95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci. , 03 January 2022

Sec. Geohazards and Georisks

Volume 9 - 2021 | https://doi.org/10.3389/feart.2021.803721

This article is part of the Research Topic Monitoring, Early Warning and Mitigation of Natural and Engineered Slopes View all 15 articles

Groundwater leakage in the loess gully terrain is one of the main hazards of coal seam mining at shallow burial depth. The burial depth of the 5−2 coal seam is less than 50 m from the ground in the gully of the study site. The fissures that expand upward after mining can easily penetrate the ground to form a water-conducting channels. During rainy periods, there is a potential risk of groundwater leakage. In order to reveal the characteristics of plane development and the dynamic evolution of gully ground fissures, the typical U-shaped gully in the northern Shaanxi coal mine was studied using the field measurement methods of “On-site measurement” and UAV aerial photography. Based on the experimental platform of ground fissure leakage developed and designed by the team, an indoor test model corresponding to the actual situation was established. In addition, the mathematical models of actual flood inrush, fissure width, and flood flow in the channel were established. The actual mine water flow and the mine drainage capacity were compared and analyzed, thus proposing criteria for classifying gully mining ground fissure collapsed water hazards. These criteria can provide theoretical references for predicting fissure leakage hazard zones in the ground gully of shallow buried coal seams. According to the development height of the water-conducting fissure zone (WCFZ), the treatment methods of ground fissures in gullies under different security conditions were designed, which was applied in the field with good results. The results showed that the treatment methods in this paper could effectively prevent the leakage of groundwater in the gullies along the ground fissures.

Coal resources are the main resource of China. Coal production in western China accounts for about 65% of the total production in China (Zhuo et al., 2018). In recent years, China has vigorously promoted the construction of large coal bases in the west. Effective development of coal resources in the west is an important guarantee for the energy needs of China. The land subsidence caused by coal mining leads to environmental damage and affects the normal land application (Chen et al., 2020). Coal resources of the Jurassic coal fields in northern Shaanxi are characterized by shallow burial and thin overlying bedrock (Huang, 2005; Huang 2009). Under geological conditions of the loess gully (Zhang et al., 2019; Lian et al., 2020; Duan et al., 2021), after the coal seam is retrieved, the top cover generally collapses as a whole due to the relatively simple structure of the overlying bedrock, making the WCFZ directly reach the ground (Liu et al., 2017; Prakash et al., 2018). Subsequently, the zone becomes a channel and pathway for groundwater to flow into the mining area (Wang et al., 2016; Zhang et al., 2015). After coal seam retrieval, the terrain of loess gully above the shallow buried coal seam can cause groundwater in the gully to leak downhole when mining the coal below and to the side, resulting in a severe threat of water leakage (Zhang et al., 2010; Ju and Xu, 2015; Hou et al., 2019; Yang et al., 2019). Therefore, mine water hazard control is still an important task in coal mine safety.

Xie et al. (2021) studied the formation mechanism and development height of hydraulic conductivity fissure zone in coal seam mining by field measurement. Yang et al. (2012) mastered the relationship between ground fissures and the progress of pushing mining and measured the amount of ground subsidence by establishing ground observation stations. Li et al. (2017) revealed that the ground fissures in the wind-deposited sand area had “M” type dynamic development characteristics with the self-healing characteristics of rapid closure. Some scholars predicted the development height of the WCFZ in coal seam retrieval by numerical simulation. In addition, scholars predicted the risk of groundwater leakage in the mining area by comparing the development height of the “two zones” with the burial depth of the coal seam roof (Zhang et al., 2012; Zhu et al., 2014). In recent years, the mining-induced fissures in coal seams and their water leakage problems have been studied from different perspectives (Ma et al., 2013; Xu et al., 2019; Hu and Zhao, 2021). However, only few quantitative analyses have been conducted to study the water leakage caused by mining ground fissures in shallow buried coal seam gullies and the risk of water hazards caused by leakage.

In order to solve the hazard of ground water leakage caused by shallow buried coal seam mining in western China, the dangerous degree of ground water leakage from shallow buried coal seams was calculated by the self-developed and designed water leakage test platform and based on the characteristics of ground fissure development in the field investigation. Through this study, some theoretical references can be provided for preventing and controlling water hazards from gully leakage in shallow buried coal seam overburden mining.

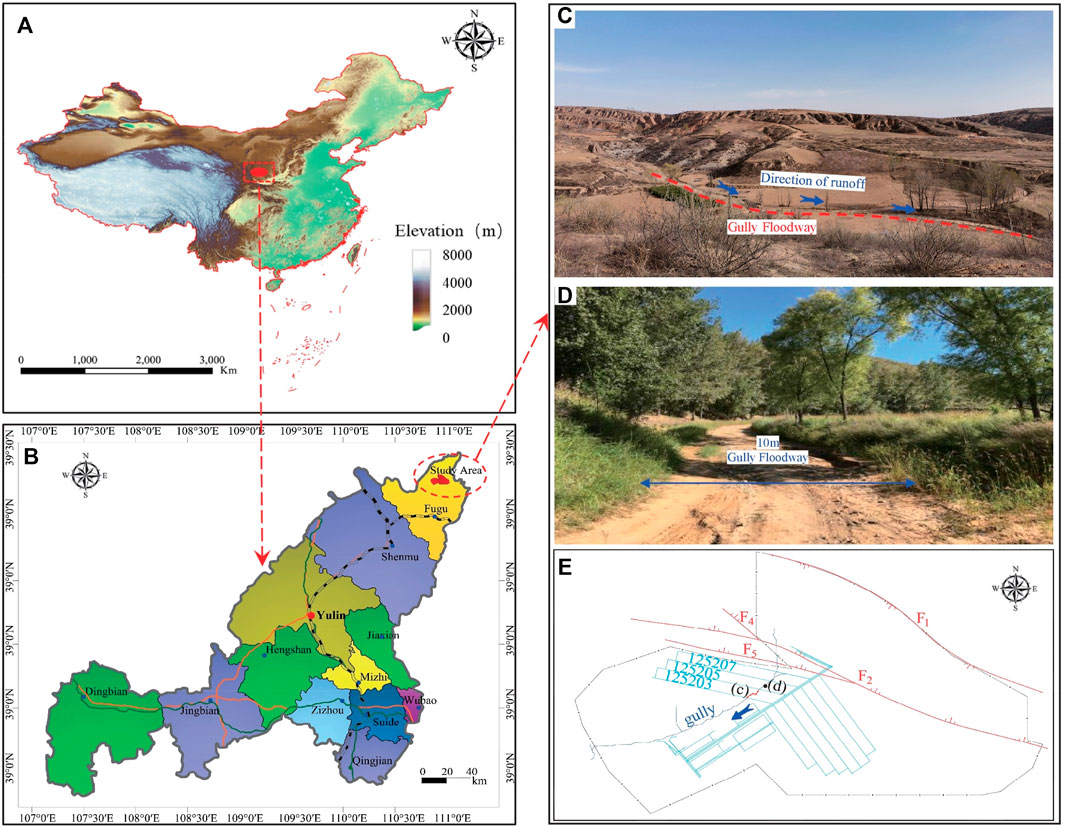

The study site is located in Fugu County, Yulin City, in the northeast corner of the Shenfu mining area of the Jurassic coalfield in northern Shaanxi Province. The study site is cut gully erosion, and the gullies are developed in different directions, showing a loess gully landscape. The study site is located in the interior of western China. The rainfall is mainly concentrated in July to September, accounting for 64% of the total annual rainfall, especially the most in July, with an average of 128.48 mm, accounting for 25.56% of the total annual rainfall. The high frequency of heavy rainfall is likely to cause floods and other geological hazards.

Figure 1 shows the specific location of working faces 125203, 125205, and 125207 in the study site. The above working faces are located in the west-central part of the mine, diagonally crossing the gully, at an angle of orientation approximately 45° to the direction of the gully. The gully is seasonally flowing, and the bedrock is exposed in the lower part of the gully. The bedrock is mainly covered by the Neoproterozoic laterite and Quaternary loess above the bedrock. The average mining height of the above working faces is 2.31 m, and the comprehensive mechanized coal mining process is used for recovery. In the bottom area of the gully, the burial depth of the 5−2 coal seam is about 20–35 m. Figure 2 shows the over-gully profile of the working face in the study site.

FIGURE 1. Location and topography of the working face in the study site. (A) Location of study area in China; (B) Location of study area in Yulin, China; (C) Site map of gully morphology; (D) Site map of gully floodway.

A hazard zoning prediction of gully leakage in shallow buried coal seam was proposed using the experimental platform of ground gully fissure leakage independently developed and designed by the team. The specific process of the proposed prediction method is shown in Figure 3 and is divided into five steps.

First step: UAV remote sensing technology was used to largely map the ground fissure characteristics of the typical working face retrieved in the study site, so as to grasp the characteristics of ground fissure development in the gully. Through on-site measurement, its plane spreading pattern and dynamic full development process are mastered.

Second step: The flood flow of the main channel in the study site was obtained through the field measurement of the overwater cross-section, the height of the flood level scour line, the channel development characteristics, and the formula calculation method.

Third step: The relationship between gully flood leakage, gully fissure width, and gully flood flow was simulated by converting the similar ratio between indoor experiments and actual geological conditions in the study site using the above-mentioned platform. The amount of gully flood leakage can be determined by observing water leakage at different flow rates and fissure widths.

Fourth step: After establishing the criteria for classifying gully flooding hazards, the prediction results of different gully water leakage hazards were obtained by comparing the current situation of mine water gushing and the drainage capacity of the mine drainage system.

Fifth step: Based on the prediction of gully leakage hazard, bubble fissure safety zoning, and ground land type, different treatment methods of ground gully fissures were proposed.

According to the actual production plan of the mine, the scope of the field investigation is the gully section of 125203 working face retrieval. By applying UAV remote sensing technology and actual on-site measurements, the dynamic development pattern of ground fissures and the development characteristics of the ground fissure plane, including the development number, location, and the development width of ground fissures, are shown.

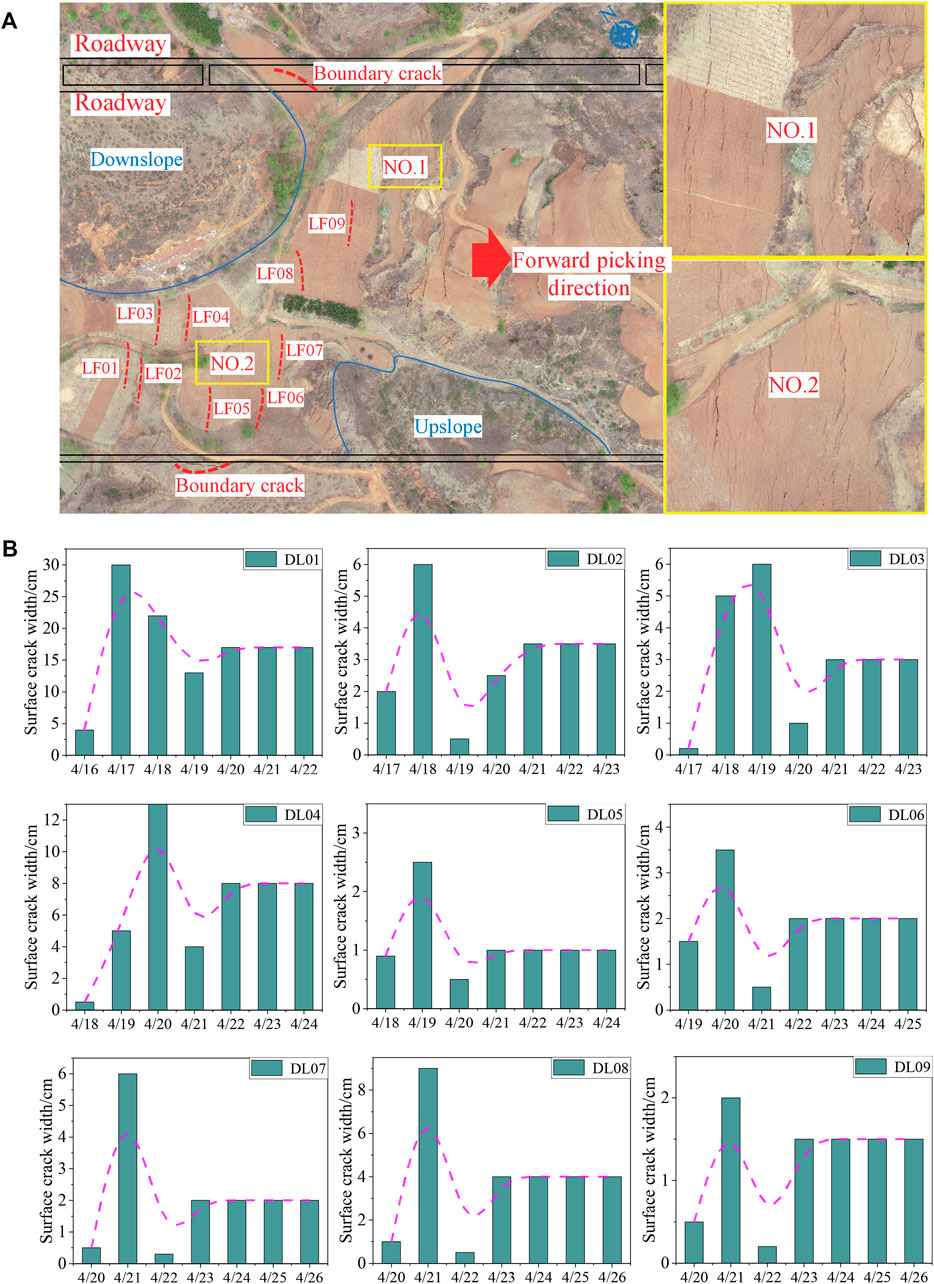

The dynamic development of the fissures at the bottom of the gully in the study site from the initial appearance to the stable development stage was measured in the field. Figure 4 shows the whole process of the dynamic changes of 10 typical ground fissures in the gully area of the 125203 working face. The ground fissures cannot be completely closed during the whole stage of “initial appearance → maximum development width → stable.” The whole development cycle is about 5 days.

FIGURE 4. Aerial photography and actual measurement of ground fissures on site: (A) Aerial photograph of ground fissures after retrieval; (B) Dynamic development characteristics of ground fissures in the gully.

By fitting the maximum width to the stable width, the linear positive correlation function is satisfied. The fitted curve equation is shown in Figure 5. The specific fitted linear regression model equation is Widthstab = 0.57816 × Widthmax−0.3441, R2 = 0.9809.

The ground fissures in the gully cannot be completely closed during the whole stage of “initial appearance → maximum width of development → stability.” According to the development characteristics of ground fissures, the treatment of ground fissures must be conducted at the end of the gully in the working face to avoid the potential risk of water leakage in the mine gully.

After completing over-gully retrieval of 125203 working faces and the dynamic evolution of ground fissures, the stable width of ground fissures in parallel open-off cut at the bottom of the gully in the study site was measured again on May 8, 2020. A total of 50 ground fissures were investigated. Among these fissures, 3 of them have a width less than 5 cm, accounting for 64%; 10 of them have the width of 5–10 cm, accounting for 20%; 5 of them are 10–20 cm in width, accounting for 10%; 3 have a width greater than 20 cm, accounting for 6% (Figure 6).

The geological conditions of working faces 12503, 125205, and 125207 in the study site are the same through field exploration near the working faces and drilling exploration in the vicinity of the study site. The development of ground fissures in the gully when the over-gully section of 125203 working face was retrieved from the site showed that about 100 ground fissures were generated in the over-gully section after 125203 working face was retrieved (Figure 4A), and the length of the over-gully section reached about 450 m within the 125203 working face. The ground fissures after gullying in the 125205 and 125207 working faces were compared and analogously analyzed. The length of the gullying section in the 125205 working face was about 400 m, and the length of the gullying section in the 125207 working faces was about 300 m. The analogous analysis of ground fissure number in different widths in the 125203 working face showed that about 90 ground fissures were generated after the over-gullying in working face 125205, and 68 ground fissures were generated after the over-gullying in working face 125207.

Whether the groundwater of the gully during the rainy season causes water hazards in the mine requires the following three conditions:

1) Whether there is a river on the ground, or whether there will be rainfall when the surface cracks occur.

2) Whether groundwater routing channels can be formed after the coal seam is retrieved.

3) Whether the amount of groundwater flowing from the gully into the underground mining area during rainfall (Qre-dr) is greater than the remaining drainage capacity of the mine drainage system (Bq—the difference between the mine drainage capacity and the normal mine surge).

Combining the rainfall characteristics of the study site, the 5-year flood flows for the study site watersheds were calculated using the formula for flood flows in small watersheds applicable to the study site:

where Q5% represents the 5-year flood flow (m3/s); F represents the designed watershed area (km2); J represents the average specific drop in the main channel (‰), J = 11.49‰ (measured on topographic and geological maps); H6p represents the duration of rainstorms with a design frequency of 6 h (mm), based on Yulin Hydrology Manual, H6p = 56 mm.

The results of the 5-year flood flow calculation for each working face in the study site are shown in Table 1.

In the vertical direction, whether the ground fissure in the study site becomes a channel of water collapse affecting mine safety production can be determined by comparing the difference in the burial depth of coal seam (Dm) and the development height of the WCFZ (HWCFZ) after coal seam retrieval. If Dm—HWCFZ < 0, the ground fissure will penetrate the surface and become a channel and path for groundwater to flow into the mining area.

Based on the statistical results of the development height of the “three zones” in the shallow buried coal seam in Yushen mining area, Wang et al. (2020) suggested that the development range of the upstream fissure zone should be selected according to the fissure mining ratio of 18–28 times.

According to the geological conditions of the study site and many previous studies (Fan et al., 2019), the guide height of the comprehensive mining working face is generally 21–30 times the mining height, about 26 times on average. The riser height is generally 2.12–6.97 times the mining height, about 5 times on average.

Based on the statistical results of the development height of the “three zones” in the shallow buried coal seam in the Yushen mining area (Fan et al., 2019; Wang et al., 2020), the height of WCFZ is generally 21–30 times of the mining height, about 26.5 times on average, and the height of FZ is generally 2.12–6.97 times of the mining height, about 5 times on average.

In this study, WCFZ of the comprehensive mining working face is selected 26.5 times the mining height, and FZ of the comprehensive mining working face is selected 5 times the mining height.

where Hm is the coal seam mining height and HFZ is the height of the FZ.

where Hm is the coal seam mining height and HWCFZ is the height of WCFZ.

Figure 7 shows the contour map of the development height of the WCFZ of 5−2 coal seam.

According to the site survey, the actual width of the bottom of the gully is 10 m, and the bottom of the leakage gully in the experiment is 0.4 m. Therefore, the determined model ratio with the corresponding geometric ratio is 25:1.

In order to improve the safety of conversion according to the proportional model, the ground fissure width developed in each interval section was calculated according to the maximum width of the fissure in that section when calculating the gully leakage. Due to the limited experimental conditions, ground fissures with a width less than 20 cm were calculated using 50 cm as the maximum limit value to obtain the gully fissure width values required for the experiment (Table 2).

By simulation experiments, the leakage amounts with ground fissure width of 0.2, 0.4, 0.8, and 2.0 cm and the leakage amount of gully with different flood flows and different experimental widths were obtained (Table 3).

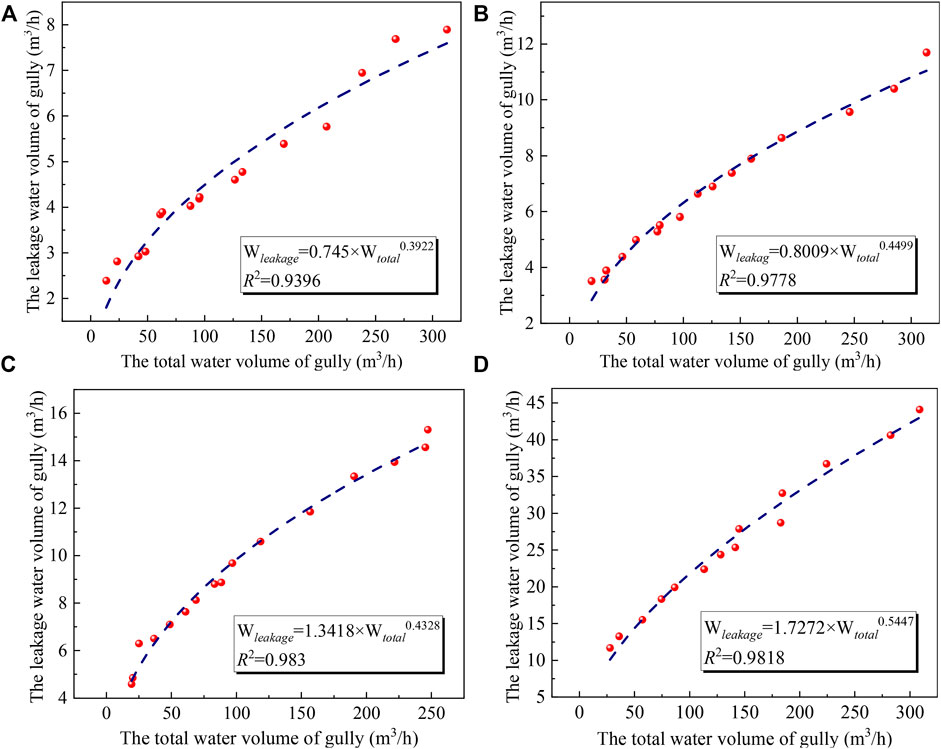

The experimental data on gully leakage of ground fissures of different widths and water flows were compiled and analyzed. In this way, the relationship between the total water volume of a single ground fissure that is not of the same width and the amount of gully leakage was obtained. The regression relationship is shown in Figure 8.

FIGURE 8. Leakage for different experimental fissure widths: (A) 0.20 cm; (B) 0.40 cm; (C) 0.80 cm; (D) 2.00 cm.

The above relationship shows that the overall positive correlation trend between gully leakage and total gully water. The geometric model ratio of λL = 25:1 was obtained according to the ratio of the actual width of the river channel to the width of the experimental model channel.

The indoor leakage experimental platform was designed according to the gravity similarity criterion. The corresponding ratios are: the corresponding total water flow ratio is λQ = λL2.5 = 252.5 = 3125:1; the flow velocity ratio is λV = λL0.5 = 250.5 = 5. Since the initial velocity of both the experimental platform and the actual gully water flow is 0, the corresponding leakage ratio is consistent with the geometric ratio of λL = 25:1 (Wei et al., 2019).

Converting the geometric and flow ratios of the above experimental model to the actual model, and based on the leakage reduction coefficients of the study site with similar geological conditions by the study (Hou et al., 2020), the leakage volume between different flood volumes and seam widths in the gully under actual conditions in the region is obtained by the following equations:

1) When the actual seam width of the gully is <5 cm:

2) When the actual seam width of the gully is 5–10 cm:

3) When the actual seam width of the gully is 10–20 cm:

4) When the actual seam width of the gully is >20 cm:

where q is represents single fissure leakage (m3/h); a = 0.3 is the leakage discount factor [9]; Qf represents actual flood volume in the gully (m3/h); λL is the geometric ratio between the experiment and the practical situation; λQ is the flow ratio between the experiment and the practical situation.

The average water output of the mine in 2018 in the study site was 27.5 m3/h, and the maximum water output was 46.4 m3/h. In 2019, the average water output of the mine was 30.27 m3/h, and the maximum water output was 38.5 m3/h. In 2020, the average water output of the mine was 40.81 m3/h, and the maximum water output was 45 m3/h.

The water flow in the underground production process and the configuration of the drainage system show that the maximum drainage capacity (Qdr-max) of the mine drainage system is 360 m3/h.

The remaining drainage capacity (Qre-dr) of the mine can be obtained by subtracting the maximum daily drainage amount by the actual drainage capacity of the drainage system (Qm-max).

By applying the characteristics of ground fissure development in the study site obtained in the previous paper, the amount of gully outburst water (Bq) of different working faces was calculated for comparing the amount of gully outburst water with the remaining drainage capacity. In this way, the risk degree of water hazard from gully outburst water in the study site could be determined. If Qre-dr > Bq, the risk is low; if Qre-dr < Bq, the risk is high. The specific results are shown in Table 4.

According to the evaluation of the degree of risk of water hazard from gully collapse, the ground fissures should be treated after the end of over-gully retrieval in the working face of the study site to avoid potential water hazards from gully collapse in the mine.

A ground fissure treatment grade based on the correspondence between the development height of HWCFZ and Dm is created according to Dynamic Evolutionary Characteristics of Ground Fissures, as shown in Table 5. This treatment grade provides a scientific basis for the accurate and efficient treatment of different types of ground fissures.

The relationship between the burial depth of the 5−2 coal seam in the study site and the development height of the hydraulic conductivity fissure zone after mining the coal seam is analyzed. The type of fissure in the gully section of the study site is predicted by the classification criteria of fissure safety in the mining gully. The predicted results of the safety zoning of fissure in the overlying rock layer of the 5−2 coal in the gully of the study site are given in Figure 9.

According to the ground fissure development characteristics of the gully after the 5−2 coal seam retrieval and the water collapse level map of different gully sections in the study site, if the retrieval location 125203, 125205, and 125207 working faces pass through the gully before the onset of the rainy season from July to September, the water catchment area at the bottom of the gully will easily collapse into the well along the ground fissure, posing a certain threat of water collapse and water hazards to the safe retrieval of the working faces.

The results of the field measurements show that the ground fissures are stable after 5 days. In order to avoid the secondary fracture of ground fissures to destroy the treatment effect, 1 week after the working face is completely mined over the gully, the ground fissures in the gully should be treated in time and completed before the rainy season comes. The main factor affecting the amount of water leakage from the working face is the width of the surface cracks. The indoor leakage experimental platform obtained the amount of leakage from ground fissures of different widths in gullies, and found the overall positive correlation trend between gully leakage and total gully water.

Converting the geometric and flow scales of the above experimental model to the actual model, and the actual water leakage hazards on different working faces are obtained. The results of water leakage experiments show that if the working face is not treated after mining, there is a certain threat of water leakage risk in the mine.

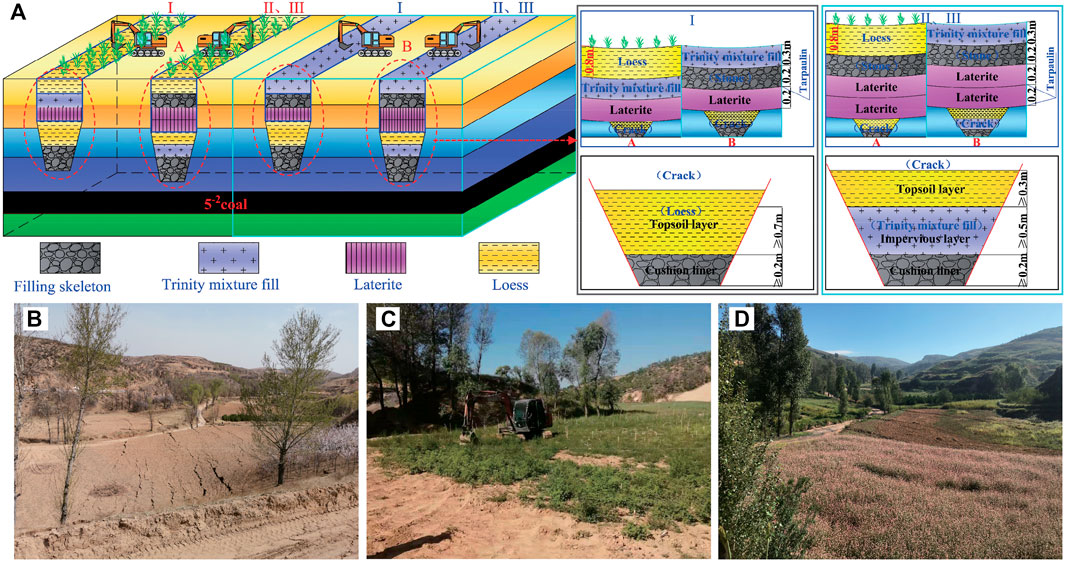

A ground fissure treatment grade based on the correspondence between the development height of HWCFZ and Dm, the grades of different working faces in the study site are Type “I” and Type “II.” Based on the above, in order to reduce the treatment cost and shorten the period, different grades of treatment methods are proposed. In the following, the 125203 working face is taken as an example to discuss the treatment of ground fissures.

Firstly, the ground was excavated as a whole. Secondly, “I” type was backfilled according to “cushion liner” and “topsoil layer.” “II and III” types were backfilled according to “cushion liner,” “impervious layer,” and “topsoil layer.” Finally, the excavated river was treated from bottom to top with red clay, gravel, interlayer tarpaulin, trinity mixture fill, or loess. The specific number and thickness of backfill layers are shown in Figure 10. If the treatment area is farmland (area A), the thickness of the topsoil layer after excavation and backfilling needs to reach 0.8 m, and the filling material is loose loess to ensure normal cultivation after treatment. After excavation and backfilling in area B, the thickness of the topsoil layer needs to be greater than 0.3 m, and the filling material is trinity mixture fill. When the safety of fissure is “IV,” it is safe. After the workings are retrieved, the water-conducting fissured zone will not penetrate the ground. There is no threat of water leakage or water hazard in the mine, so there is no need for treatment. After ground treatment, the original slope of the terrain will be maintained and not affect the normal flooding.

FIGURE 10. Diagram of ecological restoration and treatment effects: (A) treatment repair schematic; (B) before treatment; (C) during treatment; (D) after treatment.

In this study, the quantitative calculation and risk prediction of water leakage caused by surface cracks in gully terrain are carried out, on the basis of which the corresponding treatment methods are put forward. The research results were applied in the field treatment of Anshan coal mine in Shaanxi, which proved the practicality and reliability of the method. The main conclusions are drawn as follows:

1) In this study, we have used the self-developed and designed water leakage test platform, and the mathematical prediction model between the amount of gully flood leakage and the width of gully fissures and gully flood flow was obtained. The prediction model shows that the overall positive correlation trend between gully leakage and total gully water is changing.

2) Given the water hazard in mines caused by frequent flowing water in the gully and flooding along with the mining fissures during heavy rainfall seasons, the criteria for classifying the risk of water leakage from the mining fissures in the gully were proposed. Besides, a method for predicting the amount of water leakage from the mining fissures in the gully was proposed, and the safety of bubbling fissures was evaluated.

3) The zoning of the risk of water leakage was divided according to the remaining drainage capacity of the mine. The dynamic development of mining ground fissures is about 5 days. Therefore, the treatment of ground fissures in the gully should be started 1 week after the shallow buried coal seam is completely retrieved over the gully and mined back, which can better ensure the treatment effect. The field application results show that the treatment method can effectively prevent water hazards by mining ground fissures in the gully, which is of significance to prevent gully collapse accidents and improve coal mine safety production.

The original contributions presented in the study are included in the article/supplementary material. Further inquiries can be directed to the corresponding authors.

DF and EH designed the study; DF, XX, and PH investigated the ground fissures; DF, XC, and TL completed the water leakage experiment process; DF analyzed the information obtained from the experiment; DF and EH improved the manuscript draft. All authors have read and agreed to the published version of the manuscript.

This research was supported by the National Natural Science Foundation of China (No. 42177174), the Basic Research Program of Natural Science of Shaanxi Province (2020ZY-JC-03), and the Shaanxi Province Joint Fund Project (2021JLM-09).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Chen, Q., Li, J., and Hou, E. (2020). Dynamic Simulation for the Process of Mining Subsidence Based on Cellular Automata Model. Open Geosciences 12, 832–839. doi:10.1515/geo-2020-0172

Duan, Z., Yan, X., Sun, Q., Tan, X., and Dong, C. (2021). Effects of Water Content and Salt Content on Electrical Resistivity of Loess. Environ. Earth Sci. 80, 1–15. doi:10.1007/s12665-021-09769-2

Fan, L. M., Ma, X. D., Jiang, Z. Q., Sun, K., and Ji, R. J. (2019). Review and Thirty Years prospect of Research on Water-Preserved Coal Mining(in Chinese). Coal Sci. Tech. 47, 1–30. doi:10.13199/j.cnki.cst.2019.07.001

Hou, E. K., Che, X. Y., Feng, J., Duan, Z. H., Gao, L. J., and Li, J. (2019). Abundance of Aquifers in Yushenfu Coal Field and the Measures for Water-Preserved Coal Mining(in Chinese). J. China Coal Soc. 44, 813820. doi:10.13225/j.cnki.jccs.2018.6046

Hou, E. K., Che, X. Y., Long, T. W., Ye, Z. N., and Wen, Q. (2020). Prediction Method of Water Inrush from Ground Cracks in Shallow Buried Seams(in Chinese). J. China Coal Soc. 45, 4154–4162. doi:10.13225/j.cnki.jccs.2020

Hu, W., and Zhao, C. (2021). Evolution of Water Hazard Control Technology in China's Coal Mines. Mine Water Environ. 40, 334–344. doi:10.1007/s10230-020-00744-0

Huang, Q. X. (2005). Study on Loading Distribution Law on Key Roof and its Structure upon Mining Face under Thick sandy Layer(in Chinese). J. China Univ. Mining Tech. 34, 289–293. CNKI:SUN:ZGKD.0.2005-03-0 06.

Huang, Q. X. (2009). Simulation of clay Aquifuge Stability of Water Conservation Mining in Shallow-Buried Coal Seam(in Chinese). Chin. J. Rock Mech. Eng. 28, 987–992. CNKI:SUN:YSLX.0.2009-05-019.

Ju, J., and Xu, J. (2015). Surface Stepped Subsidence Related to Top-Coal Caving Longwall Mining of Extremely Thick Coal Seam under Shallow Cover. Int. J. Rock Mech. Mining Sci. 78, 27–35. doi:10.1016/j.ijrmms.2015.05.003

Li, L., Wu, K., Hu, Z. Q., Xu, Y. K., and Zhou, D. W. (2017). Analysis of Developmental Features and Causes of the Ground Cracks Induced by Oversized Working Face Mining in an Aeolian Sand Area. Environ. Earth Sci. 76, 1–12. doi:10.1007/s12665-017-6452-9

Lian, B., Peng, J., Zhan, H., Huang, Q., Wang, X., and Hu, S. (2020). Formation Mechanism Analysis of Irrigation-Induced Retrogressive Loess Landslides. Catena 195, 1–13. doi:10.1016/j.catena.2019.104441

Liu, H., Deng, K., Lei, S., Bian, Z. F., and Chen, D. Y. (2017). Dynamic Developing Law and Governance Standard of Ground Fissures Caused by Underground Mining(in Chinese). J. Min. Saf. Eng. 34, 884–890. doi:10.13545/j.cnki.jmse.2017.05.009

Ma, L. Q., Du, X., Wang, F., and Liang, J. M. (2013). Water-Preserved Mining Technology for Shallow Buried Coal Seam in Ecologically-Vulnerable Coal Field: A Case Study in the Shendong Coal Field of China. Disaster Adv. 6, 268–278.

Prakash, A., Kumar, N., Kumbhakar, D., Singh, A. K., and Paul, A. (2018). A Safe Depillaring Design for Shallow Depth of Cover with Influence of Surface Ground Movements: a Study in Jharia Coalfield. Arabian J. Geosci. 11, 1–8. doi:10.1007/s12517-018-3508-410

Wang, F., Tu, S., Zhang, C., Zhang, Y., and Bai, Q. (2016). Evolution Mechanism of Water-Flowing Zones and Control Technology for Longwall Mining in Shallow Coal Seams beneath Gully Topography. Environ. Earth Sci. 75, 1–16. doi:10.1007/s12665-016-6121-4

Wang, S. M., Shen, Y. J., Sun, Q., and Hou, E. K. (2020). Scientific Issues of Coal Detraction Mining Geological Assurance and Their Technology Expectations in Ecologically Fragile Mining Areas of Western China(in Chinese). J. Mining Strata Control. Eng. 2, 5–19. doi:10.13532/j.jmsce.cn10-1638/td.20200817.001

Wei, B. Q., Huang, L., Yuan, H. S., Li, L. B., and Jin, H. X. (2019). Hydraulic Characteristics and Optimization of Fishway Combined with Vertical Slot and Nature-like Section(in Chinese). Hydro-Sci. Eng. 4, 9–16. doi:10.16198/j.cnki.1009-640x.2019.04.002

Xie, X., Hou, E., Wang, S., Sun, X., Hou, P., Wang, S., et al. (2021). Formation Mechanism and the Height of the Water-Conducting Fractured Zone Induced by Middle Deep Coal Seam Mining in a Sandy Region: A Case Study from the Xiaobaodang Coal Mine. Adv. Civil Eng. 2021, 1–11. doi:10.1155/2021/6684202

Xu, Y., Wu, K., Li, L., Zhou, D., and Hu, Z. (2019). Ground Cracks Development and Characteristics of Strata Movement under Fast Excavation: a Case Study at Bulianta Coal Mine, China. Bull. Eng. Geol. Environ. 78, 325–340. doi:10.1007/s10064-017-1047-y

Yang, Y. K., Kang, T. H., Hao, X. L., Zheng, T. B., and Wang, A. (2012). Research on In-Situ Purification Technique of Mine Water in Shendong Mining Area. Energ. Educ. Sci. Technol. 29, 209–216.

Yang, X., Wen, G., Dai, L., Sun, H., and Li, X. (2019). Ground Subsidence and Surface Cracks Evolution from Shallow-Buried Close-Distance Multi-Seam Mining: A Case Study in Bulianta Coal Mine. Rock Mech. Rock Eng. 52, 2835–2852. doi:10.1007/s00603-018-1726-4

Zhang, D., Fan, G., Liu, Y., and Ma, L. (2010). Field Trials of Aquifer protection in Longwall Mining of Shallow Coal Seams in China. Int. J. Rock Mech. Mining Sci. 47, 908–914. doi:10.1016/j.ijrmms.2010.06.018

Zhang, S. F., Hu, R. L., and Wu, X. (2012). Dynamic Prediction of Ground Deformation and Drainage Design for Shallow Thick Coal Seam Mining(in Chinese). J. China Coal Soc. 37, 301–306. doi:10.13225/j.cnki.jccs.2012.s2.035

Zhang, C., Tu, S., Bai, Q., Yang, G., and Zhang, L. (2015). Evaluating Pressure-Relief Mining Performances Based on Surface Gas Venthole Extraction Data in Longwall Coal Mines. J. Nat. Gas Sci. Eng. 24, 431–440. doi:10.1016/j.jngse.2015.04.01210

Zhang, F., Yan, B., Feng, X., Lan, H., Kang, C., Lin, X., et al. (2019). A Rapid Loess Mudflow Triggered by the Check Dam Failure in a Bulldoze Mountain Area, Lanzhou, China. Landslides 16, 1981–1992. doi:10.1007/s10346-019-01219-2

Zhu, G., Wh, X., Li, P. H., Qi, R. J., Mu, W. P., and Fu, R. Z. (2014). Coalmine Surface Water Prevention and Drainage in Loess Area(in Chinese). J. China Coal Soc. 39, 1354–1360. doi:10.13225/j.cnki.jccs.2012.s2.035

Keywords: gully leakage, leakage experiment, surface fissure management, water leakage risk, gully terrain

Citation: Feng D, Hou E, Xie X, Che X, Hou P and Long T (2022) Prediction and Treatment of Water Leakage Risk Caused by the Dynamic Evolution of Ground Fissures in Gully Terrain. Front. Earth Sci. 9:803721. doi: 10.3389/feart.2021.803721

Received: 28 October 2021; Accepted: 01 December 2021;

Published: 03 January 2022.

Edited by:

Wen Nie, Jiangxi University of Science and Technology, ChinaReviewed by:

Baoqin Lian, Northwest University, ChinaCopyright © 2022 Feng, Hou, Xie, Che, Hou and Long. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dong Feng, enlmZDIwMTgwNjE5QDE2My5jb20=; Enke Hou, aG91ZWtAeHVzdC5lZHUuY24=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.