- 1Petroleum Engineering Department, College of Petroleum Engineering and Geosciences, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia

- 2Center for Integrative Petroleum Research, College of Petroleum Engineering and Geosciences, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia

The dynamic Young’s modulus (Edyn) is a parameter needed for optimizing different aspects related to oil well designing. Currently, Edyn is determined from the knowledge of the formation bulk density, in addition to the shear and compressional velocities, which are not always available. This study introduces three machine learning (ML) models, namely, random forest (RF), adaptive neuro-fuzzy inference system with subtractive clustering (ANFIS-SC), and support vector regression (SVR), for estimation of the Edyn from only the real-time available drilling parameters. The ML models were learned on 2054 datasets collected from Well-A and then tested and validated on 871 and 2912 datasets from Well-B and Well-C, respectively. The results showed that the three optimized ML models accurately predicted the Edyn in the three oil wells considered in this study. The optimized SVR model outperformed both the RF and ANFIS-SC models in evaluating the Edyn in all three wells. For the validation data, the Edyn was assessed accurately with low average absolute percentage errors of 3.64%, 6.74%, and 1.03% using the optimized RF, ANFIS-SC, and SVR models, respectively.

1 Introduction

Rock static elastic properties are key parameters affecting in situ stress distribution prediction, hydraulic fracturing design, and wellbore stability (Labudovic, 1984; Lacy, 1997; Nes et al., 2005; Hammah et al., 2006; Fjaer et al., 2008). Nowadays, these static elastic properties are predicted using laboratory measurements (Barree et al., 2009) or empirical correlations which evaluated the static elastic parameters based on the dynamic elastic parameters predicted from the well log data (King, 1983; Brotons et al., 2016; Asef and Farrokhrouz, 2017; Karagianni et al., 2017).

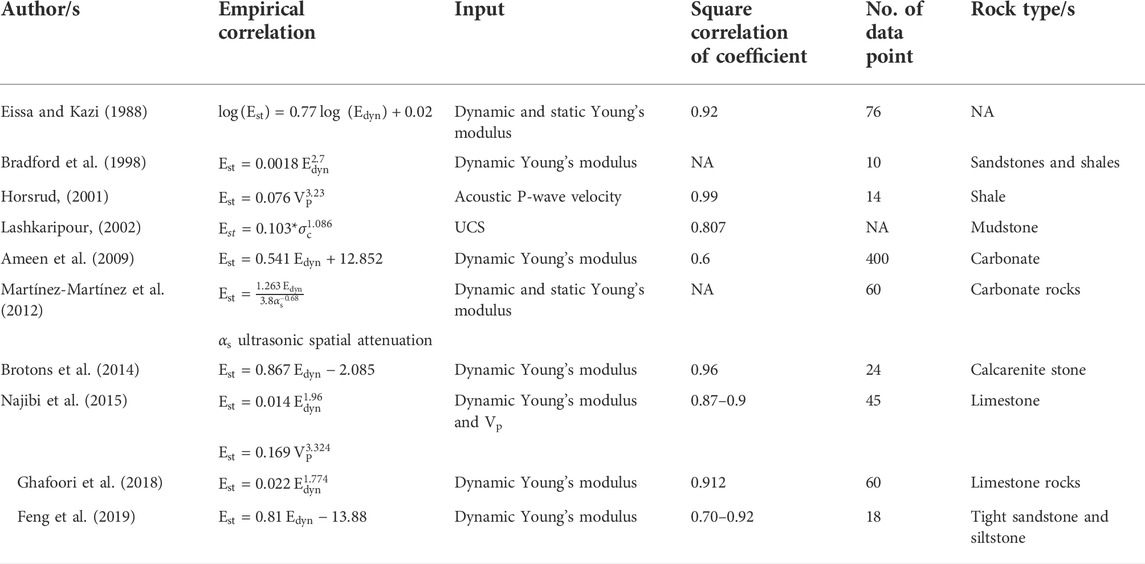

Young’s modulus is an important elastic property, and the static values of Young’s modulus (Est) could be predicted with high accuracy using laboratory measurement or predicted with empirical correlations developed to predict the Est. Table 1 lists different empirical correlations suggested for estimation of Est in different rock types.

The dynamic Young’s modulus (Edyn) which is required for Est prediction by all empirical correlations in Table 1 is currently determined from acoustic velocities and rock density using Eq. 1 (Fjaer et al., 2008). The inputs required to estimate the Edyn using Eq. 1 are obtained from the laboratory experiments or well logging, and the use of laboratory experiments limits the possibility of obtaining a continuous profile for the Edyn along the whole wellbore. On the other hand, the vertical resolution of the logging tool and the interference between the different formations significantly influence the accuracy of the well logging data.

where ρ is the bulk density of the rock (g/cm3), VS is the shear wave velocity (km/s), and VP is the compressional wave velocities (km/s).

Machine learning (ML) models were utilized successfully to estimate different parameters and to solve issues related to different aspects of petroleum engineering (Mahmoud et al., 2017; Ahmed et al., 2019; Mahmoud et al., 2020a; Mahmoud et al., 2020b; Al-Abduljabbar et al., 2021; Mahmoud et al., 2021a; Marquez, 2021; Noufal et al., 2021). In this study, the Ed-yn was correlated with the real-time measurable drilling parameters to enable real-time prediction of Edyn using three ML algorithms, namely, random forest (RF), adaptive neuro-fuzzy inference system (ANFIS-SC), and support vector regression (SVR).

2 Methodology

In this study, three ML models, namely, RF, ANFIS-SC, and SVR, were optimized to estimate Edyn from the drilling parameters, i.e., standpipe pressure (SPP), torque, drillpipe rotation speed (DSR), drilling fluid flow rate, weight-on-bit (WOB), and rate of penetration (ROP). Since these drilling parameters are obtained from the surface sensors in real-time during the drilling operation, their use could enable evaluation of the Edyn on a real-time basis.

2.1 Date description

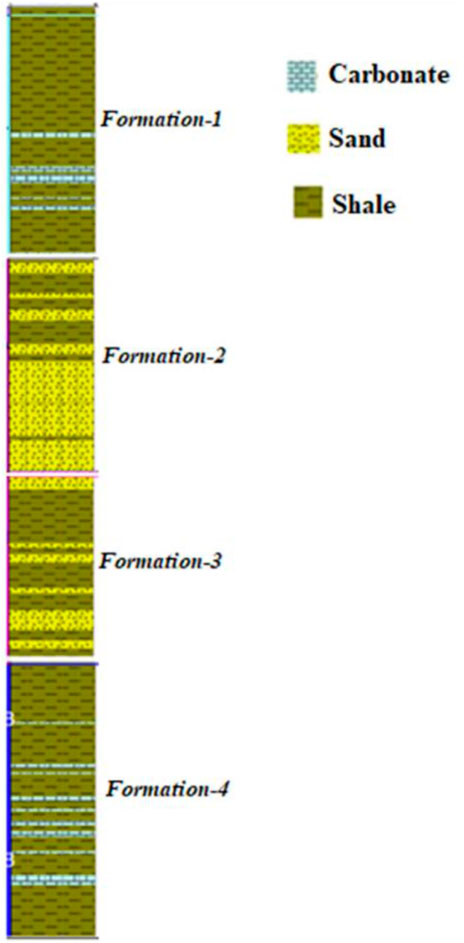

The drilling parameters and their corresponding Edyn values considered in this work were collected from three different wells; all wells are located in the same oil field from the Middle East. A total of 2054, 871, and 2912 datasets from Well-A, Well-B, and Well-C, respectively, were used to train the ML models on estimating Edyn. Well-A’s data were used to learn the ML models, as indicated in Figure 1, Well-A has complex lithology which consists of four formations of sand, shale, and carbonate.

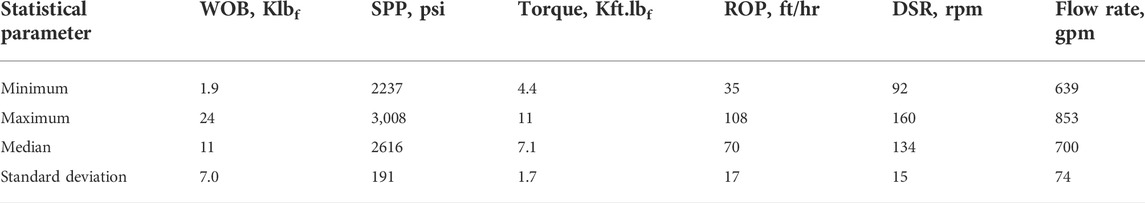

Table 2 lists the statistical features of the training data, which shows the applicable range of the optimized ML models. To ensure the high accuracy of the Edyn with the optimized ML models, the drilling data used to predict the Edyn must be within the range shown in Table 2.

2.1 Concepts of machine learning models

In total, three machine learning models were used in this work. The first model is the random forest (RF) which is a kind of ensemble model applicable to solve both regression and classification problems. In this model, hundreds or thousands decision trees are combined and trained on a slightly different set of observations. Then, in a process called bootstrapping, the splitting nodes of each tree considered only a limited number of input variables to decrease the variance and enhance the predictability of the algorithm (Efron, 1982). Finally, prediction through RF is achieved by averaging the predictions of all trees. RF was successfully applied to solve problems in petroleum engineering (Alsaihati et al., 2021; Osman et al., 2021).

The second model is the adaptive neuro-fuzzy inference system with subtractive clustering (ANFIS-SC). The adaptive neuro-fuzzy inference system (ANFIS) was developed in the early 1990s as a combination of artificial neural networks and fuzzy interference systems (Jang, 1991; Jang, 1993). This way, the ANFIS system could combine the advantages of both neural networks and fuzzy logic in a single model, and it is used mainly for classification purposes, as well as for regression problem. The subtractive clustering is used to group the data based on its potential density to identify the cluster center compared to the surrounding data points. Recently, ANFIS-SC showed high accuracy in solving petroleum engineering-related problems (Mahmoud et al., 2021b; Gamal et al., 2021).

The third model is support vector regression (SVR) which works based on the principles of the support vector machine (SVM) developed by Vapnik, 1998. The SVM was developed as a classification model, while SVR could be used to solve regression problems. Several previous studies showed the high accuracy of the SVR to identify different parameters related to the petroleum industry (Mahmoud et al., 2020c; Mahmoud et al., 2022).

2.3 Learning the machine learning models

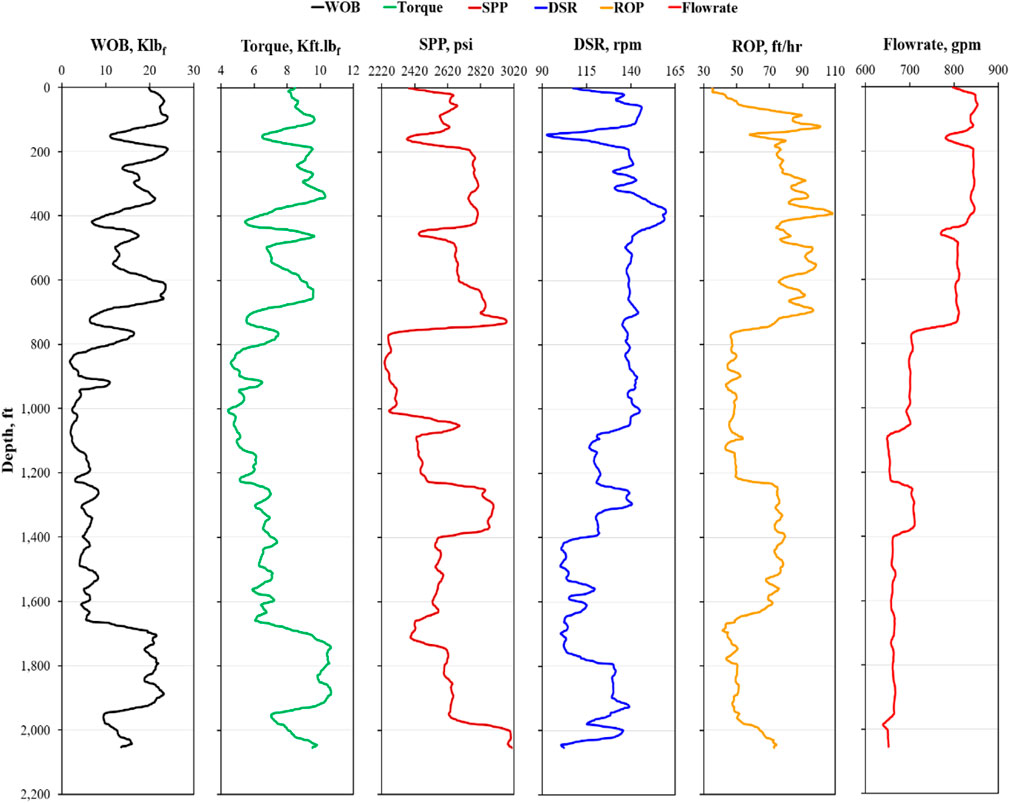

The ML models were trained and optimized in this work using the 2057 datasets of different input parameters collected from Well-A. These inputs are plotted in Figure 2 with the change of depth. To investigate the performance of the different design parameters of the RF, ANFIS-SC, and SVR algorithms in predicting Edyn, sensitivity analysis was performed on different combinations of these design parameters.

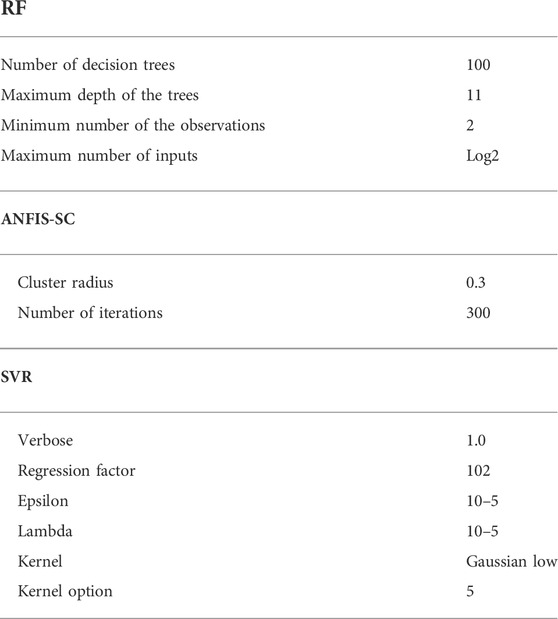

The RF model was optimized on its design parameters of the optimum number of decision trees, the maximum depth of the trees, the minimum number of observations, and the maximum number of inputs. The results showed that the RF model built with 100 decision trees, with a maximum depth of trees of 11, minimum number of observations of 2, and maximum number of inputs of log2, was the best in estimating the Edyn from the surface measurable drilling parameters.

Two design parameters of ANFIS-SC were optimized, namely, cluster radius and number of iterations. The use of cluster radius from 0.2 to 0.7 was evaluated with an increment of 0.05, while the use of iterations from 100 to 1,000 iterations was investigated. The results indicated that the optimum cluster radius was 0.3 when 300 iterations were considered to accurately predict the Edyn.

The SVR model was optimized for its design parameters of the kernel, kernel option, lambda, verbose, regression factor, and epsilon. The optimized SVR model was constructed with the “Gaussian low” kernel, kernel option of 5.0, lambda of 10–5, verbose of 1.0, regression factor of 102, and epsilon of 10–5.

To ensure evaluation of the performance of all design parameter combinations for the different ML models considered in this study, inserted for loops built in MATLAB software were used to optimize these parameters. Then, the optimum parameter combination was considered the one that predicted the Edyn with the lowest average absolute percentage error (AAPE) and highest correlation coefficient (R). The optimum parameters for all optimized models are listed in Table 3.

To avoid the model’s overfitting while training, the training data were subdivided into two subgroups, one considered for training (85% of the data) and the other group (15% of the data) was used for validation. The mean square errors for the training and validation data were observed during model training and as a function of the number of trials. These errors were decreasing with the number of trials until the model started memorizing the data because of overfitting, where the error for validation data started increasing with the number of trials, while the error for training data is still decreasing. To avoid overfitting, the optimum number of trials used to train all the ML models was then chosen as that before the validation error started increasing.

2.4 Evaluation of the accuracy of optimized models

After optimizing the ML models, they were tested using 871 data points obtained from the second well (Well-B), and finally, 2912 data points gathered from Well-C were considered for the model’s’ validation.

3 Results

3.1 Optimizing the RF, ANFIS-SC, and SVR models

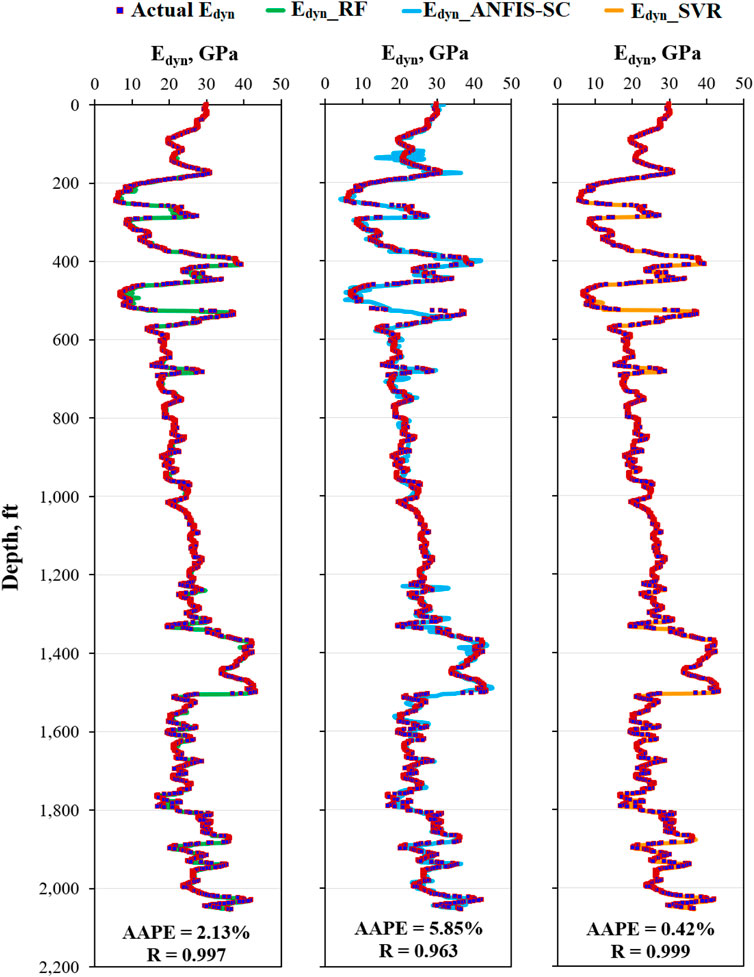

The RF, ANFIS-SC, and SVR models were learned to assess Edyn from the drilling data. The models were learned on the 2054 datasets of Well-A. Figure 3 and Figure 4 compare the actual and assessed Edyn in Well-A, respectively. The ideal matching of the actual Edyn with these predicted with the RF, ANFIS-SC, and SVR models as indicated in Figure 3 emphasizes the high precision of the optimized RF, ANFIS-SC, and SVR models, which predicted the Edyn with AAPEs of 2.13%, 5.85%, and 0.42%, and Rs of 0.997, 0.963, and 0.999, respectively.

FIGURE 3. Actual and assessed Edyn by the RF, ANFIS-SC, and SVR models for the 2054 training data points of Well-A.

FIGURE 4. Actual and assessed Edyn by the (A) RF, (B) ANFIS-SC, and (C) SVR models for the 2054 training data points of Well-A.

The cross-plots of Figure 4 also show that all the points fall in the vicinity of the 45° line, which also assures the high prediction reliability of the optimized RF, ANFIS-SC, and SVR models. As shown in Figure 4B, the coefficient of determination (R2) between the actual and estimated Edyn is 0.986. Previous results indicated that in terms of accuracy, the model could be arranged as SVR, RF, and ANFIS-SC.

3.2 Training the machine learning models

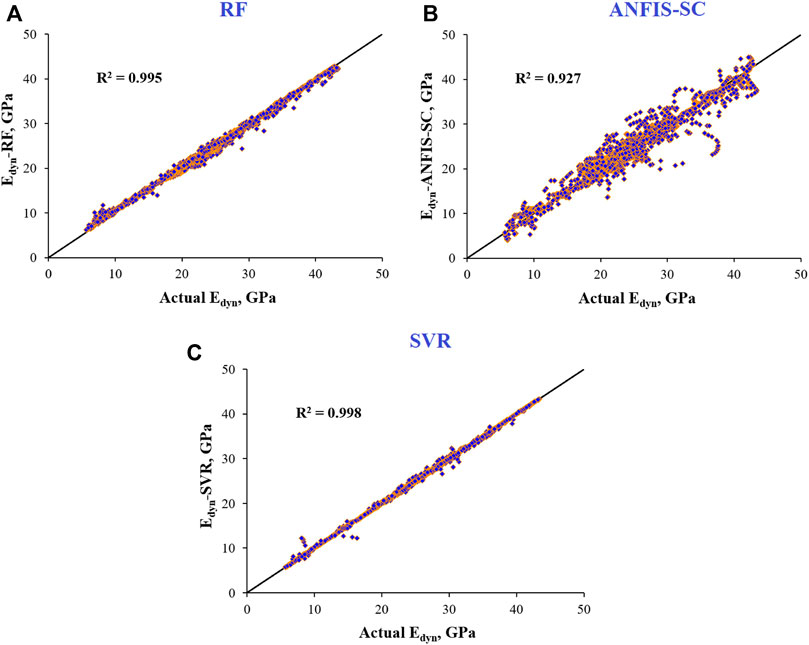

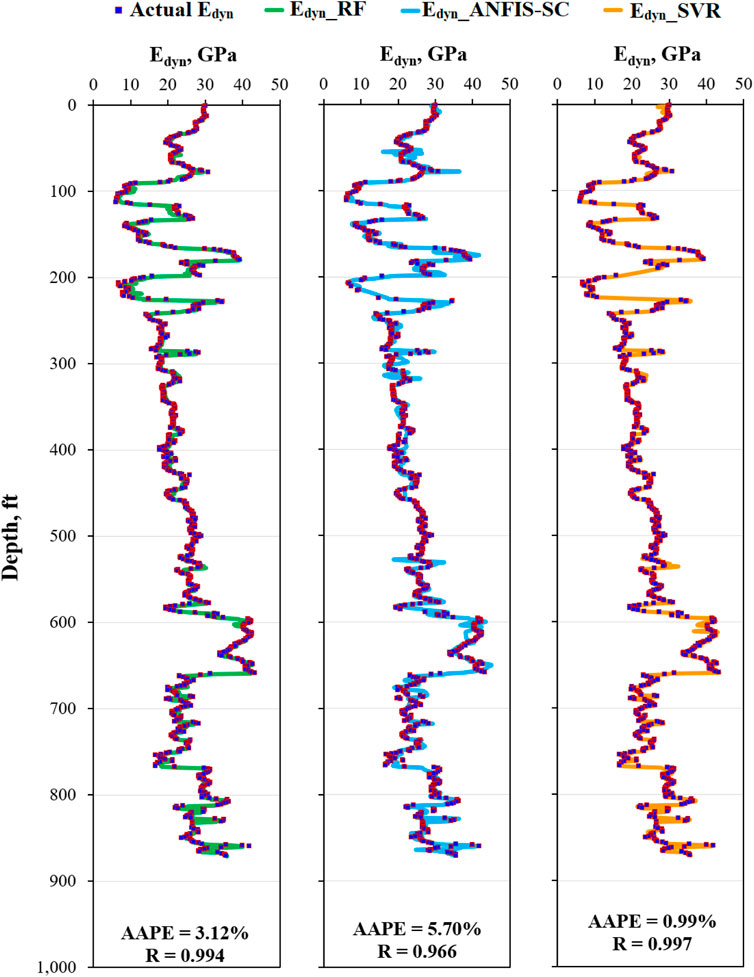

The RF, ANFIS-SC, and SVR models optimized in this study were then tested for Edyn assessment using Well-B data. Figure 5 and Figure 6 compare the actual and estimated Edyn in Well-B, respectively. Figure 5 shows that there is a perfect matching of the actual and evaluated Edyn, where the Edyn was predicted with AAPEs of 3.12%, 5.70%, and 0.99%, and Rs of 0.994, 0.966, and 0.997, using the learned RF, ANFIS-SC, and SVR models, respectively.

FIGURE 5. Actual and assessed Edyn by the optimized RF, ANFIS-SC, and SVR models for the 871 testing data points of Well-B.

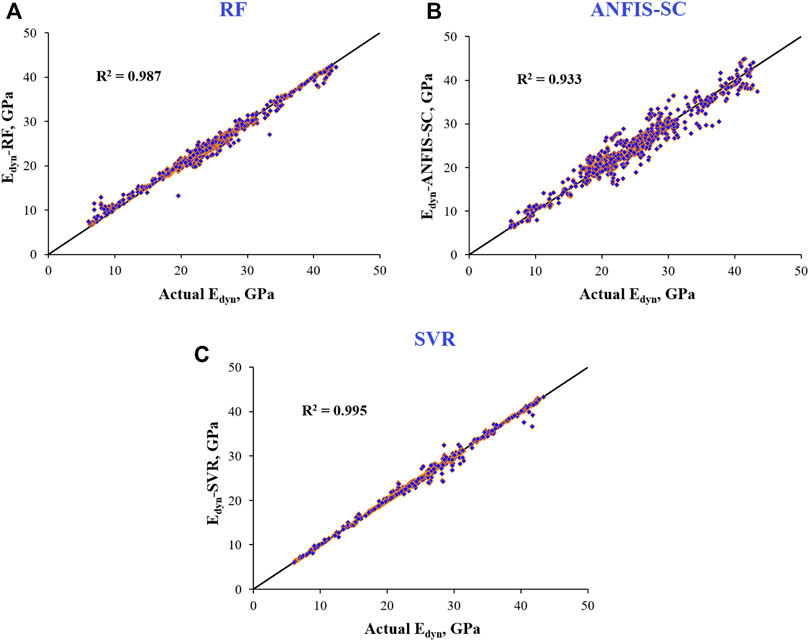

FIGURE 6. Cross-plots of the actual and assessed Edyn by the optimized (A) RF, (B) ANFIS-SC, and (C) SVR models for the 871 testing data points of Well-B.

As indicated in the cross-plots of Figure 6, all the points fall in the vicinity of the 45° line, which assures the high precision of the optimized RF, ANFIS-SC, and SVR models. The Edyn in the testing well was assessed with R2 of 0.987 using the RF model, 0.933 using the ANFIS-SC model, and 0.995 using the SVR model. Again, for the testing data, the optimized SVR model outperformed the other models in assessing the Edyn, followed by the RF model and then the ANFIS-SC model.

3.3 Validating the optimized random forest, ANFIS-SC, and support vector regression models

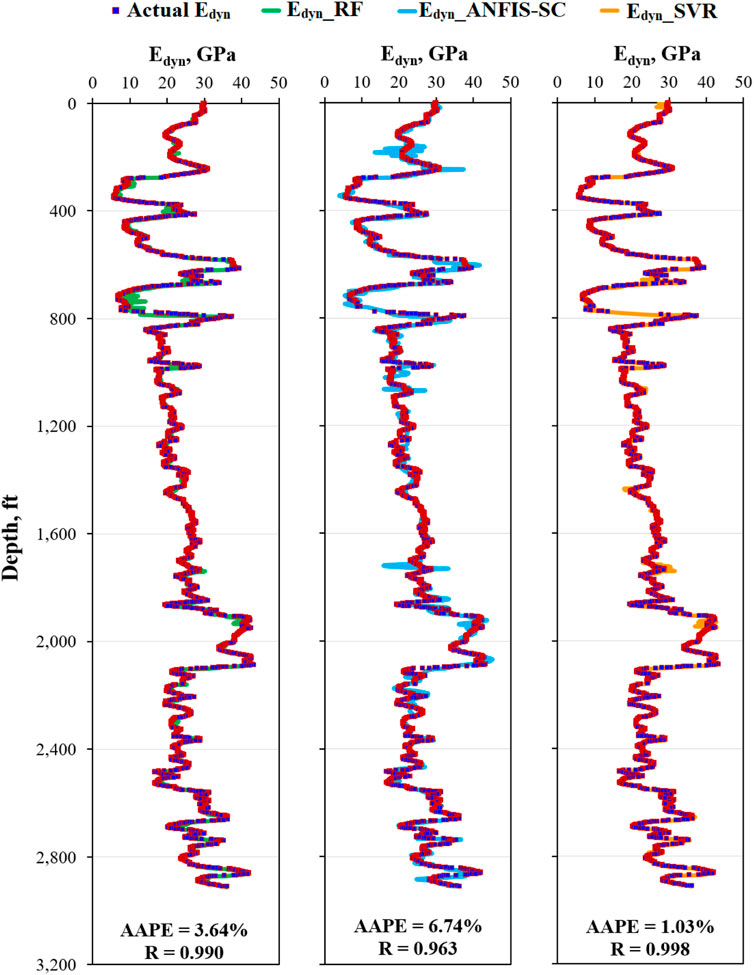

The optimized ML models were validated on the 2912 datasets of Well-C. Figure 7 and Figure 8 show the prediction accuracy of these models on evaluating Edyn for Well-C’s data. Figure 7 shows that the optimized SVR model was the most accurate among all models optimized in this work, and it assessed the Edyn accurately with a small AAPE of only 1.03% and an R of 0.998. The optimized RF model was the second most accurate, and it determined the Edyn with an AAPE and R of 3.64% and 0.990, respectively. The least precise model was the ANFIS-SC which assessed the Edyn with an AAPE of 6.74% and R of 0.963.

FIGURE 7. Actual and assessed Edyn by the optimized RF, ANFIS-SC, and SVR models, for the 2912 validation data points of Well-C.

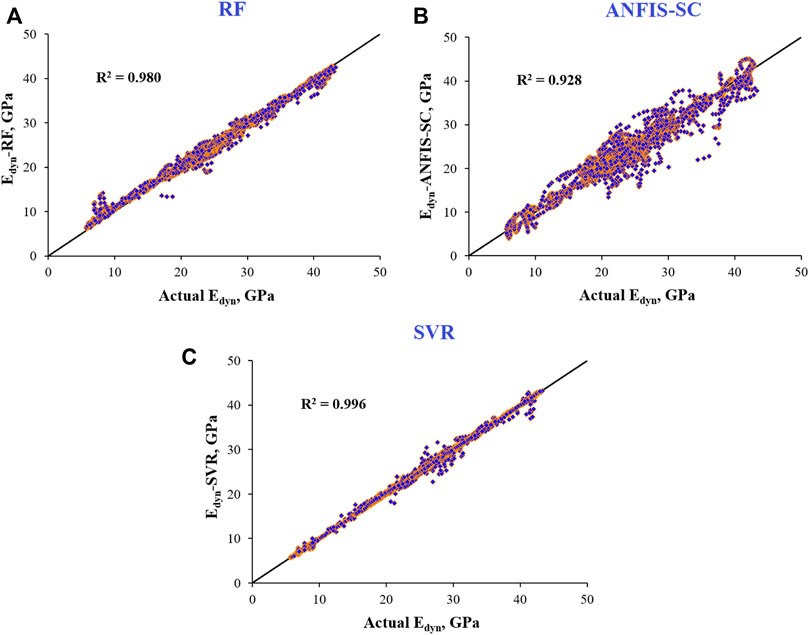

FIGURE 8. Cross-plots of the actual and assessed Edyn by the optimized (A) RF, (B) ANFIS-SC, and (C) SVR models for the 2912 validation data points of Well-C.

Visual comparison of Figure 8 also confirmed the optimized RF, ANFIS-SC, and SVR models evaluated the Edyn for the data of Well-C with R2s of 0.980, 0.928, and 0.996, respectively. This result also indicates the high reliability of the optimized models in evaluating the Edyn from the surface measurable drilling parameters only.

3.4 Comparing the precision of the random forest, ANFIS-SC, and support vector regression models

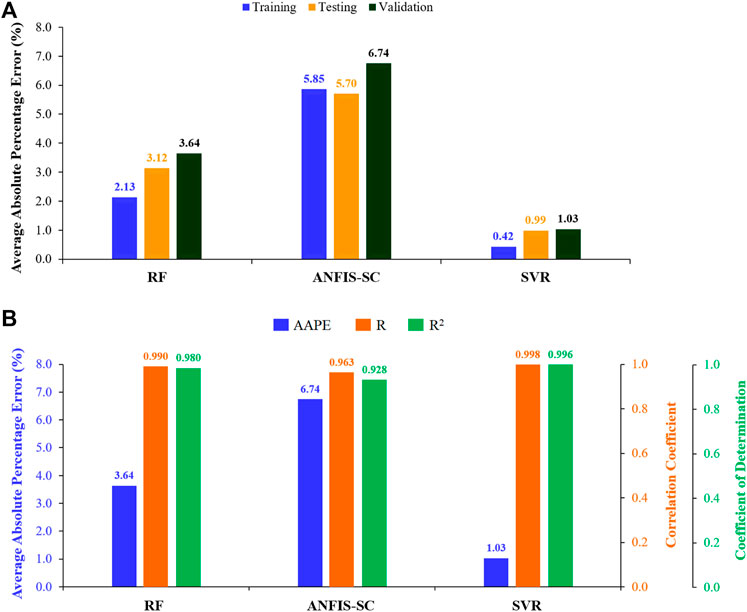

Figure 9 compares the accuracy power of the optimized models of RF, ANFIS-SC, and SVR on assessing the Edyn for training, testing, and validation data through evaluation of the accuracy measures of the AAPE, R, and R2. As indicated in Figure 9A, the SVR model estimated the Edyn with the lowest AAPE for training, testing, and validation data, followed by the RF model, and then the least accurate model was ANFIS-SC.

FIGURE 9. Comparison of the prediction accuracy of the optimized RF, ANFIS-SC, and SVR models; (A) AAPE for the training, testing, and validation data; and (B) the AAPE, R, and R2 for the validation data of Well-C.

Now, considering only the validation data of Well-C and the three measures of accuracy (Figure 9B), they also confirmed the high prediction power of the optimized SVR, which estimated the Edyn with the lowest AAPE of 1.03% and the highest R and R2 of 0.988 and 0.996, respectively.

The results showed the high precision of the optimized ML models in estimating the Edyn from the surface measurable drilling parameters; the use of these parameters enabled the possibility of real-time prediction of the Edyn.

4 Conclusion

Three ML models, namely, RF, ANFIS-SC, and SVR, were optimized for real-time assessment of the Edyn from the real-time available drilling parameters only. The ML models were optimized on 2054 datasets of the different input parameters and their corresponding Edyn and then tested and validated on 871 and 2912 datasets from another two wells. The following conclusion can be drawn based on this study:

• The three ML models accurately predicted the Edyn in the three oil wells considered in this study.

• The optimized SVR model was more accurate than the RF and ANFIS-SC models in evaluating the Edyn in all three wells.

• For the validation data, Edyn was assessed accurately with low AAPEs of 3.64%, 6.74%, and 1.03% using RF, ANFIS-SC, and SVR models, respectively.

• The use of the surface measurable drilling parameters enabled real-time assessment of the Edyn.

Data availability statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Author contributions

Conceptualization, SE; methodology, AM and HG; validation, AM, HG, and WC; formal analysis, AM and WC; writing—original draft preparation, AM; writing—review and editing, AM, SE, and WC; and supervision, SE.

Acknowledgments

The authors wish to acknowledge King Fahd University of Petroleum and Minerals for providing research facilities and permitting the publication of this work.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ahmed, S. A., Mahmoud, A. A., Elkatatny, S., Mahmoud, M., and Abdulraheem, A. (2019). “Prediction of pore and fracture pressures using support vector MachineMarch,” in Proceeding of the Paper IPTC-19523-MS Presented at the 2019 International Petroleum Technology Conference, Beijing, China, 26–28. doi:10.2523/IPTC-19523-MS

Al-Abduljabbar, A., Mahmoud, A. A., and Elkatatny, S. (2021). Artificial neural network model for real-time prediction of the rate of penetration while horizontally drilling natural gas-bearing sandstone formations. Arab. J. Geosci. 14, 117. doi:10.1007/s12517-021-06457-0

Alsaihati, A., Elkatatny, S., Mahmoud, A. A., and Abdulraheem, A. (2021). Use of machine learning and data analytics to detect downhole abnormalities while drilling horizontal wells, with real case study. J. Energy Resour. Technol. 143. doi:10.1115/1.4048070

Ameen, M. S., Smart, B. G. D., Somerville, J. M., Hammilton, S., and Naji, N. A., 2009. Predicting rock mechanical properties of carbonates from wireline logs (A case study: Arab-D reservoir, Ghawar field, Saudi Arabia). Mar. Pet. Geol. 26, 430–444. doi:10.1016/j.marpetgeo.2009.01.017

Asef, M. R., and Farrokhrouz, M. (2017). A semi-empirical relation between static and dynamic elastic modulus. J. Pet. Sci. Eng. 157, 359–363. doi:10.1016/j.petrol.2017.06.055

Barree, R. D., Gilbert, J. V., and Conway, M. (2009). “Stress and rock property profiling for unconventional reservoir stimulation,” in The SPE Hydraulic Fracturing Technology Conference, The Woodlands, Texas, January 19‐21, 2009. doi:10.2118/118703-MS

Bradford, I. D. R., Fuller, J., Thompson, P. J., and Walsgrove, T. R. (1998). “Benefits of assessing the solids production risk in a north sea reservoir using elastoplastic modelling”, in The SPE/ISRM Rock Mechanics in Petroleum Engineering, Trondheim, Norway, July 8‐10, 1998. doi:10.2118/47360-MS

Brotons, V., Tomás, R., Ivorra, S., Grediaga, A., Martínez-Martínez, J., Benavente, D., et al. (2016). Improved correlation between the static and dynamic elastic modulus of different types of rocks. Mat. Struct. 49, 3021–3037. doi:10.1617/s11527-015-0702-7

Brotons, V., Tomás, R., Ivorra, S., and Grediaga, A. (2014). Relationship between static and dynamic elastic modulus of calcarenite heated at different temperatures: The san julián’s stone. Bull. Eng. Geol. Environ. 73, 791–799. doi:10.1007/s10064-014-0583-y

Eissa, E. A., and Kazi, A. (1988). Relation between static and dynamic Young’s moduli of rocks. Int. J. Rock Mech. Min. Sci. Geomechanics Abstr. 25, 479–482. doi:10.1016/0148-9062(88)90987-4

Feng, C., Wang, Z., Deng, X., Fu, J., Shi, Y., Zhang, H., et al. (2019). A new empirical method based on piecewise linear model to predict static Poisson’s ratio via well logs. J. Pet. Sci. Eng. 175, 1–8. doi:10.1016/j.petrol.2018.11.062

Fjaer, E., Holt, R. M., Raaen, A. M., and Horsrud, P. (2008). Petroleum related rock mechanics. Netherlands: Elsevier Science. Volume 53.

Gamal, H., Elkatatny, S., and Mahmoud, A. A. (2021). Machine learning models for generating the drilled porosity log for composite formations. Arab. J. Geosci. 14, 2700. doi:10.1007/s12517-021-08807-4

Ghafoori, M., Rastegarnia, A., and Lashkaripour, G. R., (2018). Estimation of static parameters based on dynamical and physical properties in limestone rocks. J. Afr. Earth Sci. 137, 22–31. doi:10.1016/j.jafrearsci.2017.09.008

Hammah, R., Curran, J., and Yacoub, T. (2006). The influence of Young’s modulus on stress modelling results. Golden, Colorado: 41st U.S. Symp. Rock Mech. Golden Rocks 2006.

Horsrud, P. (2001). Estimating mechanical properties of shale from empirical correlations. SPE Drill. Complet 16, 68–73. doi:10.2118/56017-PA

Jang, J.-S. R. (1993). Anfis: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man. Cybern. 23 (3), 665–685. doi:10.1109/21.256541

Jang, J.-S. R. (1991). “Fuzzy modeling using generalized neural networks and kalman filter algorithm (PDF),” in The Proceedings of the 9th National Conference on Artificial Intelligence, Anaheim, CA, USA, 14–19 July. 2, 762–767.

Karagianni, A., Karoutzos, G., Ktena, S., Vagenas, N., Vlachopoulos, I., Sabatakakis, N., et al. (2017). Elastic properties of rocks. geosociety. 43, 1165. doi:10.12681/bgsg.11291

King, M. S., 1983. Static and dynamic elastic properties of rocks from the Canadian shield. Int. J. Rock Mech. Min. Sci. Geomechanics Abstr. 20, 237–241. doi:10.1016/0148-9062(83)90004-9

Labudovic, V. (1984). The effect of Poisson’s ratio on fracture height. J. Pet. Technol. 36, 287–290. doi:10.2118/10307-PA

Lacy, L. L. (1997). “Dynamic rock mechanics testing for optimized fracture designs,” in proceeding of the SPE Annu. Tech. Conf. Exhib. doi:10.2118/38716-MS

Lashkaripour, G. R. (2002). Predicting mechanical properties of mudrock from index parameters. Bull. Eng. Geol. Environ. 61, 73–77. doi:10.1007/s100640100116

Mahmoud, A. A., Elkatatny, S., Abduljabbar, A., Moussa, T., Gamal, H., and Al Shehri, D. (2020b). “Artificial neural networks model for prediction of the rate of penetration while horizontally drilling carbonate formations,” in Proceedings of the 54th US Rock Mechanics/Geomechanics Symposium, 28 June - 1 July.

Mahmoud, A. A., Elkatatny, S., Abdulraheem, A., Mahmoud, M., Ibrahim, O., and Ali, A. (2017). “New technique to determine the total organic carbon based on well logs using artificial neural network (white box),” in Proceeding of the Paper SPE-188016-MS Presented at the 2017 SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Saudi Arabia, April 24–27, 2017 (Dammam), 24–27. doi:10.2118/188016-MS

Mahmoud, A. A., Elkatatny, S., and Al Shehri, D. (2022). “Estimation of the static young's modulus for sandstone reservoirs using support vector regression,” in proceeding of the Paper presented at the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23. doi:10.2523/IPTC-22071-MS

Mahmoud, A. A., Elkatatny, S., and Al-Abduljabbar, A. (2021b). Application of machine learning models for real-time prediction of the formation lithology and tops from the drilling parameters. J. Petroleum Sci. Eng. 203, 108574. doi:10.1016/j.petrol.2021.108574

Mahmoud, A. A., Elkatatny, S., and Al-Shehri, D. (2020c). Application of machine learning in evaluation of the static Young’s modulus for sandstone formations. Sustainability 12 (5), 1880. doi:10.3390/su12051880

Mahmoud, A. A., Elkatatny, S., Alsabaa, A., and Al Shehri, D. (2020a). “Functional neural networks-based model for prediction of the static young's modulus for sandstone formations,” in Proceedings of the 54th US Rock Mechanics/Geomechanics Symposium, 28 June - 1 July.

Mahmoud, A. A., Gamal, H., Mutrif, O., and Elkatatny, S. (2021a). “Artificial neural networks-based equation for real-time estimation of the dynamic young's modulus,” in Proceeding of the Paper presented at the 55th U.S. Rock Mechanics/Geomechanics Symposium, Virtual.

Marquez, F. J. (2021). “Drilling optimization applying machine learning regression algorithms,” in Proceeding of the Paper presented at the Offshore Technology Conference, Virtual and Houston, Texas, 16–19. doi:10.4043/30934-MS

Martínez-Martínez, J., Benavente, D., and García-del-Cura, M. A. (2012). Comparison of the static and dynamic elastic modulus in carbonate rocks. Bull. Eng. Geol. Environ. 71, 263–268. doi:10.1007/s10064-011-0399-y

Najibi, A. R., Ghafoori, M., Lashkaripour, G. R., and Asef, M. R. (2015). Empirical relations between strength and static and dynamic elastic properties of Asmari and Sarvak limestones, two main oil reservoirs in Iran. J. Pet. Sci. Eng. 126, 78–82. doi:10.1016/j.petrol.2014.12.010

Nes, O.-M., Fjær, E., Tronvoll, J., Kristiansen, T. G., and Horsrud, P. (2005). “Drilling time reduction through an integrated rock mechanics analysis,” in Proceeding of the SPE/IADC Drill. Conf, Amsterdam, Netherlands, February 23–25, 2009. doi:10.2118/92531-MS

Noufal, A., Sreekantan, J., Belmeskine, R., Amri, M., and Benaichouche, A. (2021). “Machine learning in computer vision software for geomechanics modeling,” in proceeding of the Paper presented at the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 15 – 18 November. doi:10.2118/208049-MS

Osman, H., Ali, A., Mahmoud, A. A., and Elkatatny, S. (2021). Estimation of the rate of penetration while horizontally drilling carbonate formation using random forest. J. Energy Resour. Technol. 143. doi:10.1115/1.4050778

Keywords: dynamic Young’s modulus, drilling parameters, machine learning models, real-time prediction, composite formation

Citation: Mahmoud AA, Gamal H, Elkatatny S and Chen W (2022) Real-time evaluation of the dynamic Young’s modulus for composite formations based on the drilling parameters using different machine learning algorithms. Front. Earth Sci. 10:1034704. doi: 10.3389/feart.2022.1034704

Received: 01 September 2022; Accepted: 28 October 2022;

Published: 11 November 2022.

Edited by:

Qinzhuo Liao, China University of Petroleum, ChinaReviewed by:

Ibrahim Mohamed, Advantek Waste Management Services, United StatesAhmed Alsaihati, Saudi Aramco, Saudi Arabia

Copyright © 2022 Mahmoud, Gamal, Elkatatny and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Salaheldin Elkatatny, ZWxrYXRhdG55QGtmdXBtLmVkdS5zYQ==

Ahmed Abdulhamid Mahmoud

Ahmed Abdulhamid Mahmoud Hany Gamal

Hany Gamal Salaheldin Elkatatny

Salaheldin Elkatatny Weiqing Chen

Weiqing Chen