- 1Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University (Ministry of Education and Hubei Province), Wuhan, China

- 2Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas, Yangtze University, Wuhan, China

- 3School of Petroleum Engineering, Yangtze University, Wuhan, China

- 4CNPC Engineering Technology R&D Company Limited, Beijing, China

- 5Chuanxi Drilling Company CNPC Chuanqing Drilling Engineering Co. Ltd, Chengdu, China

Introduction

“Green earth” is the eternal home of human beings, where they survive and thrive indefinitely. Since the beginning of the industrial revolution, the global ecosystem has been destroyed year after year. Greenhouse gas emission contributes to global warming, and the culprit for the greenhouse effect is CO2. CO2 emissions in the atmosphere have grown roughly by 25%–30% as a result of the increasing frequency of human activities (Kazemifar, 2022). In recent years, the melting of glaciers in the Arctic and Antarctic has produced a major rise in sea levels, as well as global climate anomalies, and natural disasters occur more frequently. Perhaps, the series of events are a warning to mankind that the crisis may have crept in.

As a major energy consumer, China’s CO2 emissions are not optimistic (Liu et al., 2022). More than 120 nations across the world have committed to carbon neutrality to actively tackle climate change and the greenhouse effect. In the ninth meeting of the Central Financial and Economic Commission on 15 March 2021, Xi Jinping clearly stated that “carbon peaking” and “carbon neutrality” should be incorporated into the overall layout of ecological civilization construction, and the double carbon work is related to China’s sustainable development and the building of the community with a shared future for mankind. China will strive to meet the targets of “carbon peak” (the peak CO2 emissions) by 2030 and achieve “carbon neutrality” by 2060. The “double carbon” target has attracted strong interest across society, teaching institutions, and scientific research groups among countries. Carbon dioxide capture and storage (CCS) and carbon dioxide capture, utilization and storage (CCUS), as the emerging technologies for carbon emission reduction and greenhouse effect mitigation, are gaining traction in various industries. For the oil and gas industry, CCS and CCUS technologies will enable the industry to progress toward a green future.

Background of CCS and CCUS

Prior to the 1980s, CCS technology was still in its infancy, and it saw a period of fluctuating growth from the 1980s to the 1990s (Wang et al., 2013). Since the 21st century, CCS technology has been developed, with significant growth in the number of related projects, researchers, and patents. The development of CCUS technology can be roughly divided into three stages: birth, development, and potential commercial application. In the mid-20th century, the United States Atlantic Refining Company found that CO2, a byproduct of its hydrogen production process, can improve the fluidity of crude oil. The world’s first patent for CO2 flooding was secured by Whorton (Qin et al., 2020; Cao et al., 2022; Qi et al., 2022). Following that, CCUS technology has gained widespread attention worldwide, with various scholars conducting extensive research. Until June 2021, there were 49 CCUS technology demonstration projects in China, with a capture capacity of 296 × 104 t/a and an injection capacity of 121 × 104 t/a (Global CCS Institute, 2021).

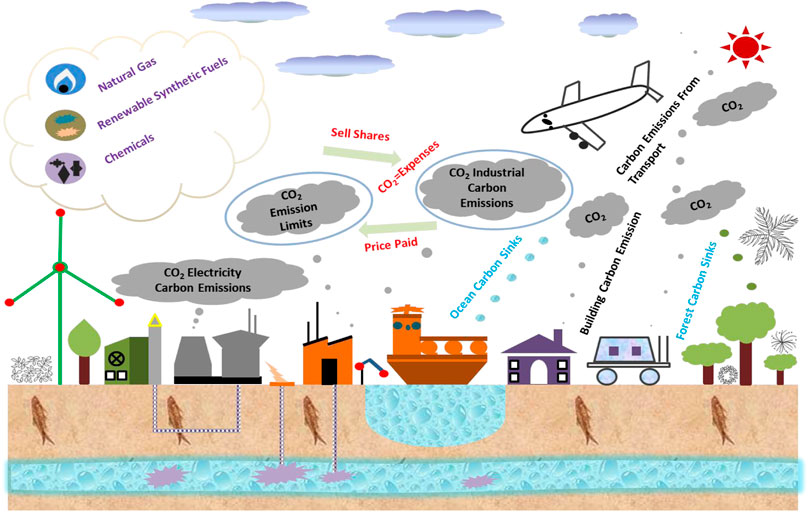

CCUS technology is a new development trend of CCS technology. CCUS, in comparison to CCS, can recycle CO2 resources for more effective carbon emission reduction (Zou et al., 2021a; Zou et al., 2021b). In the early stage, China focused on CCS, but guided by the general trend, practical demands, and double carbon target, China has gradually progressed to the CCUS stage. The CCS and the CCUS carbon industry system, which play an important role in carbon emission reduction and is the revolutionary technology for reaching carbon neutrality, encompassed carbon capture, carbon storage, carbon utilization, carbon finance, and others. Figure 1 depicts the carbon industrial system with CCS and CCUS.

Technology Development Status of CCS and CCUS

At present, China’s fossil energy structure remains “rich in coal and poor in oil and gas.” The coal-based energy structure will put great pressure on China’s carbon emission reduction. Therefore, CCS and CCUS initiatives must be implemented as soon as possible (Agency, 2009). In recent years, CCS and CCUS technologies have advanced quickly globally, and the related facilities are being built and operated at an increasing rate. The size of the facilities, the amount of CO2 captured, utilized, and stored, and the industrial chain’s expansion have all shown an upward trend (Lu, 2020).

Although China’s CCS and CCUS technologies advanced significantly in recent years, some related projects in China are still in the experimental stage. For example, in oxygen-enriched combustion capture, Tsinghua University built a 25 kw oxygen-enriched combustion platform. Huaneng Group has developed 12 × 104 t/a and 3,000 × 104 t/a capture devices in Shidongkou, Shanghai, and Beijing thermal power plants, respectively, recovering CO2 with a purity of more than 99% (Chen et al., 2018). Precombustion capture, on the other hand, uses IGCC technology (Wall, 2007).

Pipeline transportation, as an intermediate of CCUS, is likewise a major issue that needs to be solved to achieve large-scale storage and utilization. Compared with high-pressure natural gas pipeline transportation, CO2 pipeline transportation has few cases. China is a latecomer to CO2 pipeline transportation; the Daqing Oil Field has built a 6.5 km gas-phase CO2 transmission pipeline, and the Shengli Oil Field has built a 20 km one. Filling transportation is another transportation technique, but it is less common because of immaturity in technology, lack of experience, and a greater transportation requirement.

Simultaneously, safe storage of CO2 is critical to the success of CCS and CCUS projects. Currently, technically feasible solutions include geological storage, CO2-EOR, CO2-ECBM, and marine storage.

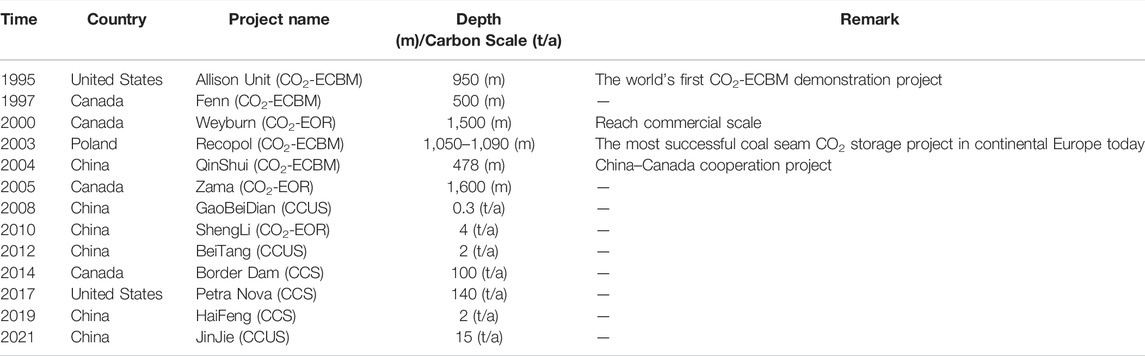

The “U" in CCUS stands for carbon utilization. The use of captured CO2 for oil flooding is a resource reuse technique as well as a means of reducing CO2 emission. CO2-EOR is one of the most important parts of CCUS and a key technology for CO2 oil flooding, which has been vigorously promoted in recent years. Some CCS and CCUS projects are shown in Table 1.

Application of CCS and CCUS in Oil and Gas Field

Although oil and gas production has incompatibility with green and low-carbon development, synergy can be accomplished via technical advancement and scientific innovation. With the rapid development and large-scale application of carbon emission reduction technologies such as CCS and CCUS, the oil and gas industry will certainly be able to move toward a green future of low-carbon, efficient, and sustainable development while ensuring the safe supply of oil and gas.

In the oil and gas industry, CCUS provides more advantages than CCS. In applications, CCUS is a well-established system technology, with three parts: CO2 capture, utilization, and storage.

CO2 capture technology refers to the separation and collection of CO2 from industrial production or the separation of oxygen from the air for oxygen-enriched combustion to achieve the purpose of CO2 concentration, thereby reducing the difficulty in and energy consumption of capture. The CCUS fully integrated demonstration project of the Sinopec Shengli Oil Field branch, which can capture and store more than one million tons of CO2 per year, is planned to start up in 2022 (Hu et al., 2022). At present, there are mainly three methods of CO2 capture: oxygen-enriched combustion capture, postcombustion capture, and precombustion capture. Oxygen-enriched combustion capture burns the fuel with a high concentration of oxygen rather than air, followed by flue gas circulation, to create flue gas mostly made up of water and CO2, which is then processed with a flue gas cooling system to achieve a high concentration of CO2. Postcombustion capture is a more mature and widely used capture method. Precombustion capture is coupled with the integrated gasification combined cycle (IGCC) process.

As early as October 1996, the CO2 storage project in the Beihai Oil Field reached 100 × 104 t per year, with a planned total CO2 storage capacity of 2,000×104 for the whole project lifetime. At present, there are four feasible methods for CO2 storage. Geological storage refers to the permanent storage of CO2 injected directly into appropriate underground formations, and the formations suitable for CO2 injection include deep saline aquifers, depleted oil and gas fields, and basaltic aquifers.

In oil and gas production sites, CO2 utilization is the injection of collected CO2 into deep underground formations to improve the extraction of oil, natural gas, water, or other resources (Li et al., 2014; Nocito and Dibenedetto, 2019). CO2 utilization, particularly improved oil recovery, is still in industrial demonstration stages in China, with a significant gap compared with the world’s advanced level, whereas developed countries in Europe and America have established successful commercial systems.

In addition, the application of CCS and CCUS in the oil and gas industry also include supercritical CO2 fracturing and CO2 flooding. When compared to traditional hydraulic fracturing, supercritical CO2 fracturing has advantages such as reducing formation damage, utilizing CO2 to increase the complexity of the fracture network, and replacing adsorbed combustible gases, with the potential to increase oil and gas production, reduce water demand, and alleviate the environmental impact. CO2 flooding technology is an oil recovery method that replenishes formation energy in low-permeability reservoirs, boosting their development efficiency. It has been widely used in oil and gas operations, and it can also make a significant contribution to carbon emission reduction.

Prospects and Challenges of CCS and CCUS

In the context of the national energy strategy, the significance of the double-carbon target is self-evident. The CCS and CCUS industries, spawned by “carbon neutrality” and “carbon peaking,” have reached a stage of rapid development. Globally, CCS and CCUS industries are rapidly developing and progressing. China’s energy reserves are characterized as “rich in coal and poor in oil and gas,” and fossil energy will continue to dominate China’s energy consumption in the short term. Therefore, CCS and CCUS are essential for China’s energy development to be healthy, safe, and environmentally friendly. CCS and CCUS technologies will usher in a green era for the oil and gas industry.

However, the large-scale application of CCS and CCUS industries in China’s oil and gas industry still encounters several challenges and obstacles:

1) The economic cost of CCS and CCUS is extremely high. According to statistics, the service expenditure of CCS and CCUS will increase over the next 10 years. The purpose of CCS and CCUS, on the other hand, is to reduce carbon emission while obtaining environmental and social benefits, but failing to benefit economically after significant investment may demotivate the enterprises and institutions.

2) Some CCS and CCUS projects have been implemented in China, although the majority are small-sized and remain in the experimental stage rather than being systemic, and the relevant technology and experience are not yet well developed.

3) CCS and CCUS have some safety and environmental risks, such as CO2 leakage and the explosion of high-pressure high-concentration supercritical CO2 during the capture, utilization, and storage process, which constitute a severe threat to the environment and safety.

Author Contributions

All the authors conceived and designed the study. QD and XL contributed toward writing the original draft and reviewing and editing.

Funding

This research was supported by the Open Foundation of Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University (Ministry of Education and Hubei Province), No. UOG 2022-03, and by the Open Fund of Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas (Yangtze University), No. YQZC202206.

Conflict of Interest

Author KZ is employed by CNPC Engineering Technology Research Institute Co. Ltd., and author LT is employed by Chuanxi Drilling Company, CNPC Chuanqing Drilling Engineering Co. Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Agency, I. E. (2009). Technology Roadmap: Carbon Capture and Storage[J]. Technol. Roadmap Carbon Capture Storage 325 (5948), 1647.

Cao, L., Lei, S., Guan, Y., Wang, Y., Zhang, Y., Tian, J., et al. (2022). CCUS Industry under Target of Carbon-Peak and Carbon-Neutrality: Progress and Challenges. Front. Energy Res. 10, 860665. doi:10.3389/fenrg.2022.860665

Chen, B., Xiao, H., Li, J., and Wang, X. (2018). Research Progress on Carbon Dioxide Capture, Utilization and Storage[J]. Appl. Chem. Ind. 47 (03), 589–592.

Hu, Q., Li, Y., Zhang, J., Yu, X., Wang, H., Wang, W., et al. (2022). Status Quo and Development Suggestions of CCUS Technology in China under the "double Carbon" strategy[J/OL]. Oil gas storage Transp.

Kazemifar, F. (2022). A Review of Technologies for Carbon Capture, Sequestration, and Utilization: Cost, Capacity, and Technology readiness[J]. Greenhouse Gases: Science and Technology.

Li, Z., Ma, J., and Zhang, X. (2014). Implementation Method and Application Prospect of CO2-EOR Technology[J]. Oil Gas Field Surf. Eng. 33 (03), 11–12.

Liu, Z., Deng, Z., He, G., Wang, H., Zhang, X., Lin, J., et al. (2022). Challenges and Opportunities for Carbon Neutrality in China. Nat. Rev. Earth Environ. 3, 141–155. doi:10.1038/s43017-021-00244-x

Lu, X. (2020). Greening the Road of Petroleum—Interview with Li Yang, Academician of Chinese Academy of Engineering[J]. Petro China (06), 12–15.

Nocito, F., and Dibenedetto, A. (2019). Atmospheric CO2 Mitigation Technologies: Carbon Capture Utilization and Storage (CCUS)[J]. Curr. Opin. Green Sustain. Chem. 21.

Qi, L., Liu, G., Li, X., and Chen, Z. (2022). Intergenerational Evolution and Presupposition of CO_2 Capture Utilization and Storage Technology from a Multidimensional Perspective[J]. Eng. Sci. Technol. 54 (01), 157–166.

Qin, J., Li, Y., Wu, D., Weng, H., and Wang, G. (2020). CCUS Global Progress and China's Countermeasures[J]. Oil Gas Geol. Recovery 27 (01), 20–28.

Wall, T. F. (2007). Combustion Processes for Carbon Capture. Proc. Combust. Inst. 31 (1), 31–47. doi:10.1016/j.proci.2006.08.123

Wang, J., Wu, Y., and Yu, H. (2013). Research Progress on Carbon Dioxide Storage Technology[J]. Chin. J. Undergr. Space Eng. 9 (01), 81–90.

Zou, C., He, D., Jia, C., Xiong, B., Zhao, Q., and Pan, S. (2021). The Connotation and Path of World Energy Transition and its Significance to Carbon Neutrality[J]. J. Petroleum 42 (02), 233–247.

Keywords: CO2 capture, CO2 utilization, CO2 storage, oil and gas, green future

Citation: Deng Q, Ling X, Zhang K, Tan L, Qi G and Zhang J (2022) CCS and CCUS Technologies: Giving the Oil and Gas Industry a Green Future. Front. Energy Res. 10:919330. doi: 10.3389/fenrg.2022.919330

Received: 13 April 2022; Accepted: 02 May 2022;

Published: 17 June 2022.

Edited by:

Qi Zhang, China University of Geosciences Wuhan, ChinaReviewed by:

Hao Yan, China University of Mining and Technology, ChinaDong Xiong, College of Petroleum Engineering, China University of Petroleum, China

Copyright © 2022 Deng, Ling, Zhang, Tan, Qi and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xingjie Ling, bGluZ3hpbmdqaWUyMDAwQDE2My5jb20=

Qiao Deng

Qiao Deng Xingjie Ling

Xingjie Ling Kui Zhang4

Kui Zhang4