- 1State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development, Beijing, China

- 2School of Petroleum Engineering, China University of Petroleum, Qingdao, China

Introduction

The successful development of shale oil is important to ensure energy security. However, shale oil recovery is typically less than 10%. Supercritical CO2/H2O huff-n-puff is a potential EOR strategy for shale oil development, but it is still in the exploratory stage. Supercritical CO2/H2O huff-n-puff exerts the capacity of two kinds supercritical fluids, and using the same well as an injection well and a production well, which solves the problem of gas channeling in shale oil reservoir after fracturing by conventional gas drive method. This paper provides a brief overview of the advantages, potential, injection method, summarize the problems and future research directions of the new technology in shale oil development, which is of great important for the shale oil reservoir developments.

Proposal of supercritical CO2/H2O huff-n-puff in shale oil reservoirs development

Shale oil is a promising energy source with great potential for development. Shale oil storages in mud shale matrix pores, micro-fractures and thin interlayers of non-source rocks in the occurrence state of free state and dissolved or absorbed state in organic kerogen (Feng et al., 2020; Xu et al., 2022). These characteristics lead to the poor development effect. The movable reserves of shale oil are generally less than 10% under the fracturing conditions of horizontal wells with existing technologies (Hoffman, 2018; Jia et al., 2019). As the low porosity and low permeability, high clay content are key characteristics of shale oil, conventional water injection development is not suitable for shale oil development because of its difficulties in injection, small sweep volume and serious water sensitivity. As the most widely used gas displacement agent, supercritical fluid CO2 has the potential to develop shale oil efficiently. Compared with CH4 and N2, CO2 is more easily miscible with crude oil, increasing the flow capacity of oil and thus improving oil recovery by 5%–25% (He et al., 2022; Jin et al., 2017; Sheng, 2015). Supercritical H2O is a fluid with better performance than supercritical CO2, with higher dissolving capacity, increasing solvent diffusion coefficient ability and better reactivity, which can improve sweep coefficient and oil washing efficiency in the process of oil displacement (Walther and Woodland, 1993; Schaef and McGrail, 2004; Li et al., 2020). Meanwhile, the better dissolving capacity and diffusion performance are beneficial for entering nanopores of organic matter, which has the potential to exploit the adsorption and dissolution oil (Weingärtner and Franck, 2005; Canıaz and Erkey, 2014; Zheng et al., 2020). Therefore, the use of supercritical CO2/H2O mixed fluid to improve shale oil recovery is considered to be a promising technology.

Status of supercritical CO2 huff-n-puff in shale oil reservoirs development

In the past few years, supercritical fluid has been applied in many fields as solvent or reaction medium due to its unique properties. Under supercritical conditions, by controlling the pressure, the reaction environment can be manipulated, which can increase the solubility of supercritical fluid in crude oil, enhance the interphase mass transfer ability, and improve the oil stripping effect and oil displacement efficiency. At present, a large number of experiments and numerical simulation studies have been carried out to improve shale oil recovery by supercritical CO2 (ScCO2) huff-n-puff. Gamadi et al., (2013), Gamadi et al., (2014) found in laboratory core-scale experiments that the use of nitrogen or CO2 huff-n-puff at different injection pressures can increase shale core recovery by approximately 10%–50%. And the effect of enhanced oil recovery relies on injection pressure, huff-n-puff cycles, core size, soaking time and gas injection rate, etc., (Hoffman, 2012; Song and Yang, 2013; Yu and Sheng, 2015; Yu et al., 2016; Zhang, 2016; Li et al., 2017).

Core-scale macroscopic experiments in laboratories have proved that ScCO2 huff-n-puff is an effective method to improve shale oil recovery. Field tests of ScCO2 huff-n-puff EOR were carried out in Bakken formation and Eagle Ford in North America. They all reported this method is effective in some extent. However, the ultimate recovery factor of different types of shale rock samples fluctuates greatly after multiple cycles of huff-n-puff. For most shale oil reservoirs, the minimum miscible pressure (MMP) of CO2 and crude oil is higher than the formation pressure, thus it could not achieve the miscible state, resulting in unsatisfied displacement effect.

The advantages of supercritical H2O injection fluid

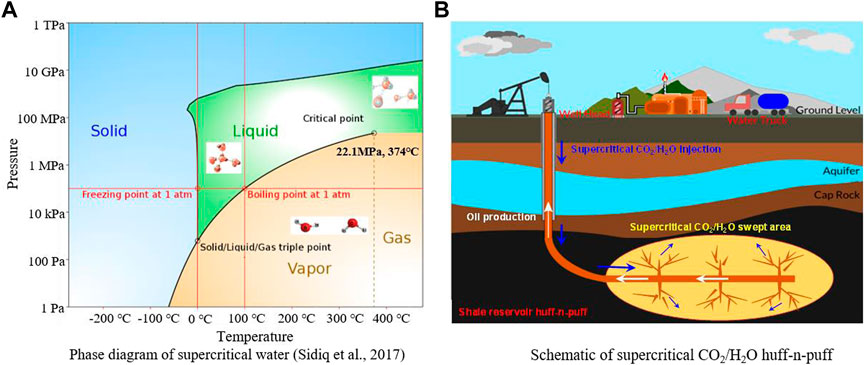

Compared with ScCO2, the properties of supercritical H2O (ScH2O) are more advantageous. As shown in Figure 1A (Sidiq et al., 2017), the condition of ScH2O is that the temperature and pressure exceed the critical point (22.1 MPa, 374°C), at which time the gas-liquid interface disappears and most of the hydrogen bonds are distorted or broken (Zhao et al., 2019). Because of the absence of surface tension, ScH2O can enter micropores and nanopores more easily. And in the vicinity of the critical point, the fluid density increases sharply with the increase of pressure, so that the supercritical fluid has a higher density, which is close to the value of liquid. Water exhibits properties closer to non-polar organic compounds and becomes a good solvent for non-polar substances. It can dissolve many solid or high boiling substances and form a homogeneous phase with organic substances (Adschiri et al., 2011). This feature creates conditions for supercritical water extraction of crude oil.

FIGURE 1. Supercritical CO2/H2O huff-n-puff in shale oil reservoirs. (A) Phase diagram of supercritical water; (B) Schematic of supercritical CO2/H2O huff-n-puff.

The viscosity of supercritical water is only one-10th of that of normal water. The low viscosity makes ScH2O and solute molecules have higher mobility, and solute molecules can easily diffuse in ScH2O (Guo et al., 2015; Zheng et al., 2020). Supercritical fluid can not only be used as reaction medium in chemical reaction, but also directly participate in reaction. Supercritical fluid can change the phase behavior, diffusion rate and solvation effect, homogenize the reaction mixture and increase the diffusion coefficient (Heltai et al., 2002; Yang et al., 2019; Chen et al., 2020), thus controlling the phase separation process and the distribution of products. When ScH2O is used as the reaction medium, its specific physical and chemical properties will affect the progress of the reaction. For example, at 400°C and 35 MPa, the ion product increases to 7 times that of the normal state, which is conducive to the formation of hydrogen bonds. This property can promote the conversion of organic kerogen in shale reservoir and drive oil out of organic matter (Akiya and Savage, 2002; Fauvel et al., 2003).

Therefore, the high dissolving ability, wide diffusivity and strong reactivity of ScH2O can improve the sweep coefficient and displacement efficiency, thereby improving the oil recovery. The flow characteristics of ScH2O in the flow process have an important impact on oil recovery, and the heat transfer process from wellbore to formation is an important factor to be considered in the energy utilization process (Nian et al., 2016; Phuoc et al., 2019; Gao et al., 2021). Because of its higher temperature, better cracking rate and larger heating area, ScH2O flooding shows better effect than hot water flooding and steam flooding (Sun et al., 2018). And in heavy oil production, the operational parameters for supercritical water injection are slightly influencing the reservoir performance, and the influence is negligible as long as a minimum miscible pressure is achieved (Nie, 2021; Ma et al., 2022). As an organic solvent, ScH2O provides a homogeneous environment for the recovery and thermal cracking of heavy oil. In addition, the properties of ScH2O can be adjusted over a wide range of temperatures and pressures, which can not only reduce the viscosity of crude oil as a heat carrier, but also eliminate seepage resistance and carbon loss in thermal recovery as a solvent (Zhao et al., 2018).

Status of supercritical CO2/H2O huff-n-puff in enhancing oil recovery

ScCO2 and ScH2O have great potential for shale oil development. The characteristics of strong mass transfer rate to crude oil, efficient extraction capacity, wide source, easy access of ScCO2, combined with the properties of ScH2O, supercritical CO2/H2O mixed fluid huff-n-puff can give full play to their respective advantages. In the process of supercritical CO2/H2O mixed fluid injection as shown in Figure 1B, the interaction of ScCO2 and ScH2O under supercritical conditions (Deleau et al., 2022), the influence of mixed fluid on pore permeability structure (Liu et al., 2020; Zhou et al., 2020) and mechanical properties (Zhou et al., 2019), the interaction of supercritical CO2/H2O-shale and its influence on shale adsorption characteristics (Yang et al., 2022) and so on, all play important roles in enhancing oil recovery.

Injection methods of supercritical CO2/H2O huff-n-puff

Supercritical CO2/H2O huff-n-puff can be divided into two methods: one is injecting supercritical fluid from the surface; the other one is to inject liquid CO2/H2O from the surface and heated in the bottom of the wellbore to achieve supercritical conditions (Fakher and Imqam, 2020; Gao et al., 2022; Ren et al., 2023). For method one, the percolation heat transfer of supercritical fluid in wellbore and reservoir is very complicated, and it is difficult to maintain the high-temperature and high-pressure (HTHP) environment of ScH2O during transportation. In addition, the mixed fluid is corrosive to the pipe string, so special attention should be paid to the HTHP resistance and corrosion resistance of pipelines in the process of preparation, storage, transportation and injection, which needs advance technology and high requirements for material. For method two, as in situ combustion, electromagnetic heating or microwave heating and other formation heat treatment to improve oil and gas recovery is more and more popular in recent years, these treatment methods can be used to achieve the supercritical temperature of CO2 and H2O. Thus, the complex heat transfer problems and stringent pipeline material requirements of supercritical fluid injection from wellbore to the reservoir can be solved. In this way, method two is more feasible.

The research direction of supercritical CO2/H2O huff-n-puff for shale oil development

Novel laboratory experiments should be designed to study the feasibility of supercritical CO2/H2O huff-n-puff in shale oil recovery. 1) The pore structure and mineral composition before and after the interaction of supercritical CO2/H2O can be studied by combining nuclear magnetic resonance technology, mercury injection method and scanning electron microscopy test. 2) The interaction between supercritical CO2/H2O and crude oil can be obtained by means of HTHP PVT test. 3) Core scale supercritical CO2/H2O huff-n-puff experiments need to be applied to evaluate the EOR performance and the optimization of operation parameters. 4) The biggest limitation of the existing experimental equipment is that it cannot meet the HTHP conditions of ScH2O, and the materials of the experimental equipment should be resistant to HTHP as well as corrosion. Nickel-based alloys have excellent strength and corrosion resistance and can be used for pipeline transportation and ScH2O storage. Therefore, experimental equipment made of nickel-based alloy can be used for indoor HTHP experiments to study the effects of temperature, pressure and injection parameters on the huff and huff effects of supercritical CO2/H2O mixed fluid. 5) It is necessary to design microscopic experiments and combined with molecular simulation technology to explore the competitive adsorption, dissolution, diffusion and displacement processes in microscopic pores during the huff-n-huff process of supercritical CO2/H2O mixed fluid, and quantitatively characterize the mobilization mechanism of crude oil in organic matter and inorganic matter.

Conclusion

In conclusion, the mixed fluid of supercritical CO2/H2O huff-n-puff can give full play to their respective advantages and have great potential for shale oil development. The main challenges of this approach are summarized in detailed below:

1) Whether the supercritical condition of CO2/H2O can be achieved under shale reservoir conditions is the focus of research. Some formation heat treatment methods such as electromagnetic heating can be combined to meet the supercritical state of CO2/H2O.

2) The interaction between supercritical CO2/H2O and shale reservoir is very important for clarifying the mechanism of supercritical CO2/H2O huff-n-huff to improve shale oil recovery. The next step is to quantitatively characterize the effects of the two fluids on rocks and pores by means of various experimental studies.

3) Laboratory core scale experiment is an important method to verify the feasibility of supercritical CO2/H2O mixed fluid huff-n-huff to improve shale oil recovery. Materials should be selected to make experimental apparatus suitable for test conditions.

4) Organic nanopores are developed in shale reservoirs. The next research direction is to determine the quantitative characterization methods of dissolution, displacement, diffusion, competitive adsorption and other processes in microscopic pores in the process of huff-n-huff, and to clarify the influence of supercritical CO2/H2O mixed fluid on organic matter.

Author contributions

In this article, LL: performed the experiments and wrote the draft. XZ: Literature review, Investigation. YS: Supervision, Investigation. MC: Writing-Reviewing and Editing; PX: contributed to the interpretation and discussion of results; JZ: Literature review, wrote the draft.

Acknowledgments

The authors would like to acknowledge financial support from the National Natural Science Foundation of China (No.51904324), Open Fund (G5800-20-ZS-KFGY017) of State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adschiri, T., Lee, Y. W., Goto, M., and Takami, S. (2011). Green materials synthesis with supercritical water. Green Chem. 13 (6), 1380–1390. doi:10.1039/c1gc15158d

Akiya, N., and Savage, P. E. (2002). Roles of water for chemical reactions in high-temperature water. Chem. Rev. 102 (8), 2725–2750. doi:10.1021/cr000668w

Canıaz, R. O., and Erkey, C. (2014). Process intensification for heavy oil upgrading using supercritical water. Chem. Eng. Res. Des. 92 (10), 1845–1863. doi:10.1016/j.cherd.2014.06.007

Chen, L., Liu, D., Zhang, H., and Li, Q. (2020). Theoretical investigations on heat transfer to H2O/CO2 mixtures in supercritical region. Sci. China Technol. Sci. 63 (6), 1018–1024. doi:10.1007/s11431-019-1515-3

Deleau, T., Letourneau, J. J., Camy, S., Aubin, J., and Espitalier, F. (2022). Determination of mass transfer coefficients in high-pressure CO2-H2O flows in microcapillaries using a colorimetric method. Chem. Eng. Sci. 248, 117161. doi:10.1016/j.ces.2021.117161

Fakher, S., and Imqam, A. (2020). Application of carbon dioxide injection in shale oil reservoirs for increasing oil recovery and carbon dioxide storage. Fuel 265, 116944. doi:10.1016/j.fuel.2019.116944

Fauvel, E., Joussot-Dubien, C., Pomier, E., Guichardon, P., Charbit, G., Charbit, F., et al. (2003). Modeling of a porous reactor for supercritical water oxidation by a residence time distribution study. Ind. Eng. Chem. Res. 42 (10), 2122–2130. doi:10.1021/ie0207616

Feng, Q., Xu, S., Xing, X., Zhang, W., and Wang, S. (2020). Advances and challenges in shale oil development: A critical review. Adv. Geo-Energy Res. 4 (4), 406–418. doi:10.46690/ager.2020.04.06

Gamadi, T. D., Sheng, J. J., Soliman, M. Y., Menouar, H., Watson, M. C., and Emadibaladehi, H. (2014). “An experimental study of cyclic CO2 injection to improve shale oil recovery,” in Presented at SPE lmproved Oil Recovery Symposium, Tulsa, 12-16 April. SPE-169142-MS. doi:10.2118/169142-ms

Gao, J., Yao, Y., Wang, D., and Tong, H. (2021). A comprehensive model for simulating supercritical-water flow in a vertical heavy-oil well. SPE J. 26 (06), 4051–4066. doi:10.2118/205496-pa

Gao, Y., Wan, T., Dong, Y., and Li, Y. (2022). Numerical and experimental investigation of production performance of in-situ conversion of shale oil by air injection. Energy Rep. 8, 1099–1112. doi:10.1016/j.egyr.2022.08.174

Guo, L., Jin, H., and Lu, Y. (2015). Supercritical water gasification research and development in China. J. Supercrit. Fluids 96, 144–150. doi:10.1016/j.supflu.2014.09.023

He, L., Jiaping, T., Siwei, M., Dongxu, L., Gang, C., and Yang, G. (2022). Application and prospects of CO2 enhanced oil recovery technology in shale oil reservoir. China Pet. explor. 27 (1), 127. doi:10.3969/j.issn.1672-7703.2022.01.012

Heltai, G., Fehér, B., Percsich, K., Barabás, B., and Fekete, I. (2002). Application of sequential extraction with supercritical CO2, subcritical H2O, and an H2O/CO2 mixture for estimation of environmentally mobile heavy metal fractions in sediments. Anal. Bioanal. Chem. 373 (8), 863–866. doi:10.1007/s00216-002-1388-6

Hoffman, B. T. (2012). “Comparison of various gases for enhanced recovery from shale oil reservoirs,” in SPE 154329, presented at SPE improved oil recovery symposium, Tulsa, OK; April 14-18. doi:10.2118/154329-ms

Hoffman, B. T. (2018). “Huff-N-Puff gas injection pilot projects in the Eagle Ford,” in Presented at the SPE Canada Unconventional Resources Conference, 13-14 March, Calgary, Alberta, Canada. SPE-189816-MS. doi:10.2118/189816-ms

Jia, B., Tsau, J.-S., and Barati, R. (2019). A review of the current progress of CO2 injection EOR and carbon storage in shale oil reservoirs. Fuel 236, 404–427. doi:10.1016/j.fuel.2018.08.103

Jin, L., Hawthorne, S., Sorensen, J., Pekot, L., Kurz, B., Smith, S., et al. (2017). Advancing CO2 enhanced oil recovery and storage in unconventional oil play—experimental studies on bakken shales. Appl. Energy 208, 171–183. doi:10.1016/j.apenergy.2017.10.054

Li, G., Lu, Y., and Glarborg, P. (2020). Development of a detailed kinetic model for hydrogen oxidation in supercritical H2O/CO2 mixtures. Energy fuels. 34 (12), 15379–15388. doi:10.1021/acs.energyfuels.0c01914

Li, L., Zhang, Y., and Sheng, J. J. (2017). Effect of the injection pressure on enhancing oil recovery in shale cores during the CO2 huff-n-puff process when it is above and below the minimum miscibility pressure. Energy fuels. 31 (4), 3856–3867. doi:10.1021/acs.energyfuels.7b00031

Liu, H., Zhu, Z., Patrick, W., Liu, J., Lei, H., and Zhang, L. (2020). Pore-scale numerical simulation of supercritical CO2 migration in porous and fractured media saturated with water. Adv. Geo-Energy Res. 4 (4), 419–434. doi:10.46690/ager.2020.04.07

Ma, H., Yang, Y., and Chen, Z. (2022). Numerical simulation of bitumen recovery via supercritical water injection with in-situ upgrading. Fuel 313, 122708. doi:10.1016/j.fuel.2021.122708

Nian, Y.-L., Cheng, W.-L., Wang, C.-L., and Han, B.-B. (2016). Analysis for formation thermal properties of water injection well from temperature data. Int. J. Therm. Sci. 101, 158–168. doi:10.1016/j.ijthermalsci.2015.11.001

Nie, B. (2021). A comprehensive model for simulating supercritical water flow in a vertical heavy oil well with parallel double tubes. J. Pet. Sci. Eng. 205, 108790. doi:10.1016/j.petrol.2021.108790

Phuoc, T. X., Massoudi, M., Wang, P., and McKoy, M. L. (2019). Heat losses associated with the upward flow of air, water, CO2 in geothermal production wells. Int. J. Heat. Mass Transf. 132, 249–258. doi:10.1016/j.ijheatmasstransfer.2018.11.168

Ren, D., Wang, X., Kou, Z., Wang, S., Wang, H., Wang, X., et al. (2023). Feasibility evaluation of CO2 EOR and storage in tight oil reservoirs: A demonstration project in the ordos basin. Fuel 331, 125652. doi:10.1016/j.fuel.2022.125652

Schaef, H. T., and McGrail, B. P. (2005). Direct measurements of pH and dissolved CO2 in H2O-CO2 brine mixtures to supercritical conditions. Greenh. Gas. Control Technol. 7, 2169–2173. doi:10.1016/B978-008044704-9/50294-9

Sheng, J. J. (2015). Enhanced oil recovery in shale reservoirs by gas injection. J. Nat. Gas. Sci. Eng. 22, 252–259. doi:10.1016/j.jngse.2014.12.002

Sidiq, H., Amin, R., and Kennaird, T. (2017). The study of relative permeability and residual gas saturation at high pressures and high temperatures. Adv. Geo-Energ. Res. 1 (1), 64–68. doi:10.26804/ager.2017.01.06

Song, C., and Yang, D. (2013). “Performance evaluation of CO2 huff-n-puff processes in tight oil formations,” in SPE Unconventional Resources Conference Canada. doi:10.2118/167217-ms

Sun, F., Yao, Y., Li, G., and Li, X. (2018). Numerical simulation of supercritical-water flow in concentric-dual-tubing wells. SPE J. 23, 2188–2201. doi:10.2118/191363-pa

Walther, J. V., and Woodland, A. B. (1993). Experimental determination and interpretation of the solubility of the assemblage microcline, muscovite, and quartz in supercritical H2O. Geochimica cosmochimica acta 57 (11), 2431–2437. doi:10.1016/0016-7037(93)90407-N

Weingärtner, H., and Franck, E. U. (2005). Supercritical water as a solvent. Angew. Chem. Int. Ed. 44 (18), 2672–2692. doi:10.1002/anie.200462468

Xu, Y., Lun, Z., Pan, Z., Wang, H., Zhou, X., Zhao, C., et al. (2022). Occurrence space and state of shale oil: A review. J. Pet. Sci. Eng. 2022, 110183. doi:10.1016/j.petrol.2022.110183

Yang, K., Zhou, J., Xian, X., Jiang, Y., Zhang, C., Lu, Z., et al. (2022). Gas adsorption characteristics changes in shale after supercritical CO2-water exposure at different pressures and temperatures. Fuel 310, 122260. doi:10.1016/j.fuel.2021.122260

Yang, X., Duan, C., Xu, J., Liu, Y., and Cao, B. (2019). A numerical study on the thermal conductivity of H2O/CO2/H2 mixtures in supercritical regions of water for coal supercritical water gasification system. Int. J. Heat Mass Transf. 135, 413–424. doi:10.1016/j.ijheatmasstransfer.2019.01.146

Yu, Y., Li, L., and Sheng, J. J. (2016). “Further discuss the roles of soaking time and pressure depletion rate in gas huff-n-puff process in fractured liquid-rich shale reservoirs,” in SPE-181471-MS paper presented in at the SPE Annual Technical Conference and Exhibition held in Dubai, UAE, 26-28 September 2016. doi:10.2118/181471-ms

Yu, Y., and Sheng, J. J. (2015). “An experimental investigation of the effect of pressure depletion rate on oil recovery from shale cores by cyclic N2 injection,” in SPE 178494 in SPE Unconventional Resources Technology Conference Held in San Antonio, Texas, 20-22 July. doi:10.2118/178494-ms

Zhang, K. (2016). “Experimental and numerical investigation of oil recovery from Bakken formation by miscible CO2 injection,” in Paper SPE 184486 presented at the SPE international Student Paper Contest at the SPE Annual Technical Conference and Exhibition held in Dubai, UAE, 26-28 September 2016. doi:10.2118/184486-stu

Zhao, Q., Guo, L., Huang, Z., Chen, L., Jin, H., and Wang, Y. (2018). Experimental investigation on enhanced oil recovery of extra heavy oil by supercritical water flooding. Energy fuels. 32 (2), 1685–1692. doi:10.1021/acs.energyfuels.7b03839

Zhao, Q., Guo, L., Wang, Y., Jin, H., Chen, L., and Huang, Z. (2019). Enhanced oil recovery and in situ upgrading of heavy oil by supercritical water injection. Energy fuels. 34, 360–367. doi:10.1021/acs.energyfuels.9b03946

Zheng, H., Yu, T., Qu, C., Li, W., and Wang, Y. (2020). Basic characteristics and application progress of supercritical water. IOP Conf. Ser. Earth Environ. Sci. 555, 012036. doi:10.1088/1755-1315/555/1/012036

Zhou, J., Yang, K., Tian, S., Zhou, L., Xian, X., Jiang, Y., et al. (2019). CO2-water-shale interaction induced shale microstructural alteration. Fuel 263, 116642. doi:10.1016/j.fuel.2019.116642

Keywords: supercritical CO2/H2O, huff-n-puff technology, shale oil EOR, injection methods, organic nanopores

Citation: Li L, Zhou X, Su Y, Xiao P, Cui M and Zheng J (2022) Potential and challenges for the new method supercritical CO2/H2O mixed fluid huff-n-puff in shale oil EOR. Front. Energy Res. 10:1041851. doi: 10.3389/fenrg.2022.1041851

Received: 11 September 2022; Accepted: 21 October 2022;

Published: 03 November 2022.

Edited by:

Fuyong Wang, China University of Petroleum, Beijing, ChinaReviewed by:

Hongsheng Wang, Virginia Tech, United StatesYue Xiao, Research Institute of Petroleum Exploration and Development (RIPED), China

Jiawei Tu, New Mexico Institute of Mining and Technology, United States

Copyright © 2022 Li, Zhou, Su, Xiao, Cui and Zheng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Lei Li, bGVpLmxpQHVwYy5lZHUuY24=

Lei Li

Lei Li Xiaomei Zhou

Xiaomei Zhou Yuliang Su1,2

Yuliang Su1,2