- 1Jincheng Power Supply Company, State Grid Shanxi Electric Power Co., Jincheng, China

- 2College of Electrical and Information Engineering, Hunan University, Changsha, China

With the development of the smart grid and energy Internet, the power industry generates huge, multi-source, heterogeneous, and highly coupled data, which are difficult to utilize. The intelligent operation and maintenance system of the power transformer based on the knowledge graph and graph neural network is developed in this article. The multi-source heterogeneous data are structured and modeled by the constructed knowledge graph, and it presents the correlation among data more intuitively. On this basis, the graph neural network is designed to achieve the prediction and excavate the deep information hidden in the data. The testing results show that the system has fully used the multi-dimensional and interrelated heterogeneous data, achieving a deep information mine. It benefits the management and strategy implementation for the system scientifically and guides the operation and maintenance of the transformer. The system is of great significance on improving the efficiency of the transformer maintenance and safe operation.

1 Introduction

With the popularization and application of the power transformer monitoring technology, all kinds of data acquired corresponding to the equipment show a geometric increase (Zhang et al., 2021; Zhou et al., 2021; Liu et al., 2022). In these massive data, there are both Euclidean structure data, such as images and time series data, and non-Euclidean structure data, such as text data. At present, the research mainly focuses on Euclidean data. He et al. (2021) proposed the use of multiple inputs and multiple output back-propagation neural networks with multiple hidden layers to extract a variety of electrical and non-electrical features for state monitoring and fault diagnosis. Wu et al. (2021) proposed an improved genetic algorithm (IGA) combined with XGBoost to form a hybrid diagnosis network for in-depth exploration of transformer fault data. Kari et al. (2016) established a transformer evaluation system based on the D-S theory by using dissolved gas and electrical test data. Qiangchao et al. (2020) used a new model of least-squares double support vector regression (LSTSVR) to predict the concentration and development trend of dissolved gas in transformer oil. However, there are few studies and applications of open, fuzzy, and unstructured text data. Zhu et al. (2021) introduced the knowledge graph in power dispatching to achieve effective management and the use of a large amount of professional knowledge. Zhang et al. (2020) proposed the use of knowledge graph to realize the automatic question-answering information-processing task. The graph neural network is mainly applied to the knowledge graph–related fields. As a newly emerging neural network in recent years, it is seldom applied in a power system. Liao et al. (2022) described the research trend of the graph neural network in key applications such as fault diagnosis and power flow calculation in the power system.

At the same time, driven by the smart grid and energy Internet, the operation and maintenance management of power transformers by power grid companies is also facing the transformation from state maintenance to predictive maintenance (Xie et al., 2020). Liu et al. (2009) proposed the design of the 220-kV substation fault information system based on a real-time detection platform. Hua (2010) adopted the method based on the NET framework to realize the construction of the substation information management system. Takahashi and Okamoto et al. (2016) designed and developed a decision-making management tool for a power equipment maintenance strategy based on the asset management technology.

As for the current power transformer operation and maintenance management, on the one hand, due to the lack of the dedicated and humanized management system, manual management still plays a dominant role in the actual operation and maintenance management business (Suwnansri, 2014). On the other hand, most databases of operation and maintenance management systems are knowledge bases of expert systems, which are not only manually compiled, unable to adapt to the current big data environment, but also difficult to store and use non-Euclidean data. In this article, the intelligent operation and maintenance system of the power transformer is designed and constructed, which uses the knowledge graph technology to store multi-source heterogeneous data structurally and modelically. On this basis, considering that there may be hidden association information between the data, the system uses the graph neural network to deeply mine the data relationship. The construction of the system realizes the transformation of transformer operation and maintenance from post-failure maintenance to pre-failure and in-failure maintenance, the shift from plan-based maintenance to overhaul-based maintenance, and from expert-experienced fault processing to scientific fault processing based on data analysis. These transformations improve the efficiency of transformer operation and maintenance management, which is of great significance to the transformer safe operation.

2 Overall Function Design of the System

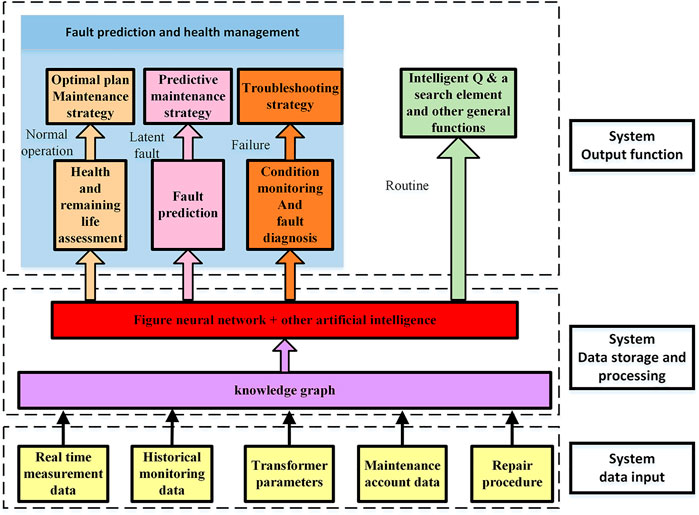

According to the existing technology and the analysis of power enterprises on power transformer operation and maintenance management business, the corresponding function positioning for each link of transformer operation and maintenance is carried out, and the functional architecture of the system is designed, as shown in Figure 1.

Multi-source heterogeneous data are taken as the input, and then, the transformer knowledge graph is constructed based on the input data, and the graph neural network technology is used for graph deep learning analysis. The system divides the transformer state into four scenarios: normal operation, latent failure, failure, and daily work. The different system functions are designed according to different situations. In the normal operation situation, the equipment’s life cycle is predicted according to the running status of the transformer; repair and maintenance plan are made based on the transformer status indicators. In the situation of latent failure, prediction of the failure time will be accomplished, and preparative plan will be made in advance. In case of failure, the causes of equipment failure are analyzed, and maintenance measures will be made. In daily work, the system provides search query and other general functions.

2.1 Construction of the Transformer Knowledge Graph and Q&A Function Based on the Knowledge Graph

Power transformer, as complex power equipment, exhibits multi-level and multi-factors which will lead to failure. Therefore, the system uses text knowledge data such as power transformer professional books, equipment maintenance rules, fault case reports, and maintenance experts’ professional experience to establish the mapping relationship between various equipment data, symptoms, abnormal phenomena and fault types, causes, and countermeasures. Meanwhile, the Chinese word segmentation technology and the triplet extraction technology are used to realize the automatic construction of the power transformer knowledge graph.

The transformer knowledge graph constructed by the system can be used to query the massive information accurately in a very short time by the powerful query function, and the massive scattered information which has been queried can be statistically analyzed. A large amount of information is scientifically stored and visualized through a quantitative model by using the transformer knowledge graph, and the deep relationship and trend between them are mined, which greatly extend the excavation and utilization of the transformer text data information.

In the case of transformer failure, the function can facilitate the transformer management personnel to use the text data such as maintenance records and equipment maintenance procedures and quickly gives the cause of transformer failure and provides maintenance measures and other feedback, which improves the management efficiency for the transformer management personnel on accident handling.

2.2 Transformer Fault Prediction Function

When the transformer is in latent fault situation, the transformer fault prediction function can accurately analyze and predict the possible transformer fault time and fault type. Power transformers in the working state will be affected by a variety of factors and produce hydrocarbons gas. As for overheating or a discharge fault in the transformer, the gas content in the oil often shows abnormal changes. Therefore, the graph neural network is constructed in our system to mine the gas content and the relationship between gases and achieves the transformer fault prediction automatically. When the transformer fails, the system can quickly classify the faults according to the gas content level in transformer oil, which provides decision-making reference for the transformer management personnel to make maintenance arrangement and fault maintenance decision. It also improves the operation and maintenance management quality and efficiency of the power transformer.

2.3 Transformer State Evaluation and Life Prediction Function

In the normal operation situation of the transformer, the function of state evaluation and life prediction scores the running state of the transformer so as to predict its remaining life. The transformer status evaluation function is based on the transformer basic attribute information, operation information, experimental information, and fault information data. The system analyzes the transformer operation state and calculates the health index through neural network models. This function can provide reference for the substation operators to arrange the maintenance plan.

3 System Key Technology

This system uses the Django framework. The bottom layer of the system is the transformer intelligent processing technology based on the graph neural network. The background database of the system uses the MySQL and Neo4j databases to store structured and unstructured data.

3.1 System Framework and Storage Database

3.1.1 System Framework

The development of this system uses the Django framework. Django is an open-source web application framework written by Python.

The Django framework uses the MVT model, which is compatible with the front-end web address system. Django divides the software system into three basic parts: Model, Template, and View.

Model: It is responsible for compiling the database according to the function designed by the system and completing the graphing between business objects and the database.

Template: It is responsible for presenting the front-end page to the user.

View: It is responsible for designing system functions and writing business logic and then coordinating calls to Model and Template.

In addition to the aforementioned three layers, Django also has a URL dispatcher. Its function is to distribute a page request for URL to different views, which then call the corresponding Model and Template and send them to the front end for display.

3.1.2 Store Database

Considering the complexity of data types of power transformers, this system uses the relational database MySQL and the non-relational graph database Neo4j to store data. Among them, the MySQL database is used to store structured data such as transformer attribute information and real-time monitoring gas data on transformers, and the Neo4j database is used to store triples extracted from the unstructured data such as equipment maintenance procedures and fault case reports to build power transformer knowledge graphs.

MySQL is a classic and easy-to-operate relational database. For the transformer property information and real-time monitoring data information in this system have a strong correlation, the MySQL database is used to store this information.

When using the MySQL database, the system creates corresponding storage data tables, according to different storage information of transformers, and then uses one-to-one, one-to-many, and many-to-many operations to associate the related data tables so as to facilitate the system store data and joint table query and other operations.

The Neo4j graph database is a mature graph engine with excellent performance and has the excellent characteristics of the non-relational database. The system saves the text information after knowledge fusion into the Neo4j graph database and uses the Neo4j graph database to construct the knowledge graph of power transformers, thus greatly improving the performance of unstructured data retrieval.

In terms of Neo4j data storage, the system adopts the LOAD CSV statement of Cypher. CSV files can be directly loaded into Neo4j by Cypher. The triplet data are converted into CSV format for storage, and then, the LOAD CSV method is used to make Neo4j read the data.

3.2 Automatic Construction Technology and Application of the Power Transformer Knowledge Graph

3.2.1 Automatic Construction Technology of the Transformer Knowledge Graph

The most basic attribute units of the knowledge graph are nodes that represent entities and edges that represent relations between entities. Therefore, to construct the knowledge graph, triples should be extracted from the text first.

In this system, first, in the transformer text participle, the text type is concise and possesses wide compatibility of the JSON format; as a result of the first word segmentation, the result is relatively rough and may contain both transformer-related words or unrelated words, thus introducing transformer professional thesaurus which optimizes the initial segmentation result and then the final segmentation result of words into a vector. Then, the dilating-gate convolutional neural network (DGCNN) was used to extract triples combined with the self-attention mechanism. Finally, the triplet set was imported into Neo4j to complete the automatic construction of the transformer knowledge graph.

3.2.2 Transformer Knowledge Graph Reasoning Technology

In order to retrieve the knowledge graph stored in Neo4j, the system connects to the Neo4j database through the Py2Neo third-party library and queries the information as needed.

The transformer knowledge graph is a large network of the knowledge structure, which takes transformer components, fault phenomena, and fault causes as nodes and connects them according to corresponding relationships. When users initiate retrieval in the system, the system can use the existing knowledge graph to detect the semantic analysis of the input information and map it to one or more entities and edge relations in the knowledge graph and then perform path reasoning, according to the edges connected to the entities or nodes connected to the edges, and finally output high-quality search results at the user end.

3.3 Gas Prediction and Fault Diagnosis Technology of Transformer Based on the Graph Neural Network

The transformer fault prediction technology based on the dissolved gas analysis, uses the graph neural network and time sequence prediction neural network to find the time sequence variation of the dissolved gases in transformer oil and the relationship between the gas content and transformer fault and then establishes the fault diagnosis and prediction model.

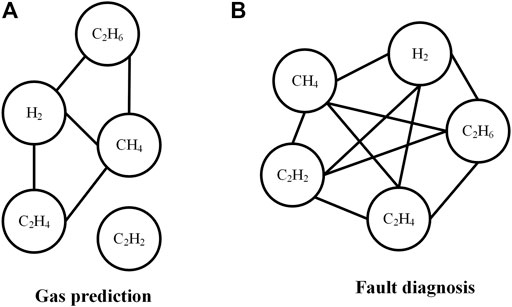

The graph neural network learns and mines information from the relation topologies. For the gas prediction model, Pearson correlation coefficients of five transformer characteristic gas content change sequences were calculated to build a topology diagram of the relationship between gases, as shown in Figure 2A; For the fault diagnosis model, considering the strong relationship between the content of five gases and transformer fault types, the topology diagram of their relationship is designed to connect with each other, as shown in Figure 2B. Because the model uses the graph neural network layer to mine the relationship information between characteristic gases of the transformer, the information learned from the model is more abundant, and the accuracy and reliability of gas prediction and fault diagnosis are improved.

3.4 Transformer State Evaluation Technology Based on the Graph Neural Network

This system selects data from the four aspects of a transformer to fulfill the prediction. There are electrical test data, dissolved gas data, insulating oil test data, and operational data to establish the transformer state evaluation system.

The system determines the values of four first-level indexes through the analytic hierarchy process. In order to mine the possible relationship information between the four first-level indicators, the relationship topology of the four indicators should be established, the graph neural network should be used to mine the relationship between the indicators, and a multi-layer linear network should be set up to accomplish the final evaluation model.

The system fully considers the relationship between the indicators and uses the graph neural network method to obtain information, which is more in line with the actual situation of the mutual influence between the four first-level indicators, and achieves a more objective transformer state evaluation.

4 System Application

4.1 Automatic Construction and Application Function of the Knowledge Graph

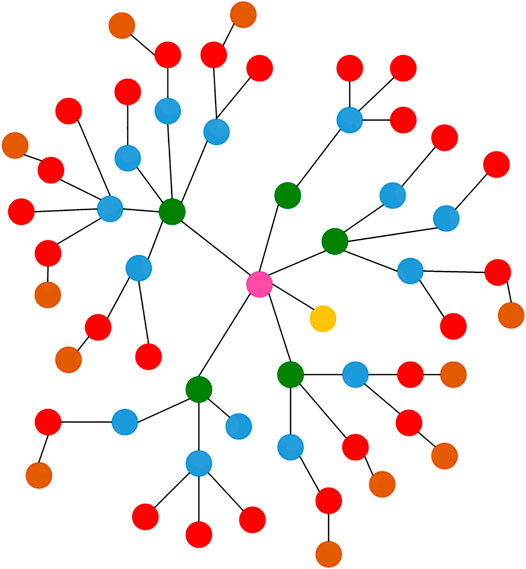

In Figure 3, each node represents an entity, each edge represents a relationship, nodes are connected by edges, and different colors of nodes represent different entity attributes. Yellow represents the equipment type (110 kv main transformer), pink represents the device type (oil-immersed transformer), green represents major components’ load switches (if any), blue for the site (e.g., oil storage tank, winding, etc.), red for the defect phenomenon such as the transformer, that is, water being affected with damp, running short circuit, etc., brown on behalf of processing measures (such as maintenance and replacement). The connected edge between the nodes represents the relationship between the two entities, such as cause, phenomenon, and measure.

When transformer faults occur, the knowledge graph can be used for fault analysis. For example, when the oil chromatographic fault occurs in the tank and the device alarms, the knowledge graph can be used to query relevant knowledge, and according to the query results, the possible cause of the fault is “partial discharge”. The measures to solve the fault can be found along the edge of the “treatment measures” of the connecting node, that is, “maintenance of the hanging cover and oil filtering treatment”.

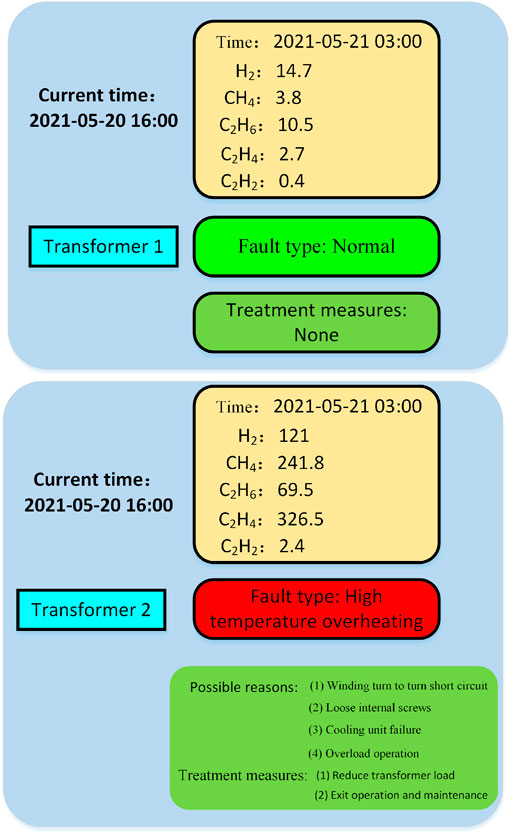

4.2 Transformer Fault Prediction Based on the Graph Neural Network

According to the recent characteristic gas content of each transformer, the system uses the fault diagnosis and prediction model to predict the gas content and transformer state. When the transformer is in abnormal state, the possible cause and treatment measures are deduced through the transformer knowledge graph. As shown in Figure 4, transformer No. 2 in the system predicts the abnormal gas content at a certain point in the future and then diagnoses the abnormal gas content and gives a warning for the high-temperature overheating fault. Meanwhile, the corresponding fault inducements and handling measures of the fault are output at the user end.

5 Conclusion

In this article, the knowledge graph technology is applied on the power transformer intelligent operation and maintenance system, and the power transformer knowledge graph is constructed by using the massive multi-source heterogeneous data generated in the process of transformer operation and maintenance, which enhances the ability of the transformer operation and maintenance system to mine massive data intelligently. At the same time, the graph neural network is used to capture the multi-dimensional coupling relationship between the data, and the transformer fault analysis and prediction technology and the transformer state evaluation technology are improved, which enhances the prediction and reasoning ability, generalization ability, and explainable ability of the neural network model.

The construction of the power transformer intelligent operations system realizes all-round management in the process of the transformer operations. During normal operation, it can undertake intelligence q&a-associated search. Before and during the accident, it forecasts the remaining life of the transformer, alarms the hidden trouble that may cause failure events, and recommends solutions, which is convenient for the arrangement of maintenance plan. After the accident, according to the fault phenomenon, it accurately locates the cause of the fault, and provides the maintenance strategy. Through predictive maintenance of the power transformers, the system reduces downtime and eliminates unnecessary maintenance, which improves the efficiency of the power transformer operation and maintenance management business. It is of great significance to the safe operation of transformers and the stability of the power system.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding authors.

Author Contributions

HH: conceptualization, methodology, validation, and writing—review; FF: software, visualization, and writing—original draft. All authors contributed to the manuscript and approved the submitted version.

Funding

This work was supported by the Science and Technology Project of State Grid Shanxi Electric Power Co., Ltd., China (SGSXJC00YCJS2100679).

Conflict of Interest

Authors WC and KZ were employed by the company Jincheng Power Supply Company, State Grid Shanxi Electric Power Co.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary Material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenrg.2022.935359/full#supplementary-material

References

He, Y., Zhou, B., Guo, S., Yang, Y., Xiang, Y., Hu, Z., et al. (2021). "Meta Ensemble Learning with Acoustic Spectrum Analysis for Intelligent Diagnosis of Direct-Buried Transformer Substations," In 2021 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Chengdu, China, 18-21 July 2021, 539–544. doi:10.1109/icpsasia52756.2021.9621612

Hua, J. (2010). "The Realization of the Support System of the Substation in .NET Framework," In 2010 Second International Conference on Future Networks, Sanya, China, 22-24 Jan. 2010, 391–394. doi:10.1109/icfn.2010.18

Kari, T., Gao, W. S., Liu, Y. Q., Yu-Qiang, C., and Hua, L. (2016). “Condition Assessment of Power Transformer Using Fuzzy and Evidential Theory,” in 2016 International Conference on Condition Monitoring and Diagnosis (CMD). Xi'an, China. 25-28 Sept. 2016, 28–31. doi:10.1109/cmd.2016.7757759

Liao, W., Bak-Jensen, B., Radhakrishna Pillai, J., Wang, Y., and Wang, Y. (2022). A Review of Graph Neural Networks and Their Applications in Power Systems. J. Mod. Power Syst. Clean Energy 10, 345–360. doi:10.35833/MPCE.2021.000058

Liu, L., Wang, B., Ma, F., Zheng, Q., Yao, L., Zhang, C., et al. (2022). A Concurrent Fault Diagnosis Method of Transformer Based on Graph Convolutional Network and Knowledge Graph. Front. Energy Res. 10, 1. doi:10.3389/fenrg.2022.837553

Liu, Y., Su, J., and Liu, F. (2009). "Design about Real-Time Fault Detection Information System of the Transformer Substation," In 2009 International Conference on Computer Engineering and Technology, Singapore, 22-24 Jan. 2009, 197–200. doi:10.1109/iccet.2009.239

Qiangchao, X., Yang, L., Tingfang, Y., Zhiyong, L., and Wei, L. (2020). "Prediction Method of Dissolved Gas Concentration in Transformer Oil Based on LSTSVR Model," In 2020 7th International Forum on Electrical Engineering and Automation (IFEEA), Hefei, China, 25-27 Sept. 2020, 29–32. doi:10.1109/ifeea51475.2020.00014

Suwnansri, T. (2014). Asset Management of Power Transformer: Optimization of Operation and Maintenance Costs. 2014 International Electrical Engineering Congress (iEECON). Chonburi, Thailand. 19-21 March 2014. 1–4. doi:10.1109/ieecon.2014.6925972

Takahashi, T., and Okamoto, T. (2016). Development of Asset Management Support Tools for Oil-Immersed Transformer. IEEE Trans. Dielect. Electr. Insul. 23, 1643–1647. doi:10.1109/TDEI.2016.005574

Wu, Z., Zhou, M., Lin, Z., Chen, X., and Huang, Y. (2021). Improved Genetic Algorithm and XGBoost Classifier for Power Transformer Fault Diagnosis. Front. Energy Res. 9, 1. doi:10.3389/fenrg.2021.745744

Xie, B., Zhao, D., and Hong, T. (2020). Transformer Monitoring and Protection in Dynamic Power Systems - A Review. Front. Energy Res. 8. doi:10.3389/fenrg.2020.00150

Zhang, F., Zhang, Y., and Xu, T. (2020). “A Review of Knowledge Graph Technology in the Field of Automatic Question Answering,” in 2020 International Signal Processing, Communications and Engineering Management Conference (ISPCEM). Montreal, QC, Canada. 27-29 Nov. 2020, 177–180. doi:10.1109/ispcem52197.2020.00042

Zhang, J., Zhang, H., Ding, S., and Zhang, X. (2021). Power Consumption Predicting and Anomaly Detection Based on Transformer and K-Means. Front. Energy Res. 9, 1. doi:10.3389/fenrg.2021.779587

Zhou, B., Zou, J., Yung Chung, C., Wang, H., Liu, N., Voropai, N., et al. (2021). Multi-microgrid Energy Management Systems: Architecture, Communication, and Scheduling Strategies. J. Mod. Power Syst. Clean Energy 9, 463–476. doi:10.35833/MPCE.2019.000237

Keywords: power transformer, intelligent operation and maintenance system, graph neural network, data management technology, knowledge graph

Citation: Chen W, Luo D, Fu F, He H and Zhang K (2022) Research on the Transformer Intelligent Operation and Maintenance System Based on the Graph Neural Network. Front. Energy Res. 10:935359. doi: 10.3389/fenrg.2022.935359

Received: 03 May 2022; Accepted: 19 May 2022;

Published: 28 June 2022.

Edited by:

Jian Zhao, Shanghai University of Electric Power, ChinaReviewed by:

Shuaihu Li, Changsha University of Science and Technology, ChinaTianguang Lu, Shandong University, China

Copyright © 2022 Chen, Luo, Fu, He and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: DianSheng Luo, bGh4MjAwNzAzMjJAaG51LmVkdS5jbg==; HongYing He, bGh4MjAwNzAzMjJAc2luYS5jb20=

WenGang Chen1

WenGang Chen1 FangYu Fu

FangYu Fu HongYing He

HongYing He