95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

MINI REVIEW article

Front. Earth Sci. , 17 January 2023

Sec. Geochemistry

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.1063042

This article is part of the Research Topic Mechanisms and Applications of Chemical Techniques for Effective Development of Unconventional Reservoirs View all 13 articles

The current status and development prospects of CCUS-EOR technology development are sorted out from the perspective of ecological development. A good foundation is laid to promote the world low-carbon development pattern and the development of CCUS-EOR technology in oil-rich, low-permeability reservoirs. By analyzing the differences between China and the United States regarding the technology level, application scale, and production effect, the development gaps between different countries in terms of CO2 burial for enhanced oil and gas recovery are derived. In response to these gaps, recommendations for responsive technology research and supporting infrastructure construction are proposed, which are of reference significance for advancing the development of large-scale CCUS technology for all of humanity.

Global climate change is gradually affecting normal human activities, and reducing greenhouse gas emissions has become an international consensus to address climate change (ROCCO et al., 2018; PARTANI et al., 2022). The shares of coal, oil, and natural gas in China’s energy consumption in 2019 are 57.7%, 18.9%, and 8.1%, respectively (LIAO and MING, 2019). In September 2020, the Chinese government pledged that China’s CO2 emissions will strive to peak by 2030 and achieve carbon neutrality by 2060. CCUS will be the only technology option to achieve near-zero emissions from this part of fossil energy (LIU et al., 2021).

According to IEA estimates, CCUS can contribute 15%–20% of the net zero emissions of CO2 (OU et al., 2021). According to the China Petroleum Institute of Economic and Technological Research forecast, more than 85% of coal and gas power will be equipped with CCUS by 2050 (GUPTA et al., 2021). Cai Bofeng et al. (Cai et al., 2021) calculated that, under the current technology development, the amount of CO2 emission reduction needed to achieve the goal of carbon neutrality by 2050 and 2060 through CCUS technology is 6 × 108 to 14 × 108t and 10 × 108 to 18 × 108 t, respectively (LIU et al., 2022). The conditions required for hydrocarbon and CO2 accumulation are very close, and the technology can not only improve oil recovery to achieve ecological development of the oil and gas industry but also achieve CO2 emission reduction.

Ecological development stems from a reflection on the environmental and ecological damage caused by modern technologies. In engineering design, it is essential to consider the ecological, social, and site-specific impacts of the technologies used, to put ecological factors at the forefront from the point of view of the whole life cycle of materials, and to carry out all work with the Earth at the center (LI et al., 2022). The ecological development of the oil and gas industry means that we can significantly reduce the total CO2 emissions from the oil and gas industry through ecological development. At this stage, we cannot achieve the ecological effect of the oil and gas industry without the CCUS-EOR technology (Figure 1).

Compared to conventional EOR technology, CCUS-EOR technology not only provides an effective way to store and utilize CO2 but also offers a more attractive increase in recovery rate compared to EOR technology. When the ecological costs are included in the calculation, CCUS-EOR technology will be less expensive than EOR technology and more widely welcomed.

The CCUS-EOR technology, as a CCUS utilization for the ecological development aspect of the oil and gas industry, promotes the flow of carbon materials in the oil and gas industrial process. By establishing a multifaceted and continuous resource cycle process through recycling, the carbon-containing waste from the previous production process is used as a production material in the next stage to serve the next phase of production activities (WANG et al., 2019). That is, by capturing CO2 and injecting it into the reservoir. CO2 enters the reservoir and reduces the viscosity of crude oil, improves the flow ratio of crude oil to water, expands the volume of crude oil, and extracts and vaporizes light hydrocarbons in crude oil. The oil is driven by mechanisms such as the mixing effect, molecular diffusion, reduction of interfacial tension, dissolved gas drive, and increased permeability to improve recovery. Alleviate environmental pollution at the same time, while it can make a large amount of CO2 buried underground, potentially changing the relationship between the oil and gas industry and the natural environment and promoting the impact of the oil and gas industry on the ecology from degradation to regeneration.

Foreign CCUS-EOR projects are mainly carried out in the United States, Canada and other countries. Especially, the United States has a mature CCUS-EOR industrial system. The U.S. CCUS-EOR project started in the 1950s, carried out fundamental technology research in the 1960s and 1970s, expanded the scale of industrial trials in the 1970s and 1990s, matured the technology package, and entered the commercialization and promotion stage after the 1980s. Since the 1980s, the scale of industrial application of CCUS-EOR technology in the United States has expanded rapidly. The project has achieved excellent application results, taking the CCUS-EOR project in the Kelly-Snyder field SACROC block in the Permian Basin of the United States as an example: the reservoir permeability of the block is 1 × 10−3–30 × 10−3 μm (ROCCO et al., 2018), geological reserves of about 4.1 × 108 t, and in 1998 The oil production declined to 40 × 104 t in 1998, the CO2 mixed-phase drive project was implemented in 2002, and the oil production exceeded 150 × 104 t in 2005, and the production has been stable for 16 years until 2020, with a cumulative oil increase of 2,456 × 104 t and a cumulative injection of CO2 3.9 × 108 t, which is expected to improve the recovery rate by more than 26 percentage points (LIN and TAN, 2021).

China’s CCUS-EOR research started early, and oil companies and related institutions started to explore CO2 oil drive technology as early as the 1960s. Still, industrialization lagged due to gas source, mechanism understanding, equipment, and other problems. Since the 21st century, the state and oil companies have set up CCUS-EOR primary scientific and technological research and demonstration projects, which have extensively promoted the breakthrough of critical technologies and the success of minefield tests (ADU et al., 2019). China Petroleum & Chemical Corporation Limited has conducted several field trials in Jiangsu, Shengli, and East China oilfields; CO2 oil drive projects have been implemented to cover geological reserves of 2,512 × 104 t, with a cumulative oil increase of 25.58 × 104 t. Among them, the CO2 near-mixed phase drive pilot test in High 89-1 block of Shengli oilfield, with a cumulative CO2 injection of 31 × 104 t and a cumulative oil increase of 8.6 × 104 t as of August 2021. It is predicted to improve the recovery rate by 17.2 percentage points. Yanchang Oilfield is also actively exploring CCUS-EOR technology and has made positive progress in integrated technology research and development and entire process low-cost commercialization engineering demonstration, and has built an annual processing capacity of 15 × 104 t in Jingbian and Wuqi pilot areas. A CCUS demonstration project with an annual processing capacity of 15 × 104 t has been built in Jingbian and Wuqi pilot areas, injecting 21.6 × 104 t of CO2.

Although there is a contradiction between oil production and low-carbon development, it can be achieved by constructing an ecological development concept with technological progress and scientific innovation. In terms of social benefits, annual buried CO2 of 3,000 × 104 t can absorb the carbon emissions of more than ten extensive refining and chemical enterprises (Zhao et al., 2021). Based on the goal of achieving carbon neutrality by 2060, the current high carbon emission infrastructure has a useful life of fewer than 40 years. By addressing a portion of CO2 emissions from coal power, cement and steel industries through the CCUS-EOR industry, we can avoid the early shutdown of newly invested infrastructure and wasted investment and enhance the cost-effectiveness of the carbon neutrality process.

In terms of economic benefits, CO2 drive is one of the main technologies to replenish reservoir formation energy and improve crude oil recovery effectively. According to the 2020 evaluation results of the China Petroleum Exploration and Development Research Institute, the geological reserves of low-permeability reservoirs suitable for CO2 drive to improve recovery in some oil fields of China are 67.3 × 108 t, which are expected to improve recovery by 16.5 percentage points on average and add 11.1 × 108 t of recoverable reserves, and can effectively bury CO2 29.5 × 108 t in the drive phase (TANG et al., 2016).

According to the preliminary evaluation of the CO2 geological storage potential of the main oil and gas reservoirs in the major oil and gas basins in China, the CO2 storage potential of reservoirs exceeds 140 × 108 t. Among them, the CO2 burial potential in the main oil areas of Songliao, Ordos, Bohai Bay and Junggar basins is high, and they are the key areas for implementing CCUS-EOR. The theoretical CO2 burial potential in the deep saline layer of major basins in China is even larger, reaching more than 6 × 1012 t. In addition, promoting the development of new CCUS-EOR industries on a large scale can also provide many employment opportunities for society.

Compared with foreign countries, the main problem facing CO2 capture in China is the high capture cost and challenges of the large-scale capture of low-concentration CO2 (PARK et al., 2021). Low-concentration chemical amine capture CO2 technology has been commercialized in foreign countries for more than 5 years at the megaton level. However, China is still in the demonstration operation stage, and steam consumption is more than 40% more than abroad (Qin et al., 2020). In terms of large-scale integrated process optimization, foreign countries have already realized commercialized process packages for million-ton carbon capture. In contrast, China still has no commercialized standard process package to offer. Foreign governments have integrated heat recovery of composite amine liquid purification technology, while China only has partial process technology integration. Foreign countries have a complete adaptation of the device transformation optimization and solutions. China is still in the initial stage of research (Zou et al., 2021).

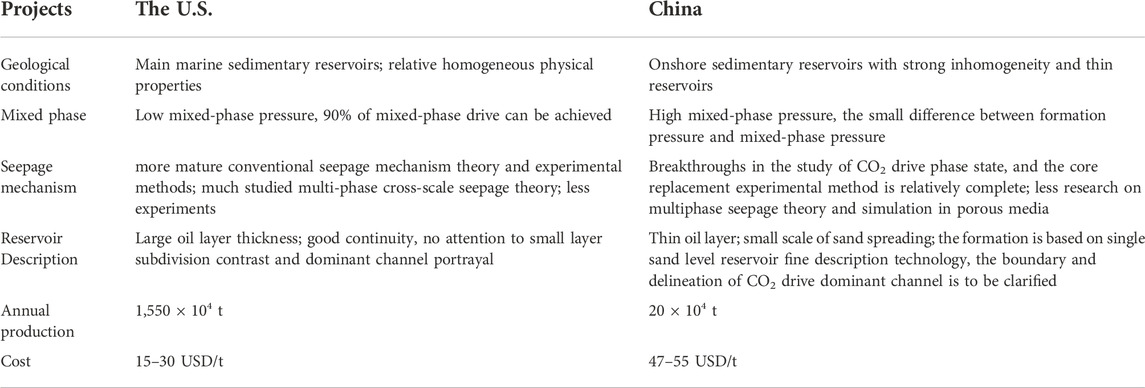

At this stage, China and North America CCUS-EOR need to be further improved in terms of technology level, application scale and production effect (Table 1). The current CO2 oil recovery enhancement range is 10%–25%, and the CO2 burial rate is about 60%–70%. Under the current technical conditions, more than 50% of the geological reserves of crude oil remain in the subsurface at the end of the oil drive life cycle. Therefore, we need more in-depth research on the mechanism of multiphase seepage in CO2-driven porous media, characterization techniques of gas drive dominant channels in strongly inhomogeneous reservoirs, rational good networks and development laws, and expansion of wave volume (ZHANG et al., 2013). The CO2 burial mechanism and main control factors of different injection methods and different geological bodies have been clarified, and the contribution degree and characterization methods of CO2 burial mechanisms such as “volume replacement, dissolution retention and mineralization reaction” of reservoir geological bodies have been determined, the evaluation methods of CO2 safe burial potential of natural gas reservoirs, saline water reservoirs and coal-bed methane reservoirs have been established, and the technique of CO2 concentration, soil concentration, and mineralization reaction have been developed. CO2 concentration, soil carbon flux, stable isotopes, and other integrated methods to monitor the CO2 leakage burial safety monitoring technology system (ZHANG et al., 2015).

TABLE 1. Comparison of Chinese and US CO2 oil drive technologies (Xiang et al).

CCUS-EOR technology is one of the effective means to reduce carbon emissions and one of the fundamental ways to utilize CO2. From the perspective of ecological development, China and the United States, as essential components in driving the world toward carbon neutrality, both countries have good potential in CCUS-EOR technology, and the combination of CO2 drive and buried reservoirs is also a significant trend for future development. By sorting out the current status and development prospects of CCUS-EOR technology development. To establish a new direction for the development of dual carbon in the world and also for the large reservoirs of low permeability in China, where the traditional water drive is inadequate, the oil and gas production enhancement scheme based on CCUS-EOR technology is proposed. The international development pattern regarding large-scale oil-driven burial and intelligent monitoring technologies is also dissected. In this way, we present the research of responsive technologies and the construction of supporting infrastructure, which to some extent, promote the large-scale use of CCUS technology for all humankind (ABUOV et al., 2022).

All authors conceived and designed the study. Write the first draft, LY, and QD; Writing review and editing, JH, and QF; Format modification, BL, XX.

Supported by the Open Foundation of Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University (Ministry of Education & Hubei Province), No. UOG2022-03; Supported by Open Fund of Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas (Yangtze University), No. YQZC202206; Supported by the Key Program of Hubei Provincial Department of Education, No. D20221303; Supported by the Natural Science Foundation of Hubei Province, No. ZRMS2022000846.

Author QD and LY were employed by Carbon Hydrogen Epoch Technology Co. Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abuov, Y., Serik, G., and Lee, W. (2022). Techno-economic assessment and life cycle assessment of CO2-EOR [J]. Environ. Sci. Technol. 56 (12), 8571–8580. doi:10.1021/acs.est.1c06834

Adu, E., Zhang, Y., and Liu, D. (2019). Current situation of carbon dioxide capture, storage, and enhanced oil recovery in the oil and gas industry. Can. J. Chem. Eng. 97 (5), 1048–1076. doi:10.1002/cjce.23393

Cai, B., Cao, L., Lei, Y., Wang, C., Zhang, L., Zhu, J., et al. (2021). Carbon dioxide emission pathways under China's carbon neutrality target %J China's Population. Resour. Environ. [J] 31 (01), 7–14. doi:10.12062/cpre.20210101

Gupta, A., Davis, M., and Kumar, A. (2021). An integrated assessment framework for the decarbonization of the electricity generation sector. Appl. Energy 288, 116634. doi:10.1016/j.apenergy.2021.116634

Li, T., Shi, Z., and Han, D. (2022). Research on the impact of energy technology innovation on total factor ecological efficiency. Environ. Sci. Pollut. Res. 29 (24), 37096–37114. doi:10.1007/s11356-021-18204-9

Liao, X., and Ming, J. (2019). Pressures imposed by energy production on compliance with China's ‘Three Red Lines’ water policy in water-scarce provinces. Water Policy 21 (1), 38–48. doi:10.2166/wp.2018.211

Lin, B., and Tan, Z. (2021). How much impact will low oil price and carbon trading mechanism have on the value of carbon capture utilization and storage (CCUS) project? Analysis based on real option method [J]. J. Clean. Prod. 298, 126768. doi:10.1016/j.jclepro.2021.126768

Liu, G., Cai, B., Li, Q., Zhang, X., and Ouyang, T. (2022). China's pathways of CO2 capture, utilization and storage under carbon neutrality vision 2060 [J]. Carbon Manag. 13 (1), 435–449. doi:10.1080/17583004.2022.2117648

Liu, W., Fan, W., Hong, Y., and Chen, C. (2021). A study on the comprehensive evaluation and analysis of China’s renewable energy development and regional energy development. Front. Energy Res. 9. doi:10.3389/fenrg.2021.635570

Ou, Y., Roney, C., Alsalam, J., Calvin, K., Creason, J., Edmonds, J., et al. (2021). Deep mitigation of CO2 and non-CO2 greenhouse gases toward 1.5 degrees C and 2 degrees C futures [J]. Nat. Commun. 12 (1), 6245. doi:10.1038/s41467-021-26509-z

Park, C., Jeong, S., Park, H., Woo, J. H., Sim, S., Kim, J., et al. (2021). Challenges in monitoring atmospheric CO2 concentrations in seoul using low-cost sensors [J]. Asia. Pac. J. Atmos. Sci. 57 (3), 547–553. doi:10.1007/s13143-020-00213-2

Partani, S., Qiu, A., Sattiraju, R., Tayade, S., and Schotten, H. D. (2022). Quantitative assessment of CCAM applications on greenhouse gas emissions. proceedings of the 2022 IEEE 95th Vehicular Technology Conference: (VTC2022-Spring), F]. 19-22 June 2022. Helsinki, Finland. IEEE.

Qin, J., Li, Y., Wu, D., Weng, H., and Wang, G. (2020). CCUS global progress and Chinese countermeasures and suggestions. J Oil Gas Geol. Recovery [J] 27 (01), 20–28. doi:10.13673/j.cnki.cn37-1359/te.2020.01.003

Rocco, M. V., Ferrer, R. J. F., and Colombo, E. (2018). Understanding the energy metabolism of World economies through the joint use of Production- and Consumption-based energy accountings. Appl. Energy 211, 590–603. doi:10.1016/j.apenergy.2017.10.090

Tang, J., Ji, S., and Jiang, L. (2016). The design of a sustainable location-routing-inventory model considering consumer environmental behavior. Sustainability 8 (3), 211. doi:10.3390/su8030211

Wang, M., Liu, P., Gu, Z., Cheng, H., and Li, X. (2019). A scientometric review of resource recycling industry. Int. J. Environ. Res. Public Health 16 (23), 4654. doi:10.3390/ijerph16234654

Xiang, Y., Hou, L., Du, M., Jia, N. H., and Lv, W. F. Research progress and development prospect of CCUS-EOR technology in China. Oil Gas Geol. Recovery [J], 1–17.

Zhang, L., Ren, B., Huang, H., Li, Y., Ren, S., Chen, G., et al. (2015). CO2 EOR and storage in Jilin oilfield China: Monitoring program and preliminary results [J]. J. Petroleum Sci. Eng. 125, 1–12. doi:10.1016/j.petrol.2014.11.005

Zhang, X., Fan, J-L., and Wei, Y-M. (2013). Technology roadmap study on carbon capture, utilization and storage in China. Energy Policy 59, 536–550. doi:10.1016/j.enpol.2013.04.005

Zhao, Z. Q, Zhang, H., Jiao, C., Wang, Q., and Lin, X. (2021). Analysis of global CCUS technology and application status. J. Mod. Chem. Ind. J. 41 (04), 5–10.

Keywords: oil and gas industry, ecological development, CO2 flooding, EOR, CCUS

Citation: Yan L, Hu J, Fang Q, Xia X, Lei B and Deng Q (2023) Eco-development of oil and gas industry: CCUS-EOR technology. Front. Earth Sci. 10:1063042. doi: 10.3389/feart.2022.1063042

Received: 06 October 2022; Accepted: 01 November 2022;

Published: 17 January 2023.

Edited by:

Zhilin Cheng, Xi’an Shiyou University, ChinaReviewed by:

Fengtao Qu, China University of Petroleum, ChinaCopyright © 2023 Yan, Hu, Fang, Xia, Lei and Deng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jiajia Hu, aHVqaWFqaWFfeWFuZ3R6ZUAxNjMuY29t; Qiao Deng, ZGVuZ3FpYW8yMDA4QDE2My5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.