94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci., 04 January 2023

Sec. Economic Geology

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.1054787

This article is part of the Research TopicRecent Advances in Unconventional Natural GasView all 10 articles

Shuai Zhang1,2*

Shuai Zhang1,2*To effectively solve the problem of regional verification of gas outbursts adjacent to close coal seam groups, a method of regional verification and index fusion of the working face was proposed to promote the general idea of advanced detection, index fusion, and the determination of the critical values, inspection, and verification. Based on the engineering background of Xiaotun Coal Mine and advanced geological exploration, drilled holes were arranged in key locations and consisted of small intervals between layers, thickened coal seams, and geological structural belts. Moreover, fusion indexes were selected according to the statistical analysis of laboratory tests and on-the-spot measurements, which can be used to determine that the critical value of the residual gas content of the fusion indexes of the six adjacent upper coal seams is 8 m3/t and K1 is 0.50 ml/g.min1/2. The results illustrate that the method for measuring residual gas content and the fusion index of the K1 value during the effect test of regional prevention measures is convenient and effective for advanced regional verification of adjacent coal seams, which can also provide a reference and guiding significance for the regional verification of adjacent coal seams of gas outbursts under similar conditions.

Coal and gas outbursts are some of the most harmful natural disasters in coal mine production (Wang et al., 2020a; Li et al., 2020; Kong et al., 2022). However, regional verification is the last link in the regional four-in-one comprehensive prevention measures for gas outbursts and is a significant checkpoint for controlling and preventing coal and gas outburst accidents (State Administration of Coal Mine Safety, 2019). Before the excavation is conducted in the adjacent coal seam with a normal distance of less than 5 m from the outburst danger zone of the coal seam, regional prevention measures for gas outbursts must be examined for the corresponding areas of the coal seam with gas outbursts in Article 29 of the 2019 edition of the Detailed Rules for the Prevention and Control of Coal and Gas Outbursts. However, determining whether to conduct regional verification is not clearly specified. Recently, scholars have investigated and discussed the regionally verified method of close coal seam groups of gas outbursts. Fan et al. (Fan, 2012), Li and Yanbin (2010), and others proposed that when excavating activities are conducted in close coal seams of gas outbursts, and after implementing regional prevention measures for coal seams of gas outbursts with close proximity and verifying their effectiveness, the regional verification may not be performed for the lower adjacent layer with a layer spacing greater than 2 m. However, the upper adjacent layer must be verified with reference to the method of regional verification of the working face of the coal seam of the gas outburst (Zhang et al., 2020). Similarly, the method for joint regional verification of the excavation working face of the close coal seam groups of gas outbursts was proposed by Hao et al. (Gui et al., 1048), which added the method of measuring the drilled holes cutting index K1 and S values for coal seams of gas outbursts and the joint arrangement of drilled holes in the range of up and down adjacent coal seams of gas outbursts at a distance of less than 5 m that filled the gap in the verification of the joint area (Wang, 2019a; Wang, 2019b). Xu (2016) and others proposed the method of joint regional verification of coal seams of gas outbursts with an interlayer spacing of less than 5 m, which was conducted in the 0116115 working face of Pinggou Coal Mine during development of safe mining of the working face. In addition, the continuous regional verified method was proposed on the basis of deep hole fixed-point sampling (Cheng, 2018), which improved the work efficiency of regional verification. However, this method is only applicable in mining the working face of the coal seam and the close distance thick coal seam, and it is difficult to popularize the verification of the adjacent coal seam of gas outbursts.

Recently, the regionally verified method of close coal seams adjacent to coal seams of gas outbursts was based on the regionally verified method of mining working faces (Jia, 2022). The verification of the area adjacent to the coal seam of gas outbursts in the excavation face is used as an example; gas control has become a major factor restricting safe and efficient production in coal roadway excavation in high-gas mines (Yang and Liao, 2023). A total of 15 through-layer drilled holes need to be arranged for each cycle to control the 8–10 m ahead of the excavation when the verification of the adjacent coal seam of the gas outburst area is conducted. Consequently, several problems exist consisting of the volume of large drilled holes and construction difficulty, low verification efficiency, high gangue content in the orifice contact powder, large tested index error, and extended time (Fan et al., 2022). These problems affect the efficient production of mining the working face of close coal seam groups with gas outbursts.

However, in most areas of southwest China, problems also exist in mining adjacent coal seam groups of gas outbursts, which results in the verification of adjacent coal seams of gas outbursts with an interlayer spacing less than 5 m and a series of the afore-mentioned problems. In this paper, a regional verification method for adjacent outburst coal seams is proposed on the basis of the fusion of regional and working face indicators, which can be used to effectively prevent coal and gas outburst accidents and thereby improve the production efficiency of the mining working face.

The general idea is to use advanced detection, index fusion, the determination of critical value, inspection, and verification to conduct regional verification of adjacent coal seams of gas outbursts.

Advanced detection, that is, of coal and rock conditions, can be done by using the coal road strip through horizontal control of the roadway and investigation of the hydrogeological conditions of the mines and pre-extraction drilled holes, which are advantageous in seeking key factors, including small interlayer spacing, coal seam thickening, and geological structure, and thus provide a basis for the fusion indexes of tested drilled hole arrangement.

Index fusion includes measuring the residual gas content of adjacent coal seams of gas outbursts and the K1 value of the drilled hole cutting gas desorption index during the test of effectiveness of the prevention measures of regional gas outbursts, which can determine whether the regional measures are effective and the degree of the outburst danger of coal seams.

The critical values thus obtained are used to measure the critical value of the fusion index through comprehensive analysis by combining laboratory tests and on-the-spot measurements.

During tunneling of the gas drainage in the floor roadway, the coal and rock conditions of the roadway horizontal control, hydrogeological conditions, and holes drilled for gas drainage in the corresponding strip area are comprehensively analyzed to accurately determine the occurrence of coal seams. During the inspection of regional outburst prevention measures, a measured point is arranged at a certain distance along the roadway extraction direction or mining direction of the working face to determine the residual gas content of the fusion index and the K1 value of the drill cutting gas desorption index. According to the investigated critical value and regional verification standard, the regional verification method of adjacent outburst coal seams for regional advanced verification and working face index fusion is established. Each inspected and tested point is prioritized in the key position area of abnormal structures including smaller interval, thickened coal seam, fault, and fold, and the points are appropriately increased (the tested point must control the two walls of the fault and the axis of the fold).

Xiaotun Coal Mine in Guizhou Province works with close-range coal seams with gas outbursts. The excavation working faces of the 16 middle and 14 transport roadways was used as testing sites, and the roadway was excavated along the direction of middle coal seam 6. The upper overlying coal seam 6 is characterized by a coal seam spacing of 1.7–9.1 m, an average coal seam spacing of 2.7 m, a coal seam thickness of 0.52–1.14 m, and an average coal seam thickness of 0.82 m. Additionally, the lower underlying coal seam 6 is characterized by a coal seam spacing of 0.9–8.4 m, an average coal seam spacing of 3.3 m, a coal seam thickness of 0.12–3.46 m, and an average coal seam thickness of 0.99 m. In addition, the upper, middle, and lower layers of coal seam 6 are all identified as coal seams of the gas outburst, and the comprehensive histogram of the measured coal strata is shown in Figure 1.

The floor gas drainage roadway of the 16 middle and 14 transport roadways is arranged with through-layer grid drilled holes with a width of 5 m × 5 m, which is beneficial for the pre-extraction 6 middle coal roadway strip of the coal seam, and regional prevention measures are taken of the gas outburst in the upper and lower layers of coal seam 6 of the corresponding area. After a period of pre-extraction, the middle, upper, and lower layers of coal seam 6 adjacent to the upper and lower sides will be tested for the effect of regional measures. Before excavation of the 16 middle and 14 transport roadways, regional verification of the upper, middle, and lower layers of coal seam 6 will be conducted. Moreover, the regionally verified method of the upper and lower layers of coal seam 6 is conducted with reference to the regionally verified method of the excavation working face of the coal seam of the gas outburst, which includes 3 groups arranged in the excavation direction of the 16 middle and 14 transport roadways using the air coal drill for a total of 15 through-bed drilled holes. These holes are drilled into the upper and lower layers of coal seam 6 per cycle. Consequently, strips of the upper layer of coal seam 6 corresponding to the area of 8–10 m in front of the excavation face and 2–4 m of the 16 middle and 14 transport roadways are controlled by this method. However, this is characterized by the difficult construction of regionally verified drilled holes and a large amount of engineering of drilled holes, drilled hole cuttings with a lot of gangue, and a low accuracy of regionally verified indicators; these problems have seriously restricted the safe and efficient excavation operation of the excavation working face in the 16 middle and 14 transport roadways (Hu et al., 2008; Jiang et al., 2018; Yang et al., 2019).

In the outer section of the 16 middle and 14 transport roadways (200–410 m) (the mileage is based on the opening point of the 16 middle and 14 transport roadways) of the tested area, 293 pre-extraction drill holes were placed in the construction area of the floor drainage roadway. Figure 2 shows the occurrence of coal seams in the tested area of the 16 middle and 14 transport roadways according to the coal and rock in the regional pre-extraction drilled holes.

The representative upper coal seam is characterized by a relatively close distance to the middle coal seam and an interlayer spacing of less than 5 m. At 270 m and 410 m of the 16 middle and 14 transport roadways, upper coal seam 6 is relatively close to middle coal seam 6. Furthermore, the area where the coal seam is thickened on upper coal seam 6 occurs at 280 m, 320 m, and 365 m and there is a small fault in the upper coal seam at a distance of 340 m.

According to Article 69 of the Detailed Rules for the Prevention and Control of Coal and Gas Outbursts, if the regional prevention measures of gas outbursts for pre-extracted coal seam gas are adopted, the effect of the regional outburst prevention measures must be checked. In addition, the residual gas pressure or other tested residual gas pressure can also be used (this selection should comply with the procedures required by article 57 of these rules) according to the site conditions and considering that the residual gas content index is preferred as the inspection index and indicates that validated indicators and methods are tested.

Therefore, the residual gas content index is used as the regional index of the fusion index for the verification of the adjacent coal seam region of gas outbursts when the effect of the regional prevention measures of gas outbursts is tested.

Presently, the prediction methods of the working face consist of the cuttings index, compound index, and R value index methods. Among them, the key tested indicators are the index of the gas desorption of drilled hole cuttings, the volume of drilled hole cuttings, and the initial velocity of gas emissions of the drilled holes.

The index of the cutting volume refers to the slag discharge volume of 1 m drilled holes with a diameter of φ42 mm of the spiral drilled pipe. However, in Xiaotun Coal Mine area, the tested drill holes of the prevention measures of regional gas outbursts are generally constructed with tools at a diameter of φ75 mm or φ94 mm. Moreover, the critical value of the amount of cuttings has not been investigated due to the different size of the drilling tool and the amount of slag discharge. Therefore, this indicator is not suitable for simultaneous measurement of residual gas content, which should not be taken as the fusion index of the working face in the verification of the adjacent layer area.

The initial velocity index of the gas emission from the hole requires that the initial velocity q is measured within 2 min after the drill is suspended. In addition, the drilled depth of the tested drill holes is generally tens of meters and the drill pipe cannot be withdrawn within 2 min. Therefore, this index is not suitable for the simultaneous measurement of residual gas content, which also should not be taken as the fusion index of the working face in the verification of adjacent layer areas.

The measurement of the gas desorption index of drilled hole cuttings and the residual gas content index are both selected for the measurement of drilled hole cuttings, which can be simultaneously measured. Consequently, the gas desorption index of drilled hole cuttings is the fusion index of the working face during the verification of the adjacent layer area.

In conclusion, the cutting gas desorption index is selected as the regionally verified fusion index of the working face in the adjacent coal seam of a gas outburst when the effect of the regional prevention measures are tested.

The coal in upper coal seam 6 in Xiaotun Coal Mine is high metamorphic anthracite coal, and the effect of regional prevention measures of gas outbursts is tested by the residual gas content index, whose critical value is the 8 m3/t recommended in the Detailed Rules for the Prevention and Control of Coal and Gas Outbursts. After nearly 15 years of on-site practice, it was proven that the gas dynamic phenomenon and abnormal gas outburst never occur when the residual gas content of upper coal seam 6 dropped below 8 m3/t, which illustrates that the reference value of 8 m3/t is safe and reliable for testing the effect of the measures (Zhang, 2009; Zhang, 2014; Zhang et al., 2016; Lv, 2018; Wang et al., 2020b).

1) Determination of the experimental threshold

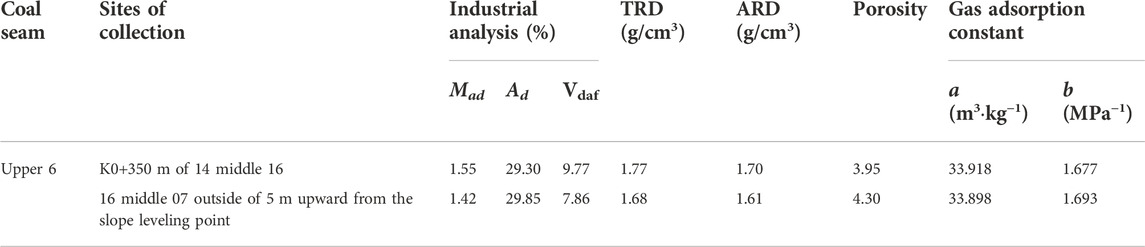

The coal samples of upper coal seam 6 and the relatively soft coal samples of the non-obvious soft layer were collected by the grooving method, and only 2 coal samples were collected due to the few exposed locations of upper coal seam 6. These samples were tested in the laboratory and the measured results of the adsorption constant and industrial analysis indexes are shown in Table 1 (dry coal samples were used for this coal sample collection and site inspection).

TABLE 1. Tested results of experimental parameters including the gas adsorption constant and industrial analysis indexes of upper coal seam 6.

The coal samples with a particle size of 1–3 mm were selected to investigate the relationship between the experimental gas pressure and the K1 value of the drilled hole cutting desorption index. The balanced pressures were set to 0.30, 0.5, 0.75, 1.00, 1.25, and 1.50 MPa. Then, two coal samples were tested in the laboratory under different balanced pressures and the K1 value of the drilled hole cutting desorption index was obtained.

The results of the K1 value were fitted according to different balanced pressure conditions. The relationships of the power exponential relationship between the gas pressure P and the K1 value were fitted as shown in Eqs 1, 2.

where K1 is the gas desorption index of the drilled hole cuttings, ml/g.min1/2; and P is the gas pressure of the coal seam, MPa.

According to the theory of Langmuir gas adsorption, the relationship between the gas content W and the gas pressure P is shown in formula (3) (Bai et al., 2019).

where W is the gas content of the coal seam, m3/t; a and b are the coal seam gas adsorption constants, respectively, m3·kg−1, MPa−1; Mad is the coal seam moisture, %; and Ad is the coal seam ash, %.

Simultaneously, for Eqs 1–3, the relationships between the gas content W of the coal seam and the value of the desorption index K1 of the drilled hole cuttings can be established in upper coal seam 6 as shown in Eqs 4, 5.

According to the relationship model, the W-K1 value is established by the experimental parameters of measurement, the gas desorption index K1 values of drilled hole cuttings are 0.56 and 0.51 ml/g.min1/2, respectively, and the smaller value of 0.51 ml/g.min1/2 is selected as the critical laboratory value when the residual gas content of the regional fusion index is 8 m3/t.

2) Determination of the critical value in on-the-spot tests

During the effect test of the 16 middle and 11 transport roadways (mileage K0+360–750 m), 26 groups of the seam desorption index K1 values of drilled hole cuttings were followed in upper coal seam 6.

The fitted curve has the highest fit with the power exponential function using the reflection of the drawn discrete point graph, the removed points with large dispersion, and the fitted relationship between gas content and cutting desorption as shown in Figure 3. The fitted relationship is shown in formula (6).

According to the fitted formula of the field investigation, the value of K1 of the desorption index of the drilled hole cuttings is 0.50 ml/g.min1/2 when the calculated gas content is 8 m3/t.

Analysis of the desorption index K1 values of the drilled hole cuttings calculated from laboratory tests and on-the-spot investigation showed that the critical values of K1 are 0.51 ml/g.min1/2 and 0.50 ml/g.min1/2, respectively. In addition, to ensure safe production in the mine and reduce the outflow of gas from the adjacent layers to the excavation space, the minimum value should be selected as the critical value of the regionally verified index K1 value in the upper coal seam area. Finally, 0.50 ml/g.min1/2 was selected as the critical value of the regionally verified indexes of upper coal seam 6 of Xiaotun Coal Mine.

In areas with complex geological structures or pre-drained gas areas of coal seams where non-directional drill holes are used, at least two regional verifications should be conducted for every 30 m of advance of the anti-burst measurement (State Administration of Coal Mine Safety, 2019). Combined with the above-mentioned outburst coal seam mining working face and the inspection effect of regional measures and verified requirements, the requirements for the drilled hole arrangement to determine the fusion indexes during the regional verification of the gas outburst area on upper coal seam 6 of Xiaotun Coal Mine are as follows:

1) When regional verification of the coal seam adjacent to upper coal seam 6 is conducted in the coal road strip area of middle coal seam 6, the arrangement of drilled holes requires at least two inspection and tested points every 30 m along the coal roadway strip. This is favorable to determine the residual gas content index and gas desorption index of drilled hole cuttings in upper coal seam 6. Furthermore, tested drill holes should be arranged areas with a small interval, thickened coal seam, and complex geological structure.

2) When the working face area of middle coal seam 6 is regionally verified against the area adjacent to upper coal seam 6 of gas outbursts and the mining area does not exceed 120 m, the arrangement of the drilled holes requires that at least two inspection and tested points are arranged at intervals of 30 m along the advancing direction of the coal face. Otherwise, at least three inspection and tested points should be arranged at intervals of 30 m along the advancing direction of the coal face, which is favorable for the measurement of the residual gas content index and drilled hole cutting gas desorption index of upper coal seam 6. In addition, the location of the tested drilled holes should be arranged in areas with small interlayer spacing, thickened coal seams, and complex geological structures.

Field applications were conducted in the 16 middle and 14 transport roadways (410–620 m); two inspection and tested points were arranged at every interval of 30 m and there were a total of 14 groups of inspection points. The results of the fusion index are shown in Figure 4.

According to the regional verification of the 16 middle and 14 transport roadways of 410–620 m, the maximum residual gas content measured by the fusion index is 6.71 m3/t and the maximum K1 value of the drilled hole cutting gas desorption index is 0.31 ml/g.min1/2; these values do not exceed the specified critical values of 8 m3/t and 0.50 ml/g.min1/2. More importantly, there are no dynamic phenomenon consisting of jet holes, jacking drilled holes, and abnormal gas emissions from adjacent layers during tunneling, which showed safe and efficient tunneling of 16 middle and 14 transport roadway. Therefore, in the tested area, the drilled length of the regional verified drill holes was reduced by 8700 m with a reduced construction cost of more than 500000 Yuan. Moreover, the average excavation speed increased from approximately 90 m/month to 150 m/month with the increase in the average excavation speed by 1.6 times.

1) Through laboratory tests and on-the-spot statistical analysis, the W-K1 relationship model was established and the critical value of K1 was determined to be 0.50 ml/g.min1/2 when the gas content in upper coal seam 6 was 8 m3/t.

2) The layout requirements for the regionally verified drill holes and the judgment principle of regionally verified results for the fusion indexes of upper coal seam 6 in Xiaotun Coal Mine were established.

3) The method of regional verification and index fusion of the working face was proposed to adhere to the general idea of advanced detection, index fusion, determination of the critical values, inspection, and verification, which also showed that the method was feasible and effective through inspection and verification. Moreover, the method provides a new idea and method for the regional verification of mining working faces in similar mining areas in Guizhou Province, and also provides practical experience and a scientific basis for the formulation of relevant industrial normative clauses for the regional verification of close coal seam groups adjacent to coal seams of gas outbursts.

The original contributions in this study are included in the article/Supplementary Material, and further inquiries can be directed to the corresponding author.

SZ, as an industry expert and writer, completed the overall content of the paper and related experiments.

This work was financially supported by the National Key R&D Program (2017YFC0804206) and the projects from Chongqing Research Institute, China Coal Science and Industry Group (2022ZDXM07).

SZ was employed by the China Coal Science and Industry Group, Chongqing Research Institute Co., Ltd.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Bai, G., Zhou, X., and Shiping, W. (2019). Numerical simulation and application of increasing gas drainage by CO2 injection in low permeability coal seam[J]. Coal Field Geol. Explor. 47 (03), 77–84. doi:10.3969/j.issn.1001-1986.2019.03.013

Cheng, J. (2018). Investigation on the occurrence mechanism and joint outburst prevention method of close seam group [D]. China: Anhui University of technology.

Fan, C., Wen, H., Li, S., Bai, G., and Zhou, L. (2022). Coal seam gas extraction by integrated drillings and punchings from the floor roadway considering hydraulic-mechanical coupling effect. Geofluids 2022, 1–10. doi:10.1155/2022/5198227

Fan, X. (2012). Discussion on the regionally verified method of close coal seam of gas outburst [J]. Coal Eng. (10), 45–47.

Gui, H., Wen, G., and Zhang, G. A joint area verified method for driving face of close coal seam of gas outburst [P]. Cn104806291a, 2015-07-29.

Hu, Q., Zhou, S., and Zhou, X. (2008). Mechanical mechanism of coal and gas outburst process [J]. Acta coal Sin. 33 (12), 1368–1372.

Jia, Y. (2022). Research on local comprehensive outburst prevention measures for coal roadway driving faces in outburst coal seams [J]. China Coalbed Methane 19 (02), 36–39.

Jiang, X., Fan, S., and Cheng, Z. (2018). Comprehensive gas control mode of three zone linkage based on combined up and down well extraction [J]. Coal Sci. Technol. 46 (6), 107–113. doi:10.13199/j.cnki.cst.2018.06.018

Kong, B., Cao, Z., Sun, T., Qi, C., and Zhang, Y. (2022). Safety hazards in coal mines of Guizhou China during 2011–2020. Saf. Sci. 145, 105493. doi:10.1016/j.ssci.2021.105493

Li, Y., and Yanbin, H. (2010). Analysis on the regional verification and effect test method of coal seam of gas outburst in Jiaozuo mining area [J]. Coal mine Saf. 41 (11), 86–88.

Li, H., Ma, J., Wang, Z., Wang, W., and Liu, Y. (2020). A gas outburst prevention and control strategy for single thick coal seams with high outburst risk: a case study of hudi coal mine in qinshui basin. Energy Sci. Eng. 8 (7), 2471–2491. doi:10.1002/ese3.680

Lv, G. (2018). Investigation on the method of determining the critical value of gas content for the effect inspection of regional prevention measures of gas outburst [J]. Coal Eng. 50 (8), 105–108.

State Administration of Coal Mine Safety (2019). Detailed rules for prevention and control of coal and gas outbursts [M]. Beijing: Coal Industry Press.

Wang, L., Lu, Z., Chen, D., Liu, Q., Chu, P., Shu, L., et al. (2020). Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 129, 104800. doi:10.1016/j.ssci.2020.104800

Wang, F., Liang, Y., Sun, Z., Li, L., and Li, X. (2020). Determination of the sensitivity index and its critical value for outburst risk prediction: A case study in fuxiang mine, China. Adsorpt. Sci. Technol. 38 (9-10), 502–527. doi:10.1177/0263617420963735

Wang, S. (2019). Study the critical value of outburst effect inspection index in the case of regional gas predrainage. IOP Conf. Ser. Earth Environ. Sci. 358 (2), 022007. doi:10.1088/1755-1315/358/2/022007

Wang, W. (2019). Determination of gas emission radius based on drilled cuttings index method [J]. Inn. Mong. Coal Econ. (09), 142–143.

Xu, T. (2016). Discussion on the regionally verified method of the working face of the close coal seam groups of gas outburst [J]. Energy Technol. Manag. 41 (2), 59–66.

Yang, S., and Liao, Y. (2023). Research on gas grading control method of coal roadway heading face in high gas mine[M]. Adv. Geol. Resour. Explor., 237–242. CRC Press.

Yang, F., Zheng, J., and Wang, L. (2019). Study on gas overrun control technology in mining working face of close seam group [J]. Coal Sci. Technol. 47 (5), 126–131. doi:10.13199/j.cnki.cst.2019.05.020

Zhang, Y., Lv, G., and Liu, H. (2016). Investigation on the critical value of gas content in gas outburst prediction index of outburst coal seam area [J]. Coal Sci. Technol. 44 (11), 82–87. doi:10.13199/j.cnki.cst.2016.11.016

Zhang, E., Zhu, Q., and Liu, Y. (2020). Comprehensive prediction and verification of coal seam outburst risk [J]. J. North China Univ. Sci. Technol. 17 (04), 19–26+42.

Keywords: W-K1 relationship model, index fusion of the region and working face, regional verification, adjacent coal seam, gas outburst

Citation: Zhang S (2023) A regionally verified method for fusion indexes of gas outbursts in adjacent seams within close coal seam groups. Front. Earth Sci. 10:1054787. doi: 10.3389/feart.2022.1054787

Received: 27 September 2022; Accepted: 08 November 2022;

Published: 04 January 2023.

Edited by:

Chaojun Fan, Liaoning Technical University, ChinaReviewed by:

Qiming Huang, Shandong University of Science and Technology, ChinaCopyright © 2023 Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shuai Zhang, emhhbmc1Nzg4MDM2ODNAMTI2LmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.