- 1Engineering Technology Research Institute of Southwest Oil and Gas Field Company, PetroChina, Chengdu, China

- 2Key Laboratory of Oil and Gas Well Stimulation Technology of Southwest Oil and Gas Field Company, Chengdu, China

- 3Southwest Oil and Gas Field Company, PetroChina, Chengdu, China

It is challenging to get water-based fracture fluid to flow back into low-pressure gas reservoirs. In order to solve the problem, supercritical CO2 is a novel type of non-aqueous fracturing technique with a wide range of applications prospect in low-pressure tight sandstone. In order to determine whether supercritical CO2 fracturing with low-pressure tight sandstone is feasible tight sandstone cores from the Jinqiu Gas field in the Sichuan Basin were used to evaluate the influence of supercritical CO2 on the formation sensitivity of sandstone reservoirs. Supercritical CO2 was used to interact with tight sandstone samples under formation conditions, and then the changes in velocity sensitivity, water sensitivity, salinity sensitivity, alkaline sensitivity, acid sensitivity, and stress sensitivity of tight sandstone were observed. Velocity sensitivity damage decreased by 5.4%, water sensitivity damage decreased by 13.3%, salinity sensitivity damage decreased by 16.6%, alkaline sensitivity damage decreased by 2%, acid sensitivity damage decreased by 14.4%, and stress sensitivity damage increased by 8% after the interaction between tight sandstone and supercritical CO2. This finding provides a quantitative assessment of the impact of supercritical CO2 on formation sensitivity, and it can be used to build a supercritical CO2 fracturing scheme for low-pressure water-sensitive tight sandstone.

Introduction

With the accelerated development of the world economy and the increasing problem of energy shortage, the efficient development of unconventional oil and gas resources is the main means to effectively alleviate the energy crisis. However, the porosity, permeability, and formation pressure of unconventional oil and gas reservoirs are very low (Jiao, 2019; Peng et al., 2019). In order to obtain industrial production, it is usually necessary to carry out hydraulic fracturing for unconventional oil and gas reservoirs, inject high-pressure fluid with proppant into the formation, break the reservoir rock, and form artificial fractures. After the construction is completed, the high-pressure fluid is discharged back to the ground, and the proppant is left in the formation to avoid the re-closure of artificial fractures as a channel for oil and gas flow so as to improve the production of unconventional oil and gas reservoirs (Zhao et al., 2017; Dong et al., 2018; Peng et al., 2020).

At present, with the world economy’s rapid growth and the growing problem of energy scarcity, the efficient development of unconventional oil and gas resources is the most effective means of effectively alleviating the energy crisis (Umar et al., 2022). Unconventional oil and gas reservoirs, on the contrary, have relatively low porosity, permeability, and formation pressure (Jiao, 2019; Peng et al., 2019). Hydraulic fracturing for unconventional oil and gas reservoirs, which involves injecting high-pressure fluid with proppant into the formation, breaking the reservoir rock, and forming artificial fractures, is normally required to achieve industrial production. The high-pressure fluid is a flow back to the ground when the construction is completed, and the proppant is left in the formation to prevent the re-closure of artificial fractures as a channel for oil and gas flow, thereby improving the production of unconventional oil and gas reservoirs (Zhao et al., 2017; Dong et al., 2018; Peng et al., 2020).

For a long period, water-based fracturing fluid was the primary fluid used in fracturing. It is widely used in the fracturing construction of tight sandstone because of its simple formula, low cost, and ease of access (Peng et al., 2016). However, as reservoir stimulation technology advances and post-fracturing evaluation methods improve, it has been discovered that water-based fluids can affect the treatment of fracturing stimulation to tight sandstone gas reservoirs. It has also been discovered that water-based fracturing fluid has some drawbacks; for example, hydraulic fracturing cannot be widely used in places where water resources are scarce (Akrad et al., 2011; Gupta, 2011; Liu et al., 2014; Jia et al., 2018; Wang et al., 2018). These factors limit the widespread use and use of hydraulic fracturing in tight sandstone. River sands of the Shaximiao formation tight sandstone of Jinqiu gas reservoirs, for example, are extensively spread and rich in oil and gas resources in the Sichuan Basin. Water-based fracture fluid is difficult to flow back in low-pressure gas reservoirs of Jinqiu gas field, Sichuan Basin, because the tight sandstone reservoir pressure coefficient is 0.45–1.05 and the pressure coefficient of some sand bodies is too low (Zheng et al., 2021). As a result, in order to effectively improve gas recovery from low-pressure tight sandstone reservoirs, new stimulation technical approaches are urgently needed (Cao et al., 2017; Hazarika and Boruah, 2022).

CO2 is a type of non-aqueous fracturing fluid that is sensitive to temperature and pressure. When the temperature and pressure of the reservoir exceed CO2’s critical temperature (31.1°C) and critical pressure (7.39 MPa), CO2 is in a supercritical state (Nikolai et al., 2019; Mouahid et al., 2022). Supercritical CO2 has a high density, low viscosity, low surface tension, and a high diffusion coefficient, allowing it to move heat and mass efficiently (Cabeza et al., 2017). The use of this fracturing fluid has no negative effects on the reservoir (Day et al., 2008; Lin et al., 2008), and it may effectively avoid formation blockage around the well, safeguard the oil and gas reservoir, and increase reservoir permeability, with supercritical CO2 flowing back extremely easily. Supercritical CO2 fracturing, which has unparalleled benefits over conventional hydraulic fracturing, has been proven in studies conducted both at home and abroad to be the key to the development of unconventional natural gas resources. Many research accomplishments have been accumulated in the interaction mechanism between supercritical CO2 and rock (Zhou et al., 2019; Lin et al., 2022), physics structure (Gathitu et al., 2009; Ao et al., 2017), microstructure (Jiang et al., 2016), and replacement mechanism (Chen et al., 2022; Memon et al., 2022), and so on. Because the adsorption capacity of methane in shale is lower than that of supercritical CO2, supercritical CO2 can be used to substitute methane in shale reservoirs, allowing more shale gas to be recovered and more CO2 to be stored in situ (Zhou et al., 2018; Memon et al., 2022). As a result, supercritical CO2 fracturing has some advantages in reservoirs, particularly for water-sensitive formations, low-pressure reservoirs, and water-stressed areas, making it one of the most environmentally benign fracturing techniques.

The reservoir holding clay minerals, carbonate minerals, and iron-bearing minerals will come into contact with external fluids and solid particles at every construction link of oil and gas exploration and development, causing precipitation owing to incompatibility (Moghadasi et al., 2004; Xu et al., 2016). It either causes clay mineral expansion or reservoir particle migration, obstructing the pore throat and lowering reservoir permeability, disrupting the oil and gas flow channel, limiting the stimulation effect, and lowering the oil and gas final recovery ratio. As a result, prior to the development of an oil or gas field, a potential reservoir sensitivity assessment should be carried out to establish the type and extent of potential reservoir damage so that appropriate preventive countermeasures can be taken (Wilson et al., 2014; Fang et al., 2016).

Reservoir sensitivity refers to the nature of changes in reservoir pore structure and permeability caused by various physical or chemical interactions between reservoir and external fluids. In oil and gas field exploration and production, general reservoir sensitivity encompasses velocity sensitivity, water sensitivity, salinity sensitivity, acid sensitivity, alkali sensitivity, and stress sensitivity (Reinicke et al., 2010; Al-Yaseri et al., 2015; Zhang et al., 2019). The combination of internal potential harm components and external conditions causes reservoir sensitivity damage. Understanding the mechanism of reservoir sensitivity generation can aid in the development of tailored exploiting strategies for various reservoirs. Internal potential damage factors include lithology, physical properties, pore structure, sensitivity, and fluid properties, whereas external conditions include various external factors that cause reservoir damage, such as changes in reservoir pore structure and physical properties during the construction process, with the former changing as the latter changes (Bahrami et al., 2012; Zhou et al., 2022). As a result, analyzing the formation sensitivity of supercritical CO2 fracturing in low-pressure tight sandstone reservoirs is crucial; unfortunately, no relevant reports have been published so far.

This study was conducted to discuss the implications of supercritical CO2 fracturing on reservoir development. The effect of supercritical CO2 on the formation sensitivity of sandstone reservoirs is investigated. Tight sandstone cores were taken from the Jinqiu Gas field in Sichuan Basin, and different tight sandstone samples were treated with supercritical CO2, evaluating changes in microstructure, velocity sensitivity, water sensitivity, salinity sensitivity, alkaline sensitivity, acid sensitivity, and stress sensitivity. Furthermore, the effect of supercritical CO2 on the formation sensitivity of tight sandstone is quantified, and the interaction mechanism between supercritical CO2 and low-pressure tight sandstone is optimized. This finding provides a quantitative assessment of the impact of supercritical CO2 on formation sensitivity, and it can be used to build a supercritical CO2 fracturing scheme for low-pressure water-sensitive tight sandstone.

Materials and Methods

Core Sample

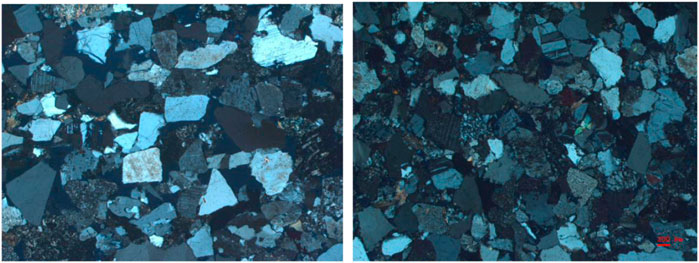

The Jinqiu gas field’s Shaximiao formation is a delta-lake sedimentary formation. The estuary dam and distributary channels overlap, generating a large-scale thick-layer mesh sand group with a sand body thickness of about 15∼30 m, which is an important channel and area for natural gas storage and flow. The Shaximiao formation is made up of a variety of rock types, including conglomerate, sandstone, and mudstone. The main rock type is dark purple mudstone, followed by fine sandstone. Quartz has the highest mineral content, followed by feldspar, and debris has the lowest. Figure 1 shows that sorting is good, the roundness is subcircular and subangular, and the particle contact is points and lines. Sandstone has a low compositional maturity and a medium structural maturity and developed intergranular pores, reservoir porosity of 8.0∼16.0%, average porosity of 10.4%, and permeability of 0.01∼1 mD. It has poor porosity and permeability overall. Residual intergranular pore and feldspar dissolved pore make up the majority of the reservoir space, and the reservoir type is pore type (Zhang et al., 2022). The thick reservoir is dispersed along the favorable sedimentary microfacies region in a continuous pattern. The pressure coefficient of the same sand group in different periods and different rivers in the same era varies (0.4∼1.3), demonstrating the “one reservoir for one river” characteristics. The pressure coefficient of some sand bodies is low. The pressure coefficient of the sand body 7#, for example, is just approximately 0.47, so the pressure outlet cannot flow back freely because there is no gas or liquid there, necessitating gas lifting for gas testing.

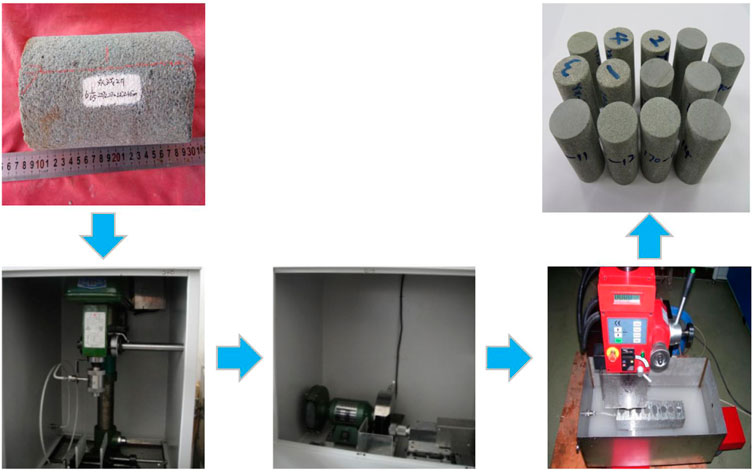

First, underground cores with a diameter of 10 cm and a length of 5∼15 cm were chosen from reasonably undeveloped cracks and bedding in the perforated interval, upper and lower portions, based on sample processing requirements. Then, using a core drilling machine, cylindrical core samples of 2.5 cm in diameter were drilled in the direction of the reservoir fluid. Following that, core samples with uneven ends were removed with a core cutter to get cylindrical core samples with a diameter of 2.5 cm and a length of 5.5 cm. Finally, a lapping machine was used to flatten the two ends of core samples so that they could be used in tests. Figure 2 depicts the core processing flow. The core diameter is 2.5 cm, and the length must be at least 1.5 times the diameter. Core samples should have flat end surfaces and cylindrical surfaces, and the end surface should be perpendicular to the cylindrical surface with no flaws such as missing angles. In order to avoid mistakes, the same depth section of a well’s core samples was chosen, and the processed core samples with a permeability of 1∼10 mD were manually screened for the experiment.

Core samples of about 1 cm knocked off from underground cores of 10 cm in diameter were selected for microscopic experimental evaluation.

Apparatus

Visualization equipment for interaction between supercritical CO2 and rock is shown in Figure 3, and it includes a CO2 gas cylinder, CO2 storage tank, cold bath, CO2 booster pump, visual reactor, heating jacket, and control systems. The pressure bearing capacity of the whole unit is 50 MPa, the temperature range is from −5°C to 150°C, the volume of the visual reactor is 500 ml, and the volume of the CO2 storage tank is 5 L. By using the control system and changing the parameters of the heating jacket and CO2 booster pump, the interaction process between supercritical CO2 and rock at different temperatures, pressures, and times can be realized. The experimental system key core component is visual reactor, and the interaction process between supercritical CO2 and rock can be observed in real time through the visual reactor with sapphire glass.

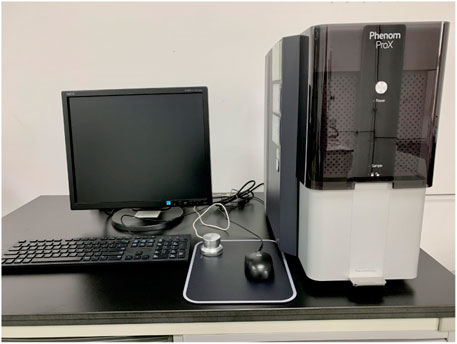

The scanning electron microscope equipment is shown in Figure 4, and it is mainly composed of an electron microscope, electron gun filament, vacuum system, automatic sample, and image acquisition and processing system. It can quickly obtain high-quality images with rich surface features, which can be used to analyze sub-micron or nano-scale samples because the highest magnification is 150,000 times, and the resolution is better than 10 nm. The purpose of SEM is to examine and determine the type, shape, occurrence, and distribution of clay minerals and other types of cement, examine the rock pore structure, particularly the size, morphology, and wall characteristics of the throat, and comprehend the spatial relationship between pore structure and various types of cement, fillings, and debris particles. SEM can see the expansion properties before and after clay mineral hydration, in addition to the aforementioned conventional findings. It is used to investigate the interaction of supercritical CO2 with rock, examine the trends in reservoir physical parameters such as porosity, permeability, and mineral composition, and provide a foundation for sensitivity analysis.

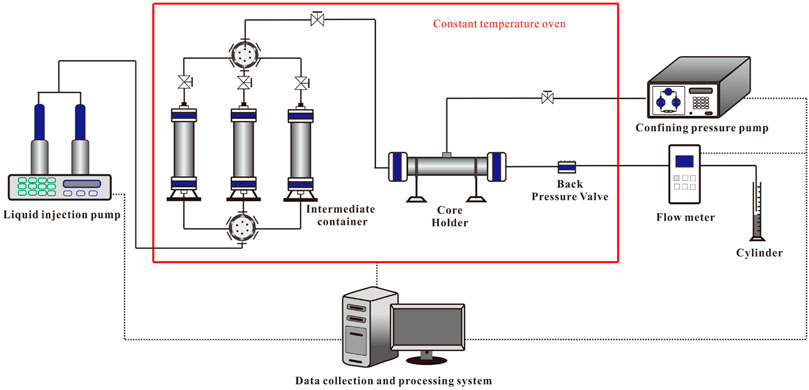

The core displacement equipment is shown in Figure 5. It consists of a liquid injection pump, intermediate container for storing standard saline water and acid fluid, core holder, confining pressure pump, flow meter, constant temperature oven, back pressure valve, data collection and processing system, and core displacement equipment flowchart as shown in Figure 6. Equipment parameters: maximum injection pressure 70 MPa, core size Φ25 mm × L40∼80 mm, maximum temperature 150°C, fluid logging permeability 0.0001∼1,000 mD, constant speed constant pressure pump flow 0.01∼40 ml/min. Simulation of a high-temperature environment by a constant temperature oven and simulation of actual formation pressure by a back pressure valve can restore the seepage environment of cores under formation conditions, simulate oil and gas well development and production processes, and then evaluate the effect of various development schemes and processes on improving reservoir permeability and oil and gas productivity, such as reservoir sensitivity research and relative permeability curve determination.

The Experiment of Liquid

Standard saline water having the same salinity as formation water, namely, 8% (mass ratio NaCl: CaCl2: MgCl2·6H2O = 7:0.6:0.4) was used in the velocity sensitivity, water sensitivity, and salinity sensitive experiments.

The acid sensitivity experiment used formation water or normal saline water with the same salinity as formation water, namely, 8% (mass ratio NaCl: CaCl2: MgCl2·6H2O = 7:0.6:0.4) and a 15% HCl acid fluid.

The water used in the alkali sensitivity study was standard saline water with the same salinity as formation water, namely, 8%.

Methods

The sensitivity of a reservoir is evaluated as follows. First, from the standpoint of petrographic analysis, the sensitive mineral properties were examined, and the potential damage factors of the reservoir were investigated. Second, representative samples were chosen for a sensitivity experiment that measured the permeability of rock before and after contact with various external fluids to assess the damage caused by external fluids to the reservoir.

Various liquids related to formation damage were injected under experimental conditions, or seepage conditions (net confining pressure, etc.) were changed to determine the permeability of core samples in order to judge the damage of critical parameters, experimental fluids, and seepage conditions to core sample permeability, in accordance with Darcy’s law.

SEM and sensitivity experiments were conducted on core samples before and after contact between supercritical CO2 and tight sandstone core samples to quantify the influence of supercritical CO2 on tight sandstone sensitivity.

The following are the primary experimental steps, which are based on the People’s Republic of China’s petroleum and natural gas industry standard, SY/T 5358-2010 formation damage evaluation.

1) Tight sandstone core samples were evaluated for their original microstructure.

2) In the velocity sensitivity experiment, simulated formation water was injected into samples at various constant flow velocities to evaluate the liquid permeability of simulated formation water passing through cores and the critical velocity and velocity sensitivity damage of samples.

3) In the water sensitivity experiment, simulated formation water, saline water with half the salinity of simulated formation water, and distilled water were injected at a velocity lower than critical velocity as the initial test fluid, intermediate test fluid, and final test fluid, respectively, to measure the permeability of samples and determine water sensitivity damage.

4) In the salinity sensitivity experiment, saline water of various salinities was prepared and injected into samples in the order of high to low salinity (salinity was reduced by half) to determine the permeability of saline water of various salinities passing through core samples to determine the salinity sensitivity damage of samples.

5) To examine the acid sensitivity of samples, the initial permeability was tested with standard saline water, then 15% HCl solution was introduced into samples for saturation for 2 h, and lastly, the acidified permeability was measured with standard saline water.

6) In the alkali sensitivity experiment, saline water of various pH levels was used to test the permeability of samples to determine their alkali sensitivity damage.

7) In the stress sensitivity experiment, the difference between confining pressure and injection pressure was gradually increased from 2.5 to 20 MPa and then gradually dropped to 2.5 MPa to determine sample permeability and stress sensitivity damage.

8) The samples were placed in a visualization equipment visual reactor to see how supercritical CO2 interacts with rock. Inject CO2 into the visual reactor and configure the pressure and temperature to keep CO2 supercritical for a specific amount of time. After 24 h of interaction at 15 MPa and 60°C, the pressure in the visual reactor was reduced to ambient, and tight sandstone core samples were allowed to cool naturally.

9) After the interaction between supercritical CO2 and tight sandstone core samples, referring to 1–7, the microstructure, velocity sensitivity, water sensitivity, salinity sensitivity, acid sensitivity, alkali sensitivity, and stress sensitivity of tight sandstone core samples were investigated.

Results and Discussion

Effect of Supercritical CO2 on Microstructure of Tight Sandstone

Reservoir sensitivity is generally caused by sensitivity minerals in the reservoir, which are susceptible to physical, chemical, or physicochemical reactions with external fluids, resulting in a significant reduction in permeability. The sandstone contains sensitive minerals in the debris particles, matrixes, and cement. They have a small particle size (<20 μm) and a large specific surface area and are commonly dispersed on the pore surface and throat, where they are most likely to come into touch with external fluids.

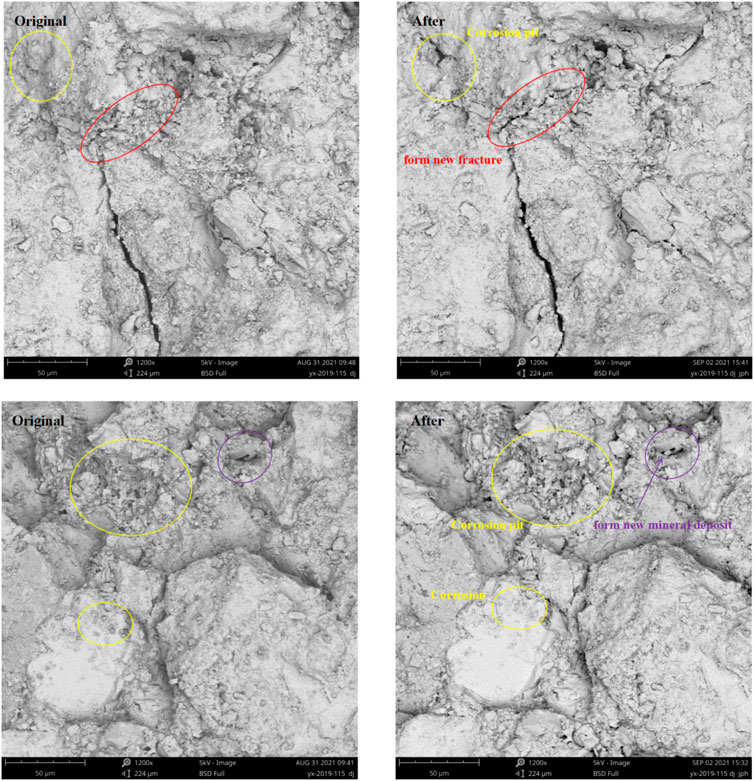

SEM was used to examine the microstructure of tight sandstone core samples before and after supercritical CO2 action at magnifications of ×1200. Figure 7 depicts the experimental results of the microstructure.

The tight sandstone core’s original surface was rather level, and the pores were very small. Residual intergranular pores, intergranular pores, dissolution holes, and microfractures are the most common types of primary pores.

During interaction with tight sandstone, supercritical CO2 will somewhat dissolve feldspar, quartz, and clay particles, according to researchers. The SEM results revealed that after 48 h of interaction between tight sandstone and supercritical CO2 at 60°C and 10 MPa, weak dissolution of feldspar and clay minerals occurred, forming a curved dissolution fracture of about 40 microns in length with irregular pores of about 10 microns and multiple small holes of 1–3 microns in diameter. A tiny quantity of irregular mineral precipitation with a diameter of 1–2 microns also formed, plugging the original pores (Figures 7A,B). In general, corrosion and dissolution of quartz, feldspar, and clay minerals enhanced the porosity and permeability of samples following interaction with supercritical CO2, but precipitation of produced calcite and other minerals at the pore lowered the porosity and permeability of samples.

Effect of Supercritical CO2 on Velocity Sensitivity

Changes in the velocity or pressure of external or reservoir fluids cause the initiation and plugging of pore throats of particles in the reservoir. The phenomenon of reservoir permeability reductions due to pore throat plugging by reservoir particle migration caused by velocity changes of external fluids or reservoir fluids is known as reservoir velocity sensitivity.

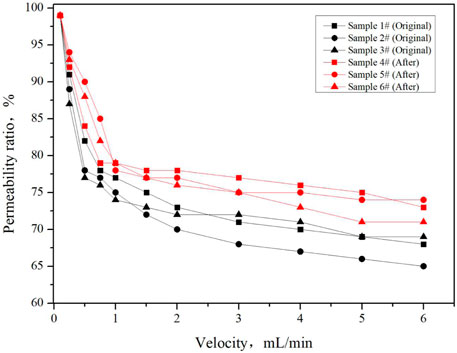

After 24 h of interaction between supercritical CO2 and tight sandstone core samples at 60°C and 15 MPa, simulated formation water at various constant flow velocities was injected into the samples to evaluate the velocity sensitivity of the samples before and after supercritical CO2 action at room temperature using core displacement equipment. Figure 8 depicts the experimental results of sample velocity sensitivity.

Small particles are always present in the reservoir, either strongly cemented, semi-consolidated, or even loosely distributed between the pore wall and large particles. When the flow velocity of external fluids or reservoir fluids was increased from 0.1 to 6.0 ml/min, particles migrated into the pore and plugged the pore throat, decreasing reservoir permeability. As shown in Figure 8, at the flow velocity of 0.5 ml/min, the permeability of Samples 2# and 3# decreased by 22% and 23%, respectively, causing flow velocity sensitivity, with a critical velocity of 0.25 ml/min; at the flow velocity of 0.75 ml/min, the permeability of Samples 1# and 4# decreased by 22% and 21%, respectively, causing flow velocity sensitivity, with a critical velocity of 0.50 ml/min; at the flow velocity of 1 ml/min, the permeability of Samples 5# and 6# decreased by 22% and 21%, respectively, causing flow velocity sensitivity, with a critical velocity of 0.75 ml/min. This revealed that after interacting with supercritical CO2 and tight sandstone core samples, corrosion and dissolution of quartz, feldspar, and clay minerals increased sample porosity and permeability, while precipitation of formed calcite and other minerals at the pore decreased sample porosity and permeability but had little effect on sample velocity sensitivity. The ultimate permeability rate increased from 67.3% to 72.7%, and the velocity sensitivity damage rate dropped by 5.4% as the average critical velocity of samples increased from 0.31 to 0.67 ml/min.

Effect of Supercritical CO2 on Water Sensitivity

The phenomenon of reservoir permeability decreases due to hydration, expansion, dispersion, and migration of clay minerals due to their incompatibility with external fluids, which is dependent on the type and content of clay minerals in the reservoir, is referred to as reservoir water sensitivity. The purpose of the water sensitivity experiment is to find out how the reservoir expands, disperses, and migrates and how much the permeability of the reservoir decreases.

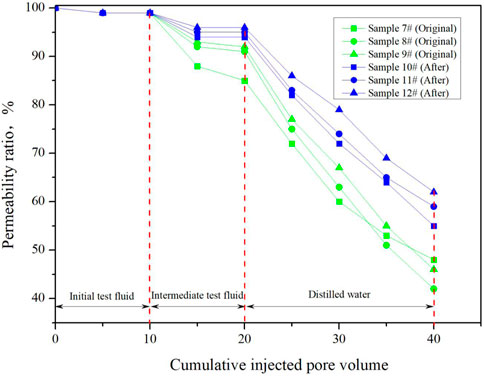

In order to evaluate the water sensitivity of samples before and after supercritical CO2 action at a velocity lower than critical velocity using core displacement equipment, simulated formation water, saline water with salinity half that of simulated formation water, and distilled water were injected as initial test fluid, intermediate test fluid, and final test fluid, respectively. Figure 9 depicts the experimental results of the water sensitivity of samples.

Clay minerals in the reservoir can balance with any natural reservoir fluid through cation exchange as the cumulative injected fluid increases. External fluid, on the contrary, changes the properties of pore fluid and breaks the balance during drilling, completion, and stimulation. The expandable clay will hydrate, expand, further disperse, fall off, and migrate in the presence of low salinity external fluid (such as distilled water), lowering and even blocking the pore throat, reducing reservoir permeability, and causing reservoir damage. As shown in Figure 9, when simulated formation water was injected as the initial test fluid, the permeability of six samples did not change significantly; when saline water with salinity half the simulated formation water was injected as intermediate test fluid, the permeability of six samples decreased, 8∼15% for Samples 7#–9#, and 4∼6% for Samples 10#–12#; and when distilled water was injected as final test fluid, the permeability of six samples further decreased, 52∼58% for Samples 7#–9#, and 38%∼45% for Samples 10#–12#. After interacting with supercritical CO2 and tight sandstone core samples, corrosion and dissolution of quartz, feldspar, and clay minerals increased sample porosity and permeability, while the dissolution of water sensitivity minerals reduced the effect of salinity on sample permeability. The water sensitivity went from moderately high to moderately weak, and the water sensitivity damage rate went down by 13.3%.

Effect of Supercritical CO2 on Salinity Sensitivity

Reservoir salinity sensitivity is a measure of the reservoir’s ability to tolerate low-salinity fluids, with critical salinity as the mass index. It refers to the phenomenon of reservoir permeability decreases owing to hydration and expansion of clay minerals in saline water with varied salinities. When fluids of varying salinity flow through a clay-containing reservoir, the permeability of core samples changes little at first as the salinity decreases; however, when the salinity reaches a critical value, the permeability decreases dramatically as the salinity continues to decrease, and the salinity at this point is referred to as critical salinity.

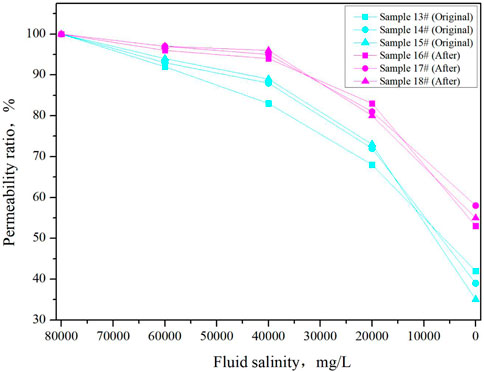

After 24 h of interaction between supercritical CO2 and tight sandstone core samples at 60°C and 15 MPa, saline water with various salinities was prepared and injected into samples in the order of high to low salinity (salinity was reduced by half) to measure the permeability of saline water with various salinities passing through core samples to evaluate the salinity sensitivity of samples before and after supercritical CO2 action at a velocity lower than critical velocity. Figure 10 depicts the experimental results of the salinity sensitivity of samples.

The clay particles became unstable, dropped off, and plugged the pore throat as salinity declined in sequence, resulting in a decrease in reservoir permeability. Figure 10 shows that when simulated formation water was injected as the initial test fluid, the permeability of six samples did not change significantly; when saline water with a salinity of 60,000 mg/L was injected as test fluid, the permeability of six samples decreased, 6∼8% for Samples 13#–15# and 3∼4% for Samples 16#–18#; when saline water with a salinity of 40,000 mg/L was injected as test fluid, the permeability of six samples decreased, 11∼17% for Samples 13#–15# and 4∼6% for Samples 16#–18#; when saline water with a salinity of 20,000 mg/L was injected as test fluid, the permeability of six samples decreased, 27∼32% for Samples 13#–15# and 17∼20% for Samples 16#–18#; and when distilled water was injected as final test fluid, the permeability of six samples further decreased, 58∼65% for Samples 13#–15# and 42∼47% for Samples 16#–18#. Therefore, the critical salinity was 40,000 mg/L for Samples 13#–15# and 20,000 mg/L for Samples 16#–18#. This indicated that after interacting with supercritical CO2 and tight sandstone core samples, the porosity and permeability of the samples increased due to corrosion and dissolution of quartz, feldspar, and clay minerals. The effect of salinity on permeability was reduced by the breakdown of water-sensitive minerals, and low-salinity liquid had a smaller effect on permeability. The critical salinity of the samples was reduced from 40,000 to 20,000 mg/L, and the salinity sensitivity damage rate was reduced by 16.6%.

Effect of Supercritical CO2 on Alkaline Sensitivity

Alkali sensitivity is the phenomenon in which reservoir permeability decreases as a result of precipitation caused by alkaline fluids (pH > 7) reacting with reservoir rock or fluid. Although the reaction between alkaline fluid and formation rock is much weaker than that between acid fluid and formation rock, due to the long contact duration, the effect of alkaline fluid on reservoir permeability is still significant.

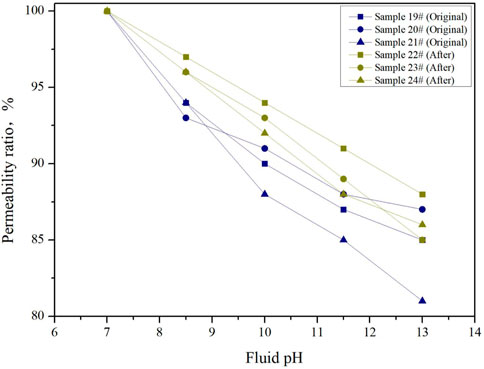

After 24 h of interaction between supercritical CO2 and tight sandstone core samples at 60°C and 15 MPa, saline water with different pH was prepared to evaluate sample permeability and determine alkali sensitivity damage before and after supercritical CO2 action at a velocity lower than critical velocity using core displacement equipment. Figure 11 depicts the experimental results of alkali sensitivity of samples.

With the increase in pH, the formation of minerals and alkaline fluid exchanged ions to form water sensitivity minerals or directly generated precipitation materials to block the pore, so clay particles became unstable, fell off, and plugged the pore throat, resulting in a decrease in reservoir permeability. The permeability damage under five pH values was evaluated in the experiment. As can be seen from Figure 11, at pH = 7, the permeability of six samples did not change significantly; at pH = 8.5, the permeability of six samples decreased, 6∼7% for Samples 19#–21# and 3∼4% for Samples 22#–24#; at pH = 10, the permeability of six samples decreased, 9∼12% for Samples 19#–21# and 6∼8% for Samples 22#–24#; at pH = 11.5, the permeability of six samples decreased, 12∼15% for Samples 19#–21# and 9∼12% for Samples 22#–24#; and at pH = 13, the permeability of six samples decreased, 13∼19% for Samples 19#–21# and 12∼14% for Samples 22#–24#. The permeability of samples slightly decreased as pH increased, but there was no alkali sensitivity damage. Although the mineral composition and microstructure of the samples changed as a result of the interaction between supercritical CO2 and tight sandstone core samples, the sensitivity of the alkaline fluid remained relatively unchanged. The rate of alkali sensitivity damage was lowered by only 2%.

Effect of Supercritical CO2 on Acid Sensitivity

Acid sensitivity is the phenomenon in which reservoir permeability decreases as a result of precipitate or particles produced by acid fluids reacting with acid sensitivity minerals and fluids in the reservoir. Acid sensitivity causes two types of reservoir damage: one causes chemical precipitation, and the other causes the original rock structure to be destroyed, causing or aggravating velocity sensitivity. The most complicated category of reservoir sensitivities is acid sensitivity. The goal of the acid sensitivity evaluation experiment is to investigate whether and how much the acid prepared for the reservoir will damage the formation so that the acid fluid formula may be improved and more effective acid fluid types and treatment methods can be sought.

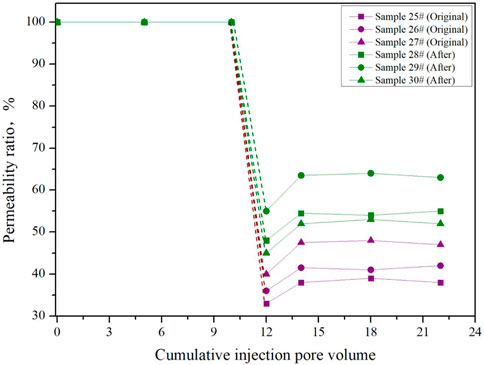

After 24 h of interaction between supercritical CO2 and tight sandstone core samples at 60°C and 15 MPa, the initial permeability was tested with standard saline water, then 15% HCl solution was injected for saturation for 2 h, and finally, the acidified permeability was measured with standard saline water to evaluate the acid sensitivity of samples before and after supercritical CO2 action at a velocity lower than critical velocity using core displacement equipment. Figure 12 depicts the experimental results of acid sensitivity of samples.

Acid sensitivity minerals cause permeability to decrease by forming chemical precipitate or releasing particles when they react with acid fluid in the reservoir. Acid sensitivity minerals for hydrochloric acid are mainly minerals with high iron content, such as chlorite, chlorite- montmorillonite mixed-layer minerals, ankerite, and pyrite, with which hydrochloric acid reacts without producing direct precipitation, but the reaction products react again to produce an insoluble or insoluble secondary precipitation, such as silicate, aluminum silicate, hydroxide, or sulfide. Meanwhile, acid-released particles may plug the pore throat. As can be seen from Figure 12, when 15%HCl was injected, the permeability of six samples decreased significantly, 53∼62% for Samples 25#–27# and 37∼48% for Samples 28#–30#. This revealed that after interacting with supercritical CO2 and tight sandstone core samples, corrosion and dissolution of quartz, feldspar, and clay minerals increased sample porosity and permeability. In contrast, the dissolution of acid-sensitive minerals reduced the influence of acid on sample permeability. Acid sensitivity dropped from fairly strong to moderately weak, and the rate of acid sensitivity damage dropped by 14.4%.

Effect of Supercritical CO2 on Stress Sensitivity

The pore pressure decreases with the output of fluid inside the reservoir during the exploitation of oil and gas reservoirs and the original state of force balance of reservoir rock changes. As a result, the interaction of rock deformation and fluid seepage results in a change in reservoir permeability induced by net stress changes in the rock. The goal of the stress sensitivity evaluation experiment is to determine how much the throat deforms, closes, or opens as the net overlaying pressure changes and how much the rock seepage capability changes.

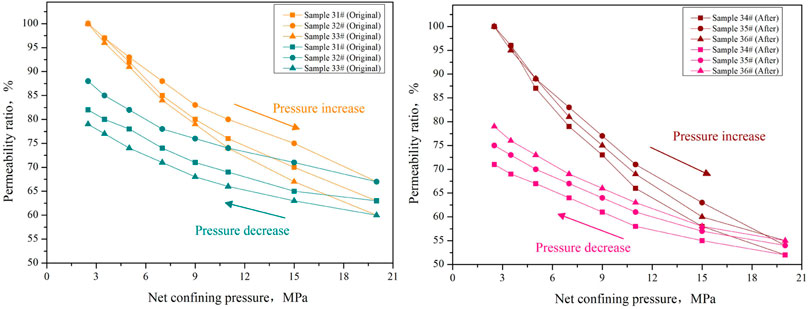

Standard saline water was used after 24 h of interaction between supercritical CO2 and tight sandstone core samples at 60°C and 15 MPa, and the difference between confining pressure and injection pressure was gradually increased from 2.5 to 20 MPa and then decreased to 2.5 MPa to evaluate the stress sensitivity of samples before and after supercritical CO2 action at a velocity lower than critical velocity using core displacement equipment. Figure 13 depicts the experimental results of sample stress sensitivity.

According to rock mechanics theory, a change in stress state will eventually result in rock compression or expansion, that is, elastic or plastic deformation of rock, which will inevitably change the pore structure and pore volume of rock, affecting fluid seepage. As shown in Figure 13, after the increase in net confining pressure from 2.5 to 20 MPa, the permeability of Samples 31#–32# and Samples 33#–36# decreased by 33∼40% and 45∼48%, respectively, with average critical stress of 9 and 6.3 MPa corresponding to a 20% permeability decrease, respectively. After the decrease in net confining pressure from 20 to 2.5 MPa, the permeability of Sample 31#–32# and Sample 33#–36# was recovered to 79%∼82% and 71%∼79% of the initial core permeability, respectively. This showed that after interaction between supercritical CO2 and tight sandstone core samples, corrosion and dissolution of quartz, feldspar, and clay minerals increased the porosity and permeability of samples, and the pore structure and volume of rock changed more under stress conditions. The rate of stress sensitivity damage increased by 8%.

Summary and Conclusion

1) Water-based fracture fluid is difficult to flow back in low-pressure gas reservoirs of Jinqiu gas field, Sichuan Basin, because the tight sandstone reservoir pressure coefficient is 0.45–1.05 and the pressure coefficient of some sand bodies is too low. Supercritical CO2 fracturing has some advantages in reservoirs, particularly for water-sensitive formations, low-pressure reservoirs, and water-stressed areas, making it one of the most environmentally benign fracturing techniques.

2) After interacting with supercritical CO2, Jinqiu Gas field tight sandstone weak dissolution of feldspar and clay minerals occurred, forming a curved dissolution fracture, a tiny quantity of irregular mineral precipitation also formed, plugging the original pore velocity, and sensitivity damage decreased by 5.4%, water sensitivity damage decreased by 13.3%, salinity sensitivity damage decreased by 16.6%, alkaline sensitivity damage decreased by 2%, acid sensitivity damage decreased by 14.4%, and stress sensitivity damage increased by 8%.

3) Quantify the effect of supercritical CO2 on tight sandstone formation sensitivity, and improve the interaction mechanism between supercritical CO2 and low-pressure tight sandstone. This finding provides a quantitative evaluation of the effects of supercritical CO2 on formation sensitivity, and it can be used to build a supercritical CO2 fracturing scheme for low-pressure water-sensitive tight sandstone.

Data Availability Statement

The original contributions presented in the study are included in the article/supplementary material. Further inquiries can be directed to the corresponding author.

Author Contributions

HP is responsible for the overall structure and revision. LZ, JY, and HH help evaluate and improve the paper. JP, XG, and ZW help in setting up the device test, writing, and the experiment.

Funding

This work was funded by the Scientific Research and Technology Development Project of Southwest Oil and Gas Field Company, PetroChina, Project No. 20210302-05.

Conflict of Interest

HP, JY, JP, HH, XG, and ZW were employed by the company Engineering Technology Research Institute of Southwest Oil and Gas Field Company, PetroChina, and Key Laboratory of Oil and Gas Well Stimulation Technology of Southwest Oil and Gas Field Company. LZ was employed by the company Southwest Oil and Gas Field Company, PetroChina

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akrad, O., Miskimins, J., and Manika, P. (2011). “The Effects of Fracturing Fluids on Shale Rock Mechanical Properties and Proppant Embedment,” in Paper Presented at the SPE Annual Technical Conference and Exhibition, Denver, CO, October 2011 (OnePetro). doi:10.2118/146658-MS

Al-Yaseri, A. Z., Lebedev, M., Vogt, S. J., Johns, M. L., Barifcani, A., and Iglauer, S. (2015). Pore-Scale Analysis of Formation Damage in Bentheimer Sandstone with In-Situ NMR and Micro-Computed Tomography Experiments. J. Pet. Sci. Eng. 129, 48–57. doi:10.1016/j.petrol.2015.01.018

Ao, X., Lu, Y., Tang, J., Chen, Y., and Li, H. (2017). Investigation on the Physics Structure and Chemical Properties of the Shale Treated by Supercritical CO2. J. CO2 Util. 20, 274–281. doi:10.1016/j.jcou.2017.05.028

Bahrami, H., Rezaee, R., and Clennell, B. (2012). Water Blocking Damage in Hydraulically Fractured Tight Sand Gas Reservoirs: An Example from Perth Basin, Western Australia. J. Pet. Sci. Eng. 88-89, 100–106. doi:10.1016/j.petrol.2012.04.002

Cabeza, L. F., de Gracia, A., Fernández, A. I., and Farid, M. M. (2017). Supercritical CO2 as Heat Transfer Fluid: A Review. Appl. Therm. Eng. 125, 799–810. doi:10.1016/j.applthermaleng.2017.07.049

Cao, Y., Zhang, J., Zhai, H., Fu, G., Tian, L., and Liu, S. (2017). CO2 Gas Fracturing: A Novel Reservoir Stimulation Technology in Low Permeability Gassy Coal Seams. Fuel 203, 197–207. doi:10.1016/j.fuel.2017.04.053

Chen, K., Liu, X., Nie, B., Zhang, C., Song, D., Wang, L., et al. (2022). Mineral Dissolution and Pore Alteration of Coal Induced by Interactions with Supercritical CO2. Energy 248, 123627. doi:10.1016/j.energy.2022.123627

Day, S., Fry, R., and Sakurovs, R. (2008). Swelling of Australian Coals in Supercritical CO2. Int. J. Coal Geol. 74 (1), 41–52. doi:10.1016/j.coal.2007.09.006

Dong, Z., Tang, S., Ranjith, P. G., and Lang, Y. (2018). A Theoretical Model for Hydraulic Fracturing through a Single Radial Perforation Emanating from a Borehole. Eng. Fract. Mech. 196, 28–42. doi:10.1016/j.engfracmech.2018.04.029

Fang, W., Jiang, H., Li, J., Li, W., Li, J., Zhao, L., et al. (2016). A New Experimental Methodology to Investigate Formation Damage in Clay-Bearing Reservoirs. J. Petroleum Sci. Eng. 143, 226–234. doi:10.1016/j.petrol.2016.02.023

Gathitu, B. B., Chen, W.-Y., and McClure, M. (2009). Effects of Coal Interaction with Supercritical CO2: Physical Structure. Ind. Eng. Chem. Res. 48 (10), 5024–5034. doi:10.1021/ie9000162

Gupta, S. (2011). “Unconventional Fracturing Fluids: What, Where and Why,” in Technical Workshops for the Hydraulic Fracturing Study, Arlington, VA, February 2011 (US EPA).

Hazarika, S., and Boruah, A. (2022). Supercritical CO2 (SCO2) as Alternative to Water for Shale Reservoir Fracturing. Mater. Today Proc. 50, 1754–1757. doi:10.1016/j.matpr.2021.09.187

Jia, Y., Lu, Y., Elsworth, D., Fang, Y., and Tang, J. (2018). Surface Characteristics and Permeability Enhancement of Shale Fractures Due to Water and Supercritical Carbon Dioxide Fracturing. J. Pet. Sci. Eng. 165, 284–297. doi:10.1016/j.petrol.2018.02.018

Jiang, Y., Luo, Y., Lu, Y., Qin, C., and Liu, H. (2016). Effects of Supercritical CO2 Treatment Time, Pressure, and Temperature on Microstructure of Shale. Energy 97, 173–181. doi:10.1016/j.energy.2015.12.124

Jiao, F. (2019). Re-Recognition of "Unconventional" in Unconventional Oil and Gas. Pet. Explor. Dev. 46 (5), 847–855. doi:10.1016/s1876-3804(19)60244-2

Lin, H., Fujii, T., Takisawa, R., Takahashi, T., and Hashida, T. (2008). Experimental Evaluation of Interactions in Supercritical CO2/Water/Rock Minerals System under Geologic CO2 Sequestration Conditions. J. Mater Sci. 43 (7), 2307–2315. doi:10.1007/s10853-007-2029-4

Lin, R., Yu, Z., Zhao, J., Dai, C., Sun, Y., Ren, L., et al. (2022). Experimental Evaluation of Tight Sandstones Reservoir Flow Characteristics under CO2–Brine–Rock Multiphase Interactions: A Case Study in the Chang 6 Layer, Ordos Basin, China. Fuel 309, 122167. doi:10.1016/j.fuel.2021.122167

Liu, H., Wang, F., Zhang, J., Meng, S., and Duan, Y. (2014). Fracturing with Carbon Dioxide: Application Status and Development Trend. Pet. Explor. Dev. 41 (4), 513–519. doi:10.1016/s1876-3804(14)60060-4

Memon, S., Feng, R., Ali, M., Bhatti, M. A., Giwelli, A., Keshavarz, A., et al. (2022). Supercritical CO2-Shale Interaction Induced Natural Fracture Closure: Implications for scCO2 Hydraulic Fracturing in Shales. Fuel 313, 122682. doi:10.1016/j.fuel.2021.122682

Moghadasi, J., Müller-Steinhagen, H., and Jamialahmadi, M. (2004). Model Study on the Kinetics of Oil Field Formation Damage Due to Salt Precipitation from Injection. J. Pet. Sci. Eng. 43 (3-4), 201–217. doi:10.1016/j.petrol.2004.02.014

Mouahid, A., Claeys-Bruno, M., Bombarda, I., Amat, S., Ciavarella, A., Myotte, E., et al. (2022). Supercritical CO2 Extraction of Oil from Moroccan Unroasted Argan Kernels: Effects of Process Parameters to Produce Cosmetic Oil. J. CO2 Util. 59, 101952. doi:10.1016/j.jcou.2022.101952

Nikolai, P., Rabiyat, B., Aslan, A., and Ilmutdin, A. (2019). Supercritical CO2: Properties and Technological Applications-A Review. J. Therm. Sci. 28 (3), 394–430. doi:10.1007/s11630-019-1118-4

Peng, Y., Li, Y., and Zhao, J. (2016). A Novel Approach to Simulate the Stress and Displacement Fields Induced by Hydraulic Fractures under Arbitrarily Distributed Inner Pressure. J. Nat. Gas Sci. Eng. 35, 1079–1087. doi:10.1016/j.jngse.2016.09.054

Peng, Y., Zhao, J., Sepehrnoori, K., Li, Y., and Li, Z. (2020). The Influences of Stress Level, Temperature, and Water Content on the Fitted Fractional Orders of Geomaterials. Mech. Time-Depend Mater 24 (2), 221–232. doi:10.1007/s11043-019-09417-0

Peng, Y., Zhao, J., Sepehrnoori, K., Li, Z., and Xu, F. (2019). Study of Delayed Creep Fracture Initiation and Propagation Based on Semi-analytical Fractional Model. Appl. Math. Model. 72, 700–715. doi:10.1016/j.apm.2019.03.034

Reinicke, A., Rybacki, E., Stanchits, S., Huenges, E., and Dresen, G. (2010). Hydraulic Fracturing Stimulation Techniques and Formation Damage Mechanisms-Implications from Laboratory Testing of Tight Sandstone-Proppant Systems. Geochemistry 70, 107–117. doi:10.1016/j.chemer.2010.05.016

Umar, M., Farid, S., and Naeem, M. A. (2022). Time-Frequency Connectedness Among Clean-Energy Stocks and Fossil Fuel Markets: Comparison between Financial, Oil and Pandemic Crisis. Energy 240, 122702. doi:10.1016/j.energy.2021.122702

Wang, J., Elsworth, D., Wu, Y., Liu, J., Zhu, W., and Liu, Y. (2018). The Influence of Fracturing Fluids on Fracturing Processes: A Comparison between Water, Oil and SC-CO2. Rock Mech. Rock Eng. 51 (1), 299–313. doi:10.1007/s00603-017-1326-8

Wilson, M. J., Wilson, L., and Patey, I. (2014). The Influence of Individual Clay Minerals on Formation Damage of Reservoir Sandstones: A Critical Review with Some New Insights. Clay Min. 49 (2), 147–164. doi:10.1180/claymin.2014.049.2.02

Xu, C., Kang, Y., You, Z., and Chen, M. (2016). Review on Formation Damage Mechanisms and Processes in Shale Gas Reservoir: Known and to Be Known. J. Nat. Gas Sci. Eng. 36, 1208–1219. doi:10.1016/j.jngse.2016.03.096

Zhang, B. J., Pan, K., and Wu, C. J. (2022). Compound Gas Accumulation Mechanism and Model of Jurassic Shaximiao Formation Multistage Sandstone Formations in Jinqiu Gas Field of the Sichuan Basin. Nat. Gas. Ind. 42 (1), 51–61. doi:10.3787/j.issn.10000976.2022.01.005

Zhang, L., Zhou, F., Zhang, S., Wang, Y., Wang, J., and Wang, J. (2019). Investigation of Water-Sensitivity Damage for Tight Low-Permeability Sandstone Reservoirs. ACS Omega 4 (6), 11197–11204. doi:10.1021/acsomega.9b01286

Zhao, J., Peng, Y., Li, Y., and Tian, Z. (2017). Applicable Conditions and Analytical Corrections of Plane Strain Assumption in the Simulation of Hydraulic Fracturing. Pet. Explor. Dev. 44 (3), 454–461. doi:10.1016/s1876-3804(17)30052-6

Zheng, Y., Han, X., Zeng, J., Zhou, C., Zhou, L., and Chen, W. (2021). Practice of High-Intensity Volume Fracturing in the Shaximiao Formation Tight Sandstone Gas Reservoirs of the Qiulin Block, Central Sichuan Basin. Nat. Gas. Ind. B 8 (4), 367–375. doi:10.1016/j.ngib.2021.07.007

Zhou, D., Zhang, G., Prasad, M., and Wang, P. (2019). The Effects of Temperature on Supercritical CO2 Induced Fracture: An Experimental Study. Fuel 247, 126–134. doi:10.1016/j.fuel.2019.02.099

Zhou, J., Xie, S., Jiang, Y., Xian, X., Liu, Q., Lu, Z., et al. (2018). Influence of Supercritical CO2 Exposure on CH4 and CO2 Adsorption Behaviors of Shale: Implications for CO2 Sequestration. Energy Fuels 32 (5), 6073–6089. doi:10.1021/acs.energyfuels.8b00551

Keywords: supercritical CO2, tight sandstone, formation sensitivity, fracturing technology, experimental evaluation

Citation: Peng H, Zhou L, Yang J, Peng J, Han H, Gou X and Wang Z (2022) Influence of Supercritical CO2 on the Formation Sensitivity of Tight Sandstone. Front. Energy Res. 10:922941. doi: 10.3389/fenrg.2022.922941

Received: 18 April 2022; Accepted: 02 May 2022;

Published: 08 June 2022.

Edited by:

Yibo Li, Southwest Petroleum University, ChinaReviewed by:

Zhezhi Liu, Chongqing University of Science and Technology, ChinaXingguang Xu, China University of Geosciences Wuhan, China

Copyright © 2022 Peng, Zhou, Yang, Peng, Han, Gou and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Huan Peng, MjgyNjAwMTIwQHFxLmNvbQ==, b3JjaWQub3JnLzAwMDAtMDAwMi01MzA3LTAzMDc=

Huan Peng

Huan Peng Lang Zhou3

Lang Zhou3