- 1Department of Chemical Engineering, University of Bath, Bath, United Kingdom

- 2Department of Chemical Engineering, College of Engineering and Agro-Industrial Technology, University of the Philippines Los Baños, Los Baños, Philippines

- 3Chemical Engineering Department, De La Salle University-Manila, Manila, Philippines

- 4Process Systems Enterprise Ltd., London, United Kingdom

- 5Samsatli Solutions, Ventonlace, Flatwoods Crescent, Bath, United Kingdom

- 6College of Energy, Xiamen University, Xiamen, China

The undeniable environmental ramifications of continued dependence on oil-derived jet fuel have spurred international efforts in the aviation sector toward alternative solutions. Due to the limited options for decarbonization, the successful implementation of bio-aviation fuel is crucial in contributing to the roster of greenhouse gas emissions mitigation strategies for the aviation sector. Since fleet replacement with low-carbon technologies may not be a feasible option, due to the long lifetime and significant capital cost of aircraft, “drop-in” alternatives, which can be used in the engines of existing aircraft in a seamless transition, may be required. This paper presents a detailed analysis of the supply chain components of bio-aviation fuel provision: feedstocks, production pathways, storage, and transport. The economic and environmental performance of different potential bio-feedstocks and technologies are investigated and compared in order to make recommendations on short- and long-term strategies that could be employed internationally. Hydroprocessed esters and fatty acids production pathway, utilizing second-generation oil-seed crops and waste oils, could be an effective immediate solution with the potential for substantial greenhouse gas emissions savings. Microalgal oil could potentially offer far greater yields of bio-aviation fuel and reductions in greenhouse gas emissions, but the technology for large-scale algae cultivation is inadequately mature at present. Fischer-Tropsch production pathway using lignocellulosic biomass has the potential for the highest greenhouse gas emissions savings, which could potentially be the solution within the medium- to long-term plans of the aviation industry, but further research and optimization are required prior to its large-scale implementation due to its limited technological maturity and high capital costs. In practice, the “ideal” feedstocks and technologies of the supply chains are heavily dependent on spatial and temporal criteria. Moreover, many of the parameters investigated are interlinked to each other and the measures that are effective in greenhouse gases emissions reduction are largely associated with increased cost. Hence, policies must be streamlined across the supply chain components that could help in the cost-effective and sustainable deployment of bio-aviation fuel.

Introduction

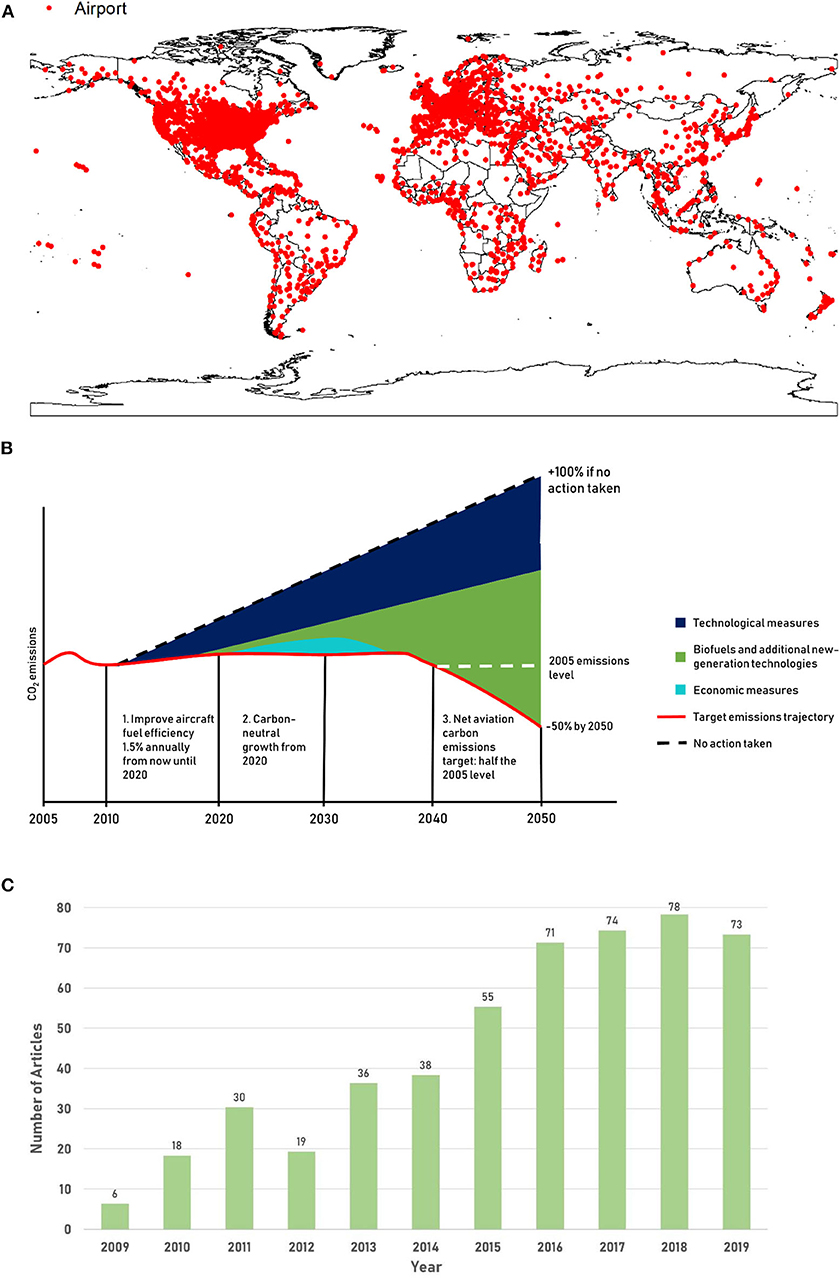

The aviation industry plays a major role in the global economy, serving as a crucial backbone for nearly 57 million jobs and USD 2.2 trillion in global GDP. Businesses, especially those involving international transactions, rely on its speed and efficiency. By 2035, the Air Transport Action Group (ATAG) expects 7.2 billion passengers will be served by the airline industry through the world's major airports as shown in Figure 1A, which is twice the number of passengers in 2016 (ATAG, 2012). Consequently, this surge in aviation demand is projected to result in 3.1 billion tons of GHG emissions by 2050, which is 4 times greater than the 2015 baseline of 0.78 billion tons.

Figure 1. Recent trends for the the aviation industry: (A) Global Airport Distribution (Plotted using data from www.arcgis.com, 2019); (B) Potential global atmospheric CO2 emissions released by the aviation sector under various development conditions (IATA, 2009); and (C) Publication history on bio-aviation fuel research (Plotted using data from Scopus accessed on January 17, 2020).

It is a significant challenge to find a sustainable solution for the aviation industry's GHG emissions reduction due to the ambitious target set at 50% less than the 2005 baseline (IATA, 2009). The International Air Transport Association (IATA) and the International Civil Aviation Organisation (ICAO) developed the four pillars to achieve this goal: (1) technological improvements, (2) operational improvements, (3) measures based on the market, and (4) alternative jet fuel (AJF) (Gutiérrez-Antonio et al., 2013). Figure 1B displays the timeline of the various trajectories based on the actions taken by the industry. Without actions taken, the emissions will be twice as much as the 2005 level.

To date, technological improvements have already begun contributing to the GHG emissions reduction target. Airframe and engine manufacturers have made significant technological leaps including lighter and stronger composite materials than ever before, new innovative aircraft designs with improved aerodynamics and incrementally more efficient engines (Rye et al., 2010). For example, 15 billion liters of fuel, and 80 million tons of CO2, were saved by retro-fitting wing tip devices to the wings of over 5,000 existing aircraft (ATAG, 2019). By also using weight reduction measures on cargo containers, GHG emissions decreased by 10,000 t/year (ATAG, 2014). These improvements allow greater efficiency in mileage and lower fuel consumption during travel. However, the slow incremental changes in already-mature engine technology and the long lifetime (>25 years) of existing fleets point toward AJF as a much faster and potentially more cost effective option to reduce emissions (Bauen et al., 2009). AJF can be easily utilized in existing fleets, hence avoiding large capital costs involved with buying newer models. Biofuel, as an AJF, promises a tremendous cut in GHG emissions and possible achievement of the ambitious target by 2040 as depicted in Figure 1B. Thus, the bulk of the reduction can be attained by replacing conventional jet fuel (CJF) with this alternative.

CJF produced from crude oil is a blend of various kerosene hydrocarbons. The hydrocarbon length of jet fuel is between that of gasoline and diesel. In a classical refinery, shown in Figure S1, jet fuel (or kerosene) is the middle distillate making up to 10% of the crude oil fraction while the majority are gasoline and diesel. Table S1 shows the comparison of the physicochemical properties of gasoline, jet fuel and diesel. As fuel for aviation, jet fuel is preferred over gasoline as it is less volatile and denser; while compared to diesel, jet fuel is lighter and less prone to wax at low temperatures (Yang et al., 2019). An AJF should have physical and chemical properties similar to CJF. A suitable aviation fuel must have high cold stability, for temperatures −47 to 40°C and elevations above 30,000 feet and have sufficient energy density to supply the high energy demand of long-haul flights (The Engineering ToolBox, 2003; Wilbrand, 2018). The industry uses two major kerosene-based CJF: Jet A and Jet A-1. With a lower melting point of −4oC, Jet A-1 is the better choice for international flights. The desirable composition of a jet fuel should be 75–85 vol% consisting of paraffins, iso-paraffins, and cycloparaffins and the remaining 15–25 vol% of olefins and aromatics. Other important characteristics include global availability, acceptable costs, good combustion characteristics, and good flow behavior. Hence, AJF being a “drop-in” fuel can be easily integrated into existing infrastructure allowing a seamless transition (Rye et al., 2010). An AJF must also have lower carbon footprints over their life cycle than CJF, which typically have a carbon footprint of roughly four tons per ton of fuel (de Jong et al., 2017a).

Bio-aviation fuel (also known as bio-jet fuel, renewable jet fuel or aviation biofuel in some literature) or BAF (for short in this paper), a type of biofuel for the air transport sector, is recognized as a short- to medium-term solution toward an overall reduction of the sector's GHG emissions. Table S2 shows the standard specifications for both CJF and BAF, with which manufacturers must strictly comply (Wilbrand, 2018; Yang et al., 2019). Clearly, the resulting emissions profiles of an aircraft running on BAF would be very similar to one on Jet A-1 (Rye et al., 2010). But the closed carbon cycle established by sequestering atmospheric CO2 during biomass growth and released at the end of its life cycle as BAF, results in its significantly lower overall carbon emissions compared to CJF (Bosch et al., 2017). While this makes BAF an attractive AJF option, several issues arose in its implementation. It has not been receiving sufficient investments due to inadequate government support and industry commitment, unreliable supply of feedstocks, uncertain commerciality of the production pathways, and lack of supply chain certification (Gegg et al., 2014).

Figure 1C presents recent bibliometric trends for bio-aviation fuel research. The data were obtained from Scopus using the keywords: bio-jet fuel, biojet fuel, bio-aviation fuel, aviation biofuel, or renewable jet fuel. In the last 10 years, there is generally an increasing trend in research on BAF, which reflects increasing recognition of the need to decarbonize the aviation sector through AJF options. Recent reviews of BAF considered the progress and issues in the production pathways (Gutiérrez-Antonio et al., 2017) and of fuel performance (Yang et al., 2019). Reimer and Zheng (2017) discussed possible strategies for enabling commercial BAF uptake, such as the simultaneous implementation of taxes on CJF and incentives for BAF utilization. The possibility of BAF production from different feedstocks, such as microalgae (Bwapwa et al., 2018), lignocellulosic biomass (Cheng and Brewer, 2017), urban and agricultural wastes (Jiménez-Díaz et al., 2017), and vegetable oils (Vásquez et al., 2017) have also been discussed in recent review papers. Kandaramath Hari et al. (2015) presented production pathways utilizing second- and third-generation feedstocks with qualitative discussion on the feedstock. These studies provided insights on the status and future direction of the bio-aviation fuel industry. However, existing review papers are limited to individual components of the supply chain for BAF provision (e.g., raw materials, pretreatment, and conversion technologies) and there are currently no reviews discussing logistics strategies (e.g., storage and transportation of resources) or the economic and environmental analysis of the whole supply chain. Therefore, this review paper addresses this gap by being the first to provide a critical review of bio-aviation fuel from a whole-system supply chain perspective.

The focus of this review paper is on bio-aviation fuel examined holistically of its supply chain components: feedstock, production pathways, storage and transport. This review is organized into six sections. The next section gives an overview of bio-aviation fuel. The section on feedstocks for biomass-derived synthetic paraffinic kerosene is a comprehensive discussion of key feedstocks, which includes their cultivation requirements, supply chain models and economic and environmental impacts. The three most prominent production technologies are compared in the section of production pathways for synthetic paraffinic kerosene, in terms of their advantages and limitations, as well as their economic and environmental impacts. The storage and transport technologies for raw materials, intermediates, and final jet fuel product are discussed in the section on storage and transport of feedstocks and bio-aviation fuel. The penultimate section offers critical analyses, recommendations and future direction of each supply chain component. The key conclusions of this review paper are found in the final section.

Bio-aviation Fuel

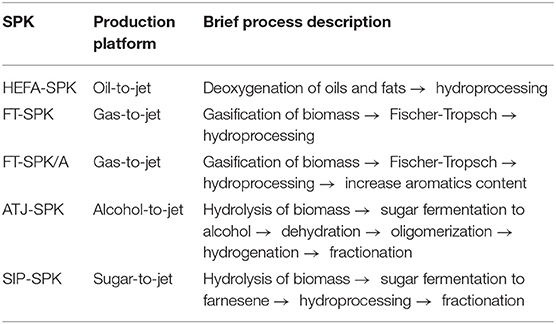

Bio-aviation fuel is a biomass-derived synthesized paraffinic kerosene (SPK) that is blended into conventionally petroleum-derived jet fuel (Yang et al., 2019). Table 1 presents the five types of SPK for blending (in specified volume fraction) with CJF as certified in ASTM D7566-19a (Table S2). The production platforms with their brief process description under which these SPK are classified are also presented in Table 1. The hydroprocessed esters and fatty acids production pathway (HEFA), an oil-to-jet production platform, produces HEFA-SPK via the deoxygenation of oils and fats followed by hydroprocessing (Yang et al., 2019). Hydrothermal liquefaction of plant or algal oil and fast pyrolysis of cellulose followed by jet fuel upgrading are also other oil-to-jet platforms (Wang and Tao, 2016). The gas-to-jet platform involves the gasification of biomass to produce syngas, which is converted to paraffinic and olefinic hydrocarbons by the Fischer-Tropsch production pathway (FT) and, subsequently, hydroprocessed to produce FT-SPK. FT-SPK/A can also be produced by gas-to-jet platform but with the addition of alkylated and bio-based aromatics (Yang et al., 2019). In the alcohol-to-jet production platform or pathway (ATJ), biomass are hydrolyzed to produce fermentable sugars, the sugars are fermented to produce alcohols, and then they are dehydrated, oligomerized, hydrogenated and fractionated to produce ATJ-SPK (Yang et al., 2019). The sugar-to-jet production platform or direct sugar-to-hydrocarbon jet fuel synthesis (DSCH) involves the hydrolysis of fermentable sugars from biomass, the fermentation of these sugars to farnesene the hydroprocessing of farnesene and fractionation to produce SIP-SPK (Yang et al., 2019). Catalytic reforming of sugar or sugar intermediates via chemical or biochemical process followed by upgrading to jet fuel via aqueous phase reforming and direct sugar to hydrocarbons are other sugar-to-jet platforms (Wang and Tao, 2016).

Table 1. Five types of synthetic paraffinic kerosene based on the production platform (Wang and Tao, 2016; Yang et al., 2019).

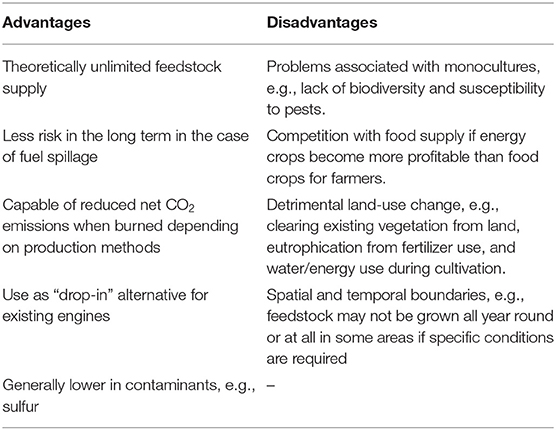

A summary of the advantages and disadvantages of BAF is presented in Table 2, but to ensure that it is truly an environmentally-friendly alternative, emissions savings are required over all phases of production: extraction, refining and transport. Energy security, price stability, and job creation are added potential gains that can be reaped. Rural development in terms of augmented employment in farming and production and increased productivity of non-arable marginal land can be expected with the deployment of bio-aviation fuel. Despite its economic benefits, deployment has not been receiving sufficient investment (Gegg et al., 2014). Hendricks et al. (2011) added that investments in the form of subsidies and legislative support are needed by the production pathways in order for them to become economically competitive against crude refinery production.

Table 2. Advantages and disadvantages of bio-aviation fuel (Rye et al., 2010; Hendricks et al., 2011; Gegg et al., 2014; Bosch et al., 2017; de Jong et al., 2017a).

The challenges faced by BAF are similar to those of biofuels, in general: the main one being how to ensure that the feedstocks, which come from biomass or other carbon-based sources, are secure, sustainable, economically viable, and sufficiently available within both time and location of demands (Hendricks et al., 2011; Su et al., 2015). With the aviation industry along with the sectors of heating, chemicals, road transport, and electricity, exerting efforts to decouple from fossil fuel dependence by shifting to biomass, their demands for the same feedstocks create a new supply competition (de Jong et al., 2017c). The following sections discuss the feedstocks and critically analyse their cultivation requirements, feasibility and sustainability of their supply chains, and their economic, and environmental performance. The discussions are focused specifically on feedstocks for bio-aviation fuel production but many of the issues also apply to production of biofuels in general since they share the same feedstocks.

Feedstocks for Biomass-Derived Synthetic Paraffinic Kerosene

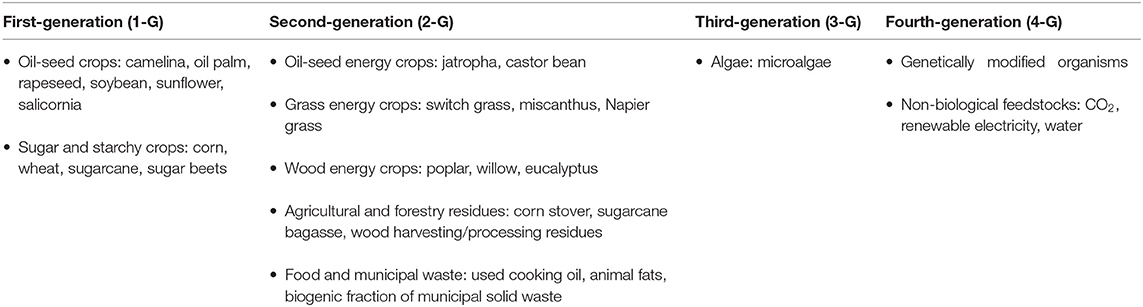

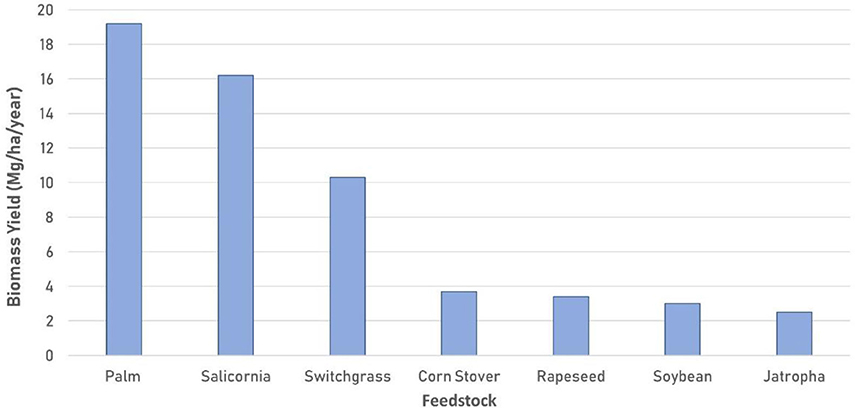

Feedstocks can be categorized as follows: first-generation (1-G), second-generation (2-G), third-generation (3-G), and fourth-generation (4-G). Table 3 presents some examples for BAF production in each category. An important factor in choosing a feedstock is its availability. For cultivated feedstocks, their availability, and potential yield are interrelated. Figure 2 shows the potential yields for a number of 1-G and 2-G feedstocks. Oil palm has the highest yield at 19.2 t/ha/year among these feedstocks. For 3-G feedstocks, the potential yield for microalgae has been reported to be much higher at 91 t/ha/year but there is uncertainty in this value due to algae cultivation being mostly from lab- to pilot-scale (Bwapwa et al., 2018).

Table 3. Feedstocks for bio-aviation fuel production (Rye et al., 2010; Warshay et al., 2011; Kandaramath Hari et al., 2015; ATAG, 2017; Chiaramonti Horta and Nogueira, 2017; Rödl, 2018; Roth et al., 2018; Staples et al., 2018; Alalwan et al., 2019).

Figure 2. Typical potential yields of some 1-G and 2-G feedstocks for BAF production (Plotted using data from Stratton et al., 2010).

First-Generation Feedstocks

Edible food crops, such as oil palm, corn, sugarcane, sugar beets, and wheat, belong to 1-G category (Lee and Lavoi, 2013). Sugar, starch, fat, and/or oil contents are extracted from these crops. Fats or oils can be easily converted to jet fuel through the well-established HEFA. Sugar or starch can be processed by the emerging DSCH technology. ATJ is another emerging technology, which is of high interest to the USA for their excess supply of 1-G ethanol from corn (Radich, 2015). While corn uses water efficiently, the sheer volume to be cultivated will result in high water demand and increased fertilizer use. Ramping up cultivation can strain a country's water resources and cause water-related issues like shortages and eutrophication. These are the main drawbacks in choosing 1-G feedstocks since most food crops typically have high water and nutrient demands (Table 4). Another main challenge of 1-G feedstock production is competition for land, water, and energy inputs with food production (Moioli et al., 2018). To circumvent scarcity of land resources, expansion to forestland has been the convenient option but at the expense of deforestation and biodiversity loss (Keles et al., 2018). Oil palm cultivation, a well-established food crop and promising BAF feedstock, has been linked to these adverse consequences (Vijay et al., 2016; Khatun et al., 2017).

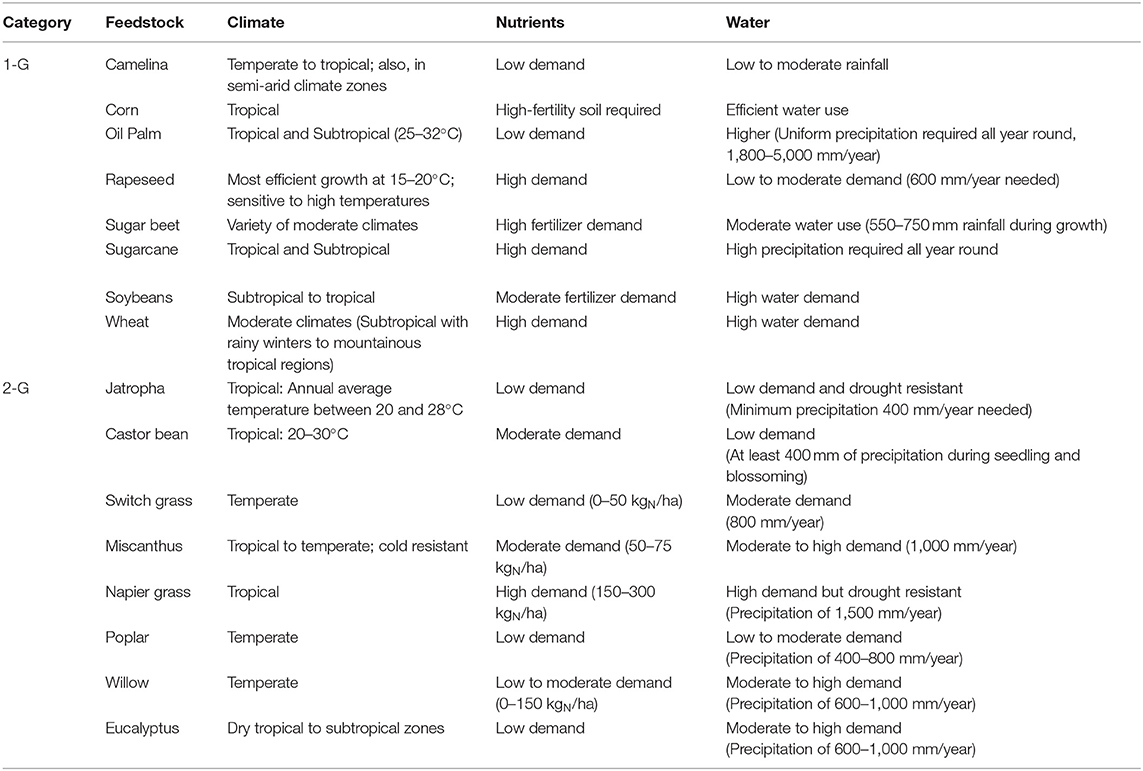

Table 4. Comparison of the cultivation requirements of various 1-G and 2-G feedstocks (Escobar et al., 2009; Hickman et al., 2010; Fazio and Barbanti, 2014; Searle and Malins, 2014; Curneen and Gill, 2016; Surian Ganba et al., 2016; Liu W. et al., 2017; Campbell, 2018; Fabio and Smart, 2018; Fischer et al., 2018; Rödl, 2018).

Oil Palm

To date, HEFA is the only renewable jet fuel technology implemented industrially (Roth et al., 2018). Feedstock cost accounts for a significant fraction in the total production costs (Bosch et al., 2017). Palm oil can potentially offset the high cost of hydrogen in the HEFA being the least cost vegetable oil. Thus, there is a growing interest in oil palm as feedstock for bio-aviation fuel production (Schoneveld, 2010; Ernsting, 2017). Oil palm cultivation is an attractive business with relatively low nutrient demand, as shown in Table 4. Natural precipitation can also substantially satisfy the high-water requirements of plantations, which are mostly located in tropical and subtropical countries. Currently, Malaysia and Indonesia are at the forefront of palm oil production that supply more than 80% of the global demand driven mainly by food industries (Schoneveld, 2010). As the competing industry, biodiesel production is a recent growing demand for palm oil due to its higher energy output per unit energy input compared to other edible oils (Ail and Dasappa, 2016; Pirker et al., 2016).

Globally, oil palm plantations have already expanded by about 12 million hectares between 2000 and 2012 in large portions of tropical forests in Malaysia and Indonesia (Pirker et al., 2016). When either primary or secondary forests are converted to plantations, biodiversity loss has been well-associated with it (Koh and Wilcove, 2008). Rich concentrations of birds and mammals are highly at risk to extinction in the vulnerable forests of Southeast Asia, South America, Mesoamerica, and Africa (Vijay et al., 2016). Oil palm expansion is also well-associated with the degradation of peatlands. Instead of acting as carbon sinks, peatlands become net GHG emitters after their conversion to agricultural lands. Plantations in Southeast Asia, that were once peatlands, were estimated to have surface GHG emissions of 54 to 115 tCO2eq/ha/yr (Page et al., 2011). In palm oil mills, waste management of palm oil mill effluent (POME) is the main issue. Raw POME has a high biochemical oxygen demand (>25,000 mg/L) and large volumes are generated yearly (Madaki and Seng, 2013). In 2015 alone, 60.88 and 94.76 million tons were generated in Malaysia and Indonesia, respectively (Choong et al., 2018). Due to high treatment costs, discharging of raw or partially treated POME to land or water bodies continues as an industry practice resulting in large-scale water pollution and ecosystem degradation (Madaki and Seng, 2013).

For oil palm to become a “good” feedstock option for bio-aviation fuel production, sustainable practices in the cultivation and processing phases must be implemented. Selection of suitable available land through ecosystem service mapping can improve plantation sustainability as expansion to forestlands, land-use conversion of peatlands, and/or disruption to the environment can all be avoided. Optimal agronomic practices to maximize oil yield and minimize resource inputs can also reduce the negative impacts of plantations (Khatun et al., 2017). Improvements in sustainability of palm oil mills will need capital investments on biological treatment methods. These will not only eliminate POME but will also yield higher value products, which include fertilizers, livestock feeds, and biogas (Wu et al., 2009). To lower overall costs, the use of ultrasonic and membrane technology as an integrated system is a solution with good economic potential for biogas production (Abdurahman and Azhari, 2018). It has been recommended that mills are equipped with biogas capture to reduce overall GHG emissions by about 30% and improve biofuel net energy yield (Kaewmai et al., 2012; Harsono et al., 2014).

Current consumption of land transport biofuels and the resulting benefits of rural development and employment has already expanded the role of supply chains of 1-G crops, like oil palm, from food feed and fiber provision to fuel provision (KPMG International, 2013; Sims et al., 2015). However, the growing demand for food-based biofuels has been linked to rising global food prices and food supply imbalances (KPMG International, 2013; Oladosu and Msangi, 2013; Buchspies and Kaltschmitt, 2018). In the case of oil palm, the gap between supply and demand is expected to widen further in the future (Khatun et al., 2017). Hence, the inclusion of BAF production to the supply chain agenda of oil palm could further increase the complexity and challenges (KPMG International, 2013). In this arena, mathematical modeling and optimization techniques can aid in comprehending and formulating strategies for the needed transformation of future food supply chains that can sustainably provide food and non-food commodities simultaneously (FAO, 2014; Zhu et al., 2018). For example, Tapia and Samsatli (2020) developed an optimisation model for multi-product oil palm supply chains that ensures sustainable land and water use and biodiversity protection. It may be technically feasible to integrate BAF production with food production from 1-G feedstocks but the policies and management have to be systematically assessed and sustainably implemented (Sims et al., 2015).

Second-Generation Feedstocks

Non-edible 2-G biomass resources can circumvent the food vs. fuel dilemma of 1-G feedstocks (Alalwan et al., 2019). These are classified into two main groups: energy crops and waste biomass. Waste biomass is further categorized into agricultural and forestry residues and food and municipal wastes. Regardless of the classification, 2-G feedstocks are either oil- or sugar-rich materials. However, in contrast to 1-G crops, the sugars of 2-G feedstocks are trapped in the tough and recalcitrant lignocellulosic matrix of plant cell walls that need pretreatment with enzymes/microorganisms and/or thermochemical transformations for biofuel conversion (Boichenko et al., 2013; Lee and Lavoi, 2013). The technical barriers and high costs of these conversion technologies are the main issues of 2-G feedstocks utilization (Alalwan et al., 2019). However, the relatively high abundance and low use competition of lignocellulosic 2-G feedstocks make them a promising alternative to 1-G crops (Rödl, 2018; Correa et al., 2019). Waste biomass utilization also offers far greater benefits, such as realization of circular economies, waste management, and environmental protection (Ahorsu et al., 2018; Richter et al., 2018). To date, production of biodiesel and bioethanol for land transport from 2-G feedstocks still lags behind 1-G feedstocks (Su et al., 2015). For land transport, Millinger et al. (2017) predicted in the long-term that liquid biofuels from 1-G feedstocks will be more cost-competitive than those from 2-G feedstocks, while gaseous biofuels derived from 2-G feedstocks for gas-powered vehicles is seen to be the more cost- and resource-effective option in the medium-term. Nevertheless, liquid biofuels from 2-G feedstocks may become more important for the aviation sector, where gaseous fuels are not feasible (Millinger et al., 2017). However, the supply of 2-G feedstocks must be proven adequate, stable, and affordable. In the following subsections, various 2-G feedstocks for BAF production are reviewed from this perspective.

Energy Crops

Oil-seed energy crops, like jatropha (Jatropha curcas) and castor bean (Ricinus communis), have no food value, as their oils are toxic for human consumption (Shahare et al., 2017; Molefe et al., 2019). The oil content of jatropha and castor bean is typically 30–40 and 50–60% of the seed weight, respectively (Tao et al., 2017; Heinrich, 2018). Transesterification, catalytic cracking (pyrolysis) or hydroprocessing can process castor bean oil to produce BAF (Molefe et al., 2019). The hydrocracking of oils from castor bean and jatropha for enhanced BAF production has been recommended by Molefe et al. (2019). Compared to castor bean, available literature shows jatropha as the more widely studied energy crop (Rye et al., 2010; Güell et al., 2012; Roda et al., 2015; Chiaramonti Horta and Nogueira, 2017; Heinrich, 2018; Neuling and Kaltschmitt, 2018; Yang et al., 2019). There have been both test and commercial flights using jatropha-blended jet fuel (Su et al., 2015; Chiaramonti Horta and Nogueira, 2017). Currently, markets of jatropha and castor bean as BAF feedstocks are not yet mature (Tao et al., 2017).

Several grass and wood energy crops have been proposed as 2-G feedstocks for BAF production via thermochemical and/or biochemical routes (Kandaramath Hari et al., 2015). The high lignocellulose content and readily available harvesting technologies make grass energy crops attractive for biofuel production (Herr et al., 2012). Rödl (2018) identified the following grasses:

• Switch grass is a perennial crop native to North America with an average annual yield of 12 t/ha/yr (Jacobson, 2013b; Rödl, 2018). It has a highly promising techno-economic and environmental performance as feedstock (Warshay et al., 2011). Experimental studies have been conducted for its conversion to BAF through fast pyrolysis-hydrotreating route (Howe et al., 2015), coal- and biomass-to-liquid hydrocarbon process (Folkedahl et al., 2011); and bio-based hydrocarbons production pathways (Sinha et al., 2015; Frederix et al., 2016). Techno-economic analysis reveals a break-even price of USD 1/L (or USD 5/gal) for ATJ fuel from switch grass (Yao et al., 2017); while life cycle assessment (LCA) shows that BAF from switch grass has lower emissions than from fossil sources (Agusdinata et al., 2011). No literature can be found reporting any large-scale production and/or test flights of switch grass-derived BAF.

• Miscanthus is a family of perennial plants from its native origins in Asia and Africa brought to Europe as a garden plant (Rödl, 2018). The species, Miscanthus x giganteus, is of great research interest due to its high productivity with an average annual yield of 25 t/ha/yr (Jacobson, 2013a; McIsaac, 2014). Miscanthus has been shown to have greater bioenergy potential than switch grass, based on studies in USA and Europe (Scagline-Mellor et al., 2018). Despite several studies demonstrating viable production of jet fuel precursors like syngas (Jayaraman and Gökalp, 2015; Couto et al., 2017; Dupuis et al., 2019), pyrolysis oil (Conrad et al., 2019; Wang and Lee, 2019), and ethanol (Lee and Kuan, 2015; Boakye-Boaten et al., 2017; Lask et al., 2019), there is little to no systematic literature focusing on the conversion of miscanthus to BAF. Nevertheless, there have been proposed demonstration facilities for the production of miscanthus-derived jet fuel (Ondrey, 2012; BBI International, 2018).

• Napier grass or elephant grass (Pennisetum purpureum) is a perennial grass from the tropics with reported high yields of 20–140 t/ha/yr (Fontoura et al., 2015; Chang et al., 2017; Lamb et al., 2018; Rödl, 2018). It is a promising feedstock for the production of both solid and liquid biofuels (Fontoura et al., 2015; Lamb et al., 2018). However, little to no literature is available for systematic study of its conversion to BAF. Research to date has been on the production of jet fuel precursors, such as syngas (Khezri et al., 2019; Mohammed et al., 2019), pyrolysis oil (Suntivarakorn et al., 2018; Mohammed et al., 2019), and alcohols (Camesasca et al., 2015; He et al., 2017). Napier grass cultivation in Southeastern USA is highly considered as BAF feedstock via ATJ (United States Department of Agriculture - Research, 2012; Anderson, 2016).

Compared to grasses, woods have higher biomass availability per area and lower logistics costs that could make them a better feedstock option (Murphy et al., 2015). Woody energy crops for biofuel production are usually short rotation coppices. These are fast growing trees that within a cycle or rotation (<10 years) are coppiced/planted and then harvested (Murphy et al., 2015; Rödl, 2018). Moreover, short rotation coppices can supplement low supply of grass energy crops during drought periods (Murphy et al., 2015). Rödl (2018) has also identified the following short rotation coppices as BAF feedstock produced at near intensive agro-industrial scale:

• Poplar (Populus spp.) is a family of temperate perennial trees that is also cultivable in warmer regions (Fazio and Barbanti, 2014; Searle and Malins, 2014; Rödl, 2018). Globally, 70 nations grow poplar, with 91% in natural forests and the remainder in plantations, with an average annual yield of 9 t/ha (Ball et al., 2005; Rödl, 2018). Although it is mainly utilized for paper and timber production, poplar utilization for bioenergy is gaining traction among European countries (Ball et al., 2005). With the underlying reason for product diversification and expansion, poplar is a promising BAF feedstock (Crawford et al., 2016). Recent studies confirmed that poplar-derived hydrocarbons via pyrolysis and fermentation could be upgraded to jet fuel by hydrogenation (Crawford et al., 2016; Zhang et al., 2016). No literature can be found regarding test flights running on jet fuel derived from poplar.

• Willow (Salix spp.) is a genus of perennial flowering trees that grow from temperate to boreal regions with annual yields ranging in 4–10 t/ha (Searle and Malins, 2014; Rödl, 2018). About 94, 6, and 1% of willows worldwide grow in natural forests, plantations, and agro-forestry systems, respectively. Wood production is the main application of willows (Ball et al., 2005). Its application for heat and electricity production is a growing trend among Northern hemisphere nations (Sassner et al., 2006; Woytiuk et al., 2017). Several experimental studies demonstrated willows as a viable source of jet fuel precursors, which include alcohols (Sassner et al., 2006; Han et al., 2013), syngas (Giudicianni et al., 2017; Woytiuk et al., 2017), and pyrolysis oil (Giudicianni et al., 2017; Miettinen et al., 2017). Despite these, no literature can be found on systematic studies of BAF production from willows.

• Eucalyptus (Eucalytpus spp.) is a group of fast-growing trees originating from Australia (Gonzalez et al., 2011b; Searle and Malins, 2014; Rödl, 2018). Plantations cover more than 20 million hectares worldwide with an average productivity of 10 t/ha annually (Ferreira et al., 2019). Intensive cultivation is driven primarily by paper and biomass demands (Gonzalez et al., 2011b; Surian Ganba et al., 2016). Bioenergy applications of eucalyptus is a growing sector in many parts of the world (Gonzalez et al., 2011c; De Jesus Eufrade Junior et al., 2016). In terms of BAF production, eucalyptus has been shown to be a promising feedstock in Brazil (Cantarella et al., 2015). Techno-economic assessments show that the ethanol-to-jet fuel production pathway is more favorable than the butanol-to-jet fuel route but both are currently not cost competitive alternatives (Silva Braz and Pinto Mariano, 2018). Initial assessment of integrating BAF production from eucalyptus in Brazilian sugarcane biorefineries also show a favorable economic and environmental performance (Klein et al., 2018). No references can be found on test flights running on eucalyptus-derived jet fuel.

Table 4 presents resource demands for cultivating the energy crops that were discussed. In contrast to 1-G feedstocks, energy crops typically (except for Napier grass) have low to moderate demand for fertilizers. Thus, their cultivation in non-fertile and non-food productive marginal lands has been the main recommendation (Murphy et al., 2015; Callegari et al., 2019; Lask et al., 2019). Dependent on the type of land-use change (LUC), energy crops grown and farming practices, cultivation in degraded or abandoned land may improve biodiversity by providing opportunities for habitat (Pedroli et al., 2013). The cultivation in metal-contaminated marginal lands can also lead to phytoremediation (Ruttens et al., 2011; Pandey et al., 2016; Zalesny et al., 2019). The clean-up of highly saline and polluted agricultural soils with halophyte energy crops (e.g., Salicornia bigelovii) is another promising ecosystem service (Abideen et al., 2014). However, there are several drawbacks of cultivation in marginal lands. Marginal lands may have poor water access and supply that may be detrimental to water-intensive energy crops (Yan et al., 2018; Jiang et al., 2019). While some energy crops, like jatropha and Napier grass, could be argued as water-use efficient or even drought resistant, their yields are better with irrigation, which is highly recommended for farming in marginal lands (von Maltitz et al., 2014; Wani et al., 2016; Lamb et al., 2018). Hence, energy crops may indirectly compete with food production via water consumption. Marginal lands typically also have low agro-economic performance. Growing energy crops in these lands may be high in cost and result in lower yields (Searle and Malins, 2014; Jiang et al., 2019). Often, commercial biomass developers opt for highly productive lands that give better returns on investment. Therefore, energy crops have a high risk of competing with food production for suitable lands and of expanding into forestlands (Schoneveld, 2010; Keles et al., 2018). Clearly, inclusion of energy crops in the portfolio of BAF feedstock requires optimal land-use for truly genuinely available and suitable marginal land (Schoneveld, 2010; Popp et al., 2014).

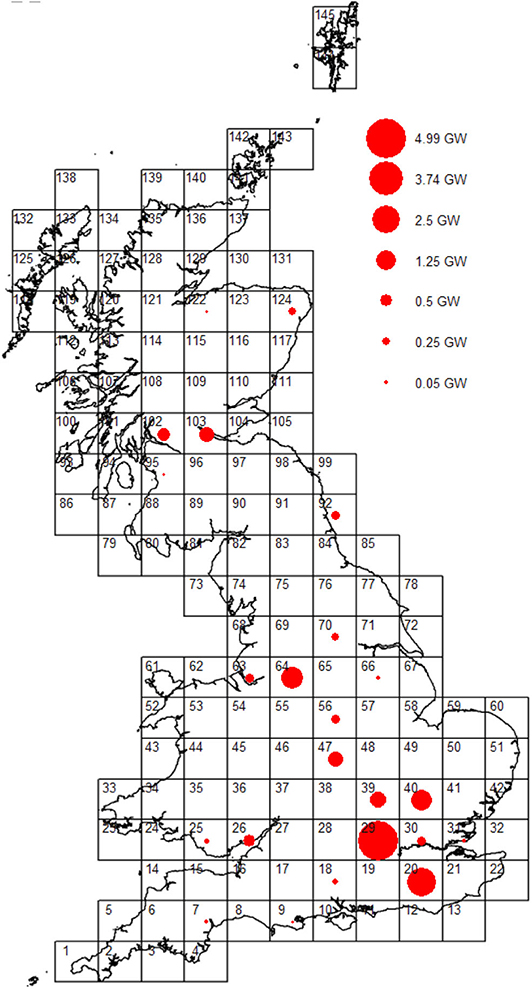

The high economic costs associated hinder the commercialization of most lignocellulosic feedstocks (Correa et al., 2019). Hence, actual supply chains have yet to be fully realized. Notwithstanding, mathematical modeling and optimization techniques have been applied to model these supply chains. Potential minimization of costs within the agricultural, transport, and industrial activities of the supply chain has been shown (Atashbar et al., 2016, 2018). To date, a few modeling studies have been published on energy crop supply chains for BAF provision. Perkis and Tyner (2018) presented a sequential start-up model, based on mixed-integer non-linear programming, with the aim of minimizing the production and logistics costs of jet fuel from switch grass in Indiana, USA. Domínguez-García et al. (2017) developed a multi-objective mixed-integer linear programming (MILP) model to plan strategically a cellulosic aviation fuel industry in Mexico. The model considers bio- and fossil-resources, biomass farming sites, and processing technologies (including hydrogen production) in the minimization of cost and CO2 emissions of the supply chain. Samsatli et al. (2015) formulated a novel MILP for the Biomass Value Chain Model (BVCM) for the UK, which can comprehensively model a large variety of bioenergy system pathways including BAF production from energy crops. This model is also a flexible optimization toolkit that can account economic and environmental impacts. Samsatli and Samsatli (2018b) presented an optimisation model for the combined supply chains for biomass and wind energy to meet demands for services in the heat, power and mobility sectors. A general MILP model was also proposed by Samsatli and Samsatli (2018a) for designing energy supply networks of eco-towns using biomass. The cost optimization feature in these supply chain studies is important in demonstrating the cost-competitiveness and attractiveness to investors of an energy crops-based BAF business (Martinkus et al., 2018). However, a full-scale implementation of energy crops for jet fuel production would not only entail economic impacts. Both impacts on and synergies with food (land), water, energy, and environment sectors are expected that are not typically assessed and analyzed holistically in most biomass supply chain models (Tapia et al., 2019).

Waste Biomass

Waste biomass could be better feedstocks over energy crops as they have no land requirement (as they are co-produced from activities in agro-forestry, domestic, commercial, and industrial sectors), little to no economic value, and lower water footprints than cultivated crops (Caicedo et al., 2016; Chiaramonti Horta and Nogueira, 2017; Mathioudakis et al., 2017; Rödl, 2018). Given the low-cost of most waste biomass, BAF developers have been rapidly considering these as feedstock (Mawhood et al., 2016; Barbosa, 2017; Wenger and Stern, 2019). BAF production from waste streams could be a superior option given that the energy requirements and emissions associated with cultivation only need to be accounted for once. If the amount of resources used for purifying and upgrading wastes into jet fuel is less than that for cultivated feedstocks, wastes will prove to be a more cost-effective option for the aviation industry's emissions reduction.

The first group of waste biomass come in the form of many agricultural and forestry residues. These are typically lignocellulosic by-products resulting from cultivation, harvesting, logging, and post-harvest activities (e.g., milling, crushing, wood processing etc.) (Dornack et al., 2018; Staples et al., 2018). Primary and secondary agricultural or crop residues include corn stover, sugarcane bagasse, wheat straw, rice straw, rice hull, palm kernel, and empty fruit bunches. On the other hand, primary and secondary forestry residues include unprocessed portions of felled trees (e.g., leaves, stumps, branches, and treetops), wood pulp, wood chips, scrap wood, cutter shavings, and saw dust (de Corato et al., 2018; Dornack et al., 2018). Technologies to convert these lignocellulosic wastes into jet fuel precursors, such as syngas, pyrolysis oil, ethanol and butanol, are already available (de Corato et al., 2018; Huzir et al., 2018; Pandiyan et al., 2019; Schmitt et al., 2019). There have been initiatives reported of BAF derived from agro-forestry residues via isobutanol-to-jet and direct sugar-to-farsenene routes (AviationPros, 2015; Green Car Congress, 2016; Chiaramonti Horta and Nogueira, 2017).

Systematic studies focusing on the production of BAF from agricultural and forestry residues are still few. Xue et al. (2017) presented a rational process design of integrating acetone-butanol-ethanol production from corn stover and their successive catalytic conversion (76% efficiency) to long chain ketones as jet fuel precursors. The economic and environmental analysis of Agusdinata et al. (2011) showed corn stover as BAF feedstock with least total unit cost and GHG emissions in meeting the GHG emissions reduction of USA's aviation industry by 2050 but it can only compete in the short-term when CJF prices are high. LCA by Trivedi et al. (2015) confirmed that corn stover-based BAF via FT and advance fermentation have lower GHG emissions than CJF at 87 and 55%, respectively. Sugarcane bagasse, produced at 200 million tons annually, can be a significant feedstock for the production of biofuels for both road and air transport via established thermochemical production pathways like gasification and pyrolysis (Nicodème et al., 2018). Michailos (2018) conducted a techno-economic and life cycle analysis of BAF (farnesane) production from sugarcane bagasse via direct sugar to hydrocarbon route. With a low yield of 12.1% w/w fuel per sugarcane bagasse, the minimum jet fuel selling price (MJSP) would be USD2018 2.78/L (4 times greater than CJF) suggesting government subsidies will be needed; while 49% reduction in GHG emissions against CJF would be expected indicating a favorable sustainability potential. Roda et al. (2015) assessed the available crop residues for BAF production in Malaysia, an agricultural and developing country, to a maximum of 3.8 million liters per year from the waste streams of oil palm, rubber, sugarcane, coconut, and rice industries. Although the quantity of oil palm residues is highest in Malaysia, the associated environmental concerns of its cultivation constraints its sustainable availability. There are also oil-rich agro-forestry residues that can be potential BAF feedstocks. Rice bran, a by-product of rice milling and annually produced at 75 million t/year, contains 10–20% w/w oil (Sharif et al., 2014; Nguyen et al., 2019). Nguyen et al. (2019) designed a transesterification process in the presence of Ni(II)-Schiff base chelate promoter catalyst and H2 gas environment to convert rice bran oil to a biodiesel product with even better cetane index values and lower glycerol impurities than the conventional biodiesel. The hydrotreatment of rice bran oil in the presence of NiMo/Al2O3 catalyst has also been performed yielding fuel products with similar to enhanced properties than petroleum ones (El Khatib et al., 2018). Alternatively, eucalyptus leaves can also be a source of high-octane oil, which has a potential biofuel application for road and aviation transport (Kainer and Kulheim, 2016; Masimalai and Subramaniyan, 2017). Due to yearlong production of forestry residues, they can be more preferable BAF feedstocks than crop residues (Richter et al., 2018). Shah et al. (2019) showed that upgraded pyrolysis oil from sawdust of eucalyptus blended with waste cooking oil has similar physico-chemical characteristics to aviation kerosene. Alves et al. (2017) also found that ethanol-to-jet production pathway is a favorable techno-economic design for BAF production from eucalyptus residues in Brazil. Ganguly et al. (2018) also conducted a well-to-wake (WTW) LCA of BAF production from mild bisulfite pretreated forestry residues via butanol-to-jet production pathway that revealed a 78% reduction in global warming impact compared to CJF.

Food and municipal wastes are the second group of waste biomass that can be considered as feedstocks for BAF production. According to de Corato et al. (2018) and Dornack et al. (2018), this group consists of the following:

• Animal and fish farming wastes (e.g., manure, excreta, scales, scraps);

• Food processing wastes (e.g., de-oiled seed meals/cakes, exhausted pulps, slaughterhouse wastes, feathers, animal fats);

• Industry and commercial processing wastes from beer, wine, baking, dairy, and cheese industries;

• Household/urban wastes (used cooking oil or UCO, used engine oils, kitchen wastes, spent coffee grounds, and tea bags);

• Spoiled (unmarketable) vegetables, fruits, meat, bread, cheese, and other by-products;

• Landscape management wastes (e.g., pruning, branches, twigs, leaves, flowers);

• Biomass/organic portion of municipal solid waste (MSW); and

• Biomass/organic portion of sewage sludge.

In the aviation industry, low cost UCO (waste cooking oil in some literature) is currently the only waste stream of practical use due to HEFA (Roth et al., 2018). The hydrotreating process of UCO is also continually being improved, such as development of a one-pot reaction, contrary to the conventional two-step process (Zhang Z. et al., 2018), and screening of catalyst and process conditions for better quality jet biofuel (Chen and Wang, 2019). There have been many demonstration and commercial flights running on UCO-derived or UCO-blended jet fuel (Chiaramonti Horta and Nogueira, 2017; Yang et al., 2019). UCO from households and restaurants ending up in the gutter has been recently used as jet fuel blends in Boeing flights in China (Karmee, 2017). Animal fats (e.g., tallow, yellow grease), is another low cost food waste stream and a promising feedstock for BAF production (Chiaramonti Horta and Nogueira, 2017). Biofuels produced from animal fats potentially have better combustion quality over those produced from oil-seed crops (Popov and Kumar, 2013). Tallow was reported to be an environmentally favorable feedstock for biodiesel production due to its low life cycle GHG emissions (Kalnes et al., 2011). However, the demand by the transportation sector for tallow has to compete with increasing demands from the cosmetic and biochemical industries (Ernsting, 2017). World consumption of animal fat, together with vegetable fat, has also increased due to biodiesel consumption (Mielke, 2018). Though animal fats can be easily converted to jet fuel by hydroprocessing (Buchspies and Kaltschmitt, 2018; Zhang B. et al., 2018), no literature can be found on commercial or demonstration flights running on animal fat-derived jet fuel.

MSW has also been increasingly considered as BAF feedstock. Dabe et al. (2019) reviewed the various existing and advancing thermo- and bio-chemical production pathways of syngas and alcohols from MSW as precursors for BAF conversion. Dabe et al. (2019) added that the current technologies could already enable the utilization of the high-energy value of MSW and alleviate problems associated with landfills. In fact, Fulcrum Bioenergy is reported to produce jet fuel via FT commercially by processing 30,000 t/year of MSW by 2020 (Richter et al., 2018). On the one hand, Swedish Biofuels is expected to complete an ATJ demonstration facility this year (2019) that will process 5,000 t/year of MSW along with other waste streams (Mawhood et al., 2016). However, systematic studies focusing in the production of BAF from MSW seem limited. This lack of data on the performance and cost of MSW conversion technologies hinders strategic decision-making. Pham et al. (2010) performed a techno-economic assessment of a mixed fermentation process that uses MSW to produce jet fuel, gasoline and diesel in the USA. MSW comes with a tipping fee that is an average price of USD2010 45/dry ton. For a 40 t/h plant with internal production of hydrogen, the MJSP is USD2010 0.33/L. Suresh et al. (2018) conducted a techno-economic and environmental assessment with Monte Carlo uncertainty analysis of BAF from MSW via FT and ATJ in the USA. The results revealed that production costs of BAF from MSW are still more expensive than CJF production with a MJSP of USD2018 0.99/L and USD2018 1.20/L of BAF via FT and ATJ, respectively. However, both show about 93% increase in net present value due to the GHG emissions savings via implementation of carbon pricing. Compared to CJF, life cycle GHG emissions reduce by 63% and 41% with BAF from MSW via FT and ATJ, respectively. There have been no reported test flights yet with jet fuel derived from MSW.

Logistical complexity and variable availability of waste biomass are the primary challenges as BAF feedstock (Iakovou et al., 2010; Mawhood et al., 2016). The bulkiness of some can lead to high logistic operating costs and constrain the capacity of centralized processing plants (Mawhood et al., 2016). Collection, transportation and storage of large amounts of biomass wastes, like animal manure and MSW, are additional issues due to health and safety risks (Rentizelas et al., 2009; Downie and van Zwieten, 2013). Other waste management inadequate legislation, such as landfills, incineration and recycling, can potentially hinder their streamlined acquisition (Mawhood et al., 2016). The highly uncertain availability of waste biomass remains an issue for their sustainable utilization (Roth et al., 2018). Many of the candidates as feedstocks are not available all year round and at the same location where they are needed (Staples et al., 2018). Compared to energy crops, studies on the potential and actual availability of waste biomass are limited (Roth et al., 2018). Hence, conversion technologies need to be robust in order to adapt to their variability and still produce the desired BAF product (Mawhood et al., 2016; Conrad et al., 2019).

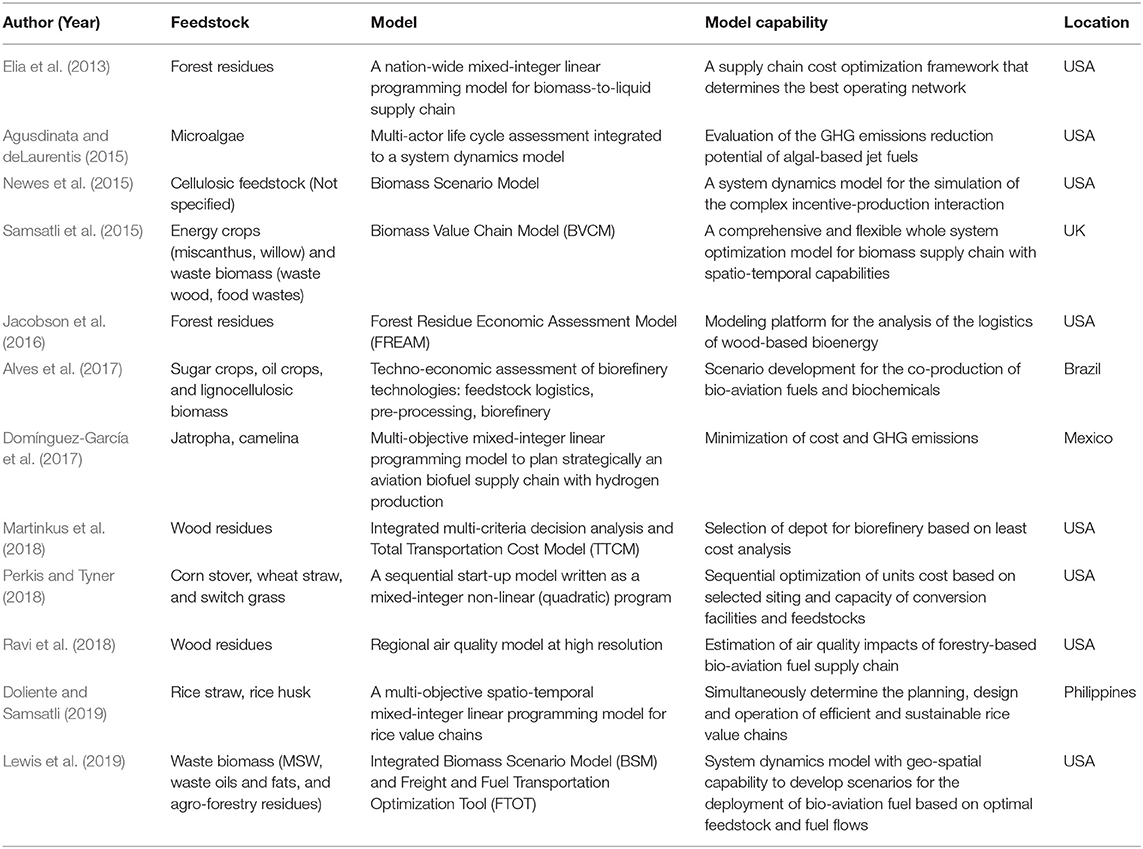

Table 5 summarizes all the supply chain models specifically for BAF provision reviewed in this paper. Studies on the supply chain of waste biomass for BAF production are still few. Most literature available are supply chain models for forest residues. Jacobson et al. (2016) developed a Forest Residue Economic Assessment Model (FREAM), a supply chain model integrated with GIS data and stakeholder engagement, for the simulation and cost estimation of harvest, transport, and conversion of forest residues. A regional-scale production of BAF via ethanol-to-jet production pathway in Inland Northwest of USA was conducted revealing a total production cost of USD2016 1.23/L with capital and transport accounting at 15 and 32%, respectively, of the total cost per ton of forest residue processed. Martinkus et al. (2018) integrated multi-criteria decision analysis and a total transportation cost model for the assessment of existing industrial facilities within a forest residue-based depot-and-biorefinery supply chain. A least cost supply chain for woody biomass conversion into aviation fuel in Inland Northwest, USA was determined, which showed the capital and operational costs for disaggregated biomass pre-processing in depots are lower than an integrated biorefinery. Elia et al. (2013) developed a MILP model for the cost optimization of a biomass-to-liquid supply chain producing diesel, gasoline, and jet fuel using forest residues in the whole of USA. The BVCM by Samsatli et al. (2015) is also capable of optimizing the cost and GHG emissions for a forest residue- and/or other waste biomass-based supply chain for jet fuel provision. Alves et al. (2017) performed a techno-economic assessment of co-producing renewable jet fuel and high-value platform chemicals in Brazil through a supply chain comprising feedstock logistics, decentralized pretreatment facilities and a centralized biorefinery. Their results showed the ethanol-to-jet processing of eucalyptus residues or sugarcane residues as the most economically feasible. Contrary to studies focusing on economics, Ravi et al. (2018) studied the environmental impacts of a forest residue-based BAF supply chain in the Pacific Northwest of USA. Using a regional air quality model with high-resolution, their results showed that the biorefineries can be a substantial local source of NOx and CO but regionally the increase is insignificant. Moreover, the utilization of the residues in the supply chain results in air quality and health benefits outweighing the negative effects of pile burning. On the other hand, the sequential start-up model programme by Perkis and Tyner (2018) assessed the economic performance of a corn stover- and wheat straw-based BAF supply chain in Indiana, USA. The study found that the first batch of investors would opt for corn stover and situate conversion facilities near locations of high feedstock availability. Vast quantities of rice straw and rice husk in many rice producing counties can be a potential waste stream for BAF production (Roda et al., 2015). The MILP model for efficient and sustainable rice supply chains by Doliente and Samsatli (2019) is the first to consider biomass-based production pathways of jet fuel using rice crop residues as a feedstock. Lastly on waste biomass-based supply chains for jet fuel, Lewis et al. (2019) coupled the Biomass Scenario Model, a system dynamics model, to study the supply chain evolution in the USA, with the Freight and Fuel Transportation Optimization Tool, to determine optimal transport flows and routes. Their results show that BAF production from 75 million to 4 billion liters per year is achievable with a mix of waste biomass streams and conversion technologies (HEFA leading in the short term and followed by advanced technologies in the long term). By considering the geo-spatial availability and holistically viewing the supply chain, these studies demonstrate the promising benefits of waste biomass and the respective conversion technologies in the provision of BAF (Mawhood et al., 2016; Gutiérrez-Antonio et al., 2017). Despite these efforts, the supply and demand for waste biomass-derived BAF continue to be insignificant to CJF (Mawhood et al., 2016).

Third-Generation Feedstocks

Algae are of high interest due to having no food value, high yields with virtually no land requirement, and relatively low cost requirements (e.g., grown in suspensions requiring only sunlight, simple nutrients, and CO2 that can be from industrial flue gases) (Cheng and Timilsina, 2011; Lee and Lavoi, 2013; Atashbar et al., 2018; Richter et al., 2018). Algae are capable of growing in polluted water or water unsuitable for agriculture that can simultaneously lower operating costs and provide wastewater treatment benefit (Acheampong et al., 2017; Alalwan et al., 2019). The demand for water (regardless of quality) by algae to produce 1 L of biodiesel is about 300–1,000 L, which is lower than most 1-G feedstocks (e.g., 5,500 and 15,000 L for canola and soybean, respectively).

Microalgae is a type of algae dedicated for BAF production (Warshay et al., 2011; Rocca et al., 2015; ATAG, 2017; Richter et al., 2018). They are unicellular organisms with excellent photosynthetic efficiency and carbon fixation capability (Rocca et al., 2015; Su et al., 2017). Popov and Kumar (2013) have summarized the many advantages of microalgae over land-based crops as follows:

• High annual growth rates, e.g., an annual potential of 91 t/ha/yr (Stratton et al., 2010);

• High lipid content, e.g., average of 2–19%w/w (dry) but with some species in excess of 50% w/w (dry) (Rocca et al., 2015; Su et al., 2017);

• No competition with food crops; and

• Production of high value co-products.

Microalgae as a feedstock promises both high productivity and availability of fatty acids readily convertible to BAF via HEFA (Ames, 2014; Tao et al., 2017). Thermochemical routes via pyrolysis and hydrothermal liquefaction technologies are also increasingly being developed to simplify and diversify the production pathways (Chiaramonti et al., 2017). Hence, microalgae is widely regarded for large-scale biofuel production (Stratton et al., 2010). While there has been significant investment into algae biofuels, a number of logistical and technological issues persists (Warshay et al., 2011; Richter et al., 2018). Issues in cultivation, harvesting, and oil extraction technologies, which are still inefficient and/or capital- and resource-intensive, along with prohibitive environmental impacts block commercialization (Doshi et al., 2016; Su et al., 2017; Behrendt et al., 2018). There have been a number of trial and pilot microalgae production plants, and demonstration flights run on algal-derived jet fuel but to date there is still no economically feasible production (Mawhood et al., 2016; Chiaramonti Horta and Nogueira, 2017; Bwapwa et al., 2018; Richter et al., 2018).

Ames (2014) estimated the global potential of algal oil ranges from 350 billion liters per year (limited productivity scenario) to 2 trillion liters per year (high productivity scenario) with cultivation in Asia and North America to have the highest potential. However, locations having high availability of marginal lands, tropical to semi-arid climate, and close proximity to sustainable water and CO2 sources are also favorable cultivation sites. Roth et al. (2018) reviewed the important criteria in selecting suitable sites for cultivating microalgae for BAF production. These include climatic conditions (e.g., available solar radiation and ambient temperature); terrain (commonly limited to <5% slope); sources of water (fresh or salt water); sources of carbon dioxide (e.g., power, biogas, or fermentation plants) and; sources of nutrients (e.g., synthetic fertilizer or dissolved nutrients in wastewater). Chiaramonti et al. (2017) added that, in contrast to land-based crops, it can be technically feasible to modify the suitability of a site for microalgae cultivation (e.g., temperature control, artificial lighting, and long-distance gas/liquid pipelines) but the economic and ecological costs associated with the alteration can become prohibitive. In the perspective of planning a microalgae supply chain for BAF provision, both the geo-spatial and temporal aspects of microalgae cultivation must be incorporated for optimal economic and environmental performance. With butanol as a pre-cursor to jet fuel, Arabi et al. (2019) presented a multi-period MILP model for the planning and design of a microalgae supply chain for biobutanol production in Iran. They integrated fuzzy programming and data envelopment analysis to deal with uncertainties and tractability of the model, respectively. Other microalgae supply chain modeling studies focus on biodiesel provision, such as the single-objective robust MILP model for national level supply (Mohseni and Pishvaee, 2016), multi-objective fuzzy linear programming model for a multi-product supply chain (Ubando et al., 2014), and a two-objective metaheuristic model for the stochastic location-inventory-routing in a nationwide supply chain (Asadi et al., 2018). To date, only the studies of Asadi et al. (2018) and Arabi et al. (2019) considered explicitly the site suitability of microalgae cultivation. All these studies dealt with minimization of cost, while only the studies of Asadi et al. (2018) and Ubando et al. (2014) considered minimization of environmental footprints. Agusdinata and deLaurentis (2015) integrated LCA and multi-actors (stakeholder's decisions) to assess the environmental impact of an algal-based BAF supply chain in the USA. They confirmed the potential of algal biofuels, in reducing the life cycle CO2 emissions of the country's airline industry by as much 85% in 2050. While present algal technologies are still economically non-viable in the next 10 years or so, research on supply chain studies and generation of robust data must continue for microalgae-based biofuels (Behrendt et al., 2018).

Fourth-Generation Feedstocks

In the portfolio of feedstocks for sustainable aviation fuels, ATAG (2017) recognized the potential of non-biological resources and genetically modified organisms that are grouped together in a separate class called fourth-generation (4-G) feedstocks (Alalwan et al., 2019). Genetically modified organisms (e.g., microalgae, cyanobacteria, fungi, and yeast) have artificially enhanced oil and/or sugar yields and negative carbon capabilities, which are mostly in the infancy stage of research (Alalwan et al., 2019). In spite of their promising biofuel potential, more studies are needed on the health and environmental risks that these organisms can pose, on their containment, and/or mitigating strategies when they are deployed into the world's supply chains (Abdullah et al., 2019). Non-biological feedstocks (e.g., CO2, water, renewable electricity, and sunlight) can potentially be the more environmentally benign option especially when flue gases from industrial plants are utilized (ATAG, 2017; Richter et al., 2018). One route is power-to-liquid (PtL) which involves the splitting of water into hydrogen and oxygen via a renewable-electricity-powered electrolyzer and then hydrogen is combined with CO2/CO to produce BAF (ATAG, 2017; Schmidt et al., 2018). A recent techno-economic and environmental analysis by Schmidt et al. (2018) showed that the short term costs of PtL fuels (driven mainly by the price of renewable power) are greater than CJF. However, the environmental benefits of PtL fuels (e.g., nearly carbon neutral and low requirements for water and land) along with improvements in economies of scale can potentially outweigh the economics and externalities of CJF in the long-term. Another route is the use of concentrated solar energy in splitting water and CO2 to produce syngas as precursor for BAF production (Richter et al., 2018). While both routes are still at early stages of research, Richter et al. (2018) has identified two European initiatives, Sunfire and SOLAR-JET, that demonstrated the production of jet fuel with CO2, water and solar energy. In terms of the studies on supply chains of 4-G feedstocks, although limited to date, Mesfun et al. (2017) applied a spatio-temporal MILP model for the integration of power-to-gas (PtG) and power-to-liquid technologies in an Alpine energy supply. Depending on the pricing of fossil fuel and carbon, the study confirmed that renewable energy systems become more flexible when integrated with PtG and PtL technologies as these convert the excess intermittent renewable power to fuels and enable the utilization of large amounts of captured CO2 (0.20–15 million tons per year) via fuel production. When these technologies become commercially mature, BAF from 4-G feedstocks promise to be the most sustainable with the potential for negative carbon emissions and interlinking power, heating and aviation sectors (Mesfun et al., 2017; Richter et al., 2018).

Economic Analysis

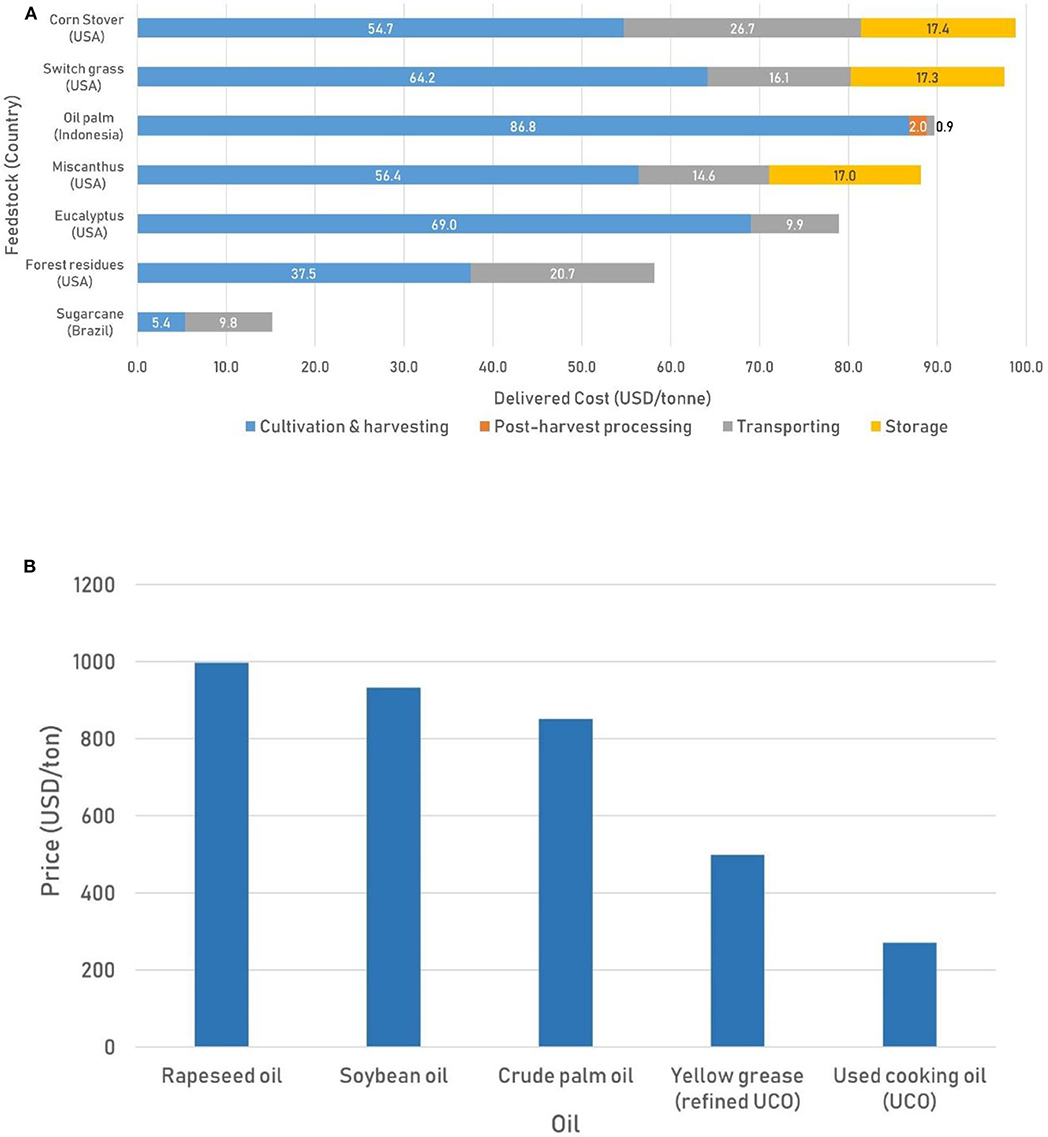

The delivered cost of a feedstock accounts for the total costs of cultivation/plantation, harvesting and other post-harvest processing, storage, and transporting to the biorefinery (Gonzalez et al., 2011a; Daystar et al., 2014). Figure 3A shows a comparison and breakdown of the delivered costs of some 1-G and 2-G feedstocks. Budzianowski and Postawa (2016) stated that the delivered cost at the biorefinery gates directly affects the economic feasibility of BAF, which can significantly contribute to the total production cost at about 50% or more, especially for food crops. Studies on the supply chain for BAF provision by Newes et al. (2015) and Alves et al. (2017) show that profitability is sensitive to the feedstock price. The comprehensive techno-economic assessment by Tao et al. (2017) on HEFA in the USA have also revealed the price of oil as one of the main cost drivers of production. Hence, its economic success as a short- to medium-term solution lies upon the choice of oil-rich feedstocks.

Figure 3. Typical economic impacts (adjusted to 2019 levels) of some 1-G and 2-G feedstocks for BAF production: (A) Delivered (farm-to-gate) cost (Plotted using data from Gonzalez et al., 2011a; Gonzales et al., 2013; de Castro et al., 2018; Harahap et al., 2019); and (B) Average market price of fresh edible and waste oils (Plotted using data from Mandolesi de Araújo et al., 2013.

Low-cost and/or high yielding oil-seed crops, such as oil palm and jatropha, are going to be the feedstock choices for BAF production (Ernsting, 2017; Tao et al., 2017). With better productivity of these crops in tropical regions (Schoneveld, 2010), countries with high jet fuel demand and low-yielding and/or expensive domestically-grown oil-rich crops would resort to importing cheaper vegetable oil from the tropics. However, importing vast quantities of oil will be costly for the environment. As the purchasing country becomes more dependent on imports, potential embargos or sanctions can also occur in the long term. Given the national burden of importation, countries should diversify their feedstocks to improve self-sufficiency (Zaher et al., 2015). Conversely, exporting countries, with favorable climatic conditions and large cultivable lands, can obtain potentially huge economic gain. In the case of the Indonesian oil palm industry, Susila (2004) reported that jobs generated in the cultivation and milling sectors resulted in the country's national economic growth and regional decrease in poverty. However, exporting can also become a national burden as these countries become dependent upon the income from exports and vulnerable to market forces demanding shifts to a new feedstock. In either case, this diversification and/or shifting to other feedstocks entails land. Agusdinata et al. (2011) has highlighted that both oil price and land availability govern the viability of a feedstock. Despite of the potential economic benefits from cultivating productive feedstocks for low-income countries in the tropical region, it is vital to note that the majority of people at risk of food-insecurity rely heavily on agricultural land for their livelihoods (Alexandratos, 1999). Thus, it is important to ensure that BAF feedstocks used do not place a greater strain upon the populations by either farming 1-G feedstocks on arable lands that would have been processed and eaten or encouraging farmers to switch to 2-G feedstock cultivation that would reduce available arable land for food production. Moreover, the rapid increase in oil palm plantations in the past three decades has been linked to deforestation, biodiversity loss and increased greenhouse gas emissions (Page et al., 2011; Pirker et al., 2016; Vijay et al., 2016). These environmental concerns result in friction toward the use of biofuels, which can negate the progress of current investments on BAF (Ernsting, 2017).

UCO and animal fats are going to be important in the choice of feedstocks for HEFA due to their lower costs (Mandolesi de Araújo et al., 2013; Tao et al., 2017). Figure 3B presents average market prices of fresh edible oils and waste oils. Although UCO has essentially negligible delivered cost, Mandolesi de Araújo et al. (2013) reported that UCO is usually priced about 2 and 3 times lower than fresh edible oil. Roth et al. (2018) added that there is a global potential of about 6 to 7 billion liters per year of bio-aviation fuel based on UCO. However, the persisting unaddressed uncertainty and variability of waste streams raises concerns about their significant contribution in the future jet fuel supply mix (Mawhood et al., 2016; Roth et al., 2018). Furthermore, the UCO demand in BAF production has to compete with established demands for biodiesel production (Roth et al., 2018). Lastly, in the view of economies of scale, Dodd et al. (2018) have recently found through a qualitative investigation of industry experts that the limited capacity of feedstocks is the major hindrance for the growth of the sustainable aviation fuels industry.

When proven commercially feasible, microalgae as a feedstock of HEFA is expected in the future. Its current high price bars its utilization as a biofuel feedstock (Tao et al., 2017). The pricing of algal oil is significant to the overall viability of a microalgae-based HEFA. They carried out a rigorous comparative cost analysis that revealed no strong correlation between production scale and the cost of producing algal oil because of increased capital costs associated with the infrastructure required for algal cultivation. Sun et al. (2011) recommended that the ideal method of improving the production costs was to identify a strain of algae capable of yielding a high lipid content while sustaining a strong growth rate. The sensitivity analysis in the same paper showed that a 2-fold increase in both lipid yield and algal production could improve cost structure of the business by half.

Given the relatively low delivered costs of MSW, agro-forestry residues and lignocellulosic energy crops, they are economically promising feedstocks for the yet commercially feasible FT and ATJ (Dupuis et al., 2019). When the more advanced technologies become commercially viable, these feedstocks are key to the medium- and long-term decarbonization of the aviation industry (Lewis et al., 2019). A direct economic comparison of feedstocks, however, is generally difficult to carry out due to the many interdependent factors for consideration, which are for some both spatially and temporally dependent. The outlook and geographic location of aviation industries are also interdependent, which have potential implications on the policies and implementation for sustainable aviation fuels (Dodd et al., 2018). Furthermore, perspectives by the society, culture and market in a specific region results in large differences in its supply chain configuration for BAF from other parts of the world (Murphy et al., 2015).

Environmental Analysis

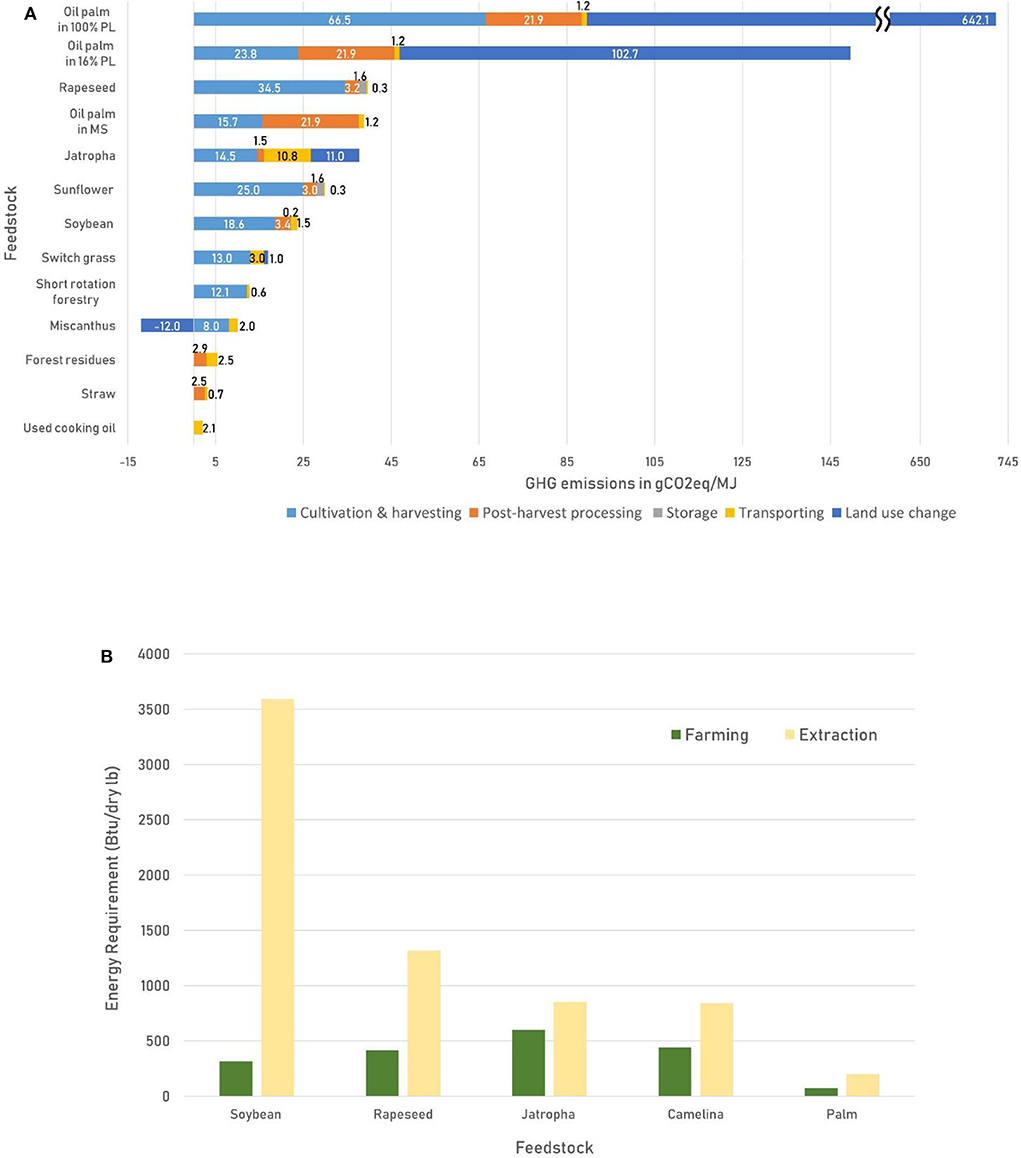

The environmental impacts of the feedstock accounts for the total emissions associated with cultivation/plantation, harvesting and/or post-harvest processing, storage, and transportation of the feedstock to the biorefinery gate (Gonzalez et al., 2011a; Daystar et al., 2014). Daystar et al. (2014) carried out this cradle-to-gate analysis of the life cycle greenhouse gas emissions of cellulosic biomass supply chains for biofuel provision in the Southern USA. Recently, O'Connell et al. (2019) conducted a similar analysis on the feedstocks supply chains for BAF provision in the EU. Figure 4A presents a comparison of the cradle-to-gate GHG emissions of feedstocks for BAF production.

Figure 4. Typical environmental impacts of some 1-G and 2-G feedstocks for BAF production: (A) Farm-to-gate GHG emissions (Plotted using data from Bailis and Baka, 2010; Wang et al., 2012; Velazquez Abad et al., 2015; O'Connell et al., 2019); and (B) Energy requirements for farming and extraction of some oil-seed crops (Plotted using data from Elgowainy et al., 2012).

Cultivation and harvesting of 1-G and 2-G feedstocks represents significant contributions to their total GHG emissions due to the continued reliance on fossil fuels in both the direct and indirect inputs of many farming activities (Pimentel, 2009; Liu X. et al., 2017). Direct inputs include diesel and gasoline to power machinery for land preparation and cultivation, pumps for irrigation, and vehicles for transportation. While indirect inputs consist of fertilizers, pesticides, water, and seeds whose embodied energy (from production to transportation in the farm) are also from fossil fuels (Azwan et al., 2016; Elsoragaby et al., 2019). Typically, GHG emissions from fertilizers account for most of the indirect inputs since their chemical production requires large amounts of natural gas (Pimentel, 2009; Liu X. et al., 2017). Post-harvest processing can also be a significant source of GHG emissions. For oil-bearing crops, oil mills require electricity and heat that are mostly fossil-based. Figure 4B depicts a comparison of the energy requirements for farming and oil milling of oil-seed crops for BAF production. To improve the environmental sustainability of a BAF feedstock, the use of biofuels in the machinery and bio-electricity/heat (from agro-forestry residues) in milling operations should be practiced (Sims et al., 2015). Storage and transport (to the mill and/or bio-refinery gates) of the harvested and/or pre-processed feedstocks usually account for a minor portion of the total GHG emissions. A transport process is a function of load and distance (Cefic ECTA, 2011). Greater GHG emissions result from transporting large amounts of feedstocks over large distances. Importing processed oil from the tropics to the EU have been reported to result in additional GHG emissions (O'Connell et al., 2019). While some storage facilities may use minimal energy, feedstock requirements may use considerable energy and lead to GHG emissions, especially when fossil-based (Egg et al., 1993; Emery et al., 2015).

Among oil-seed food crops, O'Connell et al. (2019) demonstrated that oil palm cultivation grown in mineral soil has the least GHG emissions (Figure 4A). Elgowainy et al. (2012) showed that palm oil extraction energy requirement is also the least (Figure 4B). Hence, oil palm as a BAF feedstock may be the best food crop-based option, even when considering an average of 6.0 gCO2eq emissions associated with transporting it to the EU. However, when LUC associated with cultivation happens, land-based crops like oil palm become environmentally unsustainable feedstocks. LUC can result in both direct and indirect emissions (Bauen et al., 2009). Direct LUC emissions represent activities associated with changing the land from its past condition to feedstock cultivation. While indirect LUC emissions, due to low availability of arable lands, result from land expansion at the cost of deforestation. Even without considering the indirect LUC emissions of recent land expansion of oil palm plantations, O'Connell et al. (2019) confirmed a staggering 100 to 600 times increase in GHG emissions from direct LUC of 16 and 100% peatland, respectively. The resulting life cycle GHG emissions of oil palm grown in peat land are even higher than the production of CJF at 20 gCO2eq/MJ. In the investigation of ICAO (2009), peatland forests being repurposed into plantations have increased GHG emissions by a factor of 7.5. Large amounts of carbon stored in peatlands have not only been removed from biomass clearing, but new plants grown typically have much lower carbon-storing capacities. Murdiyarso et al. (2010) quantified a 254.5 teC/ha storing capacity for natural peatland reduces to 24.2 teC/ha for oil palm cultivation. Hence, large-scale clearing of peatland forests would potentially result in large increases in atmospheric carbon. Although the work of O'Connell et al. (2019) focused on oil palm, other land-based crops can display the same trend of increased emissions when cultivated in peatland forests. Research conducted by Wong (2008) and ICAO (2009) showed that LUCs for biomass cultivation have the potential for high GHG emissions. Page et al. (2011) recommended that the reuse of peatland for energy crop cultivation should be avoided due to its environmental consequences.

Considering that the type of land-use conversion is a vital consideration for feedstock cultivation, the use of marginal land for energy crops can ensure avoidance of LUC emissions and preservation of agricultural land (Rathmann et al., 2010; Lask et al., 2019). In the case of jatropha cultivation, direct LUC emissions of converting degraded pastureland is 42 times lower than that of converting a tropical rainforest, as shown in Figure 4A. However, energy crops like jatropha have low productivity in marginal lands, which significantly improves in suitable lands (von Maltitz et al., 2014; Wani et al., 2016; Lamb et al., 2018). Hence, their possible encroachment on both agricultural land and forestland can potentially result in significant LUC emissions and their poor environmental sustainability as BAF feedstocks (Schoneveld, 2010; Keles et al., 2018). If LUC emissions are to be significantly abated, waste streams and algae represent the best alternatives. Considering that algal cultivation continues be a long-term tech-economic endeavor, the utilization of waste streams, such as UCO, agro-forestry residues, and MSW, has to be prioritized within the short- to medium-term, as attested by several initiatives and projects of BAF developers (Mawhood et al., 2016). In Figure 7, GHG emissions of waste biomass are significantly lower than all land-crop based feedstocks. Moreover, LCA of feedstocks for high-octane gasoline production by Dupuis et al. (2019) showed waste biomass to have the lowest cradle-to-gate GHG emissions with forest residues as most environmentally benign in both feedstock and fuel production phases. Although the utilization of agro-forestry residues are going to be essential in meeting sustainable energy goals, they also play a significant role in maintaining soil carbon for productivity function and ecosystem services (Karlen et al., 2019). Hence, only a certain portion of these resources is truly retrievable from the plantations, which could be a limiting factor of their actual contribution in BAF production. At the current state of technology and GHG emissions, a similar conclusion by Roth et al. (2018) shows UCO as the most environmentally sustainable feedstock for BAF production.

A BAF cannot be preferable over the existing solution unless the net carbon emissions of its life cycle, from feedstock production, fuel conversion and combustion, are lower than CJF. Bauen et al. (2009) found that GHG emissions savings over the life cycle of biofuel production depend heavily on the feedstock used. Table S3 summarizes WTW life cycle emissions for both 2-G and 3-G feedstocks. WTW life cycle comprises both the well-to-tank (WTT) and tank-to-wake (TTW) stages. Elgowainy et al. (2012) defined the WTT stage as all GHG emissions resulting from feedstock production, fuel production, emissions associated with the creation of co-products and all transport processes within these elements. Whereas, TTW stage incorporates the combustion and use of the fuel in the engine. However, Table S3 do not consider emissions due to direct or indirect LUC. Nevertheless, WTW results show promising environmental sustainability of energy crops, waste biomass and algae as feedstocks.

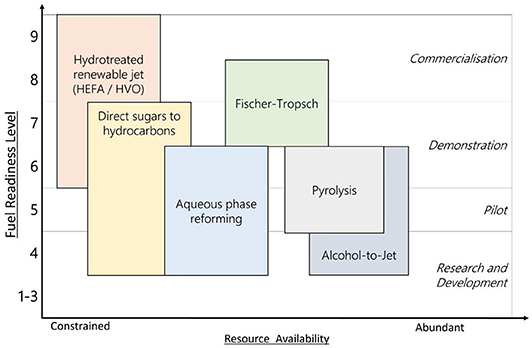

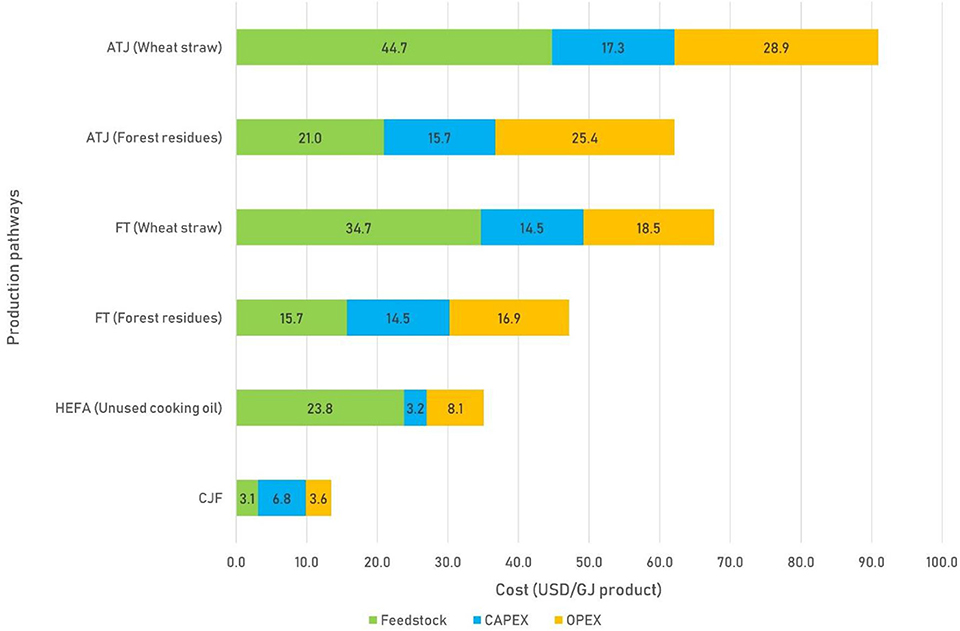

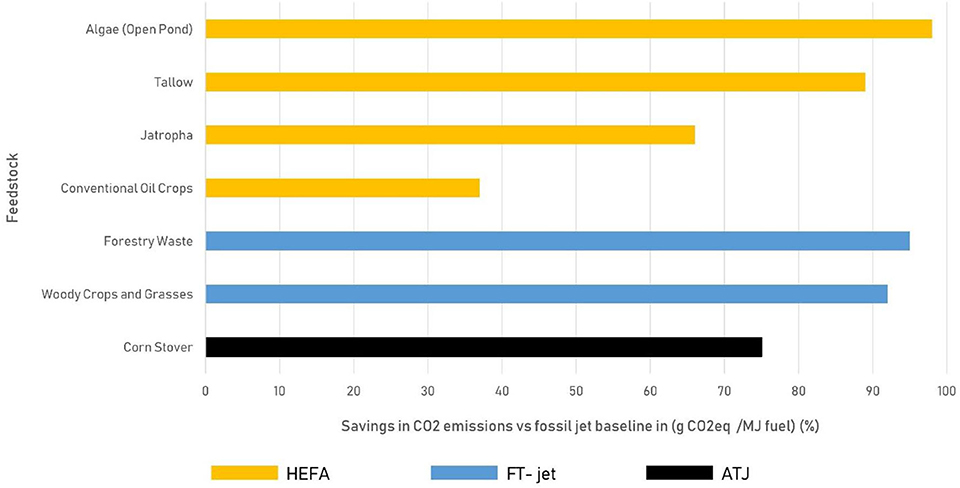

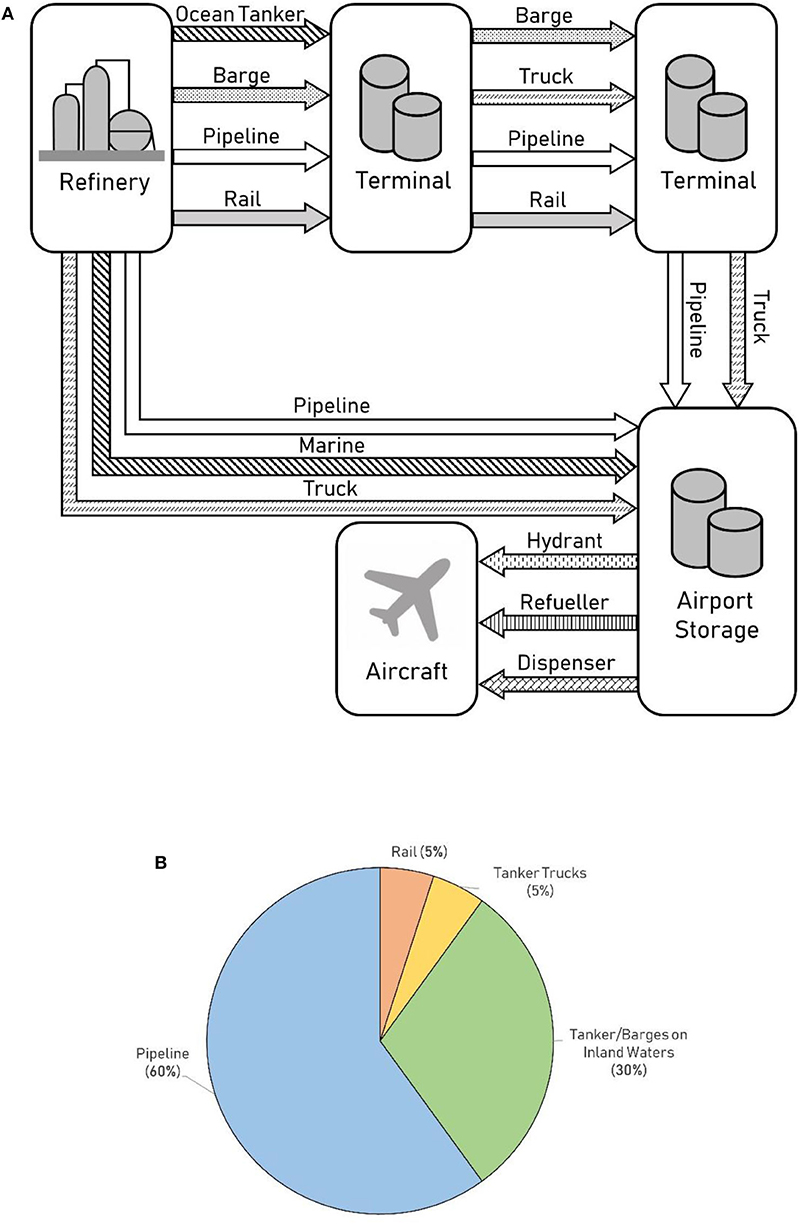

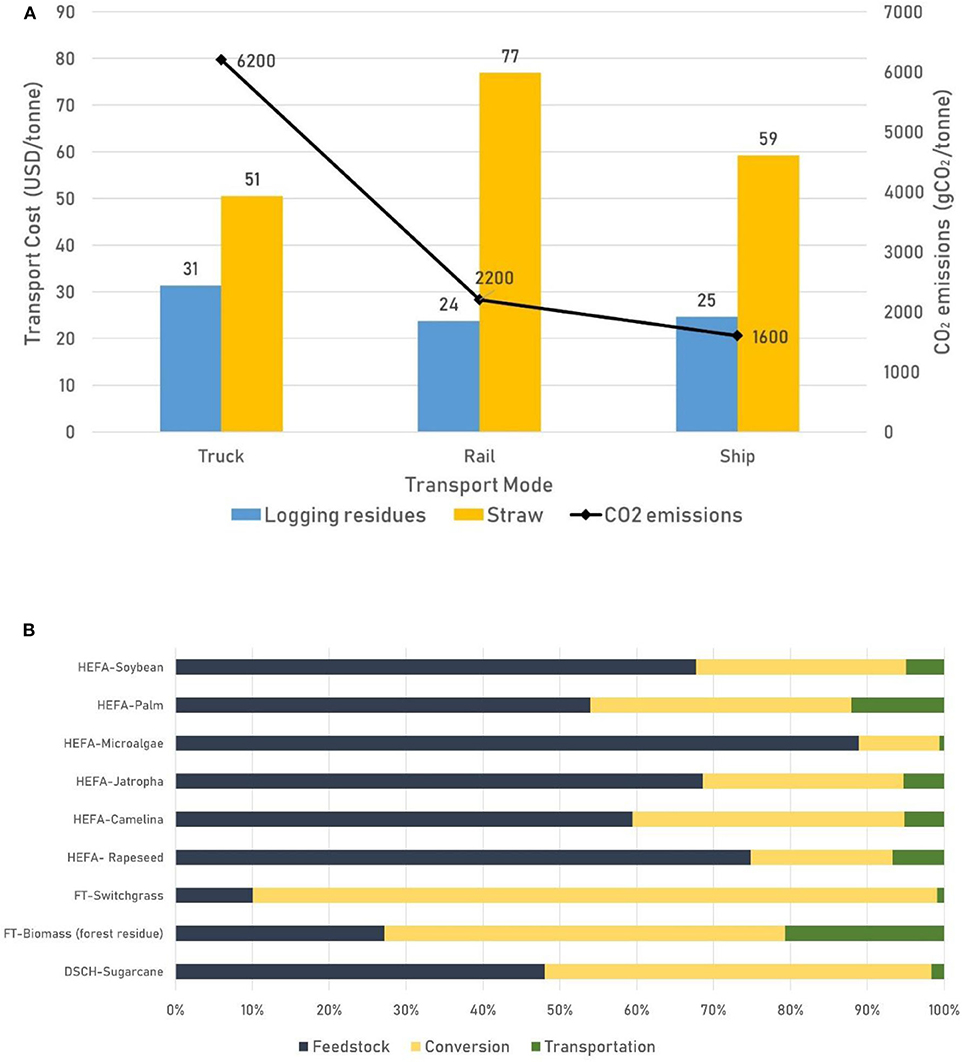

Production Pathways for Synthetic Paraffinic Kerosene