- Department of Information Systems, Faculty of Management, Comenius University in Bratislava, Bratislava, Slovakia

The implementation of climate protection cannot succeed without increasing energy efficiency in companies. Increasing energy efficiency is an important success factor for the energy transition, but unfortunately, the energy saving potentials are only insufficiently exploited. The aim of this study is, therefore, to highlight the current state of research on energy efficiency potentials in companies at the technology level. For this purpose, an extensive literature search was conducted with more than 30 keywords. After screening and cleaning, 101 articles were selected and reviewed in detail. The literature search was performed using eight evaluation criteria: origin and year of publication, type of company, type of industry, type of data, survey method, number of participants, data collection method, and analysis method. In order to evaluate the statements and results of the considered works, a SWOT analysis was used. Our analysis revealed that: 1) studies explicitly addressing energy efficiency measures and potentials at the technology level are scarce. Even fewer studies address the relationships and interactions (positive or negative) between individual measures; 2) most studies focus on large and manufacturing companies, most of which are energy intensive. SMEs in the non-manufacturing sector, such as trade, commerce, and services, are far less represented; and 3) the chosen research focus and content are often barriers, drivers, and theory models for energy efficiency, and secondary data are mostly used. Of the studies that considered primary data, 71% used a questionnaire survey. Research into the interactions between individual measures enables policymakers to target business support programs.

1 Introduction

The aim of this work is to highlight the current state of research on energy efficiency potentials in companies at the technology level and to examine whether sufficient research exists and, if so, whether there is empirical evidence to support it.

The climate protection goals required by the European Union (EU) cannot be achieved without increasing energy efficiency in companies. Increasing energy efficiency is an important success factor for the energy transition, but unfortunately, the energy saving potential, for example, in Germany is only insufficiently exploited (Gamst, 2019).

In addition to the potential within companies, however, the external potential of the energy network is also of crucial importance. For example, the Internet of Things (IoT) is being used for smart cities and grids and holds enormous potential. Hybrid approaches such as the whale optimization algorithm (WOA) are already being used to optimize energy consumption, which has efficiency advantages compared to the other algorithms (Iwendi et al., 2021).

Models such as the Lagrangian suboptimal convergent computation offloading algorithm (LSCCOA) for optimized multi-access edge computation (MEC) should also be used, as they have been shown to contribute to energy consumption reduction (Anajemba et al., 2020).

In the context of efficient communication in the wireless sensor network (WSN), routing protocols are needed to increase the detection rate. Here, the Levenberg–Marquardt neural network (LEACH-LMNN) should be mentioned as it achieves the highest detection rate (Mittal et al., 2021).

In order to promote energy efficiency, the EU is making a number of efforts to remove obstacles in companies and to increase existing potential. Energy efficiency in companies is an important contribution to climate protection [Bundesministerium für Umwelt, Naturschutz, Bau und Reaktorsicherheit (BMUB), 2015].

Energy efficiency potentials in companies are often not well known and cannot be implemented as a result. In addition to information deficits (Schmid, 2004) in companies, acceptance deficits for new technologies and solutions are often an obstacle (Hertel, 2014).

Deficits can be observed in technical solutions such as LED installation or smart meter retrofitting, organizational solutions such as energy purchasing via digital portals, but also behavioral changes such as switching off lights after work.

Many companies also have little or no knowledge of the actual total energy consumption within their company (Mittelstandsinitiative Energiewende und Klimaschutz, 2019). A further breakdown of energy consumption by work area or at plant level is also not possible in most cases (Deutscher Industrie und Handelskammer, 2018). The lack of transparency makes it difficult to identify and leverage existing energy efficiency potential, as no assessment based on economic efficiency is possible for the decision-maker.

Another challenge is that few studies address energy efficiency potential as an actual measure at the technology level (Trianni et al., 2013), for example, lighting technology. However, when this is performed, the relationships between these measures are not further considered (Sudhakara Reddy, 2013).

Therefore, Cagno et al. (2019) recommend analyzing a single company in relation to several different energy efficiency measures (EEMs) to understand the potential synergies (positive or negative) that result from implementing multiple EEMs. Stefana et al. (2019) identify and recommend further research related to the mutual influence of individual measures and their interactions. Other studies cite the investigation of correlations between individual efficiency measures as possible research studies (Trianni et al., 2021). The correlation and influence of different measures are recommended in the form of further case studies (Stefana et al., 2019).

The correlations between the individual measures and potentials are an important parameter for estimating what a company will need in the future, for example, if it has already implemented individual measures. If a correlation can be formed, for example, more targeted expansion and promotion concepts can be drawn up and investments in energy efficiency can be triggered more quickly. Therefore, it is precisely these correlations and their effects on energy efficiency measures and potentials that should be researched further.

Schützenhofer (2021) is one of the few to address the fact that an EnMS has an impact on EEM. However, the study focuses on energy efficiency as a whole and not on individual measures or even potentials. Moreover, the corridor of consideration is limited to large companies.

The following studies state that the EnMS has a positive effect on energy efficiency. Olsthoorn et al. (2017) demonstrated a positive effect of EnMS on energy efficiency. Moreover, the results of Schulze et al. (2018) provide strong empirical evidence that EnMS has a positive relationship with the energy efficiency performance of companies.

The positive and negative effects of EEM on other areas are examined in the study by Trianni et al. (2021).

Stefana et al. (2019) also show that the use of management systems is associated with an improvement and implementation of measures. In addition, the study identifies potentials at the technology level and studies are presented that look at measures for lighting and compressed air, for example.

What is missing so far, however, is a study that examines which measures are influenced by other measures and empirically demonstrates these interactions and dependencies.

In addition, most studies in the field of energy efficiency deal with manufacturing non-SME companies (Finster and Hernke, 2014; Stefana et al., 2019; Andrews and Johnson, 2016; Backlund et al., 2012; Brunke et al., 2014; Cagno et al., 2013; Cagno et al., 2019; Chiaroni et al., 2016; Cooremans, 2012; Costa-Campi et al., 2015; del Río González, 2005; Fawcett and Hampton, 2020; Fiedler and Mircea, 2012; Fleiter et al., 2012a; Fleiter et al., 2011; Hampton, 2019; Haq and Jacobsen, 2018; Hasan et al., 2019; Henriques and Catarino, 2016; Hertel and Menrad, 2016; Hoyer et al., 2020; Kinelski, 2020; König, 2020; Mickovic and Wouters, 2020; Morais et al., 2020; Olsthoorn et al., 2017; Perroni et al., 2017; Phylipsen et al., 1997; Ponomareva et al., 2019; Pye and McKane, 2000; Rohdin and Thollander, 2006; Sa et al., 2015; Safarzadeh et al., 2020; Sardianou, 2008; Schlomann and Schleich, 2015; Schulze et al., 2018; Shinkevich et al., 2020; Soepardi et al., 2019; Stephenson et al., 2015; Stephenson et al., 2010; Sudhakara Reddy, 2013; Thollander, 2010; Thollander et al., 2013; Thollander et al., 2007; Thollander and Ottosson, 2008; Trianni et al., 2014a; Trianni et al., 2017; Wagner et al., 2020; Wakabayashi and Arimura, 2020; Williams and McKane, 2013; Wohlfarth et al., 2018; Wolniak et al., 2020; Zierler et al., 2017). Smaller companies should not be ignored, however, as they exist in greater numbers overall than larger companies and the total potential of all smaller companies is enormous. Therefore, further studies should focus even more on smaller companies (SMEs) so that the general awareness of these companies for more energy efficiency becomes more present and thus a copycat effect can be triggered. There are some studies on SMEs, but they are also focused on the manufacturing sector (Anderson and Newell, 2004; Parker et al., 2009; Fernández-Viñé et al., 2010; Jochem et al., 2010; Palm and Thollander, 2010; Fleiter et al., 2012b; Thiede et al., 2012; Trianni and Cagno, 2012; Cagno and Trianni, 2013; Kostka et al., 2013; Thiede et al., 2013; Trianni et al., 2013; Williams and Schaefer, 2013; Bell et al., 2014; Cagno et al., 2014; Cagno and Trianni, 2014; Semkov et al., 2014; Trianni et al., 2014b; Catarino et al., 2015; Leloux et al., 2015; Allarton, 2016; Meath et al., 2016; Muzamwese, 2016; Rahbauer et al., 2016; Solberg Hjorth and Brem, 2016; Tallini and Cedola, 2016; Trianni et al., 2016; Fresner et al., 2017; Hilger et al., 2018; Krutwig, 2019; Schleich and Fleiter, 2019; Chen et al., 2020; Cunha et al., 2020; Giraudet, 2020; Hung and Chu, 2020; König et al., 2020; Palm and Backman, 2020; Özbuğday et al., 2020; Nigohosyan et al., 2021; Trianni et al., 2021). Therefore, in future studies, they should look at smaller non-manufacturing companies. Therefore, the study should also critically examine how many of the existing studies examine these small companies. The research question of the current state of energy efficiency in companies in relation to the interactions of individual efficiency measures at the technology level will therefore be examined.

The article is organized as follows. Section 2 presents the methodology used in this study. A comprehensive literature review was conducted. Integrated is a SWOT analysis of the literature reviewed. Section 3 presents the results of the research. This includes a discussion of the eight evaluation criteria listed in Section 2, which are used to review the publications studied. In addition, the results of the SWOT analysis are presented. In Section 4, a critical discussion of the results follows. Finally, Section 5 places the results of the work in a broader context and explains the need for further research in the field of energy efficiency.

2 Materials and methods

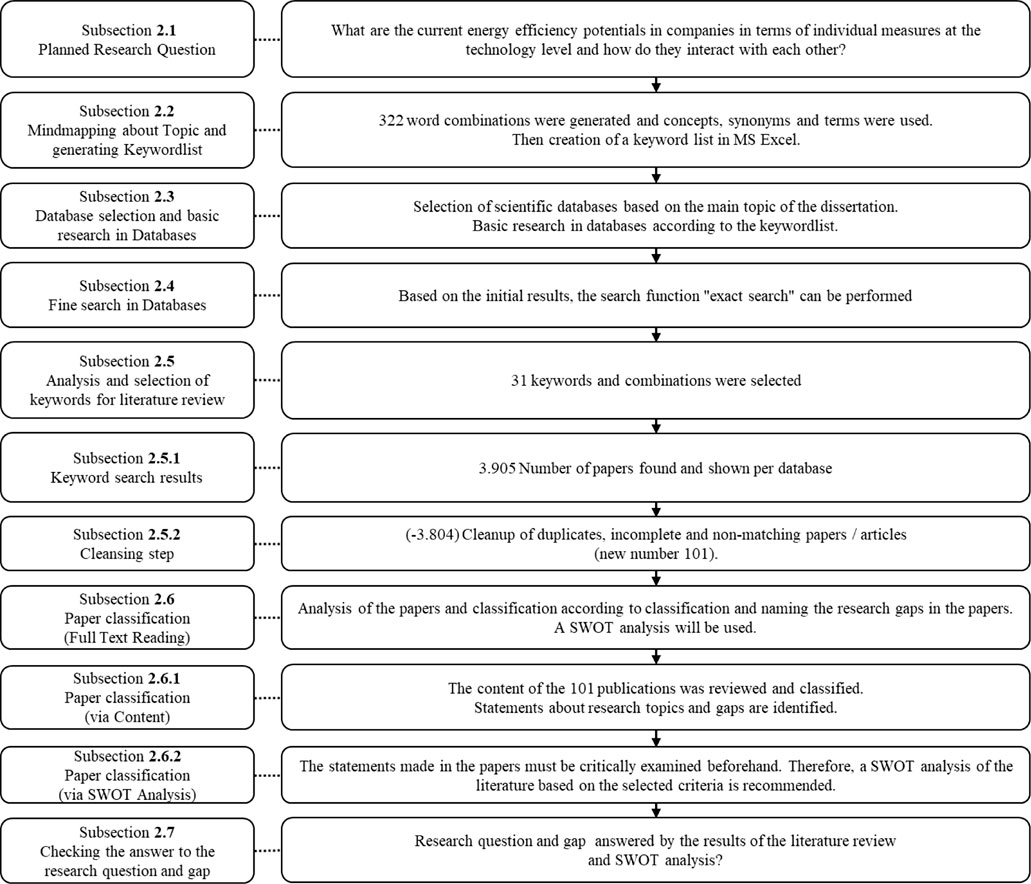

Sections 2.1–2.7, shown in Figure 1, illustrate the process of the systematic literature review. In the beginning of 2.1, the planned research question is presented, which is to be answered with the help of the existing literature. Subsequently, 2.2 describes how the search terms and combinations are created and transferred into a keyword list with the help of a so-called mind map software. Moreover, 2.3 deals with the question of which databases are used for the search and how the basic search is carried out. In 2.4, the fine search is carried out on the basis of the basic search. To achieve even better search results, the exact search is used. Then, in 2.5, the analysis and selection of keywords for the literature search is performed. Thereby, the search terms and combinations are determined. 2.5.1 shows the results of the search and 2.5.2 shows the cleaning of the search results. In 2.6, the articles are read in full and initially screened and categorized. In 2.6.1, the articles are sifted and categorized by content. The results that relate to one’s research questions can be compared with the statements of these research results. Eight evaluation criteria are used to evaluate and screen the literature. The desired research gaps are identified. In 2.6.2, a SWOT analysis is conducted with the 101 articles in relation to some criteria to critically examine the statements made in 2.6.1. In this final step 2.7 of the method, it is tested whether the research question and gap can be answered and closed by the results of the literature review and SWOT analysis.

2.1 Planned research question

What are the current energy efficiency potentials in companies in terms of individual measures at the technology level and how do they interact with each other?

The research question is to be investigated and answered in the course of the literature review. Measures and potentials at the technology level are understood in this study, for example, LED lighting replacement or the use of electric drives. If LED lighting replacement has been undertaken, have other measures been implemented or not? This question will be examined by the literature review.

The result of this literature review is to confirm or reject the research gap by the existing literature.

2.2 Mindmapping and keyword list

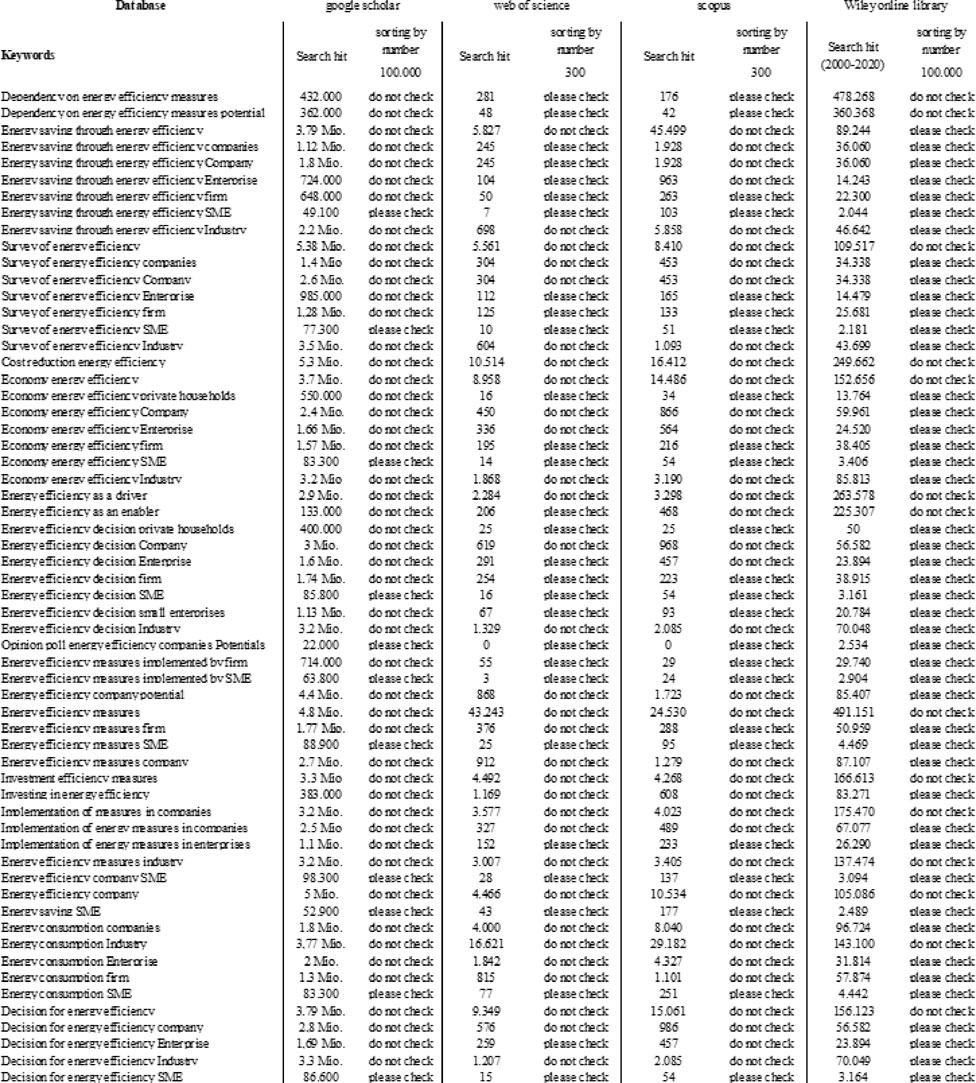

With the help of a “mind map” software, the search terms were systematically collected and further developed (Kollmann, 2016). In addition, suitable concepts, synonyms, and terms were used. The search terms were developed and agreed upon with energy efficiency experts at an event organized by the Competence Center for Energy Efficiency. Subsequently, the search terms were successively refined. Supplementary Appendix A shows how the search terms are further refined by so-called sub-nodes and sub-sub-nodes. Software is helpful at this point in the work because it refines the search terms further and further to make them suitable for one’s research question. This helps in the subsequent database search. The main focus of the database search should be on the topics of energy efficiency and digitization in companies. It is important to find study results that address energy efficiency and digitization measures at the technology level. An extract of the keyword list, see Figure 2, was then created in MS Excel. The overall presentation of the keyword list can be found in Supplementary Appendix B.

2.3 Database selection and basic research in databases

2.3.1 Database selection

Four scientific databases/publishers were used for the systematic literature search: Google Scholar, Web of Science, Scopus, and Wiley online library. The selection made aims to find a comprehensive and up-to-date number of articles related to the research focus (in the fields of management, engineering, computer science, and industrial engineering). In order to find a large number of articles, Google Scholar has been integrated into the database search. Google Scholar is the largest scientific database with about 400 million documents. In comparison, the Scopus database contains about 75 million documents.

In addition, a high scientific standard and the topicality of the researched works are important. In addition to these aspects, it is elementary that the articles have been reviewed by experts from the relevant fields in a so-called peer review process. This can be achieved for the selected databases and their contributions. A critical review of the existing articles according to these basic criteria will be carried out.

2.3.2 Basic research in databases

The basic search in the databases was carried out from 15.11.2020 to 27.06.2021. A large number of search hits were found for the 322 search terms generated. Initially, an “IF-THEN FUNCTION” was used to numerically divide the search hits in the databases into “please check” and “do not check” due to their high number of search hits. This had the advantage of removing the search hits with an excessive number of results from the search and subsequently refining the search.

The basic search could be continued on this basis. Samples were drawn from the databases and initial results were collected on the abstracts. These results help to conduct the fine search in a plausible and targeted way.

2.4 Fine search in databases

In order to conduct the fine search in a plausible and targeted way, it is necessary to check in advance, which topic areas have received less attention than others. It is precisely on these topics that a literature search should focus, because it is here that new findings and interpretations can contribute to the research. In reviewing the initial results, the following areas of focus emerged.

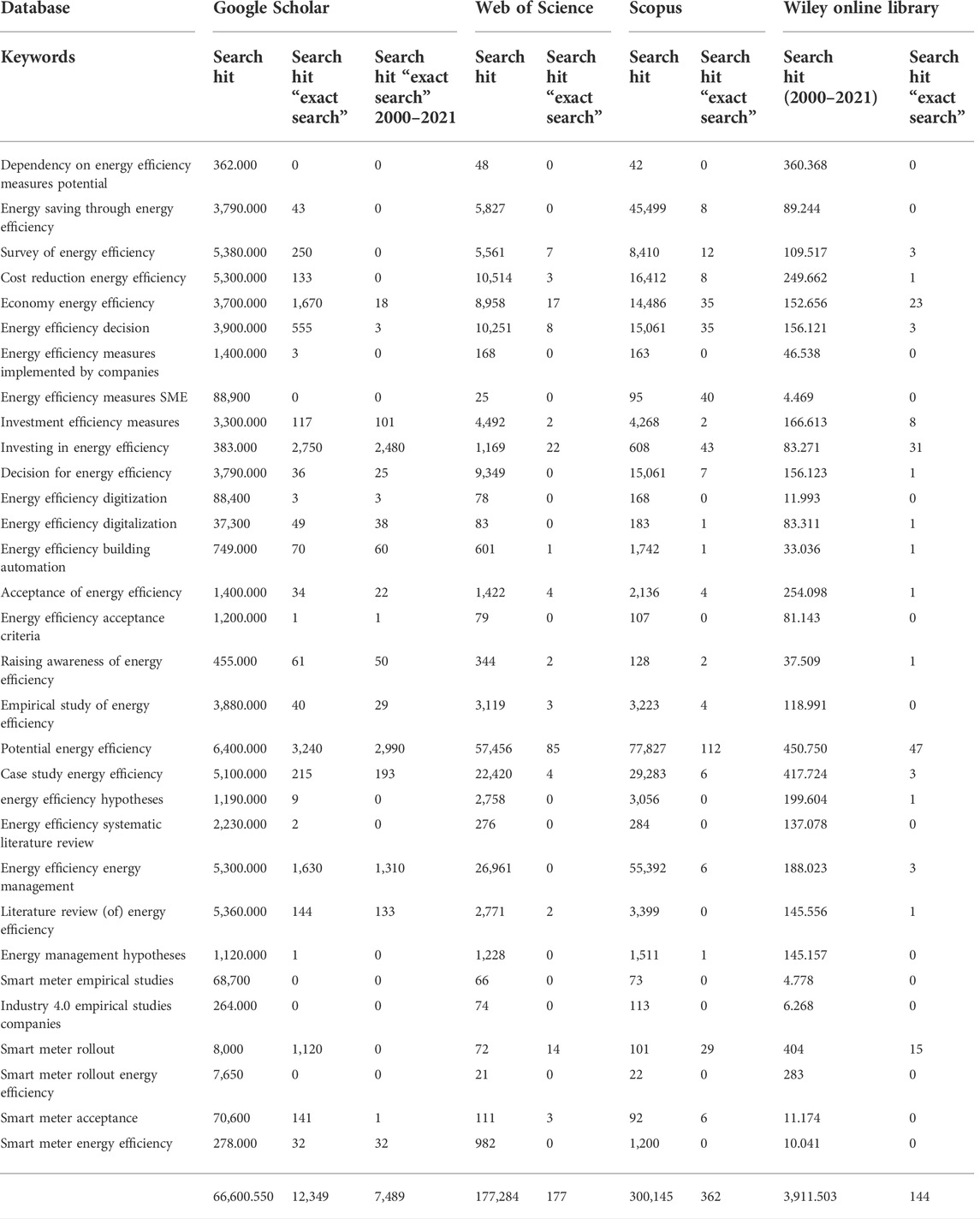

The basic research helped to narrow down the topic area and define focal points. Subsequently, as described in Table 1, the fine search was started and the exact search was applied. In this study, exact search means searching with the help of operators. Here, AND, OR, and NOT operators are used in the search to reduce and concretize the search results. In addition, the search results were limited to the years 2000–2021, especially in the large databases (for example, Google Scholar and Wiley online library). Moreover, 31 search terms and combinations were used for the literature search.

This resulted in significantly fewer documents per subject area and database. The selection of search terms is shown below.

2.5 Analysis and selection of keywords for literature review

2.5.1 Keyword search results

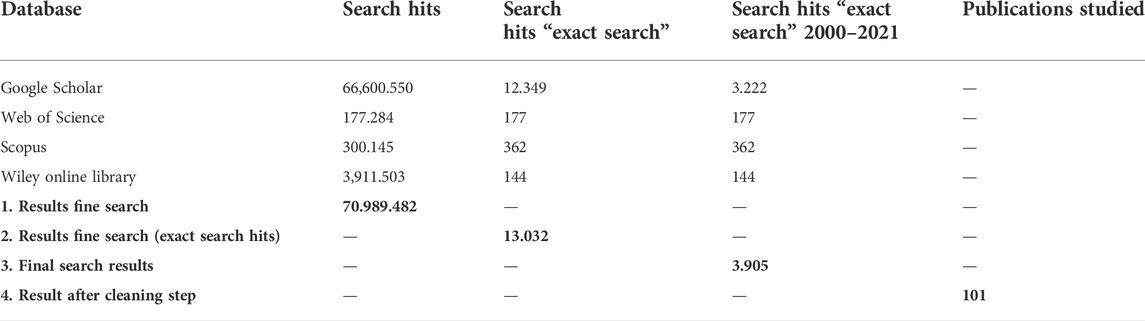

The 31 selected search words and combinations from Table 1 result in a solid basis of 71 million documents in total. This is shown in Table 2. It turned out that with the help of an exact search this number could be reduced by 99.98% to about 13,032 documents. This selection could be reduced again by about 70% to about 3,905 documents by refining the search again and partially delimiting database results (e.g., from Google Scholar).

2.5.2 Cleansing step

The process of data cleaning, see Table 2, was applied to the 3,905 hits from the database search. The goal of the data cleaning was to find and eliminate multiple publications in the databases and to evaluate and review the titles and abstracts of the remaining publications for thematic relevance. Overall, the data cleaning resulted in a set of 101 publications, while 3,804 hits from the online search were not followed up because they either appeared multiple times in the sample (as they were listed in more than one of the selected online databases) or because their content was not specifically related to the topic at hand. It was particularly noticeable that energy efficiency and digitization measures were often mentioned in the abstracts or in the titles, but were too theoretical or broad in the studies. Technology level results were rarely listed. These studies were deleted from the literature search.

2.6 Article classification (full-text reading)

Analysis of the articles and classification according to the classification and naming of the research gaps in the articles. A systematic literature review and SWOT analysis were conducted.

2.6.1 Article classification (via content)

The content of the 101 publications was reviewed and classified. The full texts were downloaded using literature software and reviewed for the following eight evaluation criteria and the strengths, weaknesses, opportunities, and threats of the publications. The contents were colored differently using the marker function. Subsequently, the contents could be evaluated as described in Section 3. This resulted in the statements on research topics and gaps.

2.6.1.1 Origin and year of publication

The origin of the study shows in which country the topic of energy efficiency in companies is important. The year of publication shows the development of the topic. This allows conclusion to be drawn about the political and economic orientation of the individual countries. Suitable articles from all over the world were found and evaluated.

2.6.1.2 Type of company

It is examined which company sizes were the subject of the studies and works found. Company size plays an important role in the implementation of energy efficiency and digitalization measures. Therefore, it is investigated how large the share of the respective company sizes was. A distinction is made between SMEs and non-SMEs. There are also studies that deal with both SMEs and non-SMEs. The definition of company size is based on the definition of the European Commission (EMPFEHLUNG DER KOMMISSION vom 6. Mai 2003 betreffend die Definition der Kleinstunternehmen sowie der kleinen und mittleren Unternehmen. Europäische Kommission, 2003).

2.6.1.3 Type of industry

It is examined whether the companies investigated are manufacturing or non-manufacturing companies. Manufacturing companies are usually more energy-intensive than non-manufacturing companies. Energy efficiency is worthwhile for all companies, but it is more likely to find economic measures where a lot of energy is consumed with high energy costs.

2.6.1.4 Type of data

The data basis used for the respective studies is to be examined. A distinction is made between primary and secondary data. Were the data collected by the authors themselves or were data from previous surveys and studies used? This distinction is initially value-free, since both sets of data have their raison d'être. Primary and secondary data can, for example, be interpreted and processed in different ways and thus promote a new perspective on a subject area (Adams, 2007).

2.6.1.5 Collection method

The collection method of the data is a meaningful tool for the literature review. It sheds light on the quality of the data. It is examined by which methods the respective author comes to the data used by him. An absolute and relative evaluation should take place.

2.6.1.6 Number of participants

Studies are available in which the data collection was generated via the participants. The absolute number of participants per study, the average number of participants, and the range should be presented.

2.6.1.7 Type of data collection (subjective or objective)

The distinction between subjective and objective data collection always depends on the respective perspective. Therefore, it should be noted that subjective data collection in this literature review means data collection that has been carried out by the company itself, that is, if the author of a study sends a questionnaire to the company and the company fills it out, then it is subjective data collection.

The danger with subjective data collection is that the same potential (whether economic or technical) may be assessed differently when evaluating energy efficiency potential. This can result in a study losing its actual validity. In practice, this means that investments in a measure are not made.

In the literature review, we speak of objective data collection when the data collection is carried out by an expert. This can be performed on site or by interview. The expert always proceeds in the same way and can make an equivalent evaluation from his empirical values.

2.6.1.8 Evaluation method

The evaluation methods used in the studies and articles considered are examined. The most important evaluation methods are listed and evaluated. An absolute and relative evaluation will be made.

The individual statistical evaluation methods covered in the considered studies and articles are to be counted together as statistical evaluation. The evaluation methods were, for example, linear regression, Mann–Whitney U-test, logit models, probit models, structural equation models, hypothesis tests, nonparametric techniques such as data envelopment analysis (DEA), and parametric techniques such as stochastic frontier analysis (SFA) and corrected ordinary least square (COLS) to measure efficiency, multivariate statistics, Gretl software, and Pearson’s coefficient.

The results of the eight evaluation criteria listed are presented in Section 3.1.

2.6.2 Article classification (via strengths–weaknesses–opportunities–threats analysis)

The statements made in the articles must be critically examined beforehand. Therefore, a SWOT analysis of the literature based on the selected criteria is recommended.

SWOT analysis is a method of strategic planning (Weihrich, 1982; Hill and Westbrook, 1997) and is an acronym for strengths, weaknesses, opportunities, and threats, which characterize the dimensions along with the entities or situations.

The analysis should be performed as follows. The evaluation of each of the authors’ statements and findings will be conducted in relation to the research question considered in this literature review. For example, technology level measures, the industry, size, and number of companies studied in the studies, and the method of data collection are important. The analysis should help define and flesh out one’s research questions and gaps.

The results of the SWOT analysis performed are included in Section 3.2.

2.7 Checking the answer to the research question and gap

In this final step 2.7 of the method, it is tested whether the research question and gap can be answered and closed by the results of the literature review and SWOT analysis. If the research question can be answered, it is proven that the research gap has already been considered and answered by another research. Nevertheless, in this case, another work in the same direction with a different focus can be purposeful.

The results of the considerations made in subsection 2.7 are discussed and interpreted in Section 4.

3 Results

3.1 Results of the literature review

3.1.1 Origin and year of publication

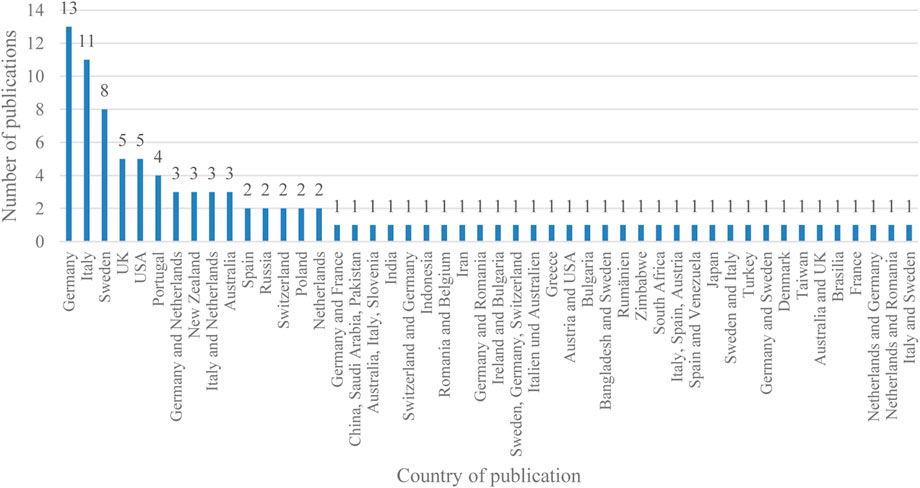

Figure 3 shows the number of publications by country. Most of the 101 articles reviewed were from Germany (13 articles) followed by Italy (11 articles) and Sweden (eight articles). Together, these articles account for about one-third of all the articles in this literature review. If the participation of these countries in other studies and articles is added, the number increases to 22 for Germany, 19 for Italy, and 13 for Sweden, resulting in a total share of over 50% of the articles reviewed (54 articles).

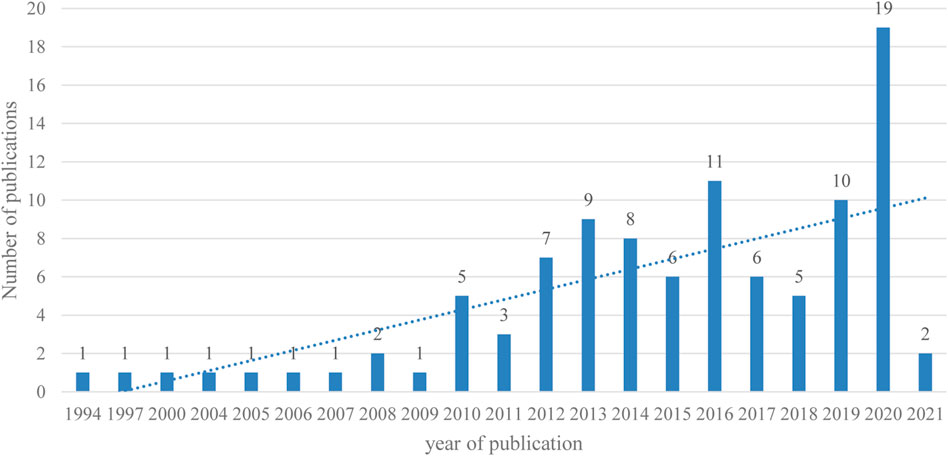

Figure 4 shows the number of publications studied by year of publication. The oldest publication is from 1994, in which the energy efficiency gap was defined for the first time by Jaffe and Stavins (1994). Until today, a positive trend (dotted line) can be derived. Increasingly, more studies on energy efficiency in companies are successively elaborated.

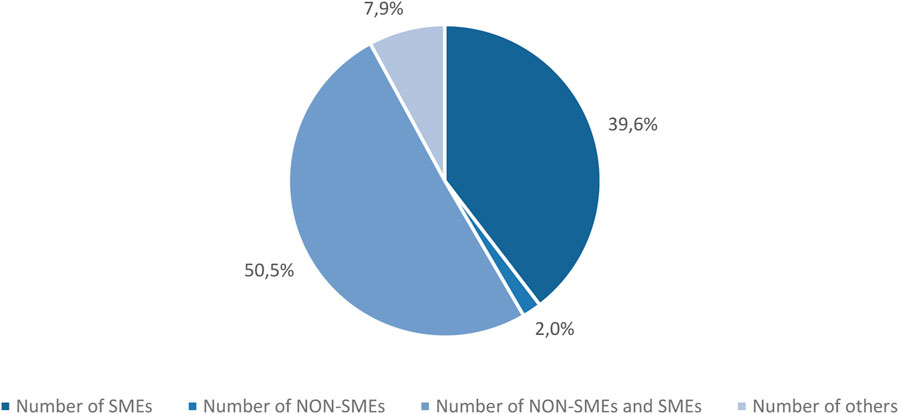

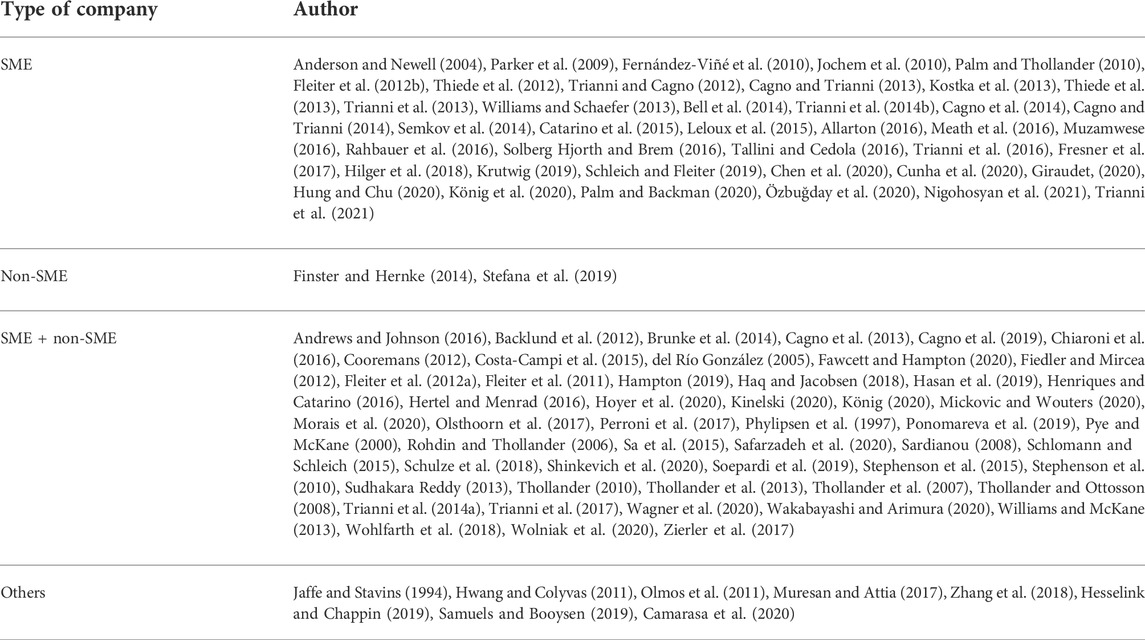

3.1.2 Type of company

Figure 5 shows the classification of the types of companies in the publications studied. Of the total 101 articles, 50.5% deal with non-SME companies, with 39.6% dealing with SME companies. In addition, 8% of the publications include, for example, 5x private households + 1x public ownership + 2x other institution/organization. The remaining 2% deal with both SMEs and non-SMEs. Table 3 shows the classification of the types of companies in the publications studied, sorted by the authors.

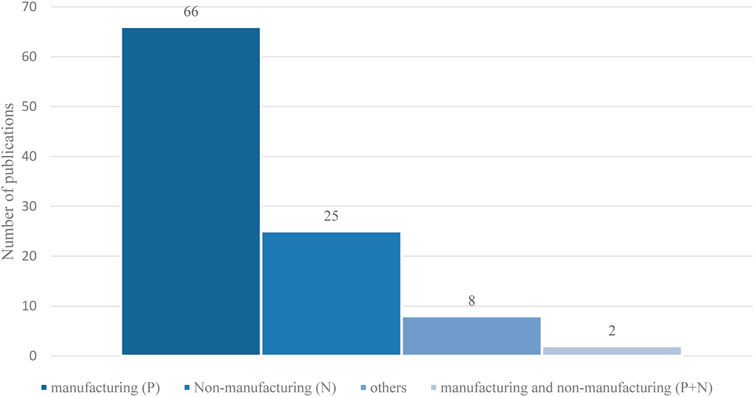

3.1.3 Type of industry

Figure 6 shows the classification of the industries of the publications studied. Moreover, 65% of the examined article deals with manufacturing companies. These companies usually have higher energy consumption than non-manufacturing companies. Among them, industries such as foundries (Thollander et al., 2013), the wood industry (Bell et al., 2014), the iron and steel industry (Brunke et al., 2014), metal processing companies (Cagno et al., 2014), automotive industry, cement, iron and steel, pulp and paper (Chiaroni et al., 2016), and food industry (Catarino et al., 2015; Solberg Hjorth and Brem, 2016) are examined. These are among the most energy-intensive industries.

Moreover, 25% of the studied articles deal with non-manufacturing companies. These companies are less often in focus than manufacturing companies due to their lower energy consumption.

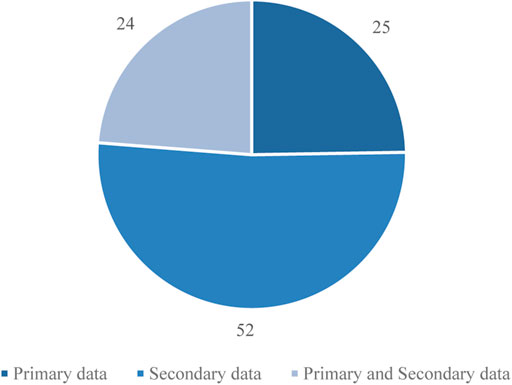

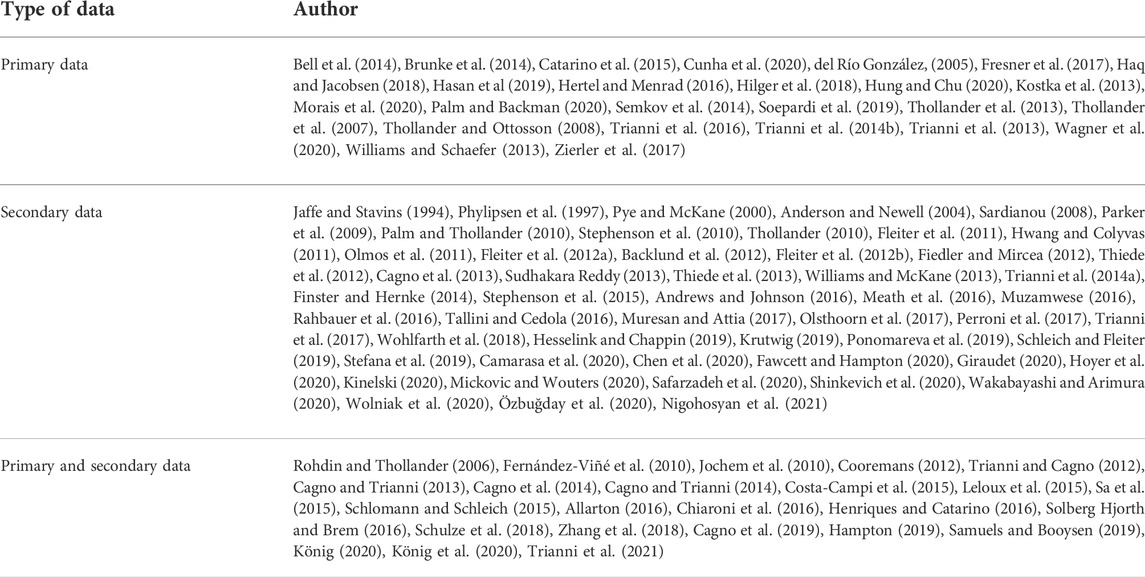

3.1.4 Type of data

When looking at the data used, there is a clear tendency toward secondary data (see Figure 7). Secondary data were used more frequently. Looking at the absolute number of cases, 51% of the data used came from secondary data and 25% from primary data.

If one looks purely at the number of pure primary data and the pure number of secondary data without the paper using both data, the proportion of secondary data increases relatively to 68%. This underlines the high data usage of about two-thirds of secondary data of the 101 articles considered. Table 4 shows the classification of the types of data in the studied publications sorted by authors.

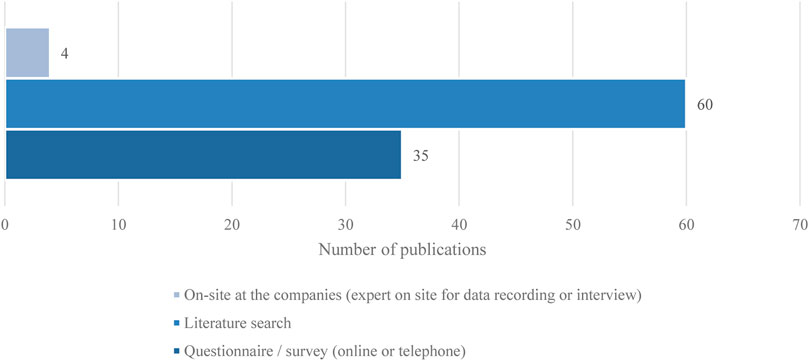

3.1.5 Collection method

The 101 articles are divided into three types of methods (see Figure 8). The most frequent method is the literature search with 59% (60 articles). Also, frequently used was the possibility to conduct a questionnaire/survey (online or telephone). This was used in 35% (35 articles). Another 4% (four articles) were identified in which the authors or experts collected data directly from the companies. Two more articles were examined that used data from previous studies and projects, these are not included in the figure.

3.1.6 Number of participants

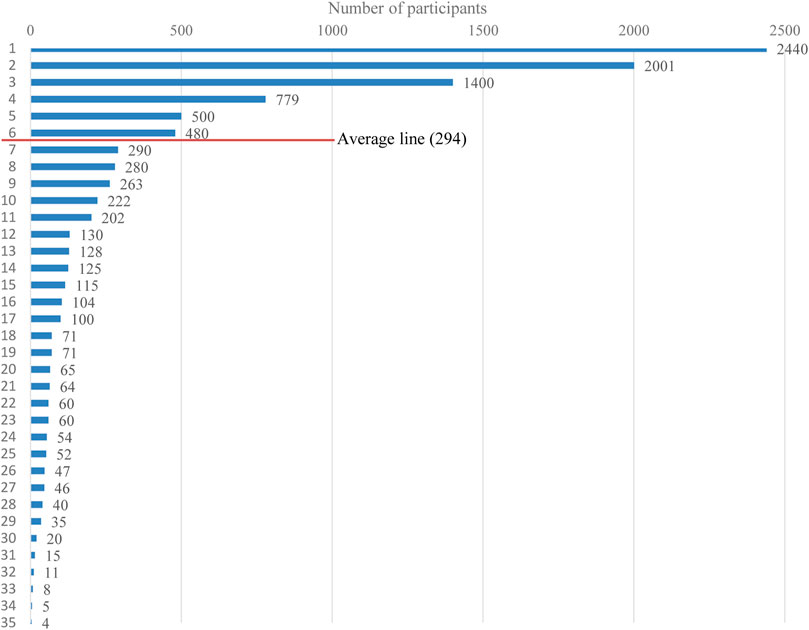

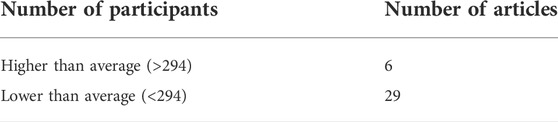

Figure 9 shows the number of participants in the publications studied. The participants of the 35 articles that used the questionnaire/survey method were examined. A range from four participants (Solberg Hjorth and Brem, 2016) to 2,440 participants (Olsthoorn et al., 2017) was possible. The average number of participants can be given as about 294 participants. As can be seen in Table 5, 6 publications have a higher average number of participants and 29 publications have a lower average number of participants to report.

3.1.7 Type of data collection

The two collection methods, questionnaire/survey and on site at the companies, are to be tested for subjectivity of data collection. Of the 101 articles, 49 articles used primary data. The 35 articles that used the questionnaire/survey method were all completed by the companies themselves. Therefore, these data are 100% subjectively collected and account for about 71% of the primary data. This means that 71% of all primary data is based on a subjective assessment by companies. This is to be critically questioned, since due to the subjectivity, even exactly the same situations can be assessed completely different with regard to energy efficiency potentials or measures. This depends on the economic and political situation in the countries as well as the individual know-how of the surveyed employees in the companies.

Only in four articles were the primary data collected by experts on site in the companies. These four articles correspond to about 8% of the total primary data.

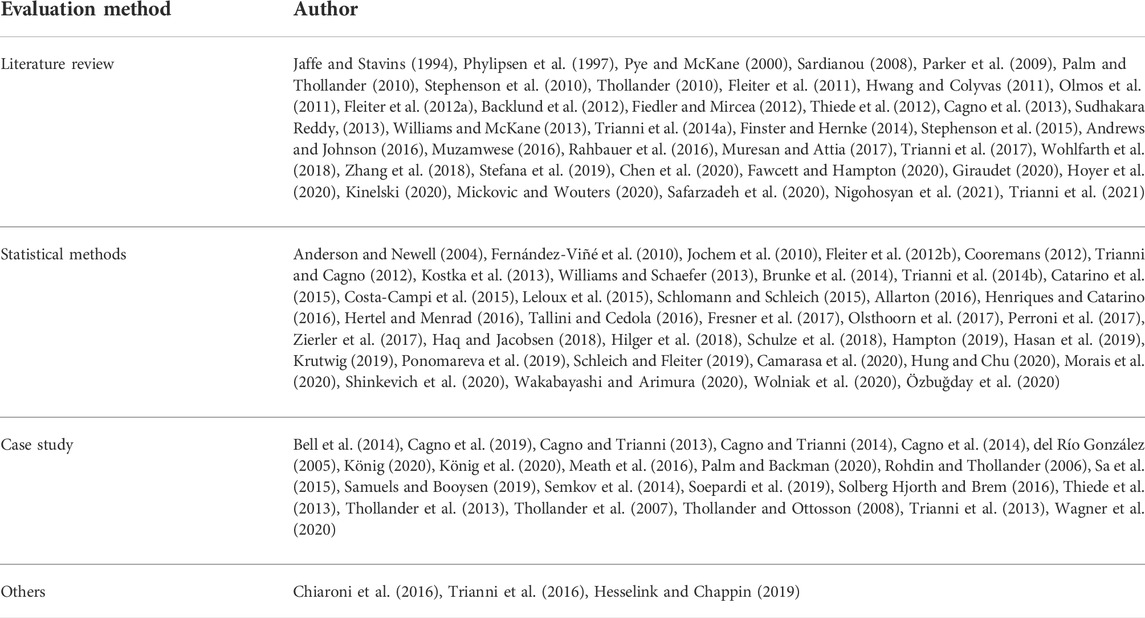

3.1.8 Evaluation method

Figure 10 shows the type of evaluation method used for the publications studied. Also, 39 articles were evaluated by means of literature analysis. In addition, 37 articles dealt with the statistical methods mentioned in 2.6.1.

Moreover, 22 of the articles were examined conducted and evaluated as case studies. Table 6 shows the type of evaluation method of the studied publications sorted by authors.

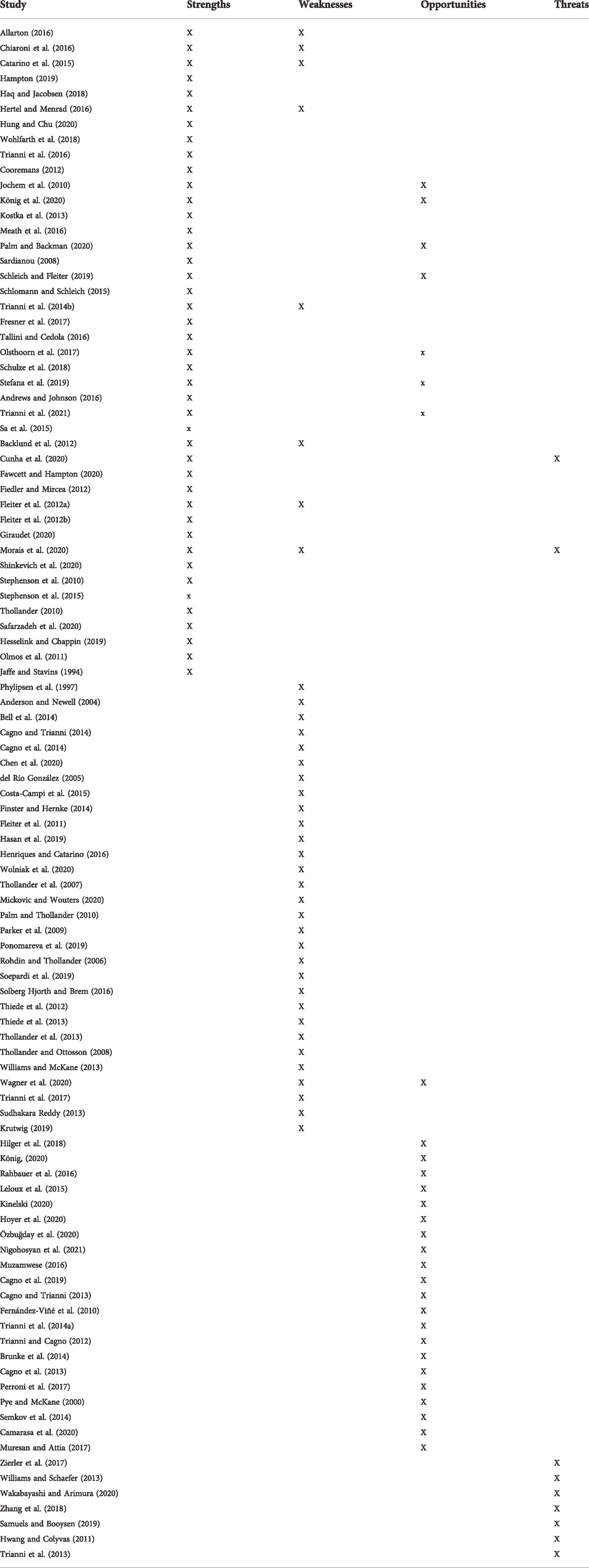

3.2 Strengths–weaknesses–opportunities–threats analysis of the articles reviewed

The SWOT analysis takes up the main statements and most important results of the examined articles with reference to the own research question and divides them into four categories: strengths, weaknesses, opportunity, and threats.

The research studies reviewed are intended to provide evidence that the energy efficiency potential in companies has been underrepresented at the technology level and that the interactions of these potentials and measures can make an important contribution to energy efficiency research.

Table 7 provides a comprehensive overview of the publications covered in the SWOT analysis. It shows which publication was used in which category of the SWOT analysis. The following summarizes the results of the SWOT analysis.

3.2.1 Strengths

• Many of the studies have a good data basis and a high number of participants (Sardianou, 2008; Jochem et al., 2010; Cooremans, 2012; Kostka et al., 2013; Trianni et al., 2014a; Catarino et al., 2015; Schlomann and Schleich, 2015; Allarton, 2016; Chiaroni et al., 2016; Hertel and Menrad, 2016; Meath et al., 2016; Trianni et al., 2016; Haq and Jacobsen, 2018; Wohlfarth et al., 2018; Hampton, 2019; Schleich and Fleiter, 2019; Hung and Chu, 2020; König et al., 2020; Palm and Backman, 2020) in the methods used. This results in a high informative value and enables transferability to other areas.

• The author (Fresner et al., 2017) collected data from 280 companies from Austria, Bulgaria, Cyprus, Italy, Romania, Slovakia, and Spain on site in the companies. In the process, the potential of the companies were recorded at the technology level.

• Starting from the feasibility assessments, the study aims to establish a possible correlation between energy efficiency indicators and a limited number of power system parameters related to production, operation, and electricity consumption (Tallini and Cedola, 2016).

• Within the scope of this study, a positive effect of energy management systems (EnMS) on energy efficiency was proven (Olsthoorn et al., 2017).

• The results of the study provide strong empirical evidence that EnMS has a positive relationship with the energy efficiency performance of firms (Schulze et al., 2018).

• The study highlights potentials on the technology level and studies are presented in which, for example, the measures for lighting and compressed air occur. Furthermore, it is shown that the use of management systems is accompanied by an improvement and implementation of measures (Stefana et al., 2019).

• The article reviews studies of corporate energy behavior and suggests areas for additional social science research (Andrews and Johnson, 2016).

• The positive and negative effects of energy efficiency measures (EEM) on other areas are examined (Trianni et al., 2021).

• Energy management and related practices are cited as one of the most important tools for improving energy efficiency in manufacturing companies (Sa et al., 2015).

• Combine investments in energy-efficient technologies with the promotion of good energy management practices. The authors argue that the inclusion of energy management components is important (Backlund et al., 2012).

• Analysis of the propensity of Portuguese SMEs to adopt EEMs. The barriers that lead to the decision of not adopting EEMs are also examined (Cunha et al., 2020).

• This article has made it clear that energy policy needs to focus much more on SMEs. They are largely overlooked by energy policy and therefore do not benefit from energy saving opportunities or contribute sufficiently to reducing carbon emissions (Fawcett and Hampton, 2020).

• Challenges and benefits of ISO 50001 implementation in an industrial environment will be presented, as well as the methodology and systematic approach, but also tools such as energy control systems and measurement devices that are useful to achieve energy transparency (Fiedler and Mircea, 2012).

• Authors propose a classification scheme for EEMs in the industry to provide a better understanding of their adoption by industrial companies and to help in the selection and design of energy efficiency strategies (Fleiter et al., 2012a).

• Evidence that quality of energy audits influences the adoption of energy efficiency measures. On-site audits were conducted by an expert (Fleiter et al., 2012b).

• Information deficits and information barriers for energy savings are the subjects of the investigation (Giraudet, 2020).

• Investigation on the technology level with measurements has taken place (Morais et al., 2020).

• Analysis of effects of digitization on energy efficiency (Shinkevich et al., 2020).

• The authors develop a theoretical approach to understand energy behavior holistically and to achieve greater adoption of energy-efficient behaviors (Stephenson et al., 2010; Stephenson et al., 2015).

• The 15 theoretical barriers are divided into three different categories, depending on the system complexity of the respective barrier (Thollander, 2010).

• In this article, the authors review and rank the major academic studies that have addressed the environmental and economic aspects of industrial energy efficiency programs (IEEPs) based on a systematic review (Safarzadeh et al., 2020).

• This study provides a systematic review of agent-based modeling studies for household energy efficiency adoption. Transfer to other actors would be possible (Hesselink and Chappin, 2019).

• The use of advanced indirect feedback on consumption behavior, critical peak pricing, and simple time-of-use tariffs is being encouraged (Olmos et al., 2011).

• The authors describe and define the energy efficiency gap (Jaffe and Stavins, 1994).

3.2.2 Weaknesses

• Most studies deal only with manufacturing and production companies (Phylipsen et al., 1997; Allarton, 2016; Anderson and Newell, 2004; Bell et al., 2014; Cagno and Trianni, 2014; Cagno et al., 2014; Catarino et al., 2015; Chen et al., 2020; Chiaroni et al., 2016; del Río González, 2005; Costa-Campi et al., 2015; Finster and Hernke, 2014; Fleiter et al., 2012a; Fleiter et al., 2011; Hasan et al., 2019; Henriques and Catarino, 2016; Hertel and Menrad, 2016; Wolniak et al., 2020; Thollander et al., 2007; Mickovic and Wouters, 2020; Morais et al., 2020; Palm and Thollander, 2010; Parker et al., 2009; Ponomareva et al., 2019; Rohdin and Thollander, 2006; Soepardi et al., 2019; Solberg Hjorth and Brem, 2016; Thiede et al., 2012; Thiede et al., 2013; Thollander et al., 2013; Thollander and Ottosson, 2008; Trianni et al., 2014a; Williams and McKane, 2013; Wagner et al., 2020; Trianni et al., 2017). These are often energy-intensive.

• Measures are usually not considered on a technological level, but on a more abstract and theoretical level such as obstacles and barriers.

• If measures are recorded at the technology level, no relationships between the individual measures have been examined to date (Sudhakara Reddy, 2013; Krutwig, 2019).

• Energy management practices are still too little in focus (Backlund et al., 2012).

3.2.3 Opportunities

• When it comes to data collection, more experts could go into companies and do on-site collection and assessment (Hilger et al., 2018; König, 2020; Palm and Backman, 2020; Wagner et al., 2020).

• Many studies that previously focused on manufacturing companies can be extended to other industries. Small and medium-sized enterprises (SMEs) are now also being examined more frequently in studies (Leloux et al., 2015; Muzamwese, 2016; Rahbauer et al., 2016; Hoyer et al., 2020; Kinelski, 2020; König et al., 2020; Özbuğday et al., 2020; Nigohosyan et al., 2021).

• A consideration at the technology level should be conducted, and the relationships of the individual measures to each other.

• The authors recommend analyzing a single company in relation to several different energy efficiency measures (EEMs) to understand the potential synergies (either positive or negative) that result from adopting a number of EEMs (Cagno et al., 2019).

• Future research should further explore factors that characterize supply chain complexity and the relationship between energy efficiency drivers and a company’s innovation characteristics (Cagno and Trianni, 2013).

• The study shows that it is important to consult and examine the opinion of an expert in a company. The statements of the employees should be critically scrutinized and plausibility checked (Fernández-Viñé et al., 2010).

• The study does not show which individual measures could influence each other and thus have a positive impact; this would be a research requirement (Stefana et al., 2019).

• Further correlations between individual efficiency measures should be investigated (Trianni et al., 2021).

• The correlation and influence of different measures can be carried out in the form of further case studies (Stefana et al., 2019).

• The authors are not aware of any study to date in which utility ownership (e.g., heating systems) influences EEM adoption (optimization or replacement) (Olsthoorn et al., 2017).

• The authors have applied this scheme to a wide range of EEMs in cross-cutting technologies, that is, motors, compressed air, lighting, and HVAC systems. First, the analysis provides a relevant contribution to structuring and sharing knowledge about EEMs, and thus to understanding the barriers that currently hinder their adoption (Trianni et al., 2014a).

• In addition, an important contribution to this research could be to evaluate the existing differences between perceived and actual barriers (information, skills, and awareness) and thus investigate them through a deeper analysis (Trianni and Cagno, 2012).

• Overview of studies on energy efficiency and management in companies. The authors confirm that an ENMS is a driver for the implementation of measures. A positive effect can be interpreted but without correlation between the individual measures (Brunke et al., 2014).

• Future research is needed to develop a taxonomy for drivers of energy efficiency and then to unfold the relationships between drivers and barriers (Cagno et al., 2013).

• Networks and best practices help companies understand and improve their energy efficiency (Jochem et al., 2010).

• The authors address the question of the relationship between the efficiency of companies and the implementation of energy efficiency measures (Perroni et al., 2017).

• Study examines how to increase management understanding in the context of energy efficiency decisions (Pye and McKane, 2000).

• The authors made a comparison between manufacturing and non-manufacturing companies (Schleich and Fleiter, 2019).

• Waste heat was studied at the technology level, transferable to other technology levels (Semkov et al., 2014).

• Future research should focus on an in-depth analysis of the differences between energy-efficient technologies (Camarasa et al., 2020).

• Detailed studies and research should be conducted in the area of thermal performance of buildings, energy performance of building services, and renewable technologies (Muresan and Attia, 2017).

3.2.4 Threats

• Evaluation methods are mostly based on subjective assessments of employees in companies, for example, (Williams and Schaefer, 2013; Zierler et al., 2017; Zhang et al., 2018; Cunha et al., 2020; Wakabayashi and Arimura, 2020).

• The investigation at the technology level is limited to the “low hanging fruits” such as lighting (Morais et al., 2020).

• Data basis and participants is partly low (Samuels and Booysen, 2019).

• Secondary data were often used in the studies (Hwang and Colyvas, 2011).

• There are hardly any known studies of efficiency potentials at the technology level (Trianni et al., 2013).

4 Discussion

4.1 Starting point of this work and objective

Energy efficiency potentials in companies are often not known and, therefore, cannot be implemented. In addition to information deficits, acceptance deficits towards new technologies and solutions are often an obstacle.

In subchapter 2.1, the research question was formulated, which should be answered with the present work. For this purpose, the current state of research was reviewed and it was checked whether an existing research gap could be identified.

The following research question was to be investigated:

What are the current energy efficiency potential in companies in the form of individual measures on the technology level and how do they interact with each other?

The research question was investigated during the literature review, but could not be answered. Thus, the research question is still valid as the research work did not answer the research question.

4.2 Origin and publication of the article

The 101 articles from the literature search were considered and evaluated using eight different evaluation criteria and a SWOT analysis. The evaluation showed that most studies were published in Germany, Italy, and Sweden. Nevertheless, it is a topic that is studied worldwide. A general trend can be observed that energy efficiency is gradually gaining momentum not only in scientific articles but also in companies.

4.3 Type of company and type of industry

Most of the studies reviewed dealt with manufacturing companies that are not SMEs. However, smaller companies should not be ignored, as they exist in greater numbers overall than larger companies, and the overall potential of all smaller companies is enormous. Therefore, further studies should focus even more on smaller companies, so that the general sensitization of these companies to more energy efficiency becomes more present and thus a copycat effect can be triggered. The current climate protection development and the CO2 levy encourage this, as all companies now have to achieve monetary savings by avoiding CO2 emissions, even through smaller measures in order to remain competitive.

4.4 Type of data, collection method, and type of data collection

Significantly more secondary data (51%) than primary data (25%) were used in the studies. The collection method was mainly via literature review and questionnaires. The questionnaires were conducted online or over the phone. This favors a subjective perception and collection of data by the employee in the company. One and the same measure or potential can be evaluated completely differently. Certainly, this uncertainty is minimized by the scientific questionnaire design, but it can lead to a strong deviation in the evaluation. Only a few studies (8%) have resorted to the possibility of sending an expert directly to the companies and recording the data directly on site. This is costly and time-consuming but ensures that the data collected are estimated with the same consistency. This does not imply that the data are more correct or accurate than those collected via questionnaires, but it does ensure consistency throughout.

4.5 Main conclusion from the strengths–weaknesses–opportunities–threats analysis of the peer-reviewed articles

Most of the articles considered had a good data basis and a high number of participants. This increases the quality of the statements and gives a good validity. In principle, this makes it possible, under the premise that the data can be collected, to extend the study to other types of companies and industries. A frequent feature of the articles is the discussion of barriers and drivers for energy efficiency.

These include the aforementioned lack of information and acceptance of new technologies, financial and economic barriers, and a lack of know-how in companies. Drivers are often efficiency issues such as cost savings and CO2 reduction.

The lack of know-how in the field of energy efficiency in the companies is often mentioned as one of the major barriers in the literature, nevertheless mainly collection methods are used in the articles, which presuppose know-how or at least a certain affinity to the topic of energy efficiency from the companies and their employees. Due to this, more experts should be sent to the companies within the framework of research work to record the measures and potentials on site in order to obtain more meaningful evaluations.

Few articles deal with energy efficiency potentials as an actual measure at the technology level, such as lighting technology. However, when this takes place, the relationships between these measures are not considered further.

The relationships between the individual measures and potentials are an important parameter for estimating what a company will need in the future, for example, if it has already implemented individual measures. If a correlation can be formed, more targeted expansion concepts can be created, for example, and investments in energy efficiency can be triggered more quickly.

Therefore, exactly these correlations and their effects on energy efficiency measures and potentials should be researched.

4.6 Limitations of our work

Only 101 articles on the subject were examined. The majority of the work originates from the European Union and is, therefore, not easily transferable to all countries and their resident companies.

The method chosen to select the search terms and synonyms is partly subjective. Even if the method subsequently follows a clear framework, this cannot be completely eliminated. Also, the cleaning process in selecting the articles to be studied is a weakness of the work. One reason may be the excessive focus on technology level measures. These measures should be examined and should be left at the end of the search and cleaning process, but this strict focus may also exclude studies that examined these technology level measures as side effects in their studies but did not contextualize them directly through the titles and abstracts.

4.7 Further research and contribution

The research question is still valid, as the reviewed articles cannot fully answer the research question. Thus, it has become apparent that there is a research gap in the area of relationships and interactions between individual energy efficiency measures and potentials from the literature review developed, there are several potential research gaps related to the research question that has been insufficiently explored. Thus, this thesis makes a theoretical contribution to a better understanding of energy efficiency research. Based on the existing literature, a specific research gap is identified and justified.

The results of this thesis have also shown that more research on smaller and non-manufacturing companies in the field of energy efficiency and digitalization is useful and necessary. Simply due to the fact that there are many small businesses and the attitudes of small and large businesses towards this topic can be diametrically different.

More studies should be conducted that capture and map energy efficiency potentials at the technology level. To this end, very practical energy efficiency potentials (e.g., LED technology and electric drives) are recorded in the companies. In addition to the potentials, a survey should also identify the measures that have already been implemented or whose potentials are classified as low or non-existent. A correlation between the individual technologies can then be derived from this and a transferable quantitative statement made for other companies.

Studies dealing with the correlations between the individual measures and their influence are also scarcely available to date.

A positive and negative effect of an energy management system (EnMS) on other energy efficiency measures and potentials has already been empirically demonstrated in a few studies. However, the empirical evidence of these studies is limited to subjective assessments, a small number of participants (here: employees and companies), and to effects on overall energy efficiency. Also, the distinction between small and large companies has not been sufficiently considered so far.

5 Conclusion

The aim of this work was to answer the research question of what energy efficiency potentials exist at the technology level in companies and what interactions they have with each other. An extensive literature search was conducted and 101 articles were found. To answer the research question, the articles were examined using a literature review and a SWOT analysis. The research question could not be answered conclusively and sufficiently and the research gap in the field of interactions between individual energy efficiency measures and potentials could thus be identified. When interactions are researched, they usually refer only to large and energy-intensive producing companies of selected industries (e.g., the steel industry). Also, the level of detail is often not extended to the technology level and is limited to the overall efficiency of a company. In addition, research data is rarely taken directly on-site and critically reviewed by an expert. These and other findings of the present study indicate a need for research in theoretical energy efficiency research, as the interactions between energy efficiency measures and potentials have not yet been explored or have been explored only inadequately.

The results of further research can primarily make a theoretical contribution to a better understanding of the interactions and effects of individual energy efficiency measures.

If it is known what interactions exist as a result of energy efficiency measures, the state can, for example, launch more targeted support programs and thus achieve greater acceptance of the programs among companies, which leads to higher implementation. Companies often do not know which measures they should implement next, while the government does not know the implementation status of the companies. This knowledge gap makes synergies difficult but can be gradually overcome through best practice measures and research such as the present one.

For companies, regardless of whether they take advantage of subsidy programs or not, it is possible to deduce which measures other companies are implementing or which existing potential can trigger synergy effects.

In the following, it is planned to answer the open research question by means of a case study and to qualitatively and quantitatively answer the interactions of the individual measures with the help of hypotheses on individual technology areas. Research data on this has already been collected via the EU-funded project network of regional competence centers for energy efficiency. The case study picks up 12 focus topics (measures on technology level) from the companies and compares their frequencies in the companies. From this, the current status of energy efficiency in the companies can be presented. In addition, the selected hypotheses are used to compare measures at the technology level with each other, so that, for example, empirical evidence can be provided as to whether companies with an energy management system have a lower energy efficiency potential than companies without an energy management system. Furthermore, the findings obtained in this study are empirically tested in the case study.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

TK and NK contributed to the conception and design of the study. All authors contributed to manuscript revision and read and approved the submitted version.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenrg.2022.934859/full#supplementary-material

Abbreviations

CO2, carbon dioxide; EEM, energy efficiency measures; EnMS, energy management system; ERDF, European regional development fund; EU, European Union; IoT, Internet of Things; KEFF, energy efficiency competence center; LEACH-LMMN, Levenberg–Marquardt neural network; LED, light-emitting diode; LSCCOA, Lagrangian suboptimal convergent computation offloading algorithm; SME, small and medium-sized enterprises; SWOT, strengths-weaknesses-opportunities-threats; UM BW, ministry of the environment of Baden–Württemberg; WOA, whale optimization algorithm; WSN, wireless sensor network.

References

Adams, J. (2007). Research methods for graduate business and social science students. Los Angeles: SAGE Publications. Response.

Allarton, R. (2016). “Higher education support to small medium enterprises: A local experience in energy efficiency,” in Sustainable development research at universities in the United Kingdom: Approaches, methods and projects. Editor W. Leal Filho(Cham: Springer International Publishing), 173–192.

Anajemba, J. H., Yue, T., Iwendi, C., Alenezi, M., and Mittal, M. (2020). Optimal cooperative offloading scheme for energy efficient multi-access Edge computation. IEEE Access 8, 53931–53941. doi:10.1109/access.2020.2980196

Anderson, S. T., and Newell, R. G. (2004). Information programs for technology adoption: The case of energy-efficiency audits. Resour. Energy Econ. 26 (1), 27–50. doi:10.1016/j.reseneeco.2003.07.001

Andrews, R. N., and Johnson, E. (2016). Energy use, behavioral change, and business organizations: Reviewing recent findings and proposing a future research agenda. Energy Res. Soc. Sci. 11, 195–208. doi:10.1016/j.erss.2015.09.001

Backlund, S., Thollander, P., Palm, J., and Ottosson, M. (2012). Extending the energy efficiency gap. Energy Policy 51, 392–396. doi:10.1016/j.enpol.2012.08.042

Bell, M., Carrington, G., Lawson, R., and Stephenson, J. (2014). Socio-technical barriers to the use of energy-efficient timber drying technology in New Zealand. Energy Policy 67, 747–755. doi:10.1016/j.enpol.2013.12.010

Brunke, J.-C., Johansson, M., and Thollander, P. (2014). Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 84, 509–525. doi:10.1016/j.jclepro.2014.04.078

Bundesministerium für Umwelt, Naturschutz, Bau und Reaktorsicherheit (BMUB) (2015). Klimaschutz durch Energieeffizienz: Konzept zur Erhöhung der Energieeffizienz, insbesondere durch die Weiterentwicklung der Energiebesteuerung sowie flankierender Maßnahmen. [Online]. Available at: https://www.bmu.de/fileadmin/Daten_BMU/Download_PDF/Klimaschutz/klimaschutz_durch_energieeffizienz_zusammenfassung_bf.pdf. www.bmub.bund.de (Accessed May 13, 2020).

Cagno, E., Moschetta, D., and Trianni, A. (2019). Only non-energy benefits from the adoption of energy efficiency measures? A novel framework. J. Clean. Prod. 212, 1319–1333. doi:10.1016/j.jclepro.2018.12.049

Cagno, E., and Trianni, A. (2014). Evaluating the barriers to specific industrial energy efficiency measures: An exploratory study in small and medium-sized enterprises. J. Clean. Prod. 82, 70–83. doi:10.1016/j.jclepro.2014.06.057

Cagno, E., and Trianni, A. (2013). Exploring drivers for energy efficiency within small- and medium-sized enterprises: First evidences from Italian manufacturing enterprises. Appl. Energy 104, 276–285. doi:10.1016/j.apenergy.2012.10.053

Cagno, E., Trianni, A., Worrell, E., and Miggiano, F. (2014). Barriers and drivers for energy efficiency: Different perspectives from an exploratory study in The Netherlands. Energy Procedia 61, 1256–1260. doi:10.1016/j.egypro.2014.11.1073

Cagno, E., Worrell, E., Trianni, A., and Pugliese, G. (2013). A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 19, 290–308. doi:10.1016/j.rser.2012.11.007

Camarasa, C., Heiberger, R., Hennes, L., Jakob, M., Ostermeyer, Y., and Rosado, L. (2020). Key decision-makers and persuaders in the selection of energy-efficient technologies in EU residential buildings. Buildings 10 (4), 70. doi:10.3390/buildings10040070

Catarino, J., Henriques, J., and Egreja, F. (2015). Portuguese SME toward energy efficiency improvement. Energy Effic. 8 (5), 995–1013. doi:10.1007/s12053-015-9325-7

Chen, X., Despeisse, M., and Johansson, B. (2020). Environmental sustainability of digitalization in manufacturing: A review. Sustainability 12 (24), 10298. doi:10.3390/su122410298

Chiaroni, D., Chiesa, M., Chiesa, V., Franzò, S., Frattini, F., and Toletti, G. (2016). Introducing a new perspective for the economic evaluation of industrial energy efficiency technologies: An empirical analysis in Italy. Sustain. Energy Technol. Assessments 15, 1–10. doi:10.1016/j.seta.2016.02.004

Cooremans, C. (2012). Investment in energy efficiency: Do the characteristics of investments matter?’. Energy Effic. 5 (4), 497–518. doi:10.1007/s12053-012-9154-x

Costa-Campi, M. T., García-Quevedo, J., and Segarra, A. (2015). Energy efficiency determinants: An empirical analysis of Spanish innovative firms. Energy Policy 83, 229–239. doi:10.1016/j.enpol.2015.01.037

Cunha, P., Neves, S. A., Marques, A. C., and Serrasqueiro, Z. (2020). Adoption of energy efficiency measures in the buildings of micro-small- and medium-sized Portuguese enterprises. Energy Policy 146, 111776. doi:10.1016/j.enpol.2020.111776

del Río González, P. (2005). Analysing the factors influencing clean technology adoption: A study of the Spanish pulp and paper industry. Bus. Strategy Environ. 14 (1), 20–37. doi:10.1002/bse.426

Deutscher Industrie und Handelskammer (2018). Strompreise drücken auf die Stimmung: Energiewende-Barometer 2018. [Online]. Available at: https://www.dihk.de/resource/blob/12568/912c6ffc0c20b318294acce30e1fc83b/energiewende-barometer-2019-data.pdf (Accessed May 4, 2020).

Europäische Kommission (2003). Empfehlung DER Kommission vom 6. Mai 2003 betreffend die Definition der Kleinstunternehmen sowie der kleinen und mittleren Unternehmen. Available at: https://op.europa.eu/en/publication-detail/-/publication/6ca8d655-126b-4a42-ada4-e9058fa45155/language-en ((2003/361/EG)) (Accessed May 4, 2020).

Fawcett, T., and Hampton, S. (2020). Why & how energy efficiency policy should address SMEs. Energy Policy 140, 111337. doi:10.1016/j.enpol.2020.111337

Fernández-Viñé, M. B., Gómez-Navarro, T., and Capuz-Rizo, S. F. (2010). Eco-efficiency in the SMEs of Venezuela. Current status and future perspectives. J. Clean. Prod. 18 (8), 736–746. doi:10.1016/j.jclepro.2009.12.005

Fiedler, T., and Mircea, P.-M. (2012). “‘Energy management systems according to the ISO 50001 standard — Challenges and benefits’,” in 2012 International Conference on Applied and Theoretical Electricity (ICATE 2012), Craiova, Romania, 25 - 27 October 2012 (Piscataway, NJ: IEEE).

Finster, M. P., and Hernke, M. T. (2014). Benefits organizations pursue when seeking competitive advantage by improving environmental performance. J. Industrial Ecol. 18 (5), 652–662. doi:10.1111/jiec.12106

Fleiter, T., Hirzel, S., and Worrell, E. (2012a). The characteristics of energy-efficiency measures – A neglected dimension. Energy Policy 51, 502–513. doi:10.1016/j.enpol.2012.08.054

Fleiter, T., Schleich, J., and Ravivanpong, P. (2012b). Adoption of energy-efficiency measures in SMEs—an empirical analysis based on energy audit data from Germany. Energy Policy 51, 863–875. doi:10.1016/j.enpol.2012.09.041

Fleiter, T., Worrell, E., and Eichhammer, W. (2011). Barriers to energy efficiency in industrial bottom-up energy demand models—a review. Renew. Sustain. Energy Rev. 15 (6), 3099–3111. doi:10.1016/j.rser.2011.03.025

Fresner, J., Morea, F., Krenn, C., Aranda Uson, J., and Tomasi, F. (2017). Energy efficiency in small and medium enterprises: Lessons learned from 280 energy audits across Europe. J. Clean. Prod. 142, 1650–1660. doi:10.1016/j.jclepro.2016.11.126

Gamst, G. (2019). “Die Energiewende beginnt im Gebäude. Wie Unternehmen von grüner Gebäudetechnik profitieren,” in Csr und energiewirtschaft. Editors A. Hildebrandt, and W. Landhäußer (Berlin: Springer-Verlag GmbH), 119–132. [S.l.], GABLER.

Giraudet, L.-G. (2020). Energy efficiency as a credence good: A review of informational barriers to energy savings in the building sector. Energy Econ. 87, 104698. doi:10.1016/j.eneco.2020.104698

Hampton, S. (2019). Making sense of energy management practice: Reflections on providing low carbon support to three SMEs in the UK. Energy Effic. 12 (6), 1473–1490. doi:10.1007/s12053-018-9750-5

Haq, A., and Jacobsen, H.-A. (2018). Prospects of appliance-level load monitoring in off-the-shelf energy monitors: A technical review. Energies 11 (1), 189. doi:10.3390/en11010189

Hasan, A. S. M. M., Hossain, R., Tuhin, R. A., Sakib, T. H., and Thollander, P. (2019). Empirical investigation of barriers and driving forces for efficient energy management practices in non-energy-intensive manufacturing industries of Bangladesh. Sustainability 11 (9), 2671. doi:10.3390/su11092671

Henriques, J., and Catarino, J. (2016). Motivating towards energy efficiency in small and medium enterprises. J. Clean. Prod. 139, 42–50. doi:10.1016/j.jclepro.2016.08.026

Hertel, M. (2014). Adoption energieeffizienter Techniken in KMU: Das Management im Fokus einer empirischen Untersuchung (Zugl.: München, Techn. Univ., Diss., 2013). [Online]. Wiesbaden: Springer Gabler. Available at: http://gbv.eblib.com/patron/FullRecord.aspx?p=1731410 (Accessed May 5, 2020).

Hertel, M., and Menrad, K. (2016). Adoption of energy-efficient technologies in German SMEs of the horticultural sector—The moderating role of personal and social factors. Energy Effic. 9 (3), 791–806. doi:10.1007/s12053-015-9400-0

Hesselink, L. X., and Chappin, E. J. (2019). Adoption of energy efficient technologies by households – barriers, policies and agent-based modelling studies. Renew. Sustain. Energy Rev. 99, 29–41. doi:10.1016/j.rser.2018.09.031

Hilger, L., Schneiders, T., Meyer, F. P., and Kroll, J.-P. (2018). “‘Use of smart technologies for energy efficiency, energy- and load management in small and medium sized enterprises (SMEs)’,” in 2018 7th International Energy and Sustainability Conference (IESC), Cologne, Germany, 17-18 May 2018 (Piscataway, NJ: IEEE), 1–8.

Hill, T., and Westbrook, R. (1997). SWOT analysis: It's time for a product recall. Long. Range Plan. 30 (1), 46–52. [Online]. doi:10.1016/S0024-6301(96)00095-7

Hoyer, C., Gunawan, I., and Reaiche, C. H. (2020). The implementation of industry 4.0 - a systematic literature review of the key factors. Syst. Res. Behav. Sci. 37 (4), 557–578. doi:10.1002/sres.2701

Hung, D.-F., and Chu, C.-N. (2020). An integrated framework for elucidating the energy-saving decision-making process of Small- and medium-sized Enterprises in Taiwan. Energy Effic. 13 (4), 711–734. doi:10.1007/s12053-020-09853-9

Hwang, H., and Colyvas, J. A. (2011). Problematizing actors and institutions in institutional work. J. Manag. Inq. 20 (1), 62–66. doi:10.1177/1056492610387705

Iwendi, C., Maddikunta, P. K. R., Gadekallu, T. R., Lakshmanna, K., Bashir, A. K., and Piran, M. J. (2021). A metaheuristic optimization approach for energy efficiency in the IoT networks. Softw. Pract. Exper. 51 (12), 2558–2571. doi:10.1002/spe.2797

Jaffe, A. B., and Stavins, R. N. (1994). The energy-efficiency gap what does it mean? Energy Policy 22 (10), 804–810. doi:10.1016/0301-4215(94)90138-4

Jochem, E., Mai, M., and Ott, V. (2010). Energieeffizienznetzwerke – beschleunigte Emissionsminderungen in der mittelständischen Wirtschaft. Z. Energiewirtsch. 34 (1), 21–28. doi:10.1007/s12398-010-0002-4

Kinelski, G. (2020). The main factors of successful project management in the aspect of energy enterprises’ efficiency in the digital economy environment. Polityka Energetyczna –. Energy Policy J. 23 (3), 5–20. doi:10.33223/epj/126435

Kollmann, T. (2016). Das 1 x 1 des Wissenschaftlichen Arbeitens: Von der Idee bis zur Abgabe. 2nd edn. Wiesbaden: Springer Gabler.

König, W. (2020). Energy efficiency in industrial organizations––A cultural-institutional framework of decision making. Energy Res. Soc. Sci. 60, 101483. doi:10.1016/j.erss.2020.101483

König, W., Löbbe, S., Büttner, S., and Schneider, C. (2020). Establishing energy efficiency—drivers for energy efficiency in German manufacturing small- and medium-sized enterprises. Energies 13 (19), 5144. doi:10.3390/en13195144

Kostka, G., Moslener, U., and Andreas, J. (2013). Barriers to increasing energy efficiency: Evidence from small-and medium-sized enterprises in China. J. Clean. Prod. 57, 59–68. doi:10.1016/j.jclepro.2013.06.025

Krutwig, M. (2019). “A data analysis of a SME energy audit program in Germany,” in 19th International Multidisciplinary Scientific GeoConference SGEM2019, Energy and Clean Technologies, Albena, Bulgaria, 30 June - 6 July, 2019. STEF92 Technology.

Leloux, M., Harkema, S., and Popescu, F. (2015). Accelerating the adoption process of renewable energy sources among SMEs, Ann. Univ. Oradea. Econ. Sci. 1, 247–255.

Meath, C., Linnenluecke, M., and Griffiths, A. (2016). Barriers and motivators to the adoption of energy savings measures for small- and medium-sized enterprises (SMEs): The case of the ClimateSmart business cluster program. J. Clean. Prod. 112, 3597–3604. doi:10.1016/j.jclepro.2015.08.085

Mickovic, A., and Wouters, M. (2020). Energy costs information in manufacturing companies: A systematic literature review. J. Clean. Prod. 254, 119927. doi:10.1016/j.jclepro.2019.119927

Mittal, M., Iwendi, C., Khan, S., and Rehman Javed, A. (2021). Analysis of security and energy efficiency for shortest route discovery in low‐energy adaptive clustering hierarchy protocol using Levenberg‐Marquardt neural network and gated recurrent unit for intrusion detection system. Trans. Emerg. Tel. Tech. 32 (6). doi:10.1002/ett.3997

Mittelstandsinitiative Energiewende und Klimaschutz (2019). Praxisleitfaden Chancen der Digitalisierung für den Klimaschutz. [Online]. Available at: https://www.mittelstand-energiewende.de/fileadmin/user_upload_mittelstand/MIE_vor_Ort/Leitf%C3%A4den/digital_klima_navi_final.pdf (Accessed June 10, 2020).

Morais, D., Gaspar, P. D., Silva, P. D., Andrade, L. P., and Nunes, J. (2020). Energy consumption and efficiency measures in the Portuguese food processing industry. J. Food Process. Preserv. doi:10.1111/jfpp.14862

Muresan, A. A., and Attia, S. (2017). Energy efficiency in the Romanian residential building stock: A literature review. Renew. Sustain. Energy Rev. 74, 349–363. doi:10.1016/j.rser.2017.02.022

Muzamwese, T. C. (2016). Challenges and opportunities for mainstreaming industrial energy efficiency in small-to-medium-sized industries in Zimbabwe. WIREs Energy Environ. 5 (5), 510–518. doi:10.1002/wene.203

Nigohosyan, D., Vutsova, A., and Vassileva, I. (2021). Effectiveness and efficiency of the EU-supported energy efficiency measures for SMEs in Bulgaria in the period 2014–2020: Programme design implications. Energy Effic. 14, 24. doi:10.1007/s12053-021-09933-4

Olmos, L., Ruester, S., Liong, S.-J., and Glachant, J.-M. (2011). Energy efficiency actions related to the rollout of smart meters for small consumers, application to the Austrian system. Energy 36 (7), 4396–4409. doi:10.1016/j.energy.2011.04.003

Olsthoorn, M., Schleich, J., and Hirzel, S. (2017). Adoption of energy efficiency measures for non-residential buildings: Technological and organizational heterogeneity in the trade, commerce and services sector. Ecol. Econ. 136, 240–254. doi:10.1016/j.ecolecon.2017.02.022

Özbuğday, F. C., Fındık, D., Metin Özcan, K., and Başçı, S. (2020). Resource efficiency investments and firm performance: Evidence from European SMEs. J. Clean. Prod. 252, 119824. doi:10.1016/j.jclepro.2019.119824

Palm, J., and Backman, F. (2020). Energy efficiency in SMEs: Overcoming the communication barrier. Energy Effic. 13 (5), 809–821. doi:10.1007/s12053-020-09839-7

Palm, J., and Thollander, P. (2010). An interdisciplinary perspective on industrial energy efficiency. Appl. Energy 87 (10), 3255–3261. doi:10.1016/j.apenergy.2010.04.019

Parker, C. M., Redmond, J., and Simpson, M. (2009). A review of interventions to encourage SMEs to make environmental improvements. Environ. Plann. C. Gov. Policy 27 (2), 279–301. doi:10.1068/c0859b

Perroni, M. G., Gouvea da Costa, S. E., Pinheiro de Lima, E., and Vieira da Silva, W. (2017). The relationship between enterprise efficiency in resource use and energy efficiency practices adoption. Int. J. Prod. Econ. 190, 108–119. doi:10.1016/j.ijpe.2016.08.023

Phylipsen, G., Blok, K., and Worrell, E. (1997). International comparisons of energy efficiency-Methodologies for the manufacturing industry. Energy Policy 25 (7-9), 715–725. doi:10.1016/s0301-4215(97)00063-3

Ponomareva, O., Maiorova, T., Litovskaya, Y., and Nazarova, O. (2019). Eco-management in condition of metallurgical production digitization. IOP Conf. Ser. Mat. Sci. Eng. 497, 012083. doi:10.1088/1757-899x/497/1/012083

Pye, M., and McKane, A. (2000). Making a stronger case for industrial energy efficiency by quantifying non-energy benefits. Resour. Conservation Recycl. 28 (3-4), 171–183. doi:10.1016/s0921-3449(99)00042-7

Rahbauer, S., Menapace, L., Menrad, K., and Decker, T. (2016). Adoption of green electricity by small- and medium-sized enterprises in Germany. Renew. Sustain. Energy Rev. 59, 1185–1194. doi:10.1016/j.rser.2016.01.079

Rohdin, P., and Thollander, P. (2006). Barriers to and driving forces for energy efficiency in the non-energy intensive manufacturing industry in Sweden. Energy 31 (12), 1836–1844. doi:10.1016/j.energy.2005.10.010

Sa, A., Paramonova, S., Thollander, P., and Cagno, E. (2015). Classification of industrial energy management practices. Energy Procedia 75, 2581–2588. doi:10.1016/j.egypro.2015.07.311

Safarzadeh, S., Rasti-Barzoki, M., and Hejazi, S. R. (2020). A review of optimal energy policy instruments on industrial energy efficiency programs, rebound effects, and government policies. Energy Policy 139, 111342. doi:10.1016/j.enpol.2020.111342

Samuels, J. A., and Booysen, M. J. (2019). Chalk, talk, and energy efficiency: Saving electricity at South African schools through staff training and smart meter data visualisation. Energy Res. Soc. Sci. 56, 101212. doi:10.1016/j.erss.2019.05.022

Sardianou, E. (2008). Barriers to industrial energy efficiency investments in Greece. J. Clean. Prod. 16 (13), 1416–1423. doi:10.1016/j.jclepro.2007.08.002

Schleich, J., and Fleiter, T. (2019). Effectiveness of energy audits in small business organizations. Resour. Energy Econ. 56, 59–70. doi:10.1016/j.reseneeco.2017.08.002

Schlomann, B., and Schleich, J. (2015). Adoption of low-cost energy efficiency measures in the tertiary sector—an empirical analysis based on energy survey data. Renew. Sustain. Energy Rev. 43, 1127–1133. doi:10.1016/j.rser.2014.11.089

Schmid, C. (2004). Energieeffizienz in Unternehmen: Eine handlungstheoretische und wissensbasierte Analyse von Einflussfaktoren und Instrumenten. Zürich: ETH Zürich Eidgenössische Technische Hochschule Zürich.

Schulze, M., Heidenreich, S., and Spieth, P. (2018). The impact of energy management control systems on energy efficiency in the German manufacturing industry. J. Industrial Ecol. 22 (4), 813–826. [Online]. doi:10.1111/jiec.12625

Schützenhofer, C. (2021). Overcoming the efficiency gap: Energy management as a means for overcoming barriers to energy efficiency, empirical support in the case of Austrian large firms. Energy Effic. 14 (5), 45. doi:10.1007/s12053-021-09954-z

Semkov, K., Mooney, E., Connolly, M., and Adley, C. (2014). Efficiency improvement through waste heat reduction. Appl. Therm. Eng. 70 (1), 716–722. doi:10.1016/j.applthermaleng.2014.05.030

Shinkevich, M. V., Vertakova, Y. V., and Galimulina, F. F. (2020). Synergy of digitalization within the framework of increasing energy efficiency in manufacturing industry. Int. J. Energy Econ. Policy 10 (3), 456–464. doi:10.32479/ijeep.9397

Soepardi, A., Chaeron, M., and Wijiatmoko, G. (2019). “Barriers to improved energy efficiency in the Indonesian steel industry: Empirical evidence,” in 2019 IEEE International Conference on Industrial Engineering and Engineering Management: IEEM2019, Macau. Macao, 15-18 December, 2019 (Piscataway, NJ: IEEE), 760–763.

Solberg Hjorth, S., and Brem, A. (2016). How to assess market readiness for an innovative solution: The case of heat recovery technologies for SMEs. Sustainability 8 (11), 1152. doi:10.3390/su8111152

Stefana, E., Cocca, P., Marciano, F., Rossi, D., and Tomasoni, G. (2019). A review of energy and environmental management practices in cast iron foundries to increase sustainability. Sustainability 11 (24), 7245. doi:10.3390/su11247245

Stephenson, J., Barton, B., Carrington, G., Doering, A., Ford, R., Hopkins, D., et al. (2015). The energy cultures framework: Exploring the role of norms, practices and material culture in shaping energy behaviour in New Zealand. Energy Res. Soc. Sci. 7, 117–123. doi:10.1016/j.erss.2015.03.005

Stephenson, J., Barton, B., Carrington, G., Gnoth, D., Lawson, R., and Thorsnes, P. (2010). Energy cultures: A framework for understanding energy behaviours. Energy Policy 38 (10), 6120–6129. doi:10.1016/j.enpol.2010.05.069

Sudhakara Reddy, B. (2013). Barriers and drivers to energy efficiency – a new taxonomical approach. Energy Convers. Manag. 74, 403–416. doi:10.1016/j.enconman.2013.06.040

Tallini, A., and Cedola, L. (2016). Evaluation methodology for energy efficiency measures in industry and service sector. Energy Procedia 101, 542–549. doi:10.1016/j.egypro.2016.11.069

Thiede, S., Bogdanski, G., and Herrmann, C. (2012). A systematic method for increasing the energy and resource efficiency in manufacturing companies. Procedia CIRP 2, 28–33. doi:10.1016/j.procir.2012.05.034

Thiede, S., Posselt, G., and Herrmann, C. (2013). SME appropriate concept for continuously improving the energy and resource efficiency in manufacturing companies. CIRP J. Manuf. Sci. Technol. 6 (3), 204–211. doi:10.1016/j.cirpj.2013.02.006

Thollander (2010). Categorizing barriers to energy efficiency—an interdisciplinary perspective doi:10.1016/j.apenergy.2010.04.019

Thollander, P., Backlund, S., Trianni, A., and Cagno, E. (2013). Beyond barriers – a case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 111, 636–643. doi:10.1016/j.apenergy.2013.05.036