95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

OPINION article

Front. Earth Sci. , 09 January 2023

Sec. Geochemistry

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.1035771

This article is part of the Research Topic Mechanisms and Applications of Chemical Techniques for Effective Development of Unconventional Reservoirs View all 13 articles

It is well known that there are many technical methods for improving oil recovery, including gas miscible flooding, thermal oil recovery, chemical flooding, and microbial oil recovery. Among these, CO2 flooding is one of the key technologies for improving oil recovery that achieves the goal of reducing carbon emissions (Jia et al., 2019). Given the increasing awareness regarding human environmental protection, the development of a low-carbon economy is an irresistible global trend. The concepts of “carbon peak” and “carbon neutrality” have gradually gained popularity. Carbon neutrality has also spawned the carbon capture, utilization, and storage (CCUS) industry (Zou et al., 2021). CO2 flooding is one of the main carbon utilization technologies that makes full use of carbon resources to enhance oil recovery while promoting the development of a low-carbon economy. This paper reviews and summarizes the developments regarding CO2 flooding in domestic and foreign scenarios, discusses the mechanism and process of CO2 flooding, analyzes the technological challenges, and provides some corresponding solutions.

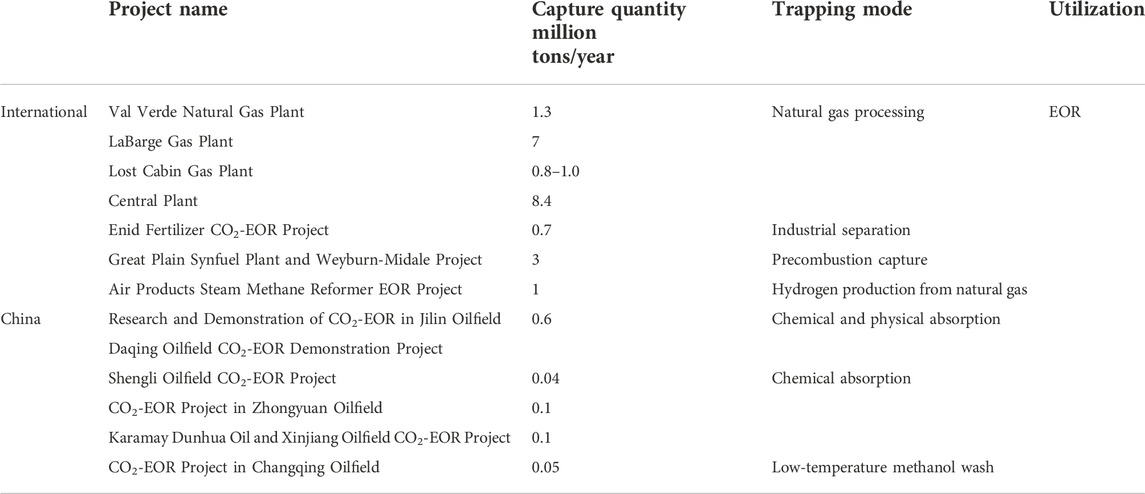

CO2 flooding has been used globally to enhance oil recovery for more than 30 years and is becoming more popular. Therefore, an increasing number of researchers are engaged in research on CO2 flooding (Chen et al., 2015). There are many reported CCUS-EOR projects from domestic and foreign investigators, as shown in Table 1. Research on CO2 flooding began in the 1950s (Whorton et al., 1952), and some European countries had earlier used CO2 flooding to enhance oil recovery. The former Soviet Union first began studying CO2 injection enhanced oil recovery (EOR) technology in 1952. In 1968, CO2 flooding tests were carried out in the Tuimajin Oilfield, which achieved a 15% increase in the final crude oil recovery (Qin et al., 2015). CO2 flooding developed the fastest in the United States, which has the largest number of CO2 flooding projects accounting for more than 90% of the global total. CO2 flooding affords good economic benefits, with an annual oil production of about 1,500 × 104 t for five consecutive years and oil recovery increase of 7–15% (Hitesh et al., 2008; British Petroleum Company, 2017; British Petroleum Company, 2018). In the 21st century, greenhouse gas emission reductions have further promoted rapid development of CO2 flooding technology (Shen and Liao, 2009; Koottungal, 2014).

TABLE 1. International CCUS-EOR projects [modified according to Xiang et al. (2022)].

Since the 1960s, China has started paying attention to CO2 flooding technology and has successively carried out indoor research on CO2 flooding. In 1963, the first study on CO2 flooding was carried out in the Daqing Oilfield in China. From 1991 to 1993, immiscible displacement tests of CO2 by alternating gas and water injection were carried out in the eastern Sanan Oilfield. In 1995, Jilin Oilfield carried out the CO2 single-well huff and puff test and obtained 1420 t of increased crude oil through multiple tests. In 1998, Shengli Oilfield carried out the CO2 single-well huff and puff test to obtain increased crude oil outputs by more than 200 t. Subsequently, China has continued to strengthen research on CO2 flooding technology. At present, research on CO2 flooding for EOR in the Jilin Oilfield is relatively mature (Chen et al., 2012).

CO2 flooding has been increasingly used in recent times. Understanding and mastering the oil displacement mechanism can therefore promote technological progress.

There are nine mechanisms of CO2 flooding:

1) Viscosity reduction: Carbon dioxide and crude oil have good mutual solubilities. Temperature and pressure also affect the solubility of CO2 in crude oil, and extremely high temperatures are not conducive to viscosity reduction (Li et al., 2008).

2) Improve oil–water mobility ratio: CO2 increases the viscosity of water and decreases the viscosity of crude oil. These two viscosities tend towards each other, thus improving the mobility ratio of crude oil to water and expanding the swept volume (Luo et al., 2012).

3) Expansion effect: The dissolution of CO2 in crude oil greatly expands the volume of the oil. The greater the degree of expansion, the stronger is the ability to flow and easier it is to replace (Gu et al., 2007).

4) Extraction and gasification of light hydrocarbons in crude oil: CO2 can be used to extract and gasify light components in crude oil, thereby reducing the relative density of crude oil and enhancing recovery (Roper et al., 1992).

5) Miscible effect: When the pressure reaches the miscible pressure, CO2 mixes with the light hydrocarbons in crude oil to form an oil zone, which greatly improves oil recovery during the oil displacement process (Grigg and Siagian, 1998).

6) Molecular diffusion: The water phase hinders diffusion of carbon dioxide molecules into the oil phase, completely inhibiting the release of the light hydrocarbons from the oil phase to carbon dioxide. Therefore, sufficient time is required for the carbon dioxide molecules to fully diffuse into the oil phase.

7) Reduce interfacial tension: In the process of CO2 flooding, mixing CO2 and the light components in crude oil (C2–C6) effectively reduces the oil–water two-phase interfacial tension, reduces the resistance of CO2 in the displacement process, and enhances oil recovery (Desch et al., 1984).

8) Dissolved gas flooding: CO2 injected into the oil layer increases its pressure, but in the displacement process, the pressure reduction causes CO2 to escape from the crude oil and occupy the pore spaces, thereby allowing dissolved gas flooding that is conducive to flooding (Gu et al., 2007).

9) Acidizing plugging improves permeability: CO2 dissolved in water generates carbonic acid and renders the aqueous solution acidic. To a certain extent, massive injection of CO2 can flush out blockages, dredge oil circulation, and restore the production capacity of a single well (Rao et al., 2004).

CO2 flooding can be divided into two types: CO2 immiscible and CO2 miscible flooding. Expansion viscosity reduction is the main mode of CO2 immiscible flooding. For reservoirs with low pressures, high temperatures, and heavier components, the surface tension between CO2 and crude oil is large. CO2 can be used to extract some light components of crude oil, thereby expanding the crude oil, reducing its viscosity, and improving recovery. The essence of CO2 huff and puff is immiscible flooding, and the mechanism involves expanding the volume of crude oil continuously so that the tension and viscosity of the crude oil interface can be reduced. This method allows injection of carbon dioxide into the bottom of the production well. After shutting down, the carbon dioxide penetrates the reservoir, which is ultimately conducive to continued production from the well. When the formation pressure is greater than the CO2 miscible pressure and less than the formation fracture pressure, CO2 miscible flooding occurs. The injection methods may be continuous or simple, among others. Studies have shown that miscible flooding enables greater recovery than immiscible flooding.

The flooding processes include primary, secondary, and tertiary flooding. Primary flooding is the method of extracting crude oil using only natural energy. Secondary flooding is the method of increasing the reservoir pressure by injecting gas or water. EOR technology involves the use of high pressures to inject supercritical/dense-phase CO2 into the reservoir, which allows the CO2 to drive the flow of crude oil to the production well, thereby increasing oil recovery. The CO2-EOR process flow chart is as shown in Figure 1. After the CO2 is compressed, it is injected into the injection well. Then, the production well produces the oil–gas mixture, which further helps separation of the crude oil.

In recent years, with increasing awareness regarding environmental protection, CO2-EOR technology has developed gradually. This not only eases the pressure on environmental pollution but also enhances oil recovery. However, there are still some problems and challenges: 1) it is necessary to strengthen measures to tackle the problem of low CO2 oil recovery; 2) the economic issues with regard to use of CO2, such as the fact that CO2 is corrosive to the pipeline during gathering and transportation, accelerate the costs from pipeline damage; 3) gas source of CO2 flooding: owing to the increased distance between the oilfield and the city, the costs of gathering and transportation are high, which limit the development of CO2 flooding technologies.

This paper therefore suggests two areas of improvement: 1) China should continue to strengthen technical research on improving oil recovery; 2) China needs to develop breakthrough carbon dioxide capture technologies and provide inexpensive natural gas sources.

All authors conceived and designed the study. Write the first draft, XX and QD; Writing review and editing, PS and LT; Format modification, LY, JB, and WL.

This work was supported by the Open Foundation of Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University (Ministry of Education and Hubei Province, No. UOG 2022-03), Open Fund of Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas (Yangtze University, No. YQZC202206), and Hubei Provincial Natural Science Foundation Youth Project of 2022 (No. ZRMS2022000846).

PS was employed by the company Engineering Technology Research Institute of PetroChina Southwest Oil and Gas Field Company, LT was employed by the company Chuanxi Drilling Company, CNPC Chuanqing Drilling Engineering Co. Ltd.; QD and LY were employed by the company Carbon Hydrogen Epoch Technology Co. Ltd. WL was employed by the company CNOOC Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Chen, Huanqing, Hu, yongle, and Tian, Changbing (2012). Research progress of CO2 flooding and storage [J]. Oilfield Chem. 29 (01), 116–121+127.

Chen, Huanqing, Hu, Yongle, and Tian, Changbing (2015). Researches on CO2 flooding and sequestration and its significance in low carbon economy [J]. J. Southwest Petroleum Univ. Soc. Sci. Ed. 17 (5), 7. doi:10.11885/j.issn.1674-5094.2015.01.29.01

Desch, J. B., Larsen, W. K., Lindsay, R. F., and Nettle, R. L. (1984). Enhanced oil recovery by CO2 miscible displacement in the little knife field, billings county, North Dakota. J. Pet. Technol. 36 (09), 1592–1602. doi:10.2118/10696-PA

Grigg, R. B., and Siagian, U. W. R. (1998). Understanding and exploiting four-phase flow in low temperature CO2 floods. Midland, Texas: SPE Permian Basin Oil and Gas Recovery.

Gu, Libing, Li, Zhiping, and Jin, Ou (2007). The existing state of enhanced oil recovery by utilizing carbon dioxide[J]. China Min. 16 (10), 66–68. doi:10.3969/j.issn.1004-4051.2007.10.020

Hitesh, M., Marshall, C., and Khosrow, B. (2008). The potential for additional carbon dioxide flooding projects in the United States[R]. Tulsa, Oklahoma, USA: SPE Symposium on Improved Oil Recovery.

Jia, Kaifeng, Ji, Dongchao, and Gao, Jindong (2019). The existing state of enhanced oil recovery by CO2 flooding in low permeability reservoirs [J]. Unconv. oil gas 6 (1), 9.

Li, Yongtai, Liu, Yifei, and Tang, Changjiu (2008). Principle and method of enhanced oil recovery [M]. Beijing: Petroleum Industry Press, 180–188.

Luo, Zhongwei, Fang, Mengxiang, and Li, Mingyuan (2012). Carbon dioxide capture, storage and utilization technology [M]. Beijing: China Electric Power Press, 208–231.

Qin, Jishun, Han, Haishui, and Liu, Xiaolei (2015). Application and enlightenment of carbon dioxide flooding in the United States of America [J]. Petroleum Explor. Dev. 42 (02), 209–216. doi:10.11698/PED.2015.02.10

Rao, D. N., Ayirala, S. C., Kulkarni, M. M., and Sharma, A. P. (2004). Development of gas assisted gravity drainage (GAGD) process for improved light oil recovery. USA: SPE/DOE Symposium on Improved Oil Recovery.

Roper, M. K., Pope, G. A., and Sepehrnoori, Kamy (1992). Analysis of tertiary injectivity of carbon dioxide. Midland, Texas: Permian Basin Oil and Gas Recovery.

Shen, Pingping, and Liao, Xinwei (2009). Carbon dioxide geological storage and enhanced oil recovery technology [M]. Beijing: Petroleum Industry Press.

Whorton, L. P., Brownscombe, E. R., and Dyes, A. B. (1952). Method for producing oil by means of carbon dioxide. USA: U. S. Patent.

Xiang, Yong, Hou, Li, Du, Meng, Jia, Ninghong, and Lv, Weifeng (2022). Research progress and development prospect of CCUS-EOR technologies in China [J]. Oil gas Geol. recovery 5, 1–17. doi:10.13673/j.cnki.cn37-1359/te.202112048

Keywords: low carbon, CO2 flooding, flooding mechanism, carbon capture utilization and storage, enhanced oil recovery

Citation: Xia X, Deng Q, Sang P, Tan L, Yan L, Bao J and Li W (2023) Low-carbon oil exploitation: Carbon dioxide flooding technology. Front. Earth Sci. 10:1035771. doi: 10.3389/feart.2022.1035771

Received: 03 September 2022; Accepted: 13 September 2022;

Published: 09 January 2023.

Edited by:

Zhilin Cheng, Xi’an Shiyou University, ChinaReviewed by:

Dong Xiong, China University of Petroleum, ChinaCopyright © 2023 Xia, Deng, Sang, Tan, Yan, Bao and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Qiao Deng, ZGVuZ3FpYW8yMDA4QDE2My5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.