- 1College of Electrical, Energy and Power Engineering, Yangzhou University, Yangzhou, China

- 2Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education, School of Energy and Environment, Southeast University, Nanjing, China

Introduction

Thermal energy is stored in a packed bed thermal energy storage (PBTES) system by raising the temperature of the packing elements. This simple mechanism and economic feasibility (Gautam and Saini, 2020) make the PBTES promising for applications such as solar thermal power plants, building cooling systems, and waste heat recovery (Nallusamy et al., 2007). The traditional PBTES is based on sensible heat transfer and is therefore limited by a low energy density and temperature stability (Mawire et al., 2020). Compared with the traditional system, a packed bed latent heat storage (PBLHS) system based on phase-change materials (PCMs) (Wang H. et al., 2018; Wang J. et al., 2018) offers advantages such as a higher energy density, higher temperature stability, and few safety issues (Li et al., 2018; Kumar and Saha, 2021; Wang et al., 2021) and therefore is considered a promising solution for thermal energy storage (Yang et al., 2017; Zhang et al., 2020; Grabo et al., 2021).

This study reviews recent progress on low-temperature PBLHS systems with phase-change points below 100°C. A brief discussion of the working principle and impact factors of the PBLHS system is presented based on results from recent studies (Alptekin and Ezan, 2021). The performance and applications of PBLHS systems are also discussed.

Characteristics of the Packed Bed Latent Heat Storage System

Structure and Working Principle of the Packed Bed Latent Heat Storage System

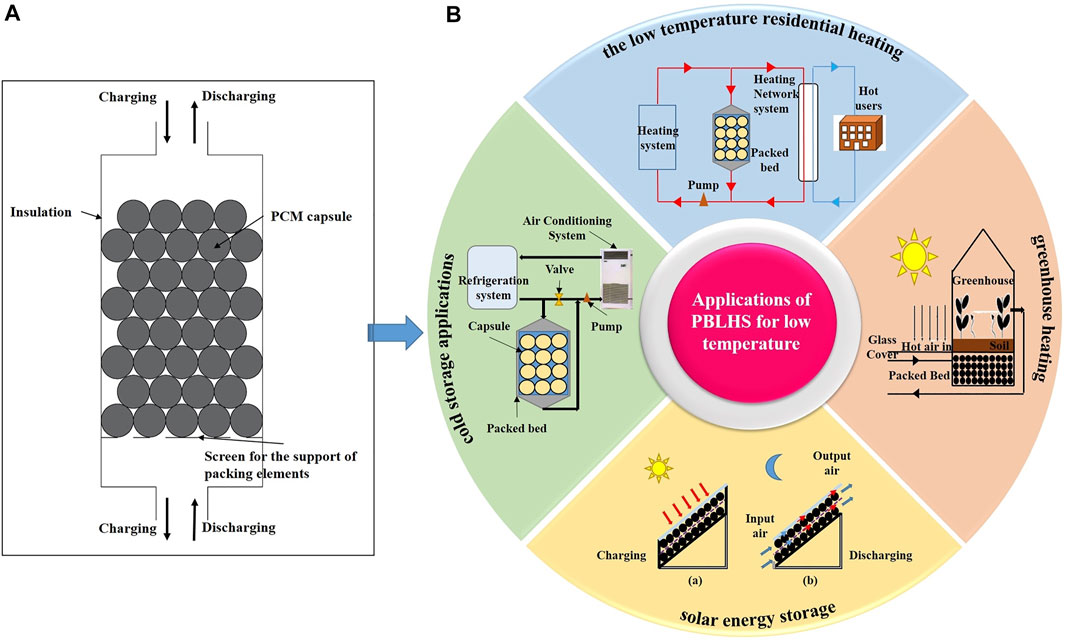

A typical low-temperature PBLHS system (Liu and Zhao, 2021; He et al., 2022) consists of a heat storage tank, a heat transfer fluid (HTF), and heat storage media (HSM). The structure of a PBLHS system is shown in Figure 1A. Capsules containing low-temperature PCMs constitute the HSM, which is supported by a screen in the lower portion of the heat storage tank. The heat storage tank is surrounded by a layer of insulation material to reduce thermal energy loss. During the charging and discharging process, the HTF percolates through the HSM (Singh et al., 2010). The HSM packing is a porous medium with a high surface-to-volume ratio at the macroscopic level, which enhances heat transfer (Yang et al., 2019; Yang et al., 2020). Heat transfer between the HSM and HTF enables the charging and discharging of the PBLHS system (Guo et al., 2021). The buoyancy effect causes the high-temperature HTF to enter the top of the heat storage tank during the charging process (Zanganeh et al., 2012). The HSM near the inlet is heated first. The temperature gradient across the HSM from the inlet to the outlet results in the lower portion of the HSM also being heated by the upper portion of the HSM (Qin et al., 2012). During the discharging process, the thermal energy stored in the HSM is released by heat transfer between the low-temperature HTF and the high-temperature HSM.

FIGURE 1. Structure and applications of a low-temperature PBLHS system. (A) Structure; (B) Applications.

Materials of the Packed Bed Latent Heat Storage System

HSMs in the form of spherical capsules have been found to exhibit superior thermohydraulic performance (Singh et al., 2013). In a low-temperature PBLHS system, the HSM consists of spherical capsules filled with PCMs, such as paraffin (Nallusamy et al., 2007; Wang et al., 2017), water (Fang et al., 2010), n-tetradecane (Wu et al., 2010), and composite materials (Cheng and Zhai, 2018). The macro-encapsulated PCMs can be made by filling a pre-made shell with liquid PCM (Liu et al., 2018). The micro-encapsulated PCMs can be fabricated by physical, chemical, or physicochemical methods, that is, spray drying (Alva et al., 2017), interfacial polymerization (Milián et al., 2017), and droplet microfluidics (Chen et al., 2013; Han et al., 2020). The use of large PCM capsules results in poor thermal performance and low energy loss. However, small PCM capsules induce a large pressure drop across the HTF (Li et al., 2018; Alptekin and Ezan, 2021). Therefore, the PCM capsule size should be determined based on a comprehensive evaluation of the thermal performance and pumping power of the PBLHS system (Pakrouh et al., 2017).

Both liquids and gases, that is, water (Cheng and Zhai, 2018), ethylene glycol (Fang et al., 2010), and air (Arfaoui et al., 2017), can be used as the HTF in the PBLHS system. A liquidus HTF has a large heat transfer ecoefficiency and can be used to fabricate a PBLHS system with a high charging/discharging rate (Felix Regin et al., 2009). However, the large flow resistance of a liquidus HTF produces a large pressure drop across the PBLHS system. Air is typically used as a gaseous HTF because of its low cost and high-temperature resistance. However, the low thermal conductivity of a gaseous HTF results in a low charging/discharging rate for the PBLHS system. Thus, a HTF should be selected by considering the influence factors for the system, including the HTF cost, estimated charging/discharging rate of the PBLHS system, and pumping power (de Gracia and Cabeza, 2017).

Factors Affecting the Packed Bed Latent Heat Storage System Performance

The various factors affecting the performance of the PBLHS system can be categorized into structural and material factors. As a PBLHS system can be treated as a porous medium at the macroscopic level, the effect of the packing structure determines the heat transfer between the HSM and the HTF, as well as the pressure drop in the PBLHS system (Deng et al., 2017). In order to maintain a balance between the heat transfer and pressure drop, the size and aspect ratio of the HSM should be optimized. A high void fraction, that is, a high ratio of the volume of the voids in the bed to the total bed volume, enhances the thermal conductivity of the HSM but induces a large pressure drop across the PBLHS system.

The thermal properties of the materials in the PBLHS system determine the heat transfer in the system, including convection and conduction. Specifically, heat transfer within the PBLHS system combines conduction between the wall and HSM, convection between the HSM and HTF, convection between the wall surface and HTF, and even radiation from the HSM. The effective thermal conductivity is used as a comprehensive measure of the heat transfer within the PBLHS system.

Performance Evaluation of the Packed Bed Latent Heat Storage System

Energy efficiency is typically used to evaluate the energy storage performance of a PBLHS system and is expressed as the ratio between the energy recovered from the PBLHS system and the energy delivered to the PBLHS system (Yang and Garimella, 2010). Arfaoui et al. used a PBLHS system with air as the HTF and CaCl26H2O as the PCM to increase the efficiency of a solar air collector. The maximum absorbed energy reached 730 kJ, and the daily energy efficiency was approximately 47% Arfaoui et al. (2017).

However, irreversible losses were not considered in the energy analysis. The exergy efficiency, the ratio of the total exergy recovered from the PBLHS system to the total exergy delivered to the PBLHS system, is preferred as a measure of the comprehensive system performance (Saha and Das, 2020; Mawire et al., 2021). Cheng et al. found that the exergy efficiency decreases from 83.1% to 79.4% as the capsule size increases from 9.5 mm to 47.5 mm (Cheng and Zhai, 2018).

As applications of the PBLHS system are sometimes limited by the large capital investment involved, it is important to consider the cost of a PBLHS system. The levelized cost of electricity (LCOE) is the most commonly used indicator of the economic feasibility of a PBLHS system. Tehrani et al. performed a techno-economic comparative analysis on a PBLHS system and a shell-and-tube latent storage system based on the thermal storage capacity for a 19.9 MWe solar power plant. The cost of a PBLHS system with a wall thickness of no more than 0.1 mm is ∼10 US$ kWhth Mostafavi Tehrani et al. (2019).

Applications of Low-Temperature Packed Bed Latent Heat Storage Systems

A low-temperature PBLHS system can be integrated with residential heating (He et al., 2019b; Xu et al., 2020), greenhouse heating (Baddadi et al., 2019), and solar collectors (Desai et al., 2022). Baddadi et al. (2019)designed a greenhouse with a PBLHS system, utilizing CaCl2.6H2O as the PCM and air as the HTF. The system was found to enhance the greenhouse microclimate. Cheng and Zhai (2018) reported a cascaded packed bed based on cool thermal energy storage, with water and a composite material (C-L/O) as the HTF and PCM, respectively. The most efficient 24-stage unit had a 15.1% lower charging time than a single-stage unit and a similar thermal performance to a 3–5 stage system. He et al. (2019a) designed a PBLHS system integrated with a water tank to enhance the electric power load regulation capacity and the heat-supply capacity. The energy storage capacity increased by 29.62% theoretically. Wu et al. (2022) also discussed the application and optimization of the PBLHS system in hot-water supply, theoretically and experimentally. The system has better thermal stratification when the PCM units are placed at a higher place and near the inlet of the high-temperature water, and the flow rate is 3 L/min. The PBLHS system can also be used for the drying process (Atalay, 2020), with an average energy efficiency of 68.55%.

Conclusion and Prospects

This study presents a brief introduction to the structure and the working principles of the PBLHS system. The impact factors and performance of the PBLHS system have been discussed. The packing structure of a PBLHS system significantly affects thermal performance. The PBLHS system performance is commonly evaluated using the energy efficiency and exergy efficiency, between which the exergy efficiency is more accurate and therefore preferred. In addition, applications of low-temperature PBLHS systems, especially for buildings, are introduced. However, a few studies have been carried out on the economic aspects of low-temperature PBLHS systems. Further investigations on optimizing the design and economic feasibility of low-temperature PBLHS systems are encouraged.

Author Contributions

CZ and SW developed the concept of the study. DC wrote the first draft of the manuscript. CY revised the manuscript. All authors revised the manuscript and read and approved the submitted version.

Funding

This study was supported by the Natural Science Foundation of Jiangsu Province (Grant no. BK20210239) and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (Grant no. SJCX22_1738).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alptekin, E., and Ezan, M. A. (2021). A Systematic Assessment on a Solar Collector Integrated Packed-Bed Single/multi-Layered Latent Heat Thermal Energy Storage System. J. Energy Storage 37, 102410. doi:10.1016/j.est.2021.102410

Alva, G., Lin, Y., Liu, L., and Fang, G. (2017). Synthesis, Characterization and Applications of Microencapsulated Phase Change Materials in Thermal Energy Storage: A Review. Energy Build. 144, 276–294. doi:10.1016/j.enbuild.2017.03.063

Arfaoui, N., Bouadila, S., and Guizani, A. (2017). A Highly Efficient Solution of Off-Sunshine Solar Air Heating Using Two Packed Beds of Latent Storage Energy. Sol. Energy 155, 1243–1253. doi:10.1016/j.solener.2017.07.075

Atalay, H. (2020). Assessment of Energy and Cost Analysis of Packed Bed and Phase Change Material Thermal Energy Storage Systems for the Solar Energy-Assisted Drying Process. Sol. Energy 198, 124–138. doi:10.1016/j.solener.2020.01.051

Baddadi, S., Bouadila, S., and Guizani, A. (2019). Beneficial Use of Two Packed Beds of Latent Storage Energy for the Heating of a Hydroponic Greenhouse. Energy Procedia 162, 156–163. doi:10.1016/j.egypro.2019.04.017

Chen, Y., Liu, X., and Shi, M. (2013). Hydrodynamics of Double Emulsion Droplet in Shear Flow. Appl. Phys. Lett. 102 (5), 051609. doi:10.1063/1.4789865

Cheng, X., and Zhai, X. (2018). Thermal Performance Analysis and Optimization of a Cascaded Packed Bed Cool Thermal Energy Storage Unit Using Multiple Phase Change Materials. Appl. Energy 215, 566–576. doi:10.1016/j.apenergy.2018.02.053

de Gracia, A., and Cabeza, L. F. (2017). Numerical Simulation of a PCM Packed Bed System: A Review. Renew. Sustain. Energy Rev. 69, 1055–1063. doi:10.1016/j.rser.2016.09.092

Deng, Z., Liu, X., Zhang, C., Huang, Y., and Chen, Y. (2017). Melting Behaviors of PCM in Porous Metal Foam Characterized by Fractal Geometry. Int. J. Heat Mass Transf. 113, 1031–1042. doi:10.1016/j.ijheatmasstransfer.2017.05.126

Desai, N. B., Mondejar, M. E., and Haglind, F. (2022). Techno-economic Analysis of Two-Tank and Packed-Bed Rock Thermal Energy Storages for Foil-Based Concentrating Solar Collector Driven Cogeneration Plants. Renew. Energy 186, 814–830. doi:10.1016/j.renene.2022.01.043

Fang, G., Wu, S., and Liu, X. (2010). Experimental Study on Cool Storage Air-Conditioning System with Spherical Capsules Packed Bed. Energy Build. 42 (7), 1056–1062. doi:10.1016/j.enbuild.2010.01.018

Felix Regin, A., Solanki, S. C., and Saini, J. S. (2009). An Analysis of a Packed Bed Latent Heat Thermal Energy Storage System Using PCM Capsules: Numerical Investigation. Renew. Energy 34 (7), 1765–1773. doi:10.1016/j.renene.2008.12.012

Gautam, A., and Saini, R. P. (2020). A Review on Technical, Applications and Economic Aspect of Packed Bed Solar Thermal Energy Storage System. J. Energy Storage 27, 101046. doi:10.1016/j.est.2019.101046

Grabo, M., Acar, E., and Kenig, E. Y. (2021). Modeling and Improvement of a Packed Bed Latent Heat Storage Filled with Non-spherical Encapsulated PCM-Elements. Renew. Energy 173, 1087–1097. doi:10.1016/j.renene.2021.04.022

Guo, W., He, Z., Meng, Z., and Zhang, P. (2021). A Comprehensive Investigation of the Mathematical Models for a Packed Bed Latent Heat Thermal Energy Storage System. Int. J. Energy Res. 45 (10), 15005–15021. doi:10.1002/er.6780

Han, X., Kong, T., Zhu, P., and Wang, L. (2020). Microfluidic Encapsulation of Phase-Change Materials for High Thermal Performance. Langmuir 36 (28), 8165–8173. doi:10.1021/acs.langmuir.0c01171

He, X., Qiu, J., Wang, W., Hou, Y., Ayyub, M., and Shuai, Y. (2022). A Review on Numerical Simulation, Optimization Design and Applications of Packed-Bed Latent Thermal Energy Storage System with Spherical Capsules. J. Energy Storage 51, 104555. doi:10.1016/j.est.2022.104555

He, Z., Wang, X., Du, X., Amjad, M., Yang, L., and Xu, C. (2019a). Experiments on Comparative Performance of Water Thermocline Storage Tank with and without Encapsulated Paraffin Wax Packed Bed. Appl. Therm. Eng. 147, 188–197. doi:10.1016/j.applthermaleng.2018.10.051

He, Z., Wang, X., Du, X., Xu, C., and Yang, L. (2019b). Cyclic Characteristics of Water Thermocline Storage Tank with Encapsulated PCM Packed Bed. Int. J. Heat Mass Transf. 139, 1077–1086. doi:10.1016/j.ijheatmasstransfer.2019.05.093

Kumar, A., and Saha, S. K. (2021). Performance Analysis of a Packed Bed Latent Heat Thermal Energy Storage with Cylindrical‐shaped Encapsulation. Int. J. Energy Res. 45 (9), 13130–13148. doi:10.1002/er.6639

Li, M.-J., Jin, B., Yan, J.-J., Ma, Z., and Li, M.-J. (2018). Numerical and Experimental Study on the Performance of a New Two-Layered High-Temperature Packed-Bed Thermal Energy Storage System with Changed-Diameter Macro-Encapsulation Capsule. Appl. Therm. Eng. 142, 830–845. doi:10.1016/j.applthermaleng.2018.07.026

Liu, H. B., and Zhao, C. Y. (2021). Effect of Radial Porosity Oscillation on the Thermal Performance of Packed Bed Latent Heat Storage. Engineering 7 (4), 515–525. doi:10.1016/j.eng.2020.05.020

Liu, Z., Yu, Z., Yang, T., Qin, D., Li, S., Zhang, G., et al. (2018). A Review on Macro-Encapsulated Phase Change Material for Building Envelope Applications. Build. Environ. 144, 281–294. doi:10.1016/j.buildenv.2018.08.030

Mawire, A., Ekwomadu, C. S., and Shobo, A. B. (2021). Experimental Charging Characteristics of Medium-Temperature Cascaded Packed Bed Latent Heat Storage Systems. J. Energy Storage 42, 103067. doi:10.1016/j.est.2021.103067

Mawire, A., Lefenya, T. M., Ekwomadu, C. S., and Shobo, A. B. (2020). Performance of a Medium Temperature Eutectic Solder Packed Bed Latent Heat Storage System for Domestic Applications. J. Energy Storage 28, 101294. doi:10.1016/j.est.2020.101294

Milián, Y. E., Gutiérrez, A., Grágeda, M., and Ushak, S. (2017). A Review on Encapsulation Techniques for Inorganic Phase Change Materials and the Influence on Their Thermophysical Properties. Renew. Sustain. Energy Rev. 73, 983–999. doi:10.1016/j.rser.2017.01.159

Mostafavi Tehrani, S. S., Shoraka, Y., Nithyanandam, K., and Taylor, R. A. (2019). Shell-and-tube or Packed Bed Thermal Energy Storage Systems Integrated with a Concentrated Solar Power: A Techno-Economic Comparison of Sensible and Latent Heat Systems. Appl. Energy 238, 887–910. doi:10.1016/j.apenergy.2019.01.119

Nallusamy, N., Sampath, S., and Velraj, R. (2007). Experimental Investigation on a Combined Sensible and Latent Heat Storage System Integrated with Constant/varying (Solar) Heat Sources. Renew. Energy 32 (7), 1206–1227. doi:10.1016/j.renene.2006.04.015

Pakrouh, R., Hosseini, M. J., Ranjbar, A. A., and Bahrampoury, R. (2017). Thermodynamic Analysis of a Packed Bed Latent Heat Thermal Storage System Simulated by an Effective Packed Bed Model. Energy 140, 861–878. doi:10.1016/j.energy.2017.08.055

Qin, F. G. F., Yang, X., Ding, Z., Zuo, Y., Shao, Y., Jiang, R., et al. (2012). Thermocline Stability Criterions in Single-Tanks of Molten Salt Thermal Energy Storage. Appl. Energy 97, 816–821. doi:10.1016/j.apenergy.2012.02.048

Saha, S. K., and Das, R. B. (2020). Exergetic and Performance Analyses of Two‐layered Packed Bed Latent Heat Thermal Energy Storage System. Int. J. Energy Res. 44 (3), 2208–2225. doi:10.1002/er.5081

Singh, H., Saini, R. P., and Saini, J. S. (2010). A Review on Packed Bed Solar Energy Storage Systems. Renew. Sustain. Energy Rev. 14 (3), 1059–1069. doi:10.1016/j.rser.2009.10.022

Singh, H., Saini, R. P., and Saini, J. S. (2013). Performance of a Packed Bed Solar Energy Storage System Having Large Sized Elements with Low Void Fraction. Sol. Energy 87, 22–34. doi:10.1016/j.solener.2012.10.004

Wang, F., Dong, Y., Li, Y., Xu, J., and Zhang, G. (2021). Numerical Study on the Thermal Performance of Packed-Bed Latent Heat Thermal Energy Storage System with Biomimetic Alveoli Structure Capsule. Sci. China Technol. Sci. 64 (7), 1544–1554. doi:10.1007/s11431-020-1769-9

Wang, H., Zhao, Z., Liu, Y., Shao, C., Bian, F., and Zhao, Y. (2018a). Biomimetic Enzyme Cascade Reaction System in Microfluidic Electrospray Microcapsules. Sci. Adv. 4 (6), eaat2816. doi:10.1126/sciadv.aat2816

Wang, J., Gao, W., Zhang, H., Zou, M., Chen, Y., and Zhao, Y. (2018b). Programmable Wettability on Photocontrolled Graphene Film. Sci. Adv. 4 (9), eaat7392. doi:10.1126/sciadv.aat7392

Wang, J., Sun, L., Zou, M., Gao, W., Liu, C., Shang, L., et al. (2017). Bioinspired Shape-Memory Graphene Film with Tunable Wettability. Sci. Adv. 3 (6), e1700004. doi:10.1126/sciadv.1700004

Wu, F., Wang, Z., Zhang, H., Qin, Y., You, X., and Lu, J. (2022). Experimental and Simulation Analysis on Thermal Stratification Characteristics in Solar Storage Tanks with Phase Change Materials. J. Energy Storage 46, 103722. doi:10.1016/j.est.2021.103722

Wu, S., Fang, G., and Liu, X. (2010). Thermal Performance Simulations of a Packed Bed Cool Thermal Energy Storage System Using N-Tetradecane as Phase Change Material. Int. J. Therm. Sci. 49 (9), 1752–1762. doi:10.1016/j.ijthermalsci.2010.03.014

Xu, T., Humire, E. N., Chiu, J. N.-W., and Sawalha, S. (2020). Numerical Thermal Performance Investigation of a Latent Heat Storage Prototype toward Effective Use in Residential Heating Systems. Appl. Energy 278, 115631. doi:10.1016/j.apenergy.2020.115631

Yang, X., Feng, S., Zhang, Q., Chai, Y., Jin, L., and Lu, T. J. (2017). The Role of Porous Metal Foam on the Unidirectional Solidification of Saturating Fluid for Cold Storage. Appl. Energy 194, 508–521. doi:10.1016/j.apenergy.2016.09.050

Yang, X., Yu, J., Guo, Z., Jin, L., and He, Y.-L. (2019). Role of Porous Metal Foam on the Heat Transfer Enhancement for a Thermal Energy Storage Tube. Appl. Energy 239, 142–156. doi:10.1016/j.apenergy.2019.01.075

Yang, X., Yu, J., Xiao, T., Hu, Z., and He, Y.-L. (2020). Design and Operating Evaluation of a Finned Shell-And-Tube Thermal Energy Storage Unit Filled with Metal Foam. Appl. Energy 261, 114385. doi:10.1016/j.apenergy.2019.114385

Yang, Z., and Garimella, S. V. (2010). Thermal Analysis of Solar Thermal Energy Storage in a Molten-Salt Thermocline. Sol. Energy 84 (6), 974–985. doi:10.1016/j.solener.2010.03.007

Zanganeh, G., Pedretti, A., Zavattoni, S., Barbato, M., and Steinfeld, A. (2012). Packed-bed Thermal Storage for Concentrated Solar Power - Pilot-Scale Demonstration and Industrial-Scale Design. Sol. Energy 86 (10), 3084–3098. doi:10.1016/j.solener.2012.07.019

Keywords: thermal energy storage, packed bed, latent heat, low-temperature, phase-change materials

Citation: Cao D, Yu C, Wu S and Zhang C (2022) Perspectives on Low-Temperature Packed Bed Latent Heat Storage Systems. Front. Energy Res. 10:935100. doi: 10.3389/fenrg.2022.935100

Received: 03 May 2022; Accepted: 09 May 2022;

Published: 13 June 2022.

Edited by:

Xiaohu Yang, Xi’an Jiaotong University, ChinaReviewed by:

Hao Peng, Nanjing Tech University, ChinaCopyright © 2022 Cao, Yu, Wu and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Suchen Wu, c3VjaGVud3VAc2V1LmVkdS5jbg==

Dongcheng Cao1

Dongcheng Cao1 Cheng Yu

Cheng Yu Suchen Wu

Suchen Wu Chengbin Zhang

Chengbin Zhang