94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci., 09 January 2023

Sec. Economic Geology

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.1083489

This article is part of the Research TopicRecent Advances in Unconventional Natural GasView all 10 articles

The formation and later evolution of coal-bearing basins in eastern Heilongjiang are controlled by multi-phase tectonic movements, and the Shuangyashan Basin is tectonically located at the southern end of the Sanjiang Basin in the northeast. The paper focuses on the regional geological and tectonic evolution of the Shuangyashan Basin and its influence on the gas occurrence law and extraction difficulty of the Jixian Coal Mine. The study determined that the gas occurrence of the mine in the Suibin-Jixian depression basin has regional aggregation and caprock sealing characteristics. The gas pressure and content of the 9# Coal Seam were measured in the underground test, and the results showed that the 9# coal seam is a hard-to-extract coal seam with low permeability. Aiming at the issue of hard-to-extract gas in 904 Working Face of 9# Coal Seam which is affected by depression basin and derived secondary tectonic conditions, numerical calculation and analysis of gas extraction effect of working face with different extraction parameters were carried out by COMSOL software, the results showed that: negative extraction pressure has less influence on gas extraction effect under basin conditions; when 113 mm diameter borehole is used for gas extraction, gas pressure decreases to 0.72 MPa; when the spacing of extraction borehole is 2 m, the gas pressure is reduced by 20%; when the coal seam permeability is increased by 10 times to more than 0.015 mD, the gas pressure is reduced by more than 50%. The optimized gas extraction scheme with 113 m diameter, 2 m borehole spacing, and 15 kPa negative pressure was proposed for the test working face, and combined with supercritical CO2 fracturing and permeability enhancement technology. Under underground measurement, the coal seam gas content was reduced by 39.7% compared to the original gas extraction scheme. It can be seen that the reasonable gas extraction scheme and coal seam pressure relief and permeability enhancement technology can significantly improve the gas extraction rate, and the extraction effect is remarkable.

Coal seam gas is a product of geological action (Dazhen et al., 2021). The regional tectonic background and its evolution control the formation and distribution of coalbed methane accumulation zones (Liu et al., 2022). The mine structure controls the gas zoning characteristics, and the working face structure determines the local gas enrichment area and outburst dangerous area (Zhang et al., 2022a). As a typical geological tectonic, the basin is formed under the action of crustal tectonic movement. The stratum is squeezed or stretched, a downward bending fracture occurs, and its internal structure is damaged to varying degrees. Under the influence of basin conditions, regional coalfields will be in the scope of certain closed-type tectonic traps, which are mostly reserved with low permeability hard-to-extract coal seams (Liu et al., 2021). In addition, the thickness of the overlying strata in the depression basin increases, which acts as a sealing cap for the gas occurrence in the lower coal seams, effectively blocking the gas migration and diffusion, resulting in a sharp increase in the gas content of the coal seams. Liu Li et al. proposed the gas occurrence characteristics of Cambrian-Ordovician shale in the Tarim Basin. The research results enriched the theory of marine shale gas accumulation and provided theoretical guidance for the “three depressions and four uplifts” model of marine shale (LIU et al., 2018). He Shuxian et al. discussed the influence of fracture development characteristics on gas quantity under the conditions of the Sichuan Basin. The study found that fracture development provides a channel for gas desorption, and the free gas content in the fracture development section accounts for more than 55% of the total gas content (He et al., 2022a). Therefore, there is an urgent need to extract the gas generated during coal mining under basin conditions. The coal permeability is directly related to the extraction efficiency and attainment time of coal seam gas under basin conditions (Zou et al., 2022). Domestic and foreign scholars simulated the transient changes of coal permeability by proposing the intrinsic constitutive equation on the scale of fractured coal (Abouloifa et al., 2021), proposed a new coal seam permeability measurement method based on considering the equivalent scale characteristics of coal matrix-fracture structure, effective stress, and matrix adsorption-induced strain permeability evolution model, and verified the reliability of the new method by comparing with field test data (Guo et al., 2021). For other gas extraction parameters, Huihuang Fang used the Hudi Coal Mine in the Qinshui Basin as the study area to analyze the overlying load differences in gas pressure distribution and factors affecting the effective extraction radius and found that extraction time, extraction borehole diameter, extraction negative pressure, permeability and effective extraction radius were exponentially related based on COMSOL simulation (Fang et al., 2022).

Many studies have been done by domestic and foreign scholars on the characteristics of gas occurrence in basin conditions and optimization of gas seepage characteristics and extraction parameters in mines, and a lot of results have been achieved. However, there are few studies on gas extraction in which the gas occurrence is characterized by regional aggregation and caprock sealing due to the influence of the depression basin. Based on the regional geological and tectonic evolution of the Shuangyashan basin and the study of the gas occurrence law and extraction difficulty of the Jixian Coal Mine, this paper determines that the coal seam belongs to the hard-to-extract coal seam with low permeability, and proposes the gas extraction technology and gas extraction optimization scheme by applying supercritical CO2 fracturing to pressure relief and permeability enhancement. The research results provide theoretical and technical guidance for coal seam gas extraction technology under basin conditions.

The tectonic framework of the coal-bearing basin group in eastern Heilongjiang is a product of the overlapping of the Paleo-Asian Ocean tectonic domain and the Marginal-Pacific tectonic domain and the transformation to the Marginal-Pacific tectonic domain (Zhao et al., 2022). Basin formation and later evolution are controlled by multi-phase tectonic movements, which are the main driving force for the development of the Eastern Basin Group. The coal-bearing basin is a dustpan-shaped structure in the longitudinal section, which is deep in the south and shallow in the north, steep in the south, and gentle in the north. Jixi Basin, Boli Basin, and Sanjiang Basin are distributed in order from south to north in their structural positions. Shuanghua Basin and Shuangyashan Basin are formed at the southern end of the Sanjiang Basin due to the Huanan Uplift, as shown in Figure 1A.

The Sanjiang Basin is mainly spreading in a north-easterly direction, consisting of the Suibin Depression, the Fujin Uplift, and the Qianjin Depression from west to east (GUO and WANG, 2008), as shown in Figure 1B. In the late Early Cretaceous, the Suibin Depression underwent strong alluvial-fold deformation, with massive uplift and intense denudation of the basin, a process that probably continued until the Paleogene rift, and since the Cenozoic, the Suibin Depression has undergone weak extension and subsidence, resulting in the present-day tectonic landscape. It can be seen that the Suibin Depression in the Sanjiang Basin generally shows the basin characteristics of superposition of multi-phase extrusion and extensional deformation, while the Shuangyashan-Jixian coalfield in the study area is located at the edge of the Suibin Depression basin.

The Jixian Coalfield is located in the Suibin-Jixian Depression Basin, which ranges from the Jiamusi Uplift in the west to the Fujin Uplift in the east. The coal measure strata are generally a north-dipping syncline structure, with steep western flanks and gentle eastern flanks. Secondary structures are developed in each uplift zone and depression zone. In the southern part of the Suibin-Jixian Depression, there are the Dongrong Syncline, Suoligang Anticline, Xinganzhen Syncline, Zhongfutun Anticline, and Yaolinzi Syncline, which play a controlling role in the tectonic framework of the Jixian Coalfield. The Sujiadian-Bijiashan Fault on the southwestern edge of the coalfield is obliquely connected with the near east-west Beigang Fault, forming an “arc structure” in the local area. Jixian coal mine is located in the south of the Jixian coalfield, which is part of the Shuangyashan Jixian coalfield, as shown in Figure 2A.

Jixian Coal Mine is located in the north wing of the Jixian Syncline between the Soligang Anticline and the Jixian Anticline in the depression zone. The thickened coal seam in the center of the depression basin forms a good caprock sealing to the gas enrichment area below (Wang et al., 2021a), leading to a further increase in gas content. At the same time, due to the influence of the latitudinal tectonic system, the area is subjected to north-south extrusion. The Beigang Fault lifts the southern wing of the Jixian Syncline, weathering, and denudation, while the northern wing is preserved, forming a monoclinic structure with strata striking nearly east-west and small folds developing locally due to the cutting of the fault. The complex geological and tectonic conditions in the wellfield play a controlling influence on the regional accumulation of gas in the mine.

The mineable coal seam in Ji Xian Wellfield is Chengzihe Group, the main mining nine# coal seam, the depth of the coal seam buried is 689 m; and the roof and floor of the coal seam are more stable, with mostly fine sandstone and siltstone of poor permeability, which plays an obstructive and sealing role in the migration of gas. With the increase of mining depth, the high gas area has appeared underground, the measured gas content has been as high as 14.72 m3/t, and the absolute gas emission from the working face has been as high as 20 m3/min.

Under the influence of the geological and tectonic conditions of the Suibin-Jixian Depression Basin, the Jixian mining area is subject to greater radial extrusion stress, the fissures of the coal rock body are compressed and dense, the permeability is significantly reduced, the gas is difficult to migrate in the vertical direction, blocking the communication fissure channels between the deep coal seam gas and the surface, which plays a closed role in the coal seam gas, resulting in deep coal seam with high gas content.

To better analyze the gas occurrence characteristics of the Jixian Coal Mine under the conditions of the Suibin-Jixian Depression Basin, the 904 Working Face of the 9# coal seam in the West Mining Area 2 of the Jixian Coal Mine was selected as the research area. The 904 Working Face is located at the -450 m level of the mine, geographically located in the eastern part of the West Mining Area 2. The northern part of the Working Face is the West No. Two mining area track downhill, the southern part is the Beigang Fault, the western part is the West No. Two Mining Area 905 Preparation Working Face, and the eastern part is the West No. Two Mining Area 903 Goaf. 904 Working Face mining engineering plane diagram is shown in Figure 2B. The No. One Syncline of the Jixian Mine is located in the West Mining Area 2, with an axial direction of nearly north-south and an axial length of about 1.6 km, and the No. 904 Working Face is located in the southern central axis of the No. One Syncline.

Based on the influence of the above depression basin conditions on the characteristics of mine gas occurrence, the researchers conducted underground tests on the basic parameters of 9 # coal seam gas in the 904 Working Face of the West Mining Area 2 of Jixian Coal Mine, mainly including gas pressure, gas content, borehole flow attenuation coefficient, permeability coefficient, and other indicators. The test results are shown in Table 1.

According to the underground test results, it can be seen that the 9# coal seam studied in this paper has a poor pore development degree, the ultimate adsorption a value of gas is 26.237 m3/t, the permeability coefficient of the coal seam is 0.06 m2/(MPa2•d), the maximum gas pressure of the coal seam at the measurement point is 0.22 MPa, and the 9#coal seam is determined to be the hard-to-extract coal seam with low permeability.

Under the influence of the regional depression basin conditions, secondary derivative structures exist at the working face of the Jixian Coal Mine, resulting in the regional aggregation characteristics of the mine gas occurrence. According to Figure 2B, taking 904 Working Face in the West Mining Area 2 as an example, during the formation of the Suibin-Jixian Depression Basin, No. One Syncline structure was derived from the working face, resulting in shearing of the coal seam as a soft layer and bending of the surrounding rocks as a hard layer, the primary surface of the coal seam was damaged by splitting under shearing and plastic sliding along the syncline axis, and the interlayer sliding further damaged the primary structure of the coal seam, metamorphosing it into an extremely soft or loose tectonic coal (Zhang et al., 2022b), which increases the adsorption capacity of the coal body and traps more gas in the coal seam.

Under the action of tectonic stress, the two wings of the No.1 Syncline structure of the 904 Working Face and the axis are above the neutral layer as a high-pressure zone, and below the neutral layer forms a relatively low-pressure zone, as shown in Figure 3. The non-uniformity of the stress state on both sides bounded by the neutral layer determines the zoning characteristics of the gas in the working face (Yuan et al., 2020). In addition, the upper compression thickening of the syncline makes the fractures and pores in the coal-rock mass compacted, reducing the lower gas seepage and escape; the lower layer of syncline structure produces tensile fracture or fracture surface under the action of tension, and the joints and micropores in the coal body are expanded. The expansion of space reduces the desorption pressure and forms a good gas accumulation space, which is helpful for the desorption of adsorbed gas in coal seams. Therefore, the depression basin not only affects the gas content of the mining area but also derives the secondary structure of the working face under the condition of the depression basin, which together affects the zoning of the gas content in the mining area and the difference of the gas content in the working face.

According to the test results of the underground gas parameters of the 904 Working Face in the West Mining Area 2, gas pre-drainage must be carried out in the 904 Working Face in the West Mining Area 2. To better test the effect of gas pre-drainage in the working face, the corresponding extraction system model was established using COMSOL software according to the layout of the working face and the layout of extraction boreholes, with the model size of 60 m x 25 m x 3 m, as shown in Figure 4.

Based on the original gas extraction scheme for the 904 Working Face in the West Mining Area 2 of the Jixian Coal Mine, the base parameters for the numerical simulation were determined, as shown in Table 2.

The simulation specifically investigates the effect of different extraction parameters (extraction negative pressure, borehole diameter, borehole spacing, and permeability) on the gas extraction effect of the working face, and a total of four sets of extraction parameters are designed for the comparison scheme (only the corresponding extraction parameters are changed, other parameters are the same as the original scheme). The numerical simulation parameters of the comparison scheme are shown in Table 3.

According to the 《Interim Provisions for Coal Mine Gas Extraction to Meet Standards》: “If the coal seam gas content or pressure at the depth of the initial coal seam outburst is not examined, the coal seam gas pressure is reduced to less than 0.74 MPa” Using 0.74 MPa as the extraction requirement for the study of gas pre-extraction.

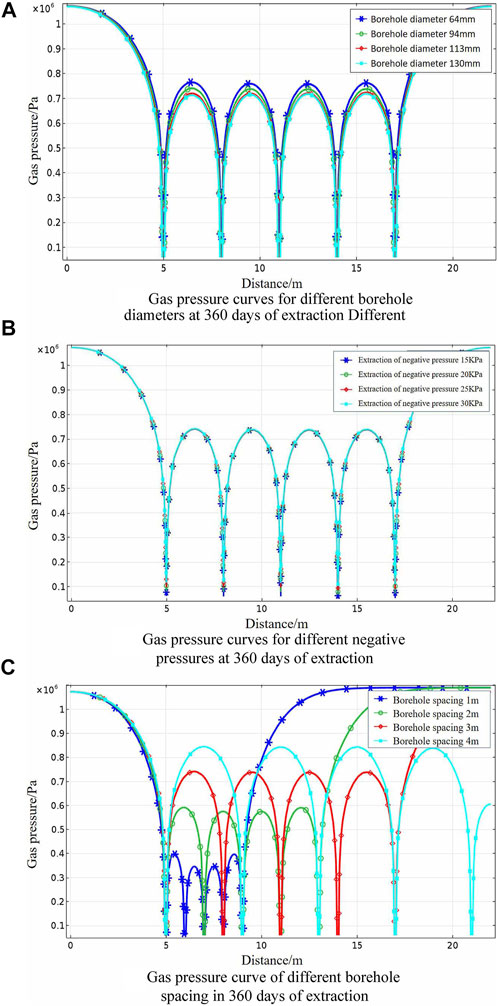

The extraction negative pressure and the coal seam gas pressure form the pressure gradient in the coal body together, which provides the power for the gas flow (Wang et al., 2021b). The practice has proved that too high or too low extraction negative pressure will seriously affect the extraction effect. Only by combining the characteristics of coal seam gas occurrence can we determine a reasonable negative pressure interval suitable for the extraction of this coal seam. Figure 5A shows the gas pressure curves of different extraction negative pressures from extraction to 360 days. It can be seen from the diagram that when the negative pressure of extraction increases or decreases, the gas pressure value does not change. It shows that the change in extraction negative pressure is not the main factor affecting the effect of gas extraction in the depression basin.

FIGURE 5. Influence curve of different extraction parameters on gas pre-extraction effect in working face.

The diameter of the extraction borehole is an important indicator for improving the efficiency of gas extraction. Large-diameter boreholes increase the exposed area of the coal body and increase the extent of the pressure relief zone around the borehole, resulting in more fissures and providing channels for the flow of coal seam gas (Li et al., 2020). However, in the actual extraction process of underground gas, increasing the diameter of the borehole can lead to difficulties in construction and sealing. As can be seen from Figure 5B, the gas pressure at the same location decreases as the diameter of the borehole increases under the same conditions of gas extraction. This indicates that the larger the diameter of the extraction borehole, the better the gas extraction effect. The gas pressure was 0.765 MPa and 0.747 MPa for borehole diameters of 64 mm and 94 mm respectively, which did not meet the extraction requirements. The gas pressures for 113 mm and 130 mm boreholes were 0.720 MPa and 0.718 MPa respectively, which met the extraction requirements. The decrease in gas pressure from 64 mm to 94 mm is greater than the decrease in gas pressure from 113 mm to 130 mm, indicating that the effect of increasing the diameter of the borehole on gas extraction is reduced to a certain extent. Under the condition of meeting the extraction requirements, it is suggested to adjust the borehole diameter to 113 mm.

Different borehole spacing affects the gas extraction flow rate and effective gas extraction area (Wei et al., 2019), which in turn affects the gas extraction effect. A reasonable borehole arrangement can effectively utilize the optimum radius of the borehole (Zhang et al., 2019) in the gas extraction process and significantly improve the gas extraction efficiency. Figure 5C shows the gas pressure curves for different borehole spacing for 360 days of extraction time. The gas pressure in the vicinity of the extraction borehole rises as the spacing of the boreholes increases. The smaller the spacing of the boreholes, the faster the gas pressure around the borehole drops and the better the extraction effect. However, the gas pressure is still high at the distance from the borehole. In the original scheme, the gas pressure is 0.737 MPa when the borehole spacing is 3 m. When the borehole spacing is 2 m, the gas pressure is 0.593 MPa, and the gas pressure decreases greatly. Therefore, it is suggested that the borehole spacing be adjusted to 2 m, and the gas extraction effect will be better.

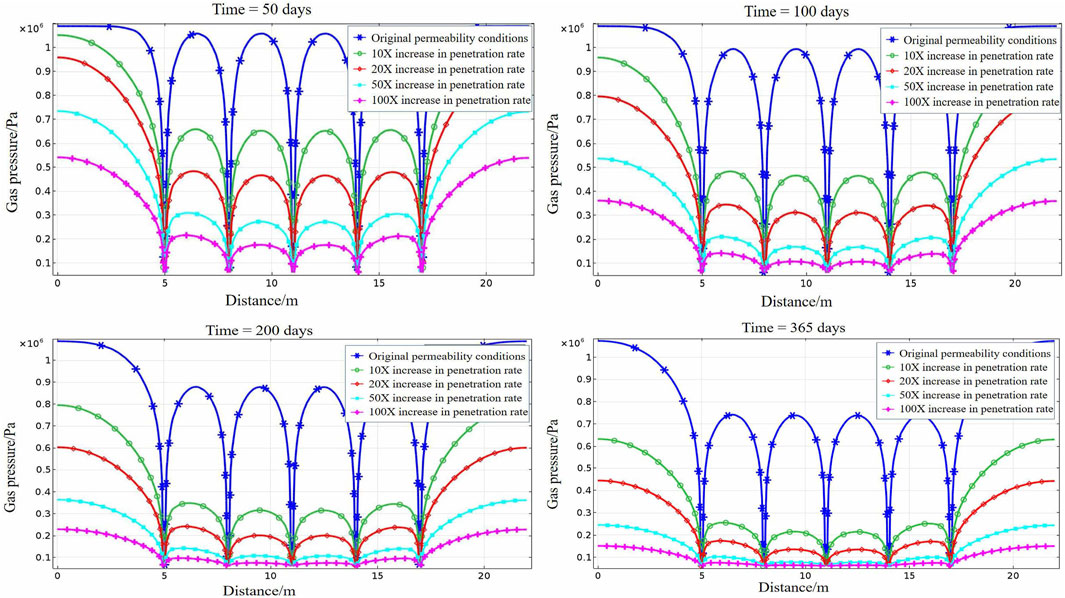

As one of the key parameters in the process of gas migration, the coal seam permeability has a direct impact on the effect of gas extraction (Jing et al., 2020; Fu et al., 2022; Vasilenko et al., 2022). Figure 6 shows the gas pressure curves at 50, 100, 200, and 365 days of gas extraction at the working face when the coal seam permeability is increased by different multiples. Comparing the gas pressure curves for different permeability at the same time, we can see that the larger the permeability, the faster the gas pressure drops and the better the extraction effect. At different times and with the same permeability, the gas pressure decreases gradually as the extraction time increases.

FIGURE 6. Gas extraction effect curve of different permeability increase times under different extraction times.

Analyze the influence of gas extraction parameters on the extraction effect of the working face, combined with the gas occurrence of the working face, and propose the optimization scheme of gas extraction parameters and boreholes arrangement: adjusting the negative pressure of extraction to 15 KPa; and using 113 m diameter, double rows of parallel holes with depths of 60 m and 140 m respectively for gas extraction of the working face. The boreholes are spaced at 2 m. Both sides of the working face are drilled parallel to each other as pre-extraction boreholes for the pre-extraction boreholes of gas from the nine# coal seam. When the pre-extraction working face becomes the mining working face, the pre-extraction borehole is used for the extraction while the mining borehole unloads the coal seam for gas extraction. Take the 904 working face as an example, the specific gas extraction boreholes optimization layout is shown in Figure 7.

According to the numerical simulation results of gas extraction under different permeability conditions, based on the application of a gas extraction optimization scheme, for the hard-to-extract coal seam with low permeability at 904 Working Face, increasing coal seam permeability can substantially improve gas extraction efficiency. At present, the pre-fracturing and permeability enhancement technologies applied underground are hydraulic fracturings, chemical blasting, and airburst fracturing. The residual fracturing fluid produced by hydraulic fracturing will cause serious harm to the environment (Yost et al., 2017), and traditional chemical blasting will have a potential risk of ignition to the gas. Therefore, airburst fracturing technology is most suitable for coal seam permeability enhancement in the gas extraction process. Among them, the supercritical CO2 airburst pressure relief technology is widely used in the field of low permeability and hard-to-extract coal seam penetration due to its large blasting range, high permeability coefficient, and strong adaptability (Wang et al., 2021c; He et al., 2022b). In this paper, the supercritical CO2 airburst fracturing technology was used to unload and increase the permeability of 904 Working Faces in the second west mining area of the Jixian Coal Mine, and the effect of coal seam permeability increase was measured underground.

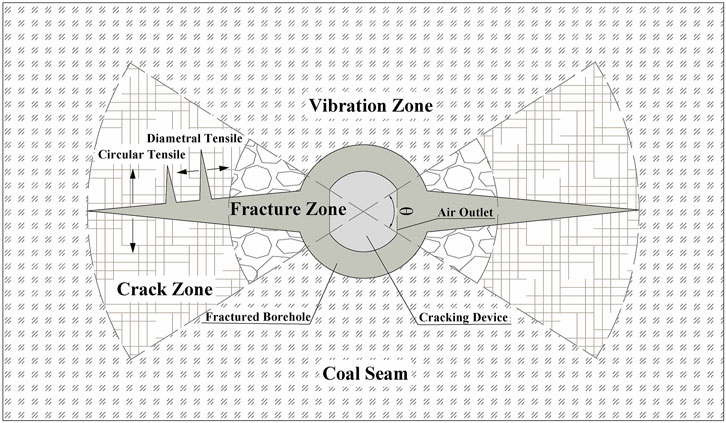

Supercritical carbon dioxide is injected into the blasting pipe, and the heating pipe is quickly excited by the initiator, after detonation in a supercritical state carbon dioxide will be rapidly vaporized, with its increasing expansion pressure to reach the ultimate strength of the fixed pressure shear plate, shear plate break, high-pressure gas released from the energy drainage head, along the fracture surface or natural fractures quickly spread, to achieve directional fracture blasting (Sun et al., 2021), from the center of the source outward in turn to form a crack zone, fracture zone, and vibration zone, the damage range as shown in Figure 8.

FIGURE 8. Comparison diagram of fracturing effect of supercritical CO2 in underground test borehole.

Multiple series blasting with ZLQ-38/300 and ZLQ-38/600 fracturing devices underground with CO2 weight of 0.17 kg and 0.26 kg respectively. The diameter of the construction borehole is 50 mm. Three boreholes were constructed in the middle roadway of the 904 Working Face for testing. The borehole spacing was 10 m, and the distance between the fracturing devices and the borehole wall was 12 mm. The multi-section fracturing device series blasting method was implemented. The effect of liquid CO2 fracturing in the underground working face is shown in Figure 9. After blasting, the borehole collapses in the hole, the hole wall is rough, and there are more broken coal blocks.

After using the supercritical CO2 fracturing technology to relieve the pressure and increase the permeability of the coal seam in the 904 working face, the gas extraction optimization scheme was used to extract the gas from the 904 working face. After the gas desorption in the underground site was completed, the gas parameters of the three test boreholes were measured. The measured results were compared with the original gas extraction scheme and the gas content measured by the gas extraction optimization scheme. The specific data is shown in Table 4.

Based on Table 4, a comparison graph of gas content measurement results is obtained as shown in Figure 10, which shows that the coal seam gas content is reduced by 15.83% by applying the optimized gas extraction scheme compared to the original gas extraction scheme. The gas content of the coal seam with supercritical CO2 fracturing and permeation technology was reduced by 28.4% compared to the coal seam without supercritical CO2 fracturing and permeation technology, and by 39.7% compared to the original gas extraction scheme before the gas extraction optimization scheme was applied. The gas extraction optimization program improves the efficiency of gas extraction in the mine; The application of supercritical CO2 fracturing technology can significantly improve the permeability of the hard-to-extract with low permeability coal seams.

1) By analyzing the tectonic evolution of the Shuangyashan Basin and the multi-phase extrusion and extensional deformation characteristics of the Suibin-Jixian Depression, it is determined that the tectonic activity has a controlling effect on the tectonic pattern of the coalfield and the coal seam gas occurrence in the Jixian Coal Mine, and the gas occurrence in the mine has the characteristics of partition aggregation and caprock sealing, and the low permeability of nine# coal seam is hard to be extracted.

2) Applying the numerical calculation method, the analysis of the gas extraction scheme for 904 Working Face of nine# coal seam in Jixian Coal Mine shows that: coal seam permeability, borehole diameter, and borehole spacing have significant effects on gas extraction effect. The gas extraction optimization scheme of extracting negative pressure of 15 KPa, borehole diameter of 113 m, spacing of 2 m, and parallel boreholes with lengths of 60 m and 140 m in the two lanes is proposed.

3) We proposed a supercritical CO2 fracturing permeability enhancement technology for low-permeability coal seams and implemented a tandem blasting method with multiple fracturing devices. Through underground measurements, the gas content of the coal seam was reduced by 39.7% compared with the original gas extraction scheme. The reasonable gas extraction scheme and coal seam pressure relief and permeability enhancement technology can significantly improve the gas extraction rate. The research results provide new ideas for the development of gas extraction technology under basin conditions.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

LT is responsible for theoretical guidance, ZZ is responsible for numerical simulation and experimental data processing, QL is responsible for theoretical analysis, YL and SW are responsible for downhole testing.

This work was financially supported by the LiaoNing Revitalization Talents Program (XLYC2007042), Liaoning Provincial Education Department Basic Scientific Research Project (Key Project)(LJKZ0325), and the National Natural Science Foundation of China (51604139).

We would like to thank all editors and anonymous reviewers for their comments and suggestions.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abouloifa, Najib, Vandamme, Matthieu, and Dangla, Patrick (2021). Modeling transient variations of permeability in coal seams at the reservoir scale. J. Nat. Gas Sci. Eng. 88 (2021), 103796. doi:10.1016/j.jngse.2021.103796

Dazhen, T. A. N. G., Shuguang, Y. A. N. G., and Shuling, T. A. N. G. (2021). Advance on exploration–development and geological research of coalbed methane in the Junggar Basin. J. China Coal Soc. 468, 2412–2425. doi:10.13225/j.cnki.jccs.CB21.0717

Fang, Hui-Huang, Zheng, C. S., Qi, N., Xu, H. J., Liu, H. H., Huang, Y. H., et al. (2022). Coupling mechanism of THM fields and SLG phases during the gas extraction process and its application in numerical analysis of gas occurrence regularity and effective extraction radius. Petroleum Sci. 19, 990–1006. doi:10.1016/j.petsci.2022.01.020

Fu, J., Li, B., Ren, C., Li, J., Wang, Z., Wu, X., et al. (2022). Coupling between damage evolution and permeability model with the adsorption effect for coal under gas extraction and coal mining conditions. Energy fuels. 3618, 10813–10831. doi:10.1021/acs.energyfuels.2c01758

Guo, Haijun, Tang, H., Wu, Y., Wang, K., and Xu, C. (2021). Gas seepage in underground coal seams: Application of the equivalent scale of coal matrix-fracture structures in coal permeability measurements. Fuel 288 (2021), 119641. doi:10.1016/j.fuel.2020.119641

Guo, Shao-bin, and Wang, Hong-liang (2008). Sequence stratigraphic characteristics and hydrocarbon prospect of mesozoic formation in Suibin depression, Sanjiang Basin. Petroleum Explor. Dev. 35, 44–51. doi:10.1016/s1876-3804(08)60007-5

He, Shun, Qin, Q., Qin, Z., and Zhou, J. (2022). Natural fracture development characteristics and their relationship with gas Contents─ A case study of wufeng–longmaxi formation in luzhou area, southern sichuan basin, China. ACS omega 738, 34066–34079. doi:10.1021/acsomega.2c03318

He, Wei, Lian, H., Liang, W., Wu, P., Jiang, Y., and Song, X. (2022). Experimental study of supercritical CO2 fracturing across coal–rock interfaces. Rock Mech. Rock Eng., 1–12. doi:10.1007/s00603-022-03070-9

Jing, Zhenhua, Balucan, R. D., Underschultz, J. R., Pan, S., and Steel, K. M. (2020). Chemical stimulation for enhancing coal seam permeability: Laboratory study into permeability variation and coal structure examination. Int. J. Coal Geol. 219, 103375. doi:10.1016/j.coal.2019.103375

Li, Hong, Liu, Y., Wang, W., Liu, M., Ma, J., Guo, X., et al. (2020). The integrated drainage technique of directional high-level borehole of super large diameter on roof replacing roof extraction roadway: A case study of the underground zhaozhuang coal mine. Energy Rep. 6, 2651–2666. doi:10.1016/j.egyr.2020.09.013

Liu, Dameng, Yao, Yanbin, and Wang, Hui (2022). Structural compartmentalization and its relationships with gas accumulation and gas production in the Zhengzhuang Field, southern Qinshui Basin. Int. J. Coal Geol. 259 (2022), 104055. doi:10.1016/j.coal.2022.104055

Liu, Junjun, Xie, J., Wang, F., Yang, B., Liu, Y., Fu, C., et al. (2021). Experiment investigation on gas flow characteristics of coal considering the integrity of coal samples. Geomatics, Nat. Hazards Risk 121, 2984–3000. doi:10.1080/19475705.2021.1987342

Liu, Luofu, Wang, Y., Chen, Y., Shen, B., and Gao, X. (2018). Gas occurrence and accumulation characteristics of Cambrian–Ordovician shales in the Tarim Basin, northwest China. Acta Geol. sinica-. Engl. Ed. 925, 1948–1958. doi:10.1111/1755-6724.13687

Sun, Keming, Chen, P., Zhang, S., Li, K., and Zhang, X. (2021). Numerical investigation of fracturing of coal with cleats caused by supercritical CO2 explosion. ACS omega 626, 16854–16868. doi:10.1021/acsomega.1c01450

Vasilenko, Tatyana, Kairillov, A., Islamov, A., Doroshkevich, A., Ludzik, K., Chudoba, D. M., et al. (2022). Permeability of a coal seam with respect to fractal features of pore space of fossil coals. Fuel 329 (2022), 125113. doi:10.1016/j.fuel.2022.125113

Wang, Fuwei, Chen, D., Wang, Q., Du, W., Chang, S., Wang, C., et al. (2021). Quantitative evaluation of caprock sealing controlled by fault activity and hydrocarbon accumulation response: K gasfield in the xihu depression, east China sea basin. Mar. Petroleum Geol. 134, 105352. doi:10.1016/j.marpetgeo.2021.105352

Wang, Kang, Pan, Hongyu, and Zhang, Tianjun (2021). Experimental study of prefabricated crack propagation in coal briquettes under the action of a CO2 gas explosion. ACS omega 638, 24462–24472. doi:10.1021/acsomega.1c02850

Wang, Zhiming, Hurter, S., You, Z., Honari, V., Sun, Y., and Zhang, S. (2021). Influences of negative pressure on air-leakage of coalseam gas extraction: Laboratory and CFD-DEM simulations. J. Petroleum Sci. Eng. 196 (2021), 107731. doi:10.1016/j.petrol.2020.107731

Wei, Pan, Huang, C., Li, X., Peng, S., and Lu, Y. (2019). Numerical simulation of boreholes for gas extraction and effective range of gas extraction in soft coal seams. Energy Sci. Eng. 75, 1632–1648. doi:10.1002/ese3.377

Yost, Erin E., Stanek, John, and Burgoon, Lyle D. (2017). A decision analysis framework for estimating the potential hazards for drinking water resources of chemicals used in hydraulic fracturing fluids. Sci. Total Environ. 574, 1544–1558. doi:10.1016/j.scitotenv.2016.08.167

Yuan, Y. U. A. N., Tang, Y., and Cao, D. (2020). Coalbed methane enrichment regularity and major control factors in the Xishanyao formation in the Western part of the Southern Junggar Basin. Acta Geol. sinica-. Engl. Ed. 942, 485–500. doi:10.1111/1755-6724.14339

Zhang, Chaolin, Xu, J., Peng, S., Li, Q., and Yan, F. (2019). Experimental study of drainage radius considering borehole interaction based on 3D monitoring of gas pressure in coal. Fuel 239, 955–963. doi:10.1016/j.fuel.2018.11.092

Zhang, Hao, Xu, L., Yang, M., Deng, C., and Cheng, Y. (2022). Pressure relief mechanism and gas extraction method during the mining of the steep and extra-thick coal seam: A case S tudy in the yaojie No. 3 coal mine. Energies 1510, 3792. doi:10.3390/en15103792

Zhang, Kaizhong, Zou, A., Wang, L., Cheng, Y., Li, W., and Liu, C. (2022). Multiscale morphological and topological characterization of coal microstructure: Insights into the intrinsic structural difference between original and tectonic coals. Fuel 321 (2022), 124076. doi:10.1016/j.fuel.2022.124076

Zhao, Xueqin, Lv, C., Jiang, Y., Zhu, H., Wang, F., and Chai, P. (2022). Geological characteristics of the mesozoic unconformities in eastern Heilongjiang, NE China: Implications for the mesozoic continental margin evolution of northeast asia. Front. Earth Sci. (Lausanne). 10, 1248. doi:10.3389/feart.2022.850324

Keywords: tectonic evolution, depression basin, low permeability coal seam, gas extraction, supercritical CO2 fracturing

Citation: Lan T, Zhang Z, LE QB, Liu Y and Wang S (2023) Study on the influence of the tectonic evolution of Shuangyashan Basin on gas occurrence and extraction in mines. Front. Earth Sci. 10:1083489. doi: 10.3389/feart.2022.1083489

Received: 29 October 2022; Accepted: 01 December 2022;

Published: 09 January 2023.

Edited by:

Yu Song, China University of Mining and Technology, ChinaReviewed by:

Quanzhong Guan, Chengdu University of Technology, ChinaCopyright © 2023 Lan, Zhang, LE, Liu and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhijia Zhang, bG50dWt5eHl6empAMTYzLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.