, a system dynamics model was developed that explores and analyzes effective solutions dealing with the various risks in the WEEE recycling process. The rest of the article is arranged as follows. The second section presents the literature review, and the risk analysis of WEEE is shown in the third section. The fourth section constructs and tests the system dynamics model, while the fifth section analyzes the simulation results of the model. The management implications are discussed in the sixth section, and the study conclusions are presented in the seventh section.

2 Literature review

2.1 Recycling and policy strategy of waste electrical and electronic equipment

Due to the rapid industrialization and urbanization in recent years, setting and achieving sustainable development goals are critically needed (Shahsavar et al., 2022). More research on sustainability continues to be concerned. Ghoushchi et al. (2021) proposed a novel approach for selecting the optimal landfill for medical waste using Multi-Criteria Decision-Making methods. Sadri et al. (2021) provided a good multidimensional evaluation of the status of ports to formulate development policies and create green ports. Pang et al. (2022) proposed to separate particles according to density, and it is applied to the recovery of lithium iron phosphate from spent lithium battery materials.

The recycling and management of electronic products have become a major research focus in various fields. For example, Besiou et al. (2012) and Ardi and Leisten (2016) explored and analyzed the problems associated with the informal recycling of electronic products. Rautela et al. (2021) concluded that establishing an environmentally friendly recycling regulatory system would help maintain a sustainable and resilient environment while minimizing adverse impacts. Guo et al. (2021) measured the environmental benefits of recycling and processing of WEEE and analyzed the spatial distribution of ecological benefits to promote the rational planning and layout of the recycling and processing system.

With the gradual deepening of research on the recycling of electronic waste products, relevant studies have been conducted on the reward and punishment mechanisms and fund systems for WEEE. Wang and Da (2010; 2013) discussed the optimal parameters of the government reward and punishment mechanism of the reverse supply chain of electronic products and studied decision-making in electronic waste recycling under the government’s reward and punishment mechanism. Luo and Wang (2020) evaluated the strategy of a government subsidy closed-loop supply chain from the perspective of product greenness. Xiang et al. (2017) analyzed the problems in the fund subsidy system of waste household appliances. Zhao et al. (2018) discussed a more innovative incentive and constraint mechanism for recycling and explored the impact of fund policies for recycling treatment on production and recycling enterprises. Wang and Shen (2018) studied the restructuring of the closed-loop supply chain structure and the modification of its operation mode under the fund system of WEEE treatment and the new policy. Zhao et al. (2020) analyzed the effectiveness of the reward and punishment mechanism for the implementation of the EPR system and constructed a more effective producer-led reverse closed-loop supply chain model.

2.2 Risk management of the supply chain

Traditional research on supply chain risk management includes risk identification, assessment, and control. Kleindorfer and Saad (2005) identified and classified risks from the perspective of supply chain design and management. They divided supply chain risk into external contingencies and internal risk factors that coordinate the complex system of supply and demand. Wagner and Bode (2008) grouped the supply chain risk sources into five categories: demand-side, supply-side, infrastructure, catastrophic, and regulatory, legal, and bureaucratic. Wang et al. (2012) blended fuzzy logic with the analytic hierarchy process to analyze the overall risk of the fashion supply chain under the green initiative. Ye and Liu (2017) used knowledge-based risk control assessment to share real-time supply chain decision-making knowledge and proposed a knowledge management-based supply-chain risk-control assessment model. Ruan et al., (2021) proposed a combined optimal control method for the pollution risks in the smart cold chain for drinking water.

Several scholars also conducted research on the different types of risk preferences. For example, using system dynamics, Li et al. (2021) studied the influence of retailers’ wind avoidance behavior on the whole fresh supply chain. Zhang and Zhang (2021) and Shi et al. (2021) studied the different decisions of risk-averse retailers in the dual-channel closed-loop supply chain. The former focused on the pricing of the supply chain, while the latter focused on the influence of the degree of risk-averse behaviors of retailers in different dual-recovery channels. Wang et al. (2021) analyzed the manufacturer-dominated supply chain and introduced the fairness preference factor into the supply chain risk transfer to explore the utility and internal mechanism of member fairness preference in the pricing and income risk transfer caused by production cost fluctuations. Gu and Zhang (2016) studied the two-stage supply chain composed of risk-neutral suppliers and loss-averse retailers and investigated the retailer’s order decision-making behavior and the coordination function of revenue-sharing contracts under loss aversion.

In addition to traditional supply chain risk research, other scholars have also explored supply chain risk management with reverse logistics. Lundin (2012) discussed the changes in system risks under different closed-loop supply chain channel structures using case studies. Nakashima and Gupta (2012) designed a multi-kanban system to reduce closed-loop supply chain risks. He (2017) focused on different supply risk-sharing contract designs in the recycling process and examined the impact of supply and demand risk reduction on the financial and environmental performance of closed-loop supply chains. Jabbarzadeh et al. (2018) proposed a stochastic robust optimization model for closed-loop supply chain networks with strong adaptability for different disruption risk situations.

In summary, research on electronic products and traditional positive supply chain risk management has achieved certain results. However, the current research on e-waste has mainly focused on the recycling channels, methods, government regulations, and the fund system rewards and punishments. In addition, traditional studies on supply chain risks have concentrated on the risk management side and the different risk preference types of supply chain members, largely overlooking the closed-loop supply chain risk management for waste electrical and electronic equipment and control. Based on this, this study analyzed the risks in the WEEE closed-loop supply chain and used the catastrophe progression method for risk assessment. A system dynamics model, which includes a closed-loop supply chain process, was developed to explore effective risk control measures in the WEEE closed-loop supply chain and provide decision support for green management and sustainable development of e-waste.

3 Risk source analysis of the closed-loop supply chain of waste electrical and electronic equipment

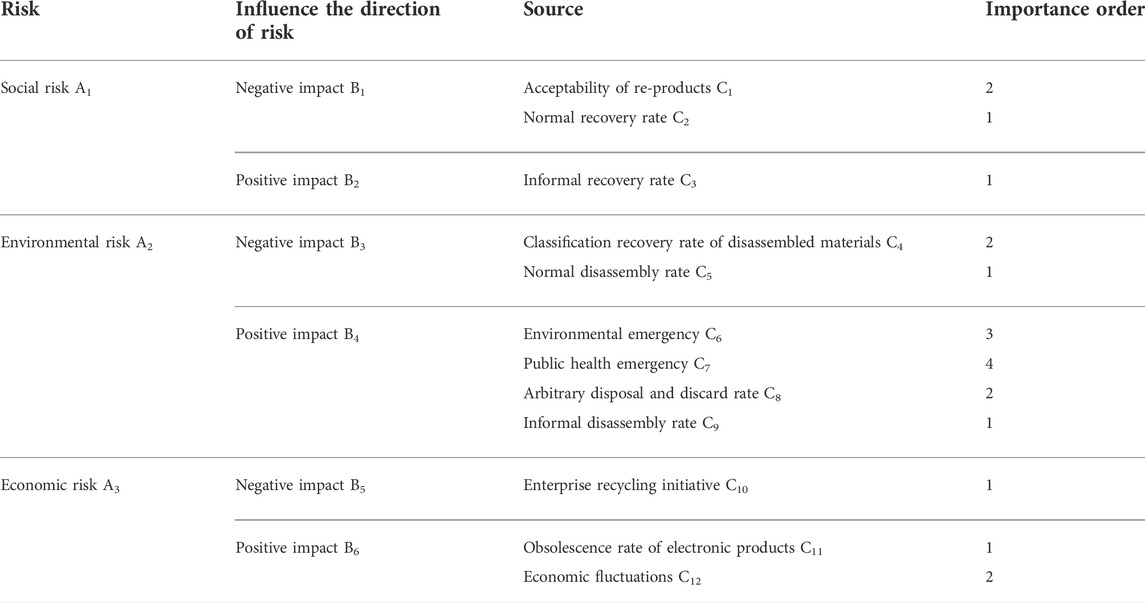

Identification of risk sources is the basis of effective risk control. In this study, from the perspectives of society, economy, and environment (A1, A2, and A3), the recycling, disassembly, classification, and recovery of WEEE in the closed-loop supply chain were considered in identifying significant sources of risks. As risk sources have varying influences on risk levels, the subdivision index was divided into positive factors (B2, B4, and B6) that increase risks and negative factors (B1, B3, and B5) conducive to risk reduction. Using the subdivision index, the importance of each source was ranked (1>2>3>4), as shown in Table 1.

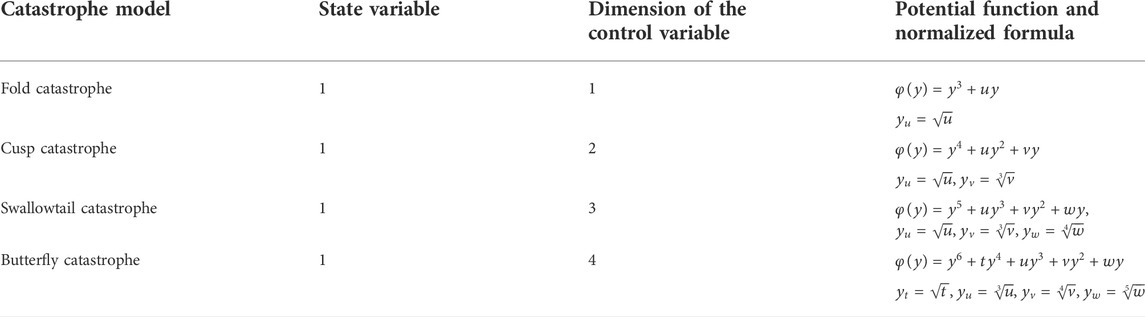

The catastrophe progression method is a comprehensive evaluation method based on fuzzy mathematics and the catastrophe theory, developed in 1972 by the French mathematician Rene Thom. There are four common catastrophe models (Table 2). In the table, t, u, v, and w represent external control variables, which are taken into the normalization formula, according to the importance of indicators. For the complementarity between indicators, the average value is used to optimize the difference between indicators. The non-complementary indicator set adopts the “minimum criterion” to determine the catastrophe level value, thereby realizing the quantitative and comprehensive evaluation of the system.

According to the catastrophe model based on the catastrophe progression method (Zhou and Zhang, 2008), B1, B3, and B6 belong to the cusp catastrophe, B2 and B5 belong to the fold catastrophe, and B4 belongs to the butterfly catastrophe. In this study, the data were collected using questionnaires and from relevant reports from the Ministry of Ecology and Environment of the People’s Republic of China and the China Household Electric Appliance Research Institute. Based on the principles of complementarity and importance ranking, the relative importance of the risk segmentation index was obtained, and each weight after normalized treatment was determined.

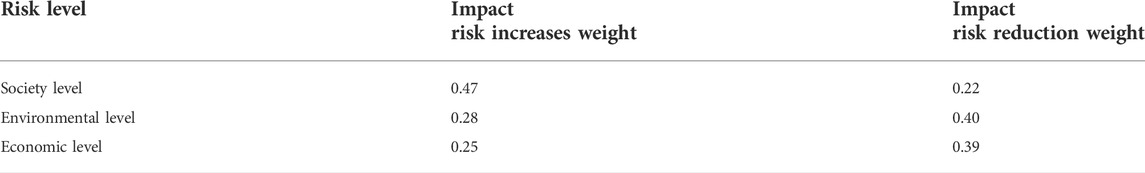

As shown in Table 3, the increased weight of impact risks accounts for the same proportion at the environmental and economic levels and has the largest proportion at the social level. The reason is that the recovery rate of informal recovery is several times higher than that of formal recovery. At the environmental level, according to China’s Ministry of Ecology and Environment, the formal disassembly rate for WEEE officially recycled is 81.82%, while the classified recovery rate for disassembled products is 98.9%. This means that the weight of risk increase is small. Similarly, the weight of risk reduction at the environmental level accounts for the largest proportion. Therefore, in order to control the risk of the closed-loop supply chain of WEEE, it is necessary to focus on the recycling link.

4 Simulation model of the closed-loop supply chain risk control for waste electrical and electronic equipment

4.1 Modeling

System Dynamics, developed by Jay Wright Forrester, is a method suitable for dealing with large-scale interactions and modeling complex dynamic systems (Hernandes Pinha and Sagawa, 2020). The system dynamics models are usually constructed and simulated by computer software. In this study, the model construction was implemented by Vensim PLE (a piece of software to construct models and simulations for System Dynamics). Based on the risk analysis results, we used system dynamics to construct a closed-loop supply-chain risk-control model for waste electrical and electronic equipment. The model was developed by accounting for the relevant social, environmental, economic, and other influencing factors and considering the main process of the WEEE closed-loop supply chain.

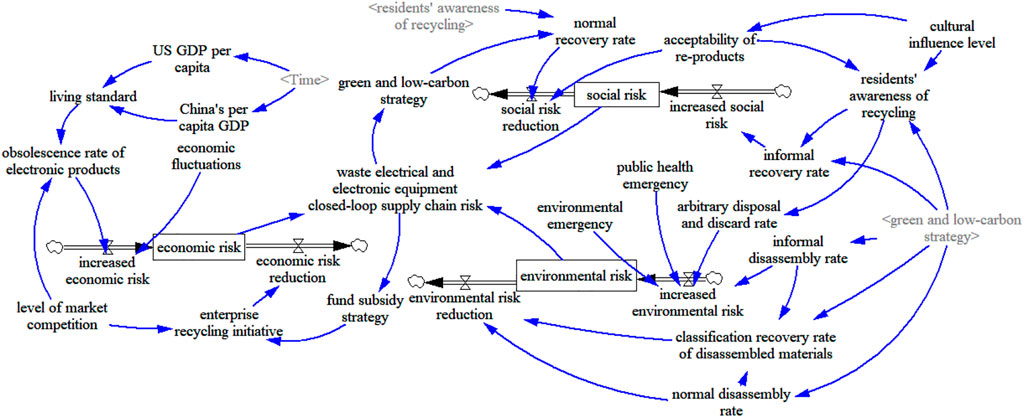

The causality diagram is shown in Figure 1. At the social level, increasing the cultural influence and acceptability of re-products can improve consumer awareness of recycling, encourage formal recycling, and reduce informal recycling. At the environmental level, the actual environmental damage is mainly caused by the dismantling process. The classification and recycling of disassembled materials are promoted in both formal and informal dismantling, but the efficiency is considerably higher in the formal process. The increase in consumer recycling awareness can encourage the reduction of arbitrary disposal and discard behavior. Finally, at the economic level, the faster the elimination of electronic products, the faster the risk increase, and the more active formal recycling and processing enterprises participate in the risk reduction.

Variables with different properties (e.g., level variable, rate variable, and auxiliary variable) and constants can be introduced through the causality analysis. In the stock-flow diagram presented in Figure 2, the social, environmental, and economic risks are the level variables, the increase or decrease of risks are the rate variables, and the green and low-carbon strategy and fund subsidy strategy are the control strategies.

4.2 Model hypothesis and parameter settings

4.2.1 Model hypothesis

Based on the risk analysis and model construction, the following hypotheses are proposed:

(1) The change in the risk system of the closed-loop supply chain of WEEE is caused by the interaction of various factors within the system, and other factors outside the system are not within the scope of the study.

(2) If there is a negative value of the risk, it means that the risk is within an acceptable range. Being no unit of risk, if there is a negative value in the change of the risk of the closed-loop supply chain of WEEE, it does not mean that there is no risk, so a negative value means that the risk is within an acceptable range.

4.2.2 Model expression setting and variable description

Vensim PLE software was also used for simulation in this study. The running cycle was set to 50 years, and the simulation step was set to 1 year. In quantifying the variables, the risk weights for the three levels were calculated using the catastrophe progression method. The relevant values of the per capita GDP were predicted by SPSS software. The initial data for the three variables (i.e., obsolescence rate of electronic products, acceptability of re-products, and consumer awareness of recycling) were obtained by questionnaire survey. Parameters on public health and environmental emergencies were obtained from the Health Commission of Guangdong Province and the China Statistical Yearbook. Other data were acquired from relevant reports from the Ministry of Ecology and Environment and the China Household Electric Appliance Research Institute.

The original data collected were processed between (0, 1); for those without specific values, the evaluation standard was defined: high −0.75, medium −0.5, and low −0.25. Some equations were adjusted in consideration of different influences of risk sources. Other indicators and dimensions were not processed here.

The main equation expressions are shown in Table 4. For variables such as the acceptability of re-products and the normal recovery rate, the maximum value is 1; for variables such as the informal recovery rate and informal disassembly rate, the minimum value is 0. For the expression of the enterprise recycling initiative, the enterprise recycling initiative is between (0, 1).

4.3 Model test

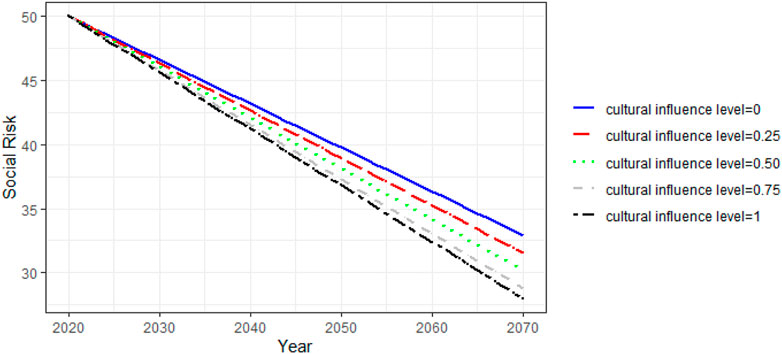

Vensim PLE software was used to check and verify the feasibility of the model logic. For the sensitivity analysis, since cultural factors mainly affect risks at the social level, they are selected when evaluating the social risks without changing the other parameters. According to previous research (e.g., Mintz et al., 2019) on the cultural impact on waste recycling and waste minimization, the level of socio-cultural influence in environmental protection in China remains relatively low, so the initial value for cultural influence in the model was set to 0.25.

The sensitivity test results are shown in Figure 3. As shown in Figure 3, when the level of cultural influence changes uniformly, the social risks also change in a consistent trend. At the higher levels of cultural influence, the decrease in social risks became more pronounced. This suggests that the model has a high sensitivity to the variable intensity of cultural influence. The sensitivity test results were consistent with the findings of Mintz et al. (2019), highlighting the importance of incorporating cultural factors into waste management strategies. Improving the socio-cultural influence levels would have a significant impact on consumer awareness toward recycling and, to a certain extent, preference for remanufactured products, thus effectively reducing social risks.

5 Analysis of simulation results

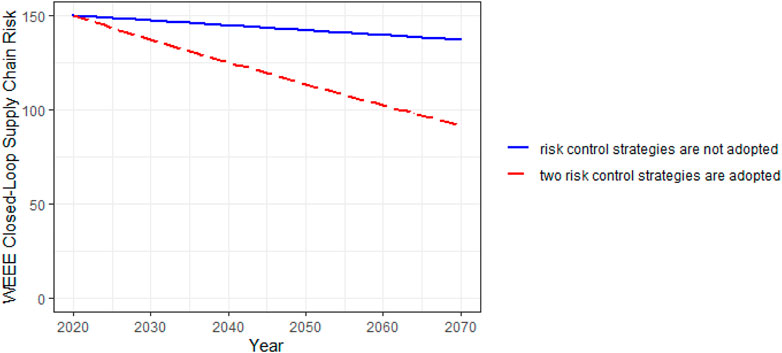

5.1 Simulation of risk control strategy adopted or not

Without changing the other variable parameters, the influence of the risk control strategy on the closed-loop supply chain risk of WEEE was explored, and the results are shown in Figure 4. As shown in the figure, when neither the fund subsidy strategy nor the green and low-carbon strategy is adopted, the closed-loop supply chain risk of WEEE shows a downward trend; however, the change range becomes relatively small when both control strategies are adopted. This suggests that to a certain extent, fund subsidies and other policies related to electronic products can improve the closed-loop supply chain of electronic products.

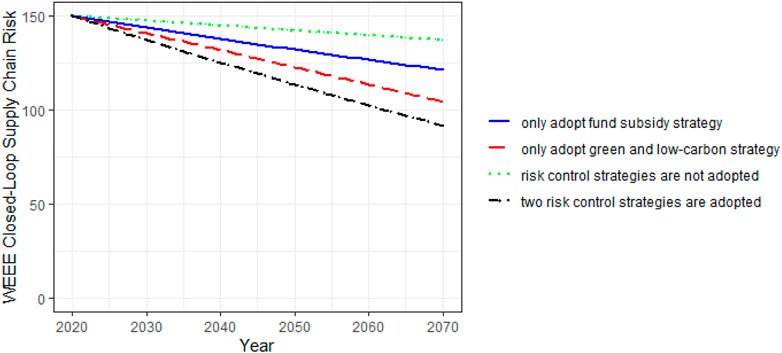

5.2 Simulation of the risk control strategy combination

Leaving the other variable parameters unchanged, four risk control strategy combinations were simulated: completely risk-free, only green and low-carbon, only fund subsidy, and combined risk control strategies. The simulation results in Figure 5 show that among the four combinations, risk reduction is greatest when the combined risk control strategies are adopted. In addition, risk reduction is greater when adopting green and low-carbon strategies compared to the fund subsidy measure.

The results suggest that green and low-carbon strategies and fund subsidies can promote risk mitigation, with the former having a greater degree of promotion. This may be because policies and regulations, when properly enacted, can significantly influence society and affect governance and management. For fund subsidies, while they can mitigate risks, their impact may be weaker, given that the fund review system is complex and often delayed and that the binding force for fund subsidies is often difficult to ensure.

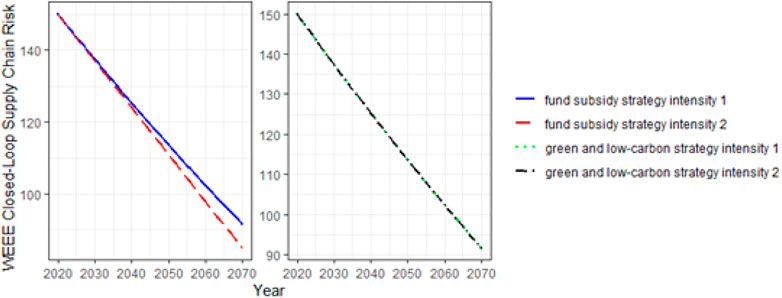

5.3 Simulation of the risk control intensity

Leaving the other variable parameters unchanged, the intensities for fund subsidies and green and low-carbon strategies were doubled, and the effects of different risk control measures were analyzed. As shown by the results in Figure 6, when the fund subsidy intensity is high, the risk reduction is faster, and the degree of decline is also greater. However, when the intensity of green and low-carbon strategies is increased, the change in the downward trend in risk is minimal. This suggests that when increasing the intensity of green and low-carbon strategies can mitigate risks, its impact is comparatively low.

6 Discussions and management implications

Based on the abovementioned findings, we propose the following management implications:

First, the recycling of WEEE is an important part of the closed-loop supply chain. In the recycling industry, enterprises should have a firm understanding of risk levels and put in place regulatory measures, such as product recovery prior to classification and corresponding rules for recycling. In addition, enterprises should strictly control the disassembly process, enact standards for the classification and recycling of dismantled materials, and conduct proper training for participants. Given that informal recycling is difficult to manage and accounts for a high proportion of the problem, enterprises should learn the best practices in recycling from developed countries and integrate them into their system.

Second, the fund subsidy strategy is an effective means to reduce WEEE risks in China. However, when implementing such a strategy, several problems and limitations may arise, such as insufficient subsidy intensity and long subsidy cycles. The standardization of fund subsidies should be further studied, analyzed, and improved.

Third, green and low-carbon strategies play a positive role in reducing WEEE risks. The government should formulate corresponding policies and regulations to improve enterprise operations and make them more standardized. The policy is conducive to market stability and can have direct and indirect effects on recycling. For example, the policy may affect consumer awareness, behavior, and enthusiasm for recycling, incentivizing the recycling of electronic and electrical waste and encouraging consumers to choose formal recycling channels.

Finally, although enhancing the intensity of risk control strategies can promote risk mitigation, the measures and strategies should be first evaluated in order to make them more effective. Our results show that even if control strategies are increased, there are times when the effect may not be significant, and implementing them would be unwarranted, given the associated costs. Therefore, determining the optimal intensity of the risk control strategy is very important.

7 Conclusion

In this study, we analyzed the relevant risk factors in recycling WEEE and used the catastrophe progression method to determine risk weights. We then constructed a system dynamics model for the simulation analysis and analyzed the impact of risk control strategies on mitigating recycling risks. The research conclusions are as follows:

(1) When both the fund subsidy and the green and low-carbon strategies are adopted, the closed-loop supply chain risk for WEEE declines faster and is more pronounced than if no control strategy is adopted. Reasonable and effective control strategies are conducive to risk reduction in the closed-loop supply chain of WEEE. Although many developed countries have achieved great results, in China, WEEE recycling needs to be significantly improved.

(2) Risk reduction is greatest when both the fund subsidy and the green and low-carbon strategies are adopted. When only one approach is adopted, implementing the green and low-carbon strategy was found to have a greater mitigation effect. The effect on risk control is better when all risk control strategies are adopted. But given the associated costs of implementing different strategies, balancing the economic and social benefits of recycling measures is very important.

(3) The greater the degree of risk control, the more pronounced the downward trend of the closed-loop supply chain risk of WEEE is. Promoting risk control has a positive effect on reducing the recycling risks of WEEE. But based on our model results, the effect of increasing the intensity of green and low-carbon strategies was found to be minimal. This means adjusting the intensity of fund subsidies is more effective in mitigating risks in WEEE recycling.

There were a few limitations to this study. Due to constraints in available data and subjectivity of the risk analysis, quantifying the value of the model parameters and determining the model equation are challenging and highly complex, which could have affected the model operation and objectivity of simulation results. Subsequent studies should consider using more comprehensive data sets, model parameters, equations, and approaches in evaluating risk analysis and WEEE recycling.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Ethics statement

Ethical review and approval were not required for the study on human participants, in accordance with the local legislation and institutional requirements. Written informed consent from the patients/ participants or patients/participant's legal guardian/next of kin was not required to participate in this study, in accordance with the national legislation and the institutional requirements.

Author contributions

RZ constructed the system dynamics model and contributed to the writing. RZ and ZH suggested the research idea. ZW contributed to the revision of the manuscript. All authors contributed to manuscript revision, read, and approved the submitted version.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 71871206).

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (Grant No. 71871206).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ardi, R., and Leisten, R. (2016). Assessing the role of informal sector in WEEE management systems: A system dynamics approach. Waste Manag. 57, 3–16. doi:10.1016/j.wasman.2015.11.038

Besiou, M., Georgiadis, P., and Van Wassenhove, L. N. (2012). Official recycling and scavengers: Symbiotic or conflicting? Eur. J. Operational Res. 218 (2), 563–576. doi:10.1016/j.ejor.2011.11.030

Ghoushchi, S. J., Bonab, S. R., Ghiaci, A. M., Haseli, G., Tomaskova, H., and Hajiaghaei-Keshteli, M. (2021). Landfill site selection for medical waste using an integrated SWARA-WASPAS framework based on spherical fuzzy set. Sustainability 13 (24), 13950. doi:10.3390/su132413950

Gu, B., and Zhang, X. (2016). Channel coordination for the supply chain with a risk-neutral manufacturer and a loss-averse retailer based on revenue-sharing contract. J. Syst. Manag. 25 (1), 67–74.

Guo, J., He, W., and Jin, M. (2021). Environmental benefits of recycling waste electrical and electronic equipment and spatial distribution. Resour. Sci. 43 (3), 626–636. doi:10.18402/resci.2021.03.18

He, Y. (2017). Supply risk sharing in a closed-loop supply chain. Int. J. Prod. Econ. 183, 39–52. doi:10.1016/j.ijpe.2016.10.012

Hernandes Pinha, A. C., and Sagawa, J. K. (2020). A system dynamics modelling approach for municipal solid waste management and financial analysis. J. Clean. Prod. 269, 122350. doi:10.1016/j.jclepro.2020.122350

Houessionon, M. G. K., Ouendo, E.-M. D., Bouland, C., Takyi, S. A., Kedote, N. M., Fayomi, B., et al. (2021). Environmental heavy metal contamination from electronic waste (E-Waste) recycling activities worldwide: A systematic review from 2005 to 2017. Int. J. Environ. Res. Public Health 18 (7), 3517. doi:10.3390/ijerph18073517

Jabbarzadeh, A., Haughton, M., and Khosrojerdi, A. (2018). Closed-loop supply chain network design under disruption risks: A robust approach with real world application. Comput. Industrial Eng. 116, 178–191. doi:10.1016/j.cie.2017.12.025

Kleindorfer, P. R., and Saad, G. H. (2005). Managing disruption risks in supply chains. Prod. Oper. Manag. 14 (1), 53–68. doi:10.1111/j.1937-5956.2005.tb00009.x

Li, Z., Yang, Y., and Huang, K. (2021). Dynamic of fresh supply chain considering risk aversion behavior. Complex Syst. Complex. Sci. 18 (3), 51–59. doi:10.13306/j.1672-3813.2021.03.008

Lin, N., Shan, Z., Zhu, C., and Ren, Y. (2015). Heavy metal and PCB contamination in river sediments of an E-waste recycling site in Qingyuan City. Environ. Chem. 34 (9), 1685–1693. doi:10.7524/j.issn.0254-6108.2015.09.2015031604

Lundin, J. F. (2012). Redesigning a closed-loop supply chain exposed to risks. Int. J. Prod. Econ. 140 (2), 596–603. doi:10.1016/j.ijpe.2011.01.010

Luo, F., and Wang, W. (2020). A research on government subsidy strategy of closed-loop supply chain considering product green degree. Industrial Eng. J. 23 (6), 18–27. doi:10.3969/j.issn.1007-7375.2020.06.003

Mintz, K. K., Henn, L., Park, J., and Kurman, J. (2019). What predicts household waste management behaviors? Culture and type of behavior as moderators. Resour. Conservation Recycl. 145, 11–18. doi:10.1016/j.resconrec.2019.01.045

Nakashima, K., and Gupta, S. M. (2012). A study on the risk management of multi Kanban system in a closed loop supply chain. Int. J. Prod. Econ. 139 (1), 65–68. doi:10.1016/j.ijpe.2012.03.016

Pang, X., Wang, C., Yang, W., Fan, H., Zhong, S., Zheng, W., et al. (2022). Numerical simulation of a cyclone separator to recycle the active components of waste lithium batteries. Eng. Appl. Comput. Fluid Mech. 16 (1), 937–951. doi:10.1080/19942060.2022.2053343

Rautela, R., Arya, S., Vishwakarma, S., Lee, J., Kim, K.-H., and Kumar, S. (2021). E-waste management and its effects on the environment and human health. Sci. Total Environ. 773, 145623. doi:10.1016/j.scitotenv.2021.145623

Ruan, M. (2021). Pollution risk combination optimization control method for drinking water's intelligent cold chain supply chain. Arab. J. Geosci. 14 (13), 1224. doi:10.1007/s12517-021-07611-4

Sadri, E., Harsej, F., Hajiaghaei-Keshteli, M., and Siyahbalaii, J. (2021). Evaluation of the components of intelligence and greenness in Iranian ports based on network data envelopment analysis (DEA) approach. J. Model. Manag. doi:10.1108/jm2-03-2021-0071

Shahsavar, M. M., Akrami, M., Kian, Z., Gheibi, M., Fathollahi-Fard, A. M., Hajiaghaei-Keshteli, M., et al. (2022). Bio-recovery of municipal plastic waste management based on an integrated decision-making framework. J. Industrial Eng. Chem. 108, 215–234. doi:10.1016/j.jiec.2022.01.002

Shi, S., Sung, J., and Deng, F. (2021). Pricing decisions of a dual-channel closed-loop supply chain with a budget constraint risk-averse retailer. Operations Res. Manag. Sci. 30 (4), 1–9. doi:10.12005/orms.2021.0102

Shittu, O. S., Williams, I. D., and Shaw, P. J. (2021). Global E-waste management: Can WEEE make a difference? A review of e-waste trends, legislation, contemporary issues and future challenges. Waste Manag. 120, 549–563. doi:10.1016/j.wasman.2020.10.016

Wagner, S. M., and Bode, C. (2008). An empirical examination of supply chain performance along several dimensions of risk. J. Bus. Logist. 29 (1), 307–325. doi:10.1002/j.2158-1592.2008.tb00081.x

Wang, J., Liu, J., and Xu, W. (2021). Research on risk transmission of manufacturer-led supply chain under fairness preference. Chin. J. Manag. Sci. 29 (10), 96–106. doi:10.16381/j.cnki.issn1003-207x.2018.1634

Wang, W., and Da, Q. (2010). Study on premium and penalty mechanisms for the electronic product reverse supply chain considering the leading of government. Chin. J. Manag. Sci. 18 (2), 62–67. doi:10.16381/j.cnki.issn1003-207x.2010.02.014

Wang, W., and Da, Q. (2013). The decision making of manufacturers for collection and remanufacturing based on premium and penalty mechanism under competition on environment. Chin. J. Manag. Sci. 21 (5), 50–56. doi:10.16381/j.cnki.issn1003-207x.2013.05.002

Wang, X., Chan, H. K., Yee, R. W. Y., and Diaz-Rainey, I. (2012). A two-stage fuzzy-AHP model for risk assessment of implementing green initiatives in the fashion supply chain. Int. J. Prod. Econ. 135 (2), 595–606. doi:10.1016/j.ijpe.2011.03.021

Wang, Y., and Shen, L. (2018). Diversified dominant modes of closed-loop supply chain under the recycling fund. Syst. Engineering-Theory Pract. 38 (10), 2526–2541. doi:10.12011/1000-6788(2018)10-2526-16

Wu, J., Chen, X., Han, Y., She, Y., Luo, X., Zhou, S., et al. (2018). Assessment of heavy metal pollution in paddy soils and rice grains from an e-waste recycling area in South China. Acta Sci. Circumstantiae 38 (4), 1628–1634. doi:10.13671/j.hjkxxb.2017.0440

Xiang, N., Mei, F., Li, J., and Tang, W. (2017). Problems and suggestions concerning the subsidy mechanism of waste household appliances treatment fund in China. Ecol. Econ. 33 (8), 134–138+143.

Ye, L., and Liu, Y. (2017). The risk control evaluation for supply chain based on knowledge management. Int. J. Comput. Sci. Eng. 14 (1), 74–83. doi:10.1504/ijcse.2017.081170

Zhang, J., Ding, J., Lu, G., Dang, Z., and Yi, X. (2015). Heavy metal contamination in farmland soils at an E-waste disassembling site in qingyuan, Guangdong, south China. Environ. Sci. 36 (7), 2633–2640. doi:10.13227/j.hjkx.2015.07.041

Zhang, Y., and Zhang, T. (2021). The impacts of retailer’s risk aversion on decision strategies of dual recycling channel closed-loop supply chains. Chin. J. Manag. 18 (4), 587–596. doi:10.3969/j.issn.1672-884x.2021.04.013

Zhao, X., You, J., Li, Y., and Huang, Y. (2018). The effect of government fund policy in promoting WEEE recycling. Chin. J. Manag. Sci. 26 (8), 42–53. doi:10.16381/j.cnki.issn1003-207x.2018.08.005

Zhao, Y., Wang, W., and Ni, Y. (2020). EPR system based on a reward and punishment mechanism: Producer-led product recycling channels. Waste Manag. 103, 198–207. doi:10.1016/j.wasman.2019.12.034

Keywords: waste electrical and electronic equipment, closed-loop supply chain, system dynamics, risk control, catastrophe progression method

Citation: Zheng R, Huang Z and Wu Z (2022) Risk control simulation of the closed-loop supply chain of waste electrical and electronic equipment based on system dynamics. Front. Energy Res. 10:963211. doi: 10.3389/fenrg.2022.963211

Received: 07 June 2022; Accepted: 26 July 2022;

Published: 30 August 2022.

Edited by:

Hosam Saleh, Egyptian Atomic Energy Authority, EgyptReviewed by:

Amal Hassan, Egyptian Atomic Energy Authority, EgyptMostafa Hajiaghaei-Keshteli, Monterrey Institute of Technology and Higher Education (ITESM), Mexico

Copyright © 2022 Zheng, Huang and Wu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zuqing Huang, aHpxMTIxMEAxNjMuY29t

Rong Zheng

Rong Zheng Zuqing Huang

Zuqing Huang Zhen Wu

Zhen Wu