94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res., 04 July 2022

Sec. Advanced Clean Fuel Technologies

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.917740

This article is part of the Research TopicThe Challenge and Opportunity of CCUS in the Development of Unconventional ResourceView all 15 articles

The lower Permian Qixia formation gas reservoir is characterized by ultra-deep buried, high temperature and high pressure (HTHP), low porosity and permeability, ultra-high closure pressure, and thin thickness in the western Sichuan Basin, China. Acid fracturing has been adopted as the main well stimulation technology. The average test production of the acid-fractured vertical well was 46 × 104 m3/d. The horizontal well with staged acid fracturing is considered a reliable measure to enhance gas production. However, the staged acid fracturing on the ultra-deep horizontal well has been challenged. The reaction rates of conventional, self-diverting, and gelled acid and the acid-etched fracture conductivity experiments under HTHP are measured to optimize the acid fracturing technique. The reaction rate of gelled acid with Qixia Fm limy dolomite at 150°C is 3.4–6.7 times faster than that with dolomite and similar to that with limestone. The gelled acid with better retardation and friction reduction performance is selected as the main acid to increase the effective acid-etched fracture length. The acid-etched fracture conductivity can be greatly enhanced by using gelled acid, increasing acid volume, and closed fracture acidizing (CFA) under a closure stress of 50 MPa. Moreover, the feasibility of staged acid fracturing for ultra-deep horizontal wells is discussed. The first stage is assembled by fracturing sleeve, spared ball drop sleeve, and circulating valve to ensure activation of the fracturing channel. The tested production is significantly enhanced with temporary plugging and open-hole packer and sliding sleeve staged acid fracturing.

Acid fracturing is widely used in carbonate (Jeon et al., 2016; Kalfayan, 2007; Asadollahpour et al., 2018), especially for low porosity and low permeability reservoirs. The effective acid-etched fracture length and conductivity are two key factors for the stimulation effect. Through several decades of development, a series of acid system, acid fracturing technique, and staged acid fracturing technique has been developed (Teklu et al., 2019; Zhu et al., 2019). The main acids are conventional acid (CA), gelled acid (GA), in situ gelled acid, self-diverting acid (SDA), surface and in situ cross-linked acid, solid acid, and organic acid (Taylor and Nasr-El-Din, 2002; Bybee 2006; Nasr-El-Din et al., 2007; Ding et al., 2010; Gomaa and Nasr-El-Din, 2010; Liu et al., 2013). The acid frac techniques are acid frac with the aforementioned single and combined acid system, such as pad-acid-fracturing (PAF), multistage alternating injection acid frac, propped acid frac, and closed fracture acidizing (CFA) (Liu and Zhao, 1998; Nelson et al., 1998; Yi et al., 2010; Pournik et al., 2011). However, acid frac of ultra-deep high temperature and high pressure (HTHP) fractured-vuggy carbonate reservoirs is challenged by rapid acid rock reaction rate caused by limited acid-etched fracture length, high closure stress caused by limited acid-etched fracture conductivity, and natural developed fissure caused uncontrolled acid leak off and limited dynamic hydraulic fracture (Xue et al., 2019; Luo et al., 2020; Peng et al., 2019a; Li et al., 2019). The average test production of the acid fractured vertical well in the Qixia Fm gas reservoir was 46 × 104 m3/d. The horizontal well with staged acid fracturing has been considered as a reliable measure to enhance gas production (Ugursal et al., 2019).

Horizontal wells have been widely used worldwide to provide a larger contact area with the reservoir to enhance well productivity. However, horizontal well cannot meet the anticipant productivity for low permeability or serious skin damage (Li et al., 2019; Yuan et al., 2019). Several artificial fractures along the horizontal segment created by staged acid fracturing are essential to enhance productivity and recovery. Through decades of development, a series of staged fracturing techniques for horizontal wells have been formed to adapt to different completion conditions. The main techniques are sealing ball staged fracturing, hydraulic jet fracturing, open-hole packer fracturing, and plug-perf fracturing (Wang et al., 2011; Li et al., 2012).

The geological conditions are complicated in the western Sichuan Basin. The well structure of an ultra-deep well is complicated for multi-pressure systems in the longitudinal direction. The lower Permian Qixia Fm gas reservoir is deep buried with true vertical depth (TVD) from 7,200 m to 7,500 m, and the measured depth (MD) of the horizontal well is deeper than 8,000 m. Moreover, the formation fluids contain sour gases such as H2S and CO2, which limited the application of plug-perf staged fracturing technology. The hydraulic jet staged acid fracturing technique is appropriate for well with a maximum depth of 6,400 m for high choke pressure (Li et al., 2012). Although the temporary plugging staged acid fracturing is widely used (Zhao et al., 2020), the validity of temporary plugging is uncertain, which may affect the stimulation effect. The packer and sliding sleeve staged acid fracturing would be a candidate but challenged on ultra-deep horizontal well.

The acid rock reaction rate and acid-etched fracture conductivity were investigated to optimize the main acid type and acid frac technique. Furthermore, two ultra-deep horizontal wells with temporary plugging, open hole packer, and sliding sleeve staged acid frac are discussed. It is referential for staged acid fracturing of ultra-deep horizontal wells.

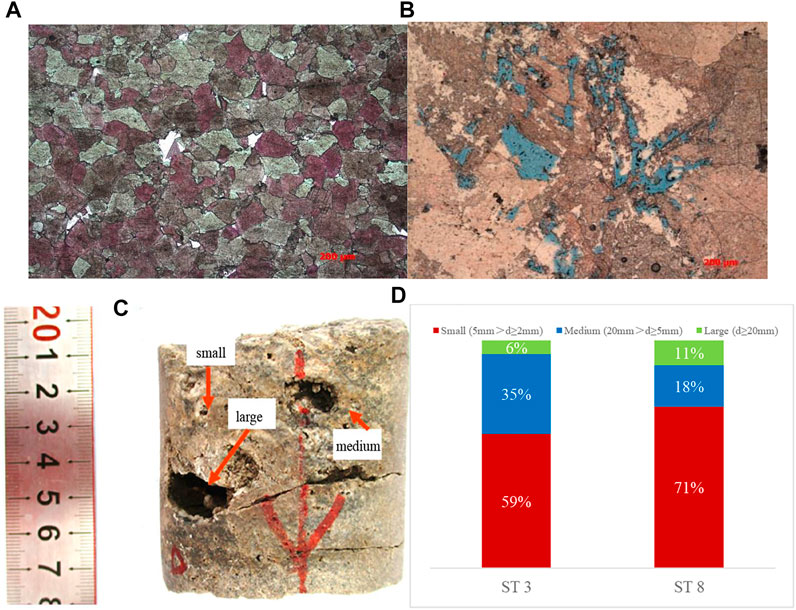

The Lower Permian Qixia limy dolomite formation is buried more than 7,200 m in the western Sichuan Basin. The reservoir spaces are mainly composed of intergranular pores, intergranular dissolved pores, and medium-to-small karst caves (Figure 1).

FIGURE 1. Reservoir spaces of Qixia Fm limy dolomite. (A) ST8 downhole core, intergranular pores; (B) ST 3 downhole core, intergranular dissolved pores; (C) ST3 downhole core, medium-to-small karst caves; and (D) percentage of karst caves with different diameters.

The gas reservoir is characterized of low porosity (ϕavg = 3.11%) and a low-to-medium-permeability (kavg < 1mD). It shows a good correlation between porosity and permeability, while the natural fissure-developed cores show significantly higher permeability (Figure 2). The well-developed natural fissures improve permeability.

The Qixia Fm is a typical HTHP sour gas reservoir with a formation temperature of 154–165°C, formation pressure coefficient of 0.013 MPa/m, an average hydrogen sulfide content of 5.77 g/m3, and average carbon dioxide content of 1.87 g/m3.

Acid fracturing has been adopted as the main well stimulation technology. The average test production of the acid fractured vertical well is 46 × 104 m3/d. The horizontal well with staged acid fracturing has been considered as a reliable measure to enhance gas production. However, the staged acid fracturing on ultra-deep horizontal well is challenged.

The rotating disk instrument is widely used for gaining acid rock reaction kinetic parameters, such as acid consumption rate, reaction rate constants, reaction order, and activation energy (Anderson 1991; Fredd, 1998a; Alkattan et al., 1998; Fredd and Fogler, 1998b; Gdanski and Van Domelen, 1999; Frenier and Hill, 2002; Li et al., 2015). Downhole cores were cut into disks, and the acid solutions of 10wt% and 15wt% were allocated by 20 wt% fresh acid and CaMg(CO3)2 powder to consider the effect of Ca2+ and Mg2+, for acid rock reaction kinetics experiments. A summary of all data obtained from the rotating-disk study is listed in Table 1.

The kinetic equations of the acid rock reaction are constructed as follows:

where J is the acid rock reaction rate, mol/(cm2·s); R is the universal gas constant, J/(mol·K); T is the temperature, K; C is the acid concentration, mol/L; the subscripts CA, GA, and SDA refer to conventional acid, gelled acid, and self-diverting acid, respectively.

The temperature has a significant influence on the reaction rate of Qixia Fm. The reaction rates were sharply increased with a temperature above 110°C. The GA and SDA showed similar retardation performance (Figure 3).

The reaction rates of 20wt% GA with Permian Qixia limy dolomite, Cambrian Longwangmiao Fm, Sinian Dengying Fm, Devonian Guanwushan Fm dolomite, and Permian Maokou Fm limestone in Sichuan Basin, were compared (Figure 4). It can be concluded that the reaction rate of Qixia limy dolomite at higher temperatures (150°C) is 3.4–6.7 times faster than that of typical dolomite, and similar to that of limestone, in Sichuan Basin. It is consistent with the previous study (Taylor et al., 2006; Rabie et al., 2014).

The friction reduction performance was compared as shown in Figure 5. The gelled acid is selected as the main acid for better retardation and friction reduction performance.

The standard and modified API fracture conductivity device is widely used for acid-etched fracture conductivity evaluation (Chen et al., 2005; Han et al., 2016; Jin et al., 2019; Li et al., 2003; Luo et al., 2008; Luo et al., 2018; Luo et al., 2019; Malagon et al., 2008; Peng et al., 2015; Xue et al., 2018; Yao et al., 2015; Zhao et al., 2017; Peng et al., 2019b; Peng et al., 2020). The influences of closure stress, temperature, injection rate, contact time, acid type, and stimulation technique on fracture conductivity were investigated.

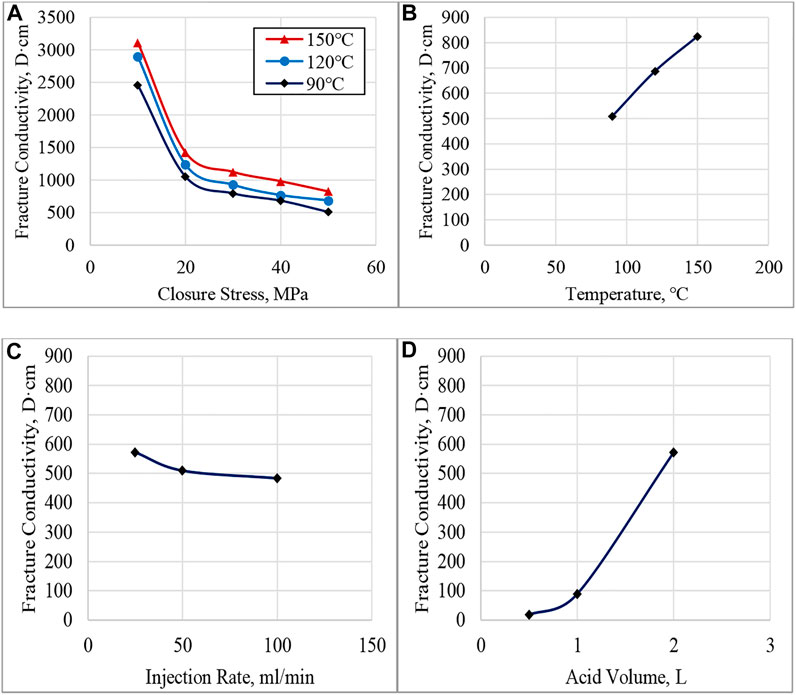

The acid-etched fracture conductivity sharply decreased with increasing closure stress from 10 to 20 MPa and slowly decreased with increasing closure stress from 20 to 50 MPa as shown in Figure 6A. The grooving etched pattern and higher fracture conductivity would be created by acid fracturing for differential acid rock reaction rate between calcite and dolomite. Then, the supporting points collapsed, the supporting area increased, and the fracture conductivity decreased sharply to slowly with increasing closure stress. The conductivity increased by 62% (from 509 D·cm to 825 D·cm) with increasing temperature from 90 to 150°C for a significantly increased reaction rate (Figure 6B). Although the effective diffusion coefficient of H+ and the reaction rate increased with increasing injection rate, the conductivity decreased by 18% (from 572 D·cm to 484 D·cm) because the increment of reaction rate is lesser than that of acid flow velocity and the acid flow too fast to react with rock (Figure 6C). The conductivity significantly increased by 25 times (from 18 D·cm to 572 D·cm) with increasing acid volume from 0.5 to 2.0 L (Figure 6D). The acid-etched fracture conductivity can be greatly enhanced by increasing acid volume.

FIGURE 6. Acid-etched fracture conductivity of Qixia Fm, Sichuan Basin. (A) Effect of closure stress; (B) effect of temperature; (C) effect of the acid injection rate; and (D) effect of acid volume.

The effect of the main acid type on conductivity was compared as shown in Figure 7. The conductivity of GA is obviously higher than that of SDA. The PAF technique will reduce the conductivity by 23.5%, and the CFA technique will enhance the conductivity by 24.6%. CFA after main acid fracturing is essential to enhance the acid-etched fracture conductivity.

The long-term acid-etched fracture conductivity experiments were conducted to evaluate the stimulation valid period. These experiments were conducted at a temperature of 90°C, pad (0.4 L) and main acid (1.0 L) injection rate of 50 ml/min, closure stress of 50 MPa, and closed acid (0.1 L) injection rate of 10 ml/min.

The retention rate of long-term acid-etched fracture conductivity ranges from 70 to 82%, with an average of 75%. Under the same acid fracturing technique and injection parameters, the initial and long-term conductivity of GA is significantly higher than that of SDA. The initial and long-term conductivity of SDA is 44.5%–47.5% of that of GA (Figure 8).

The main difficulties and countermeasures of acid fracturing are listed in Table 2.

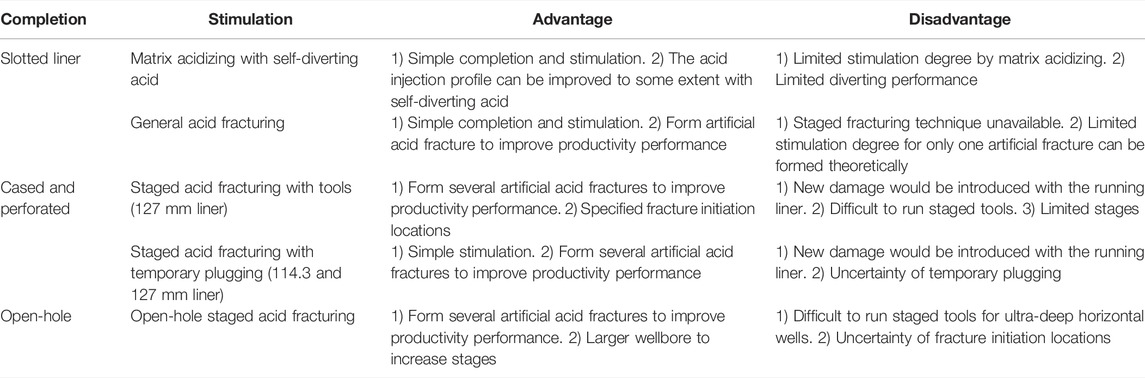

The hydraulic jet staged acid fracturing technique is unaccommodated for limited application depth, and the plug-perf staged fracturing is infeasible for casing tieback to the wellhead and unavailable coiled tube to handle the bridge plug. Therefore, the open-hole packer and sliding sleeve and temporary plugging would be the only viable staged fracturing technique. The advantages and disadvantages of different completions and related stimulation techniques are compared (Table 3). Although matrix acidizing with self-diverting acid and general acid fracturing would be the feasible technique for slotted liner completion, the stimulation effect would be limited to an inherent stimulation mechanism and unavailable staged fracturing technique. Although the staged acid fracturing with tools is feasible for liner cased and perforated completion with a liner diameter of 127 mm, the stimulation effect would be influenced by new damage introduced during liner cementing and limited stages. The temporary plugging technique would be a candidate for liner cased and perforated completion as well, but the fracturing effect would be influenced by the uncertainty of temporary plugging. The open hole staged acid fracturing would be the optimal selection to create enough artificial acid fractures along a horizontal interval of 383 m, and to enhance well productivity as much as possible.

TABLE 3. Comparison of main advantages and disadvantages of different completions and related stimulation techniques.

Well X is a perforated ultra-deep horizontal well with MD of 7,859 m, TVD of 7,271.83 m, and a continuous perforated interval of 88 m. There are two gas formations with reservoir thickness (MD) of 80.6 m, average porosity of 5.7%, average permeability of 1.6 mD, and water saturation of 7.8% from logging interpretation.

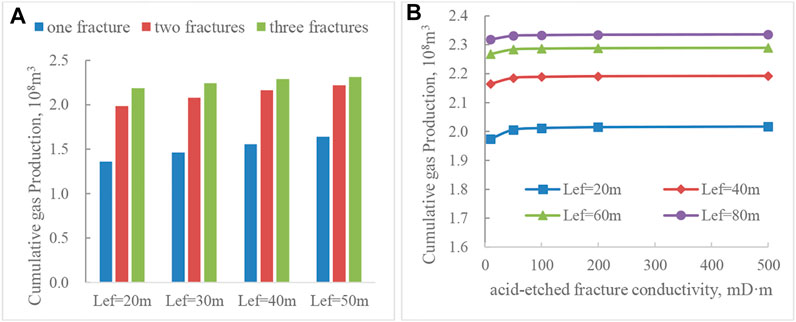

The challenge of proper acid placement is compounded in well X, for strong heterogeneous (permeability ranges from 0.1 to 19 mD and max-min ratio of 190), and small size of cemented and perforated tail pipe (inner diameter of 92.46 mm). The sealing ball temporary plugging staged fracturing is recommended to create several artificial acid-etched fractures along horizontal intervals. The productivity performance of the staged acid frac horizontal well was simulated to optimize the effects of acid-etched fracture numbers, length, and conductivity (Figure 9).

FIGURE 9. Staged acid fracturing productivity performance simulation. (A) Cumulative gas production versus fractures; (B) cumulative gas production versus fracture length and conductivity.

It is recommended that two stages with acid-etched fracture length above 50 m and conductivity above 20 D cm are preferably optimized.

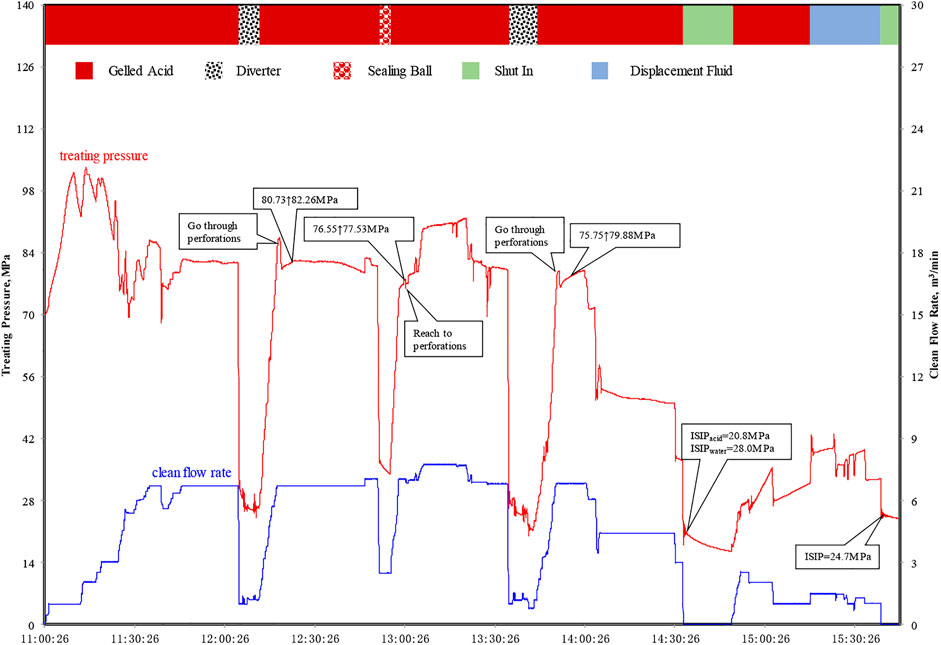

The completion fluid in the wellbore was drained out, and the tested gas production is 28.58 × 104 m3/d with a wellhead pressure of 59.08 MPa before acid frac. The temporary plugging staged acid fracturing operation curve is shown in Figure 10. The treating pressure drops significantly from 94.46 to 76.58 MPa at the injection rate of 5.35 m3/min, which indicates that the near wellbore damage is removed. The treating pressure increases from 76.55 to 77.53 MPa when the sealing balls reach the perforations. It can be concluded that the temporary plugging staged acid frac is successfully implemented. The treating pressure increases from 80.73 to 82.26 MPa at an injection rate of 6.72 m3/min, and 75.75–79.88 MPa at an injection rate of 6.83 m3/min, after the diverters go through the perforations. It can be deduced that the degradable solid diverters decreased the acid leakage and increased the net fracture pressure to propagate the fracture. The instantaneous shut-in pressure (ISIP) difference before (converted to displacement fluid) and after acidizing is 3.3 MPa, which indicates that the acid-etched fracture conductivity is effectively enhanced by CFA.

FIGURE 10. Temporary plugging staged acid fracturing with the closed fracture acidizing operation curve of well X.

The tested production is enhanced to 123.97 × 104 m3/d (calculated open flow capacity of 381.86 × 104 m3/d) under wellhead pressure of 50.5 MPa and converted bottom hole flow pressure of 84.3 MPa.

Well M is an ultra-deep horizontal well of PetroChina, with MD of 8,102.0 m, TVD of 7,498.1 m, and horizontal interval length of 383 m. The Qixia Fm is characterized by low porosity and low permeability with reservoir thickness (MD), porosity, permeability, and water saturation of 333.6 m, 5.3%, 0.97 mD, and 21.8%, respectively.

The hook load of running in open hole packer and sliding sleeve staged fracturing tools with 88.9 mm base tube using 101.6 mm drill pipe to predetermined depth was simulated using WELLPLAN under the extreme condition with an open hole friction coefficient of 0.4, and front blocking of 0 KN and 50 KN (Figure 11). The open-hole packer and sliding sleeve staged fracturing tools can be run into predetermined depth smoothly without string buckling. Moreover, the suspension packer is rotatable to drive the whole staged fracturing string to a predetermined depth. The open hole staged acid fracturing is feasible for well M.

The opening of the toe fracturing sliding sleeve to form a fracturing passage is critical for successfully staged acid fracturing. The maximum length of existing coiled tubing in domestic is about 7,700 m, and the working depth of coiled tubing under high temperature, high pressure, and sour gas environment is about 7,000 m. There is no spare measure to handle the downhole complexity and the well would be abandoned to cause huge economic losses if the toe fracturing sliding sleeve cannot be activated. The first stage is assembled by fracturing sleeve, spared pitching sliding sleeve, and circulating valve. The soluble polymer ball should be pitched in to open the spared pitching sliding sleeve if the opening of the toe fracturing the sliding sleeve failed. Therefore, the activation of the first stage fracturing channel is guaranteed. The open-hole packer and sliding sleeve staged acid fracturing tool string is shown in Figure 12. The main risks and corresponding response plans are listed in Table 4.

The productivity performance of the staged acid frac horizontal well was simulated with StimPlan, to optimize the effects of acid-etched fracture numbers, length, and conductivity. The wellbore azimuth is almost parallel to the maximum horizontal principal stress, and therefore the longitudinal fractures will be created. The productivity performance versus numbers of acid-etched fractures was simulated under fracture length of 50 m, fracture conductivity of 50 D·cm, and bottom hole flowing pressure of 75 MPa (Figure 13). The gas rate increased and its growth declined with increasing numbers of fractures, and four fractures are preferably optimized.

The productivity performance versus lengths and conductivities of acid-etched fracture was simulated under four fractures and bottom hole flowing pressure of 75 MPa (Figure 14). The gas rate increased and its growth declined with increasing fracture length and conductivity. The acid-etched fractures with a length above 50 m and conductivity above 20 D·cm are preferably optimized.

It is recommended that four stages of massive gelled acid fracturing with CFA for well M.

The completion fluid in the wellbore was drained out before stimulation to reduce the formation breakdown pressure. The tested gas production is 36.31 × 104 m3/d with a wellhead pressure of 59.99 MPa. The staged acid fracturing with the CFA operation curve is shown in Figure 15. The difference between ISIP and pumping pressure at the same injection rate of each stage is obvious. It can be concluded that the open hole staged acid fracturing of the ultra-deep horizontal well is successfully operated. The ISIP difference between stage IV before (converted to displacement fluid) and after acidizing is 1.58 MPa, which indicates that CFA effectively enhances the acid-etched fracture conductivity.

The tested production is enhanced to 142.51 × 104 m3/d, which is extremely closed to the predicted gas production (149.58 × 104 m3/d) at the initial stage, under wellhead pressure of 50.36 MPa and converted bottom hole flow pressure of 84.2 MPa. The productive performance of staged acid fractured horizontal well is significantly higher than that of acid fractured vertical wells.

The acid rock reaction and acid-etched fracture conductivity experiments of Qixia Fm tight carbonate are investigated to optimize the main acid type and acid frac technique. In addition, the feasibility of open-hole packer and sliding sleeve staged acid fracturing is discussed, and the staged acid frac tool string is optimized. Based on the research work, the following conclusions are drawn:

1) The gelled acid was selected as the main acid fracturing system for better retardation and friction reduction performance.

2) The acid-etched fracture conductivity sharply decreased with increasing closure stress, and it can be greatly enhanced by using gelled acid, increasing acid volume, and closed fracture acidizing technology.

3) The open-hole packer and sliding sleeve staged acid fracturing is feasible for the ultra-deep horizontal well. The first stage was assembled by fracturing sleeve, spared ball drop sleeve, and circulating valve to guarantee activation of fracturing channels.

4) The temporary plugging and open-hole staged massive gelled acid fracturing with closed fracture acidizing is successfully operated to significantly enhance gas production. It is referential for staged acid fracturing of ultra-deep horizontal wells.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

FL: conceptualization, formal analysis, supervision, and writing—review and editing. YF: conceptualization, data curation, investigation, methodology, validation, visualization, and writing—original draft. LL: project administration, resources, conceptualization, formal analysis, and supervision. JL: formal analysis and writing—review and editing. YC: formal analysis and supervision. ZL: conceptualization, formal analysis, and supervision. TH: methodology, validation, and visualization.

Authors FL, YF, LL, JL, YC, ZL, and TH were employed by PetroChina Southwest Oil and Gas Field Company.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The authors of this article gratefully acknowledge the support of the National Natural Science Foundation of China (NSFC, No. 51974264).

Alkattan, M., Oelkers, E. H., Dandurand, J.-L., and Schott, J. (1998). An Experimental Study of Calcite and Limestone Dissolution Rates as a Function of pH from −1 to 3 and Temperature from 25 to 80°C. Chem. Geol. 151, 199–214. doi:10.1016/s0009-2541(98)00080-1

Anderson, M. S. (1991). Reactivity of San Andres Dolomite. SPE Prod. Eng. 6 (2), 227–232. doi:10.2118/20115-pa

Asadollahpour, E., Baghbanan, A., Hashemolhosseini, H., and Mohtarami, E. (2018). The Etching and Hydraulic Conductivity of Acidized Rough Fractures. J. Petroleum Sci. Eng. 166, 704–717. doi:10.1016/j.petrol.2018.03.074

Bybee, K. (2006). Continuous Improvements in Acid Fracturing at Lake Maracaibo. J. Pet.. Tech. 58 (7), 54–56. doi:10.2118/0706-0054-jpt

Chen, H., Guo, J., and Zhao, J. (2005). Problems and Countermeasures to Stimulate Sour Gas Reservoir with Low Permeability. Nat. Gas. Ind. 25 (7), 89–91. (In Chinese). doi:10.3321/j.issn:1000-0976.2005.07.030

Ding, Y., Li, Y., Xu, Y., Cheng, X., Wang, Y., Zhang, F., et al. (2010). “Propped Fracturing with a Novel Surface Cross-Linked Acid in High Temperature Deep Carbonate Formation,” in Paper SPE 127312 presented at North Africa Technical Conference and Exhibition, Cairo, Egypt, 14-17 Feb. doi:10.2118/127312-ms

Fredd, C. N., and Scott Fogler, H. (1998b). The Kinetics of Calcite Dissolution in Acetic Acid Solutions. Chem. Eng. Sci. 53 (22), 3863–3874. doi:10.1016/s0009-2509(98)00192-4

Fredd, C. N. (1998a). The Influence of Transport and Reaction on Wormhole Formation in Carbonate Porous Media: A Study of Alternative Stimulation Fluids. PhD dissertation. Michigan: U. of Michigan.

Frenier, W. W., and Hill, D. G. (2002). “Effect of Acidizing Additives on Formation Permeability during Matrix Treatments,” in Paper SPE 73705 presented at the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, Louisiana, 20-21 Feb. doi:10.2118/73705-ms

Gdanski, R., and Van Domelen, M. S. (1999). “Slaying the Myth of Infinite Reactivity of Carbonates,” in Paper SPE 50730 presented at the SPE International Symposium of Oilfield Chemistry, Houston, 16-19 Feb. doi:10.2118/50730-ms

Gomma, A. M., and Nasr-El-Din, H. A. (2010). “New Insights into Wormhole Propagation in Carbonate Rocks Using Regular, Gelled and In-Situ Gelled Acids,” in Paper SPE 133303 presented at SPE Production and Operations Conference and Exhibition, Tunis, Tunisia, 8-10 Jun.

Han, H., Sang, Y., and Yang, J. (2016). Experimental Study and Application of Stimulation Technologies for Sinian Dengying Formation Reservoirs in the Sichuan Basin. Nat. Gas. Ind. 36 (1), 81–88. (In Chinese). doi:10.3787/j.issn.1000-0976.2016.01.010

Jeon, J., Bashir, M. O., Liu, J., and Wu, X. (2016). “Fracturing Carbonate Reservoirs: Acidizing Fracturing or Fracturing with Proppants?,” in Paper SPE 181821 presented at SPE Asia Pacific Hydraulic Fracturing Conference, Beijing, China, 24-26 Aug.

Jin, X., Zhu, D., Hill, A. D., and Mcduff, D. (2019). “Effects of Heterogeneity in Mineralogy Distribution on Acid Fracture Efficiency,” in Paper SPE 194377 presented at SPE Hydraulic Fracturing Technology Conference and Exhibition, Woodlands, Texas, 5-7 Feb.

Kalfayan, L. J. (2007). “Fracture Acidizing: History, Present State, and Future,” in Paper SPE 106371 presented at SPE Hydraulic Fracturing Technology Conference, College Station, Texas, 29-31 Jan.

Li, G., Sheng, M., Tian, S., Huang, Z., Li, Y., and Yuan, X. (2012). Multistage Hydraulic Jet Acid Fracturing Technique for Horizontal Wells. Pet.. explor. Dev. 39 (1), 100–104. doi:10.1016/s1876-3804(12)60021-4

Li, N., Feng, Y., Liu, P., Luo, Z., and Zhao, L. (2015). Study of Acid-Rock Reaction Kinetics under High Temperature and Pressure Conditions Based on the Rotating Disk Instrument. Arab. J. Sci. Eng. 40 (1), 135–142. doi:10.1007/s13369-014-1504-x

Li, N., Zhao, L., Zhang, Q., Ren, X., and Liu, P. (2003). Acid Etched Fracture Conductivity Study in Acid Fracturing. Drill. Prod. Technol. 26 (3), 22–25. (In Chinese). doi:10.3969/j.issn.1006-768X.2008.06.019

Li, Q., Chen, W., Lu, Y., and Xiao, Q. (2019). Etched Surface Morphology Analysis Experiments under Different Reaction Rates. J. Petroleum Sci. Eng. 172, 517–526. doi:10.1016/j.petrol.2018.09.063

Liu, H., and Zhao, Z. (1998). “Successful Application of Multistage Acid Fracturing Technology in Changqing Gas Field,” in Paper SPE 50911 presented at SPE International Oil and Gas Conference and Exhibition, Beijing, China, 2-6 Nov. doi:10.2118/50911-ms

Liu, M., Zhang, S., Mou, J., Zhou, F., and Shi, Y. (2013). Diverting Mechanism of Viscoelastic Surfactant-Based Self-Diverting Acid and its Simulation. J. Petroleum Sci. Eng. 105, 91–99. doi:10.1016/j.petrol.2013.03.001

Luo, Y., Liu, A. H., Wang, J. M., Yang, C. Y., and Qi, W. S. (2008). Application of Crosslinked Acid Sand-Adding Acid-Fracturing Technique in Complex Lithologic Reservoir. Acta Pet.. Sin. 29 (2), 266–269. (In Chinese). doi:10.3321/j.issn:0253-2697.2008.02.020

Luo, Z., Zhang, N., Zhao, L., Liu, H., Luo, P., and Liu, J. (2019). Innovative Encapsulating Acid with Release Dually Controlled by the Concentration of Hydrogen Ions and Temperature. Energy fuels.. 33 (6), 4976–4985. doi:10.1021/acs.energyfuels.9b00673

Luo, Z., Zhang, N., Zhao, L., Yao, L., and Liu, F. (2018). Seepage-stress Coupling Mechanism for Intersections between Hydraulic Fractures and Natural Fractures. J. Petroleum Sci. Eng. 171, 37–47. doi:10.1016/j.petrol.2018.07.019

Luo, Z., Zhang, N., Zhao, L., Zeng, J., Liu, P., and Li, N. (2020). Interaction of a Hydraulic Fracture with a Hole in Poroelasticity Medium Based on Extended Finite Element Method. Eng. Analysis Bound. Elem. 115, 108–119. doi:10.1016/j.enganabound.2020.03.011

Malagon, C., Pournik, M., and Hill, A. D. (2008). The Texture of Acidized Fracture Surfaces: Implications for Acid Fracture Conductivity. SPE Prod. Oper. 23 (3), 343–352. doi:10.2118/102167-pa

Nasr-El-Din, H. A., Solares, J. R., Al-Zahrani, J. A., and Garzon, F. O. (2007). “Acid Fracturing of Gas Wells Using Solid Acid: Lessons Learned from First Field Application,” in Paper SPE 110895 presented at SPE Annual Technical Conference and Exhibition, Anaheim, California, 11-14 Nov. doi:10.2118/110895-ms

Nelson, R. L., Jamieson, F. M., and Jenkins, R. A. (1998). “Multiple Pad-Acid Fracs in a Deep Horizontal Well,” in Paper SPE 39943 presented at SPE Rocky Mountain Regional/Low-Permeability Reservoirs Symposium, Denver, Colorado, 5-8 Apr.

Peng, Y., Li, Y., Zhao, J., Wang, L., Zhang, Y., and Luo, P. (2015). Simulation and Analysis of Acid-Etched Fracture Conductivity of Fracture-Cavity Carbonate Reservoir. Acta Pet.. Sin. 36 (5), 606–611. (In Chinese). doi:10.7623/syxb201505010

Peng, Y., Zhao, J., Sepehrnoori, K., Li, Y., and Li, Z. (2019b). The Influences of Stress Level, Temperature, and Water Content on the Fitted Fractional Orders of Geomaterials. Mech. Time-Depend Mater 24, 221–232. doi:10.1007/s11043-019-09417-0

Peng, Y., Zhao, J., Sepehrnoori, K., Li, Y., Yu, W., and Zeng, J. (2019a). Study of the Heat Transfer in Wellbore during Acid/Hydraulic Fracturing Based on Semi-analytical Transient Model. SPE J. 24 (2), 877–890. doi:10.2118/194206-pa

Peng, Y., Zhao, J., Sepehrnoori, K., and Li, Z. (2020). Fractional Model for Simulating the Viscoelastic Behavior of Artificial Fracture in Shale Gas. Eng. Fract. Mech. 228, 106892. doi:10.1016/j.engfracmech.2020.106892

Pournik, M., Nasr-El-Din, H. A., and Mahmoud, M. A. (2011). A Novel Application of Closed-Fracture Acidizing. SPE Prod. Oper. 26 (1), 18–29. doi:10.2118/124874-pa

Rabie, A. I., Shedd, D. C., and Nasr-El-Din, H. A. (2014). Measuring the Reaction Rate of Lactic Acid with Calcite and Dolomite by Use of the Rotating-Disk Apparatus. SPE J. 19 (6), 1192–1202. doi:10.2118/140167-pa

Taylor, K. C., and Nasr-El-Din, H. A. (2002). “Coreflood Evaluation of In-Situ Gelled Acids,” in Paper SPE 73707 presented at International Symposium and Exhibition on Formation Damage Control, Lafayette, Louisiana, 20-21 Feb.

Taylor, K. C., Nasr-El-Din, H. A., and Mehta, S. (2006). Anomalous Acid Reaction Rates in Carbonate Reservoir Rocks. SPE J. 11 (4), 488–496. doi:10.2118/89417-pa

Teklu, T. W., Park, D., Jung, H., Amini, K., and Abass, H. (2019). Effect of Dilute Acid on Hydraulic Fracturing of Carbonate-Rich Shales: Experimental Study. SPE Prod. Oper. 34 (1), 170–184. doi:10.2118/187475-pa

Ugursal, A., Zhu, D., and Hill, A. D. (2019). Development of Acid Fracturing Model for Naturally Fractured Reservoirs. SPE Prod. Oper. 34 (4), 735–748. doi:10.2118/189834-pa

Wang, X., Liu, G., Wang, D., and Economides, M. J. (2011). “The Use of Sealing Ball Staged Fracturing,” in Paper SPE 140529 presented at SPE Hydraulic Fracturing Technology Conference, Woodlands, Texas, 24-26 Jan.

Xue, H., Huang, Z., Liu, F., Liu, P., Wang, H., Zhang, B., et al. (2019). “3D Acid Fracturing Simulation and Application in the Upper Sinian Dengying Fm Gas Reservoirs in China,” in Paper IPTC 19137 presented at International Petroleum Technology Conference, Beijing, China, 26-28 Mar.

Xue, H., Huang, Z. X., Zhao, L. Q., Jiang, W. D., Liu, P. L., and Liang, C. (2018). A Simulation Study on the Preflush Acid Fracturing Considering Rock Heterogeneity. Nat. Gas. Ind. 38 (2), 59–66. (In Chinese). doi:10.3787/j.issn.1000-0976.2018.02.008

Yao, M. T., Mou, J. Y., Li, D., Xue, Y. P., Jiang, F., and Zhang, L. F. (2015). An Experimental Study of Long-Term Conductivity in High Temperature and Pressure Carbonate Formation. Sci. Tech. Eng. 15 (2), 193–195. (In Chinese). doi:10.3969/j.issn.1671-1815.2015.02.035

Yi, X., Lu, Y., Li, Q., Li, Y., and J, W. (2010). On New Acid Fracturing Technique with Proppant-Carrying Crosslinked Acid on Carbonate Reservoirs. China Sci. Pap. 5 (11), 837–839. doi:10.3969/j.issn.2095-2783.2010.11.001

Yuan, L., Wang, Y., Li, Q., Chen, K., and Li, Y. (2019). Evaluation of a Control-Released In-Situ Generated Acid Tablet for Acid Fracturing. J. Petroleum Sci. Eng. 174, 384–393. doi:10.1016/j.petrol.2018.09.081

Zhao, L., Chen, X., Zou, H., Liu, P., Liang, C., Zhang, N., et al. (2020). A Review of Diverting Agents for Reservoir Stimulation. J. Petroleum Sci. Eng. 187, 106734. doi:10.1016/j.petrol.2019.106734

Zhao, L. Q., Gao, Y. J., Yuan, X. F., Luo, Z. F., and Yuan, Z. B. (2017). Research on Flow Conductivity of Acid Etched Fracture of Carbonate Reservoir under High Temperature. Rsvr. Eval. Dvlopmt. 7 (1), 20–26. (In Chinese). doi:10.3969/j.issn.2095-1426.2017.01.004

Keywords: staged acid fracturing, ultra-deep horizontal well, tight carbonate, acid-etched fracture length, acid-etched fracture conductivity, open-hole staged acid fracturing

Citation: Liu F, Fan Y, Li L, Li J, Chen Y, Lv Z and He T (2022) Case Study of Successfully Staged Acid Fracturing on the Ultra-Deep Horizontal Well for the Qixia Fm HTHP Tight Carbonate Gas Reservoir in China. Front. Energy Res. 10:917740. doi: 10.3389/fenrg.2022.917740

Received: 11 April 2022; Accepted: 26 May 2022;

Published: 04 July 2022.

Edited by:

Yu Peng, Southwest Petroleum University, ChinaReviewed by:

Li Chengyong, Chengdu University of Technology, ChinaCopyright © 2022 Liu, Fan, Li, Li, Chen, Lv and He. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fei Liu, bGl1ZmVpMTA2MjhAYWxpeXVuLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.