- 1School of Safety Science and Emergency Management, Wuhan University of Technology, Wuhan, China

- 2School of Resources and Environmental Engineering, Wuhan University of Technology, Wuhan, China

- 3School of Energy and Environment, Zhongyuan University of Technology, Zhengzhou, China

- 4Xin’an Coal Mine, Henan Dayou Energy Co., Luoyan, China

When blasting to enhance permeability in deep-buried soft coal mining face with a hard roof whose gas drainage requirement is higher, the charging hole and control hole (which doubles as drainage hole) are easy to be deformed and damaged, seriously affecting the blasting implementation and effect. Combining with the stratum characteristics of soft coal seam and hard surrounding rock, the idea of arranging boreholes near the surrounding rock to reduce deformation, inspired by the end effect, is put forward. Then, the experimental research on the deformation characteristics of boreholes at different distances from the surrounding rock is carried out, and the results show that the closer the borehole is to the roof (floor), the smaller the deformation, under the same stress conditions and within a certain distance. Based on this, a new scheme of arranging control holes and blasting holes near the roof and floor is proposed and designed. The field test results show that the blasting of 60 m deep holes are successfully realized and the remarkable permeability enhancement effect is achieved, verifying the feasibility and effectiveness of the improved scheme. This study explores a new blasting permeability enhancement scheme with practical value and reference significance for deep-buried soft coal mining face with a hard roof.

Introduction

Gas dynamic disasters with noteworthy burstiness, destructiveness, and complexity often cause huge casualties and property losses (Yu et al., 2013; Wang et al., 2021), and its most important and fundamental technical means of prevention and control is gas drainage (Li, 2015; Zhou et al., 2016; Nikitenko and Glukhikh, 2021). However, coal seams with the risk of gas-dynamic disasters are always not only with high gas content but of poor permeability, resulting in a small drainage radius and poor drainage effect, which requires permeability enhancement to strengthen gas drainage (Lei et al., 2016; Cheng and Pan, 2020; Zhang et al., 2020).

Among a variety of common technologies of permeability enhancement, controlled blasting with the advantages of simple process and high efficiency, has been more and more widely studied and applied (Bhandari, 1980; Zhang and Liu, 2013; Guo et al., 2020). It is found that the gas drainage rate of the working face was increased by more than 17% in the pre-drainage test of underground deep hole pre-splitting blasting (Wang et al., 2012). By analyzing the changes in coal stress and longitudinal wave velocity in different blasting ranges, Zhicheng Xie and others predicted the effective cracking radius and effective influence radius and then optimized the drilling layout, and brought the net drainage quantity after blasting which is 1.54∼2.24 times higher than that before blasting (Xie et al., 2017). To improve the gas drainage effect of a coal seam with high gas content and low permeability, hydraulic-controlled blasting of a deep hole was carried out to provide pressure relief and to increase the permeability of a coal seam. The mechanism for pressure relief and permeability improvement caused by the hydraulic-controlled blasting was then analyzed. It was found that the outcomes were the result of joint action by the blasting force and the hydraulic pressure (Ye et al., 2017). Based on the analysis of the influence of the charging structure on the propagation characteristics of explosion stress waves and the zoning of blasting cracks, the field test of coal seam deep hole-shaped charge blasting was designed and carried out. The results showed that the charging structure affects the permeability enhancement effect of coal seam deep hole-shaped charge blasting (Guo et al., 2018a). It is calculated that the single drilled fracture crack extension range is 3.11∼5.24 m according to the coal seam deep-hole pre-splitting blasting joint mechanism and fracture propagation mechanics model, providing a theoretical basis for choosing the appropriate hole spacing (Ti et al., 2018). The multi-hole pre-splitting blasting technology is proposed and applied and it was found that the permeability of the coal seam which improved by deep hole pre-splitting blasting was 2.5 times than that of the original coal seam (Huang et al., 2019). To reduce gas disasters in low permeability and high-gas coal seams and improve gas pre-drainage efficiency, by comparing and analyzing the damage distribution nephogram of coal and rock mass under the influence of different millisecond blasting time intervals and the blasting effect of the simulation model, the optimal layout parameters of multilayer through cracks were obtained theoretically (Zhao et al., 2021).

These research and application results of blasting permeability enhancement technology have played an important role in coal seam gas control, but most are aimed at shallow or hard coal seams, and focused on the blasting mechanism, charging structure, or permeability enhancement effect. Few studies have been carried out on the problem that the charging hole and control hole (doubles as drainage hole) are easy to be deformed and damaged in deep-buried soft coal seams, which seriously affects the blasting implementation and effect. With the increase of mining intensity and depth, gas dynamic disasters become more and more serious and complex. Not only does the high incidence zone expand from the coal roadway heading face to the mining face with a much wider range, but gas dynamic disasters of the mining face directly covered with hard rock, under the disturbance of roof breaking, often occur in the case of “low threshold”, namely lower than the conventional critical index (Yin et al., 2017; Zhao et al., 2020). It brings many problems to the gas drainage work based on blasting to enhance permeability. First, the deformation and damage of blasting holes and control holes in deep-buried soft coal seams are much more severe, resulting in slow drilling speed, small hole forming depth, low hole forming rate, and short holding time, which makes it difficult to charge in ultra-deep hole required by mining face and easy to block the control hole (doubles as drainage hole) seriously hindering gas drainage (Xue and Feng, 2018; Zhang et al., 2021). Second, with the increase of gas pressure and the decrease of permeability in deep coal bodies, the difficulty of gas drainage increases, but the standard indicators of the mining face are stricter due to the gas dynamic disasters which often occur in the case of “low threshold” under the disturbance of roof breaking. These factors have become the bottleneck problem of deep buried soft coal face gas prevention strengthened by controlled blasting permeability enhancement technology.

Aiming at this, taking 14,020 mining faces of Xin’an Coal Mine as the research background, the targeted research is carried out. On the basis of the permeability enhancement mechanism of deep hole controlled blasting in coal body combined with the stratum characteristics of soft coal seam and hard surrounding rock, the experimental research on the deformation characteristics of boreholes at different distances from the surrounding rock is carried out, and on this basis, a new blasting scheme which can control the borehole deformation and promote the implementation and permeability enhancement is designed. Finally, field tests are carried out to verify the feasibility and effectiveness of the new scheme.

Research Background

The research takes 14,020 mining faces of Xin’an Coal Mine as the background. Xin’an Coal Mine is located in the west of the Henan Province. The only minable No. 21 coal seam in the minefield is of simple structure and stable horizon. As a result of multi-period strong tectonic movements, the whole coal seam universally develops into class III–V soft coal shaped like earth and powder, with less obvious bedding and very low mechanical strength. The coal seam is covered with thick hard sandstone at close range and underlying hard mudstone, forming good engineering geological conditions. Since the “low threshold” gas dynamic disaster of the mining face has occurred many times after the mine enters deep mining, the drainage evaluation indexes gas pressure and gas content are tightened from the original 0.74 Mpa and 8 m3/t to 0.6 Mpa and 6 m3/t, respectively.

The14020 mining face is located in mining area 14 in the west of the mine. The buried depth of the coal seam in the mining face is about 600 m, the thickness varies from 2.8 to 3.2 m, with an average of 3.1 m; and the dip angle varies from 5° to 8°, with an average of 6°. The false roof of the mining face is not developed, and the direct roof is sandstone with an average thickness of 3 m. The basic roof is medium-grained sandstone with an average thickness of 8.6 m and hard lithology. The false bottom of the mining face is not developed, and the direct bottom is sandy mudstone with an average thickness of 2 m. The basic bottom is mudstone with an average thickness of 10 m.

Mechanism Analysis of Controlled Blasting to Increase Permeability

Analysis of Cracking Effect of Controlled Blasting

When ordinary blasting in the medium far from the free surface, strong shock waves and a large amount of high temperature and high-pressure gas are generated instantly. When the shock wave acts on the medium around the blasting hole, it will form dynamic stress whose strength is far greater than the medium compressive strength, resulting in the strong compression of the medium and the expansion of the original blasting hole, which also consumes a considerable part of energy. After that, the shock wave decays into a stress wave and continues to propagate around, causing the medium under its action to produce radial compression and circumferential tension. When the circumferential tensile stress exceeds the dynamic tensile strength of the medium, radial cracks radiating outward from the explosion center generate and expand continually with the propagation of stress waves until the tensile stress is lower than the medium tensile strength.

After the radial cracks are formed, the high temperature and high-pressure explosive gas quickly flows into these radial cracks promoting the cracks’ further expansion in the action pattern of wedges. As the explosive gas expands and cools down, its pressure drops to a certain extent, and the compressive elastic energy accumulated in the medium will be released, forming an unloading wave to propagate towards the center of the blast hole, which turns the medium into a radial tensile state and producing circumferential cracks. The area formed by the intersection of radial fractures and circumferential fractures is called the fracture area. When the stress wave propagates further forward, it has attenuated to the point of being only able to make the medium particles vibrate and propagate in the form of the seismic wave rather than destroy the medium and finally decays to disappear.

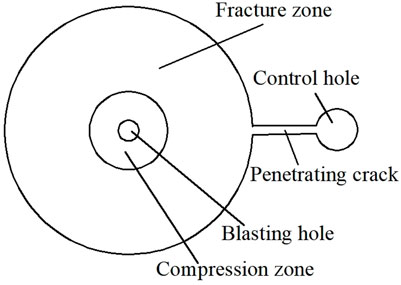

Under the strong blasting compression, unlike the near area of the blasting hole in brittle hard rock will be crushed to form a crushing circle, the near area of the blasting hole in plastic soft coal will be locally compacted forming a compaction circle, which consumes more blasting energy and greatly reduces the crack range and permeability enhancement effect (Shakeran et al., 2016; Cao et al., 2020). For this reason, the controlled blasting technology of adding a control hole at a certain distance from the blasting hole is introduced. When the explosion stress wave propagates to the auxiliary free surface provided by the additional control hole, it will produce reflection forming a tensile stress wave. The reflected wave not only causes the tensile failure of the coal body near the control hole wall but propagates to the center of the blasting hole and superimposes its generated stress on the stress field at the tip of the radial fracture promoting the expansion of radial and circumferential fracture (Guo et al., 2020). In addition, the combined action of the tensile stress caused by the reflected wave and the weak discontinuous wave behind the strong intermittent shock wave front makes the edge of the control hole produce a crack pointing to the blasting hole center and connect with the radial cracks generated firstly (Figure 1).

It should be noted that, in addition to the aforementioned functions in blasting cracking, the control hole also compensates for the space required for coal fracture avoiding or greatly reducing the compaction of coal, and improves the utilization rate of blasting energy forming a broader crack network in coal seam (Guo et al., 2018b).

Analysis of Permeability Enhancement Effect of Controlled Blasting

When the gas is extracted by a borehole, the free gas in the coal body flows into the drainage borehole under the action of its pressure and drainage negative pressure, which causes the pressure to decrease and breaks the original dynamic balance state between adsorbed gas and free gas in the coal body, so that part of the adsorbed gas is desorbed into free gas, and then enters the drainage borehole through the coal matrix and fissure in turn. This gas migration expands from the near area of the drainage hole wall to the deep and weakens gradually with the decrease of the drainage negative pressure caused by the increase of the radial distance.

According to the law of mass conservation, the migration process of gas in coal body conforms to the following equation:

where m is the gas content of coal, kg/m3; t is the gas migration time of coal body, s; ρ is the density of the gas, kg/m3;

According to the linear seepage characteristics of Darcy’s law, ignoring the influence of gravity on drainage gas migration:

where

Deformation Characteristics of Boreholes With Different Distances From Surrounding Rock

In the deep-buried soft coal mining face with a hard roof whose gas drainage requirement is higher, the implementation and permeability enhancement effect of controlled blasting is severely restricted since the borehole is easy to be deformed and damaged. Combining with the stratum characteristics of soft coal seam and hard surrounding rock in the mining face, the idea of arranging boreholes near the surrounding rock to reduce its deformation, was inspired by the relevant research results such as the end effect (Xu et al., 2017; Wang et al., 2022), is put forward and the simulation test of borehole deformation characteristics at different distances from the surrounding rock is carried out in order to provide guidance for improving the scheme design of controlled blasting to enhance permeability.

In order to conveniently and economically control the test conditions and observe the deformation and failure of rock mass, the simulation test for the deformation characteristics of boreholes with different distances from the surrounding rock is carried out, taking the 14,020 mining face of Xin’an Coal Mine as the background.

Simulation Test System of Borehole Deformation

The simulation test system of borehole deformation is shown in Figure 2. The loading device is a steel frame structure with full restraint around mainly composed of a strong rigid reaction frame, three parallel movable loading plates, the front and rear transparent limit guards reinforced with channel steel, and a loading system. It can carry out the test of front and rear plane rigid restraint and surrounding loading to the specimen with the maximum size of 800 mm × 800 mm × 200 mm. Considering the size of the simulated borehole is small and using the traditional embedded displacement sensor to measure the deformation of the surrounding rock of the borehole will affect the stress distribution and deformation of the surrounding rock of the model borehole, the pouch drainage method is designed to measure the deformation of the borehole. In order to facilitate observation and improve data accuracy, an electronic scale with an accuracy of 0.001 g is used to measure the discharge water.

Design and Implementation of Similarity Test

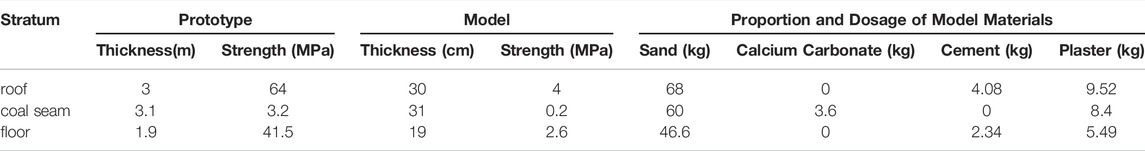

Comprehensively considering the test purpose and the performance of the simulation test device, the similarity model includes their strata: direct roof, coal seam, and direct bottom. According to the strata occurrence characteristics and mechanical parameters of 14,020 mining faces of Xin’an Coal Mine, the model materials of each layer are selected with strength as the main index and used to build a physical model according to the geometric similarity ratio of 10, the unit weight ratio of 1.6 and the stress ratio of 16. After consulting literature materials and similar conversions (Li et al., 2007), the model is made of sand, calcium carbonate, cement, and gypsum according to the ratio and dosage shown in Table 1.

After the materials of each layer are separately prepared and mixed according to the proportion, add 1% borax solution whose amount is 1/10 of its total weight and stir well, and then lay and compact layer by layer. Before laying each layer of the model, the front and rear guard plates of the experimental device shall be fixed neatly and firmly. For more convenient observation, the coal and rock stratum is sprayed orange and white, respectively.

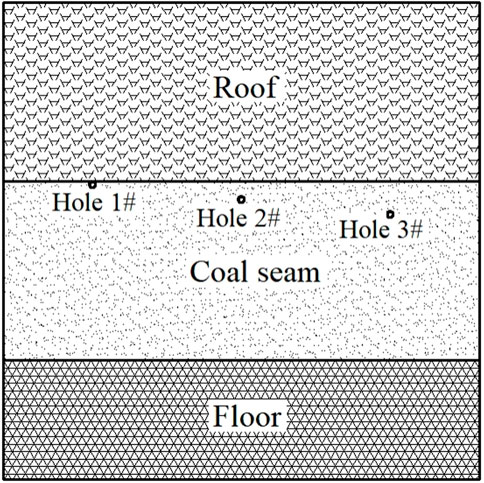

The laid model is dried for 3 days, and then the simulated borehole is excavated with an electric drill. Since it is difficult to completely repeat the process of model building, drying, and loading, the boreholes at different distances from the roof are carried out loading deformation tests on the same model and in the same loading process. According to the size of the model and borehole, it is designed to sequentially excavate three boreholes along a coal seam with a diameter of 10 mm and length of 200 mm from the position 150 mm away from the side in the model coal seam. The three boreholes are 5, 30, and 55 mm away from the roof, respectively, and their horizontal spacing is 250 mm (Figure 3).

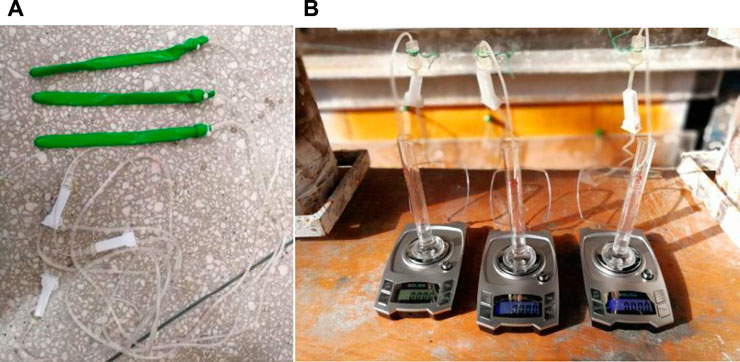

Then, the borehole deformation measuring device is installed. A pouch made of the long balloon with the length equal to the drilling depth and the diameter slightly larger than the drilling diameter is first put into every borehole (Figure 4A). Then, one end of a tube with a valve is tightly connected with the pouch’s mouth, and the other end extends into the measuring cup placed on the precision electronic scale (Figure 4B); and then, using a syringe, the pouch and the tube is completely filled with water, keeping the pouch pressed against the borehole wall and the height of the tube outer end slightly higher than the drilling hole, so that the water is extruded when and only the pouch is synchronously deformed with the borehole wall which flows wholly into the measuring cup (Figure 4).

When the aforementioned preparations are completed, the loading deformation test is carried out on the model. According to the actual situation that the side pressure coefficient of 14,020 mining face in Xin’an mine is about 1, two-way equal pressure (upper and lower, right and left) loading is slowly carried out and the borehole deformation and pouch drainage are continuously observed during the test.

Test Results Analysis

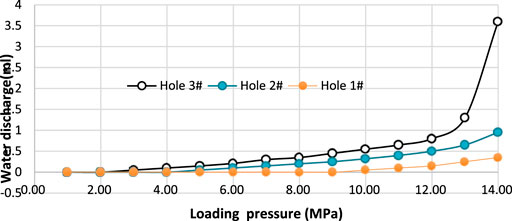

According to the water discharge measurement results reflecting the borehole deformation, the relationship between the loading pressure of the oil cylinder and the surrounding rock deformation of boreholes at a different distance from the roof are obtained (Figure 5).

As can be seen, when the pressure loaded by the oil cylinder is 1∼2 MPa, the water discharge of the three boreholes is 0 ml. When the loading pressure reaches 3 MPa, the No.3 hole that is farthest from the roof begins to drip. When the loading pressure reaches 5 Mpa, the No.2 hole begins to drip. Until the loading pressure reaches 10 MPa, the No.1 hole nearest to the roof begins to drip. The water discharge of boreholes gradually increases with the increase of loading pressure. When the loading pressure reaches 14 Mpa, the water discharge of borehole No.3 suddenly increases rapidly to 3.6 ml, and then the borehole collapses. At this time, the No.2 hole produces obvious deformation but no instability and the water discharge was 0.95 ml. While, the No.1 hole produces slight deformation, and the water discharge is only 0.35 ml.

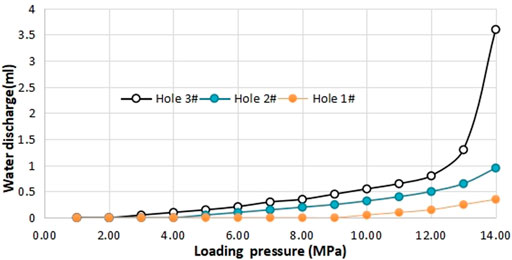

With reference to the aforementioned scheme, a similar loading deformation test of boreholes at different distances from the floor is carried out, and basically consistent results are obtained (Figure 6), which will not be described here to avoid repetition.

It can be found that, through the aforementioned simulation test results, within a certain distance, under the same stress conditions the closer the borehole is to the roof (floor), the smaller the deformation, which provides a direction and basis for improving the layout design of blasting boreholes.

Scheme Design and Field Test of Deep Hole Controlled Blasting to Enhance Permeability

Borehole Layout

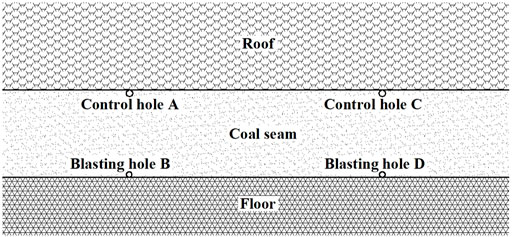

In light of the aforementioned deformation characteristics, test results of boreholes at different distances from the surrounding rock, and comprehensively considering the blasting purpose, site conditions, drilling equipment, explosive specification, and operation safety, the blasting hole is arranged adjacent to the coal seam floor and its diameter is designed to be 65 mm, for the convenience of hole forming and charging as well as avoiding blasting to break the roof affecting the safe mining of the mining face. The control hole is arranged adjacent to the roof and its diameter is designed to be 113 mm, so as to better guide the blasting energy and compensate for the space required for coal fracture, promoting the formation of a blasting joint network and gas drainage.

In order to investigate the actual effect of the improved scheme, as shown in Figure 7, two groups of controlled blasting permeability enhancement tests were designed and implemented in Xin’an 14,020 mining face. In the figure, holes A and C are control holes (doubles as drainage holes), while holes B and D are blasting holes. Their dip angles are designed according to the dip angle of the coal seam of 6°, and the orientation is perpendicular to the center line of the roadway. The depth is set as half the width of the mining face of 60 m, according to the need for gas drainage covering the mining face.

Blasting Parameters

For the safety of blasting operation, coal mine-permitted three-level emulsion explosive is selected, and radial uncoupled axial continuous charging is adopted. The radial uncoupling coefficient is controlled at 1.2∼1.8 to improve the cracking effect of blasting in coal seam (Gong et al., 2006).

According to relevant research, the relationship between uncoupled blasting crack radius and explosive radius is as follows (Liu et al., 2018):

where

where D is the detonation velocity;

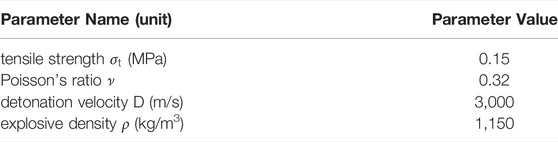

According to the aforementioned borehole layout scheme and actual relevant parameters of blasting in 14,020 mining faces of Xin’an mine (Table 2), the calculated diameter of the explosive roll is 40 mm, which can meet the requirements of fracture range for coal seam permeability enhancement.

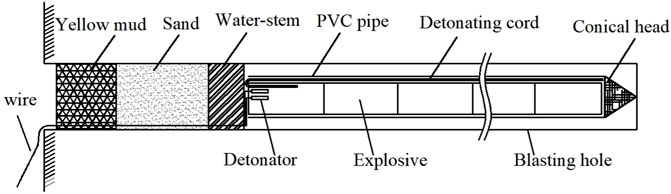

To ensure the reliability of detonating and avoid the pipe effect, double millisecond delay electric detonators with parallel connections are selected for forwarding initiation in the design, and the allowable detonating cord of the coal mine is placed along the full length of the explosive column in the auxiliary charging PVC pipe with an inner diameter of about 45 mm.

The blocking length in gas-bearing coal is generally 20 ∼ 40% of the blasting hole depth. According to the field measurement, the pressure relief zone width and equivalent discharged gas width of roadway in Xin’an mine are 15 and 21 m, respectively. Comprehensively considering the blasting safety and the permeability enhancement needs of the mining face, the blocking length is taken as 20.0 m, the charging length 40 m, and the charging amount 62 kg.

Field Test

The field test is carried out in Xin’an 14,020 mining faces according to the design scheme. First, drill the control hole and connect the pipe for gas drainage in time. Then, drill the blasting hole and fully discharge the drilling cuttings in the holes with compressed air. Afterward, a positive charge with the help of an antistatic PVC pipe with screwed joints. For smooth pipe delivery, the front end of the foremost PVC pipe is equipped with a conical head. Connect and charge the PVC pipes one by one and send them into the blasting hole. The explosive rolls shall be closely adjacent to each other, and the allowable detonating cord of the coal mine shall be placed along the full length of the explosive column. The explosive roll at the outermost end shall be inserted into two same types allowable Millisecond Electric Detonators of a coal mine with a parallel connection.

When plugging the blast hole after charging, first fill with water-stem at the inner end 2 m, then fill 12 m long sand into the borehole with compressed air hole sealer, and finally fill 6 m yellow mud and tamp it section by section with tamping bar (Figure 8). After checking and confirming the safety, blasting shall be carried out.

From the field drilling, it is found that the drilling speed of boreholes adjacent to surrounding rock is more than 50% higher than that of the traditional boreholes with the same diameter arranged in the middle of the coal seam, and the borehole forming performance is significantly improved.

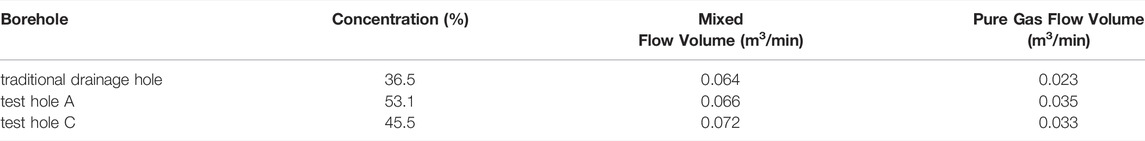

Within 1 week after blasting, the gas drainage parameters of boreholes A and C are observed every day. It is found that compared with the traditional nonblasting drainage borehole with the same diameter, depth, and drainage time drilled in the middle of the coal seam, the average gas concentration and gas pure flow volume within 1 week after blasting is significantly increased (Table 3). The drainage concentration and drainage pure flow volume of test hole A increased by 45.5 and 52.2%, respectively, and those of test hole C increased by 25.5 and 43.5%, respectively.

Conclusion

1) Based on the blasting cracking mechanism and the law of gas migration, the mechanism of controlling blasting permeability enhancement is further clarified: under the action of blasting, the stress and temperature of the coal around the blasting hole rise sharply, and substantial flow channel cracks that can improve coal permeability are produced, the exposed area and internal energy increases which promote the desorption and reduce gas viscosity, effectively improving the gas drainage effect in many ways.

2) Aiming at the problem that the borehole in a deep soft coal seam is easy to deform and destroy which affects the implementation of controlled blasting and the effect of permeability enhancement, the assumption of arranging the borehole near the surrounding rock to reduce its deformation is put forward, and the simulation test of borehole deformation characteristics at different distances from the surrounding rock is carried out. The results show that under the same stress condition, the closer the borehole is to the roof (bottom plate), the smaller the deformation, which provides the direction and basis for improving the layout design of blasting boreholes.

3) In light of the deformation characteristics test results of boreholes at different distances from the surrounding rock, and comprehensively considering the blasting purpose, site conditions, drilling equipment, explosive specifications, and construction safety, a new scheme of arranging, respectively, control hole and blasting hole near the roof and floor is proposed and designed, and the effectiveness and practicability of the new scheme are verified by field tests. The field test results show that the new scheme significantly improves the drilling speed and the borehole forming performance, successfully realizes the controlled blasting of a 60 m ultra-deep hole, and effectively improves the concentration and pure gas flow volume of drainage gas.

4) This study explores a new blasting permeability enhancement scheme with practical value and reference significance for deep-buried soft coal mining face with a hard roof.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author Contributions

DX: Conceptualization, Methodology, Formal Analysis, Writing—Original Draft. JZ: Methodology, Project Administration. GH: Visualization, Writing–review, and editing. PL: Funding, Resources, Supervision. ZZ: Investigation, Validation, Data Curation. All authors have read and agreed to the published version of the manuscript.

Funding

This study is supported by the Youth Project of the National Natural Science Foundation of China (51804356).

Conflict of Interest

Author ZZ was employed by Xin’an Coal Mine, Henan Dayou Energy Co.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

Many thanks to the National Nature Science Foundation of China for the financial support under Grant 51804356, and the relevant staff of the Xin’an Coal Mine for their great help.

References

Baisheng, B., and Xiangchun, X. (2012). Mechanism Research on Coal and Gas Outburst during Vibration Blasting. Saf. Sci. 50 (4), 741–744. doi:10.1016/j.ssci.2011.08.041

Bhandari, S. . (1980). On the Role of Stress Waves and Quasi-Static Gas Pressure in Rock Fragmentation by Blasting, 365, 383. doi:10.1016/B978-0-08-025442-5.50036-6

Cao, Y., Ma, Y., Mao, X., Yang, T., and Wang, Y. (20202020). Experimental Study on Crack Distribution and Regional Electrical Resistivity Response of Soft Coal Seams after Multi-Hole Blasting. J. Saf. Sci. Technol. 16 (10), 71–77. doi:10.11731/j.issn.1673-193x.2020.10.011

Cheng, Y., and Pan, Z. (2020). Reservoir Properties of Chinese Tectonic Coal: a Review. Fuel 260, 116350. doi:10.1016/j.fuel.2019.116350

Gong, M., Liu, W., Wang, D., Wu, H., Chen, T., and Qiu, D. (2006). Controlled Blasting Technique to Improve Gas Pre-drainage Effect in a Coal Mine. J. Univ. Sci. Technol. Beijing 2006 (03), 223–226. doi:10.13374/j.issn1001-053x.2006.03.005

Guo, D., Lv, P., Zhao, J., and Zhang, C. (2020). Research Progress on Permeability Improvement Mechanisms and Technologies of Coalbed Deep-Hole Cumulative Blasting. Int. J. Coal Sci. Technol. 7 (1), 329–336. doi:10.1007/s40789-020-00320-5

Guo, D. Y., Zhao, J. C., Zhang, C., and Zhu, T. G. (2018b). Mechanism of Control Hole on Coal Crack Initiation and Propagation under Deep-Hole Cumulative Blasting in Coal Seam. Chin. J. Rock Mech. Eng. 37 (04), 919–930. doi:10.13722/j.cnki.jrme.2017.1038

Guo, D., Zhang, C., Zhu, T., and Pan, J. (2018a2018). Effect of Charge Structure on Deep-Hole Cumulative Blasting to Improve Coal Seam Permeability. Chin. J. Eng. 40 (12), 1488–1494. doi:10.13374/j.issn2095-9389.2018.12.006

Huang, C., Zhang, Y., He, J., Luo, Y., and Sun, Z. (2019). Permeability Improvements of an Outburst‐prone Coal Seam by Means of Presplitting and Blasting with Multiple Deep Boreholes. Energy Sci. Eng. 7 (5), 2223–2236. doi:10.1002/ese3.426

Kong, X., Li, S., Wang, E., Wang, X., Zhou, Y., Ji, P., et al. (2021). Experimental and Numerical Investigations on Dynamic Mechanical Responses and Failure Process of Gas-Bearing Coal under Impact Load. Soil Dyn. Earthq. Eng. 142, 106579. doi:10.1016/J.SOILDYN.2021.106579

Lei, Y., Liu, J., Zhang, S., Zhang, W., and Wang, H. (2016). Contrast Test of Different Permeability Improvement Technologies for Gas-Rich Low-Permeability Coal Seams. J. Nat. Gas Sci. Eng. 33, 1282–1290. doi:10.1016/j.jngse.2016.06.066

Li, H. (2015). Discussion on Ways of Mine Gas Drainage and Extraction. Amr 1073-1076, 2189–2193. doi:10.4028/www.scientific.net/AMR.1073-1076.2189

Li, X., Lu, Y., Kang, Y., and Rao, B. (2007). Rock Mechanics Experiment Simulation Technology. Beijing: Science Press.

Liu, Z., Cao, Y., Zhu, G., Wang, C., and Jing, G. (2018). Pressure Relief Effect of Uncoupled Blasting Technology in High Stress Area. Explos. SHOCK WAVES 38 (02), 390–396. doi:10.11883/bzycj-2016-0180

Nikitenko, S. M., and Glukhikh, S. A. (2021). Gas Drainage in Coal Mines: Current Condition and Prospects. IOP Conf. Ser. Earth Environ. Sci. 823 (1), 012019. doi:10.1088/1755-1315/823/1/012019

Shakeran, M., Eslami, A., and Ahmadpour, M. (2016). Geotechnical Aspects of Explosive Compaction. Shock Vib. 2016 (8), 6719271. doi:10.1155/2016/6719271

Ti, Z., Zhang, F., Pan, X., Ma, Z., and Shang, Z. (2018). Permeability Enhancement of Deep Hole Pre-splitting Blasting in the Low Permeability Coal Seam of the Nanting Coal Mine. Plos One 13 (6), e0199835. doi:10.1371/journal.pone.0199835

Wang, F., Zhang, P., Cui, B., Sun, Z., and Zhang, K. (2021). Research Progress of Disaster Factors and a Prevention Alarm Index of Coal and Gas Outbursts. Arab. J. Geosci. 14 (19). doi:10.1007/s12517-021-07540-2

Wang, L., Li, X. X., and Zhao, Y. X. (2012). The Practice about Deep Hole Pre-split Blasting in Mining Faces of Low Permeability Extra-thick Seam. Amr 524-527, 781–785. doi:10.4028/www.scientific.net/AMR.524-527.781

Wang, Y., Liu, X., Pang, B., and Yu, Y . (20222022). Numerical and Experimental Study on End Effect of Waste-Soil Samples under Uniaxial Compression. Geofluids 2022, 1–11. doi:10.1155/2022/3014164

Xie, Z., Zhang, D., Song, Z., Li, M., Liu, L., and Sun, D. (2017). Optimization of Drilling Layouts Based on Controlled Presplitting Blasting through Strata for Gas Drainage in Coal Roadway Strips. Energies 10 (8), 1228. doi:10.3390/en10081228

Xu, Y., Cai, M., Zhang, X., and Feng, X. T. (2017). Influence of End Effect on Rock Strength in True Triaxial Compression Test. Can. Geotech. J. 54, 862–880. cgj-2016-0393. doi:10.1139/cgj-2016-0393

Xue, F., and Feng, X. (20182018). Spatial and Temporal Distribution Law and Influencing Factors of the Mining-Induced Deformation and Failure of Gas Boreholes. Adv. Mater. Sci. Eng. 2018, 1–15. doi:10.1155/2018/9580526

Ye, Q., Jia, Z. Z., and Zheng, C. (2017). Study on Hydraulic-Controlled Blasting Technology for Pressure Relief and Permeability Improvement in a Deep Hole. J. Petroleum Sci. Eng. 159, 433–442. doi:10.1016/j.petrol.2017.09.045

Yin, G., Li, X., Lu, J., and Li, M. (2017). Disaster-causing Mechanism of Compound Dynamic Disaster in Deep Mining under Static and Dynamic Load Conditions. Mtan Xuebao/Journal China Coal Soc. 42 (9), 2316–2326. doi:10.13225/j.cnki.jccs.2017.0139

Yu, Z. J., Jiang, F. C., Mao, X. X., and Wang, J. (2013). Hazard of Coal Mine Gas and its Preventive Measures. Amr 724-725, 1289–1292. doi:10.4028/www.scientific.net/AMR.724-725.1289

Zhang, C., Wang, E., Xu, J., and Peng, S. (2020). Experimental Investigation on Mechanics and Seepage Characteristics of Tectonic and Intact Coal Containing Gas. Appl. Sci. 10 (20), 7290. doi:10.3390/app10207290

Zhang, W. Q., and Liu, J. (2013). Study on Methods of Exploring the Loosening Radius of Deep-Hole Controlling Blasting. Amr 734-737, 650–655. doi:10.4028/www.scientific.net/AMR.734-737.650

Zhang, X. B., Shen, S. S., Feng, X. J., Ming, Y., and Liu, J. J. (2021). Influence of Deformation and Instability of Borehole on Gas Extraction in Deep Mining Soft Coal Seam. Adv. Civ. Eng. 2021 (1), 1–11. doi:10.1155/2021/6689277

Zhao, D., Wang, M., Gao, X., and Engineering, M. (2021). Study on the Technology of Enhancing Permeability by Deep Hole Presplitting Blasting in Sanyuan Coal Mine. Sci. Rep. 11. doi:10.1038/s41598-021-98922-9

Zhao, Y., Lin, B., Liu, T., Zheng, Y., Kong, H., Li, Q., et al. (2020). Mechanism of Multifield Coupling-Induced Outburst in Mining-Disturbed Coal Seam. Fuel 272 (4), 117716. doi:10.1016/j.fuel.2020.117716

Keywords: blasting, permeability enhancement, deep buried, soft coal, borehole deformation

Citation: Xuan D, Zhang J, Huang G, Li P and Zhang Z (2022) A New Blasting Permeability Enhancement Scheme For Deep-Buried Soft Coal Mining Face Based on Borehole Deformation Characteristics. Front. Earth Sci. 10:939360. doi: 10.3389/feart.2022.939360

Received: 09 May 2022; Accepted: 21 June 2022;

Published: 11 August 2022.

Edited by:

Shuren Wang, Henan Polytechnic University, ChinaReviewed by:

Zhibiao Guo, China University of Mining and Technology, Beijing, ChinaLang Liu, Xi’an University of Science and Technology, China

Copyright © 2022 Xuan, Zhang, Huang, Li and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Gang Huang , aHVhbmdnYW5nMjAxNkB3aHV0LmVkdS5jbg==

Dequan Xuan

Dequan Xuan Jianhua Zhang2

Jianhua Zhang2 Gang Huang

Gang Huang