- 1School of Civil Engineering and Architecture, Zhongyuan University of Technology, Zhengzhou, China

- 2Gengcun Coal Mine, Yi Ma Coal Industry Group, Mianchi, China

The particle size and content of tailings are important parameters affecting the rheological properties of tailings slurry. To explore their influence law and mechanism on rheological properties, the experiments of tailings slurry were designed and carried out under different particle sizes and content conditions. The rheological properties of the tailings slurry were quantified in the paper. The Bingham body model was used in the texperiment. The “double 30” theory (“particle size of 30.0 μm” and “content of 30%“) was proposed and expounded. The corresponding theoretical model is established to analyze the mechanism of the above results. The conclusion is as follows. The tailings slurry agreeed to different rheological models with different particle size and content. The rheological behavior of the tailings slurry conforms to the Herschel-Bulkley model for the tailings, whose particle size is no larger than 30.0 μm and content is no larger than 30%. With the increase of the content of fine tailings, its behavior agrees better with the Bingham model. The yield stress and viscosity of tailings slurry in the process of transportation are in accordance with the laws of “double 30” theory. “Particle size of 30.0 μm” and “content of 30%” is the critical point of rheological characteristics of tailings. Based on the obtained results, the corresponding theoretical model was established to discuss the mechanism. The rheological laws of tailings slurry can provide theoretical guidance for reducing pressure and preventing pipeline wear in the process of tailings cementation discharge and pipeline transportation in an iron mine.

Introduction

Mineral resources excavation contributes significantly to the world economy andmany industries depend on the provision of raw materials by it (Si et al., 2021a; Si et al., 2021b; Li et al., 2022a; Zhang et al., 2022). With the increase of mining depth, more and more waste tailings are produced (Liu et al., 2020; Ruan et al., 2021). Statistics show that every 10,000 tons of ore mined will produce 9,300 tons of tailings and 3,400 tons of waste rock (Yan et al., 2022), which not only has serious security hidden dangers, but also destroys the environment and the ecology seriously (Small et al., 2015; Falagán et al., 2016; Li et al., 2022b). In order to protect the ecological environment and make rational use of resources (Aldhafeeri and Fall 2017), tailings backfilling in mines has become an important method of tailings disposal and has extensive application prospect (Cao et al., 2018; Li et al., 2022c; Zheng et al., 2022; Ouattara et al., 2017161).

Cemented paste backfill (CPB) technology has become an effective way of backfill method to solve solid waste in mines, and received more attention in mining practices around the world (Fang and Fall 2018; Liu et al., 2018; Mangane et al., 2018; Qi et al., 2019). It is an engineered combination of tailings, cement and mixing water, which can be transported to underground stopes by pumping or gravity. The cementation discharge and pipeline transport of tailings slurry is an important challenge for CPB technology (Qi et al., 2018; Liu et al., 2019; Chen et al., 2020). It is important to determine the reasonable slurry concentration, cement-sand ratio and pipeline transportation parameters to ensure the efficient and stable operation of pipeline discharge system. Especially for high concentration slurry, the rheological properties of slurry become the key factor for stable and reliable operation of the system. If the liquidity of the paste is too poor, it will lead to pipe blocking accidents, which will seriously affect the mine’s productivity. It is intended to solve the above-mentioned challenges simultaneously to investigating the rheological properties and mechanism of tailings slurry.

Long-term backfill research and practice show that the strength of backfill is positively correlated with cement-sand ratio, slurry mass fraction and curing age in a certain range. There are plenty of works dealt with the different key characteristics and multiscale behavior of cemented tailings/paste backfill with different mineral additives (Li et al., 2020; Cavusoglu et al., 2021; Kasap et al., 2022; Sari et al., 2022). However, with the increase of cement addition and slurry mass fraction, the fluidity of slurry will become worse (Wu et al., 2020; Wu et al., 2021). Currently, numerous scientists are conducting experimental studies on the rheological properties of pastes. Cheng (Cheng et al., 2020a) found that the tailing particle size significantly affects the cemented paste rheological properties. Roshan (Roshani and Fall 2020) evaluate the silica mechanism on early yield stress and viscosity of CPB. The fluidity of CTWB paste is generally characterized by the yield stress and viscosity in fluid mechanics (Wu and Cai, 2015; Deng et al., 2018). (Zhang and Qiao, 2015) concluded that the effect of cement-sand ratio and mass fraction on slurry yield stress was more significant through the rheological experiment of high-mass fraction slurry of waste rock tailing. The influencing factors of slurry rheological characteristics were studied (Xu et al., 2016; Long et al., 2017), the results showed that the content of fine particles was an important factor affecting the rheological characteristics of slurry. The minimum viscosity would appear when the ratio of coarse and fine particles decreased. To evaluate the rheological properties of tailings, many scholars have extensively conducted a large amount of work on the rheological characteristics of tailings through changing the experimental method, such as studies on the effect of the installation angle of mixing blade (Yin et al., 2010), blade resistance, and stirring method (Hale Micah et al., 2009; Just and Middendorf, 2009). Some scholars also study the rheological characteristics of tailings by means of numerical simulation (Bouvet et al., 2010; Lei et al., 2017; Rakotondrandisa et al., 2019). Computational fluid dynamics (CFD) simulations have become a trend in pipeline transportation and rheological characteristics of tailings research. Zhang (Zhang et al., 2015) developed a two-dimensional pipeline model for long distances and found that the necessary condition for self-flow transport is that the pressure value generated by gravity is greater than the pressure drop. Cheng (Cheng et al., 2020b) used CFD to investigate the effect of time and tem-perature on paste transport characteristics.

Especially for high concentration tailings slurry, quantifying the influence of particles and content on rheological characteristics and laws is helpful to optimize pipeline transport parameters and reduce pipeline resistance loss. It provides the basis for the design and operation of tailings cementation discharge system. However, the research on quantifing rheological characteristics and transport performance of consolidated slurry is relatively insufficient.

To solve the existing problems above effectively and reduce the transportation costs of tailings, the quantitative laws and effects of particle size and content on the rheological properties of tailings slurry should be determined and the rheological models for different particle size and content should be studied. And the mechanism of the above-mentioned rheological law need be further elucidated based on the particle structure and mechanical properties. The experiments were carried out and the mechanism are analyzed on rheological properties of tailings slurry in the work. Tailings slurry was preparated by mixing fine tailings and whole tailings. Based on the test and the rheology principles, the rheological parameters such as yield stress and viscosity of slurry are obtained. And the consilient rheology model for the tailings slurry is determined for different content conditions by rheological test of tailings slurry. The quantified rheological laws of “double 30” theory (“particle size of 30.0 μm” and “content of 30%“) were proposed and expounded. The results make contribution to obtaining transportation parameters of tailings and further rheological properties research. The research above is beneficial to reduce pipe friction and transportation costs in the transportation proce.

Rheological test of tailings

Test materials and instruments

An iron ore is located in the west of Anhui Province, China with an anual production of five million t/a. New technology of tailing cementation and discharge is applied and the whole tailings are discharged to surface. The complicated concentration dehydration process increased the transportation difficulty of high density paste, and the transportation conditions of high density paste are rigorous. The great friction resistance is generated in the transportation process of tailings, which is harmful to tailings transportation. Pressurized transporation is required and it will increase transportation costs for tailings.

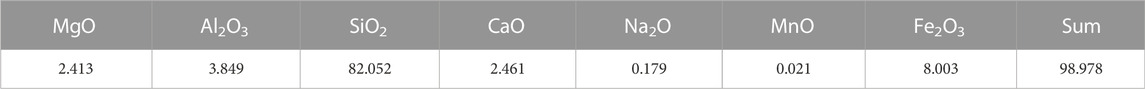

Tailings from the iron mine are used as test material which have the characteristics of more fine particle size content and poorly gradation. The initial solid content of the tailings brought to the laboratory from the mine site is 74%. Varigrained tailings are mixed with the whole tailings in the test and chemical properties of tailings slury are studied including the chemical constituents of the whole tailings and the content. The measured results of chemical constituents and their contents are shown in Table.1.

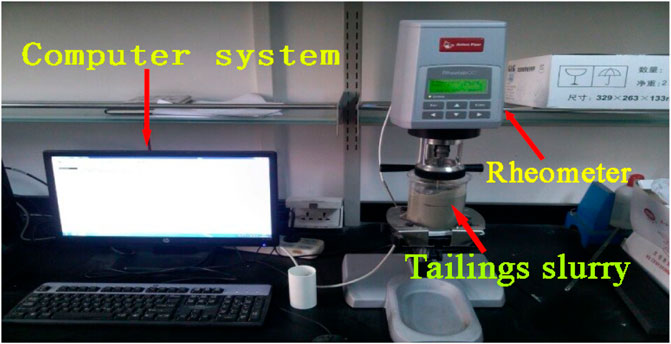

The factors affecting the rheological properties of tailings slury are very complicated. The parameters, such as slurry concentration, particle size, and fine tailings content, were considered during testing. RheolabQC rheometer was used to determine the rheological parameters of tailings in this paper. It has the advantages of strong performance and simple operation, and can test rheological parameters of various fluids. The rotating speed ranges from 0.01 to 1500 1/min. Torque range is from 0.25 to 75 mN m; The shear stress ranges from 0.5 to 30 kPa. The viscosity ranges from 1 to 1000 MPas; The temperature range is from -20–180°C; The shear rate ranges from 0.01 to 4000 1/s. The angular displacement accuracy is 2 rad. The Reynolds number of laminar flow to turbulent flow is much larger than that of high concentration mortar pipeline transportation. In addition, the mortar itself has a strong internal structure. Combined with the rheological theory, the Bingham body model was used in the texperiment. The experimental equipment is shown in Figure 1. Blade rotor was used to stir tailings and the room-temperature was 25°C. In addition, measuring cylinder (500 ml), general utility balance (1000 g), and beakers were also used.

Designation of tailings physical parameters

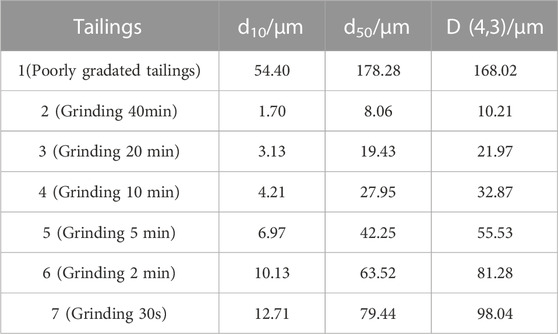

In this experiment, the ball mill was used to grind the large particles of tailings, and the milling time was set to 30 s, 2 min 5 min, 10 min, 20 min, and 40 min, respectively. The large particles of tailings were grinded based on the ball milling time above.

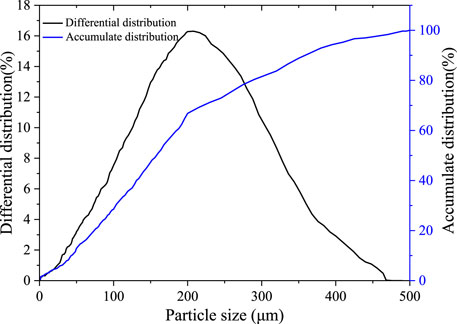

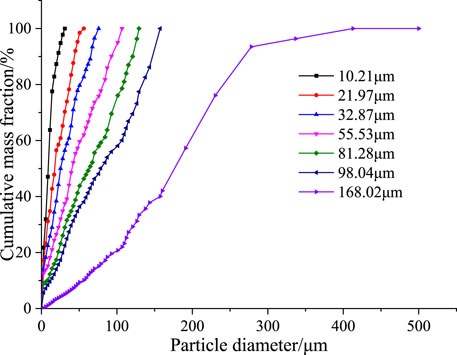

The physical parameters of tailings are shown in Table.2. The Particle size distribution is in Figure 2. The curves of the weighted average of particle size versus mass for different particle diameter is shown in Figure 3 And in the Figure. The characteristic values of particle composition for whole tailings are as follows. d10=54.27 μm, d30=135.32 μm, d60 =200.79 μm, and the median diameter is d50=178.28 μm. The diameters of the whole tailings are mainly between 80 μm and 341 μm, then the non-uniformity coefficient Cu and the curvature coefficient Cc of tailings are calculated. Cu equals to 3.636 (less than 5), and Cc equals to 1.657. The results showed the whole tailings belong to poorly gradation, which seriously affects on the process of tailings transport such as concentration, dehydration, cementation and stabilization.

FIGURE 3. Curves for different size fraction and particle diameter.

Experimental procedures

In this experiment, the optimum time interval was determined to be about 1s through multiple experiments. Note that if the time interval is too short it would cause inaccurate test results, while it would cause slurry sedimentation if the time interval is too long.

The experiment procedures were as follows:

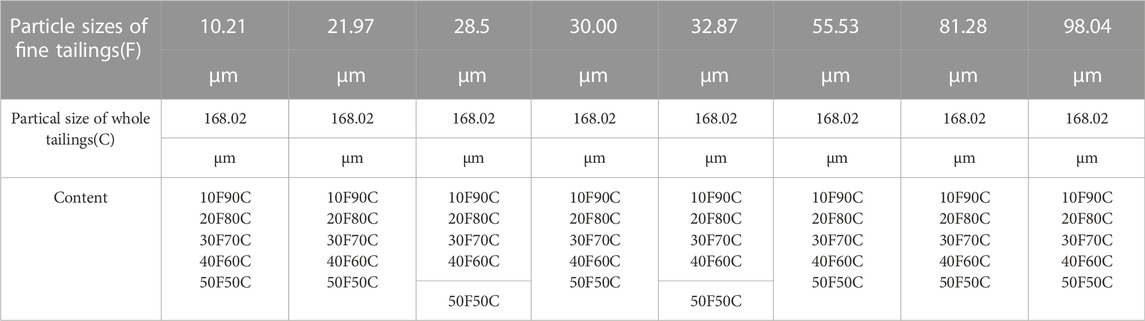

1) In the test the concentration of tailings slurry was 75%, which was made by mixing fine tailings and whole tailings. The particle sizes of fine tailings were 10.21 μm, 21.97 μm, 28.5 μm, 30.00 μm, 32.87 μm, 55.53 μm, 81.28 μm, and 98.04 μm, respectively, the partical size of whole tailings was 168.02 μm, and the contents of fine tailings were 10%, 20%, 30%, 40%, 50%, respectively. The information about the mixing ratio of tailings slurry is in Table 3.

2) The weighed tailings and water were mixed in the beaker, then the mixture above was stirred evenly with a glass rod to get tailings slurry.

3) RheolabQC rheometer was used in the test, and the time interval was 1s. In order to reduce the test error, the data was measured at least three times in every group. The final results were obtained by taking average values. When the difference coefficient was large, When the difference coefficient is large, the data with large difference will be removeed and the test was conducted again.

Test results and analysis

Test results

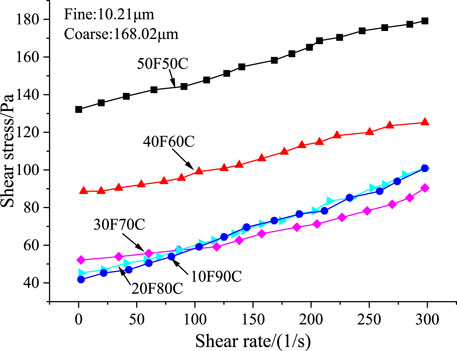

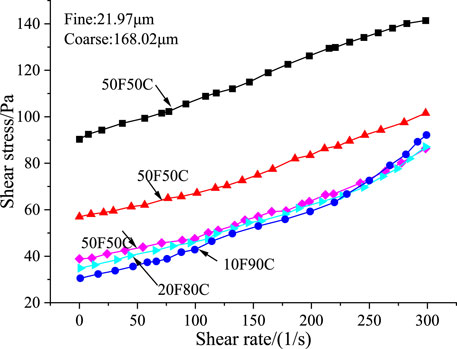

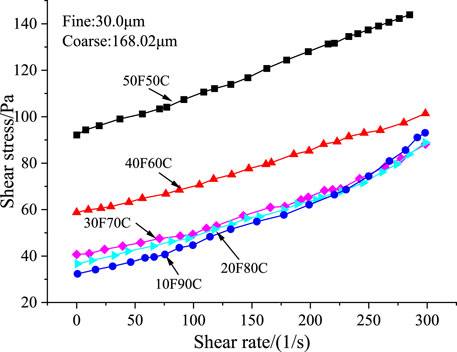

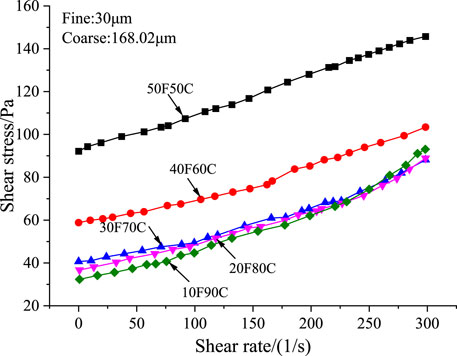

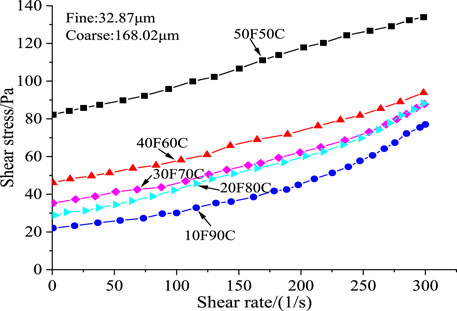

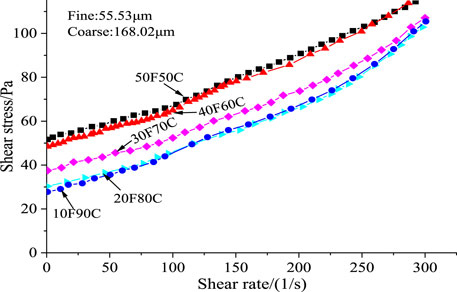

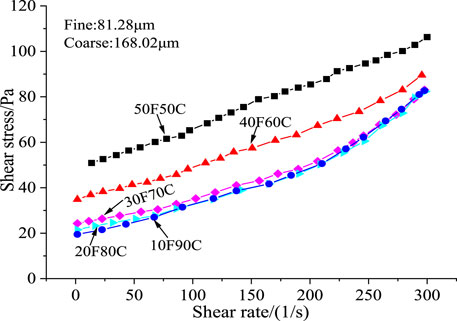

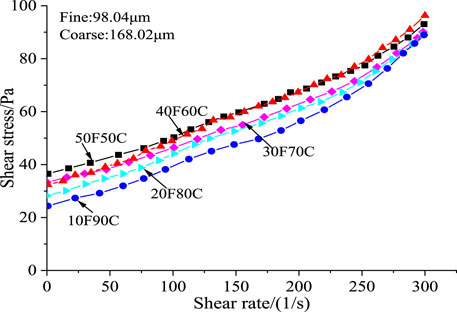

The rheological curves of tailing slurries with different particle sizes and contents are shown in Figure 4–11. 10F90C represents the mixture of 10% fine tailings and 90% whole tailings.

It can be concluded from Figure 4 Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10 Figure 11.

1) When the shear rate of rotors is constant, the shear stress increases with the increase of the contents, and the rheological curves with different contents have the same trend. This is because the high content of fine particles and increased contact area between particles, which strengthen the internal interaction of tailings slurry particles. Simultaneously, shear stress is positively correlated with shear rate. That is, the shear stress increases with the shear rate. It agrees with the results obtained by Cao et al. (2018).

2) When the particle size is less than or equal to 30.0 μm, the shear stress increases constantly with the shear rate of the rotor for the same content. The slope of curves is smaller, which means the shear stress is more stable. When the particle size is greater than 30.0 μm, the curve slope between shear stress and shear rate is larger with the same content, that is, the increase rate of shear stress is relatively larger. With the increase of contents, the shear stress also increases, but the increase range is small. For tailings with particle size of 10.21 μm, the shear stress with the content of 50% is about 2.88 times as high as that with the content of 10%. However, the shear stress with the content of 50% is almost the same as that with the content of 10% for the fine tailings with particle size of 90.04 μm. The variations show that the tailing contents have less effect on the shear stress when the particle size of tailings increases to a certain value.

3) As shown in Figure 4–11, when the content of fine tailings is less than or equal to 30%, the rheological curves of the tailings are relatively concentrated and shear stress changes little. The shear stress increases more sharply with the content less than 30% compared with that with more than 30%. The flocculation of fine particles is the dominant factor leading to the yield stress of the slurry. The more the fine particles of slurry are, the more obvious the flocculation is. The increase of contact points between particles causes the increase of frictional resistance, which hinders the tailings slurry flowing. Thus, the resistance and the yield stress are larger with high content than that with low content.

Test results analysis

There are many rheological models for tailings slurry, such as the Herschel-Bulkley model, Bingham model (Liu et al., 2018; Zhang et al., 2023). The slurries will conform to different rheological models when the particle size and contents are different.

Bingham model equation is defined as:

Herschel-Bulkley equation is defined as:

Where

When

Based on the curves in Figure 4–Figure 11 the test results are fitted by Eq 1 and 2. As there are many fitting curves and the fitting trends are similar, fine particle size of 30 μm are taken as an example and the fitting results are shown in Table 3. It can be seen that the correlation coefficients are more than 99.4% and the following conclusions are obtained.

1) When the particle size of fine tailings is less than or equal to 30 μm and the content is less than or equal to 30%, the rheological properties of tailing slurries conform to the Herschel-Bulkley model. And will transform into Bingham model with the increase of content. This is because the particle size of fine tailings is relatively small, the structure state of tailings slurry is disassembled then reforming under the influence of shear stress, and the rate of the structure reformation increases with the extent of debonding. When the contents are more than 30%, the dynamic balance of the tailing slurry system is achieved and it has a stable plastic viscosity, thus the tailings slurry system transforms into Bingham model.

2) When the particle size is greater than 30 μm, no matter how the content of tailings slurry changes, the slurry always presents Herschel-Bulkley model without transforming into Bingham.

Expanding fluid with yield stress

Because with the increase of particle size, the collision and friction between the particles becomes the main factor increaing the viscosity of the tailings slurry.

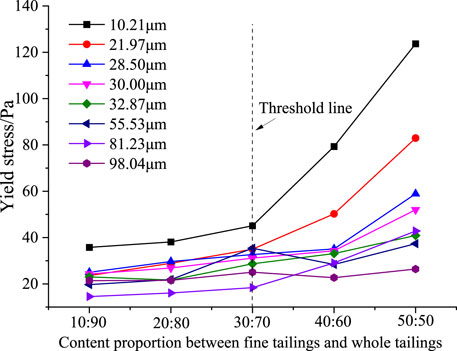

Yield stress and viscosity laws

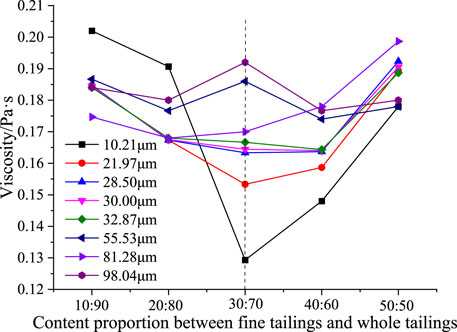

Yield stress and viscosity are the main factors affecting the flow of the slurry. Therefore, the yield stress and viscosity of different particle sizes and content are analyzed in the test. The changing curves are shown in Figure 12 and Figure 13. The following conclusions are obtained from the figures above.

1) As shown in Figure 12, the yield stress of the fine tailings with size of 10.21 μm is greater than that of other particle sizes, and the change rate of yield stress gradually enlarges with the increase of content. Meanwhile, the larger the particle size is, the more stable the yield stress is. When the particle diameter is greater than 30.0 μm, the yield stress changes less with the increase of the contents. When the particle size is less than or equal to 30 μm and the contents is less than or equal to 30%, the yield stress increases slowly. The yield stress increases rapidly when the contents are more than 30%. This is because when the particle size is small and the content is large for fine tailings, and the friction between the particles increases, thus increasing the yield stress rapidly and reducing the fluidity of tailings slurry.

2) As shown in Figure 13, when the particle size is less than or equal to 30.0 μm, the viscosities decrease with the contents of 10%, 20%, and 30%, respectively, and the smaller the particle size is, the more severe the viscosity decreases. For the particle size of 10.21 μm, the viscosity decreases to the minimum suddenly when the contents are 30%, which is due to the fact that the lubrication effect between particles is the main factor at this time. When the particle size is greater than 30 μm, the viscosity changes less and is relatively stable.

3) The viscosity and the yield stress change greatly for fine tailings with the particle size less than 30.0 μm, while that are more stable for a particle size with more than 30.0 μm. The particle size and content of fine tailings have great influence on the rheological behavior of tailings slurry.

FIGURE 12. The variation curves of yield stress with different particle diameters and contents.

Rheological laws and mechanism analysis

For the tailings backfilling disposal, the content and partical size of fine tailingd are not the larger the better, there exists an influence sphere. The filling and transportation parameters of tailing mortar were optimized in order to quantitatively elucidate the rheological characteristics of tailing mortar. In this part, a new law of rheological properties of tailing mortar is given, and the influence mechanism of particle size and content on the yield stress and viscosity of total tailings is deeply revealed from the microscopic perspective.

Rheological laws of tailings

From the rheological curves above, it is clear that the content of 30% and the particle size of 30.0 μm for fine tailings are the turning point of the tailings rheological properties. The parameter laws of particle size of 30.0 μm and content of 30% can be obtained.

1) The law of particle size of 30.0 μm is as follows. When the diameter is less than or equal to 30.0 μm, the yield stress varies greatly and increases with the contentr of fine tailings. While it is relatively stable when the particle size is more than 30.0 μm. The particle size of 30.0 μm is considered to be the turning point and the yield stress changed from stability to instability.

2) The law of content of 30% is as follows. In the test, the content of 30% can be considered to be the inflection point. When the particle size is less than or equal to 30.0 μm and the contents is less than 30%, the tailings viscosity decreased gradually with the increase of the contents, while it began to increase with the increase of the contents when the contents is more than 30%. The viscosity of tailings reaches a minimum value when the contents is 30%.

Mechanism analysis on tailings rheological law

The resistance functions in the flowing process for tailings slurry is as follows.

Particles are supposed spheres. Reynolds number (

Where,

Thus, the resistance of tailings slurry can be obtained in Eq. 6.

In the backfilling process, it is required to ensure that the particles can flow uniformly. The viscous resistance between the particles is the main factor affecting the flow of tailings slurry, and the resistance is related to the Reynolds number

For the tailings slurry,

By substituting Eq. 7 into Eq. 6, we can get

It can be seen that when the resistance remains constant, the viscosity

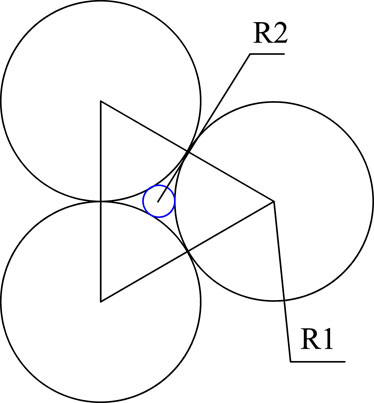

Assume that the radius of large particles and fine particles are R1 and R2, respectively. According to the geometric tangential relation, when the large particles are tangent, the small particles can be accommodated in the gap among the large particles. The relation between R1 and R2 is obtained in Eq. 7.

In the test, the median diameter is d50=178.28 μm. The tangential particle size is 29.2 μm by using Eq. 10, where the viscosity

Equation 10 can be expressed using the multi-stage particle arrangement theory (Liu et al., 2017) as

Where

In the rheological test mentioned above, it can be regarded as the two-stage gradation between fine particle tailings and coarse particle tailings. The relations between porosities and percentages can be obtained in Eq. 11.

Where

Where

According to the test,

Thus, the porosity of the filling system with two-stage gradation of tailings is 29%. The calculation results agree with the experiment results in the second section.

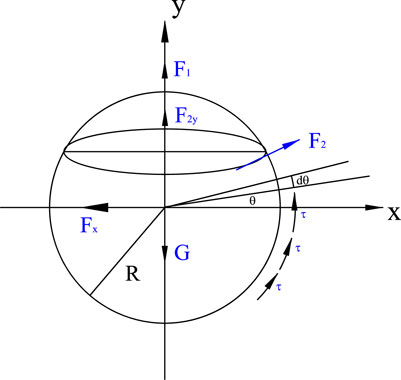

Theoretical analysis on yield stress law

The yield stress is formed by the flocculation of fine particles in the flow process of tailings slurry. Meanwhile, the coarse particles of full tailings are sinking slowly due to the overall damping effect. When the tailings particles are regarded as spheres, the stress analysis of a sphere is shown in Figure 15. F1 is the settlement resistance and the particle gravity is G. F2 is the shear resistance and F2y is the component of F2 in the Y-axis direction, which is shear stress that caused by the yield stress acting on the particles.

In Figure 15,

The equations above are integrated in Eq. 17.

When the shear resistance is constant, the yield stress

Application of rheological laws for tailings slurry

The laws of “30.0 μm of particle size” and “30% of contents” were obtained according to the rheological test above. Rheological properties of the tailings slurry and the pipe resistance parameters were analyzed, which provide reasonable references for tailings disposal in the iron mine.

In the field of tailings disposal in the iron mine, the mine increased the content of fine tailings with a particle size less than 30.0μm, and tried to ensure that the content of fine tailings was about 30%. The results showed that the field problems were improved, such as the manufacturing difficulty of high concentration tailings slurry using the concentrated dewatering process and the harsh pipeline transportation conditions. Meanwhile, the frictional resistance generated in the tailings slurry transportation process was reduced and transportation efficiency was improved, which reduced tailings disposal cost in the field.

The particle size and content of tailings have an important effect on the yield stress and viscosity of tailings slurry. And some similar phenomena also appeared in the research results of Liu et al., (2017); Zhang et al., (2023). They thougt the stress attenuation of slurry with coarse particles is much smaller than that of slurry with finer particles. The tailings slurry agreed to different rheological models with different particle size and content. Liang et al. (2022) found similar law and pointed out that the high concentration full tailing filling slurry conforms to the characteristics of Bingham fluid in non-Newtonian fluids. The rheological characteristics and corresponding rheological theories are quantified in this study. And the “double 30” theory (“particle size of 30.0 μm” and “content of 30%“) was proposed and expounded. “Particle size of 30.0 μm” and “content of 30%” is the critical point of rheological characteristics of tailings. The research results further improve the tailing transportation law, provide theoretical support for the paste filling technology of mine waste rock tailings, and are of great significance for the wide application of this technology.

A similar phenomenon is also observed for other slurries; such as cement slurries. Meanwhile, for the metal mines, the yield stress during slurry transmission can be reduced by controlling the particle size of tailings and increasing the content of fine-grained rock with particle size less than 30μm, thus reducing the transportation cost.

Conclusion

In this paper, the experiments on rheological properties of the mortar tailings were designed and carried outunder different particle sizes and content conditions. The “double 30” theory was proposed and expounded. The corresponding theoretical model is established to analyze the mechanism of the above results. The conclusion is as follows.

1) The particle size and the content of fine tailings have a significant effect on the yield stress and viscosity in the transportation process of the whole tailings slurry. When the particle size of tailings is no larger than 30.0 μm and the content is no larger than 30%, the rheological behavior of the tailings slurry conforms to the Herschel-Bulkley model. With the increase of the content of fine tailings, its behavior agrees better with the Bingham model. When the particle size is larger than 30 μm, the tailings slurry exhibits the Herschel-Bulkley model no matter how the content changes.

2) The yield stress and viscosity of tailings slurry in the process of transportation are in accordance with the laws of “double 30” theory. The theory is “particle size of 30.0 μm” and “content of 30%“. That is, the particle size of 30.0 μm in the test can be regarded as a turning point of yield stress change. When the particle size of fine tailings is no larger than 30.0 μm, the yield stress changes greatly and increases with the increase of content. When the particle size is larger than 30.0 μm, the yield stress is relatively stable. The content of 30% of the tailings slurry is a turning point for the viscosity change. For tailings with the fine particle size less than or equal to 30.0 μm, the viscosity reaches the minimum with the content of 30%.

3) The mechanisms of particle size and viscosity law are analyzed from the perspective of particle arrangement and rheological mechanics of tailings. The rheological laws of tailings slurry have been successfully applied to the tailings backfilling disposal in an iron mine, and the problem of large resistance were coped with in the process of tailings transportation. The obtained laws of tailings rheology greatly improved the transportation efficiency and reduced disposal cost of tailings in the iron mine.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

Conceptualization, ZW, LC, and MH; methodology, ZW and LC; software, MH; validation, ZW and LC; formal analysis, ZW and LC; data curation, ZW and LC; writing—original draft preparation, ZW and MH; writing—review and editing, and MH; funding acquisition, ZW. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors sincerely thank the following agents for their financial supports: Scien-tific and Technological Project of Henan Province (222102320060), Strength Improvement Plan of the Advantageous Disciplines of Zhongyuan University of Technology (SD202232), Postograduate Education Reform and Quality Improvement Proiect of Zhongyuan University of Technology (JG202220).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aldhafeeri, Z., and Fall, M. (2017). Sulphate induced changes in the reactivity of cemented tailings backfill. Int. J. Mineral Process. 166, 13–23. doi:10.1016/j.minpro.2017.06.007

Bouvet, A., Ghorbel, E., and Bennacer, R. (2010). The mini-conical slump flow test: Analysis andnumerical study. Cem. Concr. Res. 40, 1517–1523. doi:10.1016/j.cemconres.2010.06.005

Cao, S., Song, W., and Yilmaz, E. (2018). Influence of structural factors on uniaxial compressive strength of cemented tailings backfill. Constr. Build. Mat. 174, 190–201. doi:10.1016/j.conbuildmat.2018.04.126

Cavusoglu, I., Yilmaz, E., and Yilmaz, A. O. (2021). Sodium silicate effect on setting properties, strength behavior and microstructure of cemented coal fly ash backfill. Powder Technol. 384, 17–28. doi:10.1016/j.powtec.2021.02.013

Chen, S., Du, Z., Zhang, Z., Zhang, H., Xia, Z., and Feng, F. (2020). Effects of chloride on the early me-chanical properties and microstructure of gangue-cemented paste backfill. Constr. Build. Mat. 235. doi:10.1016/j.conbuildmat.2019.117504doi:117504

Cheng, H., Wu, S., Li, H., and Zhang, X. (2020). Influence of time and temperature on rheology and flow performance of cemented paste backfill. Constr. Build. Mat. 231, 117117. doi:10.1016/j.conbuildmat.2019.117117

Cheng, H. Y., Wu, S. C., Zhang, X. Q., and Wu, A. x. (2020). Effect of particle gradation characteristics on yield stress of cemented paste backfill. Int. J. Min. Metall. Mat. 27 (1), 10–17. doi:10.1007/s12613-019-1865-y

Deng, X., Klein, B., Tong, L., and de Wit, B. (2018). Experimental study on the rheological behavior of ultra-fine cemented backfill. Constr. Build. Mat. 158, 985–994. doi:10.1016/j.conbuildmat.2017.05.085

Falagán, C., Grail, B. M., and Johnson, D. B. (2016). New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 106, 71–78. doi:10.1016/j.mineng.2016.10.008

Fang, K., and Fall, M. (2018). Effects of curing temperature on shear behaviour of cemented paste backfill-rock interface. Int. J. Rock Mech. Min. Sci. (1997). 112, 184–192. doi:10.1016/j.ijrmms.2018.10.024

Hale Micah, W., Freyne Seamus., F., and Russell Bruce, W. (2009). Examining the frostresistance of high performance concrete. Constr. Build. Mater. 23 (2), 878–888. doi:10.1016/j.conbuildmat.2008.04.006

Just, A., and Middendorf, B. (2009). Microstructure of high-strength foam concrete. Mater. Charact. 60 (7), 741–748. doi:10.1016/j.matchar.2008.12.011

Kasap, T., Yilmaz, E., and Sari, M. (2022). Effects of mineral additives and age on microstructure evolution and durability properties of sand-reinforced cementitious mine backfills. Constr. Build. Mater. 352, 129079. doi:10.1016/j.conbuildmat.2022.129079

Lei, G. L., Dong, W., Zheng, M., Guo, Z. Q., and Liu, Y. Z. (2017). Numerical investigation on heat transfer and melting process of ice with different porosities. Int. J. Heat. Mass Transf. 107, 934–944. doi:10.1016/j.ijheatmasstransfer.2016.11.004

Li, B., Zhang, J. X., Liu, Y. W., Qu, L., Liu, Q., Sun, Y., et al. (2022). Interfacial porosity model and modification mechanism of broken coal grouting: A theoretical and experimental study. Surfaces Interfaces 33(6). doi:10228doi:10.1016/j.surfin.2022.102286

Li, J., Cao, S., Yilmaz, E., and Liu, Y. (2022). Compressive fatigue behavior and failure evolution of additive fiber-reinforced cemented tailings composites. Int. J. Min. Metall. Mat. 29 (2), 345–355. doi:10.1007/s12613-021-2351-x

Li, J. J., Cao, S., and Yilmaz, E. (2022). Characterization of macro mechanical properties and microstructures of cement-based composites prepared from fly ash, gypsum and steel slag. Minerals 12, 6. doi:10.3390/min12010006

Li, J. J., Yilmaz, E., and Cao, S. (2020). Influence of solid content, cement/tailings ratio and curing time on rheology and strength of cemented tailings backfill. Minerals 10 (10), 922. doi:10.3390/min10100922

Liang, X. M., Wang, H. Y., Jiang, G. J., et al. (2022). Study on rheological properties of high concentration unclassified tailings filling slurry and resistance loss along pipeline transp. China Mine Eng. 51 (3), 47–53.

Liu, L., Fang, Z., Qi, C., Zhang, B., Guo, L., and Song, K. I. (2018). Experimental investigation on the relationship between pore characteristics and unconfined compressive strength of cemented paste backfill. Constr. Build. Mat. 179, 254–264. doi:10.1016/j.conbuildmat.2018.05.224

Liu, L., Fang, Z., Qi, C., Zhang, B., Guo, L., and Song, K. I. (2019). Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol. 343, 454–464. doi:10.1016/j.powtec.2018.11.070

Liu, L., Fang, Z. Y., Wang, M., Qi, C., Zhao, Y., and Huan, C. (2020). Experimental and numerical study on rheological properties of ice-containing cement paste backfill slurry. Powder Technol. 370, 206–214. doi:10.1016/j.powtec.2020.05.024

Liu, X. H., Wu, A. X., Wang, H. J., et al. (2017). Influence mechanism and calculation model of CPB rheological parameters. Chin. J. Eng. 39 (2), 190.

Long, H. C., Xia, J. X., and Cao, B. (2017). Effect of coarse/fine materials ratio on rheological Properties. Min. Metallurgical Eng. 37 (2), 6–10.

Mangane, M. B. C., Argane, R., Trauchessec, R., Lecomte, A., and Benzaazoua, M. (2018). Influence of superplasticizers on mechanical properties and workability of cemented paste backfill. Min. Eng. 116, 3–14. doi:10.1016/j.mineng.2017.11.006

Ouattara, D., Yahia, A., Mbonimpa, M., and Belem, T. (2017). Effects of superplasticizer on rheological properties of cemented paste backfills. Int. J. Mineral Process. 161, 28–40. doi:10.1016/j.minpro.2017.02.003

Qi, C., Chen, Q., Fourie, A., Tang, X., Zhang, Q., Dong, X., et al. (2019). Constitutive modelling of cemented paste backfill: A data-mining approach. Constr. Build. Mat. 197, 262–270. doi:10.1016/j.conbuildmat.2018.11.142

Qi, C., Chen, Q., Fourie, A., Zhao, J., and Zhang, Q. (2018). Pressure drop in pipe flow of cemented paste backfill: Experimental and modelingstudy. Powder Technol. 333, 9–18. doi:10.1016/j.powtec.2018.03.070

Rakotondrandisa, A., Danaila, I., and Danaila, L. (2019). Numerical modelling of a melting-solidification cycle of a phase-change material with complete or partial melting. Int. J. Heat. Fluid Flow. 76, 57–71. doi:10.1016/j.ijheatfluidflow.2018.11.004

Roshani, A., and Fall, M. (2020). Rheological properties of cemented paste backfill with nanosilica: Link to curing temperature. Cem. Concr. Compos. 114, 103785. doi:10.1016/j.cemconcomp.2020.103785

Ruan, Z. E., Wu, A. X., Bürger, R., Betancourt, F., Wang, Y., Wang, Y., et al. (2021). Effect of interparticle interactions on the yield stress of thickened flocculated copper mineral tailings slurry. Powder Technol. 392, 278–285. doi:10.1016/j.powtec.2021.07.008

Sari, M., Yilmaz, E., Kasap, T., and Guner, N. U. (2022). Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: Effect of mineral admixtures. Constr. Build. Mater. 328, 127109. doi:10.1016/j.conbuildmat.2022.127109

Si, L., Wei, J., Xi, Y., Wang, H., Wen, Z., Li, B., et al. (2021). The influence of long-time water intrusion on the mineral and pore structure of coal. Fuel 290 (1). doi:10.1016/j.fuel.2020.119848doi:119848

Si, L., Zhang, H., Wei, J., Li, B., and Han, H. (2021). Modeling and experiment for effective diffusion coefficient of gas in water-saturated coal. Fuel 284 (1). doi:10.1016/j.fuel.2020.118887doi:118887

Small, C. C., Cho, S., Hashisho, Z., and Ulrich, A. C. (2015). Emissions from oil sands tailings ponds: Review of tailings pond parameters and emission estimates. J. Petroleum Sci. Eng. 127, 490–501. doi:10.1016/j.petrol.2014.11.020

Wu, A. X., Li, H., and Cheng, H. Y. (2021). Status and prospects of research on the rheology of paste backfill using unclassified tailings (Part 2): Rheological measurement and prospects. Chin. J. Eng. 43 (4), 451–459.

Wu, A. X., Li, H., and Cheng, H. Y. (2020). Status and prospects of researches on rheology of paste backfill using unclassified tailings (Part 1): Concepts, characteristics and models. Chin. J. Eng. 42 (7), 803–813.

Wu, D. I., and Cai, S. J. (2015). Coupled effect of cement hydration and temperature on hydraulic behavior of cemented tailings backfill. J. Cent. South Univ. 22 (5), 1956–1964. doi:10.1007/s11771-015-2715-3

Xu, W. B., Yang, B. G., Yang, S. L., et al. (2016). Experimental study on correlativity between rheological parameters and grain grading of coal gauge backfill slurry. J. Central South Univ. Sci. Technol. 47 (4), 1282–1289.

Yan, Z., Yin, S., Chen, X., and Wang, L. (2022). Rheological properties and wall-slip behavior of cemented tailing-waste rock backfill (CTWB) paste. Constr. Build. Mater. 324. doi:10.1016/j.conbuildmat.2022.126723doi:126723

Yin, X. Q., Zhao, S. M., Xie, J., et al. (2010). Theoretical analysis on the setting angle of mixing blades of twin-shaft mixer. J. wuhan Univ. Technol. 32 (19), 141–144.

Zhang, J. X., Li, B., Liu, Y. W., Fu, J., Chen, L., et al. (2022). Dynamic multifield coupling model of gas drainage and a new remedy method for borehole leakage. Acta Geotech. 17 (10), 4699–4715. doi:10.1007/s11440-021-01444-x

Zhang, L. F., Wang, H. J., Wu, A. X., et al. (2023). Study of the effect of particle size on the thixotropy of tailings paste. Chin. J. Eng. 45 (1), 1–8.

Zhang, Q. L., Liu, Q., Zhao, J. W., et al. (2015). Pipeline transportation characteristics of filling paste-like slurry pipeline in deep mine. Chin. J. Nonferrous Mater. 25, 3190–3195.

Zhang, X. X., and Qiao, D. P. (2015). Rheological properties of high-density slurry with waste rock-tailings and transmission parameter optimization. J. Kunming Univ. Sci. Technol. Nat. Sci. Ed. 40 (3), 39–45.

Keywords: rheological properties, yield stress, viscosity, rheological model, double 30 theory

Citation: Wang Z, Chen L and Hu M (2023) Experiment research and mechanism analysis on rheological properties of tailings slurry. Front. Earth Sci. 10:1083436. doi: 10.3389/feart.2022.1083436

Received: 29 October 2022; Accepted: 01 December 2022;

Published: 30 January 2023.

Edited by:

Leilei Si, Henan Polytechnic University, ChinaReviewed by:

Erol Yilmaz, Recep Tayyip Erdoğan University, TurkeyShuai Cao, University of Science and Technology Beijing, China

Copyright © 2023 Wang, Chen and Hu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhiliu Wang, Njg1NUB6dXQuZWR1LmNu

Zhiliu Wang

Zhiliu Wang Linlin Chen2

Linlin Chen2