- College of Mining, Liaoning Technical University, Fuxin, Liaoning, China

Rockburst is a complex dynamic disaster in coal mining and affected by many factors. To accurately predict the rockburst hazard among complex influencing factors, a prediction model of rockburst hazard based on the Gaussian process for binary classification (GPC) was proposed after the identification of the intrinsic relationship between multiple factors of coal mines and rockburst. Through computerized machine learning and integrated intelligent analysis, the non-linear mapping of rockburst hazard and its influencing factors was established. The multi-factor pattern recognition model was constructed using artificial intelligence. The prediction criteria of the rockburst hazard probability and the hazard probability value of the prediction area unit were determined by applying neural network and fuzzy inference methods. In addition, the rockburst hazardous zone was classified, and the corresponding technical scheme for the prevention was put forward. The validity and feasibility of the regional prediction of rockburst hazard based on GPC were verified in the engineering practice. This method is highly targeted and can improve the accuracy and precision of rockburst prediction, thus contributing to the safe and efficient production of coal mines.

Introduction

As a complex dynamic disaster in coal mining, rockburst is very hard to be accurately predicted (Qiao et al., 2021; Zhu et al., 2022). The occurrence of rockbursts is influenced by various factors and is characterized by a regional distribution (Wang et al., 2021a; Cao et al., 2021; Chen et al., 2021). As the depth of mining deepens, the number and frequency of rockbursts in mines increase (Yu et al., 2021; Xue et al., 2022). There are distinctive rockburst modes under different conditions of mining areas, mines, coal seams, structures, and stresses. Traditional linear data analysis is not accurate enough under complex mining conditions (He et al., 2020; Zhang and Jiang, 2020; Lin et al., 2022). Based on the non-linear relationship between rockburst hazard and its influencing factors, the probability prediction value of unit hazard is determined (Wu et al., 2021a; Chen et al., 2021; Yang et al., 2021; Yang and Zhang, 2021). According to the magnitude of the risk probability value of each cell, the engineering area is divided into four classes, and the regional and quantitative rockburst prediction can be significantly improved by using the multi-factor pattern recognition method.

In the prediction of mine rockburst hazards, machine learning methods have been proposed to predict rockburst hazards with good results (Ullah et al., 2022; Wojtecki et al., 2022; Xiao et al., 2022). Machine learning is a complex and cross-cutting discipline. In the prediction of rockburst hazards in mines, data from multiple sources are analyzed, and then machine learning algorithms are used to continuously learn from previous rockburst events and train computer models. The study of “neural network + machine learning” artificial intelligence prediction techniques allows monitoring and predicting the likelihood of rockburst hazards in coal mines (Wang et al., 2021b; Ke et al., 2021; Zhang et al., 2021). In order to accurately predict rockburst hazards under complex conditions, a rockburst hazard prediction model based on the Gaussian process for binary classification (GPC) was proposed (Hui and Zhang, 2020; Davis et al., 2021).

For the rockburst situation in Jixian Coal Mine, a GPC-based rockburst hazard prediction, prevention, and control technology system was established based on theoretical analysis (Iwata and Tanaka, 2022), and the intrinsic relationship between multiple influencing factors and rockburst was determined using a multi-factor pattern identification method. By dividing the engineering area into prediction units and determining the pattern identification criteria and unit hazard probability values (Gladyr et al., 2021), the rockburst hazard area of the on-site engineering area was classified, and corresponding management measures were proposed (Wu et al., 2021b).

Principles of the Gaussian process for binary classification

Statistically, the Gaussian process is a stochastic process: the distribution of any finite variable set is a Gaussian distribution. In other words, for any integer n ≥ 1 and any family of random variables X, the joint probability distribution of the corresponding process state f(X) at time t obeys the n-dimensional Gaussian distribution. All statistical characteristics of the Gaussian process are determined by its mean and covariance function. In the field of machine learning, the Gaussian process refers to a machine learning method based on the Gaussian stochastic process and Bayesian learning theory.

The Gaussian process for binary classification (GPC) model is a kind of classification model based on the machine learning principle of the Gaussian process. In the GPC model, let an input x correspond to the output value of the binary classification mark y, y ∈ {−1,1}, and the observation data set is

For a given x, the p

For a given potential function, the observed value is an independent Bernoulli distribution variable, whose likelihood function is

The prior distribution of potential functions is

where K is a covariance matrix of order m × m, Kij = k(xi,xj,θ), k() is a positive definite covariance function related to θ, and θ is a hyper-function.

The covariance function of the Gaussian process model needs to be satisfied: a non-negative positive definite covariance matrix can be generated for any point set. The commonly used covariance function is the squared exponential function, namely,

where the hyper-function θ = {

According to Bayes’ rule, after obtaining the actual observation value, a posterior distribution of the potential function f is obtained as follows:

The aforementioned equation is the learning process of GPC, and the following is the prediction process of GPC. The conditional probability of the potential function value f* corresponding to x* is

The prediction probability of y* is

When the predicted probability value of Y* is greater than 0.5, then y* = 1; otherwise, y* = −l. Eqs 5 and 6 have no analytical solutions. Approximate solutions can be obtained by using Laplace’s method and expectation propagation method (Villacampa–Calvo and Hernández–Lobato, 2020; Chakir et al., 2022). Let m and A be the mean and variance of the approximate solutions, respectively, and the approximate Gaussian distribution of the posterior distribution of the potential function f is

Similarly, the posterior distribution of f* can be set as an approximate Gaussian distribution:

The mean and variance are

where k* = [k(x1,x*),…,k(xm,x*)]T represents the prior covariance vector between x* and training input X. x* belongs to classification 1 of the prediction probability:

Gaussian process for binary classification-based prediction model for rockburst hazard

Main influencing factors of rockburst

The mechanism of rockburst in coal mines is complex. The occurrence of rockburst is controlled by

Establishment of the Gaussian process for binary classification model

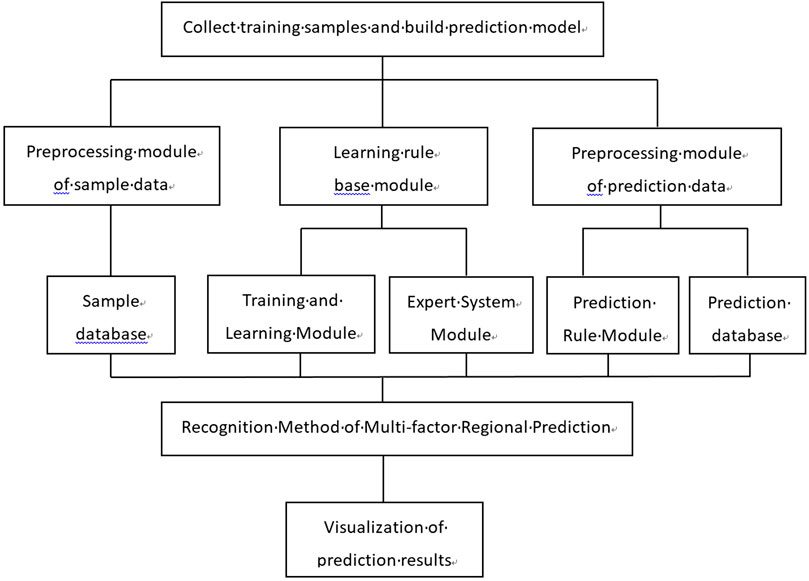

The establishment of the GPC model for the rockburst hazard prediction and the visualization of prediction results are shown in Figure 1.

(1) Rockburst cases were collected as training samples. It was assumed that there were several rockburst cases (

(2) Through learning the training samples, the optimal hyper-parameters of the covariance function were obtained by the maximum likelihood method.

(3) According to the theory of the Gaussian process and the Bayesian rule, the training samples were studied by inductive inferencing. The posterior approximate Gaussian distribution of the potential function f* of the predicted samples was obtained by Eq. 8.

(4) According to Eq. 10, the hazard probability prediction criteria of rockburst and the hazard probability value of the predicted regional unit were obtained. When the predicted probability value was in a certain critical interval, the rockburst hazard and the range of the hazardous zone were determined.

(5) Based on the aforementioned modeling steps, the MATLAB program was compiled, and the regional prediction management system was established to visualize the prediction results.

Rockburst hazard classification

According to Article 228 of Coal Mine Safety Regulation (2022 Edition), the following provisions shall be observed in the prevention and control of rockburst in mines: when coal seams with potential rockburst are mined, comprehensive prevention and control measures must be taken, such as prediction of rockburst hazard, monitoring and early warning, prevention governance, validity inspection, and safety protection. The hazard prediction of rockburst is the primary task in implementing comprehensive prevention and control measures.

According to the Detailed Rules and Regulations for Prevention of Rockburst in Coal Mines (2018 Edition), the probability prediction values of rockburst hazard were used to classify the regional hazard in the proposed classification method. Four grades of the regional rockburst hazard were obtained: non-rockburst hazard, weak rockburst hazard, medium rockburst hazard, and strong rockburst hazard. In the actual mining, when excavation roadways or working faces enter different prediction units, the risk of the areas can be determined in advance, and the corresponding preventive measures can be taken in advance.

Cases in the mining project

Introduction of rockburst in Jixian Coal Mine

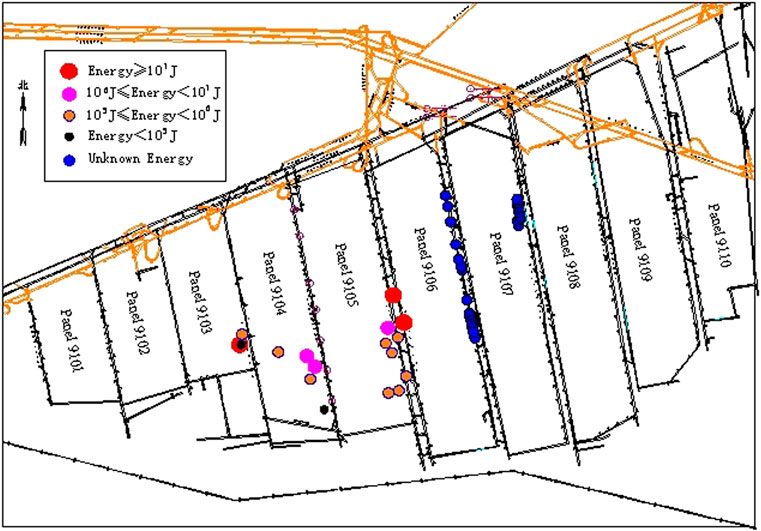

Jixian Coal Mine was put into operation in 1968. It is currently mined at a depth of 578–733 m and is a deep mining pit. The main coal seams are coal seams 3, 9, and 16. In the backstopping process of Coal Seam 9, rockburst has occurred many times. At present, more than 50 rockbursts have occurred, and the maximum energy released by rockburst was 2.7 × 107 J (Figure 2). With the extension of mining excavation, the threat of rockburst is further strengthened. Rockburst can destroy roadways and mechanical equipment and seriously restrict the safe and efficient production of coal mines. It has become an important scientific problem to be solved urgently.

Establishment of the rockburst hazard prediction model in Jixian Coal Mine

The mining geological and technical conditions of rockburst in Jixian Coal Mine were analyzed. The main influencing factors of rockburst included fracture structure, tectonic stress, roof lithology, mining depth, and mining intensity. According to the different effects of different factors on the rockburst, the Gaussian process for binary classification was applied to analyze the training samples and determine different weights. Then, quantitative analysis was carried out, and the probability prediction model of multi-factor pattern recognition for rockburst hazard was established. The multi-factor pattern recognition technology was applied for the comprehensive intelligent analysis, and then the neural network and fuzzy reasoning method were used to determine the hazard probability of each unit in the prediction zone. The studied zones were divided into finite units, and the impact of each single factor index on the unit was analyzed, and the probability value of rockburst hazard for each unit was predicted.

Prediction of rockburst hazard in Jixian Coal Mine

According to the risk prediction results of rockburst, Jixian Coal Mine was divided into a total of 4,553 units with a cell grid of 100 m × 100 m. The influencing factors, such as fracture structure, tectonic stress, roof lithology, mining depth, and mining intensity, were mapped to the unit grid. The comprehensive influence of each factor on the prediction unit was expressed by the probability value, and the hazard probability of rockburst of each unit was obtained by the method of pattern recognition.

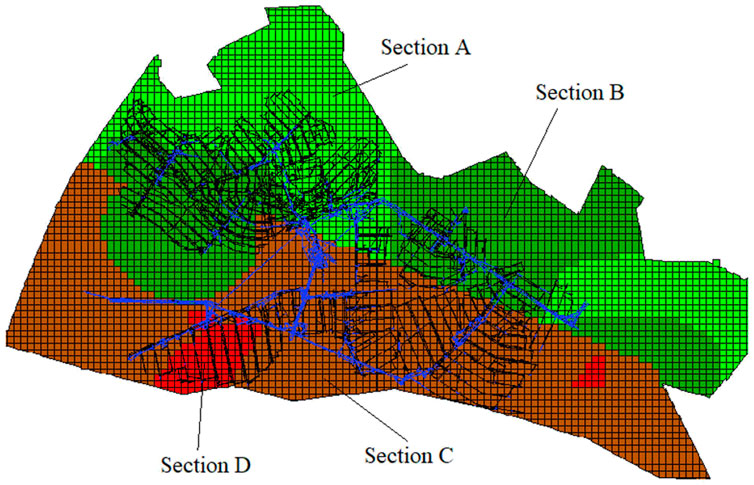

The probability values of rockburst hazard in Jixian Coal Mine of 0.25, 0.50, and 0.75 were taken as critical values. If the probability value is less than 0.25, it is the non-rockburst zone, accounting for 17.6%; between 0.25 and 0.50, it is the weak rockburst hazardous zone, accounting for 52.8%; if it is between 0.50 and 0.75, it is the medium rockburst hazardous zone, accounting for 26.4%; and if it is more than 0.75, it is the strong rockburst hazardous zone, accounting for 3.2%. Figure 3 shows the classification results of the hazardous zone of rockburst.

FIGURE 3. Classification results of hazardous zone of rockburst Section A is non-rockburst zone; Section B is weak rockburst zone, Section C is medium rockbur.

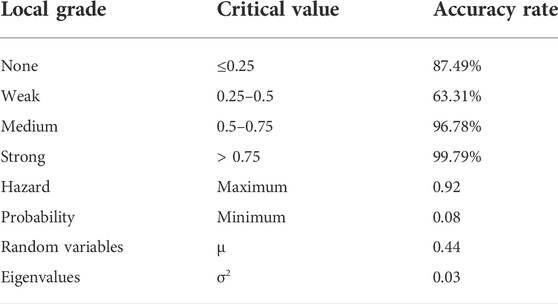

The multi-factor pattern recognition method based on machine learning completed the sub-unit probability prediction of rockburst hazard. By comparing the rockburst training samples with the predicted samples, the results showed that the prediction results were in good agreement with the actual situation, and the prediction results were highly scientific and reliable. Table 1 shows the prediction accuracy of rockburst in different grade zones.

Prediction results of rockburst hazard in Working Face 4 of Western Mining Area 2 in Jixian Coal Mine

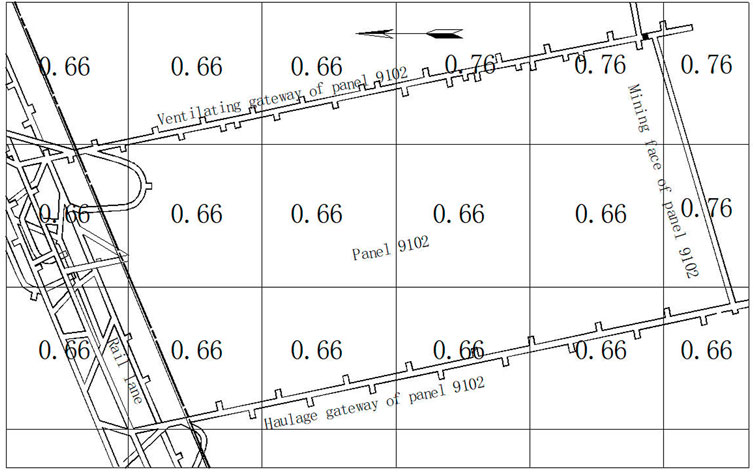

Based on the regional prediction of rockburst hazard in Jixian Coal Mine, the predicted hazard probability values of any working face, any mining area, or any location in the mine field can be obtained. Figure 4 shows the unit probability prediction value of rockburst hazard in the Working Face 4 of Western Mining Area 2.

FIGURE 4. Prediction results of multi-factor pattern recognition for rockburst hazard in panel 9102.

As shown in Figure 4, Working Face 4 in the Western Mining Area 2 is divided into 12 unit grids in line with 100 m × 100 m unit grids. There are 10 unit grids with a hazard probability value of 0.66, accounting for 83.33% of the predicted unit grids in the working face. Most areas of the working face are medium rockburst hazardous zones. There are two unit grids with a hazard probability value of 0.76, accounting for 16.67%. The area from the middle of the transportation roadway to the open-off cuts of Working Face 4 is the strong hazard rockburst zone, which is also an area prone to stress concentration and rockburst.

Through the aforementioned analysis, it is concluded that the sub-unit prediction with multi-factor pattern recognition can divide the predicted working face into several prediction units, and the probability value of each unit can be obtained. Before the roadway tunneling or mining face advances to different prediction units, the potential rockburst hazard of the location can be determined in advance, so that corresponding control measures can be taken in advance. Compared with the comprehensive index method, the hazard value of Working Face 4 was 0.62, indicating that the multi-factor pattern recognition method improves the accuracy and precision of the prediction.

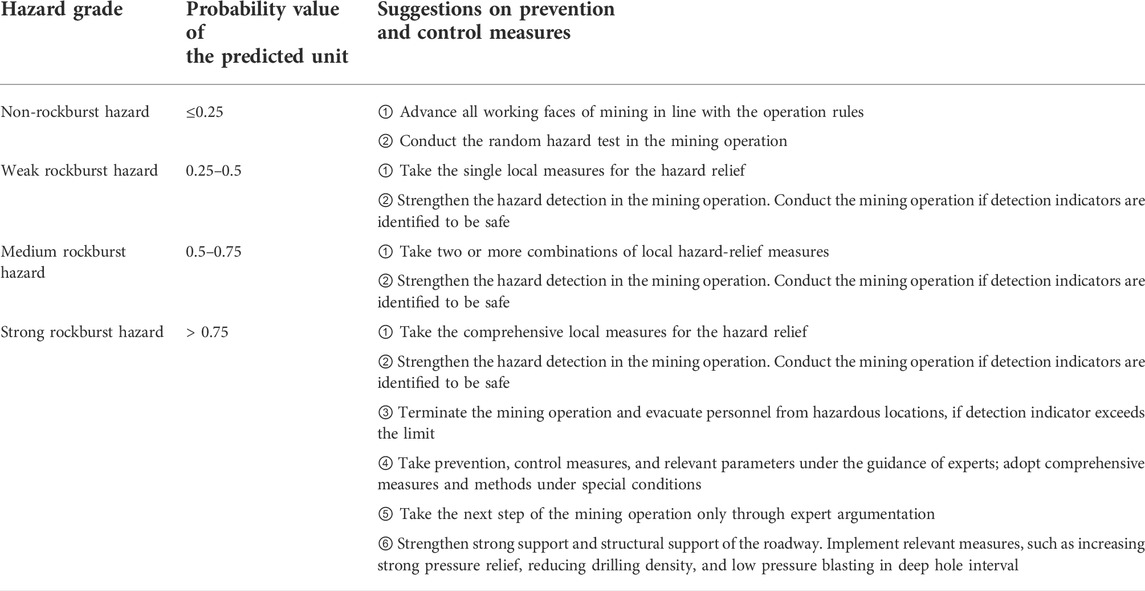

Regional prevention and control technology of rockburst hazard

By using the probability prediction method with multi-factor pattern recognition, the sub-unit probability prediction of coal seam hazard was realized, and the results were classified in line with the regional prediction grade. In the actual mining, when excavation roadways or working faces enter different prediction units, the potential rockburst hazard of the location can be obtained in advance, and corresponding preventive measures can be taken in advance. According to the hazard probability value of the prediction unit, when the conditions were suitable, regional measures were first chosen to relieve the hazard, or the corresponding local measures were taken to reduce the hazard. Regional prediction of rockburst provides a scientific basis for taking prevention and control measures against the rockburst, so as to ensure safe production in coal mines. For different hazard grades, the corresponding prevention and control measures were adopted, as shown in Table 2.

Conclusion

For the problem of rockburst hazard area prediction under complex mining conditions, traditional linear data analysis is not an ideal solution. In order to improve the precision and accuracy of prediction results, this article studies the non-linear mapping relationship between rockburst hazard and its influencing factors through machine learning of rockburst hazard training samples and draws the following conclusion based on the principle of the binary Gaussian process and the main influencing factors of rockburst:

(1) Aiming at the prediction of rockburst hazard under complex conditions, a multi-factor pattern recognition method of rockburst hazard prediction was proposed based on GPC. By learning the training samples, the non-linear mapping relationship between rockburst hazard and its influencing factors was established, and the probability prediction value of the unit hazard was determined.

(2) The probability values of rockburst hazard of 0.25, 0.5, and 0.75 were taken as critical values, and the rockburst hazard of Jixian Coal Mine was divided into four grades. The sub-unit probability prediction results of rockburst hazard in Working Face 4 are 0.66 and 0.76 in Western Mining Area 2. Through the sub-unit probability prediction of rockburst hazard, the rockburst prediction is upgraded from point prediction to regional prediction, from single-factor prediction to multi-factor prediction, and from qualitative prediction to quantitative prediction. Moreover, the accuracy of rockburst prediction is greatly improved.

(3) The prevention and control technology system of hazard prediction of rockburst was established based on GPC. According to the hazard probability value of grid units, the potential rockburst hazard of the mining location can be determined before roadway driving or working face mining advances different prediction units. It provided a scientific basis for taking effective rockburst prevention measures, so as to ensure safe production in coal mines.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

TL carried out the main construction of ideas for the study and a detailed split of the overall research problem of the study; ZZ was responsible for constructing the mathematical model, programming, and summarizing the data; JS and WZ classified and processed the field data to provide strong data support for the team research; WJ and MZ edited the graphs in the manuscript to make the conclusion of the manuscript clearer and concise; and ML and XG collected the raw data for the field real measurements.

Funding

This research was financially supported by the LiaoNing Revitalization Talents Program (XLYC2007042), Liaoning Provincial Education Department Basic Scientific Research Project (Key Project) (LJKZ0325), and National Natural Science Foundation of China (51604139).

Acknowledgments

The authors thank all editors and reviewers for their comments and suggestions.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ahmad, M., Amjad, M., Al-Mansob, R., Kaminski, P., Olczak, P., Khan, B., et al. (2022). Prediction of liquefaction-induced lateral displacements using Gaussian process regression. Appl. Sci. 12 (4), 1977. doi:10.3390/app12041977

Cao, A., Liu, Y., Jiang, S., Hao, Q., Peng, Y., Bai, X., et al. (2021). Numerical investigation on influence of two combined faults and its structure features on rock burst mechanism. Minerals 11, 1438. doi:10.3390/min11121438

Chakir, Y., Abouir, J., Aounil, I., and Benouahmane, B. (2022). Two-dimensional Laplace transform inversion using bivariate homogeneous two-point Padé approximants. Numer. Algorithms 90, 1153–1174. doi:10.1007/s11075-021-01225-3

Chen, D., Wang, E-Y., and Li, N. (2021). Rupture process assessment of rock bursts in a coal mine: Inversion of source parameters and the slip distribution on the rupture surface. Eng. Fail. Anal. 130, 105741. doi:10.1016/j.engfailanal.2021.105741

Davis, C. B., Hans, C. M., and Santner, T. J. (2021). Prediction of non-stationary response functions using a Bayesian composite Gaussian process. Comput. Statistics Data Analysis 154, 107083. doi:10.1016/j.csda.2020.107083

Gladyr, A. V., Tereshkin, A. A., Rasskazov, M. I., and Konstantinov, A. V. (2021). Application of probabilistic clustering analysis to rockburst hazard assessment of rock mass. IOP Conf. Ser. Earth Environ. Sci. 773 (1), 012061. doi:10.1088/1755-1315/773/1/012061

He, M., Li, J., and Ren, F. (2020). Rock burst criterion based on clay mineral content. Arab. J. Geosci. 13, 185–188. doi:10.1007/s12517-020-5199-x

Hui, L., and Zhang, X. (2020). Predictive analysis of impact hazard level of coal rock mass based on fuzzy inference network. J. Intelligent Fuzzy Syst. 38 (2), 1509–1518. doi:10.3233/jifs-179514

Iwata, T., and Tanaka, Y. (2022). Few-shot learning for spatial regression via neural embedding-based Gaussian processes. Mach. Learn. 1114, 1239–1257. doi:10.1007/s10994-021-06118-z

Ke, B., Khandelwal, M., Asteris, P. G., Skentou, A. D., Mamou, A., and Armaghani, D. J. (2021). Rock-burst occurrence prediction based on optimized Naïve Bayes models. IEEE Access 9, 91347–91360. doi:10.1109/access.2021.3089205

Lin, M., Gao, C., Xia, Y., Zhang, D., Liu, X., and Liang, X. (2022). Rock burst initiation and precursors in a model specimen based on acoustic emission and infrared monitoring. Arab. J. Geosci. 15 (4), 1–19. doi:10.1007/s12517-021-09423-y

Qiao, C., Guo, Y-H., and Li, C-H. (2021). Study on rock burst prediction of deep buried tunnel based on cusp catastrophe theory. Geotech. Geol. Eng. (Dordr). 39, 1101–1115. doi:10.1007/s10706-020-01547-4

Ullah, B., Kamran, M., and Rui, Y. (2022). Predictive modeling of short-term rockburst for the stability of subsurface structures using machine learning approaches: T-SNE, K-means clustering and XGBoost. Math. (Basel). 3, 449. doi:10.3390/math10030449

Villacampa-Calvo, C., and Hernández-Lobato, D. (2020). Alpha divergence minimization in multi-class Gaussian process classification. Neurocomputing 378, 210–227. doi:10.1016/j.neucom.2019.09.090

Wang, J., Apel, D. B., Dyczko, A., Walentek, A., Prusek, S., Xu, H., et al. (2021). Investigation of the rockburst mechanism of driving roadways in close-distance coal seam mining using numerical modeling method. Min. Metallurgy Explor. 38 (5), 1899–1921. doi:10.1007/s42461-021-00471-2

Wang, J., Huang, M., and Guo, J. (2021). Rock burst evaluation using the CRITIC algorithm-based cloud model. Front. Phys. 8, 593701. doi:10.3389/fphy.2020.593701

Wojtecki, Ł., Iwaszenko, S., Apel, D. B., Bukowska, M., and Makowka, J. (2022). Use of machine learning algorithms to assess the state of rockburst hazard in underground coal mine openings. J. Rock Mech. Geotechnical Eng. 14, 703–713. doi:10.1016/j.jrmge.2021.10.011

Wu, Z., Pan, P. Z., Konicek, P., Zhao, S., Chen, J., and Liu, X. (2021). Spatial and temporal microseismic evolution before rock burst in steeply dipping thick coal seams under alternating mining of adjacent coal seams. Arab. J. Geosci. 14 (20), 1–28. doi:10.1007/s12517-021-08439-8

Wu, T., Gao, Y., Zhou, Y., and Sun, H. (2021). A novel comprehensive quantitative method for various geological disaster evaluations in underground engineering: Multidimensional finite interval cloud model (MFICM). Environ. Earth Sci. 80 (20), 1–18. doi:10.1007/s12665-021-10012-1

Xiao, Y., Deng, H., Xie, Z., and Lu, H. (2022). Mine ground pressure monitoring and early warning based on deep learning data analysis. Mob. Inf. Syst. 2022, 1–12. doi:10.1155/2022/6255119

Xue, C., Cao, A., Liu, Y., Guo, W., Wen, Y., Hu, Y., et al. (2022). Mechanism and prevention practice of coal burst in deep gradual residual coal pillar area: A case study. Arab. J. Geosci. 15 (2), 1–12. doi:10.1007/s12517-022-09527-z

Yang, Y., Wei, S., and Li, K. (2021). Inverse analysis of dynamic failure characteristics of roadway surrounding rock under rock burst. Energy Sci. Eng. 9, 2298–2310. doi:10.1002/ese3.977

Yang, Y., and Zhang, Z. (2021). Surrounding rock effect on coal burst under unloading condition: A numerical study. Arab. J. Geosci. 14 (17), 1–11. doi:10.1007/s12517-021-08120-0

Yu, Y., Zhu, B., Guo, H., Chen, B., and Geng, D. (2021). Warning index associated with rock burst in deeply buried tunnels. Int. J. Geomech. 21, 04021211. doi:10.1061/(asce)gm.1943-5622.0002135

Zhang, J., Wang, M., and Xi, C. (2021). Prediction and evaluation of rockburst based on depth neural network. Adv. Civ. Eng. 2021, 1–11. doi:10.1155/2021/8248443

Zhang, M., and Jiang, F. (2020). Rock burst criteria and control based on an abutment-stress-transfer model in deep coal roadways. Energy Sci. Eng. 8, 2966–2975. doi:10.1002/ese3.715

Keywords: rockburst, machine learning, regional prediction, multi-factor pattern recognition, prevention technology

Citation: Lan T, Zhang Z, Sun J, Zhao W, Zhang M, Jia W, Liu M and Guo X (2022) Regional prediction and prevention analysis of rockburst hazard based on the Gaussian process for binary classification. Front. Earth Sci. 10:959232. doi: 10.3389/feart.2022.959232

Received: 01 June 2022; Accepted: 05 September 2022;

Published: 27 September 2022.

Edited by:

Shuren Wang, Henan Polytechnic University, ChinaReviewed by:

Jianwei Cheng, China University of Mining and Technology, ChinaFenhua Ren, University of Science and Technology Beijing, China

Copyright © 2022 Lan, Zhang, Sun, Zhao, Zhang, Jia, Liu and Guo. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhijia Zhang, bG50dWt5eHl6empAMTYzLmNvbQ==

Tianwei Lan

Tianwei Lan Zhijia Zhang

Zhijia Zhang Mancang Zhang

Mancang Zhang