95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci. , 02 May 2022

Sec. Geohazards and Georisks

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.884453

This article is part of the Research Topic Landslide Hazards in Alpine Region: Mechanics and Mitigation View all 23 articles

A series of laboratory-based water infiltration tests at room temperature have been conducted to investigate the mechanical characteristics of Heishan bentonite as a potential backfill material. The experiments were performed with an oedometer testing apparatus which facilitates the mechanical loading, the water infiltration, and the deformation measurement. The results show that both swelling pressure-initial dry density and swelling strain-moisture content have an exponential relationship. Moreover, swelling strain dramatically decreases when the applied stress exceeds a reference stress of 100 kpa. Finally, permeability tests were carried on Heishan bentonite specimen and the studied material reaches an impermeable state when the moisture content is larger than 40%. The presented properties certificate that Heishan bentonite can be employed as a backfill material in engineering practice.

Bentonite has been widely considered as backfill materials in the underground storage of high-level nuclear waste in many countries, because of its low hydraulic conductivity and high swelling capacity (Kanno and Wakamatsu, 1992; Chapman 2006; Chen et al., 2014). In many repository concepts, the backfill material is pre-compacted to a relatively dense state and it is installed in the vicinity of waste canisters (Martin et al., 2006; Romero et al., 2011; Jobmann et al., 2017). The initially unsaturated bentonite can absorb the surrounding fluids to retard the radioactive liquid waste from being transported to the underground water system, and the high swelling capacity imposes sufficient swelling pressure to the adjacent restraints. Therefore, it is critically important to evaluate the swelling behavior of compacted bentonite for the long-term stability of the underground high-level nuclear waste disposal repositories.

In this regard, numerous studies have been carried out to investigate the swelling properties for different types of bentonites (Lloret et al., 2003; Cui et al., 2011; Tang et al., 2011; Wang et al., 2012; Sun et al., 2013; Cui and Si 2014; Ye et al., 2014; Zhang et al., 2021). For example, Komine and Ogata (2003), Komine and Ogata (2004) performed a series of laboratory swelling tests and introduced new equations to quantify the swelling behavior of bentonite for the bentonite/sand mixture. Tanaka and Nakamura investigated the impacts of seawater and temperature on the swelling response of bentonite (Tanaka and Nakamura, 2005). In recent years, many works have been performed on the swelling properties of bentonite using salty water. These researches show that the compacted bentonite is an ideal backfill material in the deep disposal, especially Calcigel in Germany and Kunigel in Japan.

In China, Gaomiaozi bentonite has been accepted as backfill materials in the deep disposal of high-level radioactive waste. This bentonite is extracted from an open deposit in Gaomiaozi, Inner Mongolia autonomous region, northern China. Regarding Gaomiaozi bentonite, many researches have been conducted using oedometer tests and mockup tests. Xie et al. (2006) performed constant volume tests to study the swelling behavior and the influential factors on swelling behavior. Zhang et al. (2016) studied the swelling characteristics and compared two types of GMZ bentonites. Zhao et al. (2017) investigated the mechanical behavior on wetting-drying cycles and proposed a model based on the concept of the critical swelling-shrinkage state. Recently, Sun et al. (2020) have focused on the swelling characteristics with alkaline chemical conditions to simulate the long-term environment of Chinese repository. Great effort and progress have been made in studying the swelling behavior of different types of bentonites to better understand their mechanical behavior and optimize their engineering applications for nuclear waste disposal.

Engineering uses and industrial demands of bentonites give continued impetus to the study of these materials and a variety of bentonites should be investigated to improve the comprehension of their mechanical properties to better serve the practical engineering. On the basis of geological survey, Heishan bentonite turns out to be the most attractive competitor as a backfill material, because of its large reserves and prominent properties. In the present work, a series of oedomenter tests on Heishan bentonite have been performed for the first time to investigate the swelling behavior as a possible backfill material.

The studied bentonite in this work is mined from Heishan County in Liaoning province, 600 km northeast from Beijing, China. The Heishan bentonite is a gray powder and its main composition is montmorillonite approximately 81.6%. As a calcium-based bentonite, it has a plastic limit 48.83%, liquid limit of 960% and specific gravity of 2.5. Table 1 summarizes the basic physical properties of the studied material. Prior to preparing the bentonite samples, the studied material is processed through 74 μm sieve, oven-dried for 24 h and stored in a large airtight container for future use in laboratory testing. The bentonites are molded into specimens of 10 mm height and 61.8 mm in diameter under different statically compacted loads and these samples have dry densities of 0.983, 1.081, 1.177, and 1.278 g/cm3, respectively. A series of tests have been performed on these initial states to investigate the swelling behavior of Heishan bentonite.

The oedometer testing apparatus is used in this research and it is illustrated in Figure 1. As the main part of the testing device, the oedometer cell consists of three parts, i.e., the mechanical part to apply the vertical loadings (No.5 in Figure 1), the infiltration part to allow water moving during wetting paths (No. 1, No. 4, and No. 9) and the monitoring part to measure the vertical deformation during tests (No. 6). In the process of testing, the cutting ring (No. 3) containing the bentonite sample (No. 8) is working with other parts of the oedometer testing apparatus (No. 7) and a series of one-dimensional tests (No. 2) are carried out under various vertical stresses. During the hydration of bentonite samples, the vertical deformation is recorded by the dial gauge for every 2 h. Once the difference of two successive values is small enough (0.01 mm), the current step is completed and water to be added in water carrier continues the following step. Figure 2 is a summary of varied experimental paths to investigate the hydromechanical behavior of Heishan bentonite.

In this study, the amount of adding water provided by the Standard for geotechnical testing method (GB/T50123-2019) is adopted,

where, Δmw is the amount of adding water (g), ρd is the initial dry density (g/cm3), V is the volume of the cutting ring (cm3) and Δw is the difference between the target moisture content and the initial moisture content of dry soil specimen.

The moisture content of soil specimen is employed to represent hydraulic property and it is defined by,

where, θ is the moisture content, mw is the mass of water and ms is the mass of dry soil.

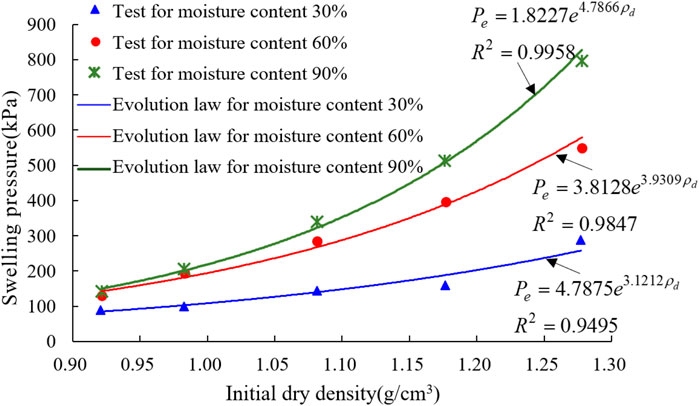

Swelling pressure is defined as the pressure required to compress the expansive clays back to its original configuration when the specimen is completely soaked. As a backfill material, the swelling pressure is of particular interest because it basically controls sealing properties. The constant-volume swelling pressure experiments have been performed to measure the swelling pressure. In these tests, the impact of initial dry density has been taken into account on the swelling pressure of the studied material.

Figure 3 is aimed at relating the swelling characteristics with the initial dry density of Heishan bentonite. To study the influence of absorbed water on the swelling behavior, the relationship between the swelling pressure and the water absorption is presented in Figure 3. Based on the plotted relationship between different dry density and swelling pressure, the swelling pressure increases exponentially as the initial dry density increases and the amount of absorbed water also amplifies the swelling pressure. Apart from attributing material swelling to the mineral phases, the pore water is exclusively attached to the swelling behavior of studied bentonite. Therefore, the initial dry density and the water absorption are key factors to affect the swelling behavior of Heishan bentonite.

FIGURE 3. Relationship between swelling pressure and initial dry density for different moisture contents.

As a result, the swelling pressure at different dry densities for Heishan bentonite can be calculated by the following empirical formula,

where, Pe is the swelling pressure (kPa), ρd is initial dry density (g/cm3), a and b are model constants presented in Figure 3.

To determine the swelling characteristics of Heishan bentonite under the condition of different loadings, swelling strain is employed in this work and it is defined as follows:

where εexp is the swelling strain, Z1 is the deformation of the specimen at the current loading stage, Z2 is the deformation at the beginning of the current loading stage, and h0 is the initial height of the specimen.

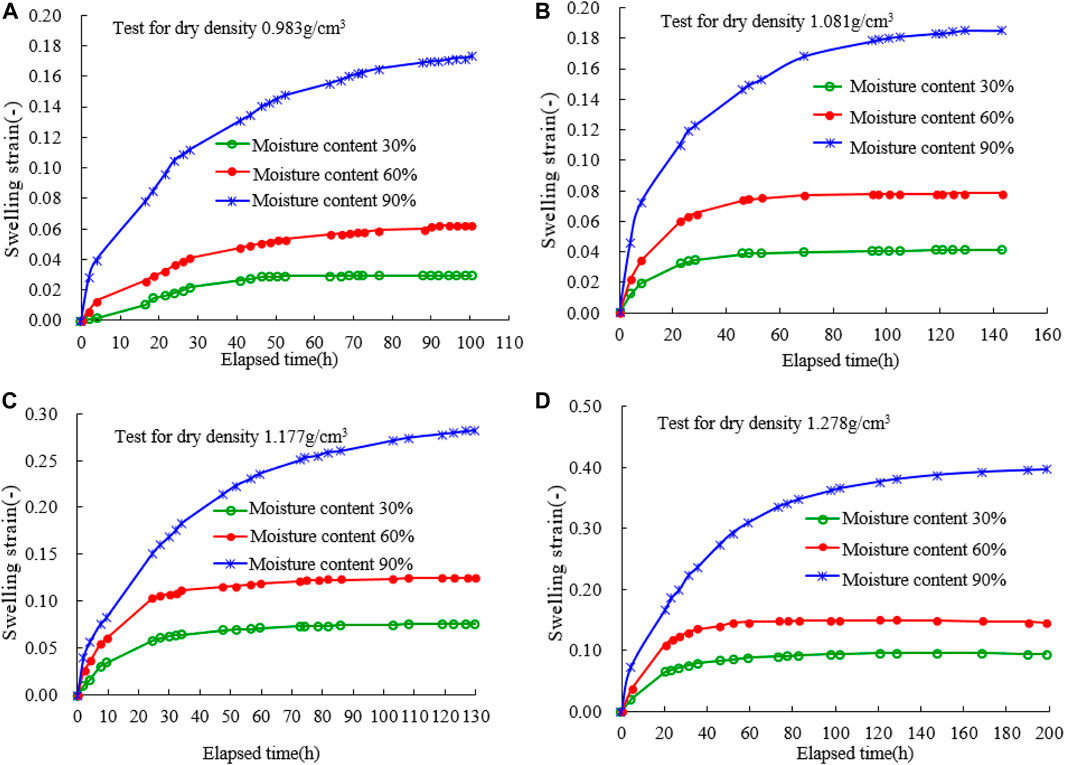

Constant applied stress and varied initial dry density. The mobilization of swelling strain with passage of time is illustrated in Figure 4 for the studied material. Taking test results at the constant applied stress of 50 kPa for instance, the curves demonstrate a distinct change in both the shapes of curves and the mobilized swelling strain for different moisture contents. For various initial dry densities (0.983, 1.081, 1.177, and 1.278 g/cm3), the increase of swelling strain is rapid at the earlier stage of tests and the curve of swelling strain tends progressively flatter with the elapsed time.

FIGURE 4. Variation of swelling behavior with initial dry density at the constant applied stress of 50 kPa.

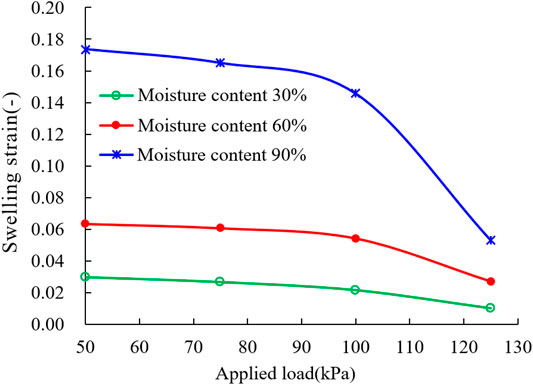

Constant dry density and varied vertical stress. To study the impact of applied stress on the swelling behavior of Heishan bentonite, typical tests of swelling behavior with different vertical stresses are carried out. Figure 5 plots the curves of swelling strain with the elapsed time under different vertical stresses of 50, 75, 100, and 125 kPa. For the initial dry density of 0.983 g/cm3, it is obvious that the swelling strain decreases with the increase of vertical stress. When the vertical stress in inferior to a reference stress pc, swelling strain varies relatively small. However, the swelling strain has a dramatic reduction as the vertical stress exceeds pc value and it indicates the bentonite expansion occurs in micro-structural level leading to a dense state of the studied sample.

FIGURE 5. Variation of swelling behavior with vertical stress at the constant initial dry density of 0.983 g/cm3.

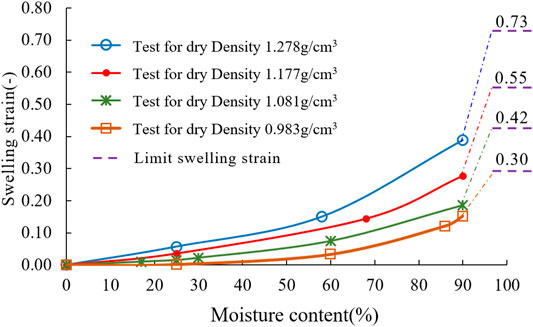

The amount of adding water is calculated according to Eq. 1 and the wetting path under a constant vertical stress of 50kpa is performed on the studied material. Figure 6 experimentally demonstrates the relationship between the moisture content and the swelling behavior of Heishan bentonite. In this plot, the swelling strains of several moisture contents have been tested and the swelling strain exponentially increases with the moisture content. To investigate the maximum swelling strain of each initial dry density, the soil specimen is wetted until it cannot absorb water and the limit swelling strain is portrayed in Figure 6. For different initial dry densities in this work, the limit swelling strain of Heishan bentonite varies from 0.3 to 0.73.

FIGURE 6. Variation of swelling behavior with moisture content at the constant applied stress of 50 kPa.

As a potential backfill material, low permeability is required to evaluate the sealing efficiency of the bentonite barrier. To study this property, the experimental testing system based on Darcy’s law is developed and it mainly consists of a N2 injector, a reference cell, a seepage cell, and a collection cell as shown in Figure 2. The soil specimen is firstly vacuumed and the confining pressure is imposed on the specimen. N2 is injected into the reference cell under pressure and the seepage test starts when the pressure in reference cell is stable. The collection cell is employed to measure the flow rate of injected gas and the permeability is defined by

where, p1 and p2 are the upstream and downstream pressure, A is the cross-sectional area, μ is the viscosity of N2, L is the length of the specimen and Q is the flow rate.

Figure 7 describes the relationship between soil permeability and moisture content and an empirical expression is proposed to simulate the fore-mentioned relationship,

where, k0 is the permeability of soil specimen at the dry state (mD), θ is the moisture content and λ is a constant.

In Figure 7 we can find that the soil permeability is exponential reduction with the moisture content increasing. When the moisture content reaches 40%, the permeability of bentonite barrier is so dense that no gas can be collected in collection cell. This suggests that Heishan bentonite has a relatively low permeability under an enough pressure and a proper moisture content.

A series of swelling pressure tests, loaded swelling tests, free swelling tests and permeability tests have been conducted on Heishan bentonites and the experimental results allow the following conclusion to be drawn.

1) swelling pressure-initial dry density relationship.

The swelling pressure of the studied material exponentially increases with the initial dry densities rising, and this value is greatly influenced by the amount of absorbed water during wetting. The proposed empirical formula is able to estimate the swelling pressure because of the small fitting tolerance.

2) Swelling strain-elapsed time relationship.

Under the condition of constant applied stress and varied initial dry density, swelling strain increases rapidly at the earlier stage of tests and then it tends progressively flatter with the elapsed time. The higher moisture content, the larger is the swelling strain. In case of constant initial dry density and varied vertical stress, swelling strain reduces significantly when the vertical stress exceeds the reference stress and it can be explained that the bentonite expansion occurs in micro-structural level under a relatively large vertical stress.

3) Swelling strain-moisture content relationship.

The swelling strain increases with the moisture content mounting and its relationship abides by an exponential law. The limit swelling strain is investigated when the soil sample cannot absorb more water and this value varies from 0.3 to 0.73 for different initial dry densities.

4) Permeability-moisture content relationship.

The bentonite permeability is exponential reduction with the increase of moisture content and the soil specimen becomes impermeable when the moisture content is larger than 40%. This suggests that Heishan bentonite has a relatively low permeability and Heishan bentonite can be employed as a backfill material in the future.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

J-HX contributed to conception and design of the study. KL wrote the whole draft of the manuscript and carried out statistical analysis. K-MS and S-CZ performed the experimental tests. All authors contributed to the submitted manuscript.

Author J-HX is employed by POWERCHINA Huadong Engineering Corporation Limited and Zhejiang Huadong Engineering Consulting Corporation Limited.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The authors would like to acknowledge National Natural Science Foundation of China and Shandong Province for funding this work through research grant 51808306 and ZR2021ME099.

Chapman, N. A. (2006). Geological Disposal of Radioactive Wastes-Concept, Status and Trends. J. Iberian Geology. 32 (1), 7–14.

Chen, Y.-G., Cui, Y.-J., Tang, A. M., Wang, Q., and Ye, W.-M. (2014). A Preliminary Study on Hydraulic Resistance of Bentonite/host-Rock Seal Interface. Géotechnique 64 (12), 997–1002. doi:10.1680/geot.13.p.209

Cui, S.-L., and Si, D.-D. (2014). Experimental Research of Swelling Behaviors with Initial Water Content and Matric Suction of Bentonite-Sand Mixtures. Geosystem Eng. 17 (6), 317–324. doi:10.1080/12269328.2014.994788

Cui, Y.-J., Tang, A.-M., Qian, L.-X., Ye, W.-M., and Chen, B. (2011). Thermal-mechanical Behavior of Compacted GMZ Bentonite. Soils and Foundations 51 (6), 1065–1074. doi:10.3208/sandf.51.1065

Jobmann, M., Flügge, J., Gazul, R., Hammer, J., Herold, P., Krone, J., et al. (2017). Investigation on Long-Term Safety Aspects of a Radioactive Waste Repository in a Diagenetic Clay Formation. (Technical report, GRS BGR DBE TEC).

Kanno, T., and Wakamatsu, H. (1992). Water Uptake and Swelling Properties of Unsaturated Bentonite Buffer Materials. Can. Geotech. J. 29, 1102–1107. doi:10.1139/t92-127

Komine, H., and Ogata, N. (2003). New Equations for Swelling Characteristics of Bentonite-Based Buffer Materials. Can. Geotech. J. 40, 460–475. doi:10.1139/t02-115

Komine, H., and Ogata, N. (2004). Predicting Swelling Characteristics of Bentonites. J. Geotech. Geoenviron. Eng. 130 (8), 818–829. doi:10.1061/(asce)1090-0241(2004)130:8(818)

Lloret, A., Villar, M. V., Sánchez, M., Gens, A., Pintado, X., and Alonso, E. E. (2003). Mechanical Behaviour of Heavily Compacted Bentonite under High Suction Changes. Géotechnique 53 (1), 27–40. doi:10.1680/geot.2003.53.1.27

Martin, P. L., Barcala, J. M., and Huertas, F. (2006). Large-scale and Long-Term Coupled Thermo-Hydro-Mechanic Experiments with Bentonite: The Febex Mock-Up Test. J. Iberian Geology. 32 (2), 259–282. doi:10.5209/JIGE.33935

Romero, E., Della Vecchia, G., and Jommi, C. (2011). An Insight into the Water Retention Properties of Compacted Clayey Soils. Géotechnique 61 (4), 313–328. doi:10.1680/geot.2011.61.4.313

Sun, D. a., Zhang, J., Zhang, J., and Zhang, L. (2013). Swelling Characteristics of GMZ Bentonite and its Mixtures with Sand. Appl. Clay Sci. 83-84 (10), 224–230. doi:10.1016/j.clay.2013.08.042

Sun, Z., Chen, Y., Ye, W. M., Cui, Y. J., and Wang, Q. (2020). Swelling Deformation of Gaomiaozi Bentonite under Alkaline Chemical Conditions in a Repository. Eng. Geology. 279, 105891. doi:10.1016/j.enggeo.2020.105891

Tanaka, Y., and Nakamura, K. (2005). Effect of Seawater and High-Temperature History on Swelling Characteristics of Bentonite. Doboku Gakkai Ronbunshu 2005 (806), 93–111. doi:10.2208/jscej.2005.806_93

Tang, C. S., Tang, A. M., Cui, Y. J., Delage, P., Schroeder, C., and Shi, B. (2011). A Study of the Hydro-Mechanical Behaviour of Compacted Crushed Argillite. Eng. Geology. 118, 93–103. doi:10.1016/j.enggeo.2011.01.004

Wang, Q., Tang, A. M., Cui, Y.-J., Delage, P., and Gatmiri, B. (2012). Experimental Study on the Swelling Behaviour of Bentonite/claystone Mixture. Eng. Geology. 124, 59–66. doi:10.1016/j.enggeo.2011.10.003

Xie, Y., Chen, Z. H., and Li, G. (2006). Test Research on Three-Dimensional Swelling Pressure of Nanyang Expansive Soil (23). J. Logist Eng. Univ. 22 (1), 11–14. (in Chinese).

Ye, W. M., Zhang, F., Chen, B., Chen, Y. G., Wang, Q., and Cui, Y. J. (2014). Effects of Salt Solutions on the Hydro-Mechanical Behavior of Compacted GMZ01 Bentonite. Environ. Earth Sci. 72, 2621–2630. doi:10.1007/s12665-014-3169-x

Zhang, L., Sun, D. A., and Liu, Y. M. (2016). Comparison between Swelling Properties of Two GMZ Bentonites. Rock Soil Mech. 37 (12), 3447–3454. doi:10.16285/j.rsm.2016.12.013

Zhang, S.-C., Li, K., Sun, K.-M., and Wang, S. (2021). Impact of Initial Moisture Content on the Shrinkage-Swelling Behavior of Heishan Bentonite. KSCE J. Civ Eng. 26 (2), 550–555. doi:10.1007/s12205-021-0060-7

Keywords: soil mechanics, heishan bentonite, mechanical behavior, hazardous waste contamination prevention, analytical modeling

Citation: Xu J-H, Li K, Sun K-M and Zhang S-C (2022) Mechanical Characteristics of Heishan Bentonite for Hazardous Waste Contamination Prevention. Front. Earth Sci. 10:884453. doi: 10.3389/feart.2022.884453

Received: 26 February 2022; Accepted: 04 April 2022;

Published: 02 May 2022.

Edited by:

Yun Zheng, Institute of Rock and Soil Mechanics (CAS), ChinaReviewed by:

Zhongzheng Wang, Queensland University of Technology, AustraliaCopyright © 2022 Xu, Li, Sun and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Kai Li, a2FpLmxpQGxpdmUuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.