94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Energy Res., 14 July 2022

Sec. Solar Energy

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.937155

This article is part of the Research TopicSolar Photovoltaic System to Meet the Sustainable Development GoalsView all 9 articles

Recently solar panels are gaining popularity in the field of non-conventional energy sources for generating green and clean electric power. On the negative side, the photovoltaic efficiency is reduced with an increase in ambient temperature. The production of energy is dropped by 0.33% for every degree Celsius above STC. Consequently, the electric power which is generated by the solar panel may not be sufficient to run the load. It is important to realize that in some applications, such as standalone electric vehicles, space for providing an additional solar panel to compensate for the decremented output power may not be feasible. By implementing the cooling arrangements, this excessive heat might be reduced. Several cooling techniques have been implemented, named as active and passive methods. This article presents a review on maximizing the efficiency of the solar panel by utilizing different cooling methods and by integrating TEG with solar panels.

An abundance of innovations is transpiring to access green electricity concretely from the solar power generation sector. Conventional power generating sources such as coal and fossil fuel produce electricity with steam by the process of burning the aforementioned items. So, the research focus turns toward non-conventional power generating sources such as solar, wind, tidal, and biomass energy. Among these, solar technology is most conspicuous and more developing than other sources due to its availability and clean energy (Rahman et al., 2017). Concurrently, In the photovoltaic conversion process, the operating temperature plays a vital role (Skoplaki and Palyvos 2009), and due to this, when atmospheric temperature ascends on the PV panel decreases their designated output power (Kalogirou and Tripanagnostopoulos 2006) and lags the efficiency due to bandgap shrinkage occurring during high concentration of impurities (Yildiz et al., 2017). It is possible to increase the efficiency of the PV by increasing the area of the solar panel, but it is not feasible in electric vehicles (Saleh et al., 2021). In the current review, the types of solar panels and their cooling arrangements were explained with efficiency and a review on maximizing the efficiency of the solar panel by utilizing various cooling methods such as air, water, the combination of both, phase-changing materials, fins, heatsink, nanofluids, and cotton wicks (Dwivedi et al., 2020) with solar panels were presented. Additionally, by combining Thermo Electric Generator (TEG) (Chen et al., 2017) with solar PV panels to extract energy from waste heat in PV panels (Jaziri et al., 2020) by the effect of Seebeck, the efficiency may be raised. The power from TEG aids to develop the additional electrical energy and also reduce the PV panel temperature (Makki et al., 2016). To obtain the voltage across the TEG, there is a desideratum of cooling the one side of TEG while the top side has been already heated because of Sun irradiance to the solar, which is transmitted to the TEG (Zelazna and Gołȩbiowska, 2020). Figure 1 shows the basic structure of PV cell with its output and cooling system.

In this review, Section 2 describes different solar panel efficiencies. Section 3 describes various methods to obtain the increase in efficiency without using any cooling techniques but by using devices to increase the irradiation.Section 4 describes the different cooling techniques classified as active and passive methods to increase the overall efficiency of the PV systems.

Solar panels can generally be classified according to the generation (Kibria et al., 2014) as first, second, and third. The initial generation has been predicated on wafer-based silicon cells, the second generation has been based on thin-film technology, and the third generation as an incipient emerging technology such as nano crystal-based, polymer-based, dye-sensitized, and perovskite-based solar cells. Figure 2 shows types of Solar cells classified according to the different parameters. Table 1 shows the comparison of different generations of cells (Guerra et al., 2018; Rathore et al., 2019; Engineering, 2018; Gaur and Tiwari, 2013).

Under the optical discernment day by day from the first generation solar panels, the monocrystalline solar panel gives a better performance compared to polycrystalline solar panel because the structure is uniform and because it is highly pure (Taşçioǧlu et al., 2016). Mostly crystalline solar cells absorb 90% of irradiance ranging from 400 to 1200 nm, but the conversion efficiency is up to 18% only while the rest are converted into heat. The PV module performance is conventionally qualified at AM1.5 with STC (Sathe and Dhoble 2017). Decrementing in efficiency per unit temperature rise is 0.4–0.5%.

To attain the maximum efficiency from the PV panel few additional arrangements are required, such as the Sun tracking method (Awasthi et al., 2020), concentrating mirrors (Bilal et al., 2016), and applying cooling techniques to the panels, which can be classified as active and passive cooling.

Solar panels are typically mounted on fixed slopes and azimuth. But to obtain maximum irradiation Sun tracking is needed. It helps maximize the incidence of the irradiation on the solar panel throughout the day which optimizes the angle at which the panel receives solar radiation (Deen Verma et al., 2020). Meanwhile, solar trackers are slightly expensive due to the moving parts and complex technology. Usually, around a $0.08 - at0.10/Watts increase depends on size and location (Bushong, 2016). Tracking systems classified according to the direction of the axis are single axis and dual axis. A single-axis tracker moves the panel on one axis of movement, and, on the other hand, a dual-axis tracker moves the rotation of the panel on two axes of movement. The dual-axis tracker provides higher efficiency when compared to the single-axis tracker. According to the experiment by Dhanabal et al. (2013), the efficiency of the dual-axis tracker is found to be 81.68%, whereas the efficiency of the single-axis tracker is only 32.17% higher than the fixed panel.

The average daily intensity per unit area using single axis and dual axis has been increased by 13.8 and 22.5%, respectively, when compared to the fixed mount. Withal the efficiency also increased by 10 and 20.7%, respectively (Hassan 2015). Rubio et al. (2007) developed an accurate Sun tracker which includes an automatic tracker and this was in the form of a hybrid system. The movement of solar is modeled by an open-loop system while the feedback controller is employed in a closed-loop system. Due to this, the motor does not consume additional energy. Taherbaneh et al. (2010) developed a fuzzy-based MPPT and it was observed that 23 W had been obtained, which was 51% of the nominal output power. In the second technique, called fuzzy-based Sun tracking, it was observed that 11 W had been approximately obtained, which was about 24.5% of the nominal output power. Then, the two above-mentioned techniques were combined. It was seen that the output power reached 78% of the nominal output power.

According to quantum dot, solar cells can utilize high-energy photons using their potency to multiple electron-hole pairs to increment the efficiency, and additionally, double Sun solar tracking technology gives the result in a considerable increase in inefficiency. Solar Tracking system is classified according to the Drives, Axis Direction, Control and Tracking Strategies and it is shown in Figure 3. The integration of solar panels with the tracking system is utilized for position tracking of the Sun for irradiation throughout the day. Malek et al.(2012) experimented with PV panels with a tracking system and obtained the amount of voltage and current with and without tracking are tabulated in Table 2.

Sun tracking systems are conventionally classified into two categories: active trackers (electrical) and passive trackers (mechanical). Electrical-based trackers can be categorized as PC-controlled time and dated-based, auxiliary bi-facial solar cell-based, and electro-optical sensor and microprocessors-based. Mechanical trackers are based on the recollection of alloys and thermal expansion of matter (Mousazadeh et al., 2009; Ponnambalam, 2018). The efficiency obtained utilizing the Sun tracking system is incremented by 37.02%. This concentrated solar radiation and high temperature cause the solar panels to get overheated, and minimization inefficiency is unavoidable.

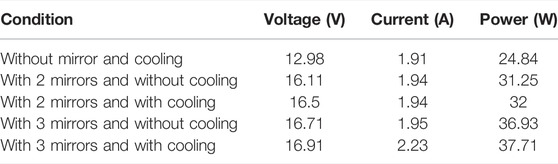

The method to ameliorate efficiency is by utilizing concentrating mirrors with solar panel integration with sun-tracking technology. The power output decreases with the increment in temperature and vice versa (Nazar 2015). The reduction of efficiency is also due to tilt angle, dust particles (Charabi and Gastli 2013), and shadowing. For a fixed tracking system, the dust accumulation decreases with tilt angle increases (Sayyah, Horenstein, and Mazumder 2014), and at 20° from the horizontal position, PVT can produce maximum energy (Sun et al., 2016). Also, due to non-linear shading, the mismatch of short circuit current causes a loss of power (Ballal et al., 2015). Concentrated photovoltaics are unlike conventional photovoltaics, and it utilizes lenses or mirrors in a curved shape to focus the sunlight onto a small area more efficiently. Commonly concentrators are an inexpensive option for increasing the efficiency of PV, which produces power in the range of 7–15 cents/Kwh depending on the size and location of the panel (Swanson 2000). Table 3 shows the voltage and current for sundry conditions (Khamooshi et al., 2014).

TABLE 3. Voltage and current values with and without using mirrors and cooling (Arshad et al., 2014).

From the Table 3, it is clear that when utilizing mirrors and coolants, the output power increases, also with the number of mirrors, which is approximately 52%. Quantum dot concentrators have more advantages, such as fewer problems of heat dissipation, sheets are inexpensive, and are congruous for architectural components, and it is a non-tracking property compared to other types of concentrators (Khamooshi et al., 2014). The PV panel is tilted with the inclination angle with respect to irradiation of the Sun. At the same time, there is a requirement to maintain the mirrors by cleaning them in a regular manner to attain better performance (Rahman and Khan 2010). The trough concentrated photovoltaic thermal system was experimentally studied, and the results show that the GaAs cell array gives better electrical performance than the crystal silicon solar cell arrays. But the thermal performance is inverted (Li et al., 2011).

PV panels absorb only the visible light for generating electrical energy (P. Kumar and Dubey 2018), and the rest of the spectrum of light is converted into heat, leading to a decrement in output performance by 0.4–0.5% per 1°C temperature rise as its standard testing conditions (Indugowda and Ranjith 2016). It is clear in the literature that the open-circuit voltage increases logarithmically with ambient irradiation, while the short circuit current is a linear function of the ambient irradiation. An increase in temperature of the cell decreases the open-circuit voltage linearly, so the solar PV panel’s efficiency is decreased. But the short-circuit current scarcely ascended with the cell temperature (Joshi, Dincer, and Reddy 2009).

The structure of various cooling systems is shown in Figure 4, but each one of them depends on different factors such as type of PV technology, place of installation, and weather conditions (Dubey, Sarvaiya, and Seshadri 2013). Depending on the aforementioned factors, the best way to minimize the heat from the solar panel is either by using active or passive cooling systems. Inactive cooling system movable parts are present, whereas, in a passive cooling system, there are no moving parts, and efficiency-wise active cooling system is better than the passive cooling system, but not cost-wise (Kalaiselvan et al., 2018). Table 4 summarizes the PV Panels with different cooling methods.

The active cooling system needs external electrical or mechanical energy, such as fans for air circulation and pumps for water circulation on the panels for heat dissipation (Shan et al., 2014). With the cooling water arrangement, the efficiency increases by 2% (Pradhan et al., 2017).

M. Abdolzadeh et al. experimented by spraying the water directly to the panel, which increased the performance efficiency of PV cell, subsystem efficiency, and overall efficiency, which were 3.26, 1.40, and 1.13, respectively, when 225 WPV panel adopted with water spraying methodology with a flow rate of 644 L/h at 16 m head. The efficiency improvement was achieved by water flow at different rates.

Ahmed AM et al. experimented with the water which flows through the tube, making holes in diameters of 2 mm diameter with a flow rate of 3, 6, and 9 L per hour, resulting in efficiencies of 8.3, 6.8, and 3.28, respectively (Ahmed and Hassan Danook 2018). So whenever a solar panel is adopted with cooling by water technology, the temperature of the panel is dropped by 4°, and performance efficiency increases by nearly 12% (Musthafa 2015). By introducing the FGM (functionally graded material) water tube systems with PV and PV-TEG, the cell efficiency increases by 30–50% and 25–40%, respectively (Yang and Yin 2011). Alberto Benato et al. also experimented with spraying technology with 1.5 bar and concluded the efficiency and power generation have increased to 13.27% and 212.31 W from 11.18% to 178.88 W, respectively (Benato et al., 2021). The merit of the water cooling method on the upper surface of the PV module is an increase in surface input radiation due to refraction in the water layer (Odeh and Behnia 2009).

To decrease the space of PV module v-trough is utilized with CPV system, with buried water heat exchange system as active cooling. Due to that, temperature has been decremented prosperously from 72.5°C to 47.2, 45.5, 41.8, and 39.3°C at flow rates of 0.01 kg/s, 0.02 kg/s, 0.03 kg/s, and 0.04 kg/s, respectively (Elminshawy et al., 2019). Figure 5 shows the structure of the water cooling method. Generally, water has high thermal conductivity and high carrying capacity than air (Moharram et al., 2013). In industrial development sectors, the utilization of water cooling methods is more effective as the heat exhauster, and it can be used as process heat, thereby curbing some expenses (Hasanuzzaman et al., 2016). The loss of efficiency due to temperature can be minimized by utilizing the water spray method also. S. Nizetic et al. additionally experimented with the spray water method on the 50 W solar panels and achieved the truncation of temperature between the non-cooled and cooled cases (Nižetić et al., 2016).

The structure of the air cooling method is shown in Figure 6. Under high irradiation conditions, the performance of cooling the PV panel by forced convention (either air or water) is better than natural convection, and up to 15% efficiency gain and temperature reduction are achieved (Mazón-Hernández et al., 2013). Amori et al. experimented with the PV with a flat plate collector at a constant air velocity of 0.0091 kg/s, and they obtained a reduction of temperature of 15.52°C with a single-pass air channel to the PV system (Amori and Adil Abd-AlRaheem, 2014). The mass flow rate plays a consequential role in solar panel cooling by decrementing the outlet temperature of the channels and tubes (Othman et al., 2016).

It covers all the natural processes and techniques of heat dissipation and modulation without any external sources. The combination of photovoltaic and thermal collectors called PV/T has plenty of advantages over standalone PV, such as occupying lesser space (Al-Waeli et al., 2016), lesser economic payback period, wastage of heat is collected by a solar collector who is in the same area behind the PV. The PV/T collectors transfer heat from the PV cells, which are absorbed from the Sun into a fluid, thereby cooling the cells and thus improving their efficiency. In this way, this excessive heat is serviceable and can be utilized to heat water or used as a low-temperature source for heat pumps. The dissipated heat energy from PV panels can be utilized in different ways and can aid in obtaining additional energy. In the PV thermal system, to exhaust the heat, different components are used, such as air collector, water collector (Besheer et al., 2016), nanofluids (Sardarabadi and Passandideh-Fard, 2016), thermoelectric generators (Greppi and Fabbri 2021), and phase-changing materials (Rao, Reddy, and Rao 2020) to improve the efficiency.

The transfer of heat from the Sun to the PVT has to be minimized by the cooling method, which was discussed above, and additionally, this heat dissipation is enhanced by utilizing fins.

Apart from various heat abbreviation methods, which are discussed earlier, another type of cooling method is by introducing the fins in the PV panel’s rear side so that the heat is radiated through the fins to the atmospheric temperature (Cuce, Bali, and Sekucoglu 2011). The overall performance of PVT is higher than the sum of the performance of solar panels alone and solar thermal systems (Van Helden et al., 2004). Figure 7 shows the V-I and P-V characteristics using fins and without fins. A.M. Elbreki et al. demonstrated one of the passive cooling with lapping fins at solar irradiance of 1000 W/m2, and the PV module has given better output efficiency of 10.68% at 24.6°C lower than the ambient temperature of 33°C (Elbreki et al., 2021). The voltage and current values with a combination of fins and PV panels are tabulated below in Table 5.

When acetone is kept as a refrigerant in micro-channel heat pipes under vacuum conditions, the instantaneous electrical efficiency is 7.6%, thermal efficiency is 54% (Verma and Kumar Tiwari 2015), and the electrical gain of PVT-MHP ascends from 17 to 74 W under irradiation between 367 and 787 W/m2 (Modjinou et al., 2017). Utilizing nanofluids such as Al2O3–water and silicon carbide (SiC)–water as a coolant to the lower concentration PVT system gives a significant decrement in temperature in the PV module, particularly at the high concentration ratio and Reynolds number (Radwan, Ahmed, and Ookawara 2016). Mohammad Sardarabadi et al. experimented with different coolants such as PVT/Water, PVT/ZnO, PVT/TiO2, and PVT/Al2O3, and the efficiency was enhanced by 12.34, 15.45, 15.93, and 18.27%, respectively (Sardarabadi et al., 2017). On the other hand, the main demerit of using nanofluids is that they have limited time stability. The completion of a heat exchanging channel using water with nanofluid as coolants have higher electrical efficiency compared to that of base fluid (Karami and Rahimi 2014).

Figure 8 shows the voltage generated from TEM utilizing different coolants at 12.30 PM. Sio2/water coolant is the most efficient coolant, which provides the highest temperature gradient (Soltani et al., 2017). The total energy rise will be 48 W when utilizing 3 wt% of Ferrofluid under an alternating magnetic field in a thermal collector integrated with a PV panel (Ghadiri et al., 2015).

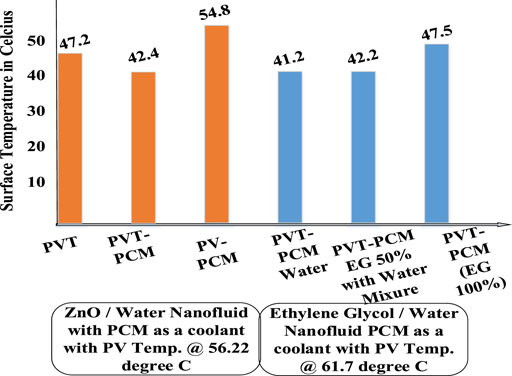

Phase Changing Materials (PCM) are usually contained in three different containers, namely grooved, tubed, and finned. T. Wongwuttanasatian et al. chose palm wax as a heat sink and analyzed it with a PV panel which resulted in a decrease in temperature from 57.9 to 51.8°C, the performance of PV cell was incremented by 5.3%, and the performance ratio was incremented by 4.8% (Wongwuttanasatian, Sarikarin, and Suksri 2020). J.G. Hernandez-Perez et al. designed a 3D model heat sink that has multidirectional airflow. This new design has the potential to be cost-effective by optimizing the dimensions needed to enhance the performance of the photovoltaic system that is affected by high temperature (Hernandez-Perez et al., 2020). Tan et al. used an aluminum heat sink in a concentrated PV with an average of 10 pores density and 0.682 porosity of aluminum foam. It gave the best enhancement inefficiency of the solar panel by removing the heat (Tan et al., 2019). Figure 9 shows the surface temperature of the PV panel with different nanofluids. Arifin et al. experimented with the CPV panel with aluminum (phase-changing material) and visually examined the results, in which the temperature ascended due to the concentrated panel, decremented from 85.3 to 72.8°C, and the output was also increased by 18.7% (Arifin et al., 2020).

FIGURE 9. Surface temperature in Celcius for different phase-changing materials (Hosseinzadeh, Sardarabadi, and Passandideh-Fard, 2018; Kazemian et al., 2018; Lee et al., 2019)

Another passive cooling method of PVT was introduced by M. Chandrasekar et al. Chandrasekar et al. (2013) used a cotton wick structure with a combination of water. The output power was increased from 41 W to 47.5 and 44.6 with a combination of cotton wick–water and cotton wick–nanofluid, respectively. In summary, by comparing all other cooling methods, the nanofluid PVT system has higher heat transfer characteristics because of higher thermal conductive characteristics (Hamzat et al., 2021).

In the recent developments of performance enhancement of PV modules, thermoelectric generators have a significant impact on the performance of the photovoltaic system. The heat transfer from the PV array by conduction method and heat transfer from the CO2 layer by convection method is used to increase the heat transfer towards TEG hot side to obtain maximum efficiency (Koushik et al., 2018).

Thermoelectric generators are devices that convert heat energy into electrical energy by the effect of Seebeck. It is similar to a thermocouple with the difference that the thermoelements are made up of semiconductors p and n, and heat is applied to the hot side and heat is removed from the cold side, both the junctions being made of copper. TEG Integrated with a PV panel will enhance its performance and minimize the amount of heat dissipation (Sahin et al., 2020). The output of a TEG generally varies non-linearly with the temperature since the properties of thermoelectric materials vary non-linearly with the temperature (Bjørk and Nielsen 2015).

Temperature distribution should be punctilious from PV to TEG. An open-circuit voltage of photovoltaic–thermal hybrid solar-generator had been ascended by 1.3% when compared to that of a PV panel working alone (Mizoshiri, Mikami, and Ozaki 2012), and it contributed about 10% output power in a hybrid system (Ju et al., 2012). In PVT-TEG, the concentrator type of thermal collector has given good performance due to the high accumulation of heat at one point (Lin, Liao, and Lin 2015). The thermal efficiency of the thermoelectric generator depends on the difference in temperature across its modules (between the hot and cold surfaces). The thermal design of the thermoelectric system plays a vital role in ensuring that there exists a maximum temperature difference across the hot and cold surfaces of the TEG (Karthick et al., 2018). An opportune design of heat recirculation through the thermoelectric generator may result in maximum conversion efficiency (Min Gao and Rowe, 2007).

The performance of the PV-TEG is not identical to the individual performance of PV and TEG alone because the heat abstraction increases the efficiency of PV and optimal location, and TEG numbers give the maximum efficiency individually (Babu and Ponnambalam 2017). The operational structure of PV-ST-TEG is shown in Figure 10, with attention to a few elements such as (Bi 2Te 3) at room temperature 9 K (acting as the cold side) and lead telluride (PbTe), which is at 500–600 K (acting as the hot side) have been identified as the thermoelectric materials. These thermoelectric materials have a quantification called the figure of merit. That is, the above-mentioned materials have a metric of measure that avails to evaluate the thermoelectric properties. The higher concentration ratio of the TEG results in higher power production due to the absorption of heat flux. H. Hashim et al. examined the photovoltaic cell with TEG in an ambient atmosphere, it reduces the power output from the solar module due to the increment in operating temperature due to large thermal resistance across TEG, but it is compensated by TEG output. In an integrated PV/T solar system, the thermal efficiency descends with ascending temperature, and it also causes a decrement in power generation efficiency (Hashim et al., 2016). Ali Salari et al. examined the performance of PVT and PVT with a thermal electric generator and attained the electrical efficiency of PVT-TEG incremented by 10.41% at STC. When inlet fluid temperature increases to 34°C from 26°C, the electrical efficiency decreases by 2.58 and 4.56% for PVT and PVT-TEG, respectively. Similarly, for the temperature variation from 26°C to 34°C, the electrical efficiency of PVT and PVT-TEG is 1.43% decremented and 0.82% incremented, respectively. The flat plate PVT operates at 100–200°C at the absorber surface, whereas the concentrated PVT operates at 800°C, which produces more heat when compared to the flat plate (Salari et al., 2020). Figure 9 shows the design structure of a photovoltaic system combined with solar thermal collectors. The combination of TEG with solar thermal and photovoltaic modules is termed a PV hybrid system (Babu and Ponnambalam 2017). The life of the PV cell is ameliorated as the thermodynamic constraints are decreased. The efficiency of the solar module also ascends based on the magnitude of thermal energy abstracted from the surface area of the module. From the difference in TEG between the hot and cold sides, the PV panel can reach 17% of efficiency with a contribution of 3% from TEG (Zulakmal et al., 2019).

The efficiency performance of solar panels alone in the amalgamated Solar-TEG system is 9.39%, and the combined efficiency is 13.8% (Wang et al., 2011). The efficiency obtained by the thermoelectric device in terms of the dimensionless figure of merit called ZT is broadly used to access the desirability of thermoelectric materials for devices and used to characterize the performance of a device such as their relative utility for an application (Kim et al., 2015). It grows with the square of the Seebeck coefficient. The TEG efficiency is resolute by the thermoelectric figure of merit (z) = α2/ρk, where ρ is electric resistivity, k is thermal conductivity, and α is the thermo emf coefficient of the TEG material (Vorobiev et al., 2006). The ascending temperature leads to the decrement of efficiency due to bandgap shrinkage, results in voltage drop, and the PV cell temperature is given by TPV = TA + cG (Raut, Shukla, and Joshi, 2018).

A phase-changing material can be introduced between PV and TEG to obtain an efficiency of 26.57% from the single PV system efficiency of 25.55% (Cui, Xuan, and Li 2016). Shen and Mason (2020) experimented with PV with TEG outdoor under direct Sun and observed that the reduction of heat due to the TEG in PV panel leads to maximizing the output power by 2.5% from the average efficiency.

Ahiska et al. (2016) compared the power generated from a PV panel and TEG and obtained the experimental results, and as the power generated from a thermoelectric panel is 30 times greater than a PV panel, they have experimented with a 1 m2 surface area of PV and TEG panels, the thermoelectric panel produces 4kw while the PV panel produces only 132 w. The thermoelectric materials can be divided into three groupings according to the temperature range (Rowe 1999), for lower temperatures up to 177°C, alloy-based bismuth in cumulating with antimony, tellurium, or selenium. For medium temperatures around 580°C, alloy-based lead (Pb), and higher temperatures, SiGe alloys are utilized to 1,025°C (Ismail and Ahmed 2009). For solar photovoltaic cells, the lower temperature range materials are preferred. In that case, Bismuth Tellurium can be used as a thermoelectric material. A 40 mm * 40 mm * 3.4 mm TEG has a thermal conductivity of 2 W/m-K, a density of 7,790 kg/m3, and specific heat of 250 J/Kg-K (Rohit et al., 2017). Zhang et al. (2020) designed PV with monocrystalline and TEG made by bismuth telluride with adhesive of thermal interface materials; the results show that the PV generation increases by 14% and TEG by 60% because of a decrement in thermal contact resistance. The enhancement of heat transfers between PV and TEG has been done by thermal interface materials. PV-TEG can be coupled in two ways, as shown in Figure 9, one is direct coupling, and another is spectrum splitting coupling [96]. In the direct method, the TEG is connected directly to the PV to generate the additional energy, while in the spectrum splitting coupling method, the energy is transmitted to PV at below 2,500 nm cut-off wavelength and TEG at above 2,500 nm.

Figure 11 shows the direct and indirect coupling of PV-TEG. Photovoltaic module gets solar irradiation through the optical concentrator significantly improves the overall efficiency, which is very promising for PV efficiency improvement (Hajji et al., 2017). A higher concentration level on the PV panel results in higher output power in TEG, but this causes a reduction in the efficiency of the PV panel due to high temperature (Zhang et al., 2014). Najafi and Woodbury (2013) have experimented with combined PVT-TEG with 36 TEG modules which have produced 145 W by PV panel and 4.4 W by TEG modules with 2.8 suns solar irradiance. Photovoltaic panels with concentrating mirroring technology give output power with a lesser number of solar panels compared to the normal requirement to produce the same output power, and this technology has the advantage of having a reduced payback period while utilizing Reflectors (Wijesuriya et al., 2017).

Building-integrated photovoltaic (BIPV) systems are replacing conventional building materials in parts of the building envelope such as the roof, skylights, and facades or embedded into the building structure (Strong 2016). Depending on the solar cell, about 6–16% of the incoming solar irradiation is converted into electricity, and the rest of the irradiation is transmitted as heat or reflected. A PV module obstructs the solar radiation on the original wall in BIPV/T installations. BAPV (building applied PV) systems installed above rooftops are limited only to the roof area, whereas systems with BIPV occupy most of the building surface area by integrating photovoltaics (Biyik et al., 2017). The solar absorptivity of a building envelope is changed when replacing/covering conventional building structures, the reflective roof, for instance, with PV modules. The use of semi-transparent PV modules changes the visible transmittance of light and subsequently the artificial lighting energy consumption profile. The BIPV method is increasingly becoming the ideal solution to be applied in urban areas (“BAPV vs. BIPV: What Are the Differences? | ASCA,” 2019).

There are varieties of BIPV technologies that can be used in building applications. The most common ways to use BIPV in building applications are shown in Figure 12 (“Building Integrated Photovoltaics_ Pros, Cons & Cost In 2022,”2022).

Industries use a huge number of solar modules for high generation of power. These panels are generally mounted on land space. Due to this, solar panels occupy a lot of space. So, an alternative is needed to save the area. The PV panels have been mounted on floating areas such as dams, reservoirs, lakes, and oceans (Patil, Wagh, and Shinde, 2017). The installation has been made by many countries in Africa, Asia, and Japan due to the low availability of land (Yousuf et al., 2020).

Floating solar module installation is an eco-friendly method. It has more advantages such as reduced shading, water evaporation, and algae growth and improved water. Some disadvantages are expensive installation and limited application of usage. The first floating solar system was installed at Napa California in 2007, it contains 1,000 panels as floated and linked with 1300 stationary panels on land. From this arrangement nearly 4 MW can be produced. Table 6 (“Solarserver | Das Internetportal Für Erneuerbare Energien,” 2020; Kumar 2021; “South East Asia’s First Floating Solar Farm,” 2013.; France 2012) illustrates various floating solar plants projects developed worldwide.

Various methods were discussed earlier to increase the efficiency of the PV panel. To enhance the efficiency further, some of the research gaps were identified to carry out needful research.

1) Materials such as copper or aluminum have to be integrated behind the PV panel so that the heat extraction is uniformly distributed in all TEGs.

2) The overall solar conversion efficiency was 40% (Zhang et al., 2012). The MPPT algorithm has to be implemented for PV and TEG in a combined algorithm.

3) With the heat sinks, the active or passive cooling method has to be added so that the temperature difference may increase. Hence, the output of TEG will increase.

4) Through active cooling technologies, the flow of air, water, or any fluid increases due to external force, which dramatically increases the rate of heat reduction, whereas, through passive cooling technologies, the rate of flow of the coolants is naturally convected.

5) Passive thermal management is a cost-effective and energy-efficient solution which uses heat sinks and thermoelectric generators to maintain optimal operating temperatures and is used to generate nano electrical energy from the heat transfers. TEGs can decrease the temperature of PV panels by transferring to the cold side, and due to the temperature gradient, the electrical energy can be produced by it. For any PV installation, passive methods can be referred to cool the panels because they are cost-effective.

In this article, the types of solar panels and their cooling systems were explained with efficiency. It has been concluded that

1) The efficiency of solar PV panels can be increased by applying tracking systems and by placing mirrors to concentrate the radiation from the Sun. However, the above-mentioned techniques increase the temperature with the light radiation, and, hence, the purpose of tracking and concentration are de-merited due to an increase in heat.

2) To decrease the heat, different cooling methods under active and passive classifications were discussed, such as air, water, a combination of both, nanofluids, phase-changing materials, and heatsinks, and also the different efficiencies of solar PV cells were obtained depending on the above-mentioned cooling techniques.

3) Withal thermoelectric generators are utilized as a passive method to convert the heat energy into electrical energy and integrate the efficiency with the photovoltaic cell. This method is integrated with PV and called PVT-TEG, obtaining the additional electrical energy with the decrement of heat from the solar panel. Also, from the above-mentioned cooling methods, a few can be applied to the TEG on the cold side so as to obtain adequate electrical energy to be integrated into the photovoltaic cell.

4) This review presents a methodology to increase the efficiency of solar PV panels without occupying any additional area; the efficiency can be improved by using TEG and cooling methods. If it is implemented in the given area, we can utilize this for solar-operated conveyances because the main drawback of the solar panel is the occupation of the area for the production of the requisite quantity of electrical energy.

Both authors contributed to content preparations and validation of context.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Ahiska, R., Nykyruy, L., Omer, G., and Mateik, G. (2016). The Thermoelectric Solar Panels. jpnu 3 (1), 9–14. doi:10.15330/jpnu.3.1.9-14

Ahmed, A. M., and Hassan Danook, S. (2018). “Efficiency Improvement for Solar Cells Panels by Cooling,” in 2nd International Conference for Engineering, Technology and Sciences of Al-Kitab, ICETS 2018, 39–42. doi:10.1109/ICETS.2018.8724625

Al-Waeli, A. H., Sopian, K., Kazem, H. A., and Chaichan, M. T. (2016). Photovoltaic Solar Thermal (PV/T) Collectors Past, Present and Future: A Review. Int. J. Appl. Eng. Res. 11 (22), 10757–10765.

Amori, K. E., and Abd-AlRaheem, M. A. (2014). Field Study of Various Air Based Photovoltaic/Thermal Hybrid Solar Collectors. Renew. Energy 63, 402–414. doi:10.1016/j.renene.2013.09.047

Arifin, Z., Tjahjana, D. D. D. P., Hadi, S., Rachmanto, R. A., Setyohandoko, G., and Sutanto, B. (2020). Numerical and Experimental Investigation of Air Cooling for Photovoltaic Panels Using Aluminum Heat Sinks. Int. J. Photoenergy 2020, 1–9. doi:10.1155/2020/1574274

Arshad, R., Tariq, S., Niaz, M. U., and Jamil, M. (2014). “Improvement in Solar Panel Efficiency Using Solar Concentration by Simple Mirrors and by Cooling,” in 2014 International Conference on Robotics and Emerging Allied Technologies in Engineering, ICREATE 2014 - Proceedings, 292–295. doi:10.1109/iCREATE.2014.6828382

Awasthi, A., Shukla, A. K., S.R., M. M., Dondariya, C., Shukla, K. N., Porwal, D., et al. (2020). Review on Sun Tracking Technology in Solar PV System. Energy Rep. 6, 392–405. doi:10.1016/j.egyr.2020.02.004

Babu, C., and Ponnambalam, P. (2017). The Role of Thermoelectric Generators in the Hybrid PV/T Systems: A Review. Energy Convers. Manag. 151 (June), 368–385. doi:10.1016/j.enconman.2017.08.060

Ballal, Rajkiran, Lakshmi, P. S., and Kumar, Girish (2015). PV Module, Irradiation, Shading, Fill Factor; PV Module, Irradiation, Shading. Fill Factor 5 (1A), 1–4. doi:10.5923/c.ep.201501.01

BAPV vs BIPV : What Are the Differences? | ASCA (2019). BAPV vs BIPV : What Are the Differences? | ASCA. Available at: https://en.asca.com/latest-news/focus-on/bapv-vs-bipv-what-are-the-differences/.

Benato, A., Stoppato, A., De Vanna, F., and Schiro, F. (2021). Spraying Cooling System for Pv Modules: Experimental Measurements for Temperature Trends Assessment and System Design Feasibility. Designs 5 (2), 25. doi:10.3390/designs5020025

Besheer, A. H., Smyth, M., Zacharopoulos, A., Mondol, J., Pugsley, A., and Adrian, Pugsley (2016). Review on Recent Approaches for Hybrid PV/T Solar Technology. Int. J. Energy Res. 40 (15), 2038–2053. doi:10.1002/er.3567

Bilal, M., Arbab, M. N., Muhammad Zain Ul, A. A., and Khattak, A. (2016). Increasing the Output Power and Efficiency of Solar Panel by Using Concentrator Photovoltaics (CPV). Int. J. Eng. Works Kambohwell Publ. Enterp. 3 (12), 98–102. Available at: www.kwpublisher.com.

Biyik, E., Araz, M., Hepbasli, A., Shahrestani, M., Yao, R., Shao, L., et al. (2017). A Key Review of Building Integrated Photovoltaic (BIPV) Systems. Eng. Sci. Technol. Int. J. 20 (3), 833–858. doi:10.1016/j.jestch.2017.01.009

Bjørk, R., and Nielsen, K. K. (2015). The Performance of a Combined Solar Photovoltaic (PV) and Thermoelectric Generator (TEG) System. Sol. Energy 120, 187–194. doi:10.1016/j.solener.2015.07.035

Building Integrated Photovoltaics_ Pros, Cons & Cost In 2022“Building Integrated Photovoltaics_ Pros, Cons & Cost in 2022.” 2022.

Bushong, S. (2016), Advantages and Disadvantages of a Solar Tracker System. Solar Power World. Available at: https://www.solarpowerworldonline.com/2016/05/advantages-disadvantages-solar-tracker-system/.

Chandrasekar, M., Suresh, S., Senthilkumar, T., and Ganesh Karthikeyan, M. (2013). Passive Cooling of Standalone Flat PV Module with Cotton Wick Structures. Energy Convers. Manag. 71, 43–50. doi:10.1016/j.enconman.2013.03.012

Charabi, Y., and Gastli, A. (2013). Integration of Temperature and Dust Effects in Siting Large PV Power Plant in Hot Arid Area. Renew. Energy 57, 635–644. doi:10.1016/j.renene.2013.02.031

Chen, J., Li, K., Liu, C., Li, M., Lv, Y., Jia, L., et al. (2017). Enhanced Efficiency of Thermoelectric Generator by Optimizing Mechanical and Electrical Structures. Energies 10 (9), 1329–1415. doi:10.3390/en10091329

Cheong Tan, W., Huat Saw, L., San Thiam, H., Yusof, F., Wang, C.-T., Chian Yew, M., et al. (2019). Investigation of Water Cooled Aluminium Foam Heat Sink for Concentrated Photovoltaic Solar Cell. IOP Conf. Ser. Earth Environ. Sci. 268 (1), 012007. doi:10.1088/1755-1315/268/1/012007

Cuce, E., Bali, T., and Sekucoglu, S. A. (2011). Effects of Passive Cooling on Performance of Silicon Photovoltaic Cells. Int. J. Low-Carbon Tech. 6 (4), 299–308. doi:10.1093/ijlct/ctr018

Cui, T., Xuan, Y., and Li, Q. (2016). Design of a Novel Concentrating Photovoltaic-Thermoelectric System Incorporated with Phase Change Materials. Energy Convers. Manag. 112, 49–60. doi:10.1016/j.enconman.2016.01.008

Deen Verma, B., Anurag Gour, A., and Dr. Mukesh Pandey, Dr. (2020). A Review Paper on Solar Tracking System for Photovoltaic Power Plant. Ijert V9 (02), 160–166. doi:10.17577/ijertv9is020103

Dhanabal, R., Bharathi, V., Ranjitha, R., Ponni, A., Deepthi, S., and Mageshkannan, P. (2013). Comparison of Efficiencies of Solar Tracker Systems with Static Panel Single-Axis Tracking System and Dual-Axis Tracking System with Fixed Mount. Int. J. Eng. Technol. 5 (2), 1925–1933.

D. Raut, P., V. Shukla, V., and S.Joshi, S. (2018). Recent Developments in Photovoltaic-Thermoelectric Combined System. Ijet 7 (4), 2619–2627. doi:10.14419/ijet.v7i4.1270910.14419/ijet.v7i2.18.12709

Dubey, S., Sarvaiya, J. N., and Seshadri, B. (2013). Temperature Dependent Photovoltaic (PV) Efficiency and its Effect on PV Production in the World - A Review. Energy Procedia 33, 311–321. doi:10.1016/j.egypro.2013.05.072

Dwivedi, P., Sudhakar, K., Soni, A., Solomin, E., and Kirpichnikova, I. (2020). Advanced Cooling Techniques of P.V. Modules: A State of Art. Case Stud. Therm. Eng. 21 (June), 100674. doi:10.1016/j.csite.2020.100674

El-Seesy, I., Ibrahim, E., Khalil, T., and Ahmed, M. H. (2012). Experimental Investigations and Developing of Photovoltaic/Thermal System. World Appl. Sci. J. 19 (9), 1342–1347. doi:10.5829/idosi.wasj.2012.19.09.2794

Elbreki, A. M., Muftah, A. F., Sopian, K., Jarimi, H., Fazlizan, A., and Ibrahim, A. (2021). Experimental and Economic Analysis of Passive Cooling PV Module Using Fins and Planar Reflector. Case Stud. Therm. Eng. 23 (December 2020), 100801. doi:10.1016/j.csite.2020.100801

Elminshawy, N. A. S., El-Ghandour, M., Elhenawy, Y., Bassyouni, M., El-Damhogi, D. G., and Addas, M. F. (2019). Experimental Investigation of a V-Trough PV Concentrator Integrated with a Buried Water Heat Exchanger Cooling System. Sol. Energy 193 (April), 706–714. doi:10.1016/j.solener.2019.10.013

Engineering, E. (2018). A Comparative Analysis and Performance of Polycrystalline and Monocrystalline PV Module, 15, 6, 1–6. doi:10.17577/IJERTCONV6IS15029

Gaur, A., and Tiwari, G. N. (20132013). Performance of Photovoltaic Modules of Different Solar Cells. J. Sol. Energy 2013, 1–13. doi:10.1155/2013/734581

Ghadiri, M., Sardarabadi, M., Pasandideh-Fard, M., and Moghadam, A. J. (2015). Experimental Investigation of a PVT System Performance Using Nano Ferrofluids. Energy Convers. Manag. 103, 468–476. doi:10.1016/j.enconman.2015.06.077

Greppi, M., and Fabbri, G. (2021). Integrated PV-TEG Cooling System and Support. February. doi:10.35629/6734-1001022126

Guerra, N., Guevara, M., Palacios, C., and Crupi, F. (2018). Operation and Physics of Photovoltaic Solar Cells: An Overview. I+D Tecnológico 14 (2), 84–95. doi:10.33412/idt.v14.2.2077

Hajji, M., Labrim, H., Benaissa, M., Laazizi, A., Ez-Zahraouy, H., Ntsoenzok, E., et al. (2017). Photovoltaic and Thermoelectric Indirect Coupling for Maximum Solar Energy Exploitation. Energy Convers. Manag. 136, 184–191. doi:10.1016/j.enconman.2016.12.088

Hamzat, A. K., Sahin, A. Z., Omisanya, M. I., and Alhems, L. M. (2021). Advances in PV and PVT Cooling Technologies: A Review. Sustain. Energy Technol. Assessments 47 (December 2020), 101360. doi:10.1016/j.seta.2021.101360

Hasanuzzaman, M., Malek, A. B. M. A., Islam, M. M., Pandey, A. K., and Rahim, N. A. (2016). Global Advancement of Cooling Technologies for PV Systems: A Review. Sol. Energy 137, 25–45. doi:10.1016/j.solener.2016.07.010

Hashim, H., Bomphrey, J. J., and Min, G. (2016). Model for Geometry Optimisation of Thermoelectric Devices in a Hybrid PV/TE System. Renew. Energy 87, 458–463. doi:10.1016/j.renene.2015.10.029

Hassan, A. A. M. 2015. “Design of a Solar Tracking System for Improving Solar Photovoltaic Efficiency,” no. 1.

Hernandez-Perez, J. G., Carrillo, J. G., Bassam, A., Flota-Banuelos, M., and Patino-Lopez, L. D. (2020). A New Passive PV Heatsink Design to Reduce Efficiency Losses: A Computational and Experimental Evaluation. Renew. Energy 147, 1209–1220. doi:10.1016/j.renene.2019.09.088

Hosseinzadeh, M., Sardarabadi, M., and Passandideh-Fard, M. (2018). Energy and Exergy Analysis of Nanofluid Based Photovoltaic Thermal System Integrated with Phase Change Material. Energy 147, 636–647. doi:10.1016/j.energy.2018.01.073

Indugowda, C. S., and Ranjith, P. K. (2016). Cooling Methods for Increasing Efficiency of PV Panel. Int. J. Sci. Dev. Res. 1 (6), 359–362. Available at: www.ijsdr.org.

Ismail, B., and Ahmed, W. (2009). Thermoelectric Power Generation Using Waste-Heat Energy as an Alternative Green Technology. Eeng 2 (1), 27–39. doi:10.2174/1874476110902010027

Jaziri, N., Boughamoura, A., Müller, J., Mezghani, B., Tounsi, F., and Ismail, M. (2020). A Comprehensive Review of Thermoelectric Generators: Technologies and Common Applications. Energy Rep. 6, 264–287. doi:10.1016/j.egyr.2019.12.011

Joshi, A. S., Dincer, I., and Reddy., B. V. (2009). Thermodynamic Performance of a Photovoltaic System. Proc. 2nd Int. Conf. Energy Sustain. 2, 33–38. doi:10.1115/es2008-54340

Ju, X., Wang, Z., Flamant, G., Li, P., and Zhao, W. (2012). Numerical Analysis and Optimization of a Spectrum Splitting Concentration Photovoltaic-Thermoelectric Hybrid System. Sol. Energy 86 (6), 1941–1954. doi:10.1016/j.solener.2012.02.024

Kalaiselvan, S., Karthikeyan, V., Rajesh, G., Sethu Kumaran, A., Ramkiran, B., and Neelamegam, P. (2018). “Solar PV Active and Passive Cooling Technologies - A Review,” in 7th IEEE International Conference on Computation of Power, Energy, Information and Communication, ICCPEIC 2018, 166–169. doi:10.1109/ICCPEIC.2018.8525185

Kalogirou, S. A., and Tripanagnostopoulos, Y. (2006). Hybrid PV/T Solar Systems for Domestic Hot Water and Electricity Production. Energy Convers. Manag. 47 (18–19), 3368–3382. doi:10.1016/j.enconman.2006.01.012

Kalogirou, S. A. (2001). Use of TRNSYS for Modelling and Simulation of a Hybrid Pv-Thermal Solar System for Cyprus. Renew. Energy 23, 247–260. doi:10.1016/s0960-1481(00)00176-2

Karami, N., and Rahimi, M. (2014). Heat Transfer Enhancement in a PV Cell Using Boehmite Nanofluid. Energy Convers. Manag. 86, 275–285. doi:10.1016/j.enconman.2014.05.037

Karthick, K., Joy, G. C., Suresh, S., and Dhanuskodi, R. (2018). Impact of Thermal Interface Materials for Thermoelectric Generator Systems. J. Elec Materi 47 (10), 5763–5772. doi:10.1007/s11664-018-6496-y

Kazemian, A., Hosseinzadeh, M., Sardarabadi, M., and Passandideh-Fard, M. (2018). Experimental Study of Using Both Ethylene Glycol and Phase Change Material as Coolant in Photovoltaic Thermal Systems (PVT) from Energy, Exergy and Entropy Generation Viewpoints. Energy 162, 210–223. doi:10.1016/j.energy.2018.07.069

Khamooshi, M., Salati, H., Egelioglu, F., Hooshyar Faghiri, A., Tarabishi, J., and Babadi, S. (2014). A Review of Solar Photovoltaic Concentrators. Int. J. Photoenergy 2014, 1–17. doi:10.1155/2014/958521

Kibria, M. T., Ahammed, A., Mahmud Sony, S., and Hossain, F. (2014). “A Review : Comparative Studies on Different Generation Solar Cells Technology,” in International Conference on Environmental Aspects of Bangladesh, 51–53.September

Kim, H. S., Liu, W., Chen, G., Chu, C.-W., and Ren, Z. (2015). Relationship between Thermoelectric Figure of Merit and Energy Conversion Efficiency. Proc. Natl. Acad. Sci. U.S.A. 112 (27), 8205–8210. doi:10.1073/pnas.1510231112

Koushik, S., Das, S., Sharma, V., Walde, P., and Maji, N. (2018). “PV and TEG Hybrid Power Generation for Enhancement of Efficiency,” in India International Conference on Power Electronics, IICPE 2018-Decem, 1–6. doi:10.1109/IICPE.2018.8709422

Kumar, H. (2021). World’s Biggest Floating Solar Farms: Top Ten by Capacity. Analysis. Available at: https://www.power-technology.com/analysis/worlds-biggest-floating-solar-farms/.

Kumar, P., and Dubey, R. (2018). Efficiency Improvement of Photovoltaic Panels by Design Improvement of Cooling System Using Back Water Cooling Tubes. Int. J. Eng. Res. Technol. (IJERT) Available at: www.ijert.org. 7 (01), 74–77. doi:10.17577/IJERTV7IS010057

Lee, J. H., Hwang, S. G., and Lee, G. H. 2019. “Energies E Ffi Ciency Improvement of a Photovoltaic Thermal.”

Li, M., Li, G. L., Ji, X., Yin, F., and Xu, L. (2011). The Performance Analysis of the Trough Concentrating Solar Photovoltaic/Thermal System. Energy Convers. Manag. 52 (6), 2378–2383. doi:10.1016/j.enconman.2010.12.039

Lin, J., Liao, T., and Lin, B. (2015). Performance Analysis and Load Matching of a Photovoltaic-Thermoelectric Hybrid System. Energy Convers. Manag. 105, 891–899. doi:10.1016/j.enconman.2015.08.054

Luboń, W., Pełka, G., Janowski, M., Pająk, L., Stefaniuk, M., Kotyza, J., et al. (2020). Assessing the Impact of Water Cooling on PV Modules Efficiency. Energies 13 (10), 2414. doi:10.3390/en13102414

Makki, A., Omer, S., Su, Y., and Sabir, H. (2016). Numerical Investigation of Heat Pipe-Based Photovoltaic-Thermoelectric Generator (HP-PV/TEG) Hybrid System. Energy Convers. Manag. 112, 274–287. doi:10.1016/j.enconman.2015.12.069

Malek, S. M. Y., Rozario, J., and Sayeed Ud Doulah, A. B. M. (201220122). An Approach to Improve PV Performance: Incorporating Q-Dot Nanocrystals and Double Sun Technology. Int. Conf. Inf. Electron. Vis. ICIEV, 618–621. doi:10.1109/ICIEV.2012.6317508

Mazón-Hernández, R., García-Cascales, J. R., Vera-García, F., Káiser, A. S., and Zamora, B. (20132013). Improving the Electrical Parameters of a Photovoltaic Panel by Means of an Induced or Forced Air Stream. Int. J. Photoenergy 2013, 1–10. doi:10.1155/2013/830968

Min Gao, G., and Rowe, D. M. (2007). Conversion Efficiency of Thermoelectric Combustion Systems. IEEE Trans. Energy Convers. 22 (2), 528–534. doi:10.1109/TEC.2006.877375

Mizoshiri, M., Mikami, M., and Ozaki, K. (2012). Thermal-photovoltaic Hybrid Solar Generator Using Thin-Film Thermoelectric Modules. Jpn. J. Appl. Phys. 51 (6 PART 2), 06FL07. doi:10.1143/JJAP.51.06FL07

Modjinou, M., Ji, J., Li, J., Yuan, W., and Zhou, F. (2017). A Numerical and Experimental Study of Micro-channel Heat Pipe Solar Photovoltaics Thermal System. Appl. Energy 206 (September), 708–722. doi:10.1016/j.apenergy.2017.08.221

Moharram, K. A., Abd-Elhady, M. S., Kandil, H. A., and El-Sherif, H. (2013). Enhancing the Performance of Photovoltaic Panels by Water Cooling. Ain Shams Eng. J. 4 (4), 869–877. doi:10.1016/j.asej.2013.03.005

Mousazadeh, H., Keyhani, A., Javadi, A., Mobli, H., Abrinia, K., and Sharifi, A. (2009). A Review of Principle and Sun-Tracking Methods for Maximizing Solar Systems Output. Renew. Sustain. Energy Rev. 13 (8), 1800–1818. doi:10.1016/j.rser.2009.01.022

Musthafa, M. Mohamed (2015). Enhancing Photoelectric Conversion Efficiency of Solar Panel by Water Cooling Fundamentals of Renewable Energy and Applications. J. Fundam. Renew. Energy Appl. 5 (4), 10–14. doi:10.4172/20904541.1000166

Najafi, H., and Woodbury, K. A. (2013). Modeling and Analysis of a Combined Photovoltaic-Thermoelectric Power Generation System. J. Sol. Energy Eng. Trans. ASME 135 (3), 1–8. doi:10.1115/1.4023594

Nazar, R. (2015). Improvement of Efficiency of Solar Panel Using Different Methods. Int. J. Electr. Electron. Eng. 07 (01), 12–17.

Nižetić, S., Čoko, D., Yadav, A., and Grubišić-Čabo, F. (2016). Water Spray Cooling Technique Applied on a Photovoltaic Panel: The Performance Response. Energy Convers. Manag. 108, 287–296. doi:10.1016/j.enconman.2015.10.079

Odeh, S., and Behnia, M. (2009). Improving Photovoltaic Module Efficiency Using Water Cooling. Heat. Transf. Eng. 30 (6), 499–505. doi:10.1080/01457630802529214

Othman, M. Y., Hamid, S. A., Tabook, M. A. S., Sopian, K., Roslan, M. H., and Ibarahim, Z. (2016). Performance Analysis of PV/T Combi with Water and Air Heating System: An Experimental Study. Renew. Energy 86 (February), 716–722. doi:10.1016/j.renene.2015.08.061

Patil, S. S., Wagh, M. M., and Shinde, N. N. (2017). A Review on Floating Solar Photovoltaic Power Plants. Int. J. Sci. Eng. Res. 8 (6), 789–794.

Ponnambalam, C. B. P. (2018). The Theoretical Performance Evaluation of Hybrid PV-TEG System. Energy Convers. Manag. 173 (April), 450–460. doi:10.1016/j.enconman.2018.07.104

Pradhan, A., Parashar, S. K. S., Ali, S. M., and Paikray, P. (2016). “Water Cooling Method to Improve Efficiency of Photovoltaic Module,” in International Conference on Signal Processing, Communication, Power and Embedded System, SCOPES 2016 - Proceedings, 1, 1044–1047. doi:10.1109/SCOPES.2016.7955600

Radwan, A., Ahmed, M., and Ookawara, S. (2016). Performance Enhancement of Concentrated Photovoltaic Systems Using a Microchannel Heat Sink with Nanofluids. Energy Convers. Manag. 119, 289–303. doi:10.1016/j.enconman.2016.04.045

Rahman, F. A., Aziz, M. M. A., Saidur, R., Bakar, W. A. W. A., Hainin, M. R., Putrajaya, R., et al. (2017). Pollution to Solution: Capture and Sequestration of Carbon Dioxide (CO 2 ) and its Utilization as a Renewable Energy Source for a Sustainable Future. Renew. Sustain. Energy Rev. 71 (January), 112–126. doi:10.1016/j.rser.2017.01.011

Rahman, R., and Khan, M. F. (2010). Performance Enhancement of PV Solar System by Mirror Reflection. ICECE 2010 - 6th Int. Conf. Electr. Comput. Eng. December, 163–166. doi:10.1109/ICELCE.2010.5700652

Rao, D. K., Reddy, K. Sudhakar, Reddy, K. S., and Rao, V. V. S. (2020). PVT Cell Performance Characteristics and Efficiency with Phase Change Material. Ijeat 9 (5), 1005–1012. doi:10.35940/ijeat.e1053.069520

Rathore, N., Panwar, N. L., Yettou, F., and Gama, A. (2019). A Comprehensive Review of Different Types of Solar Photovoltaic Cells and Their Applications. Int. J. Ambient Energy 0 (0), 1–18. doi:10.1080/01430750.2019.1592774

Rohit, G., Manaswini, D., Kotebavi, V., and R, N. S. (2017). Performance Study of Thermo-Electric Generator. AIP Conf. Proc. doi:10.1063/1.4990247

Rowe, D. M. (1999). Thermoelectrics, an Environmentally-Friendly Source of Electrical Power. Renew. Energy 16 (1–4), 1251–1256. doi:10.1016/s0960-1481(98)00512-6

Rubio, F. R., Ortega, M. G., Gordillo, F., and López-Martínez, M. (2007). Application of New Control Strategy for Sun Tracking. Energy Convers. Manag. 48 (7), 2174–2184. doi:10.1016/j.enconman.2006.12.020

Sahin, A. Z., Ismaila, K. G., Yilbas, B. S., and Al‐Sharafi, A. (2020). A Review on the Performance of Photovoltaic/Thermoelectric Hybrid Generators. Int. J. Energy Res. 44 (5), 3365–3394. doi:10.1002/er.5139

Sajjad, U., Amer, M., Ali, H. M., Dahiya, A., and Abbas, N. (2019). Cost Effective Cooling of Photovoltaic Modules to Improve Efficiency. Case Stud. Therm. Eng. 14 (March), 100420. doi:10.1016/j.csite.2019.100420

Salari, A., Parcheforosh, A., Hakkaki-Fard, A., and Amadeh, A. (2020). A Numerical Study on a Photovoltaic Thermal System Integrated with a Thermoelectric Generator Module. Renew. Energy 153, 1261–1271. doi:10.1016/j.renene.2020.02.018

Saleh, U. A., Johar, M. A., Jumaat, S. A. B., Rejab, M. N., and Wan Jamaludin, W. A. (2021). Evaluation of a Pv-Teg Hybrid System Configuration for an Improved Energy Output: A Review. Ijred 10 (2), 385–400. doi:10.14710/ijred.2021.33917

Sardarabadi, M., Hosseinzadeh, M., Kazemian, A., and Passandideh-Fard, M. (2017). Experimental Investigation of the Effects of Using Metal-Oxides/Water Nanofluids on a Photovoltaic Thermal System (PVT) from Energy and Exergy Viewpoints. Energy 138, 682–695. doi:10.1016/j.energy.2017.07.046

Sardarabadi, M., and Passandideh-Fard, M. (2016). Experimental and Numerical Study of Metal-Oxides/Water Nanofluids as Coolant in Photovoltaic Thermal Systems (PVT). Sol. Energy Mater. Sol. Cells 157, 533–542. doi:10.1016/j.solmat.2016.07.008

Sark, W. G. J. H. M. v. (2011). Feasibility of Photovoltaic - Thermoelectric Hybrid Modules. Appl. Energy 88 (8), 2785–2790. doi:10.1016/j.apenergy.2011.02.008

Sathe, T. M., and Dhoble, A. S. (2017). A Review on Recent Advancements in Photovoltaic Thermal Techniques. Renew. Sustain. Energy Rev. 76 (February), 645–672. doi:10.1016/j.rser.2017.03.075

Sayyah, A., Horenstein, M. N., and Mazumder, M. K. (2014). Energy Yield Loss Caused by Dust Deposition on Photovoltaic Panels. Sol. Energy 107, 576–604. doi:10.1016/j.solener.2014.05.030

Shen, H., and Mason, C. (2020). Outdoor Experimental Comparison between Pv Cell and Combined System Pv-Teg Waste Management View Project MPPT Algorithm View Project. Available at: https://www.researchgate.net/publication/344038693.32, 3, 279-83.

Shan, F., Tang, F., Cao, L., and Fang, G. (2014). Dynamic Characteristics Modeling of a Hybrid Photovoltaic-Thermal Solar Collector with Active Cooling in Buildings. Energy Build. 78, 215–221. doi:10.1016/j.enbuild.2014.04.037

Skoplaki, E., and Palyvos, J. A. (2009). On the Temperature Dependence of Photovoltaic Module Electrical Performance: A Review of Efficiency/Power Correlations. Sol. Energy 83 (5), 614–624. doi:10.1016/j.solener.2008.10.008

Solarserver | Das Internetportal Für Erneuerbare Energien (2020). Solarserver | Das Internetportal Für Erneuerbare Energien. Available at: https://www.solarserver.de/.

Soltani, S., Kasaeian, A., Sarrafha, H., and Wen, D. (2017). An Experimental Investigation of a Hybrid Photovoltaic/Thermoelectric System with Nanofluid Application. Sol. Energy 155, 1033–1043. doi:10.1016/j.solener.2017.06.069

Strong, Steven (2016). Building Integrated Photovoltaics (BIPV) | WBDG - Whole Building Design Guide. Washington, DC: National Institute of Building Science.

Sun, L. L., Li, M., Yuan, Y. P., Cao, X. L., Lei, B., and Yu, N. Y. (2016). Effect of Tilt Angle and Connection Mode of PVT Modules on the Energy Efficiency of a Hot Water System for High-Rise Residential Buildings. Renew. Energy 93, 291–301. doi:10.1016/j.renene.2016.02.075

Swanson, R. M. (2000). The Promise of Concentrators. Prog. Photovolt. Res. Appl. 8 (1), 93–111. doi:10.1002/(sici)1099-159x(200001/02)8:1<93::aid-pip303>3.0.co;2-s

Taherbaneh, M., Rezaie, A. H., Ghafoorifard, H., Rahimi, K., and Menhaj, M. B. (20102010). Maximizing Output Power of a Solar Panel via Combination of Sun Tracking and Maximum Power Point Tracking by Fuzzy Controllers. Int. J. Photoenergy 2010, 1–13. doi:10.1155/2010/312580

Taşçıoğlu, A., Taşkın, O., and Vardar, A. (2016). A Power Case Study for Monocrystalline and Polycrystalline Solar Panels in Bursa City, Turkey. Int. J. Photoenergy 2016, 1–7. doi:10.1155/2016/7324138

van Helden, W. G. J., van Zolingen, R. J. C., and Zondag, H. A. (2004). PV Thermal Systems: PV Panels Supplying Renewable Electricity and Heat. Prog. Photovolt. Res. Appl. 12 (6), 415–426. doi:10.1002/pip.559

Verma, S. K., and Tiwari, A. K. (2015). Progress of Nanofluid Application in Solar Collectors: A Review. Energy Convers. Manag. 100, 324–346. doi:10.1016/j.enconman.2015.04.071

Vorobiev, Y., González-Hernández, J., Vorobiev, P., and Bulat, L. (2006). Thermal-photovoltaic Solar Hybrid System for Efficient Solar Energy Conversion. Sol. Energy 80 (2), 170–176. doi:10.1016/j.solener.2005.04.022

Wang, N., Han, L., He, H., Park, N.-H., and Koumoto, K. (2011). A Novel High-Performance Photovoltaic-Thermoelectric Hybrid Device. Energy Environ. Sci. 4 (9), 3676–3679. doi:10.1039/c1ee01646f

Wijesuriya, D. T. P., Wickramathilaka, K. D. S. H., Wijesinghe, L. S., Vithana, D. M., and Perera, H. Y. R. (2017). Reduction of Solar PV Payback Period Using Optimally Placed Reflectors. Energy Procedia 134, 480–489. doi:10.1016/j.egypro.2017.09.606

Wongwuttanasatian, T., Sarikarin, T., and Suksri, A. (2020). Performance Enhancement of a Photovoltaic Module by Passive Cooling Using Phase Change Material in a Finned Container Heat Sink. Sol. Energy 195 (November 2019), 47–53. doi:10.1016/j.solener.2019.11.053

Xu, L., Xiong, Y., Mei, A., Hu, Y., Rong, Y., Zhou, Y., et al. (2018). Efficient Perovskite Photovoltaic-Thermoelectric Hybrid Device. Adv. Energy Mat. 8 (13), 1702937–1702945. doi:10.1002/aenm.201702937

Yang, D., and Yin, H. (2011). Energy Conversion Efficiency of a Novel Hybrid Solar System for Photovoltaic, Thermoelectric, and Heat Utilization. IEEE Trans. Energy Convers. 26 (2), 662–670. doi:10.1109/TEC.2011.2112363

Yildiz, A., Ozturk, E., Atilgan, A., Sbeta, M., Atli, A., and Serin, T. (2017). An Understanding of the Band Gap Shrinkage in Sn-Doped ZnO for Dye-Sensitized Solar Cells. J. Elec Materi 46 (12), 6739–6744. doi:10.1007/s11664-017-5778-0

Yousuf, H., Khokhar, M. Q., Zahid, M. A., Kim, J., Kim, Y., Cho, E-C., et al. (2020). 【FPV的综述 各个部分】 A Review on Floating Photovoltaic Technology (Not in HJRS). Curr. Photovolt. Res. 8 (3), 67–78. doi:10.21218/CPR.2020.8.3.067

Żelazna, A., and Gołębiowska, J. (2020). A PV-Powered TE Cooling System with Heat Recovery: Energy Balance and Environmental Impact Indicators. Energies 13 (7), 1701. doi:10.3390/en13071701

Zhang, J., Xuan, Y., and Yang, L. (2014). Performance Estimation of Photovoltaic-Thermoelectric Hybrid Systems. Energy 78, 895–903. doi:10.1016/j.energy.2014.10.087

Zhang, J., Zhai, H., Wu, Z., Wang, Y., Xie, H., and Zhang, M. (2020). Enhanced Performance of Photovoltaic-Thermoelectric Coupling Devices with Thermal Interface Materials. Energy Rep. 6, 116–122. doi:10.1016/j.egyr.2019.12.001

Zhang, X., Zhao, X., Smith, S., Xu, J., and Yu, X. (2012). Review of R&D Progress and Practical Application of the Solar Photovoltaic/Thermal (PV/T) Technologies. Renew. Sustain. Energy Rev. 16 (1), 599–617. doi:10.1016/j.rser.2011.08.026

Keywords: photovoltaic module, active and passive cooling, phase changing materials, heat sink, PV-TEG-heat sink

Citation: Parthiban R and Ponnambalam P (2022) An Enhancement of the Solar Panel Efficiency: A Comprehensive Review. Front. Energy Res. 10:937155. doi: 10.3389/fenrg.2022.937155

Received: 05 May 2022; Accepted: 23 June 2022;

Published: 14 July 2022.

Edited by:

Salah Kamel, Aswan University, EgyptReviewed by:

Haochun Zhang, Harbin Institute of Technology, ChinaCopyright © 2022 Parthiban and Ponnambalam. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: P. Ponnambalam, cC5wb25uYW1iYWxhbUBnbWFpbC5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.