- 1Key Laboratory of Exploration Technologies for Oil and Gas Resources, Ministry of Education, Yangtze University, Wuhan, China

- 2School of Geoscience, Yangtze University, Wuhan, China

- 3Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University Ministry of Education & Hubei Province, Wuhan, China

- 4Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas, Yangtze University, Wuhan, China

- 5Carbon Hydrogen Epoch Technology, Co., Ltd, Wuhan, China

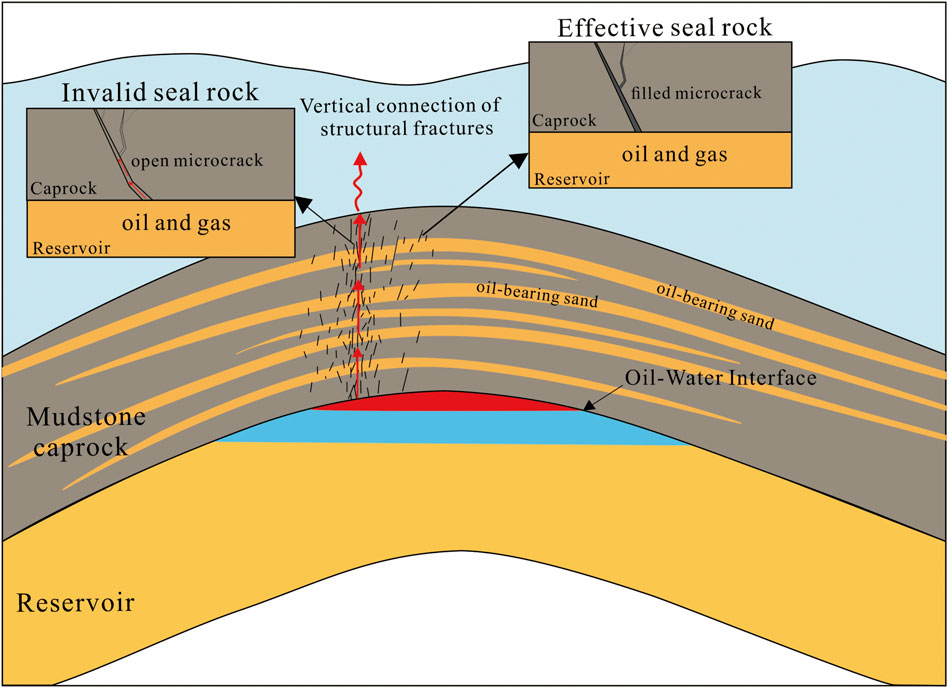

The sealing ability of caprock is affected by many factors, such as cap thickness, displacement pressure, fracture development, and lithology of caprock. Shale is one of the ideal materials for oil and gas sealing cap formation due to its low porosity and permeability. Microfractures can destroy the sealing property of shale caprock. When buried deep enough, shale will change from toughness to brittleness. In general, the greater the brittleness of shale, the more developed the fractures will be. In areas with high tectonic stress, such as the anticline axis, syncline axis and stratum dip end, the strata stress is high and concentrated, and it is easier to generate fractures. When the stress state of the caprock changes, new micro-cracks are formed or previously closed cracks are re-opened, reducing the displacement pressure of the caprock. These micro-fractures are interconnected to form microleakage spaces, which reduces the sealing capacity of the caprock.

Introduction

In recent years, the demand for oil and gas resources has been increasing daily, and the oil and gas exploration and exploitation scale at home and abroad is increasing gradually. The study of oil and gas accumulation conditions plays a vital role in oil and gas exploration. With the deepening of the research on reservoir-forming conditions of significant oil and gas fields, people gradually realize that the effectiveness of caprock plays a crucial role in reservoir-forming. Among the hydrocarbon accumulation elements, hydrocarbon generation is the basis and, trap is the condition, preservation is the key (Li et al., 1997). The caprock is the core content of the study of oil and gas preservation conditions (Xiao et al., 2006), the quality of caprock directly affects the formation, scale and preservation of the oil-gas reservoir. Caprock lithology determines its sealing ability. The caprock lithology of some large oil and gas fields is mainly evaporite and shale (Nederlof & Mohler., 1981). As a dense caprock, shale is characterized by low porosity and permeability, so it is one of the ideal materials for oil and gas sealing caprock and plays a crucial role in the accumulation and preservation of oil and gas (Jin et al., 2014).

So far, fruitful research results have been obtained, and a relatively mature theoretical foundation has been formed on the sealing property of shale caprock research. The thickness of caprock (Zieglar, 1992; Lv et al., 2005), faults development extent (Skerlec, 2002; Fu et al., 2015) and diagenetic evolution (Lu et al., 2021) have direct or indirect effects on the sealing ability of shale caprock. Most scholars at home and abroad research shale fractures mainly focus on fractured oil-gas reservoirs (Fu et al., 2022). However, the research on “micro fracture damage of mudstone caprock” has not yet formed a mature theoretical system.

Research progress on sealing of caprock

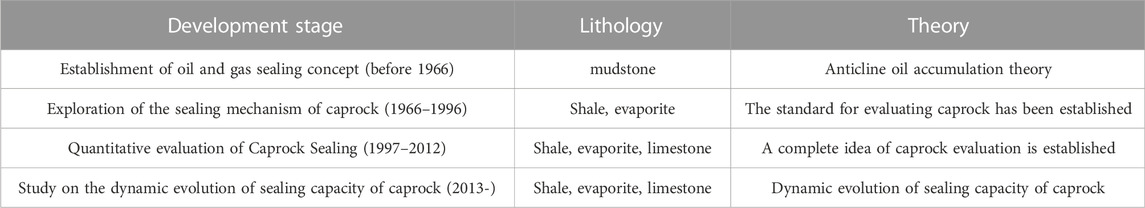

The rapid development of the global petroleum industry promotes the continuous updating and improvement of petroleum geological theories. The study of oil-gas reservoir caprock has been paid more and more attention by scholars at home and abroad. The study of cap sealing can be roughly divided into four stages, as shown in Table 1. In 1966, Smith introduced the concept of cap and fault sealing (Smith, 1966). In 1987 Watts proposed the capillary sealing mechanism and hydraulic sealing mechanism of caprock, which promoted the qualitative evaluation of caprock and fault sealing mechanism (Watts et al., 1987). In 1996, Lu put forward the overpressure sealing mechanism and hydrocarbon concentration sealing mechanism, and the method of using displacement pressure, effective stress and tensile strength to evaluate the sealing ability according to different sealing mechanisms, and established the industry standard for sealing evaluation of caprock (Lv et al., 1996). In 2013, Jin put forward the evaluation method of the dynamic evolution process of the sealing capacity of shale caprock.

Factors affecting sealing ability of caprock

The displacement pressure mainly determines the sealing ability of caprock. The greater the displacement pressure, the stronger the sealing ability of the caprock is (Dewhurst et al., 1998). There is no direct relationship between cap thickness and capillary sealing ability, so some scholars, such as Hubbert (1953), believe that cap thickness has no significance on capillary sealing ability.

However, some scholars believe that although there is no direct functional relationship between caprock thickness and capillary sealing capacity, it does not mean that caprock thickness does not affect sealing capacity (Nederlof & Mohler., 1981; Fu et al., 2003). The thicker the cap is, the more difficult it is to be damaged by fracture. The thinner the cap thickness is, the easier it is to be damaged by fracture and lose the continuity of transverse distribution. Lv (2005) believed that the thicker the caprock thickness, the larger the spatial distribution area, the stronger the ability of caprock to seal gas, and the more conducive to the accumulation and preservation of gas. Yuan (2011) believes that the displacement pressure of caprock has nothing to do with the thickness, but the height of the enclosed gas column of caprock is related to the thickness; that is, the larger the cap rocks thickness, the higher the height of the enclosed oil and gas column, and the sealing ability of caprock is stronger. Lou (2021) found that the influence of clay minerals on rock sealing performance was related to plasticity and water absorption. The excellent or medium caprock was predominantly clayey mudstone, while the inferior caprock was mainly silty mudstone. Due to the influence of tectonic changes, most caprocks are destroyed in two ways. One way is the tectonic uplift of denuded caprock, which makes the thickness of the caprock thin or even exhausted at the denuded place; Another way is that faults destroy the caprock (Fu et al., 2003). Once the fault dislocates the caprock, the continuous capping range of the caprock will be reduced, and the sealing capacity of the caprock will change. If the length of the fault is greater than the thickness of the caprock, the caprock will be broken through by the fault, losing the ability to seal oil and gas (Wibberley et al., 2008). If the caprock is thick enough, the possibility of complete dislocation of the fault can be reduced.

The sealing property of caprock is closely related to the diagenetic evolution stage. The porosity and permeability of mudstone decrease with the increase in burial depth, indicating that it can effectively seal oil and gas only when it reaches a certain burial depth. When the burial depth of mudstone increases continuously and reaches a specific diagenetic stage, the plasticity of the rock will decrease, and the brittleness will increase. Under the action of over-pressure and other geostress, the shale caprock is prone to produce micro-fractures, thus reducing the displacement pressure. Therefore, the vertical evolution of the effective caprock capacity of mudstone caprock is from poor to good to poor. The main reason for the poor sealing of deep, dense mudstone is fracture (Lu, 2021).

Destruction of shale caprock by microfractures

The degree of fracture development is generally positively correlated with the content of brittle minerals in rocks (De Paola et al., 2009; Alqahtani et al., 2013). The more brittle minerals such as quartz, feldspar and carbonates are contained, the more brittle shale and the more uncomplicated fractures are to develop (Ding, 2012). With the increase of burial depth and the enhancement of the degree of compaction diagenesis (late diagenetic stage), shale will undergo a process from toughness to brittleness. When the burial depth of shale is deep enough, the brittleness is enhanced, and cracks are easily produced due to the influence of tectonic stress, thus reducing the capillary sealing capacity. Corcoran and Dore used the density and strain at fracture to quantitatively judge the transformation process of shale from brittleness to toughness. In the brittle stage, the density of shale is greater than 2.5 g/cm3, and the strain before fracture is less than 3%. In the transition stage, the density of shale is 2.5–2.25 g/cm3, and the strain is 5%–8%. In the ductile stage, the density of shale is less than 2.25 g/cm3, and the strain is more than 8%.

Shale caprock usually contains a large number of micro-fractures. In areas with high tectonic stress, such as anticline axis, syncline axis and stratum dip end, stratum stress is high and concentrated, and fractures are developed (Brantut et al., 2011; Raduha et al., 2016). These micro-fractures are often isolated and closed under regular stress. When the stress state of the caprock changes, new micro-cracks would form or previously closed cracks would re-open, reducing the displacement pressure (Mildren et al., 2002). These micro-cracks are interconnected to form micro-leakage Spaces, which will reduce the sealing capacity of the caprock (Wu, 2020). Even locally continuous shale intervals can fail due to excessive fractures in local areas, as shown in Figure 1. The main mechanisms that cause the change of caprock stress include tectonic extrusion, tectonic uplift and abnormally high-pressure fluid (Lamarche et al., 2012; Orlic & Wassing., 2013). Among them, the caprock failure caused by faults belongs to the category of vertical sealing of faults, and its evaluation method has been relatively mature. However, since cracks are “invisible”, there is still a lack of effective evaluation methods.

Expectations

1) We can subdivide diagenetic stages by combining the formation and evolution of faults and fractures. In this way, the dynamic evolution process of the sealing capacity of caprock can be further studied

2) The rock mechanics of the caprock has changed dramatically during burial and uplift, and the condition of brittle-ductile transition is still a complex problem. Perhaps we can establish a quantitative characterization method for the transition from brittleness to toughness through a triaxial compression test, acoustic emission characteristics, micro deformation mechanism and deformation characteristics of the cap structure.

3) The existence of a large number of microcracks in the caprock is not necessarily a bad thing. When there is no large fault in the basin as the bottom oil and gas transportation channel, many micro-fractures developed in mudstone, shale and siltstone can be connected to form a vertical migration channel of oil and gas. When the stress field of the local layer changes, micro-cracks are easily produced at the high part of the trap. Oil and gas migrate to the upper reservoir along the vertical channel composed of fractures. Corcoran and Doré, 2002, Downey, 1984, Lv et al., 1996, Smith, 1966, Watts, 1987.

Author contributions

YT was responsible for the preliminary literature research, the writing of the whole manuscript and the drawing of the figure. YH and DW were responsible for the late revision and submission of the manuscript. QD and ZZ were responsible for providing inspiration and ideas for the manuscript.

Funding

National Natural Science Fund: 42002165.

Conflict of interest

QD was employed by Carbon Hydrogen Epoch Technology Co., Ltd

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alqahtani, A. A. (2013). Effect of mineralogy and petrophysical characteristics on acoustic and mechanical properties of organic rich shale[C]//Proceedings of the Unconventional Resources Technology Conference(URTEC), Richardson, TX, United States, 199–411.

Brantut, N., Schubnel, A., and Guéguen, Y. (2011). Damage and rupture dynamics at the brittle-ductile transition:The case of gypsum[J]. Journal of Geophysical Research. Solid earth. 116, doi:B11404

Corcoran, V., and Doré, A. (2002). Top seal assessment in exhumed basin settings-some insights from Atlantic Margin and borderland basins Koestler A G, Hunsdale R. Hydrocarbon Seal Quantification. NPF Special Publication, Iran, 89–107.

De Paola, N., Faulkner, D. R., and Collettini, C. (2009). Brittle versus ductile deforma-tion as the main control on the transport properties of low-porosity anhydrite rocks. J. Geophys. Res. 114 (B6), B06211–B06266. doi:10.1029/2008jb005967

Dewhurst, D. N., Aplin, A. C., Sarda, J. P., and Yang, Y. (1998). Compaction - driven evolution of porosity and permeability in natural mudstones: An experimental study. J. Geophys. Res. 103 (B1), 651–661. doi:10.1029/97jb02540

Ding, W., Li, C., Li, C., Xu, C., Jiu, K., and Zeng, W. (2012). Dominant factor of fracture development in shale and its relationship to gas accumulation. Earth Sci. Front. 19 (2), 212–220. CNKI:SUN:DXQY.0.2012-02 -031.

Fu, G., and Xu, F. (2003). Quantitative research on controlling of thickness to seal abilities of caprock. Nat. Gas. Geosci. 3, 186–190. doi:10.3969/j.issn.1672-1926.2003.03.006

Fu, X., Jia, R., Wang, H., Wu, T., Meng, L., and Sun, Y. (2015). Quantitative evaluation on the fault-caprock sealing capacity of Dabei-kelasu structural belt in Kuqa depression, Tarim basin, NW China. Petroleum Explor. Deveopment 42 (3), 300–309. doi:10.11698/PED.2015.03.06

Fu, X., Lv, D., Huang, J., Wang, G., Meng, L., Wang, H., et al. (2022). Fault-caprock coupling sealing mechanism and fault trap hydrocarbon accumulation model. Nat. Gas. Ind. 42 (03), 21–28. doi:10.3787/j.issn.1000-0976.2022.03.003

Lamarche, J., Lavenu, A. P., Gauthier, B. D., Guglielmi, Y., and Jayet, O. (2012). Relationships between fracture patterns, geodynamics and mechanical stratigraphy in Carbonates (South-East Basin, France). Tectonophysics 581, 231–245. doi:10.1016/j.tecto.2012.06.042

Li, M., Li, W., Cai, F., and Sun, D. (1997). Integrative study of preservation conditions of oil and gas pools. Acta Pet. Sin. 2, 44–51. doi:10.7623/syxb199702007

Lou, M., Yang, X., You, L., Dai, L., Wang, N., and Qiu, L. (2021). The main factors affecting the quality of mudstone caprock and a new idea for its evaluation. J. Chengdu Univ. Technol. Technol. Ed. 48 (01), 82–93. doi:10.3969/j.issn.1671-9727.2021.01.09

Lu, X., Liu, S., Tian, H., Ma, X., Yu, Z., Fan, J., et al. (2021). An evaluation method for the integrity of mudstone caprock in deep anticlinal traps and its application: A case study of the sinian gas reservoirs in the central sichuan basin. Acta Pet. Sin. 42, doi:10.7623/syxb202104001

Lv, Y., Fu, G., and Gao, D. (1996). Study on the cap rock of reservoir. Beijing: Petroleum Industry Press, 118–120.

Lv, Y., Fu, G., and Yu, D. (2005). Comprehensive evaluation of sealing ability of cap rock in China's large and medium gas fields and their contribution to gas accumulation. Oil Gas Geol. 6, 742–745+753. doi:10.3321/j.issn:0253-9985.2005.06.007

Mildren, S. D., and Hillis, R. R. (2002). Fast: a new approach to risking fault reactivation and related seal breach[J]. AAPG Bulletin, 2, 101–103.

Nederlof, M. H., and Mohler, H. P. (1981). Quantitative investigation of trapping effect of unfaulted caprock. AAPG Bull. 65 (5), 964–965.

Orlic, B., and Wassing, B. B. T. (2013). A study of stress change and fault slip in producing gas reservoirs overlain by elastic and viscoelastic caprocks. Rock Mech. Rock Eng. 46 (3), 421–435. doi:10.1007/s00603-012-0347-6

Raduha, S., Butler, D., Mozley, P. S., Person, M., Evans, J., Heath, J. E., et al. (2016). Potential seal bypass and caprock storage produced by deformation band to opening mode fracture transition at the reservoir/caprock interface. Geofluids 16 (4), 752–768. doi:10.1111/gfl.12177

Smith, D. (1966). Theoretical consideration of sealing and nonsealing faults. AAPG Bull. 50 (2), 363–374.

Watts, N. (1987). Theoretical aspects of cap rock and fault seals for single-and two-phase hydrocarbon columns. Mar. Petroleum Geol. 4 (4), 274–307. doi:10.1016/0264-8172(87)90008-0

Wibberley, C. A. J., Yielding, G., Toro, G. D., Kurz, W., and Imber, J. (2008). The internal structure of fault zones , implications for mechanical and fluid-flow properties. Recent Adv. Underst. fault zone Intern. Struct. a Rev. 299, 5–33.

Wu, (2020). Study on the dynamic evolution of sealing capacity of mudstone and gypsum caprocks. Northeast Petroleum University. Daqing, China, doi:10.26995/d.cnki.gdqsc.2020.000934

Xiao, K., Wo, Y., Zhou, Y., and Tian, H. (2006). Petroleum reservoiring characteristics and exploration direction in marine strata in southern China. Oil Gas Geol. 3, 316–325. doi:10.11743/ogg20060305

Keywords: caprock, shale, microfractures, sealing ability, oil-gas reservoir, petroleum migration

Citation: Tao Y, He Y, Zhao Z, Wu D and Deng Q (2023) Sealing of oil-gas reservoir caprock: Destruction of shale caprock by micro-fractures. Front. Earth Sci. 10:1065875. doi: 10.3389/feart.2022.1065875

Received: 10 October 2022; Accepted: 05 December 2022;

Published: 26 January 2023.

Edited by:

Tao Hu, China University of Petroleum, Beijing, ChinaReviewed by:

Chao Liang, China University of Petroleum, Huadong, ChinaWenyang Wang, Institute of Geology and Geophysics (CAS), China

Copyright © 2023 Tao, He, Zhao, Wu and Deng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Youbin He, aGV5YjEyMkAxNjMuY29t; Qiao Deng, MzE5MTE4MTc4OEBxcS5jb20=

Ye Tao

Ye Tao Youbin He1,2*

Youbin He1,2* Zhongxiang Zhao

Zhongxiang Zhao