94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci., 27 June 2023

Sec. Environmental Informatics and Remote Sensing

Volume 11 - 2023 | https://doi.org/10.3389/feart.2023.1201946

This article is part of the Research TopicCoal and Rock Dynamic Disasters: Advances of Physical and Numerical Simulation in Monitoring, Early Warning, and Prevention, volume IIView all 29 articles

A multi-parameter comprehensive early warning method for coal pillar-type rockburst risk based on the deep neural network (DNN) is proposed in this study. By utilizing preprocessed data from the surveillance of coal pillar impact hazards in Yangcheng Coal Mine, this study incorporates training samples derived from three distinct coal pillar-type impact hazard monitoring methodologies: microseismic monitoring, borehole cutting analysis, and real-time stress monitoring. The data characteristics of the monitoring data were extracted, evaluated, classified, and verified by monitoring the data of different working faces. This method was applied to develop the depth of multi-parameter neural network comprehensive early warning software in engineering practice. The results showed that the accuracy of the depth for burst monitoring data processing is improved by 6.89%–16.87% compared to the traditional monitoring methods. This method has a better early warning effect to avoid the occurrence of coal pillar rockburst hazard.

Currently, most impact risk monitoring data processing methods are directly obtained and classified according to warning values or processed by statistical machine learning methods based on shallow models. In the feature selection process, these methods rely more on human subjective factors, which affects the accuracy of impact risk assessment. The rockburst hazard monitoring data are processed by deep learning feature extraction methods to avoid the shortcomings of the traditional shallow learning models in feature selection (Ji et al, 2003; Jiang et al, 2014; Chen et al, 2015; He et al, 2022; Wang, 2022; Li et al, 2023).

The deep learning algorithm is derived from an artificial neural network, known as a deep neural network (DNN), which is a multilayer perceptron with multiple hidden layers. The algorithm can learn, adjust, improve, and understand huge data contents and independently find the optimal solution from data changes (Ren, 2016; Zheng, 2022; Wang et al, 2023). The rockburst hazard monitoring data are enormous, and the drilling chip method generally requires drilling multiple holes to judge the rockburst hazard of a specific roadway or working face while driving and mining (Chen et al, 2013; Zhang, 2020; Li et al, 2022). Microearthquake monitoring requires arranging 6-8 groups of measuring points. Each group of measuring points acquires and records monitoring data every 10 seconds, stress online monitoring is utilized to arrange more than a dozen groups of measuring points and record data every few seconds, and a large number of impact hazard monitoring data are obtained in actual mining scenarios. However, there are great deficiencies in the application and processing of data, especially in the in-depth mining processing of monitoring data feature information (Yuan et al, 2018; Bao et al, 2019; Ai et al, 2020). Therefore, Chen et al (2020) proposed the integrated high-precision intelligent microseismic monitoring technology based on the high-precision time synchronization strategy of PTP. In general, the velocity model database was used to match the micro-source location algorithm, and these technologies were integrated. Many chaotic initial data were abstracted into distinguishing feature information, evaluated, and classified through the DNN to ensure that the precursor information of rockburst hazard monitoring can be accurately identified in the subsequent monitoring and early warning (Pan, 2003; Bosch et al, 2007; Sun et al, 2013; Lu et al, 2021; Yin, 2022; Zhang et al, 2023).

Rockburst hazard monitoring mainly includes drilling chip method monitoring, microearthquake monitoring, stress online monitoring, and electromagnetic radiation (Jiang and Zhao, 2015; Lan and Zhang, 2022).

Among them, the drilling chip method monitoring mainly monitors the discharge amount of drilling cuttings, the change in particle size of drilling cuttings, and the change in drilling noise and strength and judges the crushing zone range, plastic zone, and elastic zone in the coal body using a number of drilling cuttings. The rockburst hazard of the coal pillar is judged by the dynamic effect during drilling to identify the stress state of the coal body (Zhu et al, 2014; Jia et al, 2019). Generally, a rockburst hazard occurs when the average pulverized coal amount per meter exceeds the critical pulverized coal amount. When the pulverized coal increases first and then decreases with the increase in the drilling depth, it is considered that there is no impact hazard but stress concentration. The dynamic properties, such as drilling suction and sticking, are based on the dynamic characteristics of the rockburst. This is more obvious from the increase in drill cuttings’ particle size of pulverized coal.

Microearthquake monitoring is mainly used to monitor the whole mine according to microseismic sensors, determine the location and energy of the seismic source, compare it with the energy calculated according to the minimum energy principle, and adjust the early warning energy combined with the actual monitoring experience of the mine to determine the monitoring indicators within the monitoring coal pillar. The driving and mining speed affect the evolution process of strata fracture movement. The determination of an early warning value for microearthquake monitoring should fully reflect the influence of tunneling and mining, with the early warning value of microearthquake monitoring for a single event being set to 105 J (Tan et al, 2022; Wang et al, 2014; Liu et al, 2022; Zhang et al, 2023).

Stress online monitoring takes coal stress increment as the rockburst hazard evaluation index. Before a rockburst hazard occurs, there will be a gradual increase in stress, and only when the stress reaches the coal failure’s ultimate stress, the rockburst will be caused. At the same time, the stress state in the coal pillar can be reflected by stress online monitoring, and the safety factor of the coal pillar can also be obtained by the coal pillar strength. The early warning of coal pillar impact hazard can be obtained based on the change in stress increment (Wang et al, 2015; Dou et al, 2020).

The impact monitoring methods are becoming complicated, with the increase in monitoring data. When monitoring is equipped with multiple monitoring systems, especially when the monitoring data are contradictory, it is a common problem to rely on one of the monitoring methods or comprehensively evaluate multiple monitoring methods simultaneously (Jiang et al, 2011; Luo et al, 2013; Lv et al, 2013; Wang et al, 2018; Liu and Li, 2023).

Microearthquake monitoring is a means of regional rockburst hazard monitoring, which has a wide monitoring range and is suitable for large-scale regional rockburst monitoring. The position and level of energy events are reflected and confirmed through microearthquake monitoring. Hence, microearthquake monitoring is an effective means of regional rockburst monitoring. The earthquake, quantity, frequency, intensity, density, scale, and properties of rock mass fracture can be monitored by microseismic monitoring. Stress online monitoring has the advantages of good continuity and the capability of monitoring stress change in the coal pillar while reflecting its stress change. Hence, it is suitable for continuous monitoring of long-term impact hazards. The position of the stress peak in the coal body and whether the supporting pressure of the coal body reaches its limit strength are based on the relationship between the drilling chip’s monitoring value obtained by the drilling chip method and the stress state and damage degree of the working face and coal pillar. The stress in coal mass is reflected by the amount of drilling chips, which effectively monitors the rockburst risk at a fixed point. The application of comprehensive multi-parameter monitoring and early warning technology of rockburst is shown in Figure 1.

For coal pillar rockburst, due to many influencing factors, rockburst has different stress characteristics and energy variation laws, and it is difficult to effectively monitor the rockburst hazard by using a monitoring method. Therefore, an appropriate monitoring method should be selected based on the expected rockburst performance characteristics (Jia et al, 2014; Zhang, 2021; Wang et al, 2022; Liu et al, 2023a; Liu et al, 2023b).

The DNN model structure includes an input layer and several hidden layers. The difference between DNN and BP neural networks is the number of hidden layers, where DNN has many hidden layers that might exceed 10 in some cases. The data enter the network from the input layer and passes through L hidden layers: H(1), H(2), H(3), and H(L), to perform data abstraction and feature extraction step by step. H(L) is the desired representation, and this process is the representation learning of DNN.

The basic unit in DNN is the node which comprises an input, a state function, and an activation function, wherein the input includes an input value and a connection weight. The input value is the same as the output value of the upper node, and the weight adjusts the node’s connection strength. The state function is the linear accumulation of the input values and weights, and the node state is controlled by an offset term. The general state function form is provided in Eq. 1, while the state function’s matrix is given in Eq. 2. The activation function is the number used to select a linear, non-linear, continuous, discrete, numerical, or probability function to control the output range (Zhang et al, 2015), as shown in Figure 2.

where xk is the kth input value of the upper layer of the network, including energy x1, frequency x2, drilling powder x3, deep hole stress x4, and shallow hole stress x5; Wk is the connection strength between the node and xk; and bi is the bias term.

Support vector machine (SVM) plays a critical role in classification and linear regression. This method uses statistical learning theory to establish a decision surface and maximize the isolation between different results. In this paper, the early warning identification results of coal pillar rockburst hazards are divided into four situations: danger (DAN), probable danger (CRI), probable danger (AN), and safety (NOR). The support vector machine classifier is extended from binary classification to a multi-class classifier. The classifier is constructed with

The DNN constructed in this paper adopts the greedy initialization method, and the data representation of the neural network is obtained by iteration of input values. The network’s internal parameters are initialized to obtain a better initial value that reduces the possibility of the network falling into the local limit value. The DNN model adopts greedy initialization layer by layer to obtain a better training effect, or the optimal value, so that the low-level network can be fully trained. First, the deep network is built by restricted Boltzmann machine (RBM), and the marked data and unlabeled data are used to find the network space W.

A fully connected directional multilayer neural network is established. The input layer h0 includes energy, frequency, powder drilling amount, deep-hole stress value, and shallow-hole stress value. The label layer contains four units: danger, probable danger, probable danger, and safety. The number of hidden layers and nodes in each hidden layer are selected through an iterative approach. In the training process, one hidden layer is trained first, this layer is fixed next, then two hidden layers are trained, and multiple hidden layers are trained according to the second method. Thereafter, the spatial parameter w of the multilayer network is found through label data. The gradient descent method is used to train the deep structure based on the exponential loss function, and the parameter space is further optimized using the labeled data. The structure of the rockburst evaluation neural network is shown in Figure 4.

According to the DNN characteristics, if the number of nodes in each layer is enough, each hidden layer’s output value contains the input data’s complete information. Thus, each hidden layer represents the input data, but the specific form is different.

The monitoring data of the drilling cutting method, microseismic monitoring data, and stress online monitoring data are analyzed based on the monitoring methods and conditions of the rockburst in Yangcheng Coal Mine. The monitoring data of rockburst hazards during mining in the 3303 working face of Yangcheng Coal Mine were collected and used as training data to develop the neural network. The layout of the 3303 working face of Yangcheng Coal Mine is shown in Figure 5.

Before using the DNN model to train the impact monitoring and early warning data, it is necessary to preprocess the mine impact monitoring data and correct and deal with some missing and obvious errors to ensure data reliability. Preprocessing of rockburst hazard monitoring data mainly checks the data’s completeness and accuracy. The specific processing methods include removing the inaccurate data, trimming the missing data, and rearranging the out-of-order monitoring data. The microseismic monitoring system extracts, records, and saves microseismic events and continuously saves energy signals. The errors in microseismic monitoring are mainly related to timing and wave velocity. However, because data processing software of the microseismic system itself has good data judgment and extraction ability, the preprocessing of microseismic monitoring data only requires checking the integrity. Online stress monitoring data errors are mainly caused by problems such as initial pressure, pipeline length, and inner diameter, so it is necessary to eliminate and correct the measuring points with abnormal initial stress and the wrong points. The problems of drilling cutting monitoring data are mainly data discontinuity, errors caused by construction conditions, and data loss caused by untimely records. Therefore, the processing of drilling cutting monitoring data needs to complete the monitoring data and eliminate the wrong parts. The rockburst hazard monitoring training samples are selected, and the data are normalized by the mapminmax function. The processing results are shown in Figure 6.

Determining the monitoring and early warning index of the drilling cutting method is performed to calculate the amount of pulverized coal in the area without impact danger and discard the first 1 m of pulverized coal. Under normal circumstances, the pulverized coal per m is G, the drilling rate index is K, the correction coefficient α is 1.1, and the critical pulverized coal amount is

The laws of early warning of impact hazards summarized from the microseismic monitoring site include total energy active high-frequency sub-vibration type, vibration silence maintaining high-frequency sub-vibration type, typical strong impact hazard early warning, monitoring daily energy release curve, and cumulative energy characteristic curve, as shown in Figure 8.

According to the monitoring experience of Yangcheng Coal Mine, early warning is required when the stress increment reaches 2 MPa, the stress of 8 m measuring point reaches 11 MPa, or the stress of 14 m measuring point reaches 12.5 MPa. High-stress concentration and sudden change are the necessary conditions to induce a rockburst, so before a rockburst occurs, the stress values of the surrounding rock all change greatly. Therefore, analyzing the borehole stress gauge reveals the change in surrounding rock stress, and when the stress changes greatly, the rockburst is warned. The typical rockburst stress monitoring curve is shown in Figure 9.

After data preprocessing, the data of microseismic monitoring, online stress monitoring, and drilling cutting monitoring are selected as experimental samples. The data are further corresponded according to timepoints to obtain input vectors, and the sample data are divided into training and verification data. The microseismic data include energy and frequency, online stress monitoring data include deep hole stress and shallow hole stress, and the drilling cutting monitoring data include the number of drilling cuttings.

In the DNN model, the performance may be improved with the deepening of the network layers, but there may also be over-fitting. For the DNN, there may be a small gradient near the input layer and a large gradient near the output layer. When the model’s learning rate is constant, the learning rate near the input layer will be slow, while that near the output layer will be too fast, which may lead to local minimum. For such problems, the neural network is generally optimized by changing the activation function or the learning rate. Using the ReLU activation function instead of sigmoid activation function solves the training gradient vanish problem, and the output of the ReLU activation function is calculated as

After preprocessing the data, five-dimensional parameters corresponding to the pulverized coal amount, energy, frequency, shallow hole stress, and deep hole stress can be obtained. The standard sample output divides the impact hazard monitoring results into four levels: danger, probable danger, probable danger, and safety. This paper uses the early warning information of rockburst hazards extracted from the monitoring data of 1310 and 3303 working faces in Yangcheng Coal Mine as training samples. According to the data characteristics, types, and quantities of judgment results, it is determined that in the pre-training stage, the number of iterations for each layer is 30, the learning rate is 0.1, and the initial impulse ν is set to 0.5. In the training stage of supervised learning, the conjugate gradient descent method is used, and the number of training steps is 3,325.

The procedure for establishing DNN multi-parameter comprehensive early warning is shown in Figure 10. The early warning process of the impact hazard using multiple parameters includes the following: when the model has not been trained, train the model by configuring training parameters to select sample data and basic algorithms; when the training is completed, directly select the data to be evaluated and import the data into the trained model to obtain the evaluation result. This method evaluates and classifies the output based on the rockburst hazard monitoring data characteristics and obtains the rockburst hazard grade.

Based on the characteristics of coal pillar rockburst monitoring data, it is determined that the functional modules of the DNN multi-parameter comprehensive early warning model include the graphic module, data loading module, and algorithm analysis module. The graphic module mainly displays data and early warning results. The data loading module is used to create new data or extract stored data and classify the data. The algorithm module is used to select the basic parameters of the neural network model, and its DNN multi-parameter comprehensive early warning software interface is shown in Figure 11.

The real-time database is established through the monitoring data obtained by the drilling chip method, microearthquake monitoring, and stress online monitoring. In addition, the continuous numerical curves of different impact hazard monitoring data are drawn, and the data are preprocessed. Intelligent identification method for coal pillar rockburst hazard monitoring finds the characteristics of monitoring data, including the relationship between indicators and causality or correlation between indicators and evaluation targets. Studying the data and mining the data characteristics are needed to establish an evaluation model. Using the DNN multi-parameter comprehensive early warning model, the imported information of rockburst hazard monitoring is evaluated, and conclusive information on the safety status of the rockburst hazard is obtained. Data processing is carried out in the multi-parameter comprehensive early warning system to obtain the interface information, as shown in Figure 12.

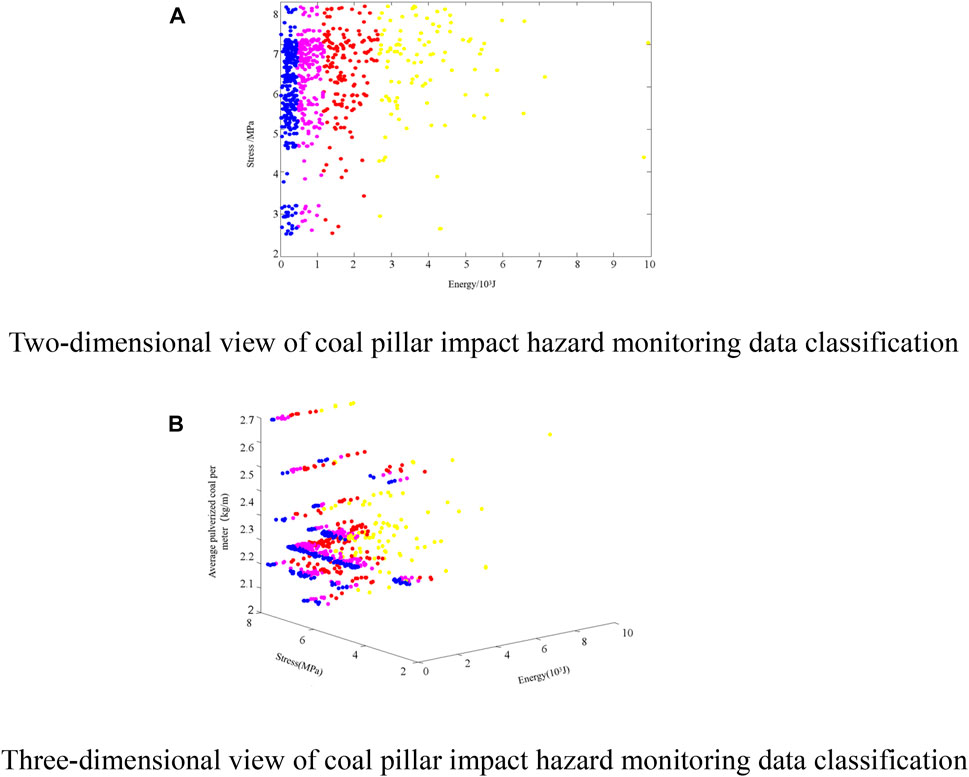

The DNN model is used to evaluate and classify the test data. Two groups of stress online monitoring and microearthquake monitoring data are selected for training to obtain two-dimensional stress and energy classification results. Three groups of microearthquake, stress, and drill chip data are selected for training to obtain three-dimensional classification stress, pulverized coal, and energy results, where yellow indicates danger, red indicates probable danger, pink indicates probable danger, and blue indicates safety. The evaluation and classification results of the test data are shown in Figure 13.

FIGURE 13. Classification results of impact ground pressure evaluation. (A) Two-dimensional view of coal pillar impact hazard monitoring data classification. (B) Three-dimensional view of coal pillar hazard monitoring data classification.

Pre-training abstractly extracted feature information of impact hazard monitoring data, learning impact hazard monitoring data through DNN, and evaluating and classifying different data groups. The node’s output value reflects the feature extraction result of the input data by the neural network in this layer structure to obtain new data representation. When the output value of a node is large, that is, closer to 1, the role and position of the node in representation are great, and conversely, the output value is small, and its importance is negligible. Hence, the situation of feature learning can be judged according to the node’s output value.

In the early warning mode of multi-parameter comprehensive early warning, comprehensive monitoring information is obtained through different monitoring means. However, there is a lack of an effective, comprehensive evaluation method when there is a contradiction in monitoring data, and the daily obtained monitoring data are not used deeply enough. Thus, the monitoring data are not mined. The DNN model is used to extract the features of the monitoring data, then evaluate and classify the monitoring data, and make early warnings of rockburst hazards according to the classification results. The DNN SVM classification method is used to judge the accuracy of the rockburst hazard. Compared to the traditional monitoring and early warning methods, this approach fully uses the monitoring data and has a better early warning effect. The specific comparison results are shown in Table 1 (Qin et al, 2022; Zhang et al, 2022).

(1) The coal pillar rockburst model is established based on the DNN analysis using the drilling chip method, stress online, and comprehensive microearthquake monitoring. The energy, stress, and pulverized coal data recorded in the mining process of Yangcheng Coal Mine are used for training, and the precursor characteristic information of rockburst hazard monitoring data is extracted to realize the evaluation and classification of rockburst hazard monitoring results, and a multi-parameter comprehensive early warning system based on DNN is designed to perform the comprehensive monitoring and early warning of the coal pillar rockburst hazard.

(2) The DNN model can learn data features independently. The DNN model is trained by the collected rockburst hazard monitoring data. The features with discrimination are extracted from the monitoring data by greedy layer-by-layer training methods. The unsupervised learning model is optimized by the symmetric hidden layer method. The supervised learning model is optimized by adding a single-layer algorithm to obtain the standard output value, which improves the data processing ability of the model.

(3) Multi-parameter comprehensive early warning based on DNN improves the early warning accuracy of rockburst risks. Compared with traditional microseismic monitoring, drilling cuttings method, online stress monitoring, and comprehensive microseismic stress early warning, the accuracy of this method is improved by 16.87%, 9.8%, 9.69%, and 6.89%, respectively. This study provides a new method for rockburst monitoring and early warning and introduces a new research idea for rockburst monitoring and early warning.

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

YG: writing—original draft, validation, formal analysis, and methodology. SG: visualization, software, and investigation. Corresponding author: writing—editing, funding acquisition, resources, and project administration. JS: resources, validation, and investigation. All authors contributed to the article and approved the submitted version.

Author YG was employed by Baodian Coal Mine, Yankuang Energy Group Co., Ltd, Zoucheng, China. Author JS was employed by Yangcheng Coal Mine, Shandong Jining Mine Luneng Coal Power Company Limited, wenshang, China. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Ai, D. H., Li, C. W., Zhao, Y. C., and Li, G. Y. (2020). Study on microseismic, electromagnetic radiation and crack propagation characteristics of coal under static load failure. Rock Soil Mech. 41 (6), 2043–2051. doi:10.16285/j.rsm.2019.0899

Bao, X. Y., Ma, F., and Han, D. Y. (2019). Risk analysis of rock burst in mining face based on online stress monitoring. Shandong Ind. Technol. (11), 73–75. doi:10.16640/j.cnki.37-1222/t.2019.11.063

Bosch, A., Munoz, X., and Marti, R. (2007). Which is the best way to organize/classify images by content? Image Vis. comput. 25 (6), 778–791. doi:10.1016/j.imavis.2006.07.015

Chen, B. R., Feng, X. T., Fu, Q. Q., Wang, B., Zhu, X. H., Li, T., et al. (2020). Integration and high precision intelligence microseismic monitoring technology and its application in deep rock engineering. Rock Soil Mech. 41 (7), 2422–2431. doi:10.16285/j.rsm.2019.1062

Chen, F., Pan, Y. S., Li, Z. H., Wang, A. W., and Xu, L. M. (2013). Analysis and evaluation of effects of borehole pressure relief measures by drilling cutting method. Chin. J. Geotech. Eng. 35, 266–270. S2.

Chen, Z., Xia, J. B., Bai, J., and Xu, M. (2015). Feature extraction algorithm based on evolutionary deep learning. Comput. Sci. 42 (11), 288–292. doi:10.11896/j.issn.1002-137X.2015.11.059

Dou, M., Wang, S. C., Gong, S. Y., Cai, W., and Li, X. L. (2020). Cloud platform for intelligent identification, monitoring and early warning of rock burst risk. J. Coal Sci. 45 (6), 2248–2255. doi:10.13225/j.cnki.jccs.ZN20.0318

He, S. Q., He, X. Q., Song, D. Z., Li, Z. L., Chen, J. Q., Xue, Y. R., et al. (2022). Multi-parameter integrated early warning model of rock burst and intelligent identification cloud platform. J. China Univ. Min. Technol. 51 (5), 850–862. doi:10.13247/j.cnki.jcumt.001440

Ji, H. G., Wang, J. A., and Cai, M. F. (2003). Relativity and unity of physical and geometrical characteristics of rockbursting events. J. China Coal Soc. 28 (1), 31–36. doi:10.3321/j.issn:0253-9993.2003.01.007

Jia, B. X., Chen, H., and Pan, Y. S. (2019). Research on multi-parameter comprehensive index rock burst prediction technology. J. Disast. Prev. Mitigat. Eng. 39 (2), 330–337. doi:10.13409/j.cnki.jdpme.2019.02.019

Jia, R. S., Sun, H. M., Fan, J. C., Wu, C. F., and Qiu, T. (2014). Multiparameter precursor information identification model and method for rockburst. Chin. J. Rock Mech. Eng. 33 (8), 1513–1519. doi:10.13722/j.cnki.jrme.2014.08.001

Jiang, F. X., Qu, X. C., Yu, Z. X., and Wang, C. W. (2011). Real time monitoring and measuring early warning technology and development of mine pressure bumping. Coal Sci. Technol. 39 (2), 59–64. doi:10.13199/j.cst.2011.02.64.jiangfx.011

Jiang, Y. D., Pan, Y. S., Jiang, F. X., Dou, L. M., and Ju, Y. (2014). State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 39 (2), 205–213. doi:10.13225/j.cnki.jccs.2013.0024

Jiang, Y. D., and Zhao, Y. X. (2015). State of the art: Investigation on mechanism, forecast and control of coal bumps in China. Chin. J. Rock Mech. Eng. 34 (11), 2188–2204. doi:10.13722/j.cnki.jrme.2015.1076

Lan, J. G., and Zhang, H. J. (2022). Research on roadway ground pressure monitoring method based on fiber grating sensor. Coal Technol. 41 (2), 121–124. doi:10.13301/j.cnki.ct.2022.02.030

Li, X. L., Zhang, X. Y., Shen, W. L., Zeng, Q. D., Chen, P., Qin, Q. Z., et al. (2023). Research on the mechanism and control technology of coal wall sloughing in the ultra-large mining height working face. Int. J. Environ. Res. Publ. Health 20 (1), 868. doi:10.3390/ijerph20010868

Li, Z. Q., Zhang, L., Shao, S. H., Qiao, M. G., Cao, S. X., and Ma, J. K. (2022). On-the-spot practice of monitoring coal stress and impact danger by drilling cuttings method. Coal Technol. 41 (5), 137–141. doi:10.13301/j.cnki.ct.2022.05.033

Liu, Q., Wei, J. H., Meng, Q. R., Cao, M., Feng, J., Huang, H., et al. (2022). Clinical characteristics and vaccine effectiveness against SARS-CoV-2 Omicron subvariant BA.2 in the children. Coal Technol. 41 (8), 203–207. doi:10.1038/s41392-022-01023-w

Liu, S. M., and Li, X. L. (2023). Experimental study on the effect of cold soaking with liquid nitrogen on the coal chemical and microstructural characteristics. Environ. Sci. Pollut. Res. 30 (3), 36080–36097. doi:10.1007/s11356-022-24821-9

Liu, S. M., Sun, H. T., Zhang, D. M., Yang, K., Li, X. L., Wang, D. K., et al. (2023a). Experimental study of effect of liquid nitrogen cold soaking on coal pore structure and fractal characteristics. Energy 275 (7), 127470. doi:10.1016/j.energy.2023.127470

Liu, S. M., Sun, H. T., Zhang, D. M., Yang, K., Wang, D. K., Li, X. L., et al. (2023b). Nuclear magnetic resonance study on the influence of liquid nitrogen cold soaking on the pore structure of different coals. Phys. Fluids 35 (1), 012009. doi:10.1063/5.0135290

Lu, X. G., Yu, X. M., and Meng, Z. H. (2021). Study on borehole strain monitoring and early warning of dynamic disasters in disturbed mining areas. Coal Technol. 40 (12), 174–178. doi:10.13301/j.cnki.ct.2021.12.041

Luo, H., Pan, Y. S., and Xiao, X. C. (2013). Multi-parameter risk evaluation and graded early warning of mine dynamic disaster. China Saf. Sci. J. 23 (11), 85–90. doi:10.16265/j.cnki.issn1003-3033.2013.11.020

Lv, J. G., Jiang, Y. D., and Zhao, Y. X. (2013). Hierarchical monitoring for coal bumps and its study and application of early warning methods. J. China Coal Soc. 38 (7), 1161–1167. doi:10.13225/j.cnki.jccs.2013.07.023

Pan, L. Y. (2003). Identification and application of omen information of rockburst. Qingdao, China: Shandong University of Science and Technology.

Qin, M., Liu, C., Wang, Q., Wang, X., Song, Y., Hu, J. W., et al. (2022). Analysis and research on microseismic monitoring and early warning parameters of ground pressure disasters in mining plants. Min. Res. Dev. 42 (10), 180–186. doi:10.13827/j.cnki.kyyk.2022.10.020

Ren, S. (2016). A feature extraction algorithm for handwritten digits based on deep learning. Changsha, China: Hunan Normal University.

Sun, Z. J., Xue, L., and Xu, Y. M. (2013). Marginal Fisher feature extraction algorithm based on deep learning. J. Electr. Inf. Technol. 35 (4), 805–811. doi:10.3724/SP.J.1146.2012.00949

Wang, C. Q., Jiang, B. Y., Gu, S. T., Tan, T. L., Wang, R. C., and Huang, R. F. (2014). Study of precursor information recognition and multiparameter early warning before rockburst of island fully mechanized caving face. Rock Soil Mech. 35 (12), 3523–3530. doi:10.16285/j.rsm.2014.12.023

Wang, D. B., Wang, Q., Li, S. C., Wang, F., Guo, N., Wang, B., et al. (2015). Stress distribution characteristics of deep mine in fully-mechanized sublevel caving face based on microseismic and online stress monitoring system. J. Min. Saf. Eng. 32 (3), 382–388. doi:10.13545/j.cnki.jmse.2015.03.006

Wang, H. L. (2022). Risk warning and prevention decision of rock burst based on cost-sensitive machine learning. Beijing, China: University of Science and Technology Beijing.

Wang, J. Y., Wang, Z. G., Chen, Y. M., and Gao, J. H. (2023). Deep artificial neural network in seismic inversion. Progr. Geophys. 38 (1), 298–320. doi:10.6038/pg2023FF0467

Wang, Y., Liu, J. H., Wang, Y. L., and Wei, Q. D. (2018). Study on multi-parameter monitoring and warning platform for rock burst. Coal Eng. 50 (4), 19–21. doi:10.11799/ce201804006

Wang, Z. D., Liu, G. L., Cui, Y., Jiang, T., Zheng, Y. C., Liang, W. Z., et al. (2022). Study on multi-parameter correlation of rock burst monitoring in deep isolated island structure area. Coal Technol. 41 (12), 63–66. doi:10.13301/j.cnki.ct.2022.12.015

Yin, L. X. (2022). Research on safety monitoring and early warning system of coal mine heading face. Energy Energy Sav. (7), 136–138. doi:10.16643/j.cnki.14-1360/td.2022.07.062

Yuan, L., Jiang, Y. D., He, X. Q., Dou, L. M., Zhao, Y. X., Zhao, X. S., et al. (2018). Research progress of precise risk accurate identification and monitoring early warning on typical dynamic disasters in coal mine. J. China Coal Soc. 43 (2), 306–318. doi:10.13225/j.cnki.jccs.dy20.0272

Zhang, C. P. (2020). Application of drill cuttings method to evaluate rock burst risk in mining face. Energy Environ. Prot. 40 (12), 20–23. doi:10.19389/j.cnki.1003-0506.2020.12.004

Zhang, J. C., Li, X. L., Qin, Q. Z., Wang, Y. B., and Gao, X. (2023). Study on overlying strata movement patterns and mechanisms in super-large mining height stopes. Bull. Eng. Geol. Environ. 82 (4), 142. doi:10.1007/s10064-023-03185-5

Zhang, L. (2021). Construction of intelligent anti-scour system in deep area of coal mine. China Coal Ind. (7), 68–70. doi:10.3969/j.issn.1673-9612.2021.07.026

Zhang, L., Shen, W. L., Li, X. L., Wang, Y. B., Qin, Q. Z., Lu, X. T., et al. (2022). Abutment pressure distribution law and support analysis of super large mining height face. Int. J. Environ. Res. Pub. Health 20 (1), 227. doi:10.3390/ijerph20010227

Zhang, Y. Y., Huo, J., Yang, W. Q., Gao, Y., and Shi, Y. H. (2015). The second generation ID card heterogeneous face verification algorithm of Deep Belief Network. J. Intell. Syst. 10 (2), 193–200.

Zheng, J. H. (2022). Random load identification method based on deep neural network. Guangzhou, China: Guangzhou University.

Keywords: deep neural network, rockburst, model training, hazard monitoring, comprehensive early warning

Citation: Guo Y, Gu S, Du R and Shen J (2023) Multi-parameter comprehensive early warning of coal pillar rockburst risk based on DNN. Front. Earth Sci. 11:1201946. doi: 10.3389/feart.2023.1201946

Received: 07 April 2023; Accepted: 13 June 2023;

Published: 27 June 2023.

Edited by:

Jingjing Meng, Luleå University of Technology, SwedenReviewed by:

Zhaolin Li, Anhui University of Science and Technology, ChinaCopyright © 2023 Guo, Gu, Du and Shen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ruimin Du, ODU3MTk2NzAyQHFxLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.