- 1XinJiang Oilfield Company, CNPC, Karamay, China

- 2Research Institute of Petroleum Exploration and Development, XinJiang Oilfield Company, CNPC, Karamay, China

Introduction

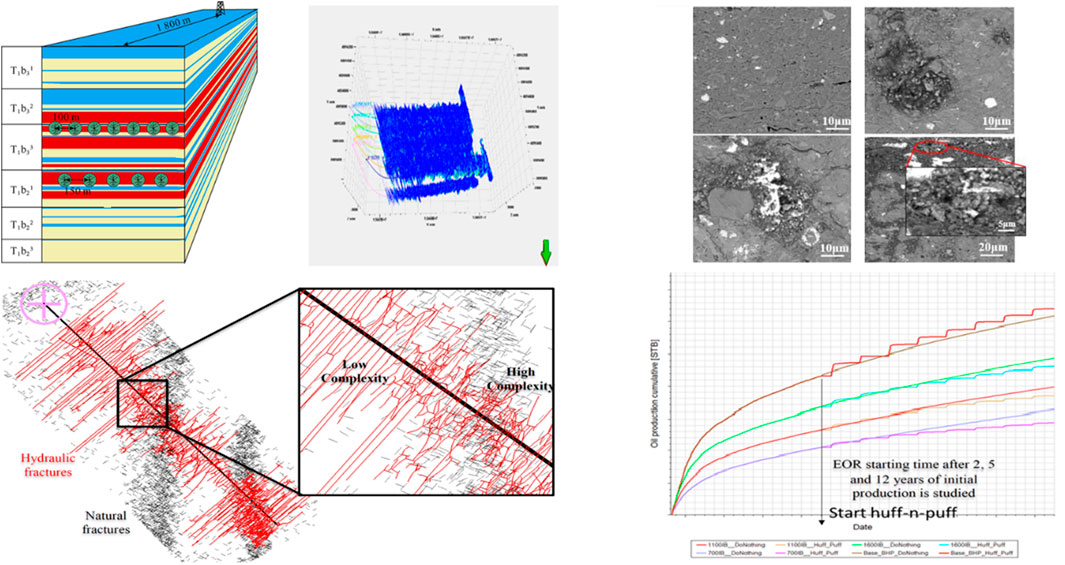

In China, the dependence on foreign oil and gas reached 70 and 45.3% in 2018 (Du et al., 2014; Zou et al., 2015; Zhao et al., 2020). The resource evaluation and the latest statistics show that the geological resources of shale oil in China reach 27 billion tons and are mainly oriented to continental basins. For shale oil reservoirs, due to the characteristics of complex lithology, strong heterogeneity, large horizontal stress difference between two directions, undeveloped natural fractures, and low effective production rate of oil reservoirs (Li et al., 2020a; Li et al., 2020b), it is necessary to take an effective development technology for shale oil reservoirs. The small-spacing stereo-staggered well pattern deployment technology is the key technology. To break through the current theoretical understanding of the bottleneck of tight fractured formation and interwell interference and to develop and innovate key development technologies such as well pattern deployment, interference control and utilization, fracturing optimization, and multiple cooperation, these technologies are matched with the small-spacing stereo-staggered well pattern deployment technology and constantly tested and improved them in practice. This article focuses on the theoretical understanding and key technologies of three-dimensional efficient development of horizontal wells with small spacing as shown in Figure 1, reviews the influencing factors of development of shale oil, and puts forward the key problems of application, prospects, and challenges that should be paid attention to in the future.

FIGURE 1. Small-spacing stereo-staggered well pattern deployment technology and CO2 injection (Pankaj et al., 2018; Li et al., 2020b; Tao et al., 2020).

Influencing Factors

From the field development effect, there are many factors affecting shale oil productivity, including geological factors and engineering factors.

Geological factors: The research results show that shale oil production mainly depends on the abundance of movable reserves. In the field exploitation practice of shale oil, the area with high abundance of movable reserves in the sweet spot should be preferred for well location deployment.

Engineering factors: The application of rotary steering technology (Janwadkar et al., 2009; Yan et al., 2021; Al Amri et al., 2021) and element logging technology (Zhu et al., 2018; Zhang et al., 2021) has greatly improved the drilling rate of horizontal wells. Research shows that the foundation of high shale oil production is to make the horizontal section as much as possible in the reservoir, especially in the area with high reserves. At the same time, the large displacement, large amount of fluid, and close-to-cut volume fracturing have now become a major means of horizontal well to increase production capacity but should be considered on a reasonable fracturing scale than the input and output. The optimal combination should be selected by considering economic cost and other constraints.

Small-Spacing Stereo-Staggered Well Pattern Deployment Technology

Based on the theoretical understanding and the early application of small-spacing infusing well pattern in North America, Xinjiang Oilfield has developed the small-spacing three-dimensional-staggered well pattern deployment technology in recent years. The small-spacing stereo-staggered well pattern deployment technology has been mentioned by Li et al. (2020).

One well pattern deployment: The distribution of small well spacing can fully utilize reserves, provide favorable conditions for the positive effect of stress interference to be fully utilized in the original stress field, and the development effect is better than the infill well pattern.

Well spacing-coordinated design: Based on the single-well EUR prediction (Valko, 2009; Clark et al., 2011) and life-cycle economic model (Chitwood et al., 2005), the single-well control range can be estimated; a reasonable initial well spacing can be set based on lateral length, and fracture length can be determined based on fracturing simulation and reservoir engineering evaluation.

Refine the development layer: The flow units are divided based on geomechanics. For single-layer reservoirs, several horizontal well networks were vertically divided based on their thickness and geomechanical flow units, and the landing position of each well network was optimized. In the case of vertical multi-thin layers, the combination mode of multi-thin layers and the best landing layer in each combination are optimized. The principle of division is with the existing main body technology, with the minimum of layers to achieve effective vertical use.

Three-dimensional-staggered well: The three-dimensional-staggered well arrangement (Cheng, 2021) can effectively reduce the adverse vertical stress interference, strengthen the favorable stress interference, enhance the complexity of fracture network, and achieve the goal of integral fracturing.

Prospects

Jimsar shale oil is a typical representative of China’s land-phase shale oil and is the first national land-phase shale oil demonstration area established in China, featuring with extremely low physical properties, thin oil layers, high viscosity, strong non-homogeneity, and large burial depth. In order to realize economic and effective exploitation of shale oil, starting from strengthening the evaluation of the sweet spot quality and selecting the right target area for development, we recognized the advantages of the lower sweet spot in terms of moveability and compressibility and put forward the idea of building production with the main force in the lower sweet spot. Drawing on the experience of the small-well spacing demonstration area in the Mahu oilfield and aiming to improve the program efficiency, eight test wells for the development of the 58th platform volume were deployed in the lower sweet spot category I area. The 200-m well spacing was used to stagger the use of two sets of reservoirs with a 10-m height difference to achieve full utilization of the reserves; the segmented cluster design was optimized to reduce the cluster spacing of the fracturing section and increase the fracturing intensity to further improve the production and recovery rate of a single well. The initial production data showed that during the fracturing period, the wells were fully communicated to achieve full control of the seam network and stress interference, and after production, the fractures in the distant wells gradually closed and the inter-well production interference weakened, which initially confirmed the rationality of the three-dimensional well network deployment. The oil recovery rate in this area was increased from 5 to 7%, and the predicted recovery rate was close to 20%, which achieved good results.

Issues, Opportunities, and Challenges

On the whole, Chinese shale oil exploration and development is still facing many problems. Chinese onshore shale oil has a complex reservoir structure, which makes it difficult to predict the location of the sweet spot accurately; most of the wells are deep, and anomalous high pressure is frequent, which makes it difficult to effectively recover; rapid sedimentation changes, strong inhomogeneity, insufficient theoretical understanding, and lack of reasonable and effective evaluation tools and diverse crude oil burial states make it difficult to develop reasonable development parameters; strong reservoir toughness easily causes insufficient complexity of the seam network; low organic matter maturity, high fluid viscosity, insufficient driving capacity, and other factors lead to poor flow ability and difficult extraction.

In view of the aforementioned problems, it is necessary to carry out research for reasonable solutions, such as establishing a comprehensive evaluation system, preferably selecting the best exploitation area and exploration target, clarifying the dessert geophysical response characteristics and establishing a systematic and complete dessert prediction identification method and system, improving shale oil drilling and completion technology, complex seam network modification technology, shale oil reservoir numerical simulation technology and effective shale oil production enhancement, stabilization technology, and continuously improving the improvement on shale oil mobility, designing the best well deployment plan, and establishing pilot areas for reservoir exploration and development.

Meanwhile, supercritical CO2 (Sc-CO2) has begun to be used in oil and gas reservoir development due to its unique physical and chemical properties. Miscibility, extraction, dissolution, and other phenomena will occur in the Sc-CO2 displacement process, which greatly improves oil displacement efficiency and can realize CO2 storage in the process of oil displacement (Jin et al., 2017; Pankaj et al., 2018), as shown in Figure 1.

Conclusion

(1) From the field development effect, there are many factors affecting shale oil productivity, including geological factors and engineering factors. The complex reservoir structure, strong reservoir toughness, low organic matter maturity, high fluid viscosity, insufficient driving capacity, and mainly fracture interference lead to poor flow ability and difficult extraction for shale oil.

(2) Small-spacing stereo-staggered well pattern deployment technology makes the interwell interference, which is the effective measure to improve the joint network complexity and also is the key to improve the single-well production.

(3) CO2 injection can not only enhance oil recovery of shale oil but also realize carbon capture, utilization, and storage.

Author Contributions

FF contributed to methodology and supervision. GS contributed to methodology and writing draft. JQ contributed to conceptualization and resources. YG contributed to validation. YL contributed to data curation and writing. DX contributed to investigation and resources.

Conflict of Interest

GS was employed by XinJiang Oilfield Company, CNPC. FF, JQ, YG, YL, and DX were employed by the Research Institute of Petroleum Exploration and Development, XinJiang Oilfield Company, CNPC.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Al Amri, Y. B. N., Al Rawahi, Q., Al Adawi, H., Al Maashari, B., Soden, L., Al Kaifi, A., et al. (2021). “Advanced Engineering Solutions to Achieve Best in Class Performance in Drilling Extended Reach Dual Lateral Wells in the Sultanate of Oman,” in Paper presented at the Abu Dhabi International Petroleum Exhibition & Conference, SPE207760. doi:10.2118/207760-ms

Cheng, L. (2021). Exploration of Geological Engineering Integrated 3D Fracturing Design for Horizontal wells in Jimsar Shale Oil Reservoirs. Pet. Geology. Eng. 35 (2), 88–92.

Chitwood, J. E., Hanrahan, S., and Adhia, G. (2005). “DeepStar - FPSO Solutions for 10,000 Fsw GOM Field Development,” in Paper presented at the Offshore Technology Conference, OTC-17200. doi:10.4043/17200-ms

Clark, A. J., Lake, L. W., and Patzek, T. W. (2011). “Production Forecasting with Logistic Growth Models,” in Paper prepared for presentation at the SPE Annual Technical Conference and Exhibition, SPE144790. doi:10.2118/144790-ms

Du, J., Liu, H., Ma, D., Fu, J., Wang, Y., and Zhou, T. (2014). Discussion on Effective Development Techniques for continental Tight Oil in China. Pet. Exploration Develop. 41 (2), 198–205. doi:10.1016/s1876-3804(14)60025-2

Janwadkar, S. S., Hummes, O., Freyer, C., Rogers, T., Simonton, S., and Black, D. L. (2009). “Innovative Design Rotary Steerable Technologies Overcome Challenges of Complex Well Profiles in a Fast Growing Unconventional Resource—Woodford Shale,” in Paper presented at the SPE/IADC Drilling Conference and Exhibition, SPE119959.

Jin, L., Hawthrone, S., Sorensen, J., Pekot, L., Kurz, B., Smith, S., et al. (2017). “Extraction of Oil from the Bakken Shales with Supercritical CO2,” in Paper prepared for presentation at the Unconventional Resources Technology Conference, URTeC-2671596.

Li, G., Qin, J., Xian, C., Fan, X., Zhang, J., and Ding, Y. (2020). Theoretical Understandings, Key Technologies and Practices of Tight Conglomerate Oilfield Efficient Development: A Case Study of the Mahu Oilfield, Junggar Basin, NW China. Pet. Exploration Develop. 47 (6), 1185–1197. doi:10.1016/s1876-3804(20)60135-0

Li, G., and Zhu, R. (2020). Progress, Challenges and Key Issues of Unconventional Oil and Gas Development of CNPC. China Pet. Exploration 25 (2), 1–13.

Pankaj, P., Mukisa, H., Solovyeva, I., and Xue, H. (2018). “Boosting Oil Recovery in Naturally Fractured Shale Using CO2 Huff-N-Puff,” in Paper presented at the SPE Argentina Exploration and Production of Unconventional Resources Symposium, SPE191823. doi:10.2118/191823-ms

Valko, P. P. (2009). “Assigning Value to Stimulation in the Barnett Shale: A Simultaneous Analysis of 7000 Plus Production Histories and Well Completion Records,” in Paper prepared for presentation at the 2009 SPE Hydraulic Fracturing Technology Conference, SPE119369.

Yan, J., Fu, Y., Guo, C., Greenwood, J. A., Wang, L., Xianyu, H., et al. (2021). “Implementation of HPHT RSS for Performance Improvement in Deep Shale Gas Drilling,” in Paper presented at the Abu Dhabi International Petroleum Exhibition & Conference, SPE20766. doi:10.2118/207662-ms

Zhang, F., Qiu, F., Fang, Q., Zhang, X., Zhang, H., Tang, F., et al. (2021). “An Accurately Determining Porosity Method from Pulsed-Neutron Element Logging in Unconventional Reservoirs,” in Paper presented at the SPWLA 62nd Annual Logging Symposium, SPE SPWLA-2021-0115. doi:10.30632/spwla-2021-0115

Zhao, W., Hu, S., Hou, L., Yang, T., Li, X., Guo, B., et al. (2020). Types and Resource Potential of continental Shale Oil in China and its Boundary with Tight Oil. Pet. exploration Dev. 47 (1), 1–11. doi:10.1016/s1876-3804(20)60001-5

Zhu, L., Zhang, C., Zhang, C., Guo, C., Jiao, Y., Chen, L., et al. (2018). Calculating the Total Porosity of Shale Reservoirs by Combining Conventional Logging and Elemental Logging to Eliminate the Effects of Gas Saturation. Petro S Journ 59, 162–184. doi:10.30632/pjv59n2-2018a4

Keywords: shale oil, three-dimensional-staggered pattern, small space, EUR, CO2

Citation: Shi G, Fei F, Qin J, Gao Y, Li Y and Xu D (2022) Application, Prospect, and Challenge of Small-Spacing Stereo-Staggered Well Pattern Deployment Technology in the Shale Oil Reservoir. Front. Energy Res. 10:859348. doi: 10.3389/fenrg.2022.859348

Received: 21 January 2022; Accepted: 14 February 2022;

Published: 04 March 2022.

Edited by:

Xun Zhong, Yangtze University, ChinaReviewed by:

Qingbang Meng, China University of Geosciences Wuhan, ChinaGuanglong Sheng, Yangtze University, China

Copyright © 2022 Shi, Fei, Qin, Gao, Li and Xu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Guoxin Shi, shigx@petrochina.com.cn

Guoxin Shi

Guoxin Shi Fanxu Fei2

Fanxu Fei2