94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci., 16 January 2023

Sec. Geohazards and Georisks

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.982937

This article is part of the Research TopicRock Landslide Risk Assessment, Stability Analysis and Monitoring for The Development of Early Warning Systems and Reinforcement MeasuresView all 24 articles

Rock joints are important factors affecting natural disasters such as landslides, and weak interlayer is the decisive factor for rock joint stability. Therefore, it is necessary to carry out shear test research on rock joints with weak interlayer. In this paper, the red sandstone was used as rock joint material, and consistent saw-tooth rock joints were produced by the 3D carving technology. According to the on-site composition analysis, the weak interlayer used in the test was obtained through remodeling. Weak interlayer with different moisture contents and filling degrees were produced by the Constant Dry Mass Method (CDMM). Shear strength test of rock joint with weak interlayer of different filling degree and moisture content under multi-level normal stress was carried out by the self-developed direct shear apparatus. The test results show that peak shear strength of rock joint with weak interlayer increases firstly and then decreases with the raise of moisture content. Peak shear strength of rock joint with weak interlayer decreases firstly and then tends to a stable value with the raise of filling degree. As the filling degree of weak interlayer changes from small (less than 1.0) to large (more than 1.0), dilatancy mode of saw-tooth rock joint changes from dilatation to contraction during shearing. Peak shear strength of rock joint with weak interlayer increases with the raise of normal stress.

Rock joint such as fault, bedding and weak interlayer is a common geological phenomenon in rock mass, and the existence of this joint is a significant source of disasters. A large number of research and achievements on rock joint are carried out by scholars (Du, et al., 2020; Luo et al., 2021). However, the study on coupling effect of moisture content and filling degree of weak interlayer is not enough. Therefore, it is of great significance to study the shear performance of rock joint with weak interlayer.

In terms of moisture content, Sun, 1981 considered moisture content was significant factors in mechanical effect of rock joint by shearing tests. Li et al. (2008) believed that shear strength of sandstone joint with weak interlayer decreased with the increase of moisture content by the shear creep test. Liu et al. (2017) considered that the cohesion and friction angle increased firstly and then decreased with the raise of moisture content by direct shear test for strongly weathered mudstone, and the optimum moisture content was 12.7%.

In terms of filling degree, Goodman, (1976) found that shear strength of rock joint was affected by the coupling effect of rock joint morphology and weak interlayer as the filling degree was smaller than 1.0. However, shear strength was controlled by weak interlayer itself as the filling degree was larger than 2.0. Ladanyi and Archambault (1977) defined the ratio of the thickness of weak interlayer (t) to the fluctuation degree of rock joint surface morphology (a) as a new variable, which is generally called filling degree. Many scholars supposed that shear strength parameters of rock joint decreased with the increase of clay content of weak interlayer (Skempton 1985; Mesri and Cepeda-Diaz, 1986; Gibo et al., 1987; Xiang, 1989). Indraratna considered that there was a critical thickness of the weak interlayer through experiments and theoretical studies (Indraratna et al., 1999; Indraratna et al., 2008; Indraratna et al., 2010; Indraratna et al., 2013; Indraratna et al., 2014). Papaliangas et al., 1993 gained that the critical filling degree of rock joint with fly ash interlayer is about 1.5 by direct shear test. Yang, 2002 used the interlayer method and the continuum method to deal with thin and thick interlayer problems respectively.

In summary, scholars have done a lot of research on the influence of moisture content and thickness on shear performance of rock joint, and have also made corresponding research results. However, there are few studies on saw-tooth rock joint with weak interlayer under coupling effect of different moisture contents, filling degrees and normal stresses. In this paper, the red sandstone is used as the upper and lower specimens, and consistent saw-tooth rock joints are produced by the 3D carving technology. Samples (38 items in total) of saw-tooth rock joint with different interlayer moisture contents and filling degrees are produced by CDMM and confining device. Shear test of saw-tooth rock joint is carried out by developed direct shear apparatus, and variation laws of shear performance (shear stress-displacement curve, peak shear strength, normal displacement, etc.) with interlayer moisture contents, filling degrees and normal stressed are analyzed.

Conventional direct shear apparatus can only carry out test of the rock joint without filling. According to the experimental characteristics of rock joint with weak interlayer, a direct shear apparatus is developed in this paper. The apparatus was mainly composed of loading platform, loading system, measuring system, controller, shear box and supporting computer software (Figure 1). The sensor measured normal and tangential load were applied by mechanical lever and stepping motor. Normal and tangential displacement were obtained by measurement sensor. Specific technical indicators of the apparatus are shown in Table 1.

The sample of rock joint was mainly composed by upper specimen, lower specimen and weak interlayer. The red sandstone used in the specimens had the same uniaxial compressive strength as the rock in the field. The weak interlayer was a mixture of montmorillonite, illite and other minerals. Moreover, the weak interlayer used in the test was obtained through remodeling according to the on-site composition analysis. The specific mix proportion is shown in Table 2.

Morphology of rock joint is one of the main factors affecting shear strength of weak interlayer (Du et al., 2022). In order to study the influence of moisture content and filling degree on shear strength, the regular saw-tooth rock joint is adopted with specific tooth height of 3 mm and width of 12 mm. Red sandstones were carved by MD-6060 numerical engraving machine. The specific steps were as follows. Firstly, the corresponding saw-tooth morphology model was established in modeling software, and the generated path file was imported into control software of the numerical engraving machine. Secondly, red sandstone was put into the engraving machine and fixed by bolts. Thirdly, the engraving program was started by the control software, and cutter head was controlled to carve the red sandstone according to specified path. Finally, the morphology of the saw-tooth was carved completely (Figure 2).

The mineral mixture was prepared by the mix proportion shown in Table 2 and placed in oven at 105°C for 12 h. The mineral mixture after drying was shown in Figure 3A. The large grains were removed through the geotechnical sieve with a diameter of 1.0 mm after static cooling in room. Appropriate amount of water was added to mineral mixture after screening, and the weak interlayer with moisture contents of 10%, 15%, 20% and 25% was prepared respectively (Figures 3B–E). The mass of weak interlayer with different thickness was determined by CDMM, as shown in formula 1. Under different filling degrees, the mass of weak interlayer corresponding to moisture contents is shown in Table 3:

Where n is the moisture content of weak interlayers; mn is the quality of weak interlayers with n moisture content, g; a is the test coefficient, g/mm, with a value of 15.22; t is the thickness of weak interlayer, mm.

FIGURE 3. Weak interlayer with different moisture content: (A) 0; (B) 10%; (C) 15%; (D) 20%; (E) 25%.

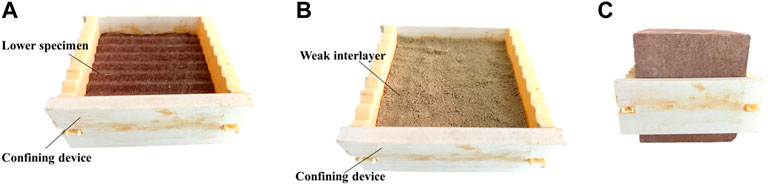

The lower specimen was fixed by self-developed confining device, and weak interlayer that corresponds to the thickness was weighed according to formula 1. Before the upper specimen was placed, weak interlayer was evenly spread on the joint of lower specimen and layered compaction. Finally, two-halves of the specimens were tied and placed on shaking table for compaction (Figure 4). Repeated these steps and prepared saw-tooth rock joint with weak interlayer samples with filling degrees of 0, 0.5, 1.0 and 2.0 respectively (Figure 5).

FIGURE 4. Process of sample preparation: (A) Installation of confining device; (B) Add weak interlayer; (C) Sample preparation.

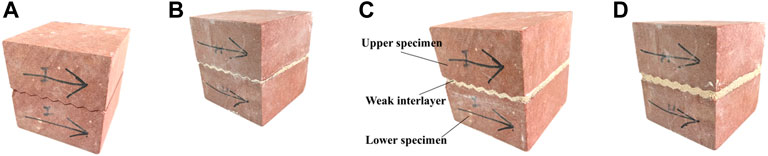

FIGURE 5. Sample of rock joint with different filling degrees: (A) k = 0; (B) k = 0.5; (C) k = 1.0; (D) k = 2.0.

The main influencing factors of the shear performance of saw-tooth rock joint with weak interlayer are moisture contents, filling degrees and normal stresses. The moisture contents of the weak interlayer are 10%, 15%, 20%, 25%. The filling degrees are 0, 0.5, 1.0, 2.0, and the normal stresses are 200 kPa, 400 kPa, 600 kPa. The specific test scheme is shown in Table 4.

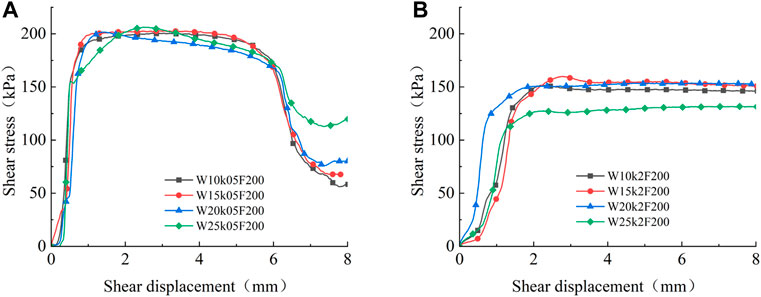

Shear stress-displacement curve of saw-tooth rock joint under the same filling degree and different moisture contents is shown in Figure 6. The test results (Figure 6) indicate that variation law of shear stress-displacement of saw-tooth rock joint with weak interlayer is approximately consistent under the same filling degree, normal stress and different moisture contents. When filling degree is 0.5, shear stress of the saw-tooth rock joint with weak interlayer firstly reaches maximum and decreases sharply with the increase of shear displacement. The main reason is that the upper specimen drops sharply after it climbs to the highest point of saw-tooth during the shear process. Moreover, shear stress of saw-tooth rock joint with weak interlayer increases firstly and then tends to a stable value with the growth of shear displacement when filling degree is larger than 2.0.

FIGURE 6. Shear stress–displacement curve under different moisture contents: (A) k = 0.5, F = 200 kPa; (B) k = 2.0, F = 200 kPa.

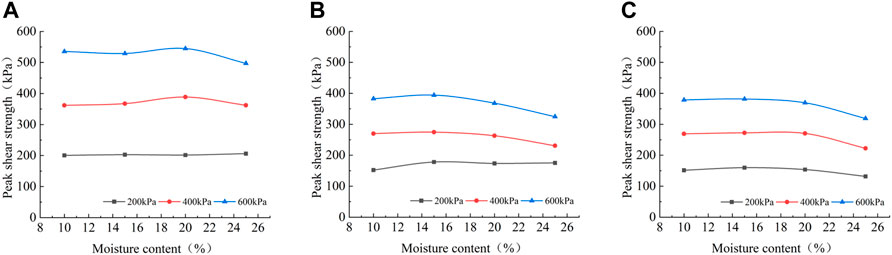

Figure 7 displays the relationship between peak shear strength of saw-tooth rock joint with weak interlayer and moisture content under the same filling degree. The test results (Figure 7) reveal that peak shear strength of saw-tooth rock joint with weak interlayer increases firstly and then declines with the increase of moisture content under the same filling degree and normal stress. Moreover, peak shear strength reaches the maximum as moisture content between 15% and 20% because the cohesion and friction angle increase with the raise of moisture content which is lower than 15% during the shear process of soil-rock interface. However, the cohesion and friction angle decrease with the raise of moisture content which is higher than 20% during the shear process.

FIGURE 7. Peak shear strength under different moisture contents: (A) k = 0.5; (B) k = 1.0; (C) k = 2.0.

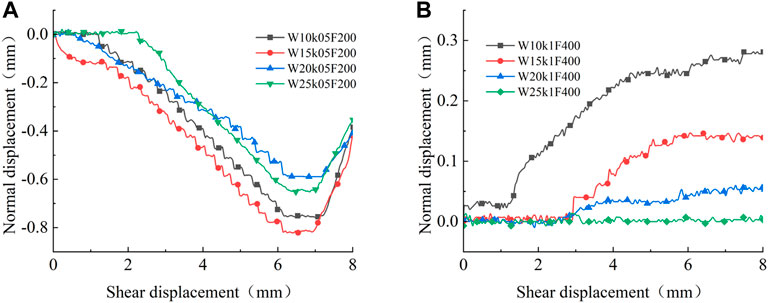

Normal-shear displacement curve of saw-tooth rock joint with weak interlayer under the same filling degree and different moisture contents is shown in Figure 8. Where, shear contraction corresponds to the positive value on the graph which is located on the upper side of the X coordinate axis. Conversely, shear dilatation corresponds negative value which is located below the X axis. It can be recognized from Figure 8 that variation of the normal-shear displacement curve of the saw-tooth rock joint with weak interlayer under different moisture content is approximately the same when filling degree is 0.5, and the upper specimen with different moisture contents reach the maximum displacement of shear dilatancy as shear displacement is 6 mm. This is due to the joint climbs to the highest point of saw-tooth after the shear displacement reaches half tooth width, which also indicates that the normal displacement is less affected by moisture content. Moreover, the normal displacement decreases with the increase of moisture content when filling degree is larger than 1.0. As moisture content increases further, the normal displacement almost does not change.

FIGURE 8. Normal–shear displacement curve under different moisture contents: (A) k = 0.5, F = 200kPa; (B) k=1.0, F=400kPa.

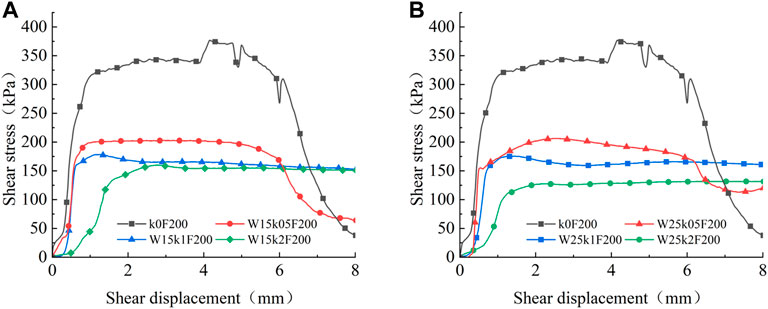

Shear stress-displacement curve of saw-tooth rock joint with weak interlayer under the same moisture content and different filling degrees is shown in Figure 9. The test results (Figure 9) reveal that the shear stress increases firstly and tends to a stable value, and finally decreases with the increase of shear displacement when there is no filling. This is due to a decline section appearing after the upper specimen climbing to the highest point of saw-tooth. Besides, shear stress boosts or drops sharply during the process of direct shear because the failure of upper and lower specimen joint surface during shearing. Shear strength of saw-tooth rock joint with weak interlayer decreases with increase of filling degree under the same moisture content, and the decreasing range also declines gradually. Peak shear strength tends to a stable value when filling degree is larger than 2.0 because failure location of the sample changes from the mutual failure inside rock masses to the location between rock masses and interlayers, and finally to the location inside interlayers with increase of filling degree. Moreover, peak shear strength does not change significantly after the filling degree reaching the critical value. When filling degree is smaller than 0.5, the shear stress of saw-tooth rock joint with weak interlayer decreases sharply after shear displacement reaches about 6 mm. While it does not appear as filling degree is larger than 1.0 because shear strength of the sample is mainly affected by rock joint as filling degree is small. It also shows that climbing process of the specimens appears under these conditions. In addition, shear strength of the specimen is affected by rock joint and weak interlayer as filling degree is large, and there will be no climbing process and sudden decrease of shear stress.

FIGURE 9. Shear stress–displacement curve under different filling degrees: (A) W = 15%; (B) W = 25%.

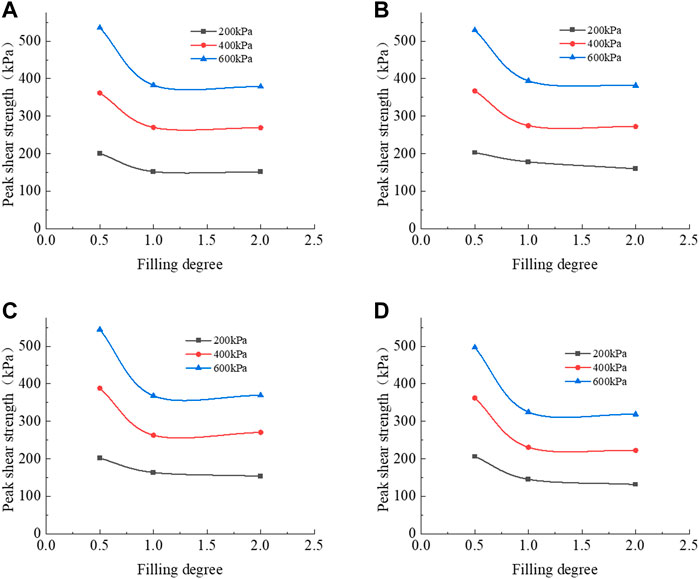

Figure 10 displays the relationship curve between peak shear strength and filling degree of saw-tooth rock joint with weak interlayer under the same moisture content. The test results (Figure 10) indicate that under the same moisture content, peak shear strength of saw-tooth rock joint with weak interlayer decreases firstly and then tends to a stable value with increase of filling degree, and peak shear strength does not change significantly after the filling degree exceeds 1.0. This is because shear strength of saw-tooth rock joint under small filling degrees is mostly borne by the rock-rock interface, which causes the shear strength be higher. Shear strength is gradually borne by soil-rock interface and soil-soil interface with the increase of filling degree which causes great reduction of the shear strength. Finally, the shear strength is completely borne by weak interlayer as the filling degree increase to critical value.

FIGURE 10. Peak Shear Strength under different filling degrees: (A) W = 10%; (B) W = 15%; (C) W = 20%; (D) W = 25%.

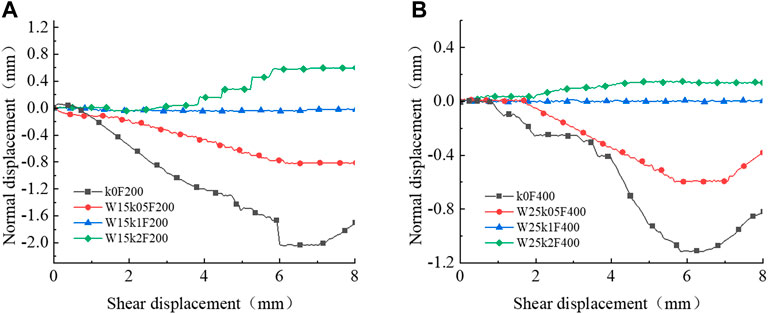

Figure 11 shows the normal-shear displacement curve of saw-tooth rock joint with weak interlayer under the same moisture content and different filling degrees. Where, shear contraction corresponds to the positive value on the graph which is located on the upper side of the X coordinate axis. Conversely, shear dilatation corresponds negative which is located below the X axis. The results (Figure 11) show that rock joint without interlayer has upward displacement (shear dilatation) under different normal stresses, and the normal displacement reaches maximum as the shear displacement reaches 6 mm. This is because the rock joint climbs to the highest point of the saw-tooth as there is no filling, and the value of 6 mm is shear displacement corresponding to the highest point of saw-tooth. It is also corresponding to stress mutation of shear stress-displacement curve in Figure 9A, which reflects that the sudden increase or decrease of shear stress is due to failure of two-halves of the specimens during shearing. Moreover, most upper specimens appear downward displacement during shear process with the increase of filling degree. The main reason is that weak interlayer is compressed through shearing, and the decrease of volume expands normal displacement.

FIGURE 11. Normal–shear displacement curve under different filling degrees: (A) W = 15%, F = 200kPa; (B) W = 25%, F = 400kPa.

Figure 12 shows the relationship between peak shear strength and normal stress. The test results (Figure 12) indicate that peak shear strength of rock joint with weak interlayer under different moisture contents increases nonlinearly with the increase of normal stress, showing the characteristics of stress effect. Moreover, peak shear strength of weak interlayer with 15% moisture content is the highest under different normal stresses. It also shows that moisture content of 15% is closer to the optimal value.

Figure 13 shows the normal-shear displacement curve of saw-tooth rock joint with weak interlayer under different normal stresses. The test results (Figure 13) indicate that upward displacement of upper specimen rock joint occurs as normal stress is low, and slope rate of shear dilatation curve slows down rapidly as rock joint reaches peak shear strength. The main reason is that weak interlayer shows dilatancy characteristics under low normal stress which causes the soil grains to move and slip. Shear dilatation characteristics of rock joint disappears with the increase of normal stress. In addition, shear dilatation turns to contraction with the further increase of normal stress, and the downward displacement of upper specimen leads to the contact wear of two-halves of specimens.

Weak interlayer is a common weak surface in rock mass, which is a key factor to control the stability of rock joint and affects safety of rock engineering. In this paper, shear strength of rock joint is studied by direct shear apparatus for joint with weak interlayer under different moisture contents, filling degrees and normal stresses. The main conclusions of shear performance of saw-tooth rock joint with weak interlayer are as follows:

(1) Peak shear strength of rock joint with weak interlayer increases firstly and then decreases with the increase of moisture content. Peak shear strength reaches the maximum as weak interlayer achieves the optimal moisture content.

(2) Peak shear strength of rock joint with weak interlayer decreases firstly and then tends to a constant value with the increase of filling degree. Peak shear strength reaches a stable value as weak interlayer exceeds the critical filling degree.

(3) Normal stress also has a significant influence on peak shear strength of saw-tooth rock joint with weak interlayer, and peak shear strength increases with the raise of normal stress.

(4) Saw-tooth rock joint with weak interlayer appears climbing phenomenon in the direct shear process under the condition of small filling degrees, and failure location is mainly between the joint surface of upper and lower specimen. However, shear contraction phenomenon appears in the direct shear process, and failure location turn to internal failure of weak interlayer under the condition of large filling degrees.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

The first author, ZL, and the second author, YZ, are responsible for the general writing of the manuscript and completing main experimental; and the third author, SD, put forward the idea and designed the study; the fourth author, MH, provided data processing assistance; and the fifth author, YL, is responsible for consulting on some test instruments.

This paper was supported by the National Natural Science Foundation of China (No. 42277147) and Special Support Plan for High Level Talents of Zhejiang Province (2020R52028). Their supports are gratefully acknowledged.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Du, H., Song, D., Chen, Z., and Guo, Z. (2020). Experimental study of the influence of structural planes on the mechanical properties of sandstone specimens under cyclic dynamic disturbance. Energy Sci. Eng. 8 (11), 4043–4063. doi:10.1002/ese3.794

Du, S., Lin, H., Yong, R., and Liu, G. J. (2022). Characterization of joint roughness heterogeneity and its application in representative sample investigations. Rock Mech. Rock Eng. 55, 3253–3277. doi:10.1007/s00603-022-02837-4

Gibo, S., Egashira, K., and Ohtsubo, M. (1987). Residual strength of smectite-dominated soils from the Kamenose landslide in Japan[J]. Can. Geotech. J. 24 (3), 456–462. doi:10.1139/t87-057

Goodman, R. (1976). Methods of geological engineering in discontinuous rocks[J]. Int. J. Rock Mech. Min. Sci. Geomechanics Abstr. 13 (10), 115. doi:10.1016/0148-9062(76)90566-0

Indraratna, B., Haque, A., and Aziz, N. (1999). Shear behaviour of idealized infilled joints under constant normal stiffness. Geotechnique 49 (3), 331–355. doi:10.1680/geot.1999.49.3.331

Indraratna, B., Jayanathan, M., and Brown, E. T. (2008). Shear strength model for overconsolidated clay-infilled idealised rock joints. Geotechnique 58 (1), 55–65. doi:10.1680/geot.2008.58.1.55

Indraratna, B., Oliveira, D. A. F., and Brown, E. T. (2010). A shear-displacement criterion for soil-infilled rock discontinuities. Geotechnique 60 (8), 623–633. doi:10.1680/geot.8.p.094

Indraratna, B., Premadasa, W., Brown, E. T., Gens, A., and Heitor, A. (2014). Shear strength of rock joints influenced by compacted infill. Int. J. Rock Mech. Min. Sci. 70, 296–307. doi:10.1016/j.ijrmms.2014.04.019

Indraratna, B., Premadasa, W., and Brown, E. T. (2013). Shear behaviour of rock joints with unsaturated infill. Geotechnique 63 (15), 1356–1360. doi:10.1680/geot.12.P.065

Ladanyi, B., and Archambault, G. (1977). “Shear strength and deformability of filled indented joints[C],” in Proceedings of International Symposium on Geotechnics of Structurally Complex Formations, Capri, Italy, 13 January, 1977, 317–326.

Li, P., Liu, J., Zhu, J., and He, H. (2008). Study on relationship between shear creep characteristics and moisture content of weak joint [J]. Geotechnics 44 (07), 1865–1871. doi:10.3969/j.issn.1000-3665.2009.06.011

Liu, H., Li, K., Yuan, Q., Liao, J., and Qin, L. (2017). Direct shear test on soil-rock interface of High fill bedding slope under different moisture contents[J]. Quick Rep. Water Conservancy Hydropower 38 (09), 46–48. doi:10.15974/j.cnki.slsdkb.2017.09.018

Luo, Z., Jiang, M., Mo, L., Zou, B., and Huang, M. (2021). Stress effect & scale effect on shear properties of double saw-tooth rock joint surface. Appl. Rheol. 31 (1), 39–49. doi:10.1515/ARH-2020-0117

Mesri, G., and Cepeda-Diaz, A. F. (1986). Residual shear strength of clays and shales. Geotechnique 36 (2), 269–274. doi:10.1680/geot.1986.36.2.269

Papaliangas, T., Hencher, S. R., Lumsden, A. C., and Manolopoulou, S. (1993). The effect of frictional fill thickness on the shear strength of rock discontinuities. Int. J. Rock Mech. Min. Sci. Geomechanics Abstr. 30 (2), 81–91. doi:10.1016/0148-9062(93)90702-f

Skempton, A. W. (1985). Residual strength of clays in landslides, folded strata and the laboratory. Geotechnique 35 (1), 3–18. doi:10.1680/geot.1985.35.1.3

Sun, W. (1981). Mechanical effect of weak interlayer thickness[J]. China: Engineering Geology Department of Wuhan University of Water Resources and Electric Power, 33–39.

Xiang, W. (1989). Empirical formula between clay content of weak interlayer and shear strength parameters[J]. Hydrogeology Eng. Geol. 48 (05), 45–46. doi:10.16030/j.cnki.issn.1989.05.011

Keywords: saw-tooth rock joint, weak interlayer, moisture content, filling degree, shear performance

Citation: Luo Z, Zhang Y, Du S, Huang M and Lyu Y (2023) Experimental study on shear performance of saw-tooth rock joint with weak interlayer under different moisture contents and filling degrees. Front. Earth Sci. 10:982937. doi: 10.3389/feart.2022.982937

Received: 30 June 2022; Accepted: 01 August 2022;

Published: 16 January 2023.

Edited by:

Bo Li, Tongji University, ChinaCopyright © 2023 Luo, Zhang, Du, Huang and Lyu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhanyou Luo, bHp5MDM5NUAxNjMuY29t; Yuanjun Lyu, bHZ5dWFuanVuMjIyQDE2My5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.