- 1College of Petroleum Engineering, Yangtze University, Wuhan, China

- 2Laboratory of Drilling and Production Engineering for Oil and Gas, Wuhan, China

- 3Western Research Institute, Yangtze University, Karamay, China

- 4Key Laboratory of CNPC for Oil and Gas Production, Yangtze University Branch, Wuhan, China

- 5Research Institute of Exploration and Exploitation, PetroChina Xinjiang Oilfield Company, Karamay, China

- 6Northwest Oilfield Company, China Petroleum & Chemical Corporation LTD., Urumqi, China

- 7Jianghan Machinery Research Institute Co., Ltd. of CNPC, Wuhan, China

Introduction

The staged fracturing technology of horizontal wells has successfully promoted the large-scale development of shale gas reservoirs around the world, but the development of shale gas reservoirs still faces problems such as large production attenuation and rapid production decline of oil and gas wells. The international oil price continued to fluctuate, and the economic benefits of new drilling were low. In search of more economical stimulation measures, some operators have turned their attention to increasing single-well production in older wells and seeking a more economical method of stimulation—horizontal well refracturing.

Refracturing refers to the second or more fracturing measures for the same layer of the same well after the first fracturing. The advantages of refracturing are as follows: 1) in the process of development, the crustal stress changes, and the fracture azimuth of refracturing will form a certain deviation from that of the initial fracturing, so as to communicate the new reservoir and (2) refracturing can open the fractures closed by the initial fracturing and solve the problems of formation blockage and low permeability near the wellbore (Foda, 2015). Therefore, different from the first fracturing, the key point of refracturing design mainly lies in the selection of candidate wells and fracture steering mechanism.

Statistics show that at least 40% of perforation clusters in shale gas horizontal wells do not contribute to production, and these deficiencies leave many opportunities for refracturing (Tao et al., 2020). Refracturing technology can improve the production of oil and gas wells, reactivate low-production wells, and expand the contact area of oil reservoirs with horizontal wells.

Development History of Refracturing Technology

The United States is the country with the earliest start, the most perfect development, and the highest annual output of shale gas in the world. In the 1990s, the United States developed a system of refracturing technology (including well selection, layer selection, fracture diversion technology, diagnostic monitoring technology, etc.) (Xinjun and Wang, 2019) and achieved certain achievements in the field of refracturing engineering in Barnett and Woodford (E. Siebrits et al., 2000). Since the 21st century, refracturing technology has been applied in major shale blocks in North America such as Bakken, Haynesville, and Eagle Ford and has achieved good results in improving the production characteristics of shale gas wells and increasing the expected final reserves of a single well. In the current oil context, fracturing technology has not only restored the overall economic recovery of U.S. shale gas but also guaranteed the profitability of developers (Karen 2001) (Wiley et al., 2004) (Eshkalak et al., 2015).

As far as China’s situation is concerned, the refracturing technology has a significant gap compared with foreign countries, and it is still in the pilot stage. It is urgent to carry out research on refracturing technology to achieve effective production increase. In the mid-to-late 1980s, China began to initially discuss and simulate the mechanism of refracturing and conduct in-depth research on well layer selection (Xiao et al., 2020). Since the development in 2012, the output of some old fracturing wells in China’s shale blocks has declined rapidly, and the wellhead pressure has been low, which directly affects the economic and effective development of oil and gas fields. Fracturing is on the agenda as an important stimulation technology (Guo 2018). In 2017, the first shale gas horizontal well in China, Changning H3-6, completed the refracturing operation (Wang et al., 2019); on December 1 of the same year, Sinopec Fuling shale gas field Jiaoye 4HF well completed the refracturing of shale gas horizontal wells (Gong, 2021). Refracturing technology is gradually becoming an important means of reducing cost and increasing efficiency of shale oil and gas in China.

Current Status of Refracturing Technology Development

At present, there are mainly three types of refracturing technologies:

• Temporary plugging and diverting technology: During the fracturing process, the temporary plugging agent is pumped, and the fracturing fluid carries the temporary plugging agent into the main fracture, plugs the degradable particles at the entrance of the fracture, and diverts the fracturing fluid to the unfractured area and forms new fractures. Eventually, the temporarily blocked particles degrade. This technology has low implementation cost, a simple process, and low risk, but it is not easy to control the diversion process in the wellbore (Garza et al., 2019).

• Mechanical isolation technology: The perforation in the production section is blocked with liner or expandable liner to obtain a new wellbore, which is then perforated for refracturing. This technology has good sealing effect, but the cost is high, the process is complicated, and the operation is difficult (Liu et al., 2021).

• Coiled tubing refracturing technology: Coiled tubing + double packer can be used for multi-stage refracturing of sliding casing in open-hole sliding casing fracturing completion and can also perforate the horizontal section of cement casing in bridge plug perforating completion, adding new fracturing points. This technology has requirements on the completion structure and is difficult to operate, so it has only been used in the early open-hole sliding sleeve ball-casting wells in the Bakken Oilfield (Shaykamalov et al., 2020).

Although there have been cases of refracturing construction of horizontal wells in shale gas reservoirs in China in recent years, they are still in the stage of small-scale testing and have not been popularized and applied. Judging from the successful cases, there are many applications of temporary plugging and diverting refracturing technology in China (Jia et al., 2020) (Cai et al., 2020); mechanical containment technology is only used in a few cases.

In addition, China’s shale reservoirs have not yet carried out large-scale horizontal well refracturing, which is mainly affected by factors such as technology and cost. In 2015, Woodmac counted the after-tax income comparison of 65 refracturing wells from the Bakken, Barnett, and Haynesville blocks before and after refracturing. Although the production and EUR have improved, the overall project is less economical.

Refracturing Technology Applications

Generally speaking, the technology mainly adopts the following three ways to restore, enhance, and increase the original well productivity:

• Repair of existing fractures: Improve fracture conductivity by removing contamination in original fractures or restoring closed fractures and pumping proppant to provide effective support.

• Open new fractures: By adding temporary plugging agent or using mechanical packing and other technologies to open the production section that was not fully opened by the first fracturing, expand the complex fracture network around the wellbore to the reservoir that was not affected by the first fracturing.

• Diverting fracturing: With the help of the horizontal stress change in the near-wellbore area of the old well, the fractures in the near-wellbore area are diverted during the refracturing process, thereby forming a complex fracture network and improving the connectivity between the wellbore and the formation.

At present, the research hot spots of refracturing technology mainly focus on how to establish the well selection standard, develop new refracturing technology, and refracturing diagnosis.

Refracturing Candidate Wells

Selecting reasonable candidate wells can improve the success rate of refracturing. The selection of candidate wells is mainly based on the following aspects: 1) wells with remaining reserves worth developing, 2) wells whose wellbore structure meets the requirements of refracturing construction, and 3) wells with low production due to one fracturing or inappropriate production methods (Yang et al., 2019).

Some scholars have shown that horizontal wells with good performance in production operation can obtain higher economic benefits as candidate wells for refracturing (Vincent, 2010). Based on well production, Endress summarized the composition of candidate wells for refracturing in major shale blocks in North America (Barnett, Eagle Ford, Haynesville, etc.). The results show that most of the candidate wells in the block are from high-production wells in the block. Only the Bakken block was developed earlier and completed wells. Fracturing technology is immature, so most of the candidate wells are low-production wells (Endress, 2015).

At present, the mainstream well selection methods are artificial intelligence and correlation analysis methods. Shahab put forward a unique well selection workflow based on big data analysis. This technology shows how to apply prediction analysis to shale and practice it in the Marcellus shale block. It proves that the data generated in the initial development process can become an information base for well selection during refracturing (Mohaghegh, 2016).

In addition, the refracturing timing of candidate wells is also important. The authors summarize the timing of fracturing for 21 refracted wells in the Eagle Ford shale block (Oruganti et al., 2015). The timing of these wells is 9–45 months after production, mostly 1–2 years. The post-refracturing production of these wells recovered to 26–160% of the initial fracturing production, and the post-refracturing production decline rate was approximately 65–127% of the pre-refracturing rate. According to field experience, operators generally select half of the wells that meet the conditions for refracturing pilot tests, explore and summarize successful experiences, and then extend them to all candidate wells.

Fracture Diverting Technology

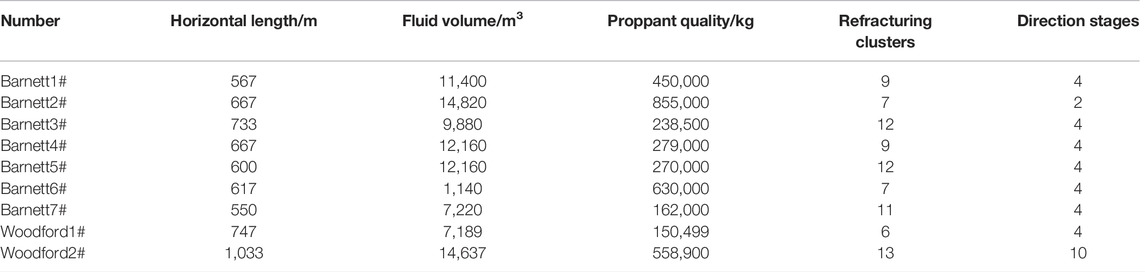

Temporary plugging and diversion technology is currently the mainstream refracturing technology. The temporary plugging and fracturing data of shale gas wells in the Barnett and Woodford Basins are shown in Table 1. It can be seen from the data in the table that this technology has a high success rate at low cost.

TABLE 1. Treatment trial data of refracturing wells (Xiao et al., 2020).

Refracturing Diagnostics

Refracturing cases show that not all diversions are effective, and some unmodified areas have not been effectively communicated after diversion. Therefore, evaluation is an important part of refracturing (Piyush and Shukla, 2018). At present, the most commonly used monitoring technology is micro seismic monitoring technology. Based on the principles of sound and seismology, the data are collected using geophones and then interpreted. In recent years, some scholars have proposed that electromagnetic monitoring technology can make up for the accuracy of micro seismic monitoring, but this technology has not been widely recognized and needs further research (Basu and Sharma, 2014).

The Fuling shale gas field in the Sichuan Basin uses micro seismic monitoring technology to monitor the fracturing fractures of the Jiaoshiba block “well factory” in real time and successfully monitors the geometric size and distribution position of artificial fractures under the “well factory” fracturing model, which plays an important guiding significance for the optimization of fracturing parameters in the later stage (Liu et al., 2016).

Prospects and Challenges of Refracturing Technology

China’s shale resources are widely distributed, with huge development potential and market potential. According to the China Mineral Resources Report, by 2020, the reserves of shale gas resources increase by 77.8%, the newly added proven geological reserves will be 7,644.2 × 108 m3, and the newly added proven recoverable reserves will be 1838.4 × 108 m3. Therefore, in-depth research on shale gas will be strengthened to promote the rapid development of the shale gas industry will promote China’s economic development and ensure China’s oil and gas energy security. At present, the development time of shale gas in China is still short, and the development mode is still mainly to increase new wells. As development progresses, China’s shale gas development will also begin to transform old wells like the United States. Therefore, paying attention to the development of international shale gas transformation and carrying out relevant research in a timely manner is of positive significance to the development of shale gas in China.

Although refracturing technology has achieved good application results in some shale gas fields in China, it is still in the stage of exploration and testing and still faces the following problems and challenges. 1) With regard to the technology side, refracturing technology for shale gas wells is not yet mature. Each refracturing technique has its advantages and limitations, and it is difficult to guarantee the opening and diversion of new fractures. In addition, refracturing in different blocks or even different wells in the same shale block has very different effects. 2) With regard to the economic side, although the productivity of wells after refracturing has improved, the overall economics are poor, and there is still a large gap between profitability and newly added drilling. 3) There is also high risk. The stratigraphic stress distribution in the blocks with high concentration of production wells is complex, and it is difficult to control the extension of fractures by refracturing. In addition, accidents such as failure to open new fractures or pressure channeling near wells are prone to occurring, resulting in failure of refracturing and shutdown of multiple wells.

Author Contributions

SL: data curation. YP: formal analysis. ZH: funding acquisition.

Conflict of Interest

Authors ZH and ZY were employed by PetroChina Xinjiang Oilfield Company. SL was employed by Northwest Oilfield Company. YL was employed Jianghan Machinery Research Institute Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Basu, S., and Sharma, M. M. (2014). “A New Method for Fracture Diagnostics Using Low Frequency Electromagnetic Induction,” in SPE Hydraulic Fracturing Technology Conference, The Woodlands, Texas, USA. doi:10.2118/168606-MS

Baumbach, M., Prosser, J., James, P., Pettigrew, S., and Elvig, K. (2019). “An Eagle Ford Case Study: Improving an Infill Well Completion through Optimized Refracturing Treatment of the Offset Parent Wells,” in SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, Texas, USA. doi:10.2118/194374-MS

Cai, Z., Zhao, X., Nan, R., et al. (2020). Volume Re-fracturing Technology of Temporay Plugging and Diverting with High Displacement. Fault-Block Oil&Gas Field 27 (5), 661–665.

Endress, A. (2015). As Industry Seeks Cheaper Ways to Boost Production, Horizontal Refractures Gain Prominence. Drill. Contract. 35 (2), 46–51.

Eshkalak, M. O., Aybar, U., and Sepehrnoori, K. (2015). On the Feasibility of Re-stimulation of Shale Wells. Pet. Sci. 12 (3), 553–559. doi:10.1007/s12182-015-0036-7

Foda, S. (2015). Refracturing: Technology and Reservoir Under-standing Are Giving New Life to Depleted Unconventional Assets. J. Petroleum Technol. 67 (7), 76–79. doi:10.2118/0715-0076-jpt

Gong, T. (2021). China's First Shale Gas Reconstruction Wellbore Refrac Was Successful. Nat. Gas. Ind. 41 (01), 82.

Guo, W. (2018). Differentation Analysis on Shale Gas Production of the Horizontal Wells in Sichuan Weiyuan Block. Sci. Technol. Eng. 18 (1), 228–223.

Jia, H., Chen, H., and Zhao, J.-Z. (2020). Development of a Highly Elastic Composite Gel through Novel Intercalated Crosslinking Method for Wellbore Temporary Plugging in High-Temperature Reservoirs. SPE J. 25, 2853–2866. doi:10.2118/201090-pa

Karen, B. (2001). Refracture Reorientation Enhances Gas Production. J. Petroleum Technol. 53, 61–62.

Liu, R., Liao, R., Zhang, Y., Gao, D., Zhang, H., Li, T., et al. (2016). Application of Surface-Downhole Combined Microseismic Monitoring Technology in the Fuling Shale Gas Field and its Enlightenment. Nat. Gas. Ind. 36 (10), 56–62. doi:10.1016/j.ngib.2017.07.009

Liu, Y., Li, Y., Zhang, C., Ming, Y., Xiao, J., Han, R., et al. (2021). “First Successful Application of Casing in Casing CiC Refracturing Treatment in Shale Gas Well in China: Case Study,” in Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE. doi:10.2118/208060-MS

Mohaghegh, S. D. (2016). “Fact-Based Re-frac Candidate Selection and Design in Shale - A Case Study in Application of Data Analytics,” in Unconventional Resources Technology Conference, San Antonio, Texas, USA. doi:10.15530/URTEC-2016-2433427

Oruganti, Y., Mittal, R., Mcburney, C. J., and Rodriguez, A. (2015). “Refracturing in Eagle Ford and Bakken to Increase Reserves and Generate Incremental NPV: Field Study,” in SPE Hydraulic Fracturing Technology Conference, The Woodlands, Texas, USA. doi:10.2118/173340-ms

Pankaj, P., and Shukla, P. (2018). “Application of Refracturing Using Coiled Tubing Opens a New Door of Opportunities for Unconventional Reservoir Stimulation,” in SPE Coiled Tubing and Well Intervention Conference and Exhibition, Texas. doi:10.2118/189933-MS

Shaykamalov, R., Gaponov, M., Mukhametshin, M., Bildanov, V., Katermin, A., and Bashirov, I. (2020). “Multistage Horizontal Wells Refracturing by Means of Abrasive Jet Perforation + Frac Technology,” in SPE Symposium: Hydraulic Fracturing in Russia. Experience and Prospects, Virtual. doi:10.2118/203892-MS

Siebrits, E., Elbel, J. L., Hoover, R. S., Diyashev, I. R., Griffin, L. G., Demetrius, S. L., et al. (2000). “Refracture Reorientation Enhances Gas Production in Barnett Shale Tight Gas Wells,” in SPE Annual Technical Conference and Exhibition, Dallas, Texas. doi:10.2118/63030-ms

Tao, J., Meng, S., and Cao, G. (2020). “Experimental Study on the Impact ofSupercritical CO2 Soak Pre-treatment on Re-fracturing of Shale Oil Reservoirs,” in SPE Asia Pacific Oil & Gas Conference and Exhibition, Virtual. doi:10.2118/202421-ms

Vincent, M. C. (2010). “Refracs: Why Do They Work, and Why Do They Fail in 100 Published Field Studies?,” in SPE Annual Technical Conference and Exhibition, Florence, Italy. doi:10.2118/134330-MS

Wang, G., Xiao, Y., Zhao, H., et al. (2019). Application of Microseismic Monitoring Technology to Re-fracturing of Shale Gas Horizontal Wells. Geol. Explor. 55 (5), 1336–1342.

Wiley, C., Barree, B., Eberhard, M., and Lantz, T. (2004). “Improved Horizontal Well Stimulations in the Bakken Formation, Williston Basin, Montana,” in SPE Annual Technical Conference and Exhibition, Houston, Texas. doi:10.2118/90697-MS

Xiao, B., Li, S., Jiang, T., et al. (2020). Research Progress on Temporary-Plugging Refracturing Technology for Shale Gas Wells. Sci. Technol. Eng. 20 (24), 9707–9715.

Xinjun, G., and Wang, M. (2019). Re-fracturing Key Technologies of Shale Oil and Gas in North America and the Suggestions. OilDrilling&ProductionTechnology 41 (2), 224–229.

Keywords: shale gas, refracturing, candidate wells, construction technology, monitoring analysis

Citation: Lei S, Pan Y, Huang Z, Yao Z, Zhou Y, Wang W, Li S and Lei Y (2022) Progress and Enlightenment of Refracturing Technology for Shale Gas in North America. Front. Energy Res. 10:887203. doi: 10.3389/fenrg.2022.887203

Received: 01 March 2022; Accepted: 12 April 2022;

Published: 06 June 2022.

Edited by:

Qi Zhang, China University of Geosciences Wuhan, ChinaReviewed by:

Xiang Zuping, Fisheries Research Institute of Zhao Qing, ChinaShuyong Hu, Southwest Petroleum University, China

Copyright © 2022 Lei, Pan, Huang, Yao, Zhou, Wang, Li and Lei. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: YuHui Zhou, emh5aHRyZWVAeWFuZ3R6ZXUuZWR1LmNu

†These authors have contributed equally to this work and share first authorship

Sheng Lei

Sheng Lei Yuan Pan1,4†

Yuan Pan1,4†