95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res. , 24 August 2022

Sec. Carbon Capture, Utilization and Storage

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.826227

This article is part of the Research Topic Negative Emission Technologies View all 7 articles

In our previous work (Part I), we evaluated the thermodynamic models of the biomass-fed integrated gasification solid oxide fuel cell system with a carbon capture and storage (BIGFC/CCS) unit. In this work (Part II), the techno-economic analysis of the proposed negative emission power plants is carried out. Levelized cost of electricity, net present value (NPV), payback period, internal rate of return (IRR), and levelized cost of negative carbon (LCNC) are the key economic parameters evaluated. The results of a series of sensitivity analysis show the impact of gasification agents and stepwise increase in biochar co-production on the performance of the system. The total overnight cost is estimated to be 6197 $/kW and 5567 $/kW for the air and steam-oxygen gasification BIGFC/CCS systems, respectively. Steam-oxygen gasification is found to be more economically beneficial than air gasification one for all of the cases studied. Economically viable biochar co-production cases are identified to ascertain the influence of capital cost, operating cost, biomass cost, plant capacity factor, and tax. Moreover, the effect of the carbon credit scenario on the economic indicators is also reported. The results show that the most effective economic performance from the steam-oxygen gasification case reported an NPV of 3542 M$, an IRR of 24.2%, and a payback period of 3.3 years, with an LCNC of -322.5$/t of CO2. Compiling the results from Part I and Part II shows that it is easier to achieve negative emission using the steam-oxygen gasification of a BIGFC/CCS system. These results are expected to be helpful for stakeholders in identifying appealing negative emissions power plant projects for near and long-term future investments.

Techno-economic analysis to study the effect of biochar co-production in the BIGFC/CCS system is carried out.

The impact of air and steam-oxygen as gasification mediums on the economic performance of the system is investigated.

The effect of step-wise biochar co-production and carbon credit on the techno-economic performance of the system is assessed.

The steam-oxygen gasification system co-producing 10% biochar (by weight) is attractive one from a techno-economic perspective.

Capital costs have the largest effect on the BIGFC/CCS system of any economic factor.

The Paris Conference of the Parties held in April 2016 expressed the need to frame a universal plan to save the world from the danger of climate change due to global warming by limiting the temperature rise to well below 2°C and restricting the rise within 1.5°C above the pre-industrial level [United Nations Framework Convention on Climate Change (UNFCCC), 2016]. Highly efficient negative emission power plants are reported to meet these requirements. There is an urgent need to develop such NETs globally (Marcucci et al., 2019). Various integrated assessment models (IAMs) find that achieving these goals would imply the integration of different NETs, such as enhanced weathering, afforestation and reforestation, direct air capture, soil carbon sequestration, and bioenergy with carbon capture and storage (BECCS) (Schleussner et al., 2016). Due to its larger CO2 removal potential, most IAM models intensively apply BECCS (Van Vuuren et al., 2013). Moreover, BECCS (Child et al., 2019) is expected to be a promising pathway to achieving the negative emissions in the power plant sector.

When biomass is used as fuel in a power plant, it is assumed to be carbon-neutral (as CO2 taken from the atmosphere by the biomass during photosynthesis is released back to the atmosphere upon utilization) (Promes et al., 2015). Based on this assumption of carbon neutrality, biomass-based power plants could be considered carbon-negative when the CO2 released by the power plants is captured and sequestered in a geological formation. This eventually results in the permanent removal of CO2 from the atmosphere (Kraxner et al., 2003; Fuss et al., 2014), effectively attaining an overall negative carbon balance (Möllersten et al., 2003; Möllersten et al., 2004; Fajardy and Dowell, 2017; Mac Dowell and Fajardy, 2017). Biomass specifically is considered a suitable source of renewable energy for electricity generation due to its abundant availability, rapid growth, and its higher potential for development (Favas et al., 2017; Gu et al., 2018). The IEA bioenergy roadmap estimates the growth of bio electricity output to 3,100 TWh by 2050, which in turn requires 510 GW of electricity generation capacity (Electricity from Biomass). It forecasts that 10% of the power output is consumed by CCS in designing a negative emission power plant. Moreover, the global-level contribution of bioelectricity generation is expected to rise by 4.1% by 2035 (Electricity from Biomass; G.A. Department of Industry, 2014).

The gasification process has been identified as an optimal pathway for converting solid biomass into syngas to increase its energy density as well as for producing clean feedstock in power-generation systems (Hosseini et al., 2015). A biomass-integrated gasification combined cycle (BIGCC) has been demonstrated as a potential method of biomass-to-electricity conversion due to its higher electrical efficiency (Bridgwater, 1995; Kam et al., 2009; Ge et al., 2019). The option of combining IGCC with CCS was studied by Sanchez and Kammen (2016), who reported that it has the potential to be a viable solution for introducing the concept of BECCS in the future. This would, in principle, result in a negative-emissions power plant. The significance of achieving negative carbon emissions in IGCC combined with CCS was demonstrated by Rhodes and Keith (2005) using a simple engineering economic model. Klein et al. (2011) reported the role of CCS in Bio IGCC systems in designing a negative carbon emissions power plant.

The syngas produced in the biomass gasifier could also be used as the fuel in a solid oxide fuel cell (SOFC), and such an integrated system improves the performance and reduces the air pollutant emissions in small and medium power plants (Gadsbøll et al., 2017).

Jin et al. (2009) investigated the influence of SOFC integration on BIGCC systems and demonstrated the potential of SOFCs in enhancing the electrical efficiency of BIGCC systems. Integrating SOFC with a CCS unit is another viable option for sustainable development in the future (Wang et al., 2020). The provision of oxy-fuel combustion technology in the CCS unit is highly efficient compared to the pre-combustion method in IGFC power plants (Park et al., 2011a; Park et al., 2011b).

Aditya et al. (Thallam Thattai et al., 2017) adapted the oxy-fuel combustion process with a CCS unit in their redesigned IGFC system which used biomass co-gasification up to 70%. They reported that this system has the potential to achieve negative CO2 emissions for a net electrical exergy efficiency of 44% with a specific CO2 emissions rate of 30 kg/MWh. Moreover, their results indicated that the introduction of fuel cell in the BIGCC/CCS system reduced the total exergy loss due to the partial replacement of combustion with electrochemical oxidation occurring in the SOFC.

The present situation in the world requires a resource-efficient approach to the usage of renewable energy as it has to address various global threats, such as climate change, declining agricultural production, scarcity of water and fertilizer shortage, and the power crisis. Laird (2008) identified the option of producing biochar with bioenergy as an approach to improving the quality of water and soil. Smith (2016) assessed several NETs and showed the potential of negative carbon emissions due to soil carbon sequestration and biochar in addition to land. Moreover, it has been suggested that biochar production could be combined with BECCS to explore the potential of these NETs. Previous investigations (Hansen et al., 2015) explored the potential of gasification systems to produce bioenergy together with biochar and showed that the biochar produced could play a role in its effective soil amendment.

Fryda and Visser (2015) proved that the stability of biochar produced by the gasification process is higher than in pyrolysis. However, very little research (Shackley et al., 2012a; Shackley et al., 2012b; Ahrenfeldt et al., 2013) has been performed regarding the possibility of a combination of syngas and biochar co-production systems, despite the soil amendment characteristic of the biochar.

A techno-economic comparative study conducted by Zang et al. (2018) on four designs of BIGCC systems showed that air-gasified BIGCC systems without CCS can be more competitive than current power plant systems from an economic point of view, taking into account the cost of biomass and CO2 emissions. However, they also showed that the implementation of the CCS system might reduce the cost of the power plant, provided that CO2 tax revenue is raised to $90/ton.

Previous techno-economic investigations have identified the cost of SOFC as the main obstacle to commercializing the SOFC-integrated CCS (Slater et al., 2019). A thermo-economic optimization study performed by Caliandro et al. (2014) on an SOFC-GT hybrid system using woody biomass in small and medium scale applications reported that the cost of SOFC decreased gradually based on its production rate, as follows: $733/kWe for 100 systems/year, $494/kWe for 1,000 systems/year, $451/kWe for 10,000 systems/year, and $433/kWe for 50,000 systems/year.

Sahoo et al. (2019) studied the techno-economic analysis of biochar production from a portable system and calculated the delivered minimum selling price (MSP) per oven-dry metric ton of biochar as $1,044, using the discounted cash flow rate of return method.

Thus, a literature review clearly shows a knowledge gap existing between the role of biochar in negative emission technology (NET) as a part of BECCS and the possibility of biochar co-production in the biomass-based IGFC/GT power plants. To the best of author’s knowledge, the effects of biochar co-production on the techno-economic performance and negative emission potential of the BIGFC/CCS systems have not been reported in the literature.

In continuation of the model-based thermodynamic evaluation of BIGFC/CCS systems equipped with biochar co-production carried out in Part I (Jaiganesh et al., 2022), the specific objective of this Part II is to evaluate its techno-economic viability and, if possible, develop suggestions for economically viable process designs and operations strategies. This analysis is anticipated to contribute to the worldwide dataset on biochar, as reported by the International Biochar Initiative and the European Biochar Certificate (IBI and EBC) (EBC, 2012). Moreover, the effects of carbon credits and levelized cost of negative carbon (LCNC) on the techno-economic performance of the BIGFC/CCS system are studied to indicate the possible influence of negative emission power plants in the future.

The novelty of this work is that, for the first time in the scientific literature, the techno-economic study of biochar co-production in the BIGFC-CCS systems is discussed in relation to the identical techno-economic assumptions for different gasification agents and various proportions of biochar co-production. The important results from the thermodynamic evaluation of such systems, presented in Part I of this series, are given in Supplementary Appendix SA (Jaiganesh et al., 2022).

The significant steps taken in this research work are listed as follows:

1) This article presents a comprehensive techno-economic analysis of a novel process scheme for co-producing biochar in a large-scale BIGFC/CCS system for two different gasification agents, viz., air and steam-oxygen, and the results of the analysis are discussed.

2) A sensitivity analysis is carried out to investigate the effect of step-wise biochar yield on levelized cost of electricity (LCOE), net present value (NPV), payback period, IRR and levelized cost of negative carbon (LCNC). The influence of carbon credit measures on these key economic indicators is also analyzed simultaneously.

3) The variation of the key economic indicators for the different cases of biochar co-production is evaluated to identify the economically viable values of LCOE and LCNC. This analysis is further carried out to investigate the effects of capital cost, operating cost, biomass cost, and plant capacity factor on LCOE.

The simulated results of first law and second law analysis under different operating scenarios of the BIGFC/CCS system using the FORTRAN based software Cycle tempo (van der Stelt et al.) are discussed in Supplementary Appendix SA. These results are used to identify the economic viability of biochar co-production in the BIGFC/CCS systems in this study. The system is assumed to be in steady flow while assessing the mass and energy balances of equipment.

The Gibbs free energy minimization principle is used in the thermodynamic modeling according to which the chemical compositions of bio syngas at the outlet of the gasifier, oxy-combustion chamber, and SOFC internal reforming were evaluated (Asimptote, 2014). It was also assumed that the cell resistance of the SOFC was

Process flow diagrams for air and steam-oxygen gasification based BIGFC/CCS system with biochar co-production are shown in Figures 1, 2, respectively.

Figure 1 illustrates the primary components of the proposed BIGFC/CCS system for air gasification. In this model, the bio syngas is formed in the gasifier as the main product, and the biochar is extracted as a co-product and is stored. The raw syngas is cleaned using a set of high temperature gas cleaning devices in GCU. Cleaned bio syngas is preheated and fed to the SOFC stack, which operates at an average temperature of 900°C, and part of the anode and cathode gas is recycled to maintain the SOFC inlet temperature.

The remaining part of the cathode exit gas is supplied to the ITM, which produces high-purity oxygen from the stream due to a pressure difference across a ceramic membrane. The oxygen-depleted air stream that comes from the cathode outlet is fed into the AE, where it is expanded to produce the power output. The expander outlet stream is fed to the heat recovery unit where the waste heat of the exit stream is utilized for useful purposes before it is fed to the stack.

The fuel gas from the anode outlet and the separated oxygen from the ion transport membrane are fed into the oxy-fuel combustor. Combustion products from this combustor are expanded in a gas turbine to produce power output in a gas turbine. Since the gas turbine exit gas temperature is sufficiently high (about 900°C), a heat recovery steam generation system (HRSG) coupled with a bottoming Rankine cycle is designed to recover a certain amount of heat from the flue gas and convert it into a useful power output.

Then the flue gas (primarily a mixture of CO2 and water vapor) is fed into the CCS unit, in which the water vapor in the gaseous mixture is condensed using a moisture separator. The remaining vapor, a mixture of CO2 and H2O, is extracted to the next stage to capture the CO2. The carbon capture is carried out in three successive stages of intercooling and compression to capture the pure CO2 stream as a supercritical liquid at 30°C and 150 bar.

Figure 2 illustrates the primary components of the proposed BIGFC/CCS system for steam-oxygen gasification case. As in the air gasification, biochar is co-produced along with the bio syngas in the gasifier and then cleaned in GCU. Steam gasification is an allothermal process that requires additional heat, and the system is modified accordingly. A part of the clean syngas is then extracted, preheated, and fed to the SOFC stack. The remaining syngas is fed into the secondary oxy-fuel combustor.

As discussed in air gasification, part of the anode and cathode exit streams are recirculated. The oxygen separated using ITM is partly fed into the gasifier as a gasification agent. The remaining part of the oxygen stream is fed into the primary and secondary oxy combustors. The unutilized syngas from the SOFC is fed into the primary oxy combustor, which reacts with oxygen. The products of combustion from the secondary oxy combustor are fed into the steam generator, where the heat of the gases is used to generate steam, which is circulated through the gasifier to meet its additional heating requirements.

The steam from the gasifier is fed into the heat exchanger, where it recovers heat from the oxygen-depleted air stream flowing from the air expander, and subsequently it is recirculated to the gasifier through the steam generator. The hot flue gas from the steam generator is mixed with the gas coming out of the gas turbine through the primary oxy combustor and is fed into the HRSG and subsequently to CCS as described in the previous case.

The techno-economic analysis of the BIGFC/CCS system is assessed using economic indicators based on the calculation approach developed by NETL (Kristin Gerdes et al., 2011). In the absence of sufficient literature on cost estimates for the BIGFC/CCS systems, we have used estimates of the capital and replacement costs for SOFC systems (DOE/NETL-341/112613 Report, 2014) and ITM (DOE/NETL-2010/1402 Report, 2011) as indicated in NETL reports. The capital cost estimates for the remaining equipment such as gasifier, HRSG, and GCU reported by Zang et al. (2018) for the air and steam-oxygen gasification of BIGCC/CCS systems were scaled according to the present BIGFC/CCS system. The other important economic parameters, such as biomass cost, biochar cost, and biochar handling cost, were derived from the appropriate literature (Sahoo et al., 2019). The cost of selling waste heat recovered from the system is not considered in the present techno-economic study.

Because the current techno-economic analysis of the BIGFC/CCS system is performed based on different sources of literature (Zang et al., 2018; DOE/NETL-341/112613 Report, 2014; DOE/NETL-2010/1402 Report, 2011), the power plant location is assumed to be a generic site. Hence, the soil conditions, specific local issues such as local regulation and accessibility and special seismic location needs are not included in the present study. Because the goal of our economic analysis is only to assess the benefits of research and development in biochar co-production from the BIGFC/CCS systems, risk analysis is not performed in the present study. The cost of biomass and the annual discount rate are assumed to be equal for all of the cases considered in the present study to enable a fair comparison.

The total plant cost calculated using these estimates includes the base erected cost, engineering, procurement, and construction (EPCC) contractor cost and the project as well as process contingencies as reported in (Kristin Gerdes et al., 2011). The process equipment, supporting facilities along with the direct and indirect labor cost estimates, are considered for the calculation of the base erected cost.

The inflation-adjusted discount rate for the annual net cash flow in the present economic analysis is assumed to be 8%, as suggested by Fogarasi and Cormos (2015). The total plant cost and other cost estimates of the present techno-economic study are adjusted to the United States Dollar (based on dollar values in 2021) (Inflationcalculator, 2021).

Total plant cost (TPC) is obtained for the given BIGFC/CCS system by adding the specific plant costs for the major units of these power plants, which are scaled from reference plants by Eq. (1).

where CE is the cost of the equipment,

Table 1 lists the basic economic assumptions of all the BIGFC systems analyzed, which are high-risk investor-owned utility (IOU) projects with a capital expenditure period of 3 years, as reported elsewhere (Kristin Gerdes et al., 2011). Depreciation is applied for 20 years, with a declining balance of 150% on overnight cost estimates. Because the biomass exists in different forms, its heating value and composition are assumed to be as given in Supplementary Appendix SA.

The uncertainty in the cost estimates of various equipment used in the present study ranges between −15% and +30% as reported in NETL (Kristin Gerdes et al., 2011). It is to be noted that the present study is carried out to provide only an indicative economic analysis of biochar co-production in the BIGFC/CCS system to explore its economic viability.

Total overnight cost is a primary economic indicator of a BIGFC/CCS system, which includes total plant cost (TPC) and owner’s costs. The assumptions for calculating the owner’s costs are taken from (Kristin Gerdes et al., 2011; Zang et al., 2018), as illustrated in Table 2.

Because this study compares the techno-economic evaluation of various cases based on the similar set of economic assumptions, the cost estimates for air and steam-oxygen gasification of a BIGFC/CCS system are almost identical. It is also assumed that the various equipment costs referred in different regions are similar. The fixed and variable operating costs are calculated using reference (DOE/NETL-341/112613 Report, 2014) given by NETL 2014.

As discussed in Section 2, the CO2 produced by the system is captured in the CCS unit, and it is transported to a storage site where it is stored permanently in a reservoir. This type of storage helps remove CO2 from the atmosphere. It also requires replanting energy crops as part of the system. It is possible to mix the co-produced biochar (10% by weight) with the soil to improve the properties of the latter and avoid the formation of CO2 that should be captured and stored (Smith, 2016). Hence, the system as a whole can be considered carbon-negative, which earns carbon credit for the proposed power plant (Ghiami et al., 2021).

Kaufman et al. (2020) estimated the range of carbon credit needed in 2030 as 77–124 2018 USD per ton of CO2 to achieve the target of net zero emissions by 2050. Smith et al. (2021) reported that the cost of CO2 transport and storage is generally kept uniform all over the world at $10/ton of CO2, although they found that the cost varied across regions. Hence, we have assumed the same cost in this study to make use of the contemporary results.

LCOE is used in this study to evaluate the present value of the total cost of the BIGFC/CCS system over the assumed lifetime. LCOE can be calculated from the cost of electricity (COE) by multiplying it with the levelization factor (LF), as suggested in the NETL techno-economic analysis report (Kristin Gerdes et al., 2011) and is given by Eq. (2).

where the value of LF is 1.268 for the IOU project (Kristin Gerdes et al., 2011), and the cost of electricity (COE) is calculated using Eq. (3), which indicates the revenue earned by the BIGFC/CCS system divided by the net MW-h for the first year of operation (Kristin Gerdes et al., 2011) on the assumption of escalating the value of COE at the nominal annual rate of 3% assumed in this study.

where CCF is the capital charge factor assumed as 0.111 for three-year high-risk IOU (Kristin Gerdes et al., 2011). TOC indicates the total overnight cost, which is calculated by summing up the total plant cost and other owner’s costs. OC denotes the operating costs, for which the subscripts “var” and “fix” are used to indicate variable and fixed operating costs, respectively. CF is the capacity factor, which is assumed to be 0.85 for all the BIGFC/CCS system (Kristin Gerdes et al., 2011). MWH is the annual net megawatt-hours of the BIGFC/CCS system’s power output at full capacity.

LCNC emissions are used to measure the advantage of applying carbon credits as an economic incentive to the negative emission power plants to attract investors toward the emerging negative emission technologies (NETs). It denotes the breakeven point in terms of the techno economic analysis of a project in BIGFC/CCS systems for which NPV is zero (Cabra l et al., 2019; Cheng et al., 2021), as given in Eq. (4).

where

Pi—revenues generated by selling electricity and biochar,

Mi—operations and maintenance cost,

BMi—biomass feedstock cost, and

Gi—total amount of CO2 sequestered in tons.

Gi is expressed as a negative quantity in the relation, as it represents the amount of CO2 captured by the CCS unit. If LCNC is obtained as a negative quantity, this indicates that the power plant provides net negative CO2 emissions with a revenue-generating capacity.

The techno-economic analysis for the proposed BIGFC/CCS system is based on the thermodynamic analysis of the system for the different operating conditions, as given in Supplementary Appendix SA. The power plant system is modeled for a steady state flow of 20 kg/s. The details of TPC and TOC calculations of each component used in the BIGFC/CCS system for air and steam-oxygen gasification are shown in Table 3. The cost estimates for air and steam-oxygen gasification are calculated using the following scaling technique Eq. (1). Based on the techno-economic assumptions of the present study, economic indicators were determined with respect to the reference case of air and steam-oxygen gasification of the BIGFC/CCS systems without including biochar co-production.

TABLE 3. TPC and TOC calculations for air and steam-oxygen gasification of the BIGFC/CCS system used in the present study.

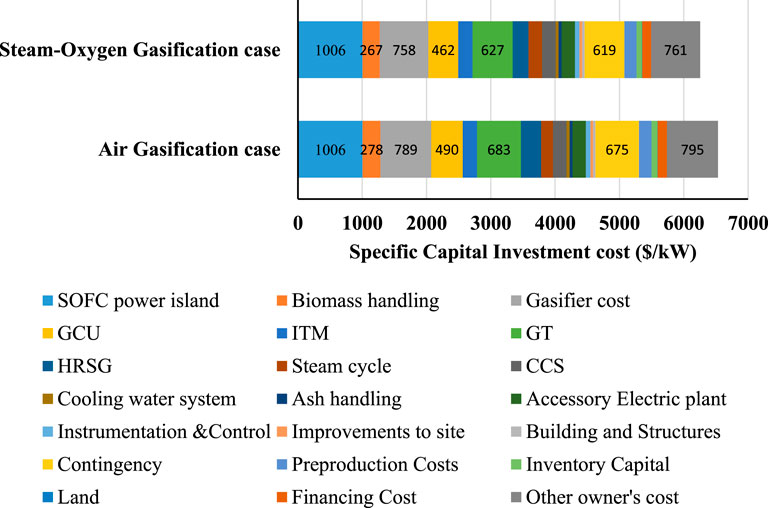

The TOC of steam-oxygen gasification for the BIGFC/CCS system (1,090.4 M$) is 20.4% higher than that of air gasification (868.3 M$) as shown in Table 3. But, at the same time, it could also be inferred from Table 3 that the specific capital investment for air gasification ($6533.7/kW) is higher than that of steam-oxygen gasification ($6254.4/kW) of the BIGFC/CCS system. This could be due to the superior thermodynamic performance of the BIGCC/CCS system for steam-oxygen gasification over air gasification , as reported in the literature (Zang et al., 2018). It is also supported by the current results of the thermodynamic evaluation of air and steam-oxygen gasification of the BIGFC/CCS system discussed in Supplementary Appendix SA. The estimated specific total overnight costs in the present study are in line with the costs reported in the literature ($1,661–7453/kW) (Cormos et al., 2013; Yan et al., 2021). The increase in TOC of the steam-oxygen gasification compared to air gasification can be attributed to the inclusion of secondary oxy-combustors and steam generators.

The specific capital investment cost distribution for the base case air and steam-oxygen gasification BIGFC/CCS system is shown in Figure 3. The cost of the biomass gasifier, gas turbine, and HRSG components make significant contributions to the specific capital investment cost of air gasification compared to steam-oxygen gasification, as shown in Figure 3.

FIGURE 3. The specific capital investment cost distribution in air and steam-oxygen gasification of the BIGFC/CCS system.

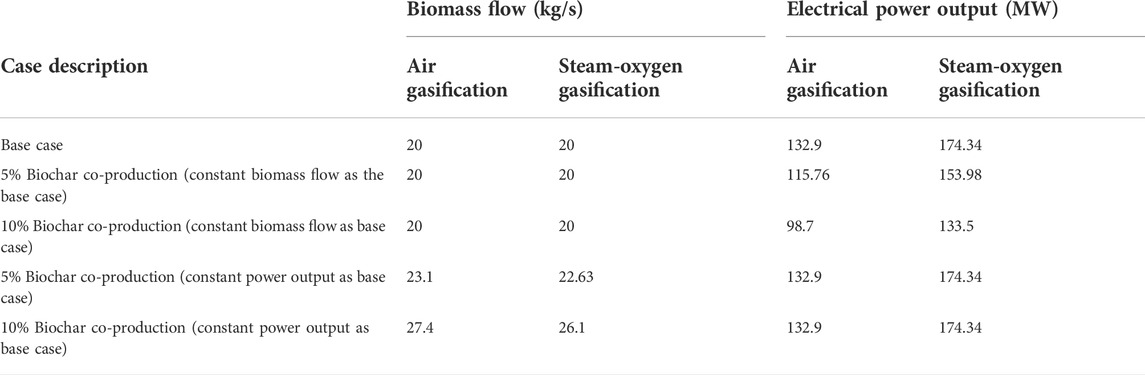

Table 4 shows the different cases of biochar co-production in the BIGFC/CCS system, as discussed in Supplementary Appendix SA; one acts by fixing the base case power output of the air and steam-oxygen gasification and the other by fixing the base case biomass feed of 20 kg/s as constant. As mentioned earlier, the base case corresponds to the performance of the BIGFC/CCS system without including the effect of biochar co-production. The proportion of biochar co-produced in the present study is limited to 10% by weight as the biochar quality is reported to be reasonable up to this limit (Meyer et al., 2011; Yao et al., 2018).

TABLE 4. The description of the various biochar co-production cases considered in the present study of BIGFC/CCS system.

Table 5 shows the COE details of the various cases discussed in the present study. For the base case, steam-oxygen gasification has a lower COE ($140.74/MWh) than that of air gasification ($158.22/MWh). This can be attributed to the fact that steam-oxygen gasification of BIGFC/CCS system has higher thermal efficiency and higher power output than air gasification, as given in Supplementary Appendix SA. Table 6 shows the LCOE estimates of various cases shown in Table 5.

Table 6 shows that the LCOE is increased from $200.6/MWh to $212/MWh for air gasification and from $178.5/MWh to $186/MWh for steam-oxygen gasification with respect to an increase in biochar co-production by up to 10% by weight.

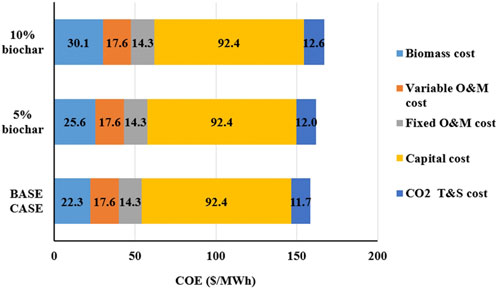

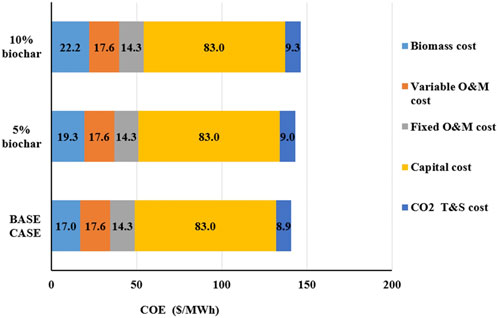

The distribution of various cost components of COE is shown in Figures 4, 5 for air and steam-oxygen gasification, respectively.

FIGURE 4. Distribution of various cost components of COE for a different proportion of biochar co-production in air gasification.

FIGURE 5. Distribution of various cost components of COE for different proportion of biochar co-production in steam-oxygen gasification.

The biomass cost component is separated from the variable cost and shown separately to illustrate its influence on the various operating conditions of the proposed BIGFC/CCS system.

It is clear from Figures 4, 5 that the proportions of the biomass cost component increase with respect to biochar co-production, while other cost components remain the same as those of the base case, except for CO2 The T&S cost component shows a slight increase in its value. this is due to the increase in biomass feed requirements with an increase in the rate of biochar co-production.

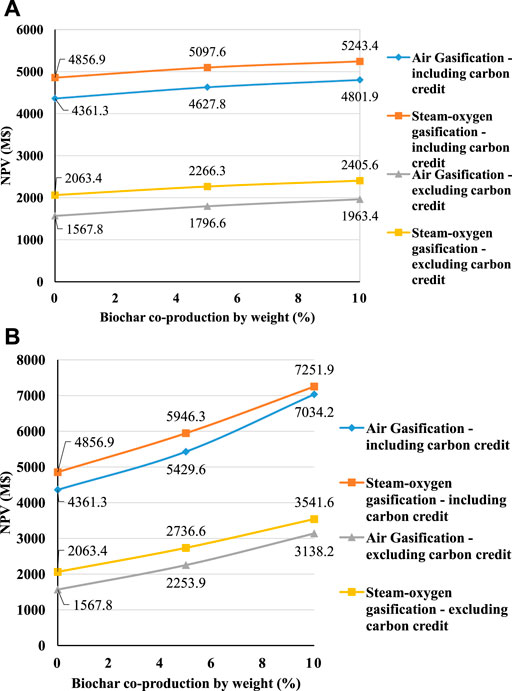

Even though the profit earned by selling the electricity is reduced as a consequence of the reduction in the biomass input to the power system, the NPV increases, as the profit earned by selling the biochar is increased significantly with respect to the increase in biochar co-production, as shown in Figures 6A,B

FIGURE 6. (A) Effect of biochar co-production on NPV for the constant biomass flow—no TAX and with/without considering carbon credit. (B) Effect of biochar co-production on NPV for the constant electrical power—no TAX and with/without considering carbon credit.

Figures 6A,B show the variation of NPV for step-wise biochar co-production (up to 10% by weight) in air gasification and steam-oxygen gasification, respectively.

In air gasification, the NPV increases from 1568 M$ to 1963 M$, whereas for steam-oxygen gasification it increases from 2063 M$ to 2406 M$, without including carbon credit for the constant biomass flow of 20 kg/s, as shown in Figure 6A. The values of NPV obtained for the present study are comparable with those reported for the efficient and inefficient BECCS systems by Mac Dowell and Fajardy (2017) as 2252 M$ and 3038 M$, respectively. When the carbon credit is taken into account, it can be seen that in air gasification the NPV increases from 4361 M$ to 4801 M$, whereas for steam-oxygen gasification it increases from 4856 M$ to 5243 M$ for the constant biomass flow of 20 kg/s, as shown in Figure 6A. A similar trend is noted in Figure 6B, which corresponds to biochar co-production for constant electrical power. It is seen that the NPV for steam-oxygen gasification is higher than that for air gasification for the entire range of step-wise biochar co-production process. Likewise, the inclusion of carbon credit increases NPV significantly. Moreover, the biochar co-production for the constant electrical power in the BIGFC/CCS system provides higher NPV than biochar co-production for the constant biomass flow.

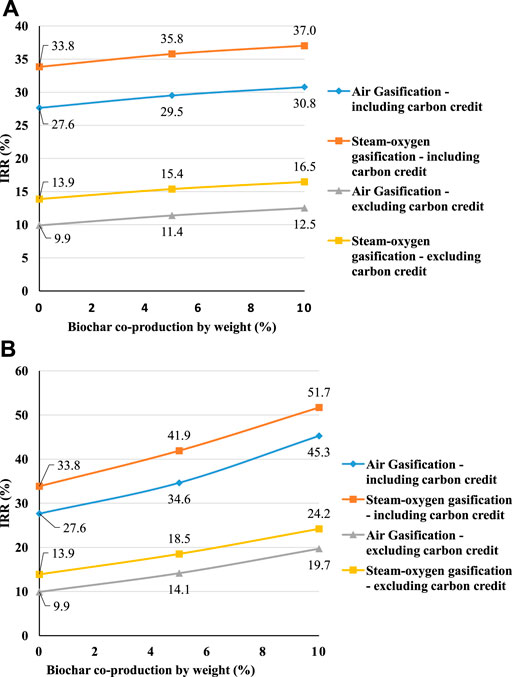

Figure 7A,B shows the variation of IRR for the step-wise biochar co-production (up to 10% by weight) in air gasification and steam-oxygen gasification, respectively. As the biochar co-production increases, IRR also increases, as shown in Figure 7A,B. In air gasification, IRR increases from 9.9% to 12.5%, whereas for steam-oxygen gasification, it increases from 13.9% to 16.5% without including the carbon credit for the constant biomass flow of 20 kg/s, as shown in Figure 7A. The values of IRR obtained in the present study are in range of the reasonable IRR value of 12% reported for any reference BECCS power plants by Mac Dowell and Fajardy (2017). When the carbon credit is taken into account, it could be seen that in air gasification , the NPV increases from 27.6% to 30.8%, whereas for steam-oxygen gasification, it increases from 33.8% to 37%, for the constant biomass flow of 20 kg/s, as shown in Figure 7A. A similar trend is noted in Figure 7B, which corresponds to the biochar co-production for the constant electrical power. Moreover, the IRR values reported in the present study lie in the range reported by Vivek et al. (2013) for biomass-based gasification power systems with and without the subsidy, as 39–52% and 19–26%, respectively. The IRR of steam-oxygen gasification is higher than that of the air gasification for the entire range of step-wise biochar co-production process. It is also noted that the inclusion of carbon credit drastically increases IRR. Moreover, the biochar co-production for the constant electrical power in the BIGFC/CCS system provides higher IRR than biochar co-production for constant biomass flow.

FIGURE 7. (A) Effect of biochar co-production on IRR for the constant biomass flow—no TAX and with/without considering carbon credit. (B) Effect of biochar co-production on IRR for the constant electrical power—no TAX and with/without considering carbon credit.

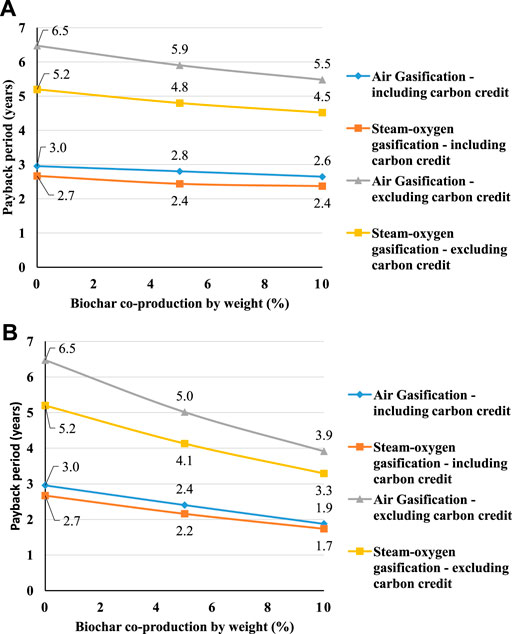

As the biochar co-production increases, the payback period is reduced, as shown in Figure 8A, B. For air gasification, the payback period falls from 6.5 to 5.5 years, whereas for steam-oxygen gasification it falls from 5.2 to 4.5 years without taking into account the carbon credit for the constant biomass flow of 20 kg/s, as shown in Figure 8A. When carbon credit is taken into account, it is seen that in air gasification the payback period falls from 3 to 2.7 years, whereas for steam-oxygen gasification, it falls from 2.7 to 2.4 years for the constant biomass flow of 20 kg/s, as shown in Figure 8A. A similar trend is noted in Figure 8B, which corresponds to the biochar co-production for the constant electrical power. The values of the payback period obtained for this study are comparable with the values reported by Vivek et al. (2013) for the biomass-based gasification power plants with and without the subsidy as 1–2 years of operation and 1–4 years of operation, respectively. The payback period for steam-oxygen gasification is lower than that for air gasification for the entire range of step-wise biochar co-production. Thus, steam-oxygen gasification is to be preferred to air gasification due to its lower payback period for the entire range of operating conditions chosen in the present study. It is also noted that the inclusion of carbon credit reduces the payback period significantly. Moreover, the biochar co-production for the constant electrical power in the BIGFC/CCS system provided a lower payback period than biochar co-production for the constant biomass flow.

FIGURE 8. (A) Effect of biochar co-production on payback period for the constant biomass flow—no TAX and with/without considering carbon credit. (B) Effect of biochar co-production on the payback period for the constant electrical power—no TAX and with/without considering carbon credit.

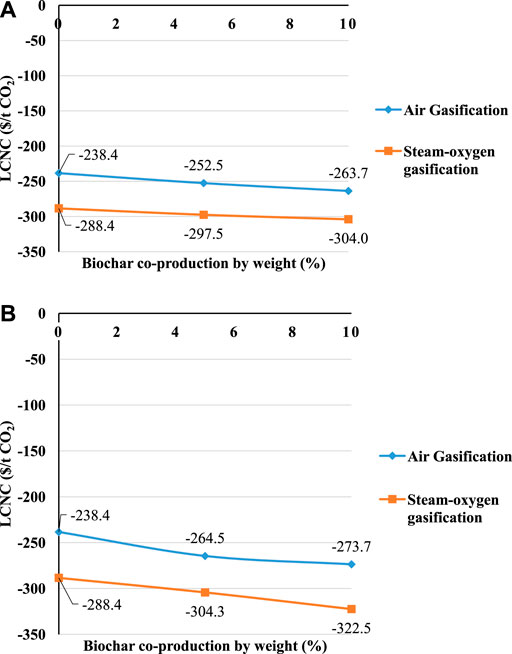

As biochar co-production increases, the LCNC falls, as the amount of negative carbon increased subsequently. as shown in Figure 9A, B. For air gasification, the LCNC falls from −$288.4/t CO2 to −$263.7/t CO2, whereas for steam-oxygen gasification it reduces from −$238.4/t CO2 to −$304/t CO2 for the constant biomass flow of 20 kg/s, as depicted in Figure 9A. The values of LCNC obtained for the present study are within the range of −$30 to −$400/t CO2 as reported by Fuss et al. (2018) on gasification-based BECCS systems. A similar trend is noted in Figure 9B, which corresponds to biochar co-production for the constant electrical power. It is seen that the LCNC of steam-oxygen gasification is lower compared to the air gasification for the entire range of step-wise biochar co-production. Moreover, biochar co-production for the constant electrical power in the BIGFC/CCS system provides lower LCNC than of biochar co-production for the constant biomass flow.

FIGURE 9. (A) Effect of biochar co-production on LCNC for the constant biomass flow—no TAX. (B) Effect of biochar co-production on LCNC for the constant electrical power—no TAX.

It is inferred from these discussions that the 10% biochar co-production case by weight for the constant electrical power in the BIGFC/CCS system yielded economically feasible results relative to other cases. Hence, this particular case is subjected to further sensitivity analysis to test the influence of parameters such as capital cost, operating costs, taxes, etc.

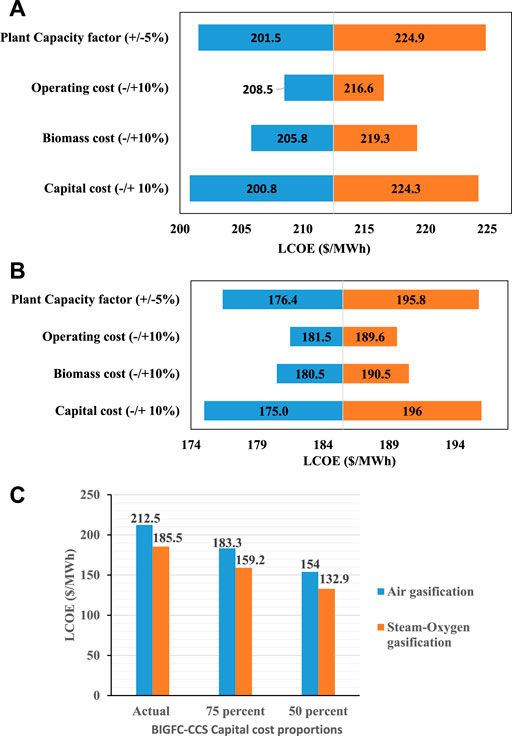

The significance of capital cost, cost of biomass, operating cost, and the plant capacity for the air gasification and steam-oxygen gasification of a BIGFC/CCS system corresponding to the 10% biochar co-production for constant electrical power is presented in Figure 10A, B The capital cost, cost of biomass, and operating cost parameters are analyzed for the range of ± 10%, whereas the plant capacity factor is analyzed for the range of ± 5%. It is noted that the capital cost and plant capacity factors have the highest impact on LCOE, followed by the biomass cost and the operating cost, as shown in Figure 10A,B.

Because capital costs are an important cost component in the sensitivity analysis, the value of LCOE is estimated for the two proportions 75% and 50% of the actual capital cost to take into account the uncertainty involved in finding the capital cost for the air and steam-oxygen 10% biochar co-production cases for constant electrical power, as shown in Figure 10C.

It is indicated in Figure 10C that the LCOE of air and steam-oxygen gasification systems are reduced to $154/MWh and $132/MWh, respectively, when the capital cost is reduced to 50% of the actual cost estimated in the present study. This range of LCOE is in the range of coal-based IGFC systems reported in the literature (DOE/NETL-341/112613 Report, 2014; Lanzini et al., 2014), and it is expected that the cost of emerging technology such as SOFC will fall, which could appreciably reduce the capital costs estimated in the current economic analysis (Caliandro et al., 2014; Slater et al., 2019).

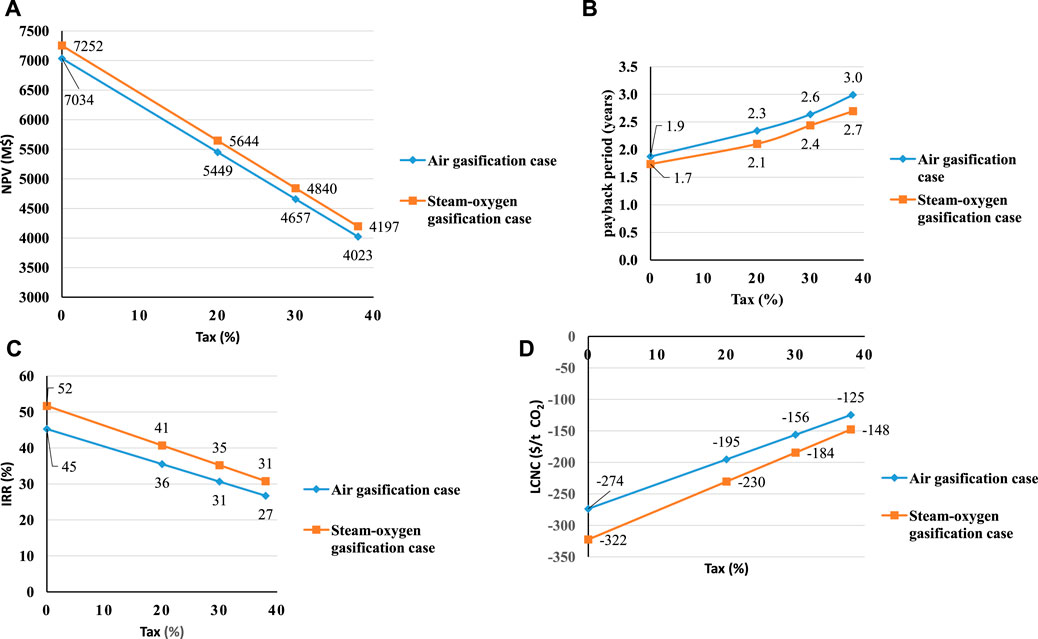

The effects of tax on the chosen economic parameters is shown in Figure 11 for the 10% biochar co-production case for the constant electrical power. The tax ranges were chosen as 20%, 30% and 38% for the present study.

FIGURE 10. (A) Sensitivity analysis for 10% biochar co-production in the air gasification BIGFC/CCS system for the constant electrical power. (B) Sensitivity analysis for 10% biochar co-production in the steam-oxygen gasification BIGFC/CCS system for the constant electrical power. (C) Sensitivity analysis on the capital cost for 10% biochar co-production in the air and steam-oxygen gasification BIGFC/CCS system for constant electrical power.

FIGURE 11. (A) Effect of TAX on NPV for 10% biochar co-production for the constant electrical power. (B) Effect of TAX on IRR for 10% biochar co-production for the constant electrical power. (C) Effect of TAX on the Payback period for the 10% biochar co-production for constant electrical power. (D) Effect of TAX on LCNC for 10% biochar co-production for the constant electrical power.

Figure 11A shows the effect of tax on NPV for the given case. NPV decreases from 7034 M$ to 4023 M$ for the air gasification case by including carbon credit for the constant electrical power. For steam-oxygen gasification, it decreases from 7252 M$ to 4197 M$.

Figure 11B shows the effect of tax on IRR for the given case. The IRR decreases from 45.3% to 26.7% for air gasification, including carbon credit for the constant electrical power. For steam-oxygen gasification, it decreases from 51.7% to 30.8%.

Effects of tax on the payback period for the given case are depicted in Figure 11C. The payback period increases from 1.9 to 3 years for air gasification considering carbon credit for the constant electrical power. For steam-oxygen gasification, it increases from 1.7 to 2.7 years.

Figure 11D illustrates the effects of tax on LCNC for the given case. Taking carbon credit into account, LCNC increases from −$274/t of CO2 to −$125/t of CO2 for the gasification at constant electrical power. For steam-oxygen gasification, it increases from −$322/t of CO2 to −$148/t of CO2.

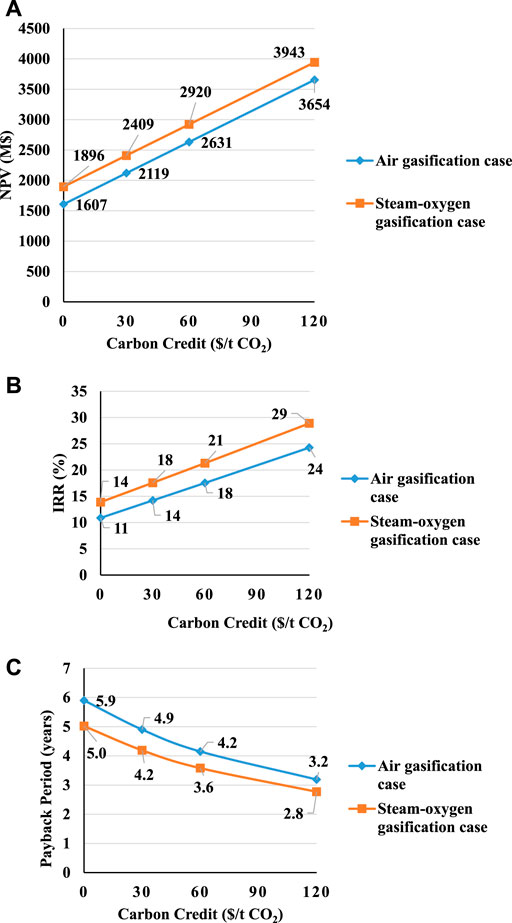

The effect of carbon credit on the chosen economic parameters for the 38% tax is shown in Figure 12 for 10% biochar co-production for the constant electrical power. The carbon credit range is assumed for the present study to be $30/t CO2, $60/t CO2, and $120/t CO2. Figure 12A shows the effect of carbon credit on NPV for the given cases. In air gasification, the NPV increases from 1607 M$ to 3654 M$. For steam-oxygen gasification, it increases from 1896 M$ to 3943 M$, for the corresponding increase in carbon credit up to $120/t CO2 for the constant electrical power, as shown in Figure 12A.

FIGURE 12. (A) Effect of carbon credit on NPV for 10% biochar co-production for the constant electrical power (applying 38% TAX). (B) Effect of carbon credit on IRR for 10% biochar co-production for the constant electrical power (applying 38% TAX). (C) Effect of carbon credit on the payback period for 10% biochar co-production for the constant electrical power (applying 38% TAX).

The influence of carbon credit on IRR for the given cases is shown in Figure 12B. In air gasification, the IRR increases from 14% to 29%, whereas for steam-oxygen gasification , it increases from 11% to 24%; for the corresponding increase in carbon credit up to $120/t CO2 for the constant electrical power, as shown in Figure 12B.

Figure 12C shows the effect of carbon credit on payback period for the given cases. In the air gasification case, the payback period decreases from 5.9 to 3.2 years. For steam-oxygen gasification, it decreases from 5 to 2.8 years, and for the corresponding increase in carbon credit up to $120/t CO2 for the constant electrical power as shown in Figure 12C.

Table 7 shows the comparative study of LCOE estimates of various BECCS systems escalated to 2021 USD in previous works (Lanzini et al., 2014; DOE/NETL-341/112613 Report, 2014; Zang et al., 2018). The LCOE values for economically viable cases found in this study (10% biochar co-production by weight for the constant electrical power) are compared with the recent developments in coal-based IGCC-CCS and IGFC-CCS systems and biomass-based IGCC-CCS systems, as shown in Table 7. It is inferred from the table that the LCOE values estimated for the current BIGFC/CCS systems are in concurrence with the order of other relevant systems. The LCOE of steam-oxygen gasification BIGFC/CCS system is closer to the coal-based IGFC/CCS system developed by NETL studies (DOE/NETL-341/112613 Report, 2014) as given in Table 7.

From this sensitivity analysis, it can be seen that the calculated economic indicators represent significant economic benefits when biochar co-production is included with the BIGFC/CCS system. Moreover, the values of economic indicators are attractive and lie within the reported ranges in the literature (Meyer et al., 2011; Mac Dowell and Fajardy, 2017; Yao et al., 2018).

In this work, a techno-economic analysis is performed to study the effect of biochar co-production in BIGFC/CCS systems in terms of certain economic parameters, such as NPV, IRR, payback period, and LCNC. The important findings of this work are summarized as follows.

1) It is easier to achieve better techno-economic benefits using steam-oxygen gasification in the BIGFC/CCS systems due to its superior thermodynamic performance compared to air gasification.

2) The techno-economic analysis shows that TOC for the air and steam-oxygen gasification based BIGFC/CCS system is $6534/kW and $6254/kW, respectively.

3) Based on the economic analysis performed for the various cases of biochar co-production, it is shown that 10% biochar co-production by weight for a constant electrical power yielded better economic benefits.

4) The LCOE of air and steam-oxygen gasification without biochar co-production is calculated as $200.6/MWh and $178.5/MWh, respectively. The LCOE for the air and steam-oxygen gasification based BIGFC/CCS systems with 10% biochar co-production by weight is increased to $212.5/MWh and $185.5/MWh (for the constant electrical power), respectively. The values of the steam-oxygen gasification BIGFC/CCS system are in line with those of coal-fed IGFC/CCS systems reported in the literature (DOE/NETL-341/112613 Report, 2014).

5) Steam-oxygen gasification brings higher NPV (1896 M$) and higher IRR (14%) along with a reduction in the lower payback period (5 years) when compared to air gasification (corresponding to 38% tax without including carbon credit).

6) The LCNC for the air gasification and steam-oxygen gasification systems (after applying 38% tax) is evaluated as −124.7 $/t CO2 and −147.7 $/t CO2, respectively. This shows that the BIGFC/CCS system could be an economically viable option for setting up negative emissions power plants.

7) Nevertheless, it is also found that the returns from the BIGFC/CCS system are improved when the carbon credit is included in the economic evaluations.

8) It is shown that the capital cost has the largest effect on the LCOE of the BIGFC/CCS system compared to the other factors.

The model based thermodynamic evaluation of process schemes discussed in Part I (Jaiganesh et al., 2022) showed that the steam-oxygen gasification based BIGFC/CCS systems could help in achieving negative emissions with high efficiencies. Furthermore, the results of this work (part 2 in the series) reveal that such systems are also economically viable. Hence, further research is required to develop detailed designs for such power plants in the future.

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

NJ: methodology, formal analysis, investigation, data curation, writing—original draft. P-CK: formal analysis, investigation, writing—review and editing. VC: formal analysis, writing—review and editing. GG: formal analysis, supervision. RK: supervision, writing—review and editing. PA: conceptualization, supervision, writing—review and editing.

The authors would like to thank Chaitanya Joglekar, Energy & Sustainability Research Institute Groningen, RUG, Groningen, for his extensive support in reviewing the manuscript. The author NJ wishes to thank and acknowledge the faculty in the Department of Mechanical Engineering, Amrita Vishwa Vidyapeetham, Amritapuri, India, for their support and fruitful discussions in our research work.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenrg.2022.826227/full#supplementary-material

Ahrenfeldt, J., Thomsen, T. P., Henriksen, U., and Clausen, R. (2013). Biomass gasification cogeneration: A review of state of the art technology and near future perspectives. Appl. Therm. Eng. 50, 1407–1417. doi:10.1016/j.applthermaleng.2011.12.040

Asimptote (2014). Cycle-tempo 5 technical notes. Netherlands: Delft University of Technology. Technical report.

Bridgwater, A. V. (1995). The technical and economic feasibility of biomass gasification for power generation. Fuel 74 (5), 631–653. doi:10.1016/0016-2361(95)00001-l

Cabral, R. P., Bui, M., and Dowell, N. M. (2019). A synergistic approach for the simultaneous decarbonisation of power and industry via bioenergy with carbon capture and storage (BECCS). Int. J. Greenh. Gas Control 87, 221–237. doi:10.1016/j.ijggc.2019.05.020

Caliandro, P., Tock, L., Ensinas, A. V., and Marechal, F. (2014). Thermo-economic optimization of a Solid Oxide Fuel Cell – gas turbine system fuelled with gasified lignocellulosic biomass. Energy Convers. Manag. 85, 764–773. doi:10.1016/j.enconman.2014.02.009

Cheng, F., Small, A. A., and Colosi, L. M. (2021). The levelized cost of negative CO2 emissions from thermochemical conversion of biomass coupled with carbon capture and storage. Energy Convers. Manag. 237, 114115. doi:10.1016/j.enconman.2021.114115

Child, M., Kemfert, C., Bogdanov, D., and Breyer, C. (2019). Flexible electricity generation, grid exchange and storage for the transition to a 100% renewable energy system in Europe. Renew. Energy 139, 80–101. doi:10.1016/j.renene.2019.02.077

Cormos, C. C., Vatopoulos, K., and Tzimas, E. (2013). Assessment of the consumption of water and construction materials in state-of-the-art fossil fuel power generation technologies involving CO2 capture. Energy 51, 37–49. doi:10.1016/j.energy.2012.12.050

DOE/NETL-2010/1402 Report (2011). “Cost and performance baseline for fossil energy plants volume 2,” in Coal to synthetic natural gas and ammonia. c.

DOE/NETL-341/112613 Report (2014). Techno-economic analysis of integrated gasification fuelcell systems.

EBC (2012). European biochar certificate -guidelines for a sustainable production of biochar. Arbaz, Switzerland: European Biochar Foundation EBC. 7043. 10. Version 6.1 of 19th June 2015. Available at: http://www.europeanbiochar.org/en/download.

Electricity from Biomass (2013) “Electricity from biomass: from small to large scale,” in Conjunction with the meeting of the Executive Committee of IEA Bioenergy, Jeju, Korea, November 12, 2013.

Fajardy, M., and Dowell, Mac N. (2017). Can BECCS deliver sustainable and resource efficient negative emissions? Energy Environ. Sci. 10 (6), 1389–1426. doi:10.1039/c7ee00465f

Favas, J., Monteiro, E., and Rouboa, A. (2017). Hydrogen production using plasma gasification with steam injection. Int. J. Hydrogen Energy 1 (1), S0360319917310546.

Fogarasi, S., and Cormos, C. C. (2015). Technico-economic assessment of coal and sawdust co-firing power generation with CO2 capture. J. Clean. Prod. 103, 140–148. doi:10.1016/j.jclepro.2014.07.044

Fryda, L., and Visser, R. (2015). Biochar for soil improvement: Evaluation of biochar from gasification and slow pyrolysis. Agriculture 5 (4), 1076–1115. doi:10.3390/agriculture5041076

Fuss, S., Canadell, J. G., Peters, G. P., Tavoni, M., Andrew, R. M., Ciais, P., et al. (2014). Betting on negative emissions. Nat. Clim. Change 4 (10), 850–853.

Fuss, S., Lamb, W. F., Callaghan, M. W., Hilaire, J., Creutzig, F., Amann, T., et al. (2018). Negative emissions—Part 2: Costs, potentials and side effects. Environ. Res. Lett. 13 (6), 063002. doi:10.1088/1748-9326/aabf9f

G.A. Department of Industry (2014). “Bureau of resources and energy economics,” in Australian energy resource assessment. Geoscience Australia.

Gadsbøll, R., Thomsen, J., Bang-Møller, C., Ahrenfeldt, J., and Henriksen, U. B. (2017). Solid oxide fuel cells powered by biomass gasification for high efficiency power generation. Energy 131, 198–206. doi:10.1016/j.energy.2017.05.044

Ge, H., Zhang, H., Guo, W., Song, T., and Shen, L. (2019). System simulation and experimental verification: biomass-based integrated gasification combined cycle (BIGCC) coupling with chemical looping gasification (CLG) for power generation. Fuel 241, 118–128. doi:10.1016/j.fuel.2018.11.091

Ghiami, S., Khallaghi, N., and Borhani, T. N. (2021). Techno-economic and environmental assessment of staged oxy-co-firing of biomass-derived syngas and natural gas. Energy Convers. Manag. 243, 114410. doi:10.1016/j.enconman.2021.114410

Gu, H., Tang, Y., Yao, J., and Chen, F. (2018). Study on biomass gasification under various operating conditions. J. Energy Inst. 92, 1329–1336. in press. doi:10.1016/j.joei.2018.10.002

Hansen, V., Muller-Stover, D., Ahrenfeldt, J., Holm, J. K., Henriksen, U. B., Hauggaard-Nielsen, H., et al. (2015). Gasification biochar as a valuable by-product for carbon sequestration and soil amendment. Biomass Bioenergy 72, 300–308. doi:10.1016/j.biombioe.2014.10.013

Hosseini, S. E., Wahid, M. A., and Ganjehkaviri, A. (2015). An overview of renewable hydrogen production from thermochemical process of oil palm solid waste in Malaysia. Energy Convers. Manag. 94, 415–429. doi:10.1016/j.enconman.2015.02.012

Inflationcalculator (2021). [Online].Available: https://smartasset.com/investing/inflation-calculator (Accessed Aug 16, 2021).

Jaiganesh, N., Kuo, P-C., Woudstra, T., Ajith Kumar, R., and Aravind, P. V. (2022). Negative emission power plants: Thermodynamic modeling and evaluation of a biomass-based integrated gasification solid oxide fuel cell/gas turbine system for power, heat, and biochar Co-production—Part 1. Front. Energy Res. 10, 803756. doi:10.3389/fenrg.2022.803756

Jin, H., Larson, E. D., and Celik, F. E. (2009). Performance and cost analysis of future, commercially mature gasification-based electric power generation from switch grass. Biofuel. Bioprod. Biorefin. 3 (2), 142–173. doi:10.1002/bbb.138

Kam, M. J. D., Morey, R. V., and Tiffany, D. G. (2009). Biomass integrated gasification combined cycle for heat and power at ethanol plants. Energy Convers. Manag. 50 (7), 1682–1690.

Kaufman, N., Barron, A. R., Krawczyk, W., Marsters, P., and McJeon, H. (2020). A near-term to net zero alternative to the social cost of carbon for setting carbon prices. Nat. Clim. Chang. 10 (11), 1010–1014. doi:10.1038/s41558-020-0880-3

Klein, D., Bauer, N., Bodirsky, B., Dietrich, J. P., and Popp, A. (2011). Bio-igcc with CCS as a long-term mitigation option in a coupled energy-system and land-use model. Energy Procedia 4, 2933–2940. doi:10.1016/j.egypro.2011.02.201

Kraxner, F., Nilsson, S., and Obersteiner, M. (2003). Negative emissions from BioEnergy use, carbon capture and sequestration (BECS)–the case of biomass production by sustainable forest management from semi-natural temperate forests. Biomass Bioenergy 24 (4–5), 285–296. doi:10.1016/s0961-9534(02)00172-1

Kristin Gerdes, K., Summers, W. M., and Wimer, J. (2011). “DOE/NETL-2011/1455 final report august 2011,” in Cost estimation methodology for NETL assessments of power plant performance.

Laird, D. A. (2008). The charcoal vision: a win-win-win scenario for simultaneously producing bio energy, permanently sequestering carbon, while improving soil and water quality. Agron. J. 100, 178. doi:10.2134/agrojnl2007.0161

Lanzini, A., Kreutz, T. G., Martelli, E., and Santarelli, M. (2014). Energy and economic performance of novel integrated gasifier fuelcell (IGFC) cycles with carbon capture. Int. J. Greenh. Gas Control 24, 169–184. doi:10.1016/j.ijggc.2014.04.028

Mac Dowell, N., and Fajardy, M. (2017). Inefficient power generation as an optimal route to negative emissions via BECCS? Environ. Res. Lett. 12 (4), 045004. doi:10.1088/1748-9326/aa67a5

Marcucci, A., Panos, E., Kypreos, S., and Fragkos, P. (2019). Probabilistic assessment of realizing the 1.5°C climate target. Appl. Energy 239, 239–251. doi:10.1016/j.apenergy.2019.01.190

Meyer, S., Glaser, B., and Quicker, P. (2011). Technical, economical, and climate-related aspects of biochar production technologies: A literature review. Environ. Sci. Technol. 45, 9473–9483. doi:10.1021/es201792c

Möllersten, K., Gao, L., Yan, J., and Obersteiner, M. (2004). Efficient energy systems with CO2capture and storage from renewable biomass in pulp and paper mills. Renew. Energy 29 (9), 1583–1598. doi:10.1016/j.renene.2004.01.003

Möllersten, K., Yan, J., and Moreira, J. R. (2003). Potential market niches for biomass energy with CO2 capture and storage – opportunities for energy supply with negative CO2 emissions. Biomass Bioenergy 25 (3), 273–285. doi:10.1016/s0961-9534(03)00013-8

Park, S. K., Ahn, J. H., and Kim, T. S. (2011). Performance evaluation of integrated gasification solid oxide fuel cell/gas turbine systems including carbon dioxide capture. Appl. Energy 88 (9), 2976–2987. doi:10.1016/j.apenergy.2011.03.031

Park, S. K., Kim, T. S., Sohn, J. L., and Lee, Y. D. (2011). An integrated power generation system combining solid oxide fuel cell and oxy-fuel combustion for high performance and CO2 capture. Appl. Energy 88 (4), 1187–1196. doi:10.1016/j.apenergy.2010.10.037

Promes, E. J. O., Woudstra, T., Schoenmakers, L., Oldenbroek, V., ThallamThattaiA, Aravind P. V., and Aravind, P. (2015). Thermodynamic evaluation and experimental validation of 253 MW integrated coal gasification combined cycle power plant in buggenum, Netherlands. Appl. Energy 155, 181–194. doi:10.1016/j.apenergy.2015.05.006

Rhodes, J. S., and Keith, D. W. (2005). Engineering economic analysis of biomass IGCC with carbon capture and storage. Biomass Bioenergy 29 (6), 440–450. doi:10.1016/j.biombioe.2005.06.007

Smith, P. (2016). Soil carbon sequestration and biochar as negative emission technologies. Glob. Chang. Biol. 22, 1315–1324. doi:10.1111/gcb.13178

Sahoo, K., Bilek, E., Bergman, R., and Mani, S. (2019). Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 235, 578–590. doi:10.1016/j.apenergy.2018.10.076

Sanchez, D. L., and Kammen, D. M. (2016). A commercialization strategy for carbon-negative energy. Nat. Energy 1, 15002. doi:10.1038/nenergy.2015.2

Schleussner, C-F., Rogelj, J., Schaeffer, M., Lissner, T., Licker, R., Fischer, E. M., et al. (2016). Science and policy characteristics of the Paris Agreement temperature goal. Nat. Clim. Chang. 6 (9), 827–835. doi:10.1038/nclimate3096

Shackley, S., Carter, S., Knowles, T., Middelink, E., Haefele, S., and Haszeldine, S. (2012). Sustainable gasification–biochar systems? A case-study of rice-husk gasification in Cambodia, Part I: Context, chemical properties, environmental and health and safety issues. Energy Policy 42, 49–58. doi:10.1016/j.enpol.2011.11.026

Shackley, S., Carter, S., Knowles, T., Middelink, E., Haefele, S., Haszeldine, S., et al. (2012). Sustainable gasification–biochar systems? A case-study of rice-husk gasification in Cambodia, Part II: Field trial results, carbon abatement, economic assessment and conclusions. Energy Policy 41, 618–623. doi:10.1016/j.enpol.2011.11.023

Slater, J. D., Chronopoulos, T., Panesar, R. S., Fitzgerald, F. D., and Garcia, M. (2019). Review and techno-economic assessment of fuel cell technologies with CO2 capture. Int. J. Greenh. Gas Control 91, 102818. doi:10.1016/j.ijggc.2019.102818

Smith, E., Morris, J., Kheshgi, H., Teletzke, G., Herzog, H., Paltsev, S., et al. (2021). The cost of CO2 transport and storage in global integrated assessment modeling. Int. J. Greenh. Gas Control 109, 103367. doi:10.1016/j.ijggc.2021.103367

Thallam Thattai, A., Oldenbroek, V., Schoenmakers, L., Woudstra, T., and Aravind, P. V. (2017). Towards retrofitting integrated gasification combined cycle (IGCC) power plants with solid oxide fuel cells (SOFC) and CO2 capture – a thermodynamic case study. Appl. Therm. Eng. 114, 170–185. doi:10.1016/j.applthermaleng.2016.11.167

United Nations Framework Convention on Climate Change (UNFCCC) (2016). Report of the conference of the parties on its twenty-first session, held in Paris from 30 november to 13 december 2015. Available at: http://unfccc.int/resource/docs/2015/cop21/eng/10.pdf.

van der Stelt, T., Woudstra, N., and Colonna, P. Cycle-tempo: a program for thermodynamic model and optimization of energy conversion systems. Netherlands: Delft university of Technology. (The Netherlands). Available at: http://www.asimptote.com.

Van Vuuren, D. P., Deetman, S., van Vliet, J., van den Berg, M., van Ruijven, B. J., Koelbl, B., et al. (2013). The role of negative CO2 emissions for reaching 2 C—insights from integrated assessment modelling. Clim. Change 118 (1), 15–27. doi:10.1007/s10584-012-0680-5

Vivek, K., Uddha, K., Dhiraj, S. K., and Chittaranjan, N. G. (2013). Biomass energy cost and feasibility of gasifier based biomass power generation system. Int J Agric Biol Eng 6 (4), 55–63.

Wang, F., Deng, S., Zhang, H., Wang, J., Zhao, J., Miao, H., et al. (2020). A comprehensive review on high-temperature fuel cells with carbon capture. Appl. Energy 275, 115342. doi:10.1016/j.apenergy.2020.115342

Yan, L., Wang, L., Wang, Z., Cao, Y., and He, B. (2021). Comparison of three biomass-based carbon-negative power generation systems. J. Clean. Prod. 285, 125424. doi:10.1016/j.jclepro.2020.125424

Yao, Z., You, S., Ge, T., and Wang, C. H. (2018). Biomass gasification for syngas and biochar co-production: Energy application and economic evaluation. Appl. Energy 209, 43–55. doi:10.1016/j.apenergy.2017.10.077

Zang, G., Jia, J., Tejasvi, S., Ratner, A., and Lora, E. S. (2018). Techno-economic comparative analysis of biomass integrated gasification combined cycles with and without CO2 capture. Int. J. Greenh. Gas Control 78, 73–84. doi:10.1016/j.ijggc.2018.07.023

AE, air expander; BECCS, bioenergy with carbon capture and sequestration; BIGFC, biomass integrated gasification fuel cell cycle; CCF, capital charge factor; CCS, CO2 capture and storage; CF, capacity factor; COE, cost of electricity; EU, European Union; GHG, greenhouse gas; GT, gas turbine; HHV, higher heating value; HRSG, heat recovery steam generators; IAM, integrated assessment model; IGCC, integrated gasification combined cycle; IOU, investor-owned utility; IRR, internal rate of return; ITM, ion transport membrane; LCNC, levelized cost of negative carbon; LCOE, levelized cost of electricity; LF, levelization factor; NET, negative emission technology; NPV, net present value; SOFC, solid oxide fuel cell; TOC, total overnight cost

Keywords: BIGFC/CCS, biochar co-production, BECCS, LCOE, NPV, IRR, payback period

Citation: Jaiganesh N, Kuo P-C, Champatan V, Gopi G, Kumar RA and Aravind PV (2022) Negative emission power plants: Techno-economic analysis of a biomass-based integrated gasification solid oxide fuel cell/gas turbine system for power, heat, and biochar co-production—part 2. Front. Energy Res. 10:826227. doi: 10.3389/fenrg.2022.826227

Received: 30 November 2021; Accepted: 05 July 2022;

Published: 24 August 2022.

Edited by:

Graeme Douglas Puxty, Energy, Commonwealth Scientific and Industrial Research Organisation (CSIRO), AustraliaReviewed by:

Bheru Lal Salvi, Maharana Pratap University of Agriculture and Technology, IndiaCopyright © 2022 Jaiganesh, Kuo, Champatan, Gopi, Kumar and Aravind. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: P.V. Aravind, QS5QdXJ1c2hvdGhhbWFuVmVsbGF5YW5pQHR1ZGVsZnQubmw=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.